battery NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1055 of 3171

POWER SUPPLY AND GROUND CIRCUIT

EC-75

C

D

E

F

G

H

I

J

K

L

MA

EC

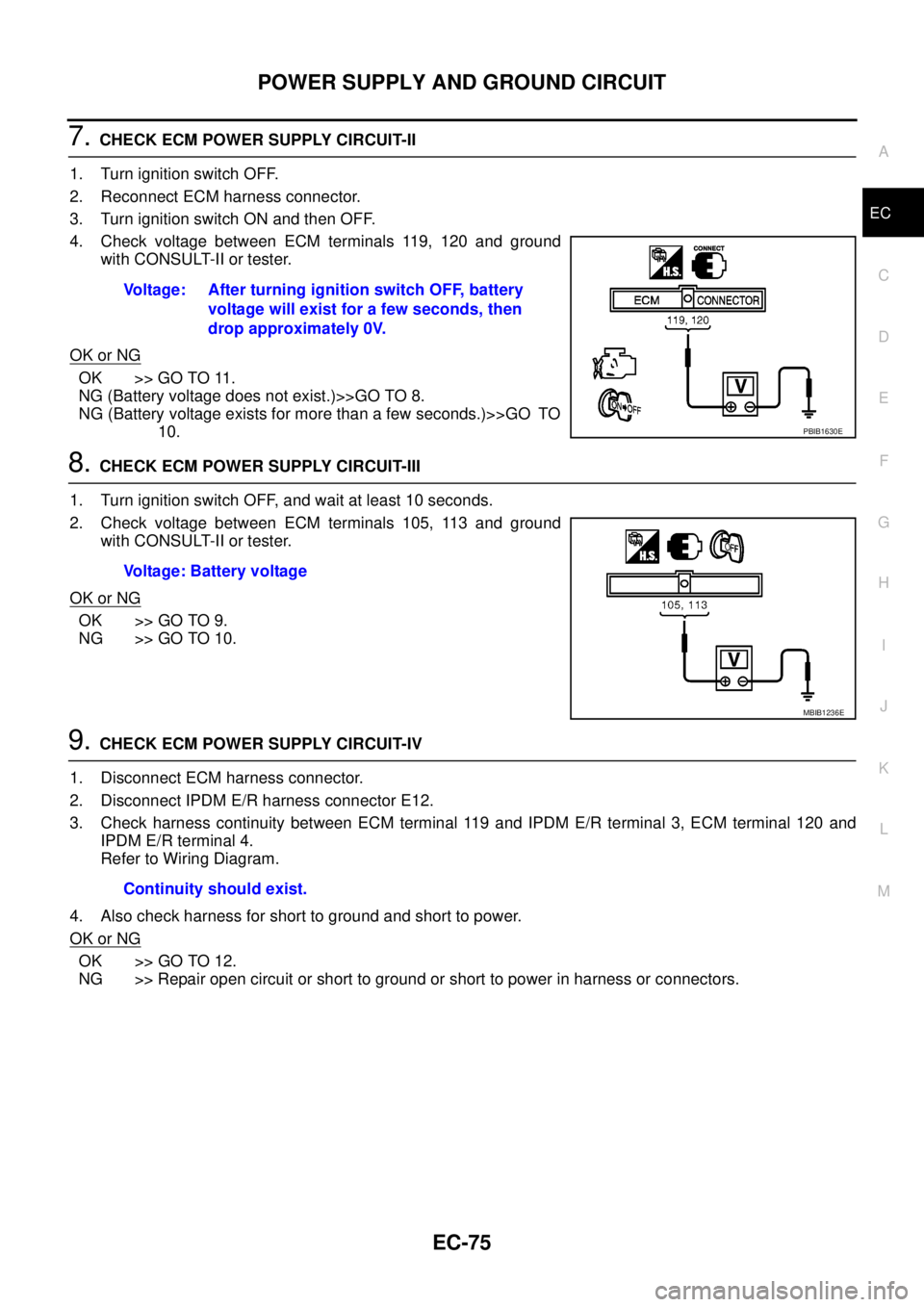

7.CHECK ECM POWER SUPPLY CIRCUIT-II

1. Turn ignition switch OFF.

2. Reconnect ECM harness connector.

3. Turn ignition switch ON and then OFF.

4. Check voltage between ECM terminals 119, 120 and ground

with CONSULT-II or tester.

OK or NG

OK >> GO TO 11.

NG (Battery voltage does not exist.)>>GO TO 8.

NG (Battery voltage exists for more than a few seconds.)>>GO TO

10.

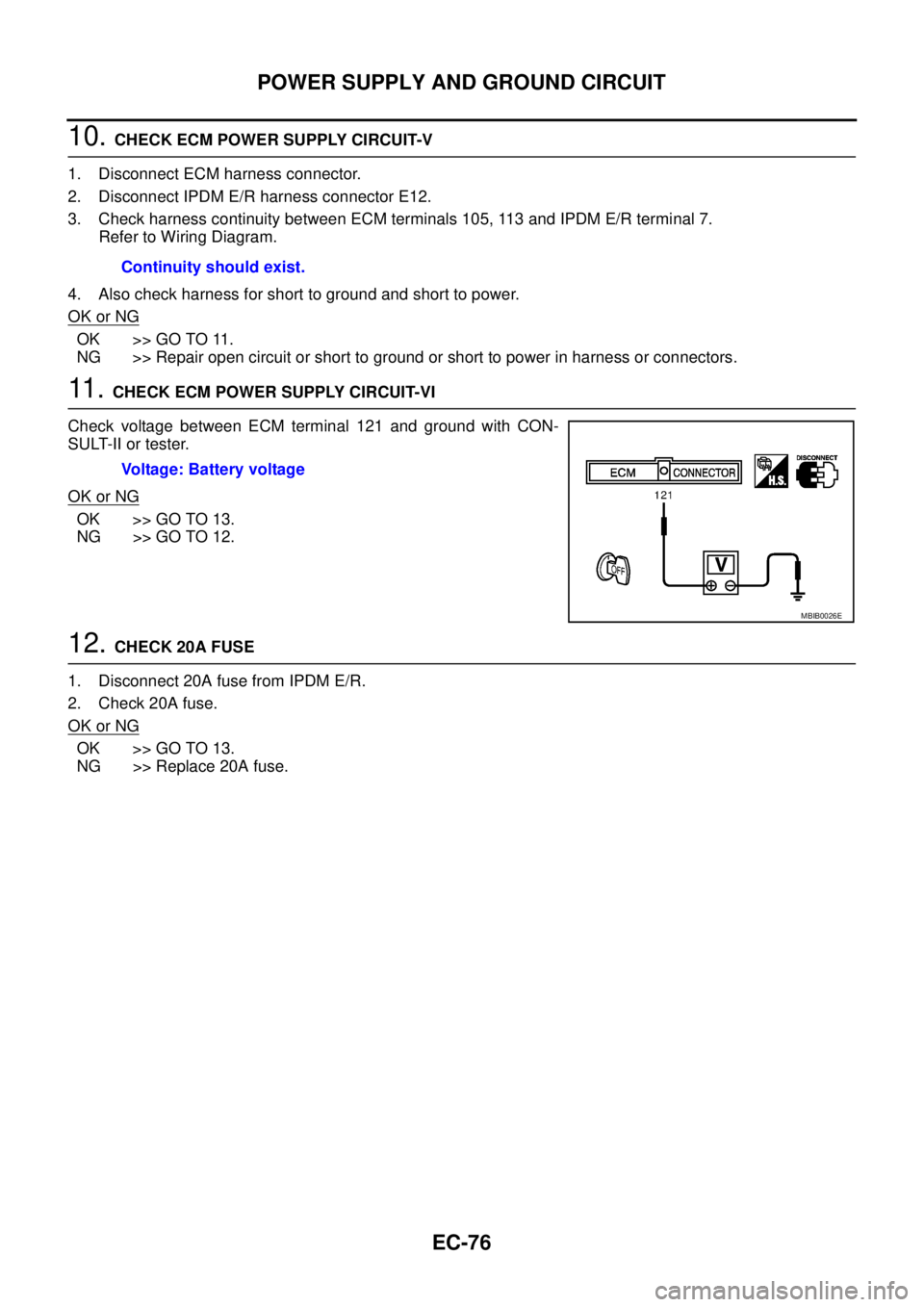

8.CHECK ECM POWER SUPPLY CIRCUIT-III

1. Turn ignition switch OFF, and wait at least 10 seconds.

2. Check voltage between ECM terminals 105, 113 and ground

with CONSULT-II or tester.

OK or NG

OK >> GO TO 9.

NG >> GO TO 10.

9.CHECK ECM POWER SUPPLY CIRCUIT-IV

1. Disconnect ECM harness connector.

2. Disconnect IPDM E/R harness connector E12.

3. Check harness continuity between ECM terminal 119 and IPDM E/R terminal 3, ECM terminal 120 and

IPDM E/R terminal 4.

Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 12.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.Voltage: After turning ignition switch OFF, battery

voltage will exist for a few seconds, then

drop approximately 0V.

PBIB1630E

Voltage: Battery voltage

MBIB1236E

Continuity should exist.

Page 1056 of 3171

EC-76

POWER SUPPLY AND GROUND CIRCUIT

10.CHECK ECM POWER SUPPLY CIRCUIT-V

1. Disconnect ECM harness connector.

2. Disconnect IPDM E/R harness connector E12.

3. Check harness continuity between ECM terminals 105, 113 and IPDM E/R terminal 7.

Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 11.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

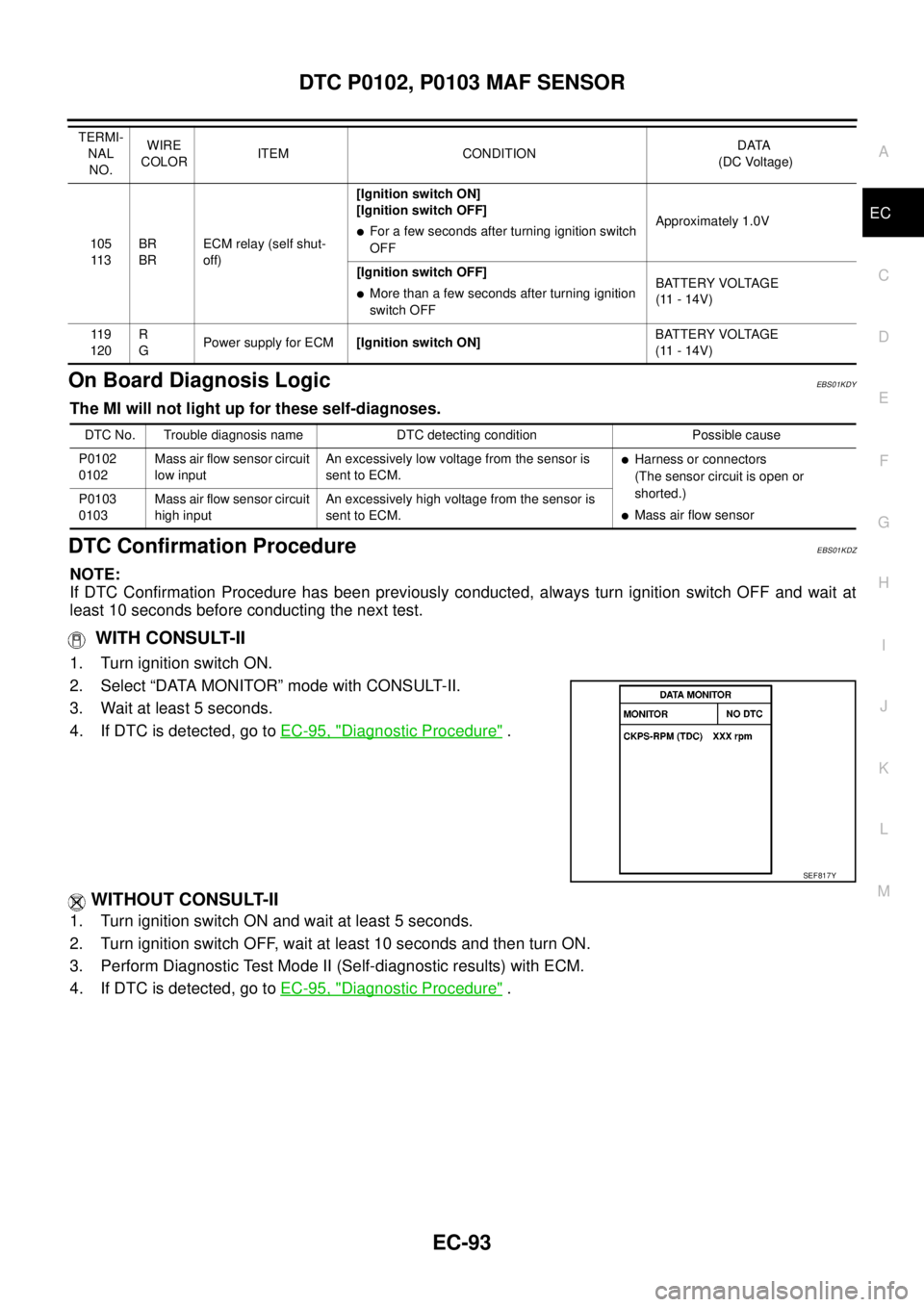

11 .CHECK ECM POWER SUPPLY CIRCUIT-VI

Check voltage between ECM terminal 121 and ground with CON-

SULT-II or tester.

OK or NG

OK >> GO TO 13.

NG >> GO TO 12.

12.CHECK 20A FUSE

1. Disconnect 20A fuse from IPDM E/R.

2. Check 20A fuse.

OK or NG

OK >> GO TO 13.

NG >> Replace 20A fuse.Continuity should exist.

Voltage: Battery voltage

MBIB0026E

Page 1073 of 3171

DTC P0102, P0103 MAF SENSOR

EC-93

C

D

E

F

G

H

I

J

K

L

MA

EC

On Board Diagnosis LogicEBS01KDY

The MI will not light up for these self-diagnoses.

DTC Confirmation ProcedureEBS01KDZ

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-II

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Wait at least 5 seconds.

4. If DTC is detected, go toEC-95, "

Diagnostic Procedure".

WITHOUT CONSULT-II

1. Turn ignition switch ON and wait at least 5 seconds.

2. Turn ignition switch OFF, wait at least 10 seconds and then turn ON.

3. Perform Diagnostic Test Mode II (Self-diagnostic results) with ECM.

4. If DTC is detected, go toEC-95, "

Diagnostic Procedure".

105

11 3BR

BRECM relay (self shut-

off)[Ignition switch ON]

[Ignition switch OFF]lFor a few seconds after turning ignition switch

OFFApproximately 1.0V

[Ignition switch OFF]

lMore than a few seconds after turning ignition

switch OFFBATTERY VOLTAGE

(11 - 14V)

11 9

120R

GPower supply for ECM[Ignition switch ON]BATTERY VOLTAGE

(11 - 14V) TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage)

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0102

0102Mass air flow sensor circuit

low inputAn excessively low voltage from the sensor is

sent to ECM.

lHarness or connectors

(The sensor circuit is open or

shorted.)

lMass air flow sensor P0103

0103Mass air flow sensor circuit

high inputAn excessively high voltage from the sensor is

sent to ECM.

SEF817Y

Page 1075 of 3171

DTC P0102, P0103 MAF SENSOR

EC-95

C

D

E

F

G

H

I

J

K

L

MA

EC

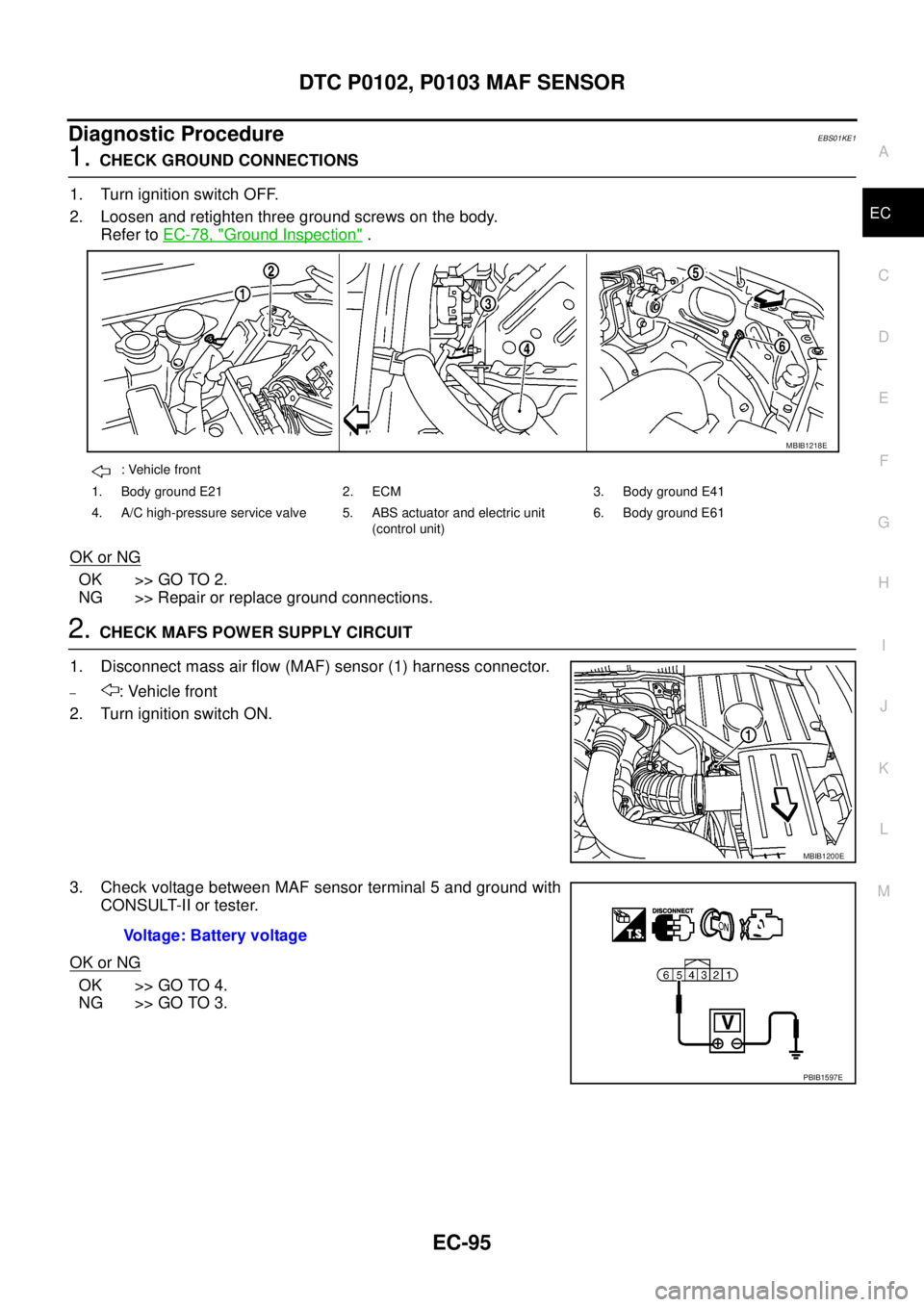

Diagnostic ProcedureEBS01KE1

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten three ground screws on the body.

Refer toEC-78, "

Ground Inspection".

OK or NG

OK >> GO TO 2.

NG >> Repair or replace ground connections.

2.CHECK MAFS POWER SUPPLY CIRCUIT

1. Disconnect mass air flow (MAF) sensor (1) harness connector.

–: Vehicle front

2. Turn ignition switch ON.

3. Check voltage between MAF sensor terminal 5 and ground with

CONSULT-II or tester.

OK or NG

OK >> GO TO 4.

NG >> GO TO 3.

: Vehicle front

1. Body ground E21 2. ECM 3. Body ground E41

4. A/C high-pressure service valve 5. ABS actuator and electric unit

(control unit)6. Body ground E61

MBIB1218E

MBIB1200E

Voltage: Battery voltage

PBIB1597E

Page 1119 of 3171

DTC P0217 ENGINE OVER TEMPERATURE

EC-139

C

D

E

F

G

H

I

J

K

L

MA

EC

PROCEDURE A

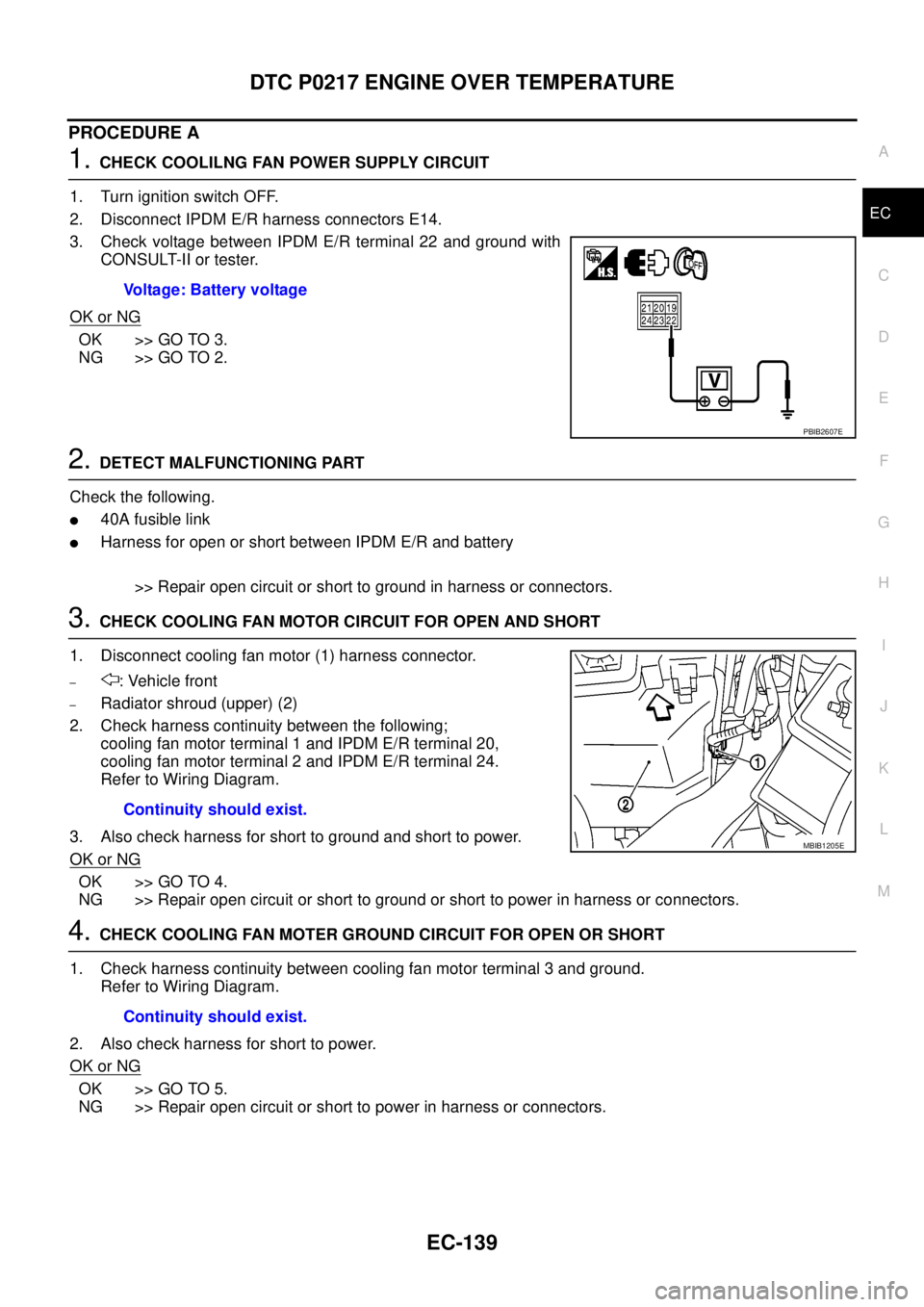

1.CHECK COOLILNG FAN POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R harness connectors E14.

3. Check voltage between IPDM E/R terminal 22 and ground with

CONSULT-II or tester.

OK or NG

OK >> GO TO 3.

NG >> GO TO 2.

2.DETECT MALFUNCTIONING PART

Check the following.

l40A fusible link

lHarness for open or short between IPDM E/R and battery

>> Repair open circuit or short to ground in harness or connectors.

3.CHECK COOLING FAN MOTOR CIRCUIT FOR OPEN AND SHORT

1. Disconnect cooling fan motor (1) harness connector.

–: Vehicle front

–Radiator shroud (upper) (2)

2. Check harness continuity between the following;

cooling fan motor terminal 1 and IPDM E/R terminal 20,

cooling fan motor terminal 2 and IPDM E/R terminal 24.

Refer to Wiring Diagram.

3. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 4.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

4.CHECK COOLING FAN MOTER GROUND CIRCUIT FOR OPEN OR SHORT

1. Check harness continuity between cooling fan motor terminal 3 and ground.

Refer to Wiring Diagram.

2. Also check harness for short to power.

OK or NG

OK >> GO TO 5.

NG >> Repair open circuit or short to power in harness or connectors.Voltage: Battery voltage

PBIB2607E

Continuity should exist.

MBIB1205E

Continuity should exist.

Page 1121 of 3171

DTC P0217 ENGINE OVER TEMPERATURE

EC-141

C

D

E

F

G

H

I

J

K

L

MA

EC

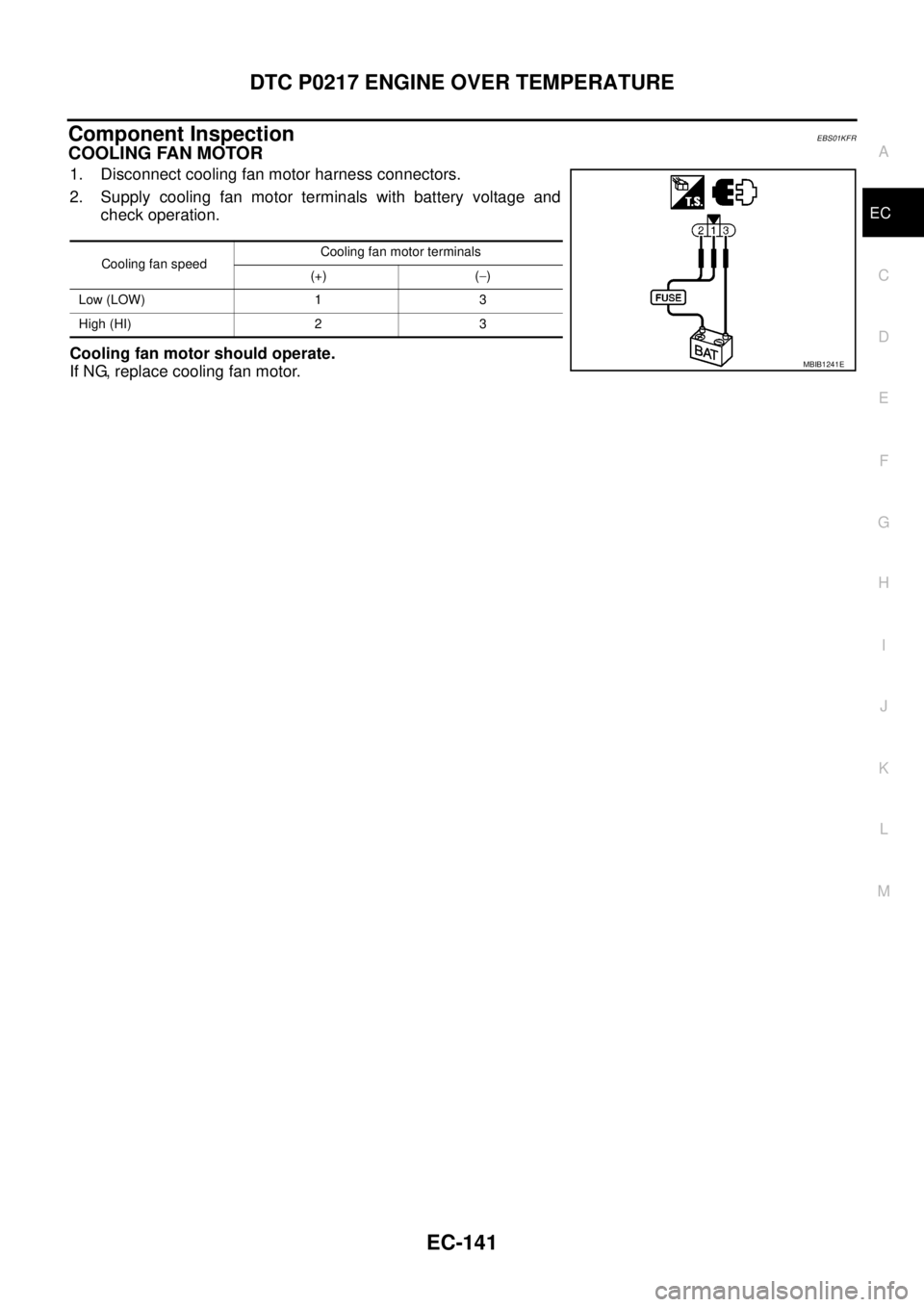

Component InspectionEBS01KFR

COOLING FAN MOTOR

1. Disconnect cooling fan motor harness connectors.

2. Supply cooling fan motor terminals with battery voltage and

check operation.

Cooling fan motor should operate.

If NG, replace cooling fan motor.

Cooling fan speedCooling fan motor terminals

(+) (-)

Low (LOW) 1 3

High (HI) 2 3

MBIB1241E

Page 1128 of 3171

EC-148

DTC P0234 TC SYSTEM

: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)

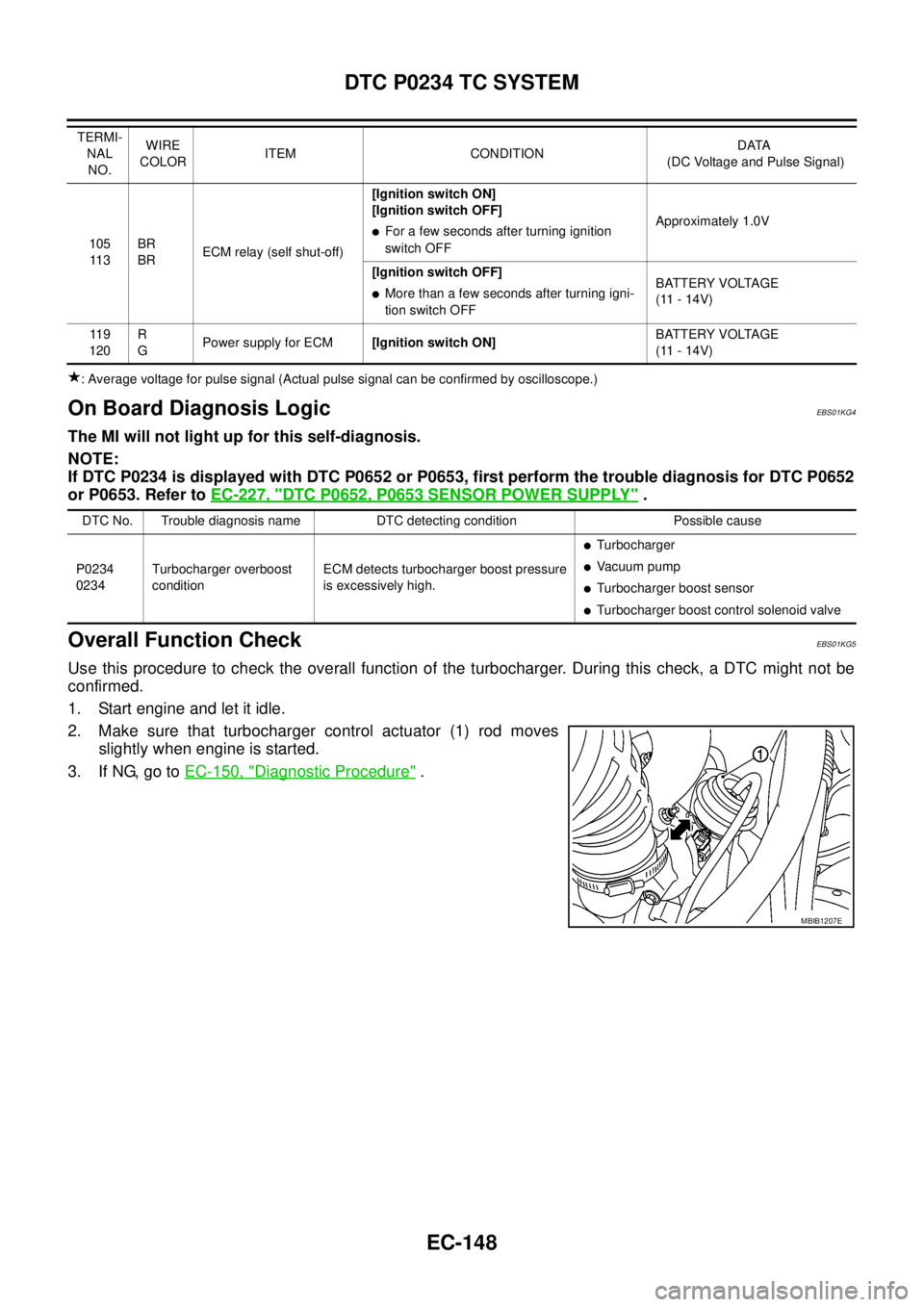

On Board Diagnosis LogicEBS01KG4

The MI will not light up for this self-diagnosis.

NOTE:

If DTC P0234 is displayed with DTC P0652 or P0653, first perform the trouble diagnosis for DTC P0652

or P0653. Refer toEC-227, "

DTC P0652, P0653 SENSOR POWER SUPPLY".

Overall Function CheckEBS01KG5

Use this procedure to check the overall function of the turbocharger. During this check, a DTC might not be

confirmed.

1. Start engine and let it idle.

2. Make sure that turbocharger control actuator (1) rod moves

slightly when engine is started.

3. If NG, go toEC-150, "

Diagnostic Procedure".

105

11 3BR

BRECM relay (self shut-off)[Ignition switch ON]

[Ignition switch OFF]lFor a few seconds after turning ignition

switch OFFApproximately 1.0V

[Ignition switch OFF]

lMore than a few seconds after turning igni-

tion switch OFFBATTERY VOLTAGE

(11 - 14V)

11 9

120R

GPower supply for ECM[Ignition switch ON]BATTERY VOLTAGE

(11 - 14V) TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage and Pulse Signal)

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0234

0234Turbocharger overboost

conditionECM detects turbocharger boost pressure

is excessively high.

lTurbocharger

lVa c u u m p u m p

lTurbocharger boost sensor

lTurbocharger boost control solenoid valve

MBIB1207E

Page 1130 of 3171

EC-150

DTC P0234 TC SYSTEM

Diagnostic Procedure

EBS01KG7

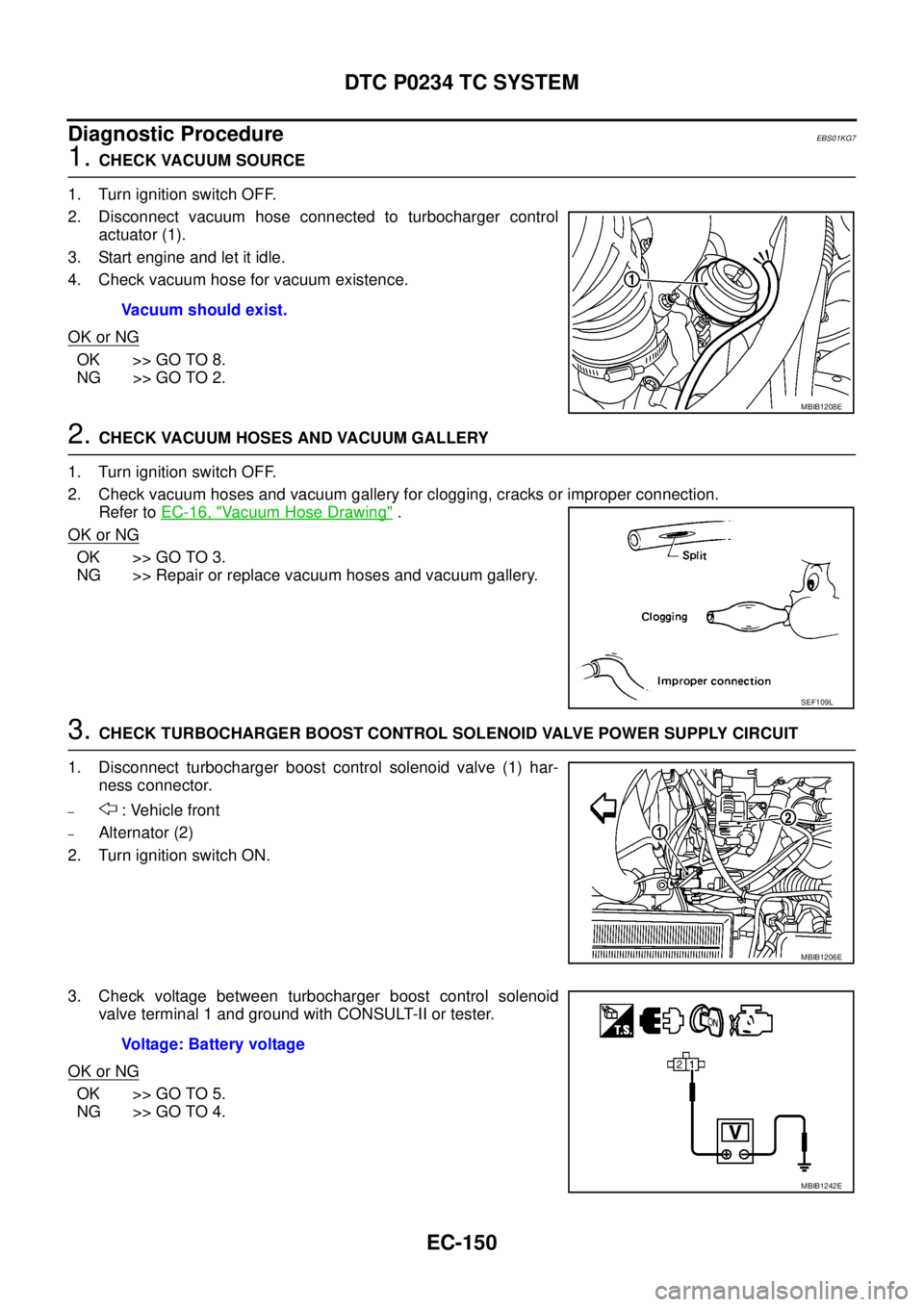

1.CHECK VACUUM SOURCE

1. Turn ignition switch OFF.

2. Disconnect vacuum hose connected to turbocharger control

actuator (1).

3. Start engine and let it idle.

4. Check vacuum hose for vacuum existence.

OK or NG

OK >> GO TO 8.

NG >> GO TO 2.

2.CHECK VACUUM HOSES AND VACUUM GALLERY

1. Turn ignition switch OFF.

2. Check vacuum hoses and vacuum gallery for clogging, cracks or improper connection.

Refer toEC-16, "

Vacuum Hose Drawing".

OK or NG

OK >> GO TO 3.

NG >> Repair or replace vacuum hoses and vacuum gallery.

3.CHECK TURBOCHARGER BOOST CONTROL SOLENOID VALVE POWER SUPPLY CIRCUIT

1. Disconnect turbocharger boost control solenoid valve (1) har-

ness connector.

–: Vehicle front

–Alternator (2)

2. Turn ignition switch ON.

3. Check voltage between turbocharger boost control solenoid

valve terminal 1 and ground with CONSULT-II or tester.

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.Vacuum should exist.

MBIB1208E

SEF109L

MBIB1206E

Voltage: Battery voltage

MBIB1242E

Page 1169 of 3171

DTC P0504 ASCD BRAKE SWITCH

EC-189

C

D

E

F

G

H

I

J

K

L

MA

EC

DTC P0504 ASCD BRAKE SWITCHPFP:25320

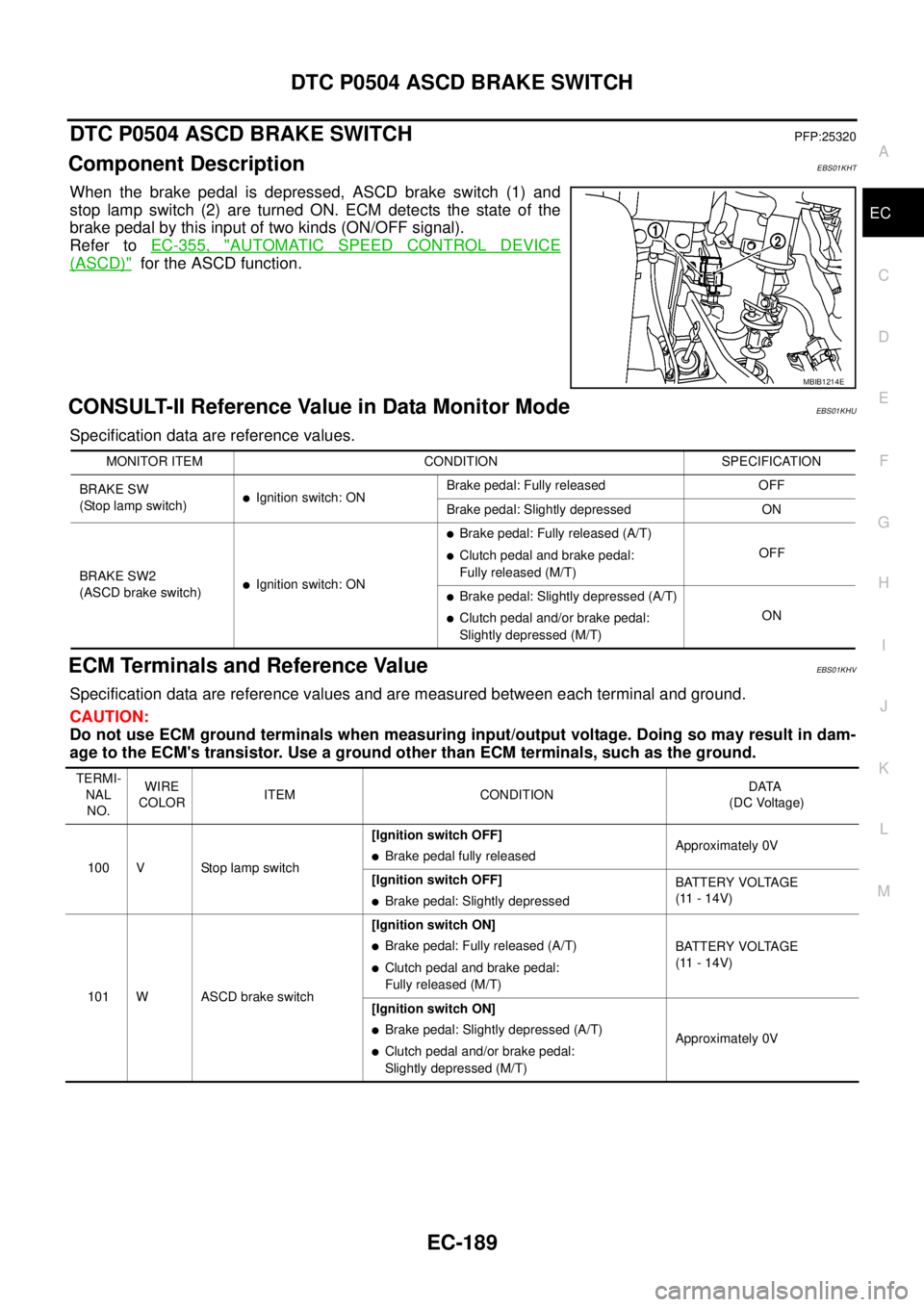

Component DescriptionEBS01KHT

When the brake pedal is depressed, ASCD brake switch (1) and

stop lamp switch (2) are turned ON. ECM detects the state of the

brake pedal by this input of two kinds (ON/OFF signal).

Refer toEC-355, "

AUTOMATIC SPEED CONTROL DEVICE

(ASCD)"for the ASCD function.

CONSULT-II Reference Value in Data Monitor ModeEBS01KHU

Specification data are reference values.

ECM Terminals and Reference ValueEBS01KHV

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

MBIB1214E

MONITOR ITEM CONDITION SPECIFICATION

BRAKE SW

(Stoplampswitch)

lIgnition switch: ONBrake pedal: Fully released OFF

Brake pedal: Slightly depressed ON

BRAKE SW2

(ASCD brake switch)

lIgnition switch: ON

lBrake pedal: Fully released (A/T)

lClutch pedal and brake pedal:

Fully released (M/T)OFF

lBrake pedal: Slightly depressed (A/T)

lClutch pedal and/or brake pedal:

Slightly depressed (M/T)ON

TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage)

100 V Stop lamp switch[Ignition switch OFF]

lBrake pedal fully releasedApproximately 0V

[Ignition switch OFF]

lBrake pedal: Slightly depressedBATTERY VOLTAGE

(11 - 14V)

101 W ASCD brake switch[Ignition switch ON]

lBrake pedal: Fully released (A/T)

lClutch pedal and brake pedal:

Fully released (M/T)BATTERY VOLTAGE

(11 - 14V)

[Ignition switch ON]

lBrake pedal: Slightly depressed (A/T)

lClutch pedal and/or brake pedal:

Slightly depressed (M/T)Approximately 0V

Page 1173 of 3171

DTC P0504 ASCD BRAKE SWITCH

EC-193

C

D

E

F

G

H

I

J

K

L

MA

EC

Diagnostic ProcedureEBS01KHZ

A/T MODELS

1.CHECK OVERALL FUNCTION-I

With CONSULT-II

1. Turn ignition switch ON.

2. Select “BRAKE SW” in “DATA MONITOR” mode with CONSULT-II.

3. Check “BRAKE SW” indication under the following conditions.

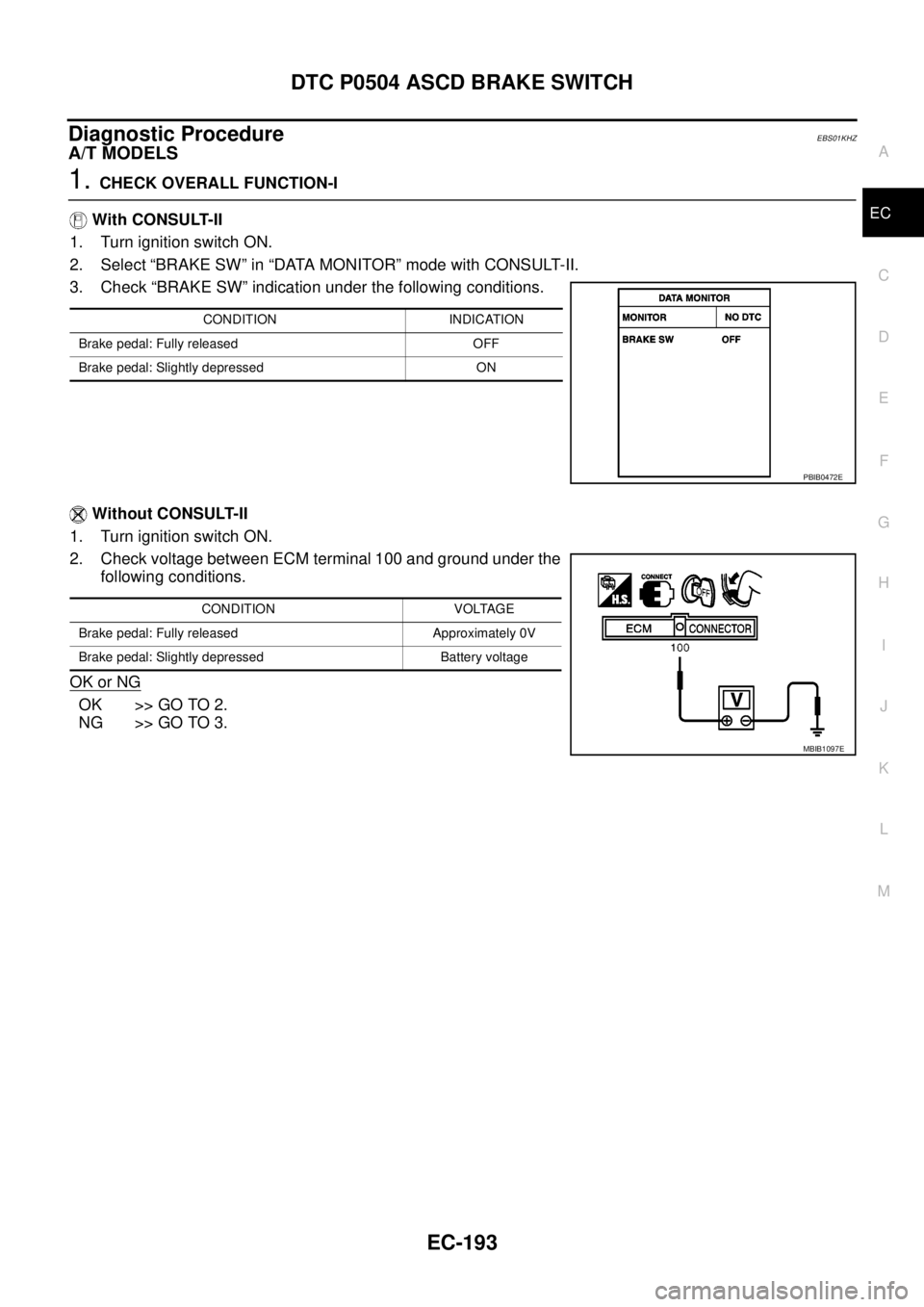

Without CONSULT-II

1. Turn ignition switch ON.

2. Check voltage between ECM terminal 100 and ground under the

following conditions.

OK or NG

OK >> GO TO 2.

NG >> GO TO 3.

CONDITION INDICATION

Brake pedal: Fully released OFF

Brake pedal: Slightly depressed ON

PBIB0472E

CONDITION VOLTAGE

Brake pedal: Fully released Approximately 0V

Brake pedal: Slightly depressed Battery voltage

MBIB1097E