light NISSAN NAVARA 2005 Repair Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1037 of 3171

![NISSAN NAVARA 2005 Repair Repair Manual TROUBLE DIAGNOSIS

EC-57

C

D

E

F

G

H

I

J

K

L

MA

EC71 LTurbocharger boost sensor

ground[Ignition switch ON]Approximately 0.3V

72 BRRefrigerant pressure sensor

ground[Engine is running]

lWarm-up conditio NISSAN NAVARA 2005 Repair Repair Manual TROUBLE DIAGNOSIS

EC-57

C

D

E

F

G

H

I

J

K

L

MA

EC71 LTurbocharger boost sensor

ground[Ignition switch ON]Approximately 0.3V

72 BRRefrigerant pressure sensor

ground[Engine is running]

lWarm-up conditio](/img/5/57362/w960_57362-1036.png)

TROUBLE DIAGNOSIS

EC-57

C

D

E

F

G

H

I

J

K

L

MA

EC71 LTurbocharger boost sensor

ground[Ignition switch ON]Approximately 0.3V

72 BRRefrigerant pressure sensor

ground[Engine is running]

lWarm-up condition

lIdle speedApproximately 0.3V

73 B Mass air flow sensor ground[Ignition switch ON]Approximately 0.3V

74 RIntake air temperature sen-

sor ground[Ignition switch ON]Approximately 0.3V

82 WAccelerator pedal position

sensor 1 power supply[Ignition switch ON]Approximately 5.3V

83 RAccelerator pedal position

sensor 1[Ignition switch ON]

lEngine: Stopped

lAccelerator pedal: Fully released0.95 - 1.17V

[Ignition switch ON]

lEngine: Stopped

lAccelerator pedal: Fully depressedMore than 4.6V

84 BAccelerator pedal position

sensor 1 ground[Ignition switch ON]Approximately 0.3V

85 —Sensor ground

(Accelerator pedal position

sensor shield circuit)[Ignition switch ON]Approximately 0.3V

87 P CAN communication line[Ignition switch ON]Approximately 2.0 - 2.6V

Output voltage varies with the

communication status.

89 SB Data link connector[Ignition switch ON]

lCONSULT-II: DisconnectedApproximately 0V - Battery volt-

age (11 - 14V)

90 WAccelerator pedal position

sensor 2 power supply[Ignition switch ON]Approximately 5.3V

91 RAccelerator pedal position

sensor 2[Ignition switch ON]

lEngine: Stopped

lAccelerator pedal: Fully released0.58 - 0.78V

[Ignition switch ON]

lEngine: Stopped

lAccelerator pedal: Fully depressedMore than 2.3V

92 BAccelerator pedal position

sensor 2 ground[Ignition switch ON]Approximately 0.3V

95 L CAN communication line[Ignition switch ON]Approximately 2.6 - 3.2V

Output voltage varies with the

communication status.

99 V Start signal[Ignition switch ON]Approximately 0.3V

[Ignition switch START]BATTERY VOLTAGE

(11 - 14V)

100 V Stop lamp switch[Ignition switch OFF]

lBrake pedal: Fully releasedApproximately 0V

[Ignition switch OFF]

lBrake pedal: Slightly depressedBATTERY VOLTAGE

(11 - 14V) TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage and Pulse Signal)

Page 1038 of 3171

![NISSAN NAVARA 2005 Repair Repair Manual EC-58

TROUBLE DIAGNOSIS

: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)101 W ASCD brake switch[Ignition switch ON]

lBrake pedal: Fully released (A/T)

lClutch NISSAN NAVARA 2005 Repair Repair Manual EC-58

TROUBLE DIAGNOSIS

: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)101 W ASCD brake switch[Ignition switch ON]

lBrake pedal: Fully released (A/T)

lClutch](/img/5/57362/w960_57362-1037.png)

EC-58

TROUBLE DIAGNOSIS

: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)101 W ASCD brake switch[Ignition switch ON]

lBrake pedal: Fully released (A/T)

lClutch pedal and brake pedal:

Fully released (M/T)BATTERY VOLTAGE

(11 - 14V)

[Ignition switch ON]

lBrake pedal: Slightly depressed (A/T)

lClutch pedal and/or brake pedal:

Slightly depressed (M/T)Approximately 0V

102 SB ASCD steering switch[Ignition switch ON]

lASCD steering switch: OFFApproximately 4.3V

[Ignition switch ON]

lON/OFF switch: PressedApproximately 0.3V

[Ignition switch ON]

lCANCEL switch: PressedApproximately 1.3V

[Ignition switch ON]

lRESUME/ACCELERATE switch: PressedApproximately 3.3V

[Ignition switch ON]

lSET/COAST switch: PressedApproximately 2.3V

103 BASCD steering switch

ground[Ignition switch ON]Approximately 0.3V

105 BR ECM relay (self shut-off)[Ignition switch ON]

[Ignition switch OFF]

lFor a few seconds after turning ignition

switch OFFApproximately 1.0V

[Ignition switch OFF]

lMore than a few seconds after turning igni-

tion switch OFFBATTERY VOLTAGE

(11 - 14V)

107

108R

RIgnition switch[Ignition switch ON]BATTERY VOLTAGE

(11 - 14V)

11 0G(A/T)

O (M/T)Park/Neutral position switch[Ignition switch ON]

lShift lever: P or N (A/T), Neutral (M/T)Approximately 0V

[Ignition switch ON]

lExcept the above positionBATTERY VOLTAGE

(11 - 14V)

113 BR ECM relay (self shut-off)[Ignition switch ON]

[Ignition switch OFF]

lFor a few seconds after turning ignition

switch OFFApproximately 1.0V

[Ignition switch OFF]

lMore than a few seconds after turning igni-

tion switch OFFBATTERY VOLTAGE

(11 - 14V)

114 B ECM ground[Engine is running]

lIdle speedApproximately 0V

11 9

120R

GPower supply for ECM[Ignition switch ON]BATTERY VOLTAGE

(11 - 14V)

121 VPower supply for ECM

(Back-up)[Ignition switch OFF]BATTERY VOLTAGE

(11 - 14V) TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage and Pulse Signal)

Page 1047 of 3171

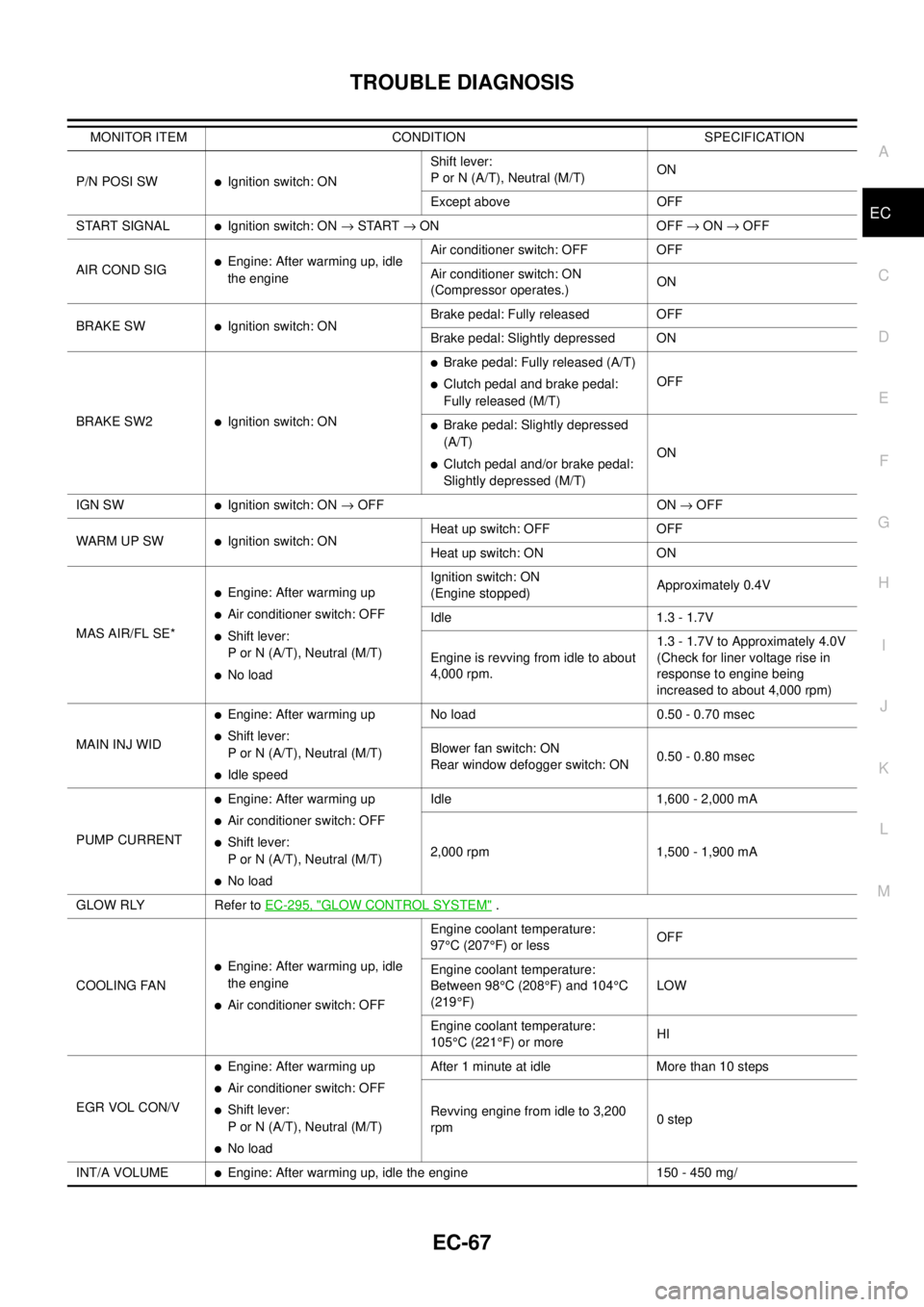

TROUBLE DIAGNOSIS

EC-67

C

D

E

F

G

H

I

J

K

L

MA

EC

P/N POSI SWlIgnition switch: ONShift lever:

P or N (A/T), Neutral (M/T)ON

Except above OFF

START SIGNAL

lIgnition switch: ON®START®ON OFF®ON®OFF

AIRCONDSIG

lEngine: After warming up, idle

the engineAir conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor operates.)ON

BRAKE SW

lIgnition switch: ONBrake pedal: Fully released OFF

Brake pedal: Slightly depressed ON

BRAKE SW2

lIgnition switch: ON

lBrake pedal: Fully released (A/T)

lClutch pedal and brake pedal:

Fully released (M/T)OFF

lBrake pedal: Slightly depressed

(A/T)

lClutch pedal and/or brake pedal:

Slightly depressed (M/T)ON

IGN SW

lIgnition switch: ON®OFF ON®OFF

WARM UP SW

lIgnition switch: ONHeat up switch: OFF OFF

Heat up switch: ON ON

MAS AIR/FL SE*

lEngine: After warming up

lAir conditioner switch: OFF

lShift lever:

P or N (A/T), Neutral (M/T)

lNo loadIgnition switch: ON

(Engine stopped)Approximately 0.4V

Idle 1.3 - 1.7V

Engine is revving from idle to about

4,000 rpm.1.3 - 1.7V to Approximately 4.0V

(Check for liner voltage rise in

response to engine being

increased to about 4,000 rpm)

MAIN INJ WID

lEngine: After warming up

lShift lever:

P or N (A/T), Neutral (M/T)

lIdle speedNo load 0.50 - 0.70 msec

Blower fan switch: ON

Rear window defogger switch: ON0.50 - 0.80 msec

PUMP CURRENT

lEngine: After warming up

lAir conditioner switch: OFF

lShift lever:

P or N (A/T), Neutral (M/T)

lNo loadIdle 1,600 - 2,000 mA

2,000 rpm 1,500 - 1,900 mA

GLOW RLY Refer toEC-295, "

GLOW CONTROL SYSTEM".

COOLING FAN

lEngine: After warming up, idle

the engine

lAir conditioner switch: OFFEngine coolant temperature:

97°C (207°F) or lessOFF

Engine coolant temperature:

Between 98°C(208°F) and 104°C

(219°F)LOW

Engine coolant temperature:

105°C(221°F) or moreHI

EGR VOL CON/V

lEngine: After warming up

lAir conditioner switch: OFF

lShift lever:

P or N (A/T), Neutral (M/T)

lNo loadAfter 1 minute at idle More than 10 steps

Revving engine from idle to 3,200

rpm0step

INT/A VOLUME

lEngine: After warming up, idle the engine 150 - 450 mg/ MONITOR ITEM CONDITION SPECIFICATION

Page 1059 of 3171

DTC U1000 CAN COMMUNICATION LINE

EC-79

C

D

E

F

G

H

I

J

K

L

MA

EC

DTC U1000 CAN COMMUNICATION LINEPFP:23710

DescriptionEBS01KDA

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

On Board Diagnosis LogicEBS01KDB

The MI will not light up for this self-diagnosis.

DTC Confirmation ProcedureEBS01KDC

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-II

1. Turn ignition switch ON and wait at least 3 seconds.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. If DTC is detected, go toEC-81, "

Diagnostic Procedure".

DTC No.Trouble diagnosis

nameDTC detecting condition Possible cause

U1000

1000CAN communication

line

lECM can not communicate to other control

unit.

lECM can not communicate for more than the

specified time.

lHarness or connectors

(CAN communication line is open or

shorted)

SEF817Y

Page 1062 of 3171

EC-82

DTC P0016 CKP - CMP CORRELATION

DTC P0016 CKP - CMP CORRELATION

PFP:10328

On Board Diagnosis LogicEBS01KDF

The MI will not light up for this self-diagnosis.

NOTE:

If DTC P0016 is displayed with DTC P0652 or P0653, first perform the trouble diagnosis for DTC P0652

or P0653. Refer toEC-227, "

DTC P0652, P0653 SENSOR POWER SUPPLY".

DTC Confirmation ProcedureEBS01KDG

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-II

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Start engine and let it idle for at least 5 seconds.

4. If DTC is detected, go toEC-82, "

Diagnostic Procedure".

WITHOUT CONSULT-II

1. Start engine and let it idle for at least 5 seconds.

2. Turn ignition switch OFF, wait at least 10 seconds and then turn ON.

3. Perform Diagnostic Test Mode II (Self-diagnostic results) with ECM.

4. If DTC is detected, go toEC-82, "

Diagnostic Procedure".

Diagnostic ProcedureEBS01KDH

1.CHECK CAMSHAFT POSITION SENSOR

Refer toEC-175, "

Component Inspection".

OK or NG

OK >> GO TO 2.

NG >> Replace camshaft position sensor.

2.CHECK SPROCKET

Visually check for chipping signal plate gear tooth.

OK or NG

OK >> GO TO 3.

NG >> Remove debris and clean the signal plate or replace sprocket.

DTC No.Trouble diagnosis

nameDTC detecting condition Possible cause

P0016

0016Crankshaft position -

camshaft position cor-

relationThe correlation between crankshaft position sen-

sor signal and camshaft position sensor signal is

out of the normal range.

lCamshaft position sensor

lCrankshaft position sensor

lTiming chain

lSignal plate

SEF817Y

Page 1066 of 3171

EC-86

DTC P0089 FUEL PUMP

DTC P0089 FUEL PUMP

PFP:16700

On Board Diagnosis LogicEBS01KDM

The MI will not light up for this self-diagnosis.

NOTE:

If DTC P0089 is displayed with DTC P0652 or P0653, first perform the trouble diagnosis for DTC P0652

or P0653. Refer toEC-227, "

DTC P0652, P0653 SENSOR POWER SUPPLY".

DTC Confirmation ProcedureEBS01KDN

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Let engine idle for at least 30 seconds.

4. If DTC is detected, go toEC-87, "

Diagnostic Procedure".

WITHOUT CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Let engine idle for at least 30 seconds.

3. Turn ignition switch OFF, wait at least 10 seconds and then turn ON.

4. Perform Diagnostic Test Mode II (Self-diagnostic results) with ECM.

5. If DTC is detected, go toEC-87, "

Diagnostic Procedure".

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0089

0089Fuel pump performanceFuel pressure is too much higher than the target

value.

lFuel pump

lAir mixed with fuel

lLack of fuel

lFuel rail pressure sensor

SEF817Y

Page 1073 of 3171

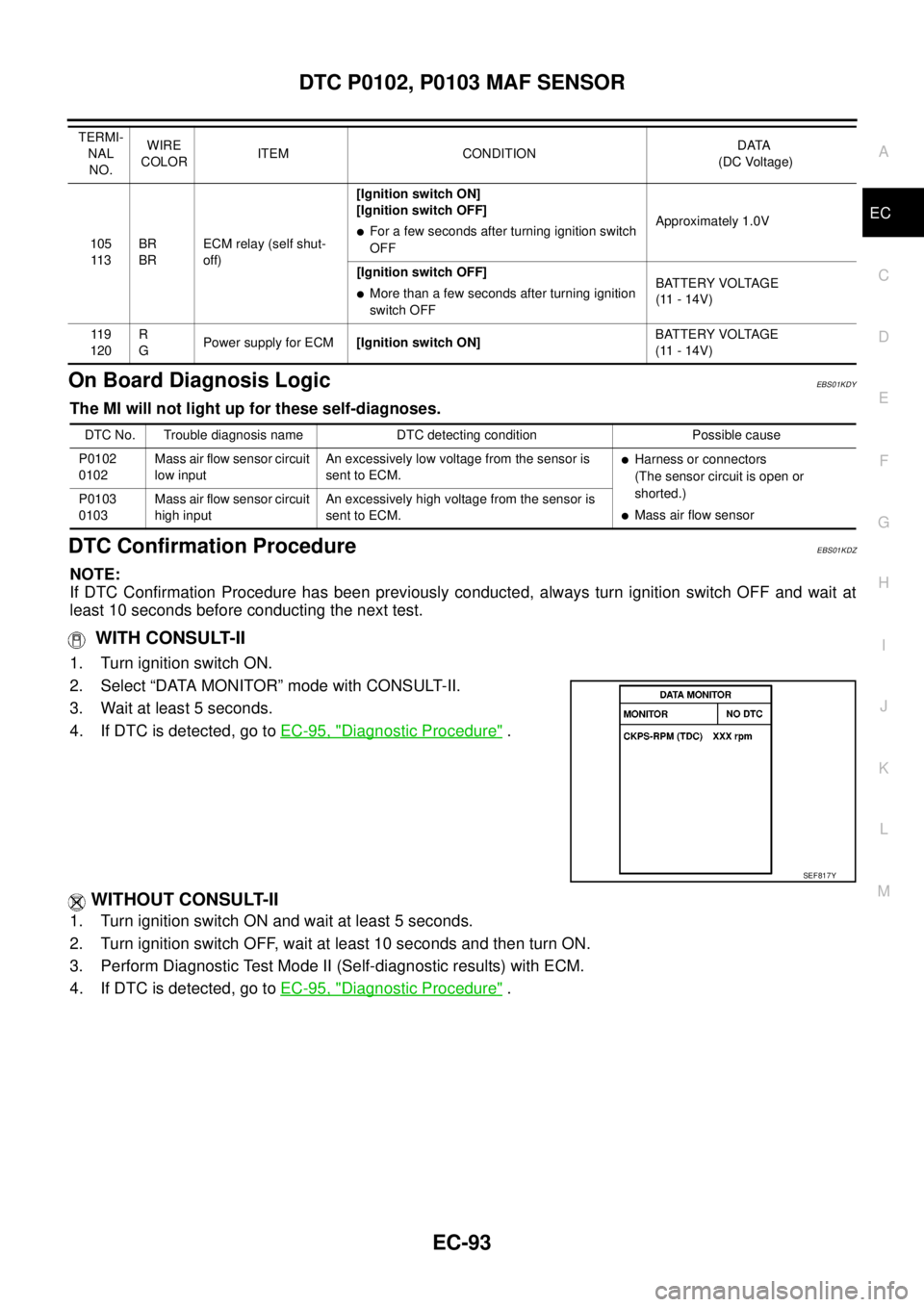

DTC P0102, P0103 MAF SENSOR

EC-93

C

D

E

F

G

H

I

J

K

L

MA

EC

On Board Diagnosis LogicEBS01KDY

The MI will not light up for these self-diagnoses.

DTC Confirmation ProcedureEBS01KDZ

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-II

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Wait at least 5 seconds.

4. If DTC is detected, go toEC-95, "

Diagnostic Procedure".

WITHOUT CONSULT-II

1. Turn ignition switch ON and wait at least 5 seconds.

2. Turn ignition switch OFF, wait at least 10 seconds and then turn ON.

3. Perform Diagnostic Test Mode II (Self-diagnostic results) with ECM.

4. If DTC is detected, go toEC-95, "

Diagnostic Procedure".

105

11 3BR

BRECM relay (self shut-

off)[Ignition switch ON]

[Ignition switch OFF]lFor a few seconds after turning ignition switch

OFFApproximately 1.0V

[Ignition switch OFF]

lMore than a few seconds after turning ignition

switch OFFBATTERY VOLTAGE

(11 - 14V)

11 9

120R

GPower supply for ECM[Ignition switch ON]BATTERY VOLTAGE

(11 - 14V) TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage)

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0102

0102Mass air flow sensor circuit

low inputAn excessively low voltage from the sensor is

sent to ECM.

lHarness or connectors

(The sensor circuit is open or

shorted.)

lMass air flow sensor P0103

0103Mass air flow sensor circuit

high inputAn excessively high voltage from the sensor is

sent to ECM.

SEF817Y

Page 1078 of 3171

EC-98

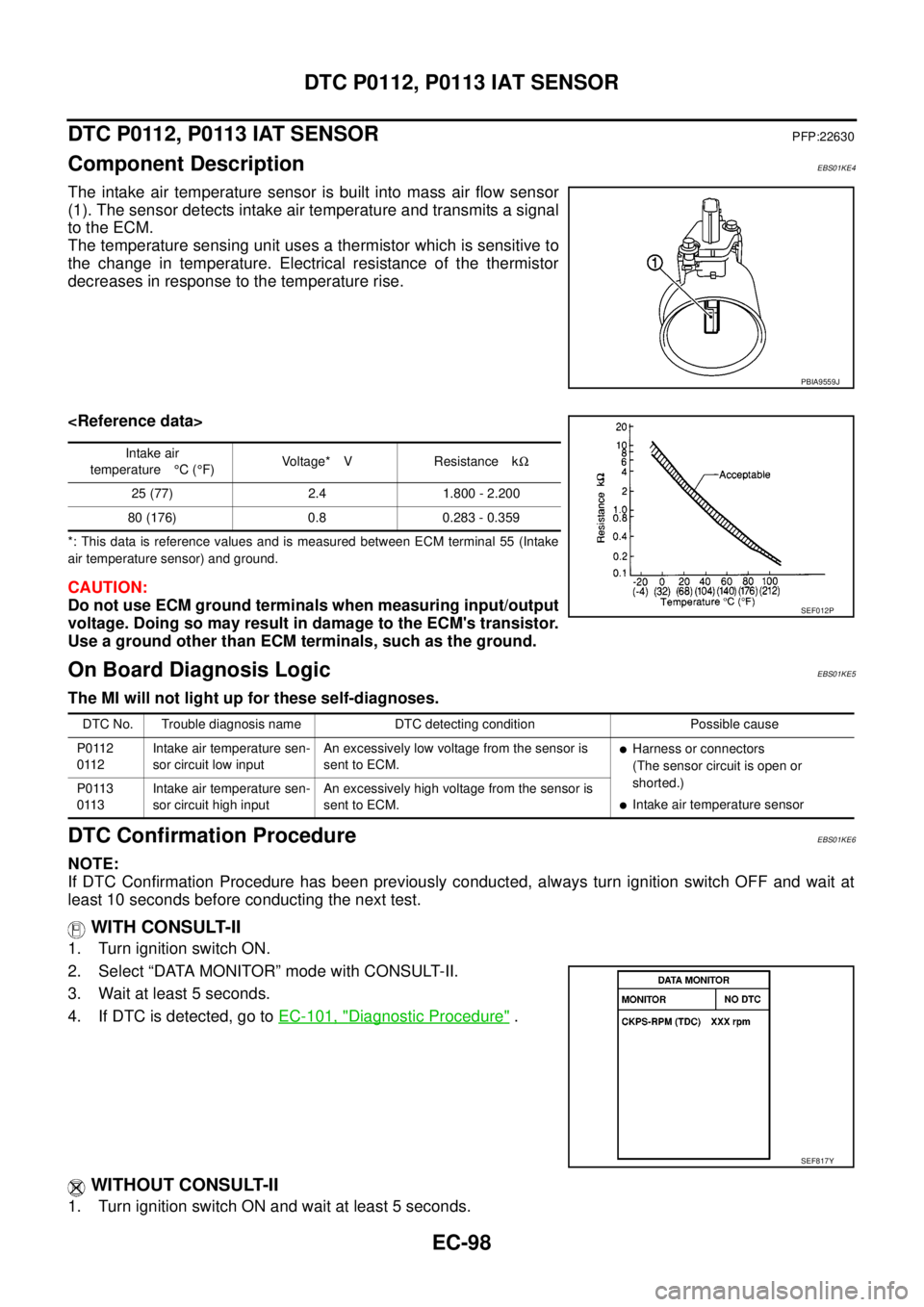

DTC P0112, P0113 IAT SENSOR

DTC P0112, P0113 IAT SENSOR

PFP:22630

Component DescriptionEBS01KE4

The intake air temperature sensor is built into mass air flow sensor

(1). The sensor detects intake air temperature and transmits a signal

to the ECM.

The temperature sensing unit uses a thermistor which is sensitive to

the change in temperature. Electrical resistance of the thermistor

decreases in response to the temperature rise.

*: This data is reference values and is measured between ECM terminal 55 (Intake

air temperature sensor) and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output

voltage. Doing so may result in damage to the ECM's transistor.

Use a ground other than ECM terminals, such as the ground.

On Board Diagnosis LogicEBS01KE5

The MI will not light up for these self-diagnoses.

DTC Confirmation ProcedureEBS01KE6

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-II

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Wait at least 5 seconds.

4. If DTC is detected, go toEC-101, "

Diagnostic Procedure".

WITHOUT CONSULT-II

1. Turn ignition switch ON and wait at least 5 seconds.

PBIA9559J

Intake air

temperature°C(°F)Voltage* V Resistance kW

25 (77) 2.4 1.800 - 2.200

80 (176) 0.8 0.283 - 0.359

SEF012P

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0112

0112Intake air temperature sen-

sor circuit low inputAn excessively low voltage from the sensor is

sent to ECM.

lHarness or connectors

(The sensor circuit is open or

shorted.)

lIntake air temperature sensor P0113

0113Intake air temperature sen-

sor circuit high inputAn excessively high voltage from the sensor is

sent to ECM.

SEF817Y

Page 1083 of 3171

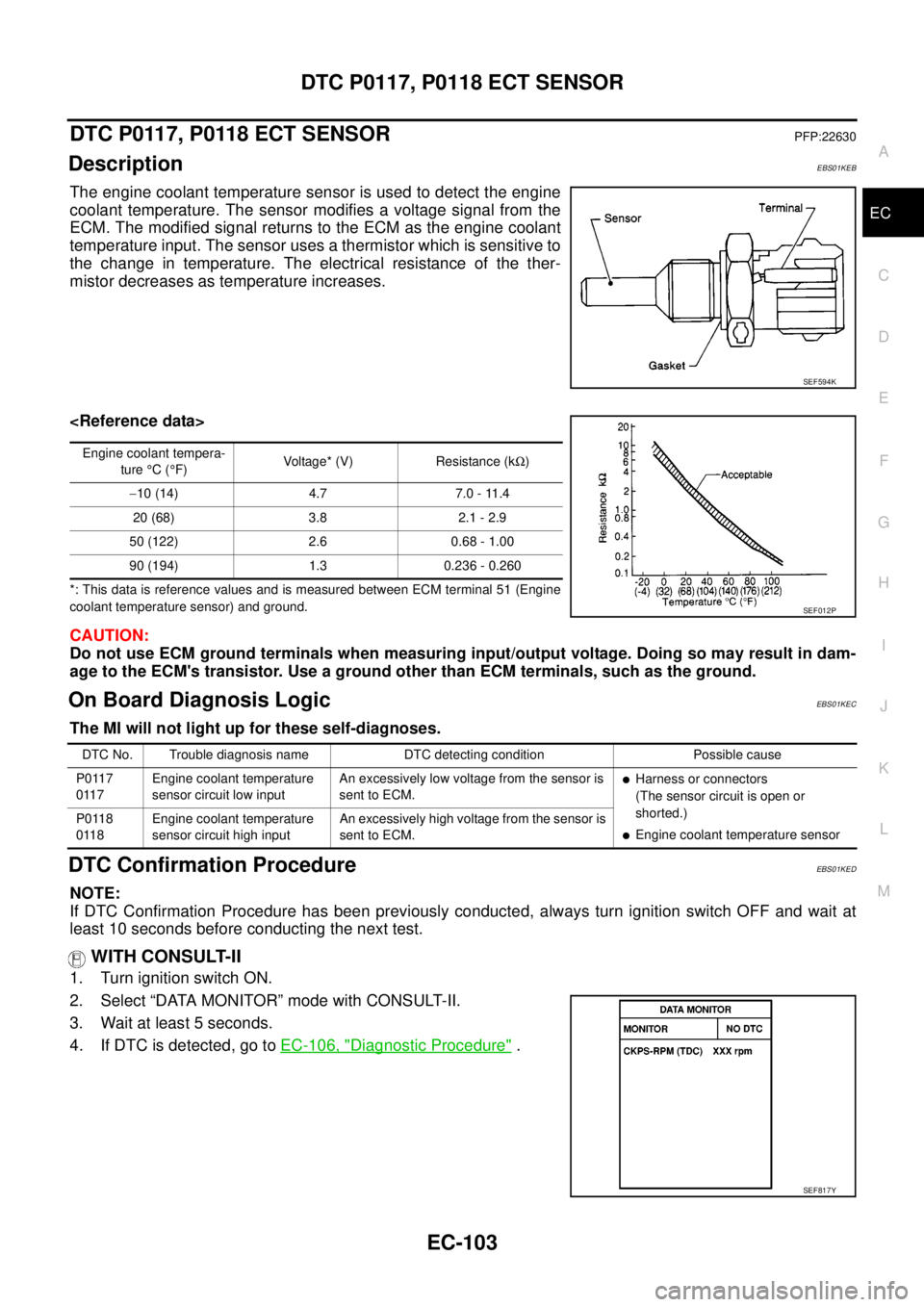

DTC P0117, P0118 ECT SENSOR

EC-103

C

D

E

F

G

H

I

J

K

L

MA

EC

DTC P0117, P0118 ECT SENSORPFP:22630

DescriptionEBS01KEB

The engine coolant temperature sensor is used to detect the engine

coolant temperature. The sensor modifies a voltage signal from the

ECM. The modified signal returns to the ECM as the engine coolant

temperature input. The sensor uses a thermistor which is sensitive to

the change in temperature. The electrical resistance of the ther-

mistor decreases as temperature increases.

*: This data is reference values and is measured between ECM terminal 51 (Engine

coolant temperature sensor) and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

On Board Diagnosis LogicEBS01KEC

The MI will not light up for these self-diagnoses.

DTC Confirmation ProcedureEBS01KED

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-II

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Wait at least 5 seconds.

4. If DTC is detected, go toEC-106, "

Diagnostic Procedure".

SEF594K

Engine coolant tempera-

ture°C(°F)Voltage* (V) Resistance (kW)

-10 (14) 4.7 7.0 - 11.4

20 (68) 3.8 2.1 - 2.9

50 (122) 2.6 0.68 - 1.00

90 (194) 1.3 0.236 - 0.260

SEF012P

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0117

0117Engine coolant temperature

sensor circuit low inputAn excessively low voltage from the sensor is

sent to ECM.

lHarness or connectors

(The sensor circuit is open or

shorted.)

lEngine coolant temperature sensor P0118

0118Engine coolant temperature

sensor circuit high inputAn excessively high voltage from the sensor is

sent to ECM.

SEF817Y

Page 1089 of 3171

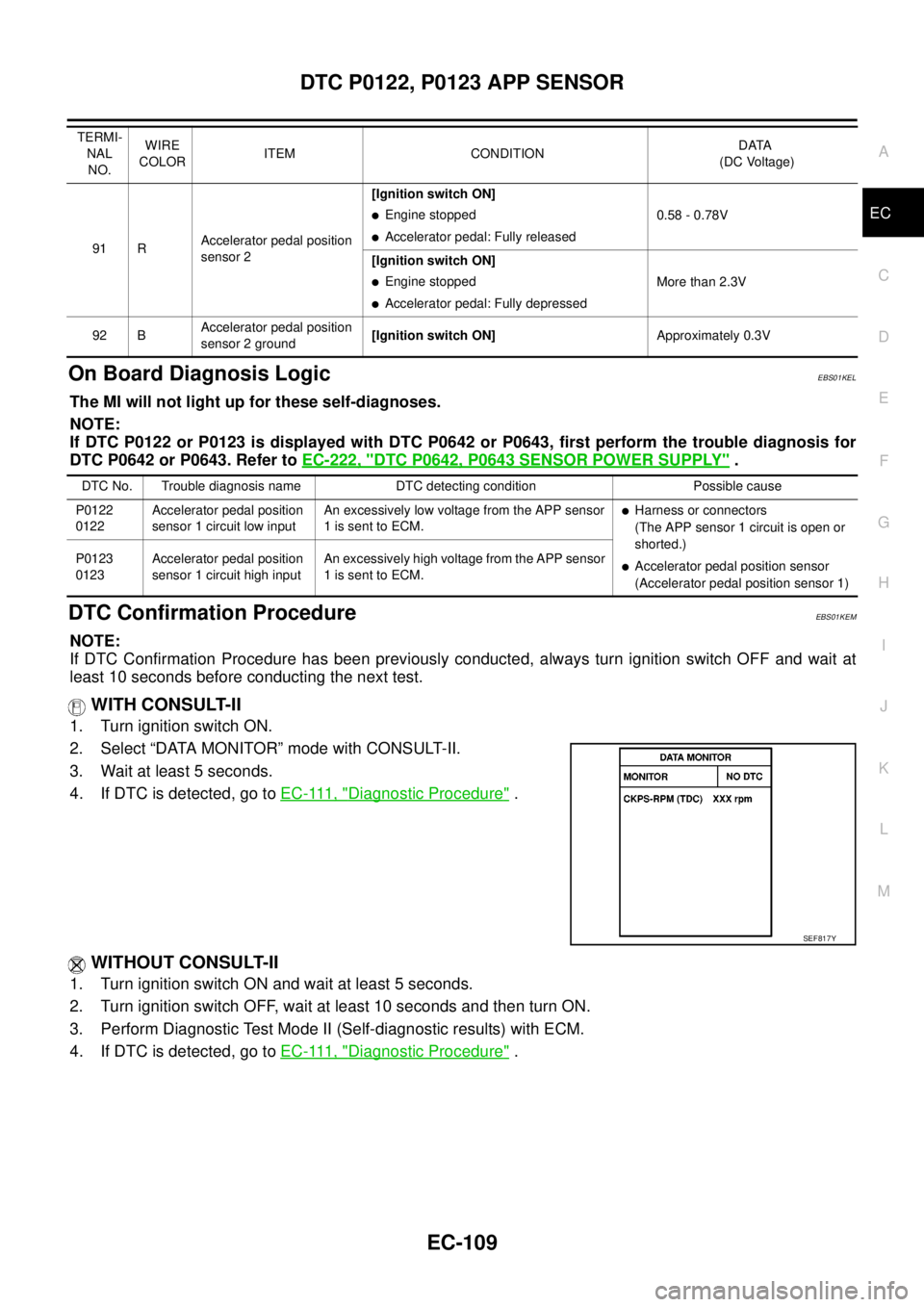

DTC P0122, P0123 APP SENSOR

EC-109

C

D

E

F

G

H

I

J

K

L

MA

EC

On Board Diagnosis LogicEBS01KEL

The MI will not light up for these self-diagnoses.

NOTE:

If DTC P0122 or P0123 is displayed with DTC P0642 or P0643, first perform the trouble diagnosis for

DTC P0642 or P0643. Refer toEC-222, "

DTC P0642, P0643 SENSOR POWER SUPPLY".

DTC Confirmation ProcedureEBS01KEM

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-II

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Wait at least 5 seconds.

4. If DTC is detected, go toE C - 111 , "

Diagnostic Procedure".

WITHOUT CONSULT-II

1. Turn ignition switch ON and wait at least 5 seconds.

2. Turn ignition switch OFF, wait at least 10 seconds and then turn ON.

3. Perform Diagnostic Test Mode II (Self-diagnostic results) with ECM.

4. If DTC is detected, go toE C - 111 , "

Diagnostic Procedure".

91 RAccelerator pedal position

sensor 2[Ignition switch ON]

lEngine stopped

lAccelerator pedal: Fully released0.58 - 0.78V

[Ignition switch ON]

lEngine stopped

lAccelerator pedal: Fully depressedMore than 2.3V

92 BAccelerator pedal position

sensor 2 ground[Ignition switch ON]Approximately 0.3V TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage)

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0122

0122Accelerator pedal position

sensor 1 circuit low inputAn excessively low voltage from the APP sensor

1 is sent to ECM.

lHarness or connectors

(The APP sensor 1 circuit is open or

shorted.)

lAccelerator pedal position sensor

(Accelerator pedal position sensor 1) P0123

0123Accelerator pedal position

sensor 1 circuit high inputAn excessively high voltage from the APP sensor

1 is sent to ECM.

SEF817Y