light NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1310 of 3171

EC-330

BRAKE SWITCH

BRAKE SWITCH

PFP:25230

DescriptionEBS01KML

STOP LAMP SWITCH

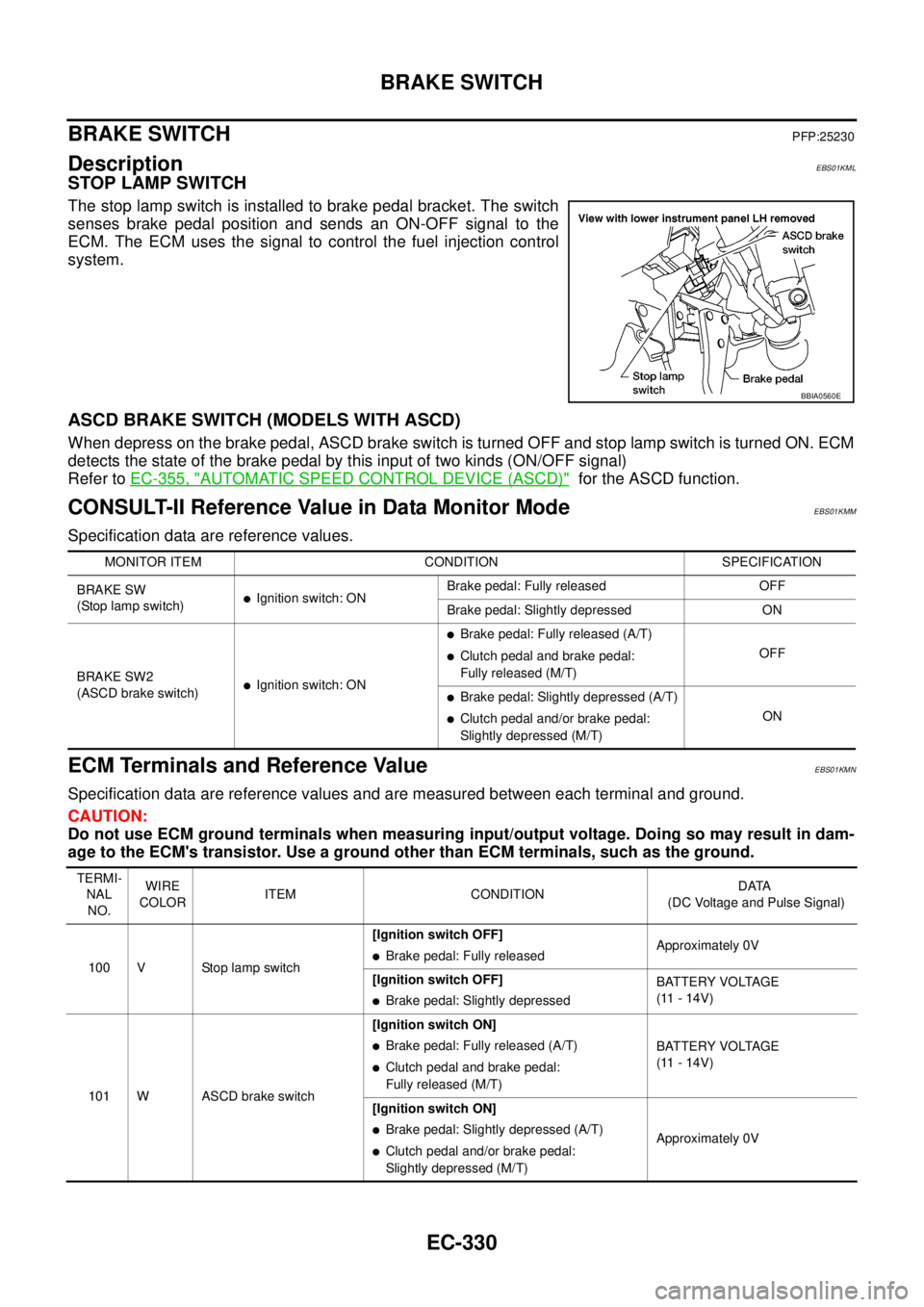

The stop lamp switch is installed to brake pedal bracket. The switch

senses brake pedal position and sends an ON-OFF signal to the

ECM. The ECM uses the signal to control the fuel injection control

system.

ASCD BRAKE SWITCH (MODELS WITH ASCD)

When depress on the brake pedal, ASCD brake switch is turned OFF and stop lamp switch is turned ON. ECM

detects the state of the brake pedal by this input of two kinds (ON/OFF signal)

Refer toEC-355, "

AUTOMATIC SPEED CONTROL DEVICE (ASCD)"for the ASCD function.

CONSULT-II Reference Value in Data Monitor ModeEBS01KMM

Specification data are reference values.

ECM Terminals and Reference ValueEBS01KMN

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

BBIA0560E

MONITOR ITEM CONDITION SPECIFICATION

BRAKE SW

(Stoplampswitch)

lIgnition switch: ONBrake pedal: Fully released OFF

Brake pedal: Slightly depressed ON

BRAKE SW2

(ASCD brake switch)

lIgnition switch: ON

lBrake pedal: Fully released (A/T)

lClutch pedal and brake pedal:

Fully released (M/T)OFF

lBrake pedal: Slightly depressed (A/T)

lClutch pedal and/or brake pedal:

Slightly depressed (M/T)ON

TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage and Pulse Signal)

100 V Stop lamp switch[Ignition switch OFF]

lBrake pedal: Fully releasedApproximately 0V

[Ignition switch OFF]

lBrake pedal: Slightly depressedBATTERY VOLTAGE

(11 - 14V)

101 W ASCD brake switch[Ignition switch ON]

lBrake pedal: Fully released (A/T)

lClutch pedal and brake pedal:

Fully released (M/T)BATTERY VOLTAGE

(11 - 14V)

[Ignition switch ON]

lBrake pedal: Slightly depressed (A/T)

lClutch pedal and/or brake pedal:

Slightly depressed (M/T)Approximately 0V

Page 1312 of 3171

EC-332

BRAKE SWITCH

Diagnostic Procedure

EBS01KMP

A/T MODELS

1.CHECK OVERALL FUNCTION-I

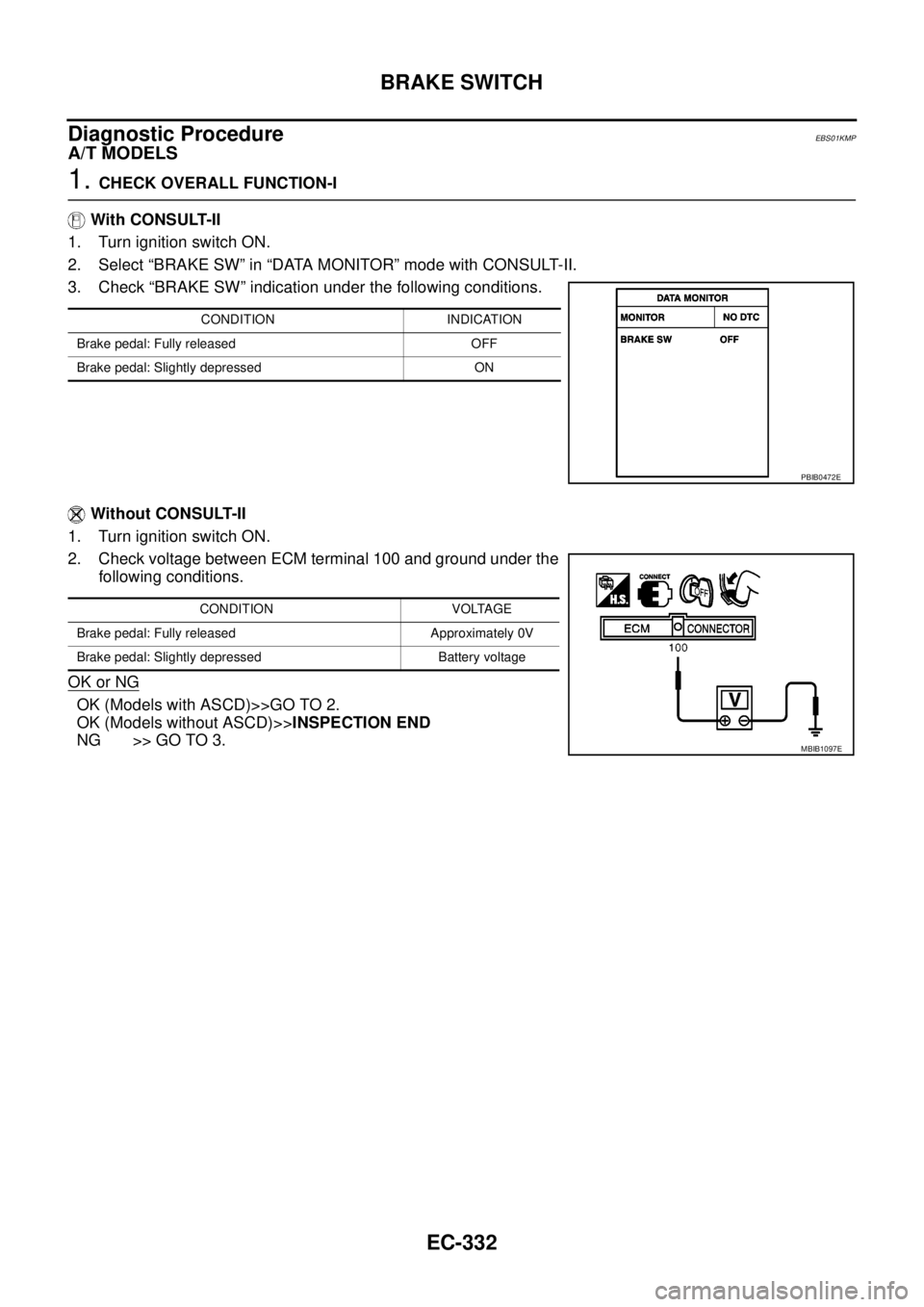

With CONSULT-II

1. Turn ignition switch ON.

2. Select “BRAKE SW” in “DATA MONITOR” mode with CONSULT-II.

3. Check “BRAKE SW” indication under the following conditions.

Without CONSULT-II

1. Turn ignition switch ON.

2. Check voltage between ECM terminal 100 and ground under the

following conditions.

OK or NG

OK (Models with ASCD)>>GO TO 2.

OK (Models without ASCD)>>INSPECTION END

NG >> GO TO 3.

CONDITION INDICATION

Brake pedal: Fully released OFF

Brake pedal: Slightly depressed ON

PBIB0472E

CONDITION VOLTAGE

Brake pedal: Fully released Approximately 0V

Brake pedal: Slightly depressed Battery voltage

MBIB1097E

Page 1313 of 3171

BRAKE SWITCH

EC-333

C

D

E

F

G

H

I

J

K

L

MA

EC

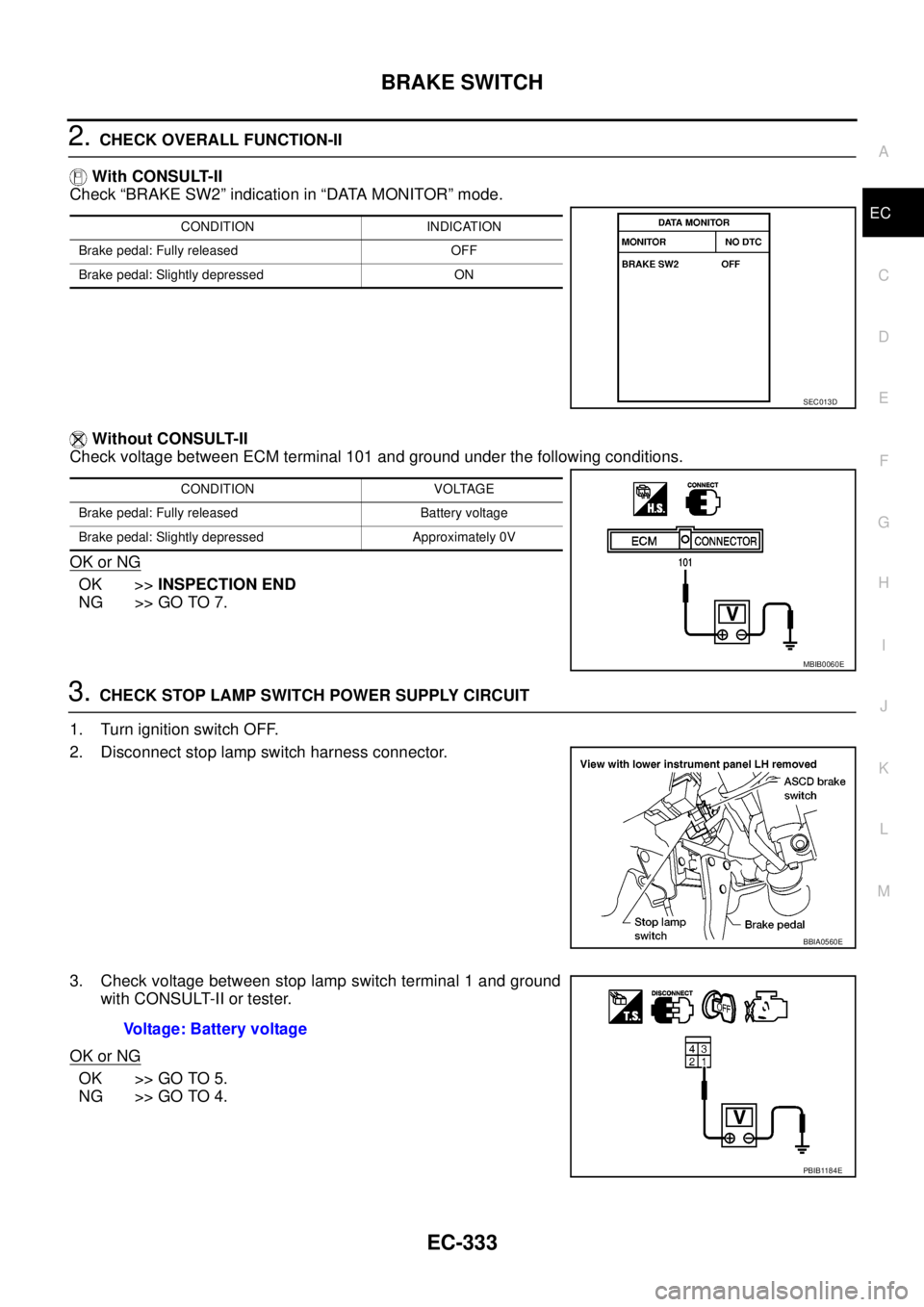

2.CHECK OVERALL FUNCTION-II

With CONSULT-II

Check “BRAKE SW2” indication in “DATA MONITOR” mode.

Without CONSULT-II

Check voltage between ECM terminal 101 and ground under the following conditions.

OK or NG

OK >>INSPECTION END

NG >> GO TO 7.

3.CHECK STOP LAMP SWITCH POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect stop lamp switch harness connector.

3. Check voltage between stop lamp switch terminal 1 and ground

with CONSULT-II or tester.

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.

CONDITION INDICATION

Brake pedal: Fully released OFF

Brake pedal: Slightly depressed ON

SEC013D

CONDITION VOLTAGE

Brake pedal: Fully released Battery voltage

Brake pedal: Slightly depressed Approximately 0V

MBIB0060E

BBIA0560E

Voltage: Battery voltage

PBIB1184E

Page 1316 of 3171

EC-336

BRAKE SWITCH

M/T MODELS

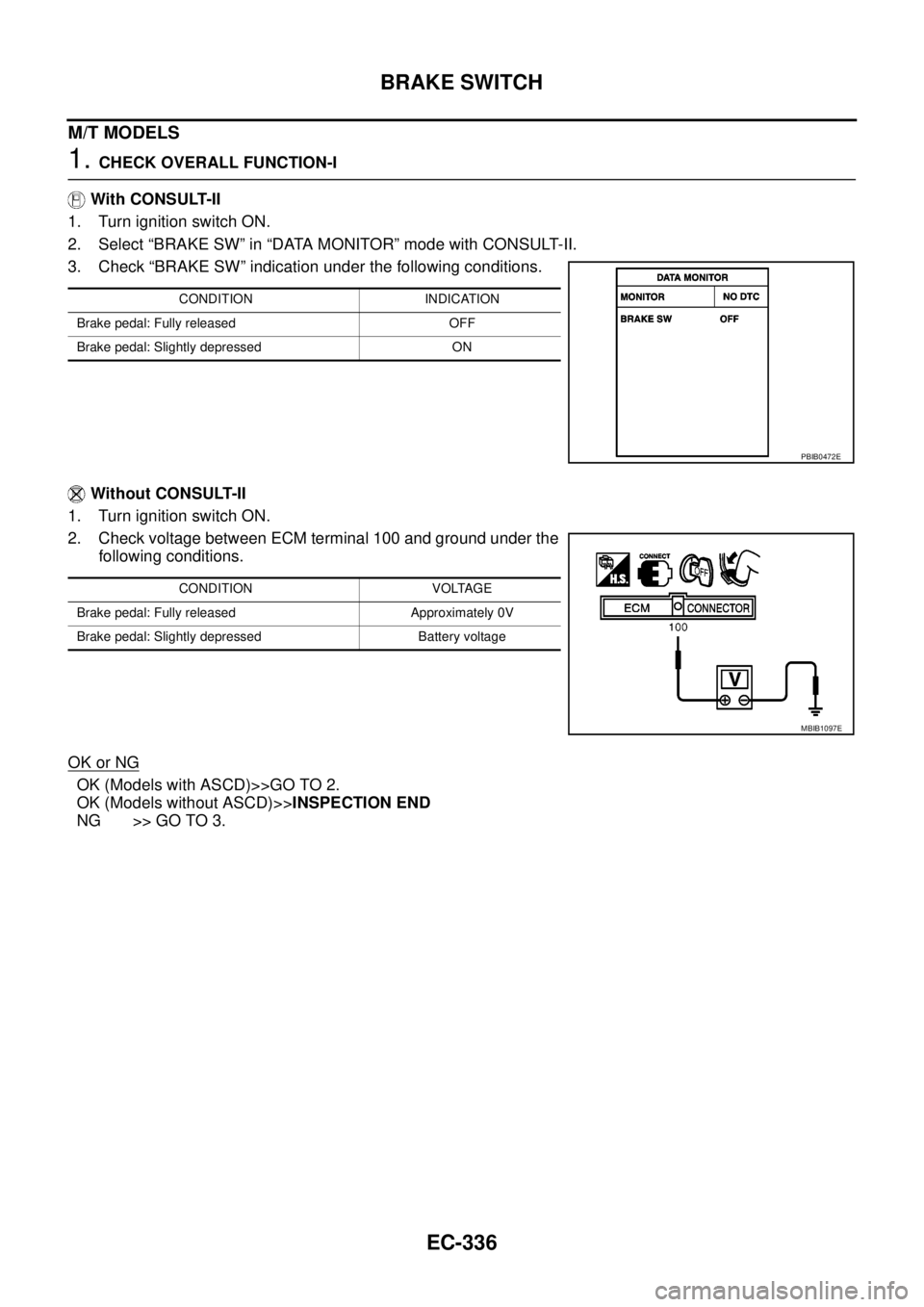

1.CHECK OVERALL FUNCTION-I

With CONSULT-II

1. Turn ignition switch ON.

2. Select “BRAKE SW” in “DATA MONITOR” mode with CONSULT-II.

3. Check “BRAKE SW” indication under the following conditions.

Without CONSULT-II

1. Turn ignition switch ON.

2. Check voltage between ECM terminal 100 and ground under the

following conditions.

OK or NG

OK (Models with ASCD)>>GO TO 2.

OK (Models without ASCD)>>INSPECTION END

NG >> GO TO 3.

CONDITION INDICATION

Brake pedal: Fully released OFF

Brake pedal: Slightly depressed ON

PBIB0472E

CONDITION VOLTAGE

Brake pedal: Fully released Approximately 0V

Brake pedal: Slightly depressed Battery voltage

MBIB1097E

Page 1317 of 3171

BRAKE SWITCH

EC-337

C

D

E

F

G

H

I

J

K

L

MA

EC

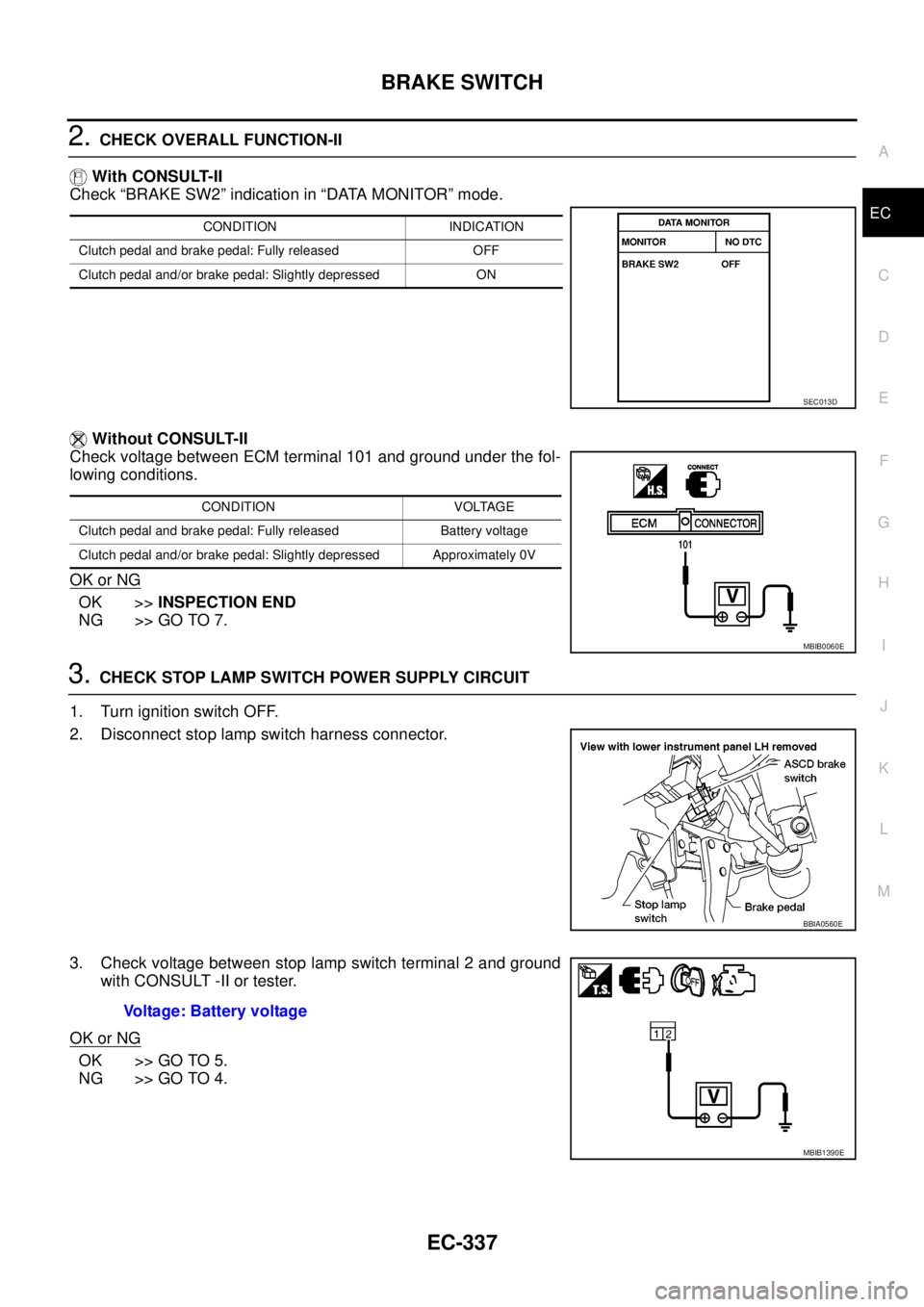

2.CHECK OVERALL FUNCTION-II

With CONSULT-II

Check “BRAKE SW2” indication in “DATA MONITOR” mode.

Without CONSULT-II

Check voltage between ECM terminal 101 and ground under the fol-

lowing conditions.

OK or NG

OK >>INSPECTION END

NG >> GO TO 7.

3.CHECK STOP LAMP SWITCH POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect stop lamp switch harness connector.

3. Check voltage between stop lamp switch terminal 2 and ground

with CONSULT -II or tester.

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.

CONDITION INDICATION

Clutch pedal and brake pedal: Fully released OFF

Clutch pedal and/or brake pedal: Slightly depressed ON

SEC013D

CONDITION VOLTAGE

Clutch pedal and brake pedal: Fully released Battery voltage

Clutch pedal and/or brake pedal: Slightly depressed Approximately 0V

MBIB0060E

BBIA0560E

Voltage: Battery voltage

MBIB1390E

Page 1318 of 3171

EC-338

BRAKE SWITCH

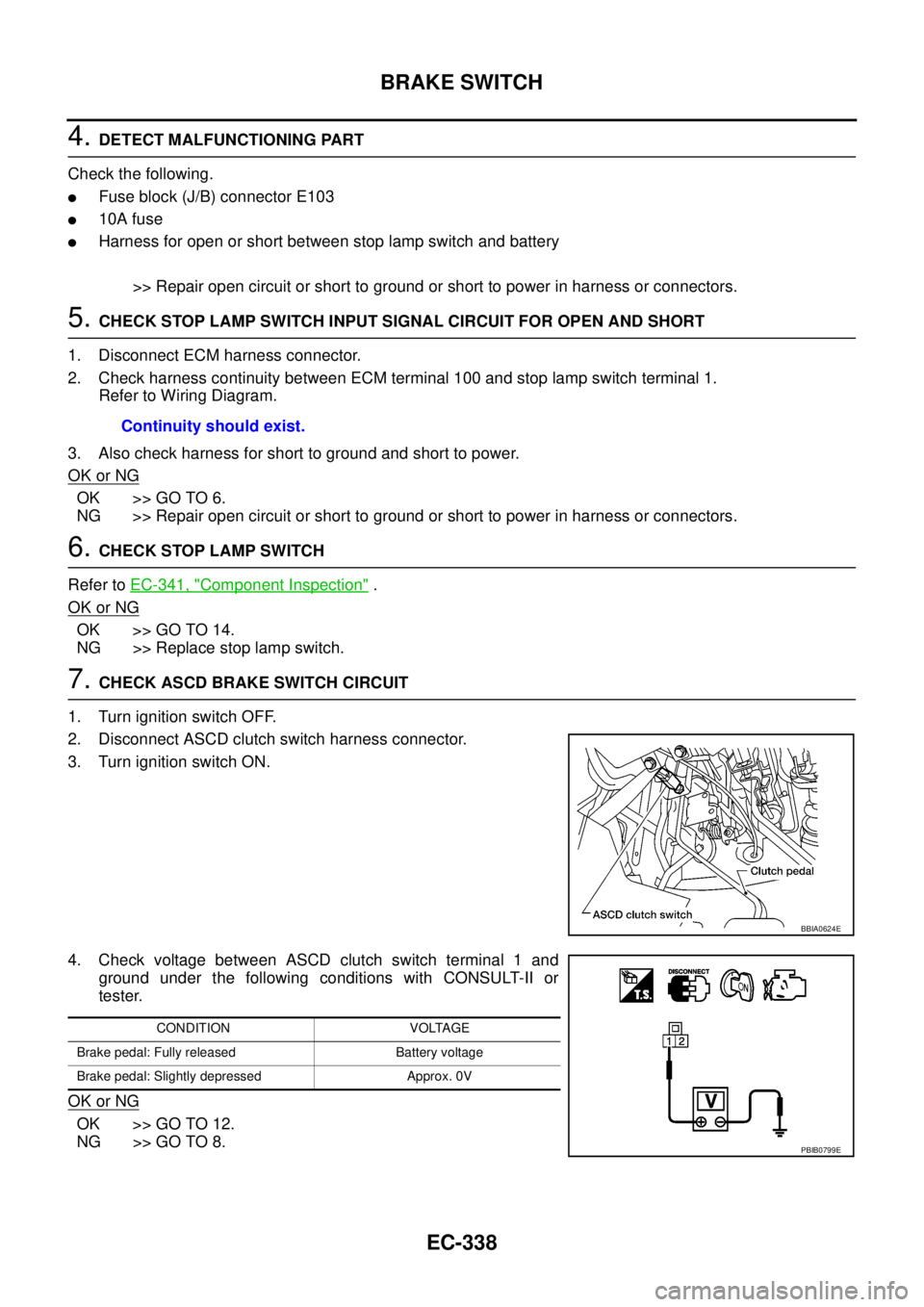

4.DETECT MALFUNCTIONING PART

Check the following.

lFuse block (J/B) connector E103

l10A fuse

lHarness for open or short between stop lamp switch and battery

>> Repair open circuit or short to ground or short to power in harness or connectors.

5.CHECK STOP LAMP SWITCH INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 100 and stop lamp switch terminal 1.

Refer to Wiring Diagram.

3. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 6.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

6.CHECK STOP LAMP SWITCH

Refer toEC-341, "

Component Inspection".

OK or NG

OK >> GO TO 14.

NG >> Replace stop lamp switch.

7.CHECK ASCD BRAKE SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ASCD clutch switch harness connector.

3. Turn ignition switch ON.

4. Check voltage between ASCD clutch switch terminal 1 and

ground under the following conditions with CONSULT-II or

tester.

OK or NG

OK >> GO TO 12.

NG >> GO TO 8.Continuity should exist.

BBIA0624E

CONDITION VOLTAGE

Brake pedal: Fully released Battery voltage

Brake pedal: Slightly depressed Approx. 0V

PBIB0799E

Page 1321 of 3171

BRAKE SWITCH

EC-341

C

D

E

F

G

H

I

J

K

L

MA

EC

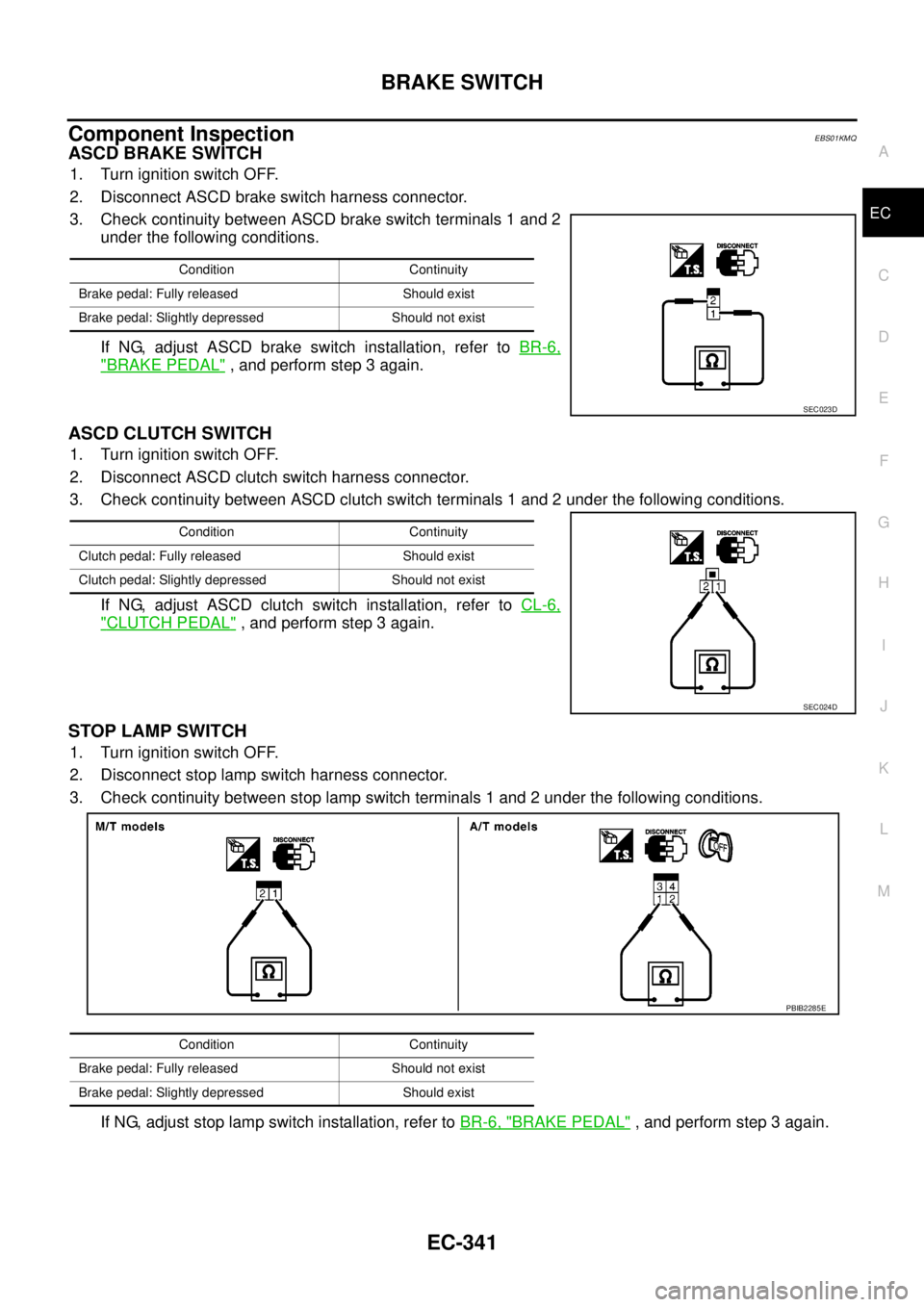

Component InspectionEBS01KMQ

ASCD BRAKE SWITCH

1. Turn ignition switch OFF.

2. Disconnect ASCD brake switch harness connector.

3. Check continuity between ASCD brake switch terminals 1 and 2

under the following conditions.

If NG, adjust ASCD brake switch installation, refer toBR-6,

"BRAKE PEDAL", and perform step 3 again.

ASCD CLUTCH SWITCH

1. Turn ignition switch OFF.

2. Disconnect ASCD clutch switch harness connector.

3. Check continuity between ASCD clutch switch terminals 1 and 2 under the following conditions.

If NG, adjust ASCD clutch switch installation, refer toCL-6,

"CLUTCH PEDAL", and perform step 3 again.

STOP LAMP SWITCH

1. Turn ignition switch OFF.

2. Disconnect stop lamp switch harness connector.

3. Check continuity between stop lamp switch terminals 1 and 2 under the following conditions.

If NG, adjust stop lamp switch installation, refer toBR-6, "

BRAKE PEDAL", and perform step 3 again.

Condition Continuity

Brake pedal: Fully released Should exist

Brake pedal: Slightly depressed Should not exist

SEC023D

Condition Continuity

Clutch pedal: Fully released Should exist

Clutch pedal: Slightly depressed Should not exist

SEC024D

Condition Continuity

Brake pedal: Fully released Should not exist

Brake pedal: Slightly depressed Should exist

PBIB2285E

Page 1337 of 3171

SERVICE DATA AND SPECIFICATIONS (SDS)

EC-357

C

D

E

F

G

H

I

J

K

L

MA

EC

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00100

General SpecificationsEBS01KN4

*: Under the following conditions:

lHeat up switch: OFF

lAir conditioner switch: OFF

lElectric load: OFF (Lights, heater fan & rear window defogger)

lSteering wheel: Kept in straight-ahead position

Mass Air Flow SensorEBS01KN5

*: Engine is warmed up to normal operating temperature and running under no load.

Intake Air Temperature SensorEBS01KN6

Engine Coolant Temperature SensorEBS01KN7

Fuel Rail Pressure SensorEBS01KN8

Fuel InjectorEBS01KN9

Glow PlugEBS01KNA

EGR Volume Control ValveEBS01KNB

Crankshaft Position SensorEBS01KNC

Refer toEC-164, "Component Inspection".

Camshaft Position SensorEBS01KND

Refer toEC-175, "Component Inspection".

Target idle speedA/T No load* (in P or N position)

750±25 rpm

M/T No load* (in Neutral position)

Air conditioner: ONA/T In P or N position 750 rpm or more

M/T In Neutral position 800 rpm or more

Maximum engine speed4,900 rpm

Supply voltageBattery voltage (11 - 14V)

Ignition switch ON (Engine stopped.) Approx. 0.4V

Idle (Engine is warmed up to normal operating temperature.) 1.3 - 1.7V *

Temperature°C(°F) Resistance kW

25 (77)1.800 - 2.200

80 (176)0.283 - 0.359

Temperature°C(°F) Resistance kW

20 (68)2.1 - 2.9

50 (122)0.68 - 1.00

90 (194)0.236 - 0.260

Supply voltageApproximately 5V

Idle (Engine is warmed up to normal operating temperature.) 1.7 - 2.0V

2,000 rpm (Engine is warmed up to normal operating tempera-

ture.)2.0 - 2.3V

Resistance [at 10 - 60°C (50 - 140°F)] 0.2 - 0.8W

Resistance [at 25°C(77°F)] Approximately 0.8W

Resistance [at 25°C(77°F)] 13 - 17W

Page 1344 of 3171

EI-6

SQUEAK AND RATTLE TROUBLE DIAGNOSES

SQUEAK AND RATTLE TROUBLE DIAGNOSES

PFP:00000

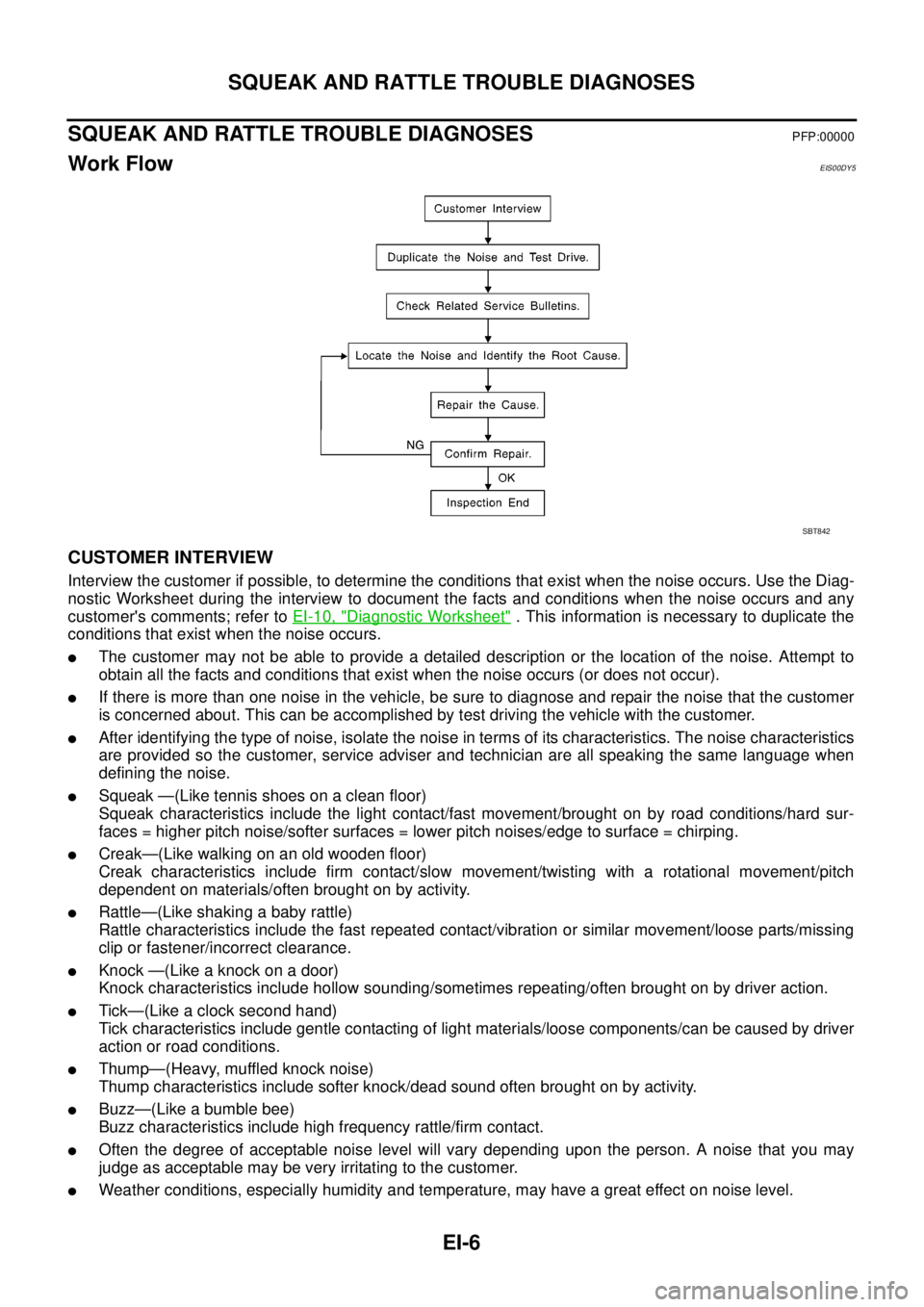

Work FlowEIS00DY5

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interview to document the facts and conditions when the noise occurs and any

customer's comments; refer toEI-10, "

Diagnostic Worksheet". This information is necessary to duplicate the

conditions that exist when the noise occurs.

lThe customer may not be able to provide a detailed description or the location of the noise. Attempt to

obtain all the facts and conditions that exist when the noise occurs (or does not occur).

lIf there is more than one noise in the vehicle, be sure to diagnose and repair the noise that the customer

is concerned about. This can be accomplished by test driving the vehicle with the customer.

lAfter identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so the customer, service adviser and technician are all speaking the same language when

defining the noise.

lSqueak —(Like tennis shoes on a clean floor)

Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard sur-

faces = higher pitch noise/softer surfaces = lower pitch noises/edge to surface = chirping.

lCreak—(Like walking on an old wooden floor)

Creak characteristics include firm contact/slow movement/twisting with a rotational movement/pitch

dependent on materials/often brought on by activity.

lRattle—(Like shaking a baby rattle)

Rattle characteristics include the fast repeated contact/vibration or similar movement/loose parts/missing

clip or fastener/incorrect clearance.

lKnock —(Like a knock on a door)

Knock characteristics include hollow sounding/sometimes repeating/often brought on by driver action.

lTick—(Like a clock second hand)

Tick characteristics include gentle contacting of light materials/loose components/can be caused by driver

action or road conditions.

lThump—(Heavy, muffled knock noise)

Thump characteristics include softer knock/dead sound often brought on by activity.

lBuzz—(Like a bumble bee)

Buzz characteristics include high frequency rattle/firm contact.

lOften the degree of acceptable noise level will vary depending upon the person. A noise that you may

judge as acceptable may be very irritating to the customer.

lWeather conditions, especially humidity and temperature, may have a great effect on noise level.

SBT842

Page 1346 of 3171

EI-8

SQUEAK AND RATTLE TROUBLE DIAGNOSES

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicone spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or rattle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation procedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid bumpers out of adjustment

2. Trunk lid striker out of adjustment

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headliner and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the console panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the console at the clip locations until the clips engage.

In addition look for:

1. Loose harness or harness connectors.

2. Front console map/reading lamp lens loose.

3. Loose screws at console attachment points.