NISSAN NAVARA 2005 Repair Workshop Manual

Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1131 of 3171

DTC P0234 TC SYSTEM

EC-151

C

D

E

F

G

H

I

J

K

L

MA

EC

4.DETECT MALFUNCTIONING PART

Check the following.

lHarness connectors E9, F4

lHarness for open or short between IPDM E/R and turbocharger boost control solenoid valve

lHarness for open or short between ECM and turbocharger boost control solenoid valve

>> Repair open circuit or short to ground or short to power in harness or connectors.

5.CHECK TURBOCHARGER BOOST CONTROL SOLENOID VALVE OUTPUT SIGNAL CIRCUIT FOR

OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminals 6 and turbocharger boost control solenoid valve termi-

nal 2.

Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 6.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

6.CHECK TURBOCHARGE BOOST CONTROL SOLENOID VALVE

Refer toEC-152, "

Component Inspection".

OK or NG

OK >> GO TO 7.

NG >> Replace turbocharger boost control solenoid valve.

7.CHECK VACUUM PUMP

Refer toEM-42, "

VACUUM PUMP".

OK or NG

OK >> GO TO 8.

NG >> Replace vacuum pump assembly.

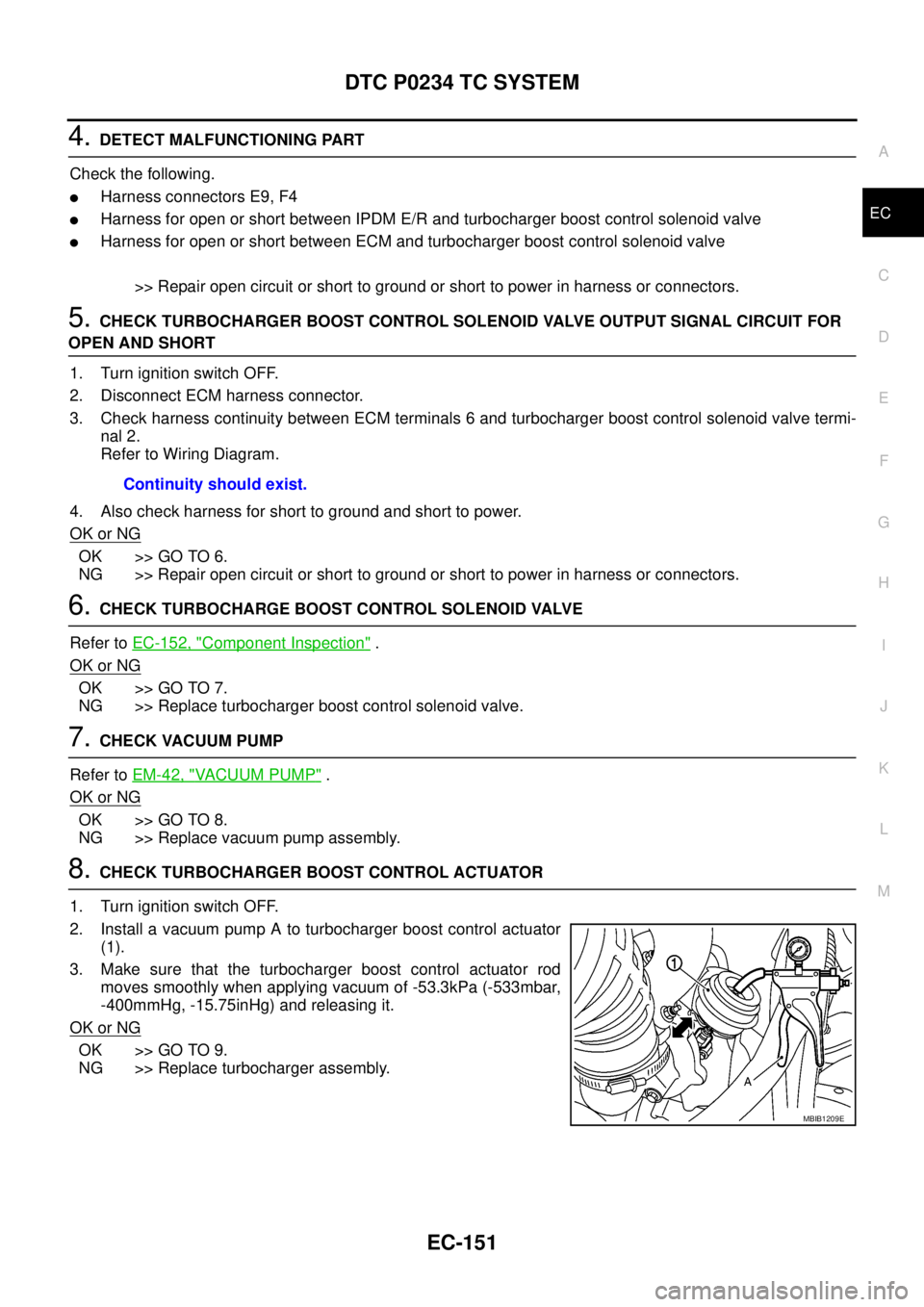

8.CHECK TURBOCHARGER BOOST CONTROL ACTUATOR

1. Turn ignition switch OFF.

2. Install a vacuum pump A to turbocharger boost control actuator

(1).

3. Make sure that the turbocharger boost control actuator rod

moves smoothly when applying vacuum of -53.3kPa (-533mbar,

-400mmHg, -15.75inHg) and releasing it.

OK or NG

OK >> GO TO 9.

NG >> Replace turbocharger assembly.Continuity should exist.

MBIB1209E

Page 1132 of 3171

EC-152

DTC P0234 TC SYSTEM

9.CHECK TURBOCHARGER BOOST SENSOR

Refer toEC-158, "

Component Inspection".

OK or NG

OK >> GO TO 10.

NG >> Replace turbocharger boost sensor.

10.CHECK INTERMITTENT INCIDENT

Refer toEC-70, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT".

>>INSPECTION END

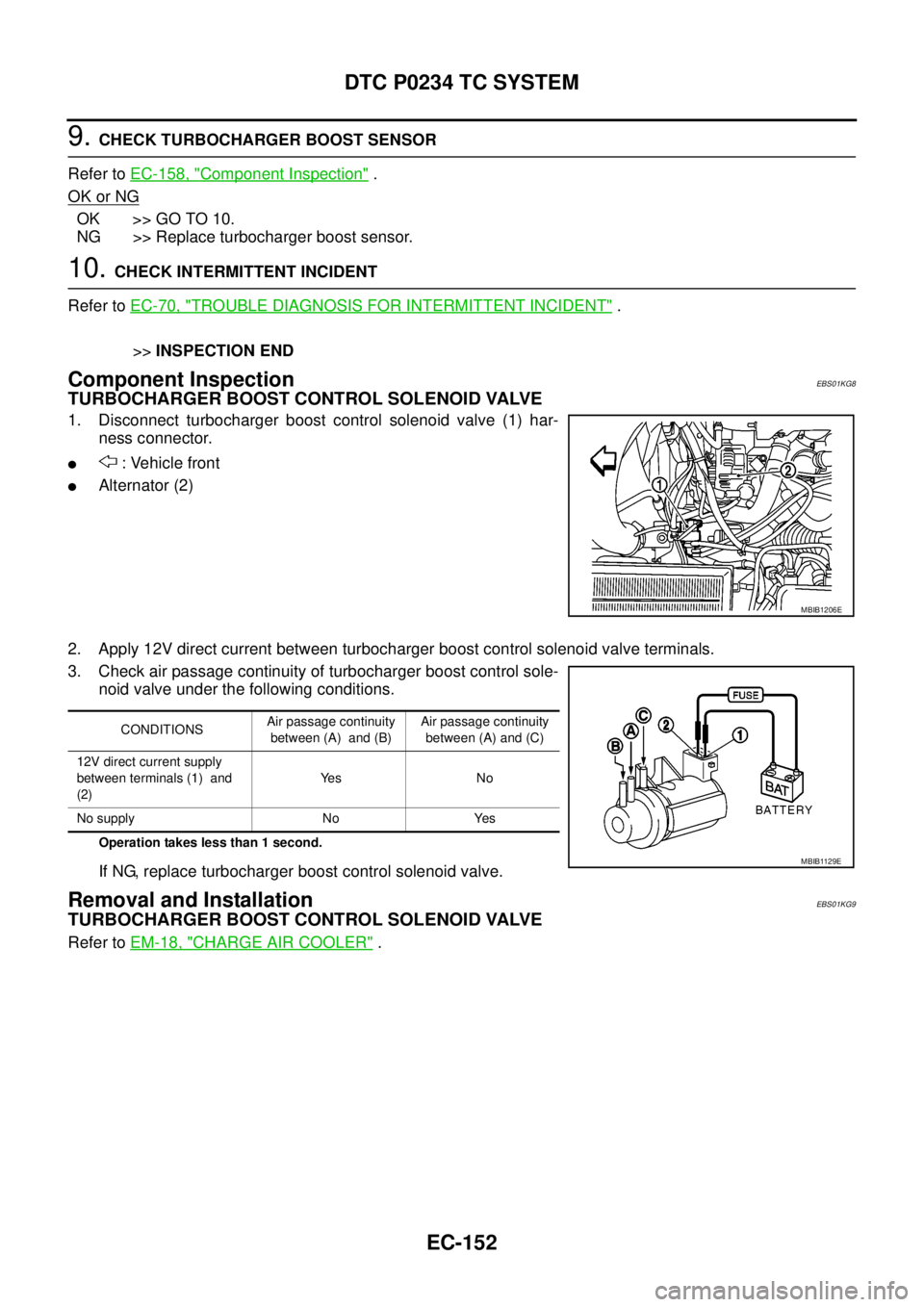

Component InspectionEBS01KG8

TURBOCHARGER BOOST CONTROL SOLENOID VALVE

1. Disconnect turbocharger boost control solenoid valve (1) har-

ness connector.

l: Vehicle front

lAlternator (2)

2. Apply 12V direct current between turbocharger boost control solenoid valve terminals.

3. Check air passage continuity of turbocharger boost control sole-

noid valve under the following conditions.

Operation takes less than 1 second.

If NG, replace turbocharger boost control solenoid valve.

Removal and InstallationEBS01KG9

TURBOCHARGER BOOST CONTROL SOLENOID VALVE

Refer toEM-18, "CHARGE AIR COOLER".

MBIB1206E

CONDITIONSAir passage continuity

between (A) and (B)Air passage continuity

between (A) and (C)

12V direct current supply

between terminals (1) and

(2)Ye s N o

No supply No Yes

MBIB1129E

Page 1133 of 3171

DTC P0237, P0238 TC BOOST SENSOR

EC-153

C

D

E

F

G

H

I

J

K

L

MA

EC

DTC P0237, P0238 TC BOOST SENSORPFP:22365

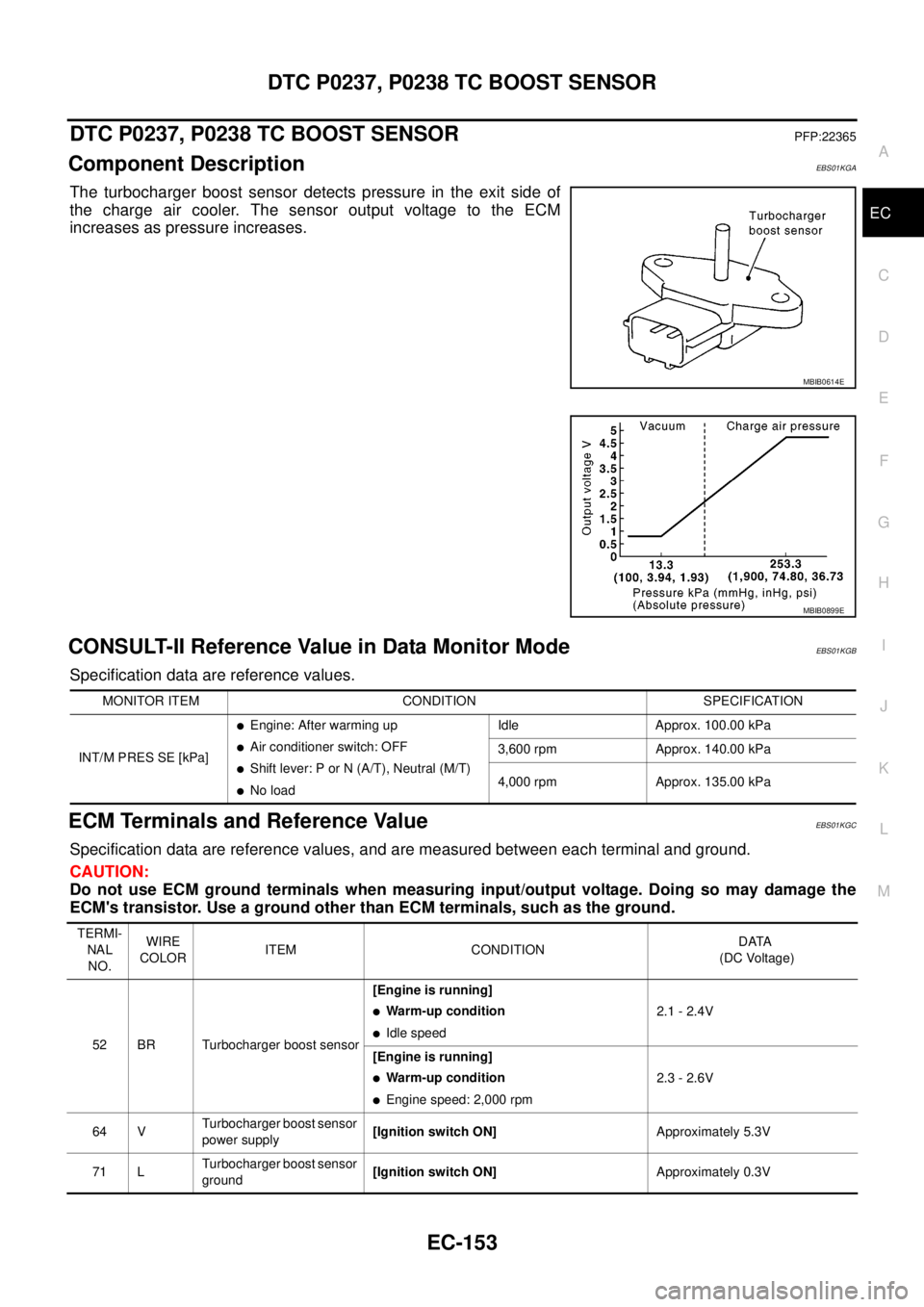

Component DescriptionEBS01KGA

The turbocharger boost sensor detects pressure in the exit side of

the charge air cooler. The sensor output voltage to the ECM

increases as pressure increases.

CONSULT-II Reference Value in Data Monitor ModeEBS01KGB

Specification data are reference values.

ECM Terminals and Reference ValueEBS01KGC

Specification data are reference values, and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

MBIB0614E

MBIB0899E

MONITOR ITEM CONDITION SPECIFICATION

INT/M PRES SE [kPa]

lEngine: After warming up

lAir conditioner switch: OFF

lShift lever: P or N (A/T), Neutral (M/T)

lNo loadIdle Approx. 100.00 kPa

3,600 rpm Approx. 140.00 kPa

4,000 rpm Approx. 135.00 kPa

TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage)

52 BR Turbocharger boost sensor[Engine is running]

lWarm-up condition

lIdle speed2.1 - 2.4V

[Engine is running]

lWarm-up condition

lEngine speed: 2,000 rpm2.3 - 2.6V

64 VTurbocharger boost sensor

power supply[Ignition switch ON]Approximately 5.3V

71 LTurbocharger boost sensor

ground[Ignition switch ON]Approximately 0.3V

Page 1134 of 3171

EC-154

DTC P0237, P0238 TC BOOST SENSOR

On Board Diagnosis Logic

EBS01KGD

The MI will not light up for these self-diagnoses.

NOTE:

If DTC P0237 or P0238 is displayed with DTC P0652 or P0653, first perform the trouble diagnosis for

DTC P0652 or P0653. Refer toEC-227, "

DTC P0652, P0653 SENSOR POWER SUPPLY".

DTC Confirmation ProcedureEBS01KGE

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-II

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Wait at least 5 seconds.

4. If DTC is detected, go toEC-156, "

Diagnostic Procedure".

WITHOUT CONSULT-II

1. Turn ignition switch ON and wait at least 5 seconds.

2. Turn ignition switch OFF, wait at least 10 seconds and then turn ON.

3. Perform Diagnostic Test Mode II (Self-diagnostic results) with ECM.

4. If DTC is detected, go toEC-156, "

Diagnostic Procedure".

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0237

0237Turbocharger boost sensor

circuit low inputAn excessively low voltage from the sensor is

sent to ECM.

lHarness or connectors

(The sensor circuit is open or

shorted.)

lTurbocharger boost sensor P0238

0238Turbocharger boost sensor

circuit high inputAn excessively high voltage from the sensor is

sent to ECM.

SEF817Y

Page 1135 of 3171

DTC P0237, P0238 TC BOOST SENSOR

EC-155

C

D

E

F

G

H

I

J

K

L

MA

EC

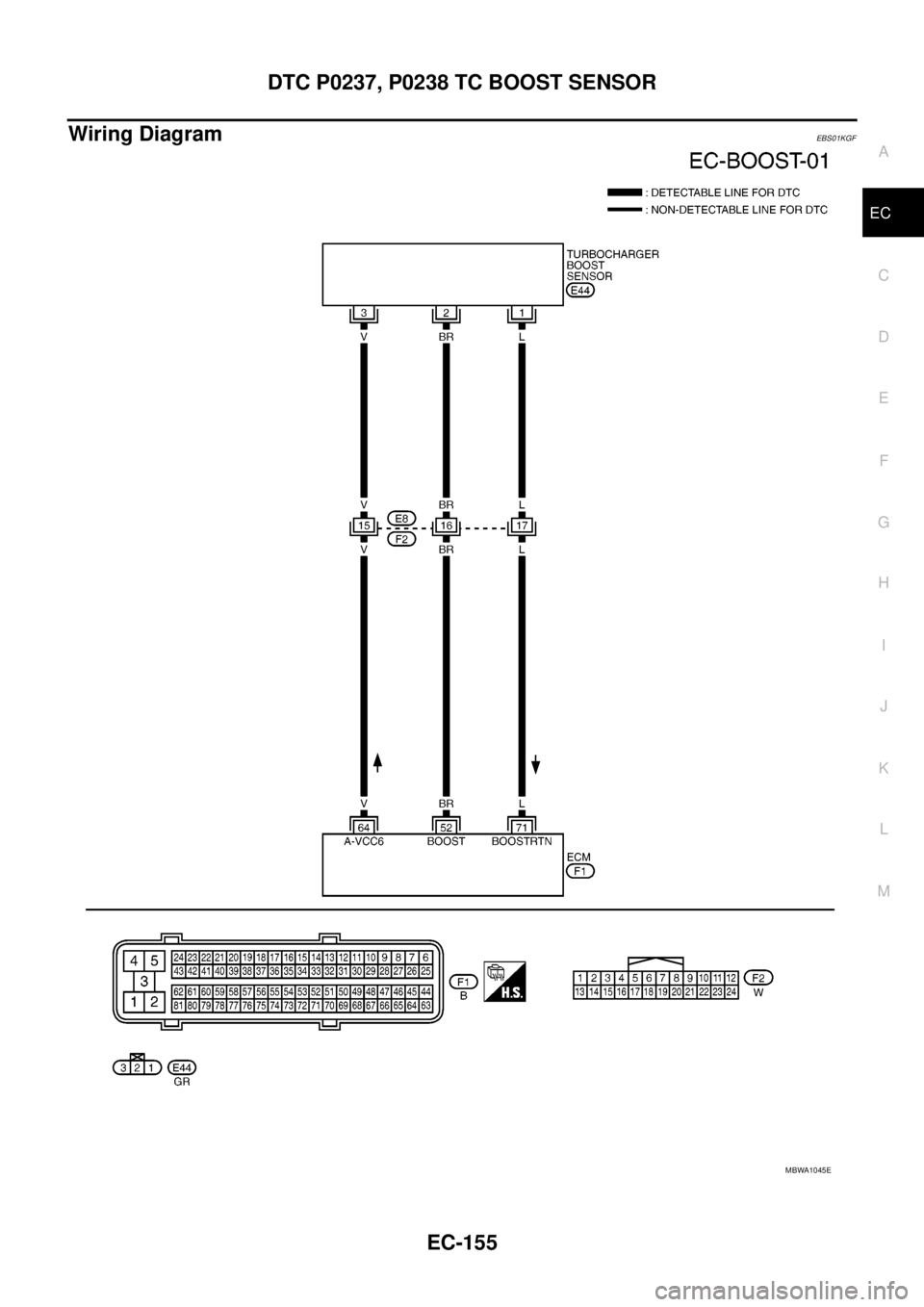

Wiring DiagramEBS01KGF

MBWA1045E

Page 1136 of 3171

EC-156

DTC P0237, P0238 TC BOOST SENSOR

Diagnostic Procedure

EBS01KGG

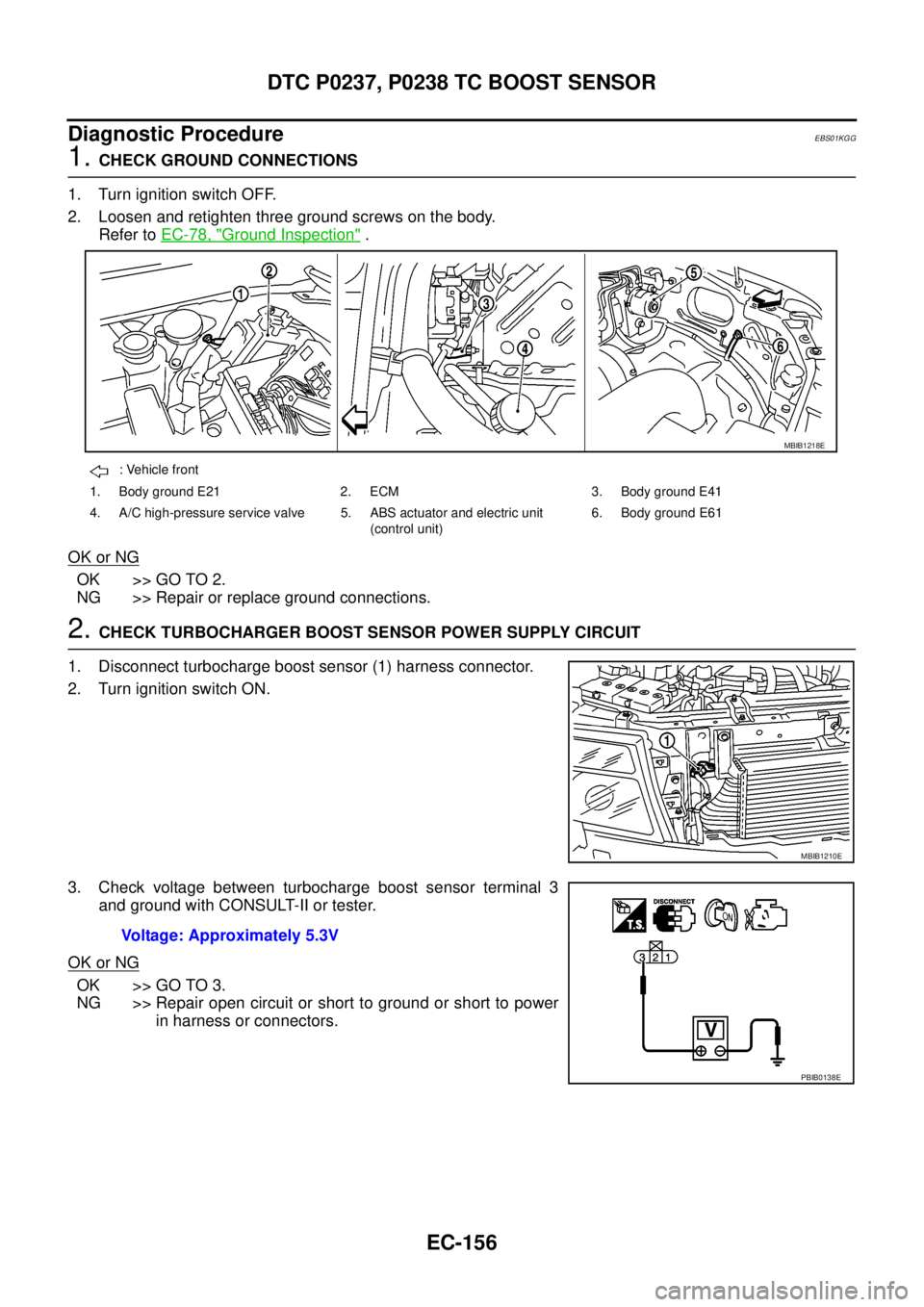

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten three ground screws on the body.

Refer toEC-78, "

Ground Inspection".

OK or NG

OK >> GO TO 2.

NG >> Repair or replace ground connections.

2.CHECK TURBOCHARGER BOOST SENSOR POWER SUPPLY CIRCUIT

1. Disconnect turbocharge boost sensor (1) harness connector.

2. Turn ignition switch ON.

3. Check voltage between turbocharge boost sensor terminal 3

and ground with CONSULT-II or tester.

OK or NG

OK >> GO TO 3.

NG >> Repair open circuit or short to ground or short to power

in harness or connectors.

: Vehicle front

1. Body ground E21 2. ECM 3. Body ground E41

4. A/C high-pressure service valve 5. ABS actuator and electric unit

(control unit)6. Body ground E61

MBIB1218E

MBIB1210E

Voltage: Approximately 5.3V

PBIB0138E

Page 1137 of 3171

DTC P0237, P0238 TC BOOST SENSOR

EC-157

C

D

E

F

G

H

I

J

K

L

MA

EC

3.CHECK TURBOCHAGER BOOST SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between turbocharger boost sensor terminal 1 and ECM terminal 71.

Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 4.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

4.CHECK TURBOCHAGER BOOST SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check harness continuity between ECM terminal 52 and turbocharger boost sensor terminal 2. Refer to

Wiring Diagram.

2. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 5.

NG >> Repair open circuit or short to ground or short to power in harness connectors.

5.CHECK TURBOCHARGER BOOST SENSOR

Refer toEC-158, "

Component Inspection".

OK or NG

OK >> GO TO 6.

NG >> Replace turbocharger boost sensor.

6.CHECK INTERMITTENT INCIDENT

Refer toEC-70, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT".

>>INSPECTION END Continuity should exist.

Continuity should exist.

Page 1138 of 3171

EC-158

DTC P0237, P0238 TC BOOST SENSOR

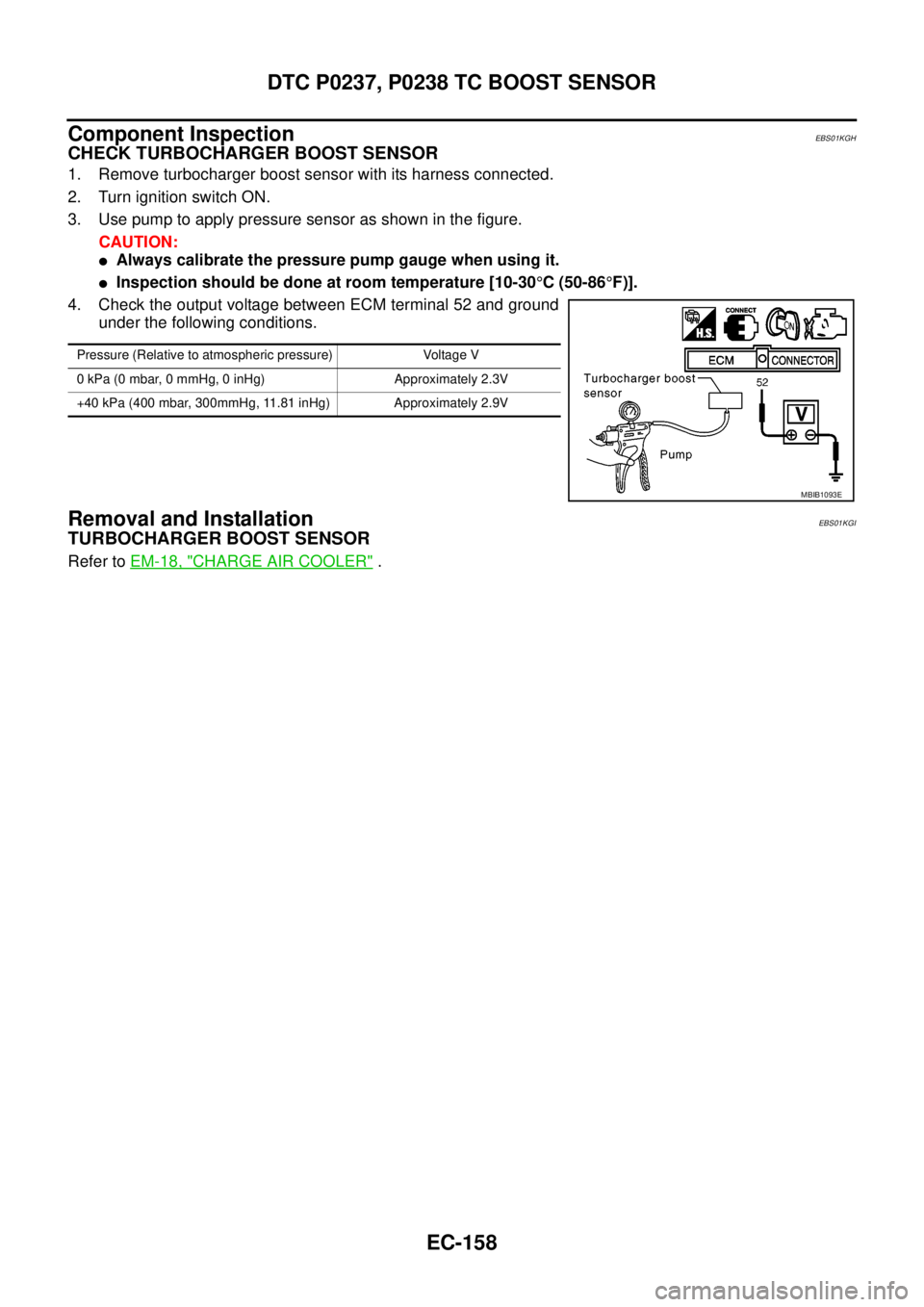

Component Inspection

EBS01KGH

CHECK TURBOCHARGER BOOST SENSOR

1. Remove turbocharger boost sensor with its harness connected.

2. Turn ignition switch ON.

3. Use pump to apply pressure sensor as shown in the figure.

CAUTION:

lAlways calibrate the pressure pump gauge when using it.

lInspection should be done at room temperature [10-30°C(50-86°F)].

4. Check the output voltage between ECM terminal 52 and ground

under the following conditions.

Removal and InstallationEBS01KGI

TURBOCHARGER BOOST SENSOR

Refer toEM-18, "CHARGE AIR COOLER".

Pressure (Relative to atmospheric pressure) Voltage V

0 kPa (0 mbar, 0 mmHg, 0 inHg) Approximately 2.3V

+40 kPa (400 mbar, 300mmHg, 11.81 inHg) Approximately 2.9V

MBIB1093E

Page 1139 of 3171

DTC P0335 CKP SENSOR

EC-159

C

D

E

F

G

H

I

J

K

L

MA

EC

DTC P0335 CKP SENSORPFP:23731

DescriptionEBS01KGJ

The crankshaft position (CKP) sensor is located on the cylinder

block rear housing facing the gear teeth (cogs) of the signal plate at

the end of the crankshaft. It detects the fluctuation of the engine rev-

olution.

The sensor consists of a permanent magnet and Hall IC.

When the engine is running, the high and low parts of the teeth

cause the gap with the sensor to change. The changing gap causes

the magnetic field near the sensor to change. Due to the changing

magnetic field, the voltage from the sensor changes. The ECM

receives the voltage signal and detects the fluctuation of the engine

revolution.

CONSULT-II Reference Value in Data Monitor ModeEBS01KGK

Specification data are reference values.

ECM Terminals and Reference ValueEBS01KGL

Specification data are reference values and are measured between each terminal and ground.

Pulse signal is measured by CONSULT-II.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)

MBIB1323E

MONITOR ITEM CONDITION SPECIFICATION

CKPS-RPM (TDC)

lRun engine and compare CONSULT-II value with the tachometer

indication.Almost the same speed as the

tachometer indication

TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage and Pulse Signal)

44 WCrankshaft position sen-

sor power supply[Ignition switch ON]Approximately 5.3V

46 R Crankshaft position sensor[Engine is running]

lWarm-up condition

lIdle speed

NOTE:

The pulse cycle changes depending on rpm

at idleApproximately 3.7V

[Engine is running]

lWarm-up condition

lEngine speed: 2,000 rpmApproximately 3.7V

65 BCrankshaft position sen-

sor ground[Ignition switch ON]Approximately 0.3V

67 —Sensor ground

(Sensor shield circuit)[Ignition switch ON]Approximately 0.3V

MBIB0879E

MBIB0880E

Page 1140 of 3171

EC-160

DTC P0335 CKP SENSOR

On Board Diagnosis Logic

EBS01KGM

NOTE:

If DTC P0335 is displayed with DTC P0652 or P0653, first perform the trouble diagnosis for DTC P0652

or P0653. Refer toEC-227, "

DTC P0652, P0653 SENSOR POWER SUPPLY".

DTC Confirmation ProcedureEBS01KGN

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-II

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Start engine and let it idle for at least 5 seconds.

If engine can not start, keep ignition switch at START position for

5 seconds.

4. If DTC is detected, go toEC-162, "

Diagnostic Procedure".

WITHOUT CONSULT-II

1. Start engine and let it idle for at least 5 seconds.

If engine can not start, keep ignition switch at START position for 5 seconds.

2. Turn ignition switch OFF, wait at least 10 seconds and then turn ON.

3. Perform Diagnostic Test Mode II (Self-diagnostic results) with ECM.

4. If DTC is detected, go toEC-162, "

Diagnostic Procedure".

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0335

0335Crankshaft position sen-

sor circuitCrankshaft position sensor signal is not detect

by the ECM when engine is running.

lHarness or connectors

(The sensor circuit is open or

shorted.)

lCrankshaft position sensor

SEF817Y