NISSAN LATIO 2010 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2010, Model line: LATIO, Model: NISSAN LATIO 2010Pages: 3745, PDF Size: 73.67 MB

Page 881 of 3745

FRONT DISC BRAKEBR-33

< SERVICE INFORMATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

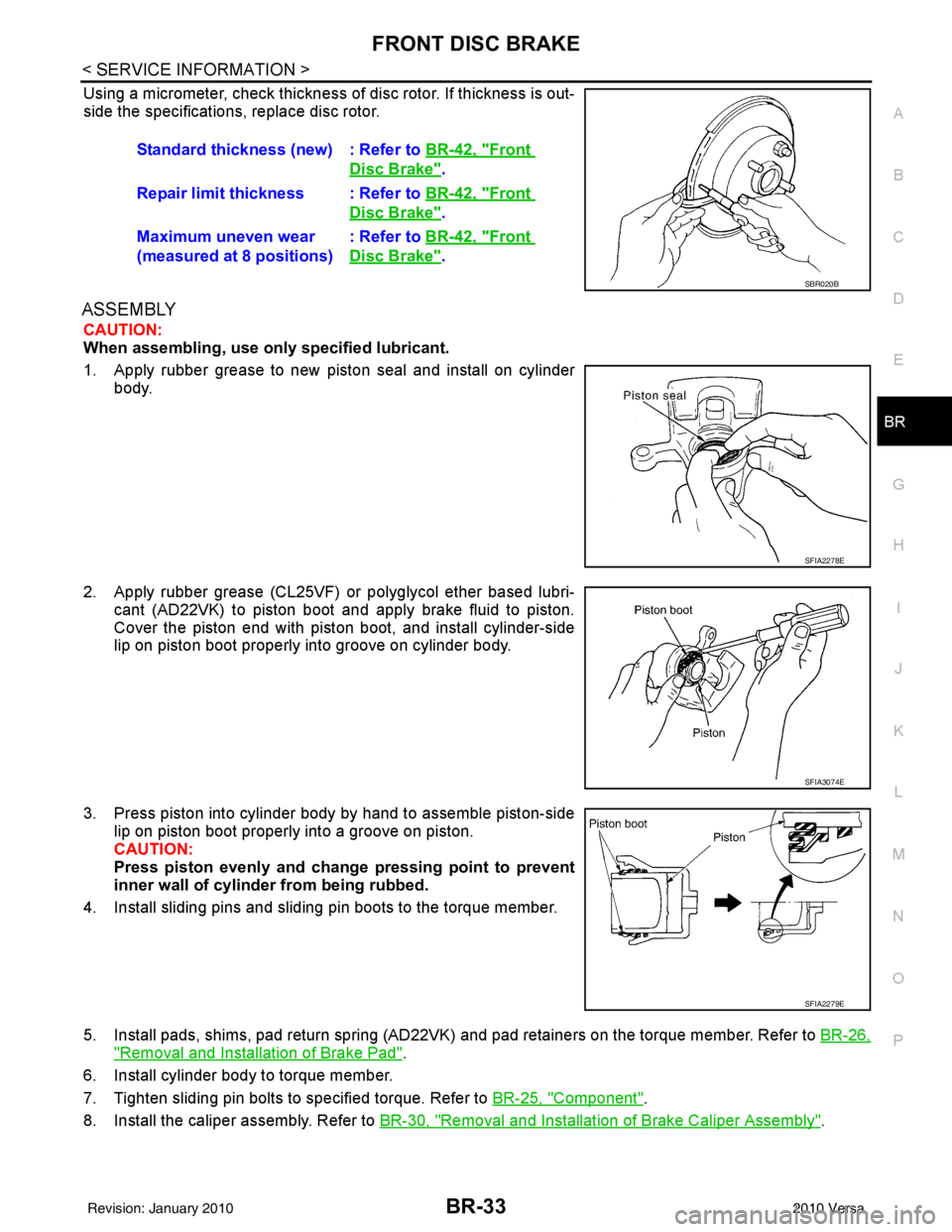

Using a micrometer, check thickness of disc rotor. If thickness is out-

side the specifications, replace disc rotor.

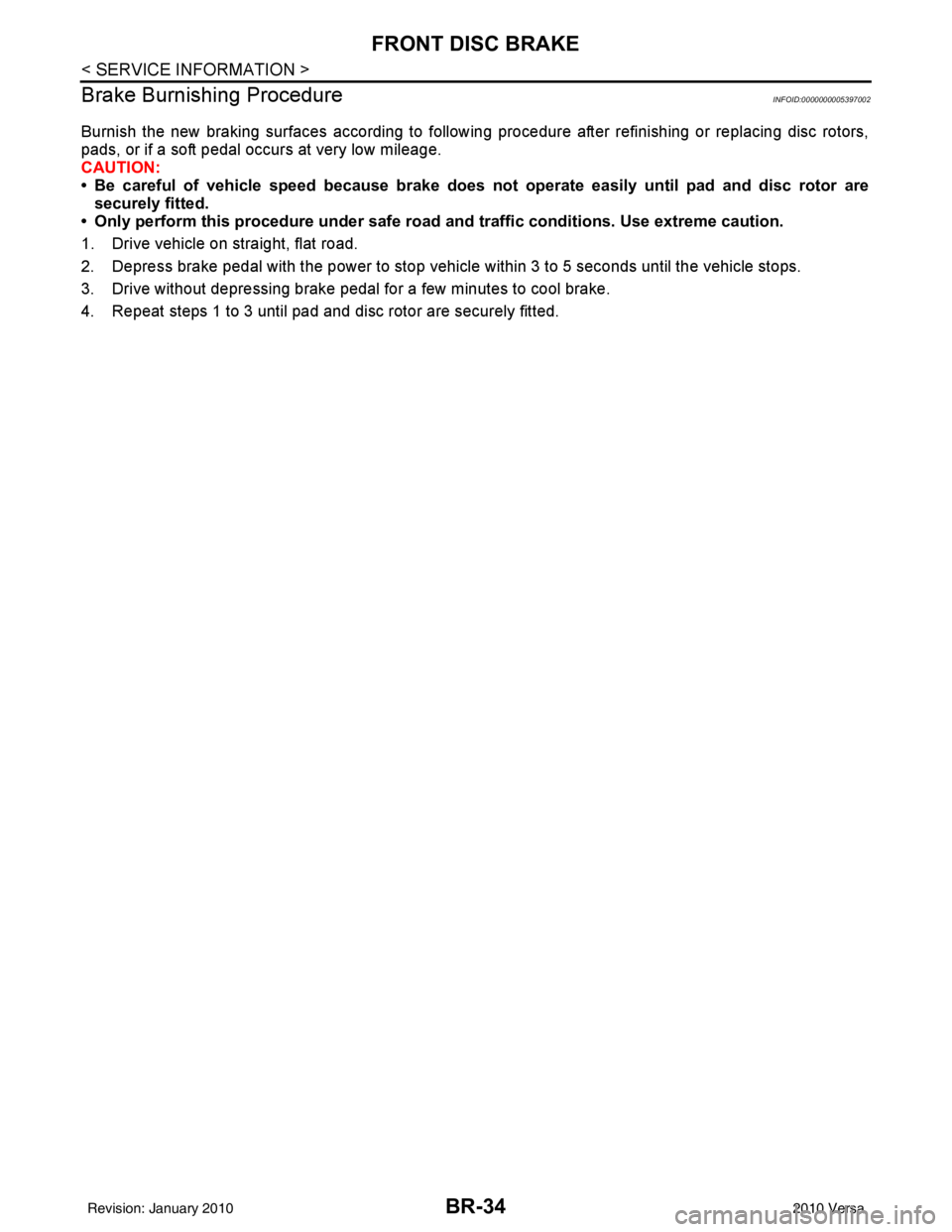

ASSEMBLY

CAUTION:

When assembling, use only specified lubricant.

1. Apply rubber grease to new piston seal and install on cylinder body.

2. Apply rubber grease (CL25VF) or polyglycol ether based lubri- cant (AD22VK) to piston boot and apply brake fluid to piston.

Cover the piston end with piston boot, and install cylinder-side

lip on piston boot properly into groove on cylinder body.

3. Press piston into cylinder body by hand to assemble piston-side lip on piston boot properly into a groove on piston.

CAUTION:

Press piston evenly and change pressing point to prevent

inner wall of cylinder from being rubbed.

4. Install sliding pins and sliding pin boots to the torque member.

5. Install pads, shims, pad return spring (AD22VK) and pad retainers on the torque member. Refer to BR-26,

"Removal and Installation of Brake Pad".

6. Install cylinder body to torque member.

7. Tighten sliding pin bolts to specified torque. Refer to BR-25, "

Component".

8. Install the caliper assembly. Refer to BR-30, "

Removal and Installation of Brake Caliper Assembly".

Standard thickness (new) : Refer to

BR-42, "

Front

Disc Brake".

Repair limit thickness : Refer to BR-42, "

Front

Disc Brake".

Maximum uneven wear

(measured at 8 positions) : Refer to

BR-42, "

Front

Disc Brake".

SBR020B

SFIA2278E

SFIA3074E

SFIA2279E

Revision: January 20102010 Versa

Page 882 of 3745

BR-34

< SERVICE INFORMATION >

FRONT DISC BRAKE

Brake Burnishing Procedure

INFOID:0000000005397002

Burnish the new braking surfaces according to following procedure after refinishing or replacing disc rotors,

pads, or if a soft pedal occurs at very low mileage.

CAUTION:

• Be careful of vehicle speed because brake does not operate easily until pad and disc rotor are securely fitted.

• Only perform this procedure under safe road and traffic conditions. Use extreme caution.

1. Drive vehicle on straight, flat road.

2. Depress brake pedal with the power to stop vehicle within 3 to 5 seconds until the vehicle stops.

3. Drive without depressing brake pedal for a few minutes to cool brake.

4. Repeat steps 1 to 3 until pad and disc rotor are securely fitted.

Revision: January 20102010 Versa

Page 883 of 3745

REAR DRUM BRAKEBR-35

< SERVICE INFORMATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

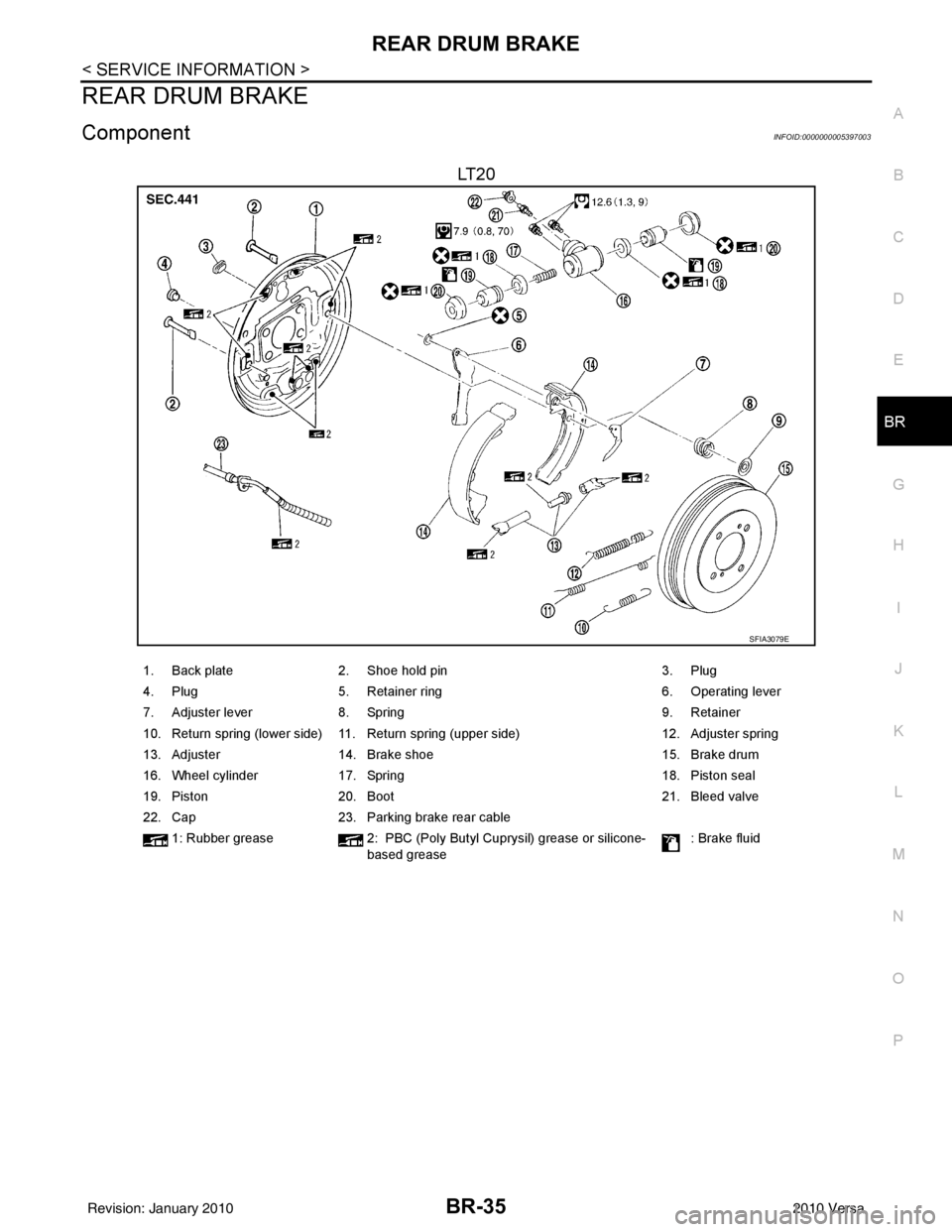

REAR DRUM BRAKE

ComponentINFOID:0000000005397003

LT 2 0

SFIA3079E

1. Back plate 2. Shoe hold pin 3. Plug

4. Plug 5. Retainer ring 6. Operating lever

7. Adjuster lever 8. Spring 9. Retainer

10. Return spring (lower side) 11. Return spring (upper side) 12. Adjuster spring

13. Adjuster 14. Brake shoe 15. Brake drum

16. Wheel cylinder 17. Spring 18. Piston seal

19. Piston 20. Boot 21. Bleed valve

22. Cap 23. Parking brake rear cable

1: Rubber grease 2: PBC (Poly Butyl Cuprysil) grease or silicone-

based grease : Brake fluid

Revision: January 20102010 Versa

Page 884 of 3745

BR-36

< SERVICE INFORMATION >

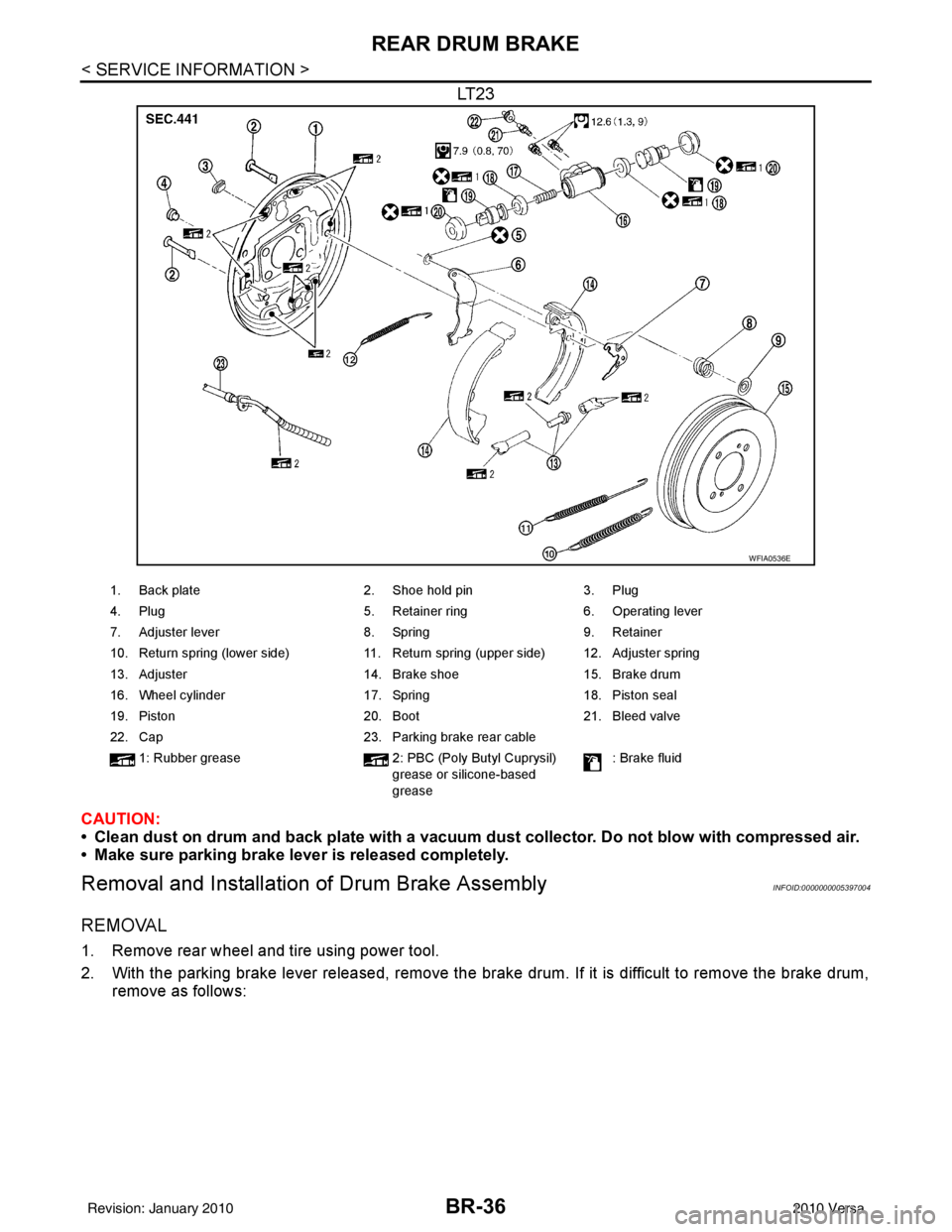

REAR DRUM BRAKE

LT23

CAUTION:

• Clean dust on drum and back plate with a vacuum dust collector. Do not blow with compressed air.

• Make sure parking brake lever is released completely.

Removal and Installation of Drum Brake AssemblyINFOID:0000000005397004

REMOVAL

1. Remove rear wheel and tire using power tool.

2. With the parking brake lever released, remove the brak e drum. If it is difficult to remove the brake drum,

remove as follows:

WFIA0536E

1. Back plate 2. Shoe hold pin3. Plug

4. Plug 5. Retainer ring6. Operating lever

7. Adjuster lever 8. Spring9. Retainer

10. Return spring (lower side) 11. Return spring (upper side) 12. Adjuster spring

13. Adjuster 14. Brake shoe15. Brake drum

16. Wheel cylinder 17. Spring18. Piston seal

19. Piston 20. Boot21. Bleed valve

22. Cap 23. Parking brake rear cable

1: Rubber grease 2: PBC (Poly Butyl Cuprysil)

grease or silicone-based

grease : Brake fluid

Revision: January 20102010 Versa

Page 885 of 3745

REAR DRUM BRAKEBR-37

< SERVICE INFORMATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

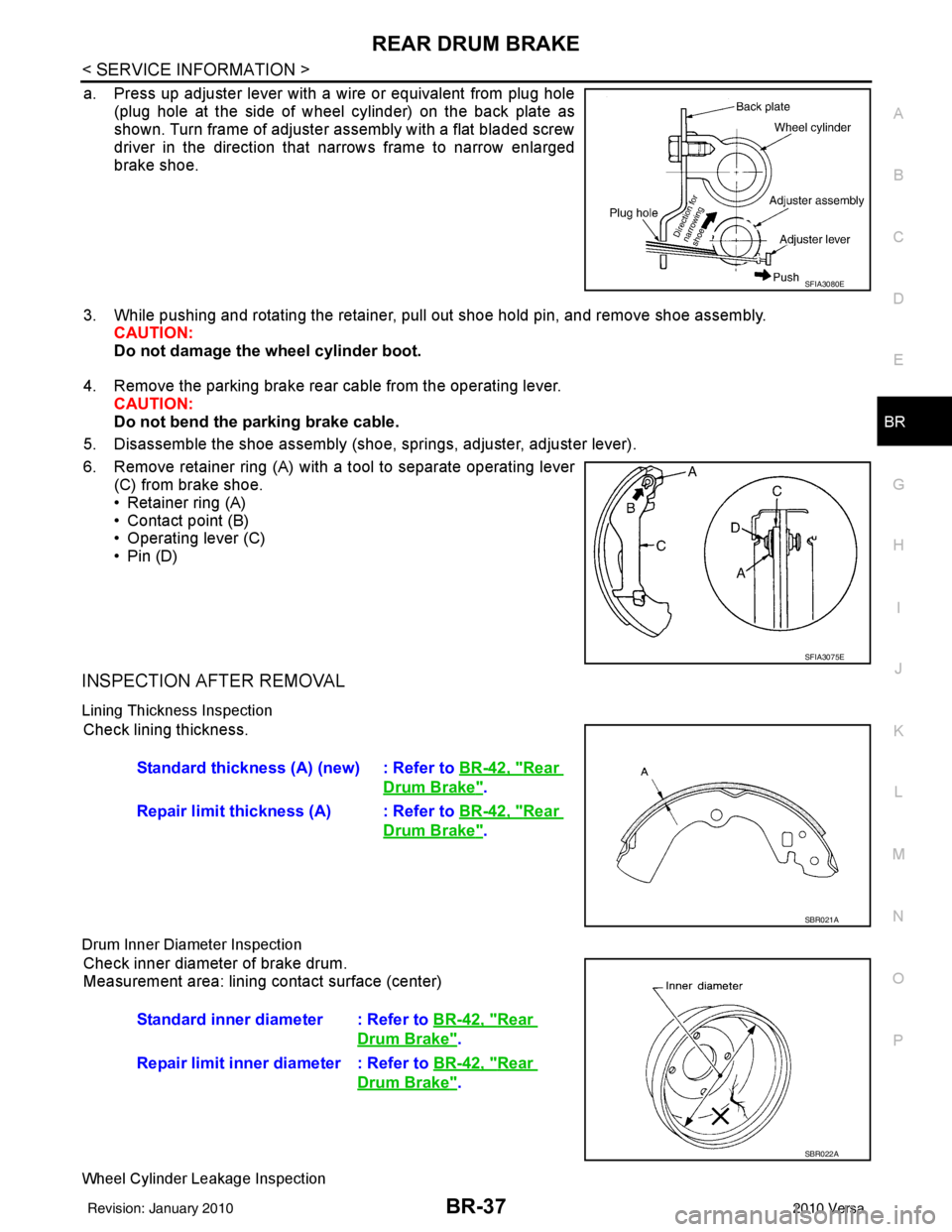

a. Press up adjuster lever with a wire or equivalent from plug hole (plug hole at the side of wheel cylinder) on the back plate as

shown. Turn frame of adjuster assembly with a flat bladed screw

driver in the direction that narrows frame to narrow enlarged

brake shoe.

3. While pushing and rotating the retainer, pull out shoe hold pin, and remove shoe assembly. CAUTION:

Do not damage the wheel cylinder boot.

4. Remove the parking brake rear cable from the operating lever. CAUTION:

Do not bend the parking brake cable.

5. Disassemble the shoe assembly (shoe, springs, adjuster, adjuster lever).

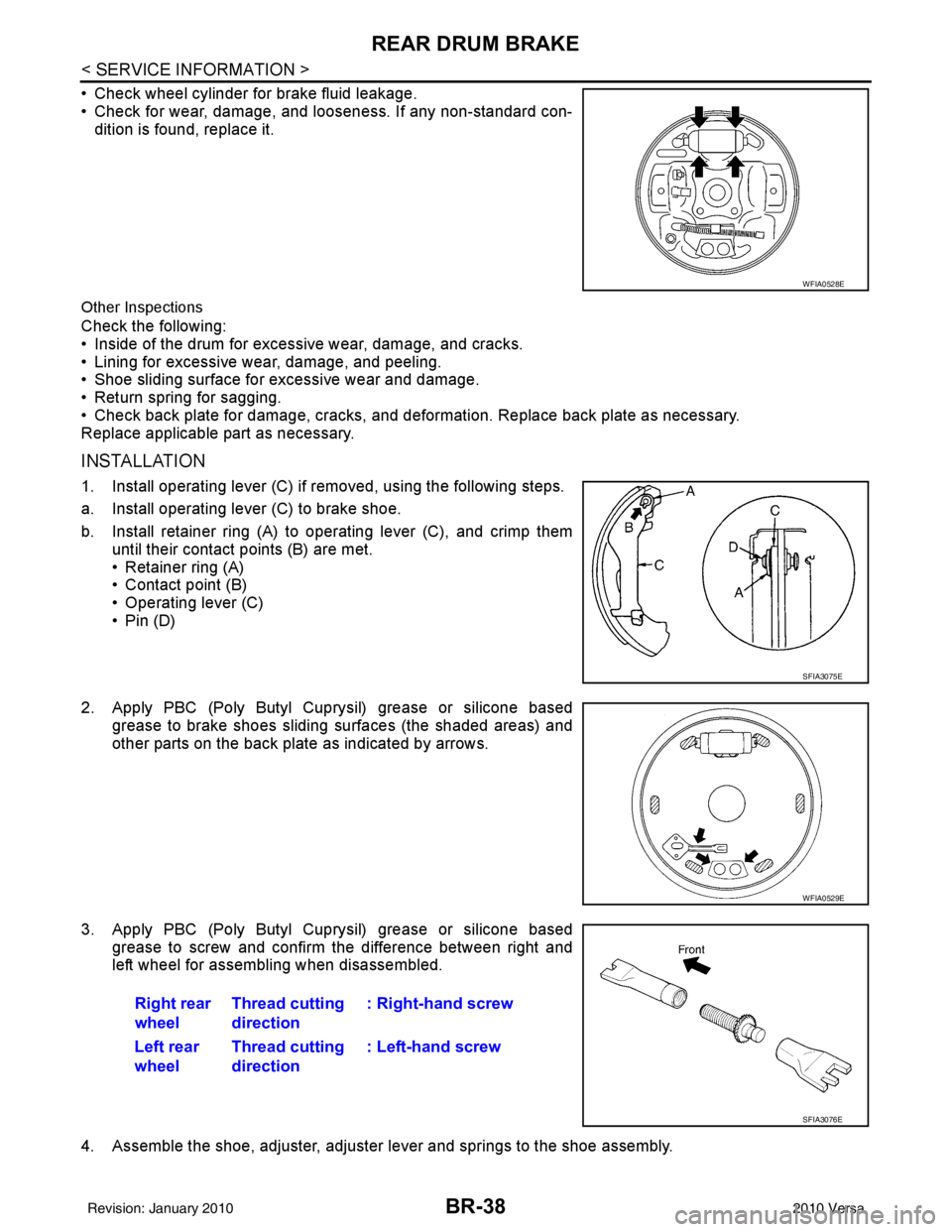

6. Remove retainer ring (A) with a tool to separate operating lever (C) from brake shoe.

• Retainer ring (A)

• Contact point (B)

• Operating lever (C)

•Pin (D)

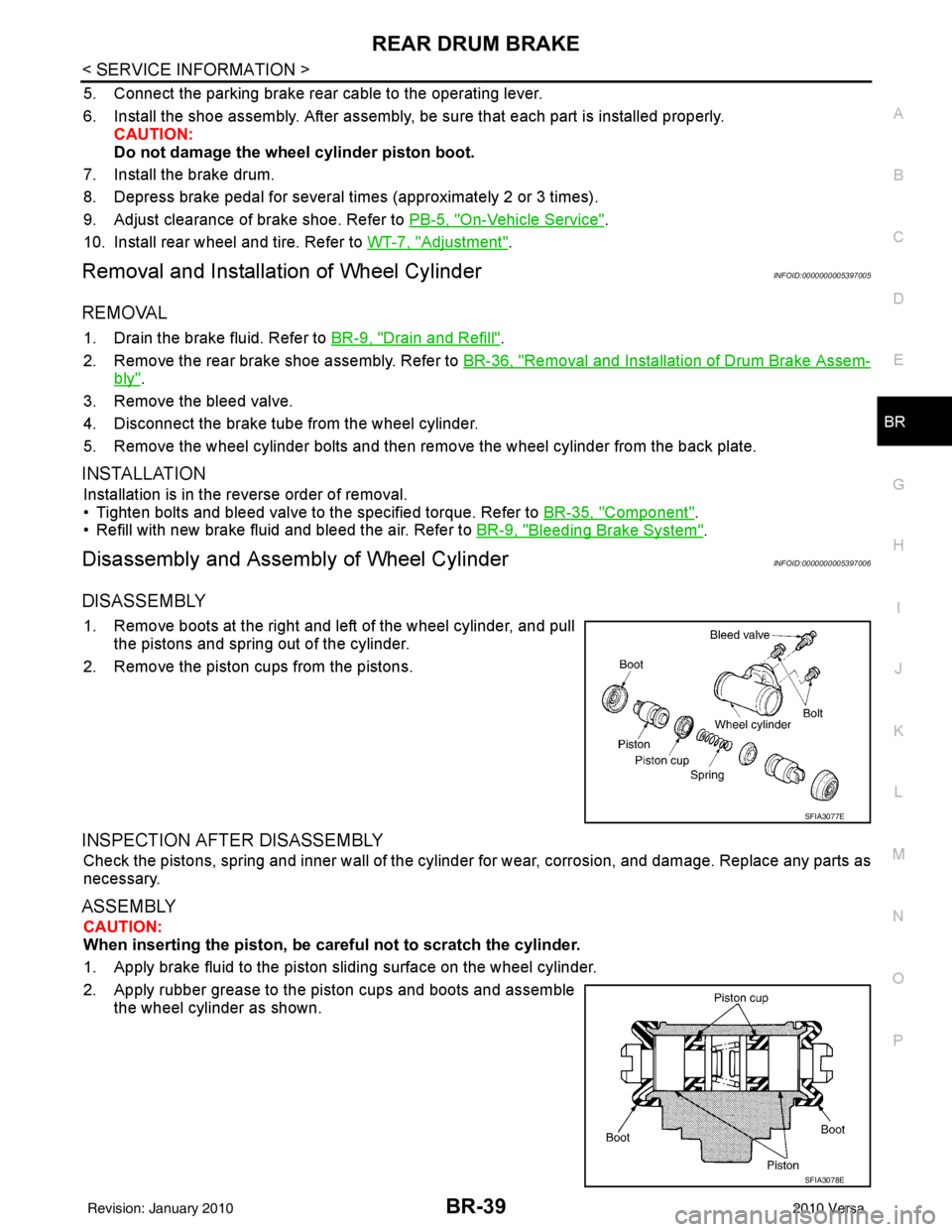

INSPECTION AFTER REMOVAL

Lining Thickness Inspection

Check lining thickness.

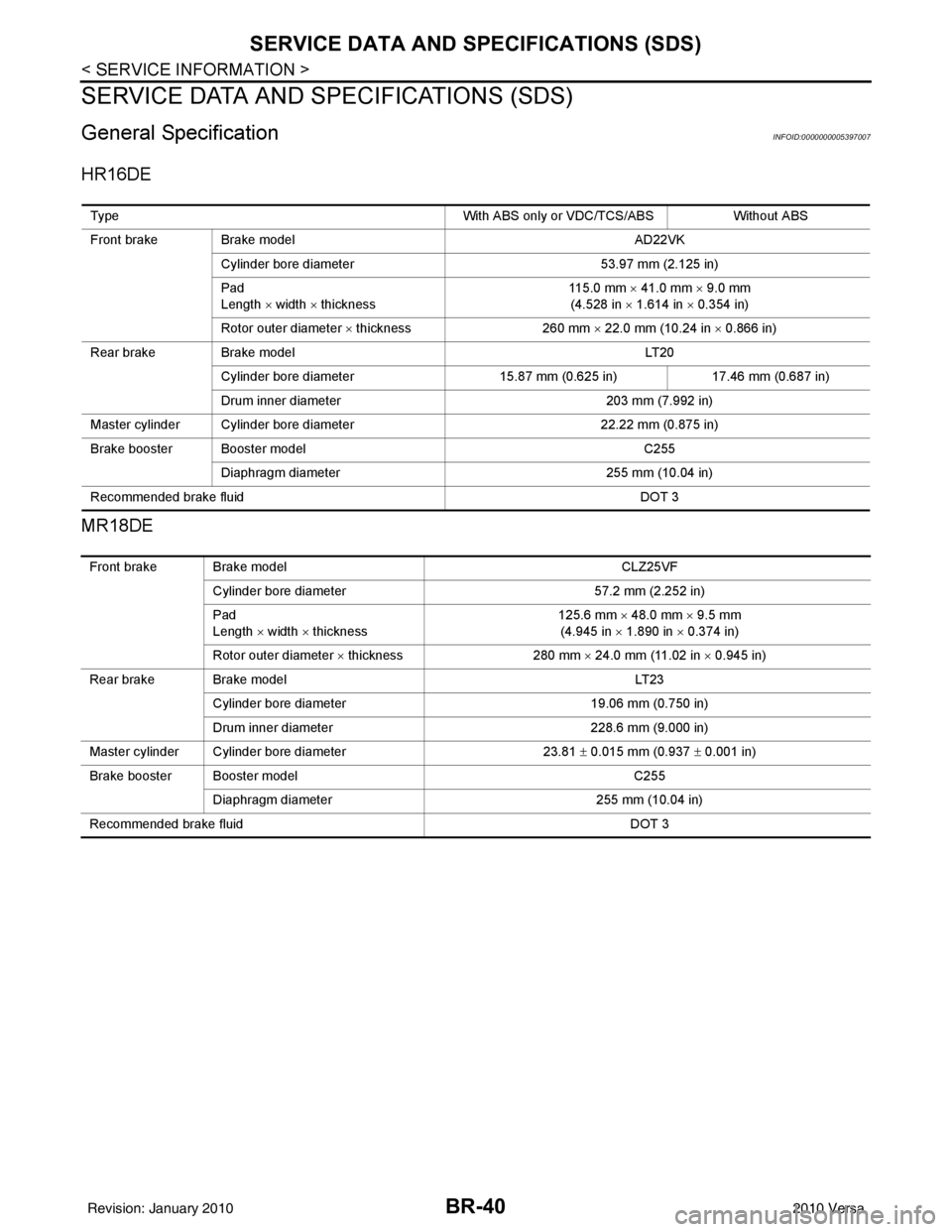

Drum Inner Diameter Inspection

Check inner diameter of brake drum.

Measurement area: lining contact surface (center)

Wheel Cylinder Leakage Inspection

SFIA3080E

SFIA3075E

Standard thickness (A) (new) : Refer to BR-42, "Rear

Drum Brake".

Repair limit thickness (A) : Refer to BR-42, "

Rear

Drum Brake".

SBR021A

Standard inner diameter : Refer to BR-42, "Rear

Drum Brake".

Repair limit inner diameter : Refer to BR-42, "

Rear

Drum Brake".

SBR022A

Revision: January 20102010 Versa

Page 886 of 3745

BR-38

< SERVICE INFORMATION >

REAR DRUM BRAKE

• Check wheel cylinder for brake fluid leakage.

• Check for wear, damage, and looseness. If any non-standard con-dition is found, replace it.

Other Inspections

Check the following:

• Inside of the drum for excessive wear, damage, and cracks.

• Lining for excessive wear, damage, and peeling.

• Shoe sliding surface for excessive wear and damage.

• Return spring for sagging.

• Check back plate for damage, cracks, and deformation. Replace back plate as necessary.

Replace applicable part as necessary.

INSTALLATION

1. Install operating lever (C) if removed, using the following steps.

a. Install operating lever (C) to brake shoe.

b. Install retainer ring (A) to operating lever (C), and crimp them

until their contact points (B) are met.

• Retainer ring (A)

• Contact point (B)

• Operating lever (C)

•Pin (D)

2. Apply PBC (Poly Butyl Cuprysil) grease or silicone based grease to brake shoes sliding surfaces (the shaded areas) and

other parts on the back plate as indicated by arrows.

3. Apply PBC (Poly Butyl Cuprysil) grease or silicone based grease to screw and confirm the difference between right and

left wheel for assembling when disassembled.

4. Assemble the shoe, adjuster, adjuster lever and springs to the shoe assembly.

WFIA0528E

SFIA3075E

WFIA0529E

Right rear

wheel Thread cutting

direction : Right-hand screw

Left rear

wheel Thread cutting

direction : Left-hand screw

SFIA3076E

Revision: January 20102010 Versa

Page 887 of 3745

REAR DRUM BRAKEBR-39

< SERVICE INFORMATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

5. Connect the parking brake rear cable to the operating lever.

6. Install the shoe assembly. After assembly, be sure that each part is installed properly. CAUTION:

Do not damage the wheel cylinder piston boot.

7. Install the brake drum.

8. Depress brake pedal for several times (approximately 2 or 3 times).

9. Adjust clearance of brake shoe. Refer to PB-5, "

On-Vehicle Service".

10. Install rear wheel and tire. Refer to WT-7, "

Adjustment".

Removal and Installati on of Wheel CylinderINFOID:0000000005397005

REMOVAL

1. Drain the brake fluid. Refer to BR-9, "Drain and Refill".

2. Remove the rear brake shoe assembly. Refer to BR-36, "

Removal and Installation of Drum Brake Assem-

bly".

3. Remove the bleed valve.

4. Disconnect the brake tube from the wheel cylinder.

5. Remove the wheel cylinder bolts and then remove the wheel cylinder from the back plate.

INSTALLATION

Installation is in the reverse order of removal.

• Tighten bolts and bleed valve to the specified torque. Refer to BR-35, "

Component".

• Refill with new brake fluid and bleed the air. Refer to BR-9, "

Bleeding Brake System".

Disassembly and Assembly of Wheel CylinderINFOID:0000000005397006

DISASSEMBLY

1. Remove boots at the right and left of the wheel cylinder, and pull

the pistons and spring out of the cylinder.

2. Remove the piston cups from the pistons.

INSPECTION AFTER DISASSEMBLY

Check the pistons, spring and inner wall of the cylinder for wear, corrosion, and damage. Replace any parts as

necessary.

ASSEMBLY

CAUTION:

When inserting the piston, be caref ul not to scratch the cylinder.

1. Apply brake fluid to the piston sliding surface on the wheel cylinder.

2. Apply rubber grease to the piston cups and boots and assemble the wheel cylinder as shown.

SFIA3077E

SFIA3078E

Revision: January 20102010 Versa

Page 888 of 3745

BR-40

< SERVICE INFORMATION >

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

General SpecificationINFOID:0000000005397007

HR16DE

MR18DE

TypeWith ABS only or VDC/TCS/ABSWithout ABS

Front brake Brake model AD22VK

Cylinder bore diameter 53.97 mm (2.125 in)

Pad

Length × width × thickness 115.0 mm ×

41.0 mm × 9.0 mm

(4.528 in × 1.614 in × 0.354 in)

Rotor outer diameter × thickness 260 mm × 22.0 mm (10.24 in × 0.866 in)

Rear brake Brake model LT20

Cylinder bore diameter 15.87 mm (0.625 in)17.46 mm (0.687 in)

Drum inner diameter 203 mm (7.992 in)

Master cylinder Cylinder bore diameter 22.22 mm (0.875 in)

Brake booster Booster model C255

Diaphragm diameter 255 mm (10.04 in)

Recommended brake fluid DOT 3

Front brake Brake modelCLZ25VF

Cylinder bore diameter 57.2 mm (2.252 in)

Pad

Length × width × thickness 125.6 mm

× 48.0 mm × 9.5 mm

(4.945 in × 1.890 in × 0.374 in)

Rotor outer diameter × thickness 280 mm × 24.0 mm (11.02 in × 0.945 in)

Rear brake Brake model LT23

Cylinder bore diameter 19.06 mm (0.750 in)

Drum inner diameter 228.6 mm (9.000 in)

Master cylinder Cylinder bore diameter 23.81 ± 0.015 mm (0.937 ± 0.001 in)

Brake booster Booster model C255

Diaphragm diameter 255 mm (10.04 in)

Recommended brake fluid DOT 3

Revision: January 20102010 Versa

Page 889 of 3745

SERVICE DATA AND SPECIFICATIONS (SDS)BR-41

< SERVICE INFORMATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

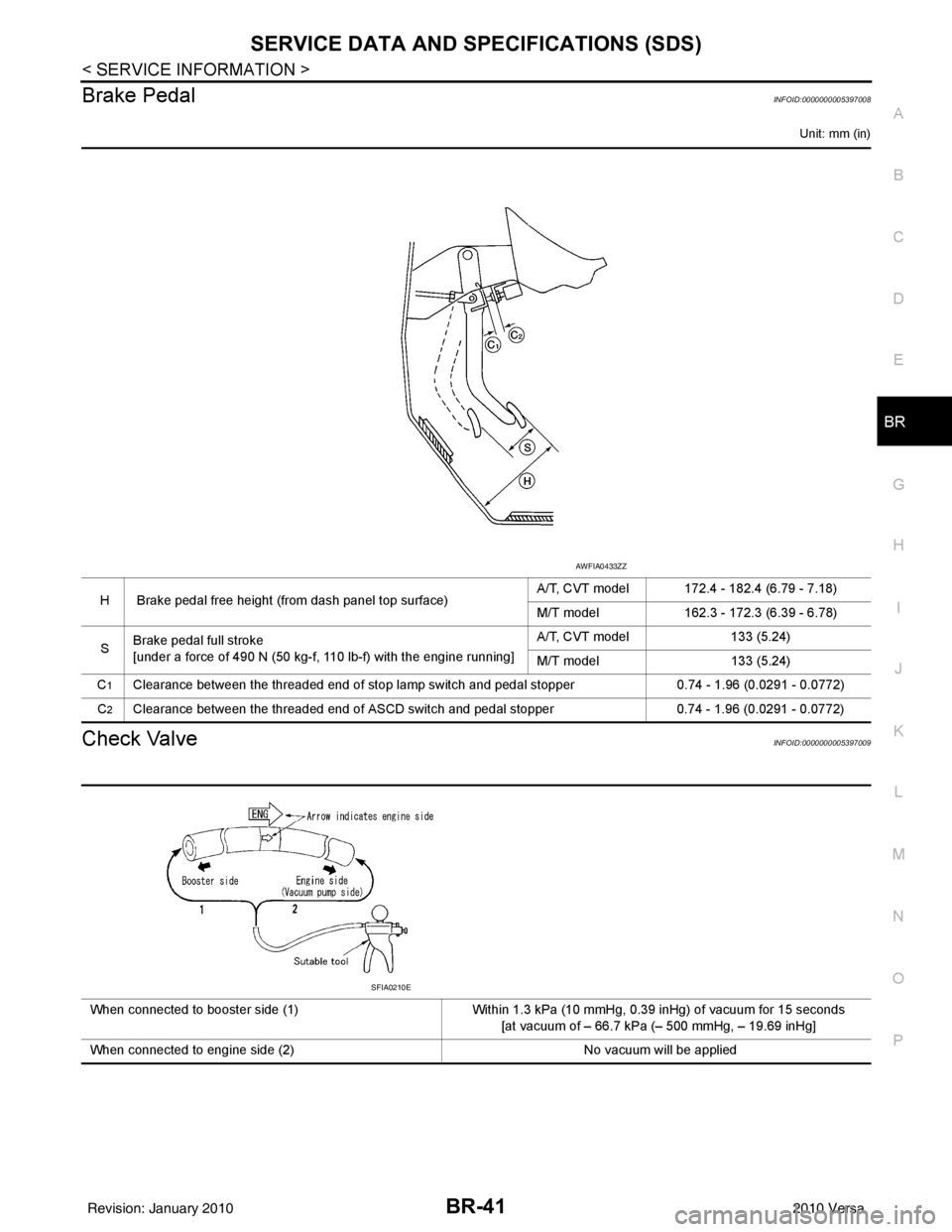

Brake PedalINFOID:0000000005397008

Unit: mm (in)

Check ValveINFOID:0000000005397009

H Brake pedal free height (from dash panel top surface) A/T, CVT model 172.4 - 182.4 (6.79 - 7.18)

M/T model

162.3 - 172.3 (6.39 - 6.78)

S Brake pedal full stroke

[under a force of 490 N (50 kg-f, 110 lb-f) with the engine running] A/T, CVT model

133 (5.24)

M/T model 133 (5.24)

C

1Clearance between the threaded end of stop lamp switch and pedal stopper 0.74 - 1.96 (0.0291 - 0.0772)

C

2Clearance between the threaded end of ASCD switch and pedal stopper 0.74 - 1.96 (0.0291 - 0.0772)

AWFIA0433ZZ

When connected to booster side (1)Within 1.3 kPa (10 mmHg, 0.39 inHg) of vacuum for 15 seconds

[at vacuum of – 66.7 kPa (– 500 mmHg, – 19.69 inHg]

When connected to engine side (2) No vacuum will be applied

SFIA0210E

Revision: January 20102010 Versa

Page 890 of 3745

BR-42

< SERVICE INFORMATION >

SERVICE DATA AND SPECIFICATIONS (SDS)

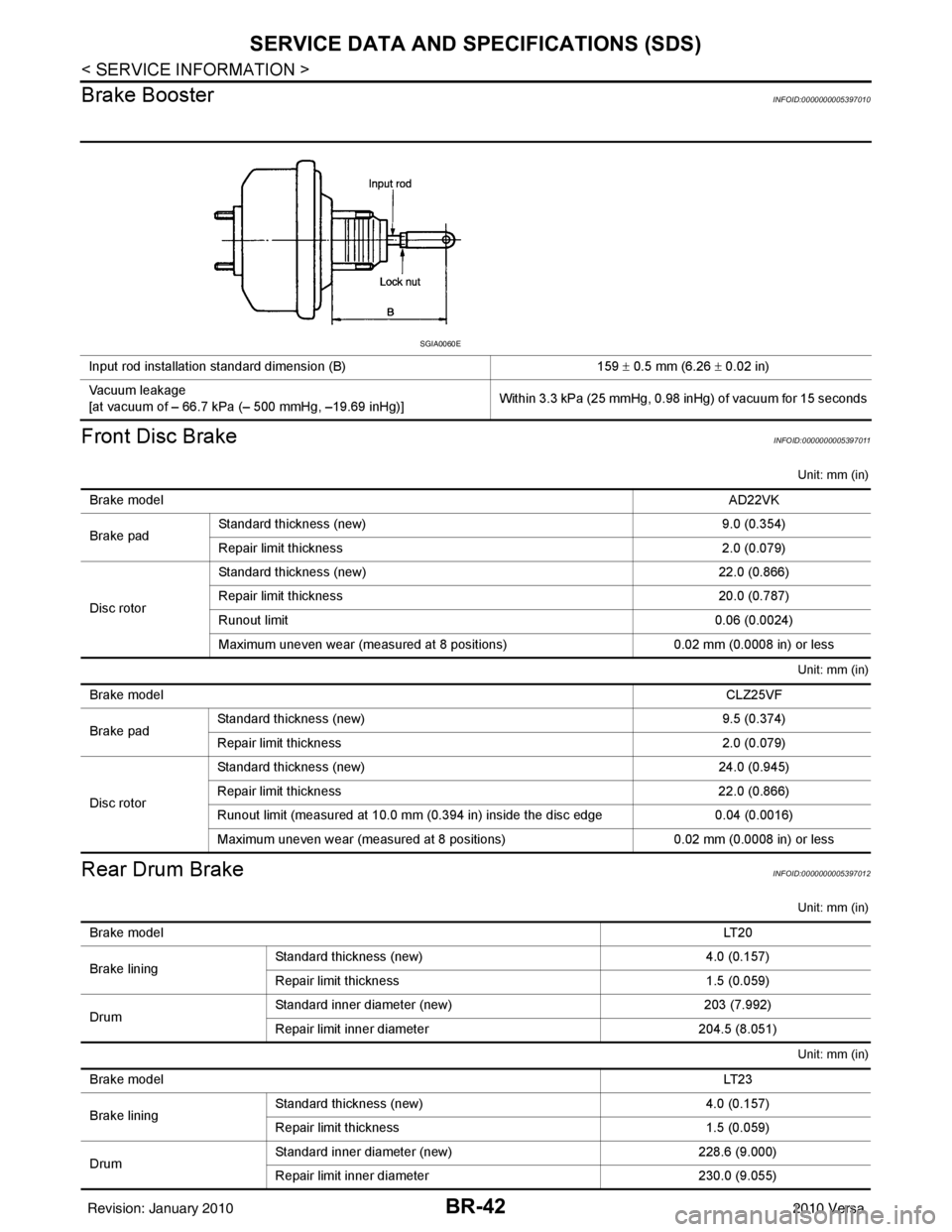

Brake Booster

INFOID:0000000005397010

Front Disc BrakeINFOID:0000000005397011

Unit: mm (in)

Unit: mm (in)

Rear Drum BrakeINFOID:0000000005397012

Unit: mm (in)

Unit: mm (in)

Input rod installation standard dimension (B) 159 ± 0.5 mm (6.26 ± 0.02 in)

Vacuum leakage

[at vacuum of – 66.7 kPa (– 500 mmHg, –19.69 inHg)] Within 3.3 kPa (25 mmHg, 0.98 inHg) of vacuum for 15 seconds

SGIA0060E

Brake model

AD22VK

Brake pad Standard thickness (new)

9.0 (0.354)

Repair limit thickness 2.0 (0.079)

Disc rotor Standard thickness (new)

22.0 (0.866)

Repair limit thickness 20.0 (0.787)

Runout limit 0.06 (0.0024)

Maximum uneven wear (measured at 8 positions) 0.02 mm (0.0008 in) or less

Brake model CLZ25VF

Brake pad Standard thickness (new)

9.5 (0.374)

Repair limit thickness 2.0 (0.079)

Disc rotor Standard thickness (new)

24.0 (0.945)

Repair limit thickness 22.0 (0.866)

Runout limit (measured at 10.0 mm (0.394 in) inside the disc edge 0.04 (0.0016)

Maximum uneven wear (measured at 8 positions) 0.02 mm (0.0008 in) or less

Brake model LT 2 0

Brake lining Standard thickness

(new) 4.0 (0.157)

Repair limit thickness 1.5 (0.059)

Drum Standard inner diameter (new)

203 (7.992)

Repair limit inner diameter 204.5 (8.051)

Brake model LT 2 3

Brake lining Standard thickness (new)

4.0 (0.157)

Repair limit thickness 1.5 (0.059)

Drum Standard inner diameter (new)

228.6 (9.000)

Repair limit inner diameter 230.0 (9.055)

Revision: January 20102010 Versa