NISSAN NAVARA 2005 Repair Workshop Manual

Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1091 of 3171

DTC P0122, P0123 APP SENSOR

EC-111

C

D

E

F

G

H

I

J

K

L

MA

EC

Diagnostic ProcedureEBS01KEO

1.CHECK GROUND CONNECTIONS

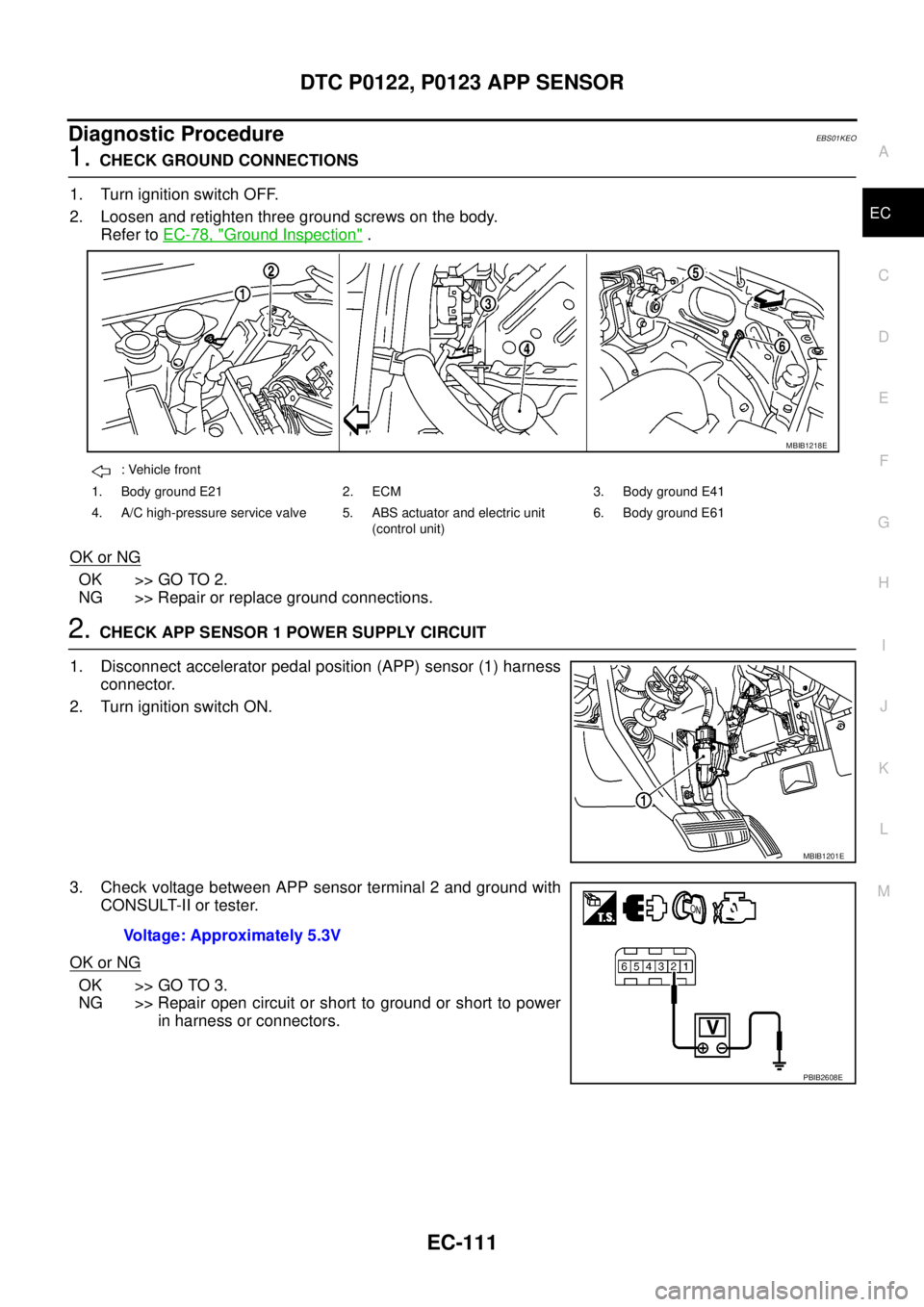

1. Turn ignition switch OFF.

2. Loosen and retighten three ground screws on the body.

Refer toEC-78, "

Ground Inspection".

OK or NG

OK >> GO TO 2.

NG >> Repair or replace ground connections.

2.CHECK APP SENSOR 1 POWER SUPPLY CIRCUIT

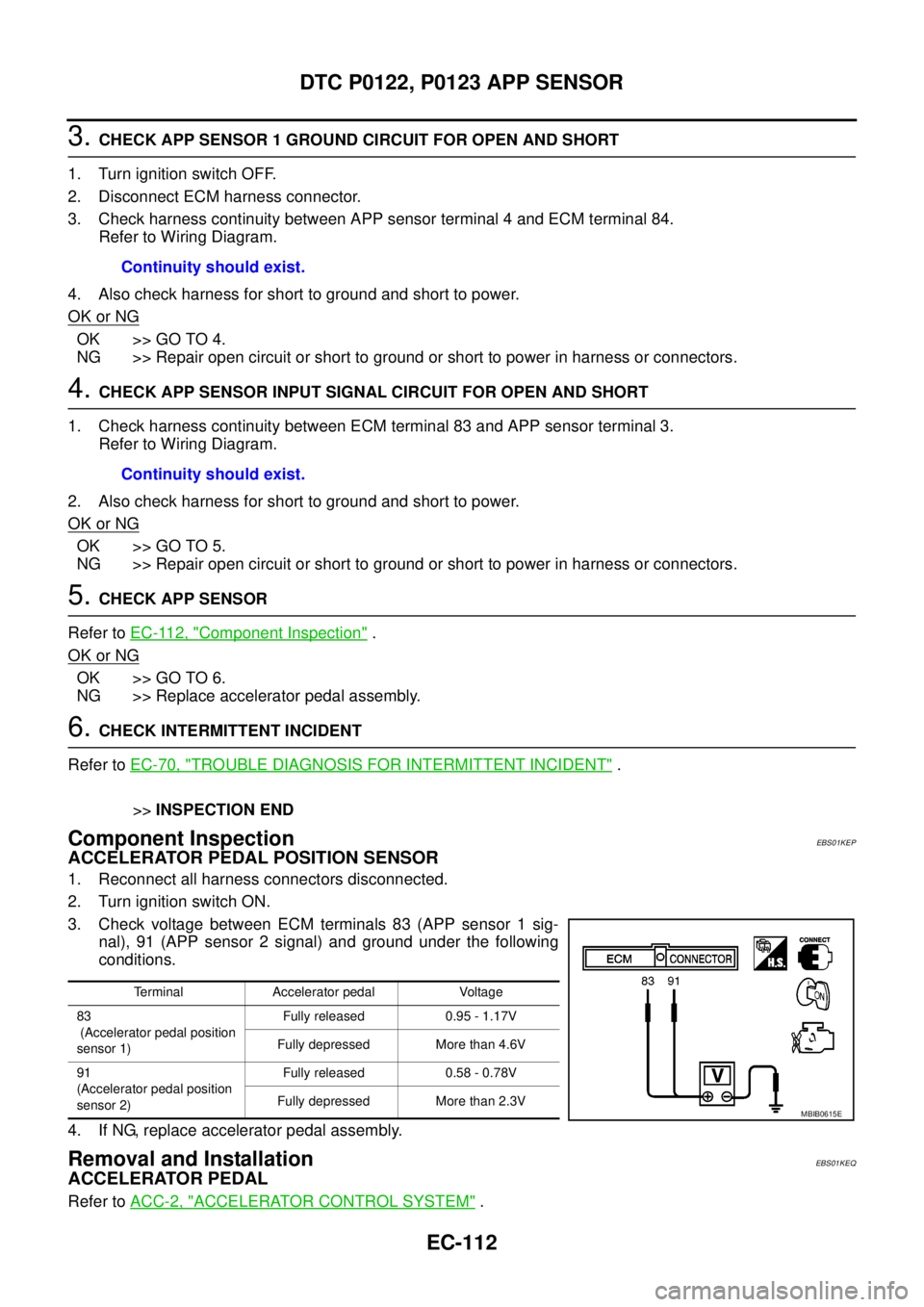

1. Disconnect accelerator pedal position (APP) sensor (1) harness

connector.

2. Turn ignition switch ON.

3. Check voltage between APP sensor terminal 2 and ground with

CONSULT-II or tester.

OK or NG

OK >> GO TO 3.

NG >> Repair open circuit or short to ground or short to power

in harness or connectors.

: Vehicle front

1. Body ground E21 2. ECM 3. Body ground E41

4. A/C high-pressure service valve 5. ABS actuator and electric unit

(control unit)6. Body ground E61

MBIB1218E

MBIB1201E

Voltage: Approximately 5.3V

PBIB2608E

Page 1092 of 3171

EC-112

DTC P0122, P0123 APP SENSOR

3.CHECK APP SENSOR 1 GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between APP sensor terminal 4 and ECM terminal 84.

Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 4.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

4.CHECK APP SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check harness continuity between ECM terminal 83 and APP sensor terminal 3.

Refer to Wiring Diagram.

2. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 5.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

5.CHECK APP SENSOR

Refer toEC-112, "

Component Inspection".

OK or NG

OK >> GO TO 6.

NG >> Replace accelerator pedal assembly.

6.CHECK INTERMITTENT INCIDENT

Refer toEC-70, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT".

>>INSPECTION END

Component InspectionEBS01KEP

ACCELERATOR PEDAL POSITION SENSOR

1. Reconnect all harness connectors disconnected.

2. Turn ignition switch ON.

3. Check voltage between ECM terminals 83 (APP sensor 1 sig-

nal), 91 (APP sensor 2 signal) and ground under the following

conditions.

4. If NG, replace accelerator pedal assembly.

Removal and InstallationEBS01KEQ

ACCELERATOR PEDAL

Refer toACC-2, "ACCELERATOR CONTROL SYSTEM". Continuity should exist.

Continuity should exist.

Terminal Accelerator pedal Voltage

83

(Accelerator pedal position

sensor 1)Fully released 0.95 - 1.17V

Fully depressed More than 4.6V

91

(Accelerator pedal position

sensor 2)Fully released 0.58 - 0.78V

Fully depressed More than 2.3V

MBIB0615E

Page 1093 of 3171

DTC P0182, P0183 FUEL PUMP TEMPERATURE SENSOR

EC-113

C

D

E

F

G

H

I

J

K

L

MA

EC

DTC P0182, P0183 FUEL PUMP TEMPERATURE SENSORPFP:16700

DescriptionEBS01KER

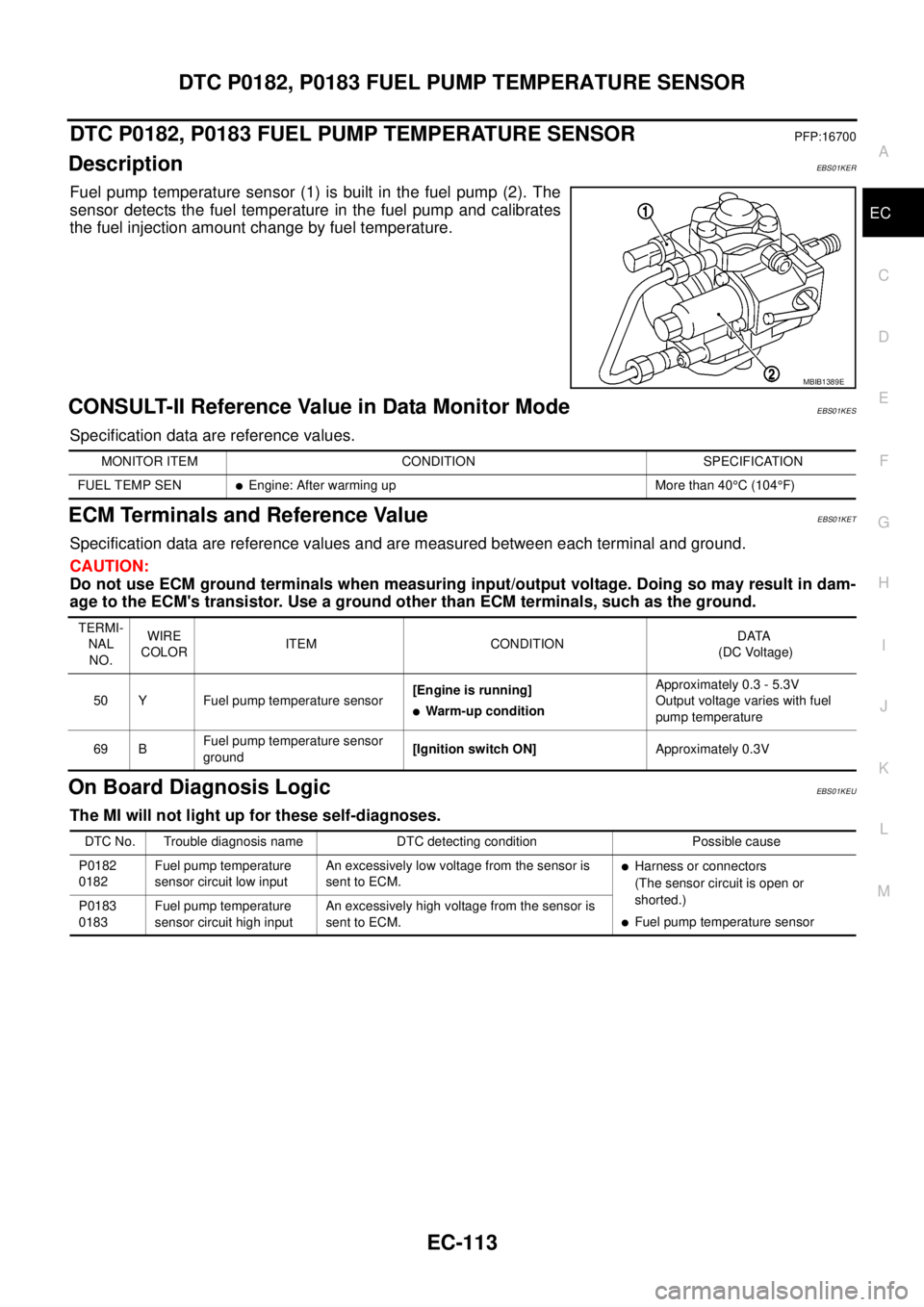

Fuel pump temperature sensor (1) is built in the fuel pump (2). The

sensor detects the fuel temperature in the fuel pump and calibrates

the fuel injection amount change by fuel temperature.

CONSULT-II Reference Value in Data Monitor ModeEBS01KES

Specification data are reference values.

ECM Terminals and Reference ValueEBS01KET

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

On Board Diagnosis LogicEBS01KEU

The MI will not light up for these self-diagnoses.

MBIB1389E

MONITOR ITEM CONDITION SPECIFICATION

FUEL TEMP SEN

lEngine: After warming up More than 40°C(104°F)

TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage)

50 Y Fuel pump temperature sensor[Engine is running]

lWarm-up conditionApproximately 0.3 - 5.3V

Output voltage varies with fuel

pump temperature

69 BFuel pump temperature sensor

ground[Ignition switch ON]Approximately 0.3V

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0182

0182Fuel pump temperature

sensor circuit low inputAn excessively low voltage from the sensor is

sent to ECM.

lHarness or connectors

(The sensor circuit is open or

shorted.)

lFuel pump temperature sensor P0183

0183Fuel pump temperature

sensor circuit high inputAn excessively high voltage from the sensor is

sent to ECM.

Page 1094 of 3171

EC-114

DTC P0182, P0183 FUEL PUMP TEMPERATURE SENSOR

DTC Confirmation Procedure

EBS01KEV

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-II

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Wait at least 5 seconds.

4. If DTC is detected, go toEC-116, "

Diagnostic Procedure".

WITHOUT CONSULT-II

1. Turn ignition switch ON and wait at least 5 seconds.

2. Turn ignition switch OFF, wait at least 10 seconds and then turn ON.

3. Perform Diagnostic Test Mode II (Self-diagnostic results) with ECM.

4. If DTC is detected, go toEC-116, "

Diagnostic Procedure"

SEF817Y

Page 1095 of 3171

DTC P0182, P0183 FUEL PUMP TEMPERATURE SENSOR

EC-115

C

D

E

F

G

H

I

J

K

L

MA

EC

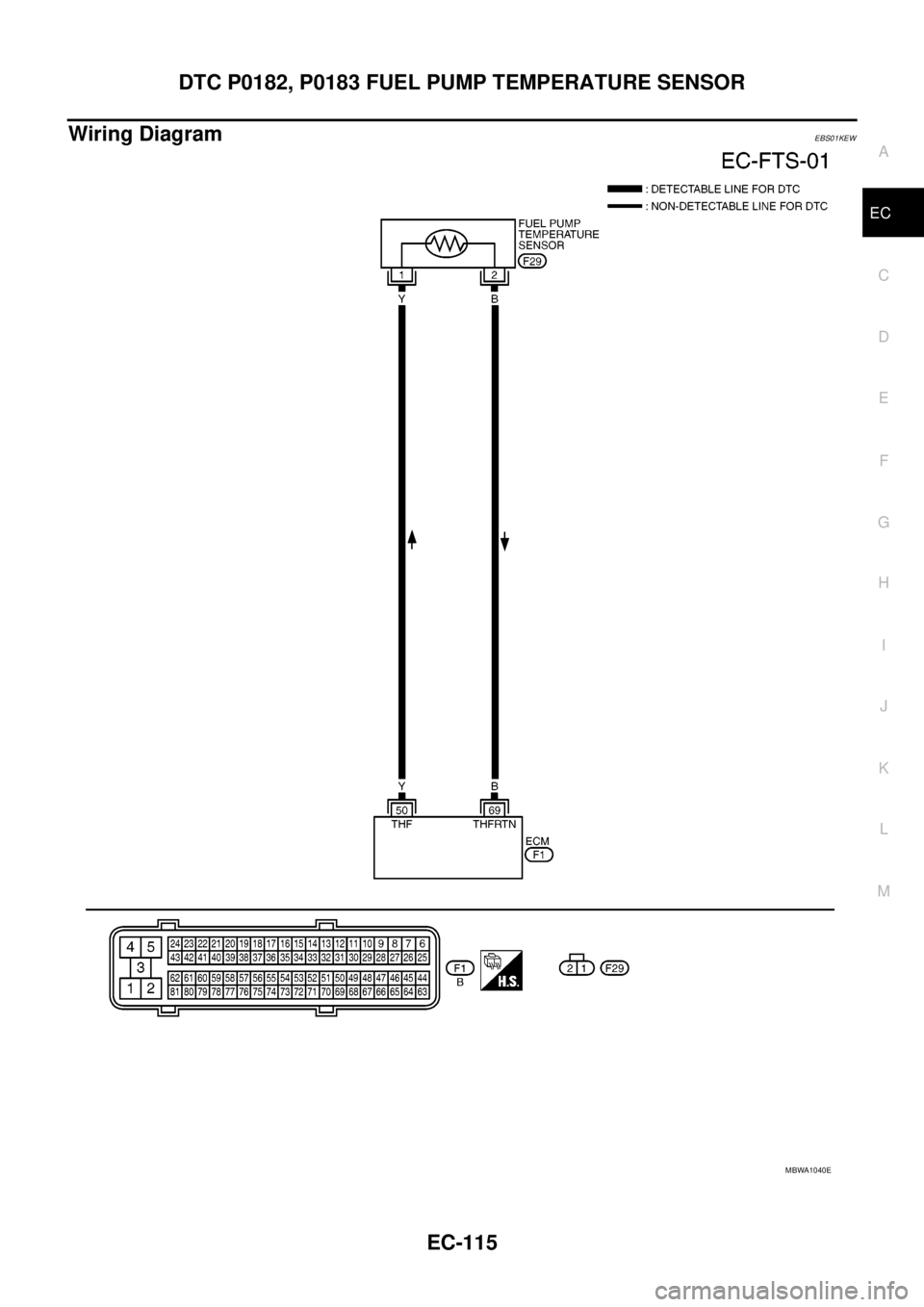

Wiring DiagramEBS01KEW

MBWA1040E

Page 1096 of 3171

EC-116

DTC P0182, P0183 FUEL PUMP TEMPERATURE SENSOR

Diagnostic Procedure

EBS01KEX

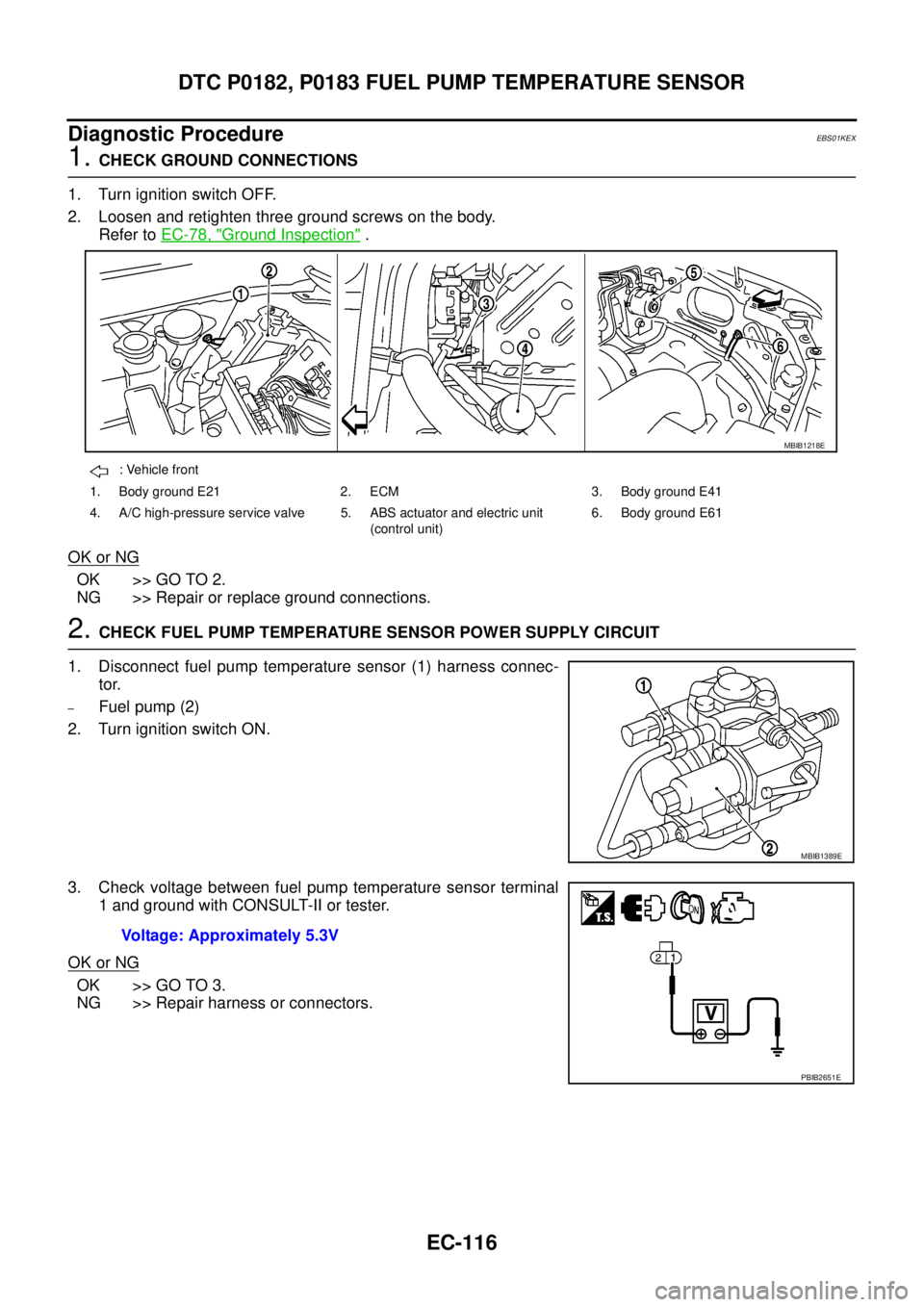

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten three ground screws on the body.

Refer toEC-78, "

Ground Inspection".

OK or NG

OK >> GO TO 2.

NG >> Repair or replace ground connections.

2.CHECK FUEL PUMP TEMPERATURE SENSOR POWER SUPPLY CIRCUIT

1. Disconnect fuel pump temperature sensor (1) harness connec-

tor.

–Fuel pump (2)

2. Turn ignition switch ON.

3. Check voltage between fuel pump temperature sensor terminal

1 and ground with CONSULT-II or tester.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connectors.

: Vehicle front

1. Body ground E21 2. ECM 3. Body ground E41

4. A/C high-pressure service valve 5. ABS actuator and electric unit

(control unit)6. Body ground E61

MBIB1218E

MBIB1389E

Voltage: Approximately 5.3V

PBIB2651E

Page 1097 of 3171

DTC P0182, P0183 FUEL PUMP TEMPERATURE SENSOR

EC-117

C

D

E

F

G

H

I

J

K

L

MA

EC

3.CHECK FUEL PUMP TEMPERATURE SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between fuel pump temperature sensor terminal 2 and ECM terminal 69.

Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 4.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

4.CHECK INTERMITTENT INCIDENT

Refer toEC-70, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT".

OK or NG

OK >> GO TO 5.

NG >> Repair or replace.

5.REPLACE FUEL PUMP

1. Replace fuel pump.

2. Perform Fuel Pump Learning Value Clearing. Refer toEC-24, "

Fuel Pump Learning Value Clearing".

>>INSPECTION END

Removal and InstallationEBS01KEY

FUEL PUMP

Refer toEM-49, "FUEL PUMP". Continuity should exist.

Page 1098 of 3171

EC-118

DTC P0192, P0193 FRP SENSOR

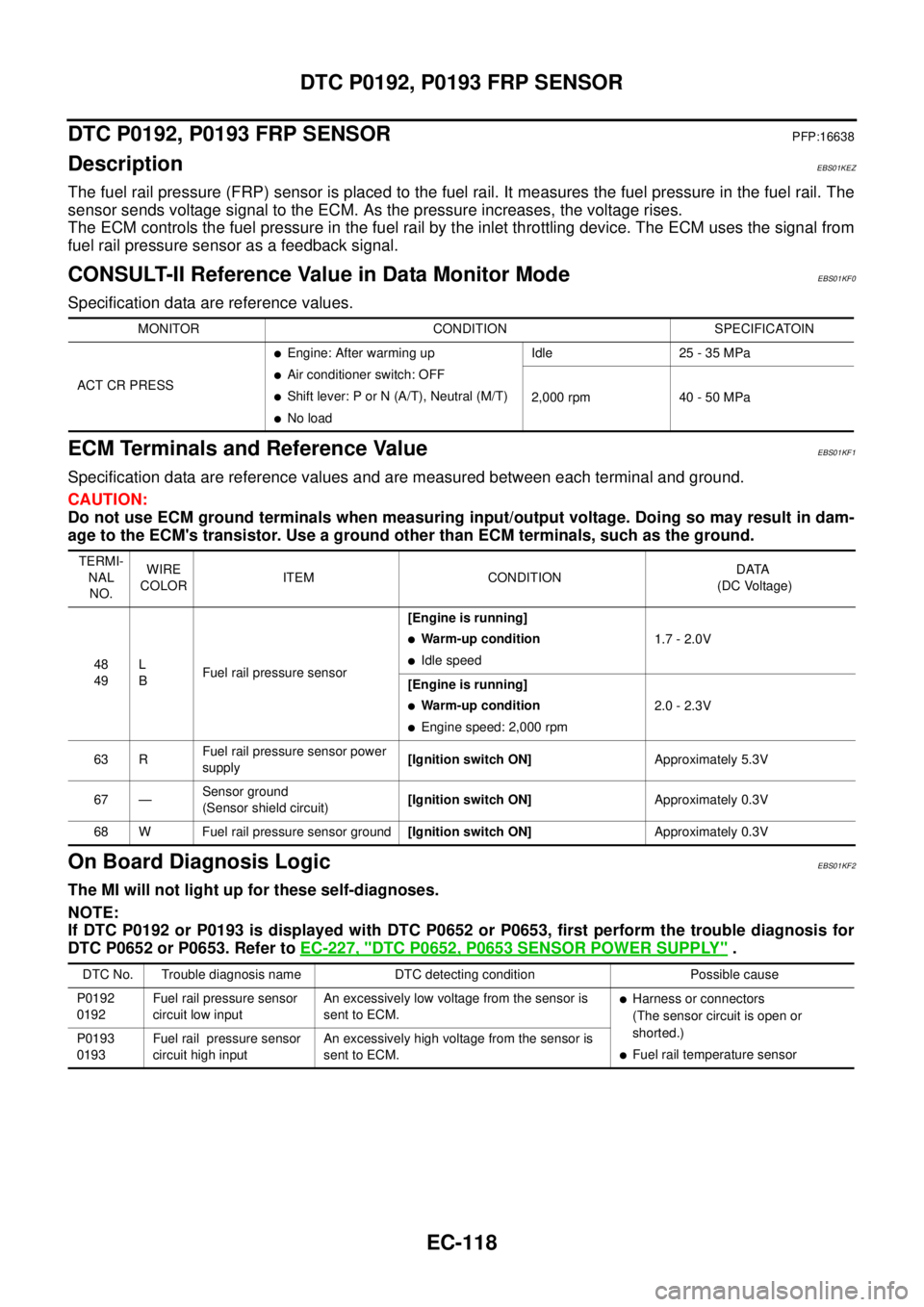

DTC P0192, P0193 FRP SENSOR

PFP:16638

DescriptionEBS01KEZ

The fuel rail pressure (FRP) sensor is placed to the fuel rail. It measures the fuel pressure in the fuel rail. The

sensor sends voltage signal to the ECM. As the pressure increases, the voltage rises.

The ECM controls the fuel pressure in the fuel rail by the inlet throttling device. The ECM uses the signal from

fuel rail pressure sensor as a feedback signal.

CONSULT-II Reference Value in Data Monitor ModeEBS01KF0

Specification data are reference values.

ECM Terminals and Reference ValueEBS01KF1

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

On Board Diagnosis LogicEBS01KF2

The MI will not light up for these self-diagnoses.

NOTE:

If DTC P0192 or P0193 is displayed with DTC P0652 or P0653, first perform the trouble diagnosis for

DTC P0652 or P0653. Refer toEC-227, "

DTC P0652, P0653 SENSOR POWER SUPPLY".

MONITOR CONDITION SPECIFICATOIN

ACT CR PRESS

lEngine: After warming up

lAir conditioner switch: OFF

lShift lever: P or N (A/T), Neutral (M/T)

lNo loadIdle 25 - 35 MPa

2,000 rpm 40 - 50 MPa

TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage)

48

49L

BFuel rail pressure sensor[Engine is running]

lWarm-up condition

lIdle speed1.7 - 2.0V

[Engine is running]

lWarm-up condition

lEngine speed: 2,000 rpm2.0 - 2.3V

63 RFuel rail pressure sensor power

supply[Ignition switch ON]Approximately 5.3V

67 —Sensor ground

(Sensor shield circuit)[Ignition switch ON]Approximately 0.3V

68 W Fuel rail pressure sensor ground[Ignition switch ON]Approximately 0.3V

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0192

0192Fuel rail pressure sensor

circuit low inputAn excessively low voltage from the sensor is

sent to ECM.

lHarness or connectors

(The sensor circuit is open or

shorted.)

lFuel rail temperature sensor P0193

0193Fuel rail pressure sensor

circuit high inputAn excessively high voltage from the sensor is

sent to ECM.

Page 1099 of 3171

DTC P0192, P0193 FRP SENSOR

EC-119

C

D

E

F

G

H

I

J

K

L

MA

EC

DTC Confirmation ProcedureEBS01KF3

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-II

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Wait at least 5 seconds.

4. If DTC is detected, go toEC-121, "

Diagnostic Procedure".

WITHOUT CONSULT-II

1. Turn ignition switch ON and wait at least 5 seconds.

2. Turn ignition switch OFF, wait at least 10 seconds and then turn ON.

3. Perform Diagnostic Test Mode II (Self-diagnostic results) with ECM.

4. If DTC is detected, go toEC-121, "

Diagnostic Procedure".

SEF817Y

Page 1100 of 3171

EC-120

DTC P0192, P0193 FRP SENSOR

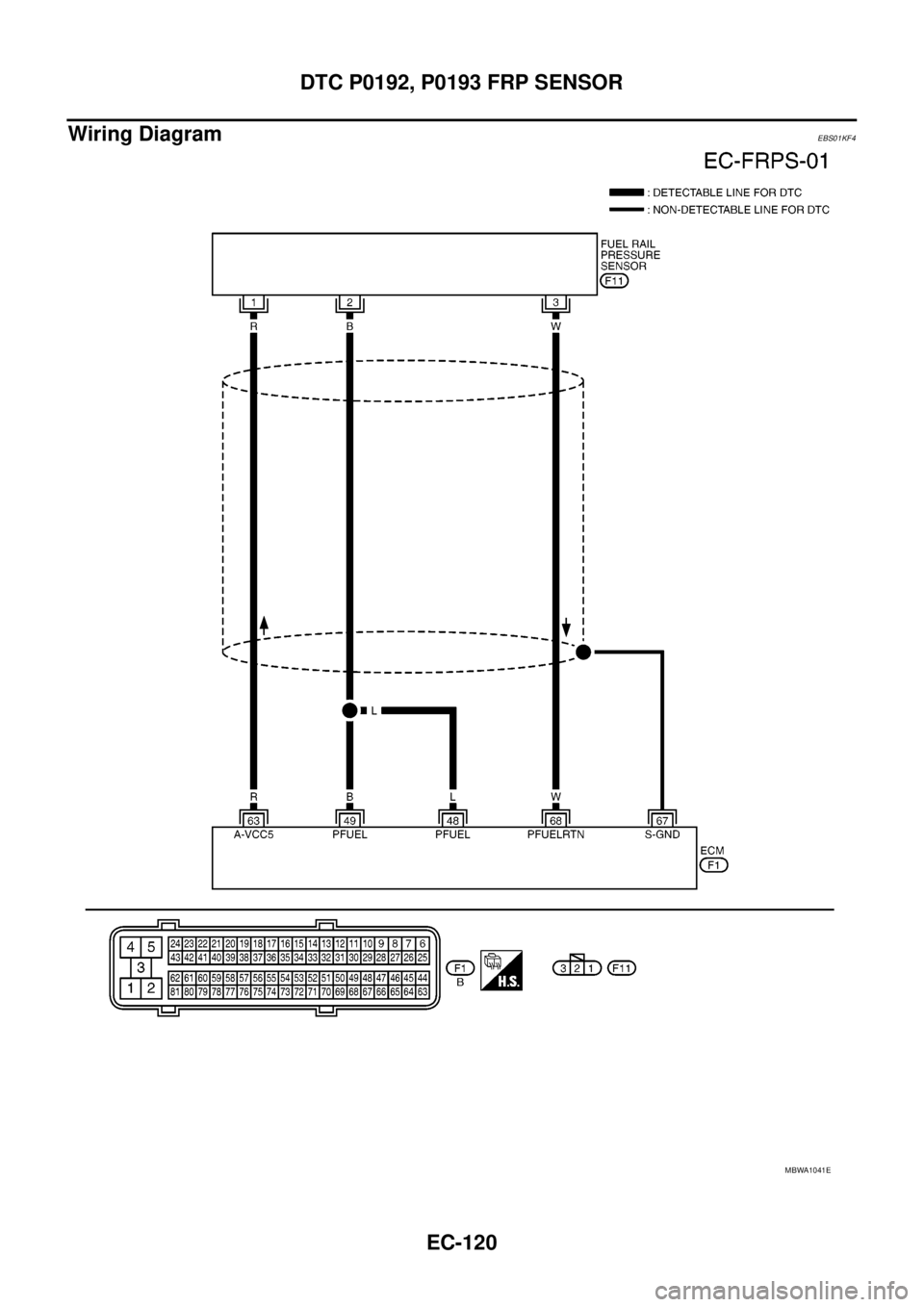

Wiring Diagram

EBS01KF4

MBWA1041E