battery NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 987 of 3171

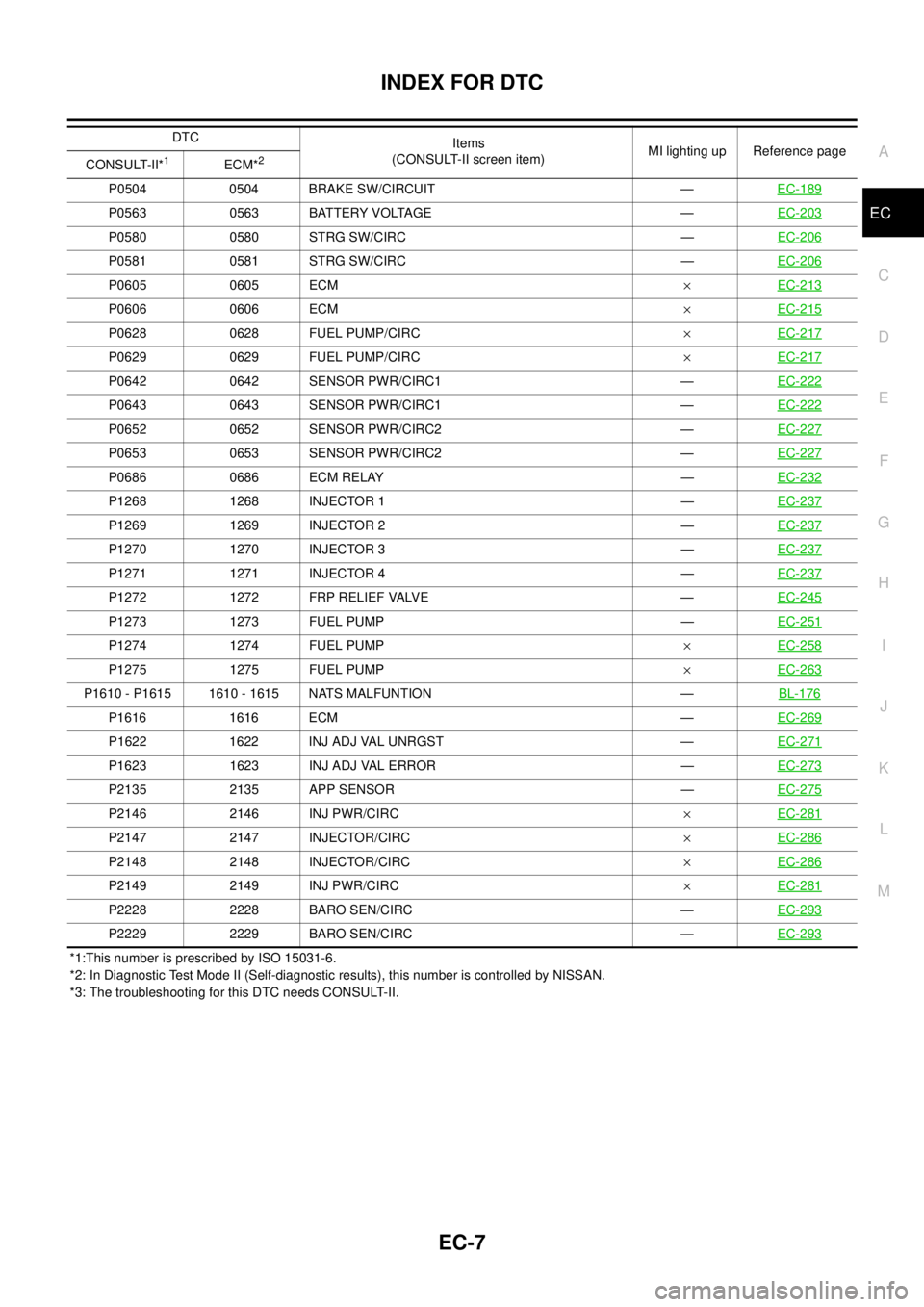

INDEX FOR DTC

EC-7

C

D

E

F

G

H

I

J

K

L

MA

EC

*1:This number is prescribed by ISO 15031-6.

*2: In Diagnostic Test Mode II (Self-diagnostic results), this number is controlled by NISSAN.

*3: The troubleshooting for this DTC needs CONSULT-II.P0504 0504 BRAKE SW/CIRCUIT —EC-189

P0563 0563 BATTERY VOLTAGE —EC-203

P0580 0580 STRG SW/CIRC —EC-206

P0581 0581 STRG SW/CIRC —EC-206

P0605 0605 ECM´EC-213

P0606 0606 ECM´EC-215

P0628 0628 FUEL PUMP/CIRC´EC-217

P0629 0629 FUEL PUMP/CIRC´EC-217

P0642 0642 SENSOR PWR/CIRC1 —EC-222

P0643 0643 SENSOR PWR/CIRC1 —EC-222

P0652 0652 SENSOR PWR/CIRC2 —EC-227

P0653 0653 SENSOR PWR/CIRC2 —EC-227

P0686 0686 ECM RELAY —EC-232

P1268 1268 INJECTOR 1 —EC-237

P1269 1269 INJECTOR 2 —EC-237

P1270 1270 INJECTOR 3 —EC-237

P1271 1271 INJECTOR 4 —EC-237

P1272 1272 FRP RELIEF VALVE —EC-245

P1273 1273 FUEL PUMP —EC-251

P1274 1274 FUEL PUMP´EC-258

P1275 1275 FUEL PUMP´EC-263

P1610 - P1615 1610 - 1615 NATS MALFUNTION —BL-176

P1616 1616 ECM —EC-269

P1622 1622 INJ ADJ VAL UNRGST —EC-271

P1623 1623 INJ ADJ VAL ERROR —EC-273

P2135 2135 APP SENSOR —EC-275

P2146 2146 INJ PWR/CIRC´EC-281

P2147 2147 INJECTOR/CIRC´EC-286

P2148 2148 INJECTOR/CIRC´EC-286

P2149 2149 INJ PWR/CIRC´EC-281

P2228 2228 BARO SEN/CIRC —EC-293

P2229 2229 BARO SEN/CIRC —EC-293

DTC

Items

(CONSULT-II screen item)MI lighting up Reference page

CONSULT-II*

1ECM*2

Page 988 of 3171

EC-8

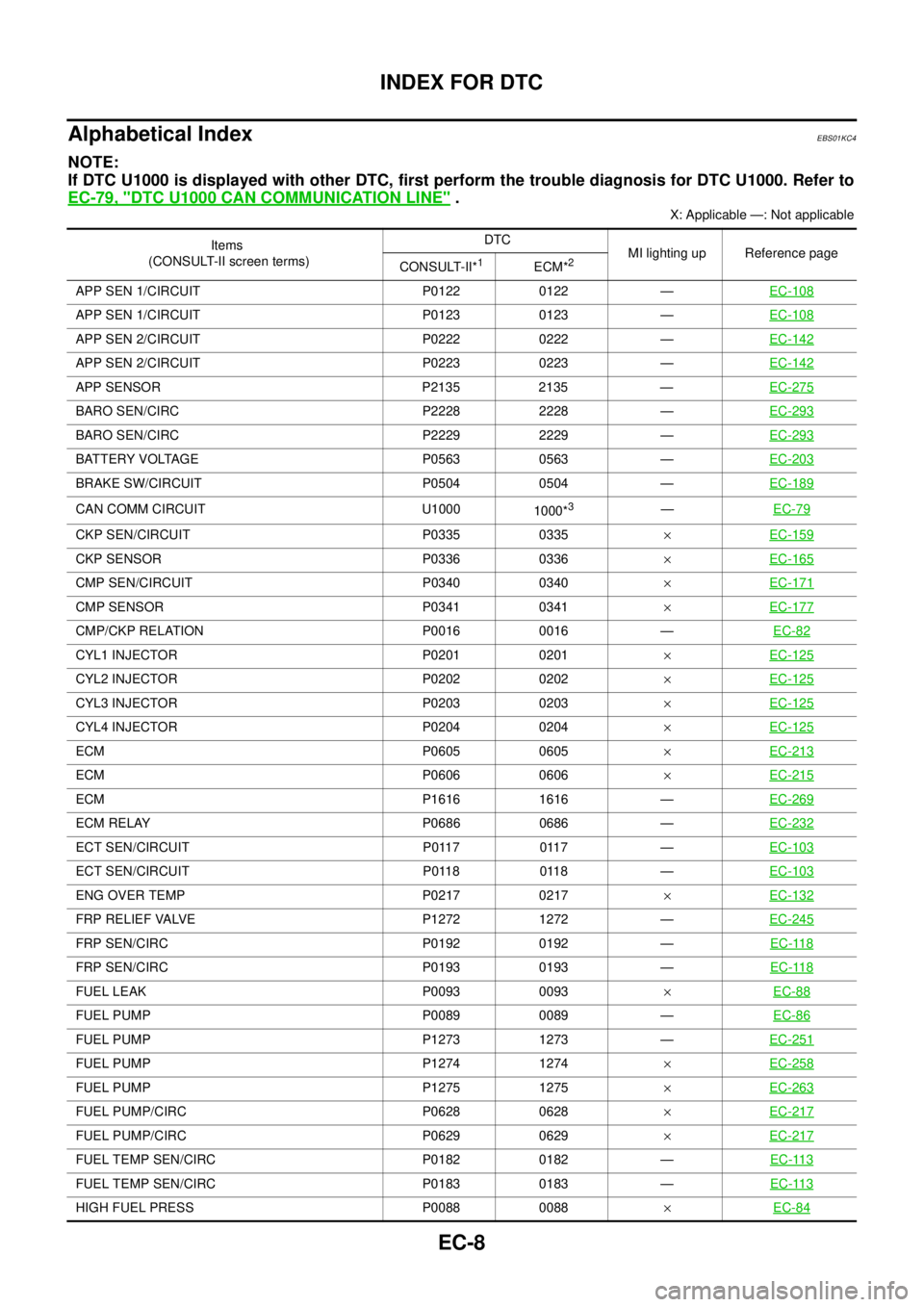

INDEX FOR DTC

Alphabetical Index

EBS01KC4

NOTE:

If DTC U1000 is displayed with other DTC, first perform the trouble diagnosis for DTC U1000. Refer to

EC-79, "

DTC U1000 CAN COMMUNICATION LINE".

X: Applicable —: Not applicable

Items

(CONSULT-II screen terms)DTC

MI lighting up Reference page

CONSULT-II*

1ECM*2

APP SEN 1/CIRCUIT P0122 0122 —EC-108

APP SEN 1/CIRCUIT P0123 0123 —EC-108

APP SEN 2/CIRCUIT P0222 0222 —EC-142

APP SEN 2/CIRCUIT P0223 0223 —EC-142

APP SENSOR P2135 2135 —EC-275

BARO SEN/CIRC P2228 2228 —EC-293

BARO SEN/CIRC P2229 2229 —EC-293

BATTERY VOLTAGE P0563 0563 —EC-203

BRAKE SW/CIRCUIT P0504 0504 —EC-189

CAN COMM CIRCUIT U1000

1000*3—EC-79

CKP SEN/CIRCUIT P0335 0335´EC-159

CKP SENSOR P0336 0336´EC-165

CMP SEN/CIRCUIT P0340 0340´EC-171

CMP SENSOR P0341 0341´EC-177

CMP/CKP RELATION P0016 0016 —EC-82

CYL1 INJECTOR P0201 0201´EC-125

CYL2 INJECTOR P0202 0202´EC-125

CYL3 INJECTOR P0203 0203´EC-125

CYL4 INJECTOR P0204 0204´EC-125

ECM P0605 0605´EC-213

ECM P0606 0606´EC-215

ECM P1616 1616 —EC-269

ECM RELAY P0686 0686 —EC-232

ECT SEN/CIRCUIT P0117 0117 —EC-103

ECT SEN/CIRCUIT P0118 0118 —EC-103

ENG OVER TEMP P0217 0217´EC-132

FRP RELIEF VALVE P1272 1272 —EC-245

FRP SEN/CIRC P0192 0192 —EC-118

FRP SEN/CIRC P0193 0193 —EC-118

FUEL LEAK P0093 0093´EC-88

FUEL PUMP P0089 0089 —EC-86

FUEL PUMP P1273 1273 —EC-251

FUEL PUMP P1274 1274´EC-258

FUEL PUMP P1275 1275´EC-263

FUEL PUMP/CIRC P0628 0628´EC-217

FUEL PUMP/CIRC P0629 0629´EC-217

FUEL TEMP SEN/CIRC P0182 0182 —EC-113

FUEL TEMP SEN/CIRC P0183 0183 —EC-113

HIGH FUEL PRESS P0088 0088´EC-84

Page 990 of 3171

EC-10

PRECAUTIONS

PRECAUTIONS

PFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EBS01KC5

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

On Board Diagnostic (OBD) System of EngineEBS01KC6

The ECM has an on board diagnostic system. It will light up the malfunction indicator (MI) to warn the driver of

a malfunction causing emission deterioration.

CAUTION:

lBe sure to turn the ignition switch OFF and disconnect the battery negative cable before any

repair or inspection work. The open/short circuit of related switches, sensors, solenoid valves,

etc. will cause the MI to light up.

lBe sure to connect and lock the connectors securely after work. A loose (unlocked) connector will

cause the MI to light up due to the open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

lCertain systems and components, especially those related to OBD, may use a new style slide-

locking type harness connector. For description and how to disconnect, refer toPG-75, "

HAR-

NESS CONNECTOR".

lBe sure to route and secure the harnesses properly after work. The interference of the harness

with a bracket, etc. may cause the MI to light up due to the short circuit.

lBe sure to connect rubber tubes properly after work. A misconnected or disconnected rubber tube

may cause the MI to light up due to the malfunction of the fuel system, etc.

lBe sure to erase the unnecessary malfunction information (repairs completed) from the ECM

before returning the vehicle to the customer.

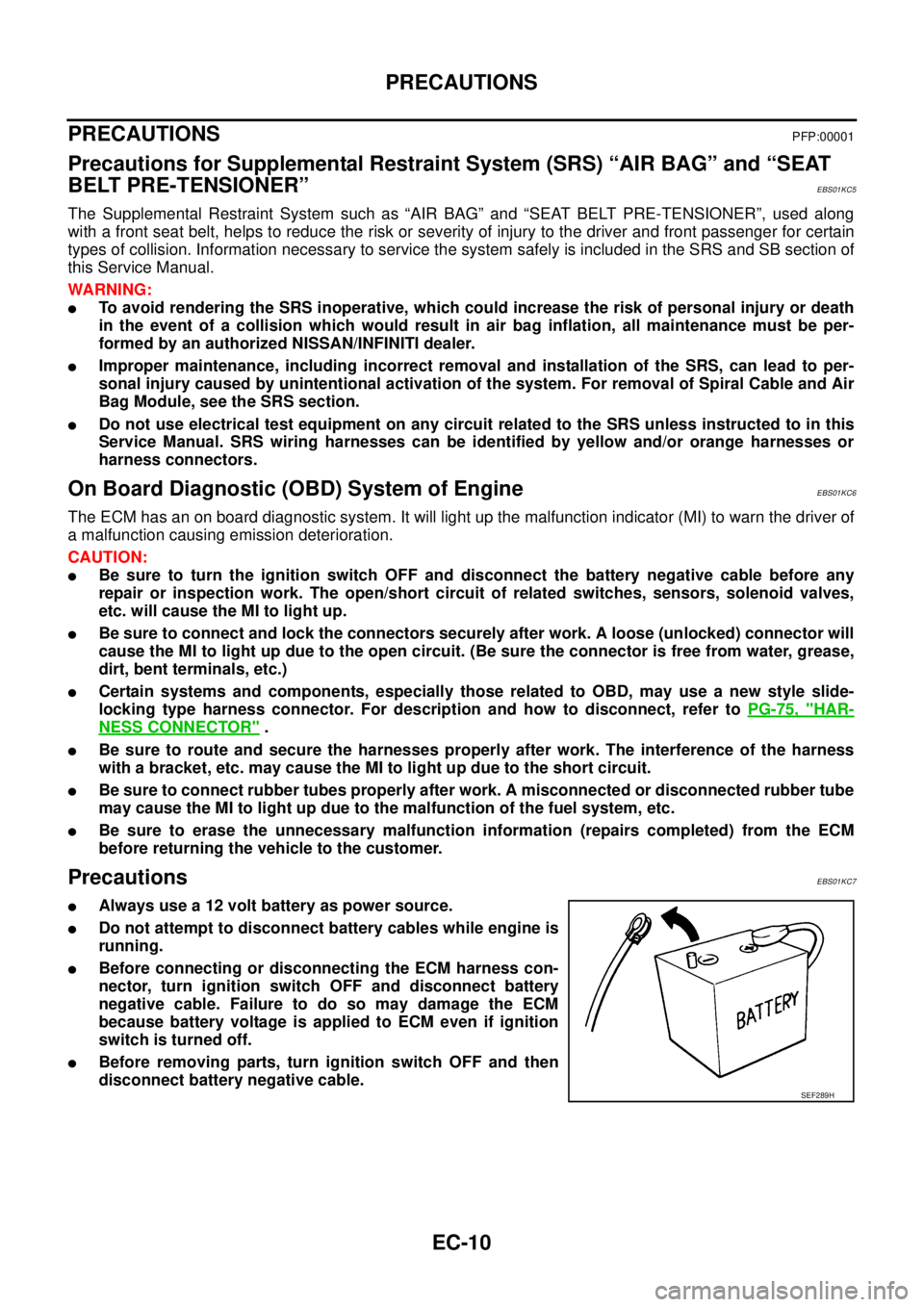

PrecautionsEBS01KC7

lAlways use a 12 volt battery as power source.

lDo not attempt to disconnect battery cables while engine is

running.

lBefore connecting or disconnecting the ECM harness con-

nector, turn ignition switch OFF and disconnect battery

negative cable. Failure to do so may damage the ECM

because battery voltage is applied to ECM even if ignition

switch is turned off.

lBefore removing parts, turn ignition switch OFF and then

disconnect battery negative cable.

SEF289H

Page 998 of 3171

EC-18

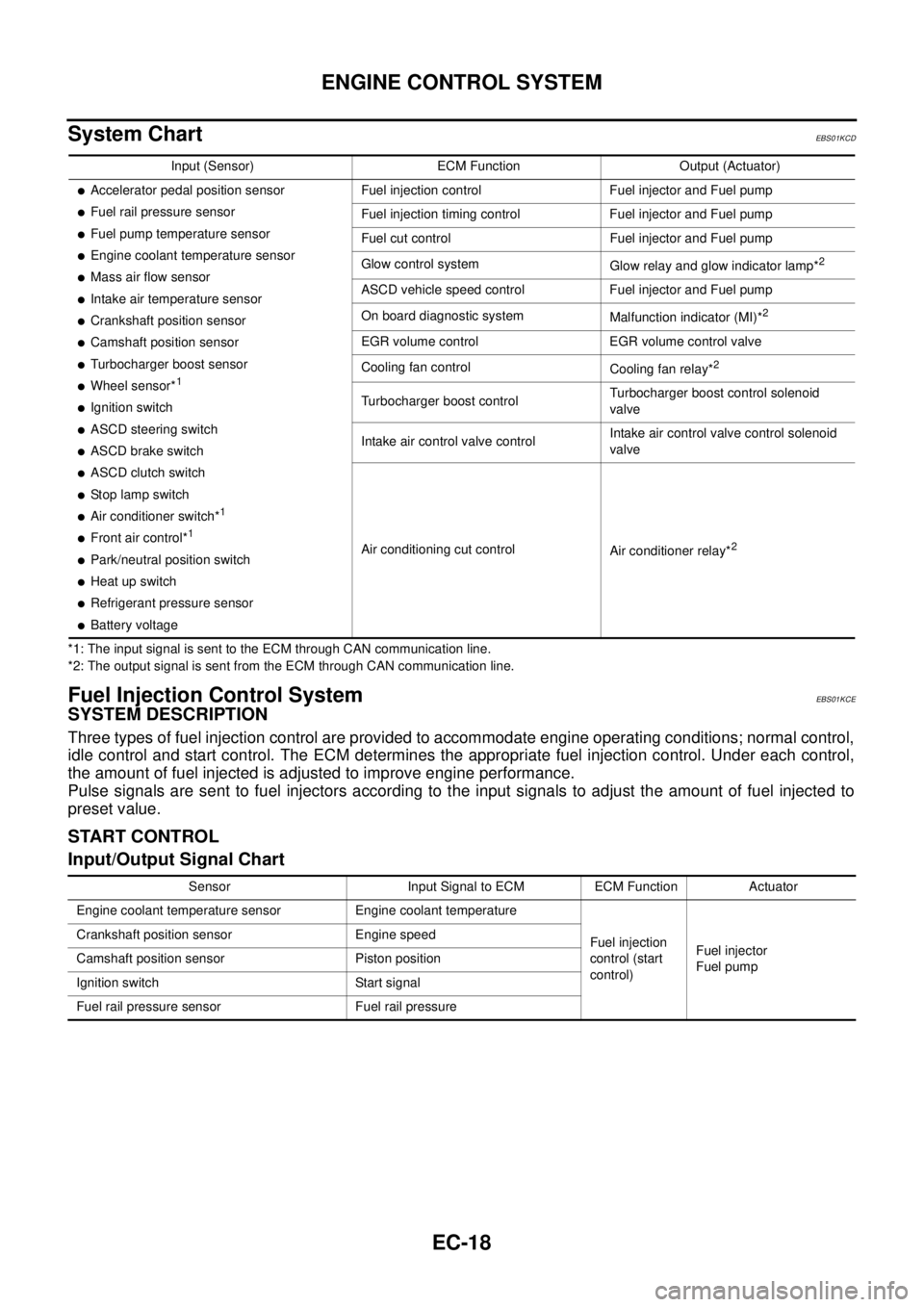

ENGINE CONTROL SYSTEM

System Chart

EBS01KCD

*1: The input signal is sent to the ECM through CAN communication line.

*2: The output signal is sent from the ECM through CAN communication line.

Fuel Injection Control SystemEBS01KCE

SYSTEM DESCRIPTION

Three types of fuel injection control are provided to accommodate engine operating conditions; normal control,

idle control and start control. The ECM determines the appropriate fuel injection control. Under each control,

the amount of fuel injected is adjusted to improve engine performance.

Pulse signals are sent to fuel injectors according to the input signals to adjust the amount of fuel injected to

preset value.

START CONTROL

Input/Output Signal Chart

Input (Sensor) ECM Function Output (Actuator)

lAccelerator pedal position sensor

lFuel rail pressure sensor

lFuel pump temperature sensor

lEngine coolant temperature sensor

lMass air flow sensor

lIntake air temperature sensor

lCrankshaft position sensor

lCamshaft position sensor

lTurbocharger boost sensor

lWheel sensor*1

lIgnition switch

lASCD steering switch

lASCD brake switch

lASCD clutch switch

lSt o p l a m p s w it c h

lAir conditioner switch*1

lFront air control*1

lPark/neutral position switch

lHeat up switch

lRefrigerant pressure sensor

lBattery voltageFuel injection control Fuel injector and Fuel pump

Fuel injection timing control Fuel injector and Fuel pump

Fuel cut control Fuel injector and Fuel pump

Glow control system

Glow relay and glow indicator lamp*

2

ASCD vehicle speed control Fuel injector and Fuel pump

On board diagnostic system

Malfunction indicator (MI)*

2

EGR volume control EGR volume control valve

Cooling fan control

Cooling fan relay*

2

Turbocharger boost controlTurbocharger boost control solenoid

valve

Intake air control valve controlIntake air control valve control solenoid

valve

Air conditioning cut control

Air conditioner relay*

2

Sensor Input Signal to ECM ECM Function Actuator

Engine coolant temperature sensor Engine coolant temperature

Fuel injection

control (start

control)Fuel injector

Fuel pump Crankshaft position sensor Engine speed

Camshaft position sensor Piston position

Ignition switch Start signal

Fuel rail pressure sensor Fuel rail pressure

Page 999 of 3171

ENGINE CONTROL SYSTEM

EC-19

C

D

E

F

G

H

I

J

K

L

MA

EC

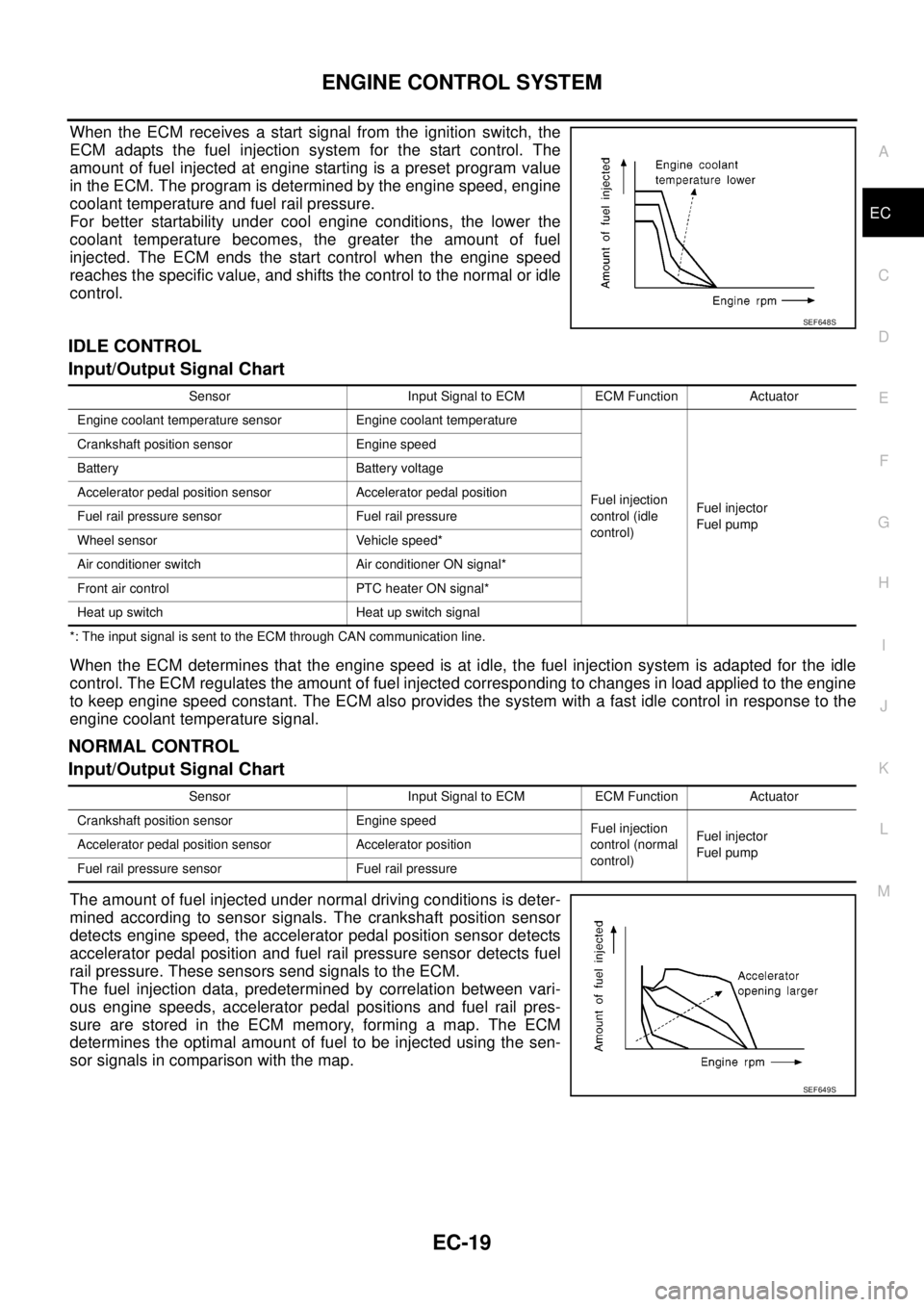

When the ECM receives a start signal from the ignition switch, the

ECM adapts the fuel injection system for the start control. The

amount of fuel injected at engine starting is a preset program value

in the ECM. The program is determined by the engine speed, engine

coolant temperature and fuel rail pressure.

For better startability under cool engine conditions, the lower the

coolant temperature becomes, the greater the amount of fuel

injected. The ECM ends the start control when the engine speed

reaches the specific value, and shifts the control to the normal or idle

control.

IDLE CONTROL

Input/Output Signal Chart

*: The input signal is sent to the ECM through CAN communication line.

When the ECM determines that the engine speed is at idle, the fuel injection system is adapted for the idle

control. The ECM regulates the amount of fuel injected corresponding to changes in load applied to the engine

to keep engine speed constant. The ECM also provides the system with a fast idle control in response to the

engine coolant temperature signal.

NORMAL CONTROL

Input/Output Signal Chart

The amount of fuel injected under normal driving conditions is deter-

mined according to sensor signals. The crankshaft position sensor

detects engine speed, the accelerator pedal position sensor detects

accelerator pedal position and fuel rail pressure sensor detects fuel

rail pressure. These sensors send signals to the ECM.

The fuel injection data, predetermined by correlation between vari-

ous engine speeds, accelerator pedal positions and fuel rail pres-

sure are stored in the ECM memory, forming a map. The ECM

determines the optimal amount of fuel to be injected using the sen-

sor signals in comparison with the map.

SEF648S

Sensor Input Signal to ECM ECM Function Actuator

Engine coolant temperature sensor Engine coolant temperature

Fuel injection

control (idle

control)Fuel injector

Fuel pump Crankshaft position sensor Engine speed

Battery Battery voltage

Accelerator pedal position sensor Accelerator pedal position

Fuel rail pressure sensor Fuel rail pressure

Wheel sensor Vehicle speed*

Air conditioner switch Air conditioner ON signal*

Front air control PTC heater ON signal*

Heat up switch Heat up switch signal

Sensor Input Signal to ECM ECM Function Actuator

Crankshaft position sensor Engine speed

Fuel injection

control (normal

control)Fuel injector

Fuel pump Accelerator pedal position sensor Accelerator position

Fuel rail pressure sensor Fuel rail pressure

SEF649S

Page 1008 of 3171

EC-28

ON BOARD DIAGNOSTIC (OBD) SYSTEM

lIf the battery is disconnected, the emission-related diagnostic information will be lost within 24

hours.

lThe following data are cleared when the ECM memory is erased.

–Diagnostic trouble codes

–Freeze frame data

–Fuel pump learning value

Actual work procedures are explained using a DTC as an example. Be careful so that not only the DTC, but all

of the data listed above, are cleared from the ECM memory during work procedures.

Freeze Frame DataEBS01KCP

The ECM records the driving conditions such as calculated load value, engine coolant temperature, engine

speed, vehicle speed and intake manifold pressure at the moment a malfunction is detected.

The data, stored together with the DTC data, are called freeze frame data and displayed on CONSULT-II. For

details, seeEC-28, "

Freeze Frame Data".

Only one set of freeze frame data can be stored in the ECM. If freeze frame data is stored in the ECM memory

and another freeze frame data occurs later, the first (original) freeze frame data remains unchanged in the

ECM memory.

Freeze frame data (along with the DTCs) are cleared when the ECM memory is erased. Procedures for clear-

ing the ECM memory are described inEC-27, "

HOW TO ERASE DTC".

NATS (Nissan Anti-theft System)EBS01KCQ

lIf the security indicator lights up with the ignition switch in

the ON position or "NATS MALFUNCTION" is displayed on

"SELF-DIAG RESULTS" screen, perform self-diagnostic

results mode with CONSULT-II using NATS program card.

Refer toBL-170, "

NATS(Nissan Anti-Theft System)".

lConfirm no self-diagnostic results of NATS is displayed

before touching "ERASE" in "SELF-DAIG RESULTS" mode

with CONSULT-II.

lWhen replacing ECM, initialization of NATS system and reg-

istration of all NATS ignition key IDs must be carried out

with CONSULT-II using NATS program card.

Therefore, be sure to receive all keys from vehicle owner.

Regarding the procedure of NATS initialization and NATS ignition key ID registration, refer to CON-

SULT-II operation manual, NATS.

Malfunction Indicator (MI)EBS01KCR

DESCRIPTION

The MI is located on the combination meter.

1. The MI will light up when the ignition switch is turned ON without

the engine running. This is a bulb check.

lIf the MI does not light up, refer toEC-354, "MI&DATA LINK

CONNECTORS".

2. When the engine is started, the MI should go off.

If the MI remains on, the on board diagnostic system has

detected an engine system malfunction.

ON BOARD DIAGNOSTIC SYSTEM FUNCTION

The on board diagnostic system has the following three functions.

SEF543X

SAT652J

Page 1010 of 3171

EC-30

ON BOARD DIAGNOSTIC (OBD) SYSTEM

How to Erase Diagnostic Test Mode II (Self-diagnostic Results)

1. Set ECM in Diagnostic Test Mode II (Self-diagnostic results). Refer toEC-29, "How to Set Diagnostic Test

Mode II (Self-diagnostic Results)".

2. Fully depress the accelerator pedal and keep it for more than 10 seconds.

The emission-related diagnostic information has been erased from the backup memory in the ECM.

3. Fully release the accelerator pedal, and confirm the DTC 0000 is displayed.

DIAGNOSTIC TEST MODE I — BULB CHECK

In this mode, the MI on the combination meter should stay ON. If it remains OFF, check the bulb. Refer toEC-

354, "MI&DATA LINK CONNECTORS".

DIAGNOSTIC TEST MODE I — MALFUNCTION WARNING

These DTC numbers are clarified in Diagnostic Test Mode II (SELF-DIAGNOSTIC RESULTS)

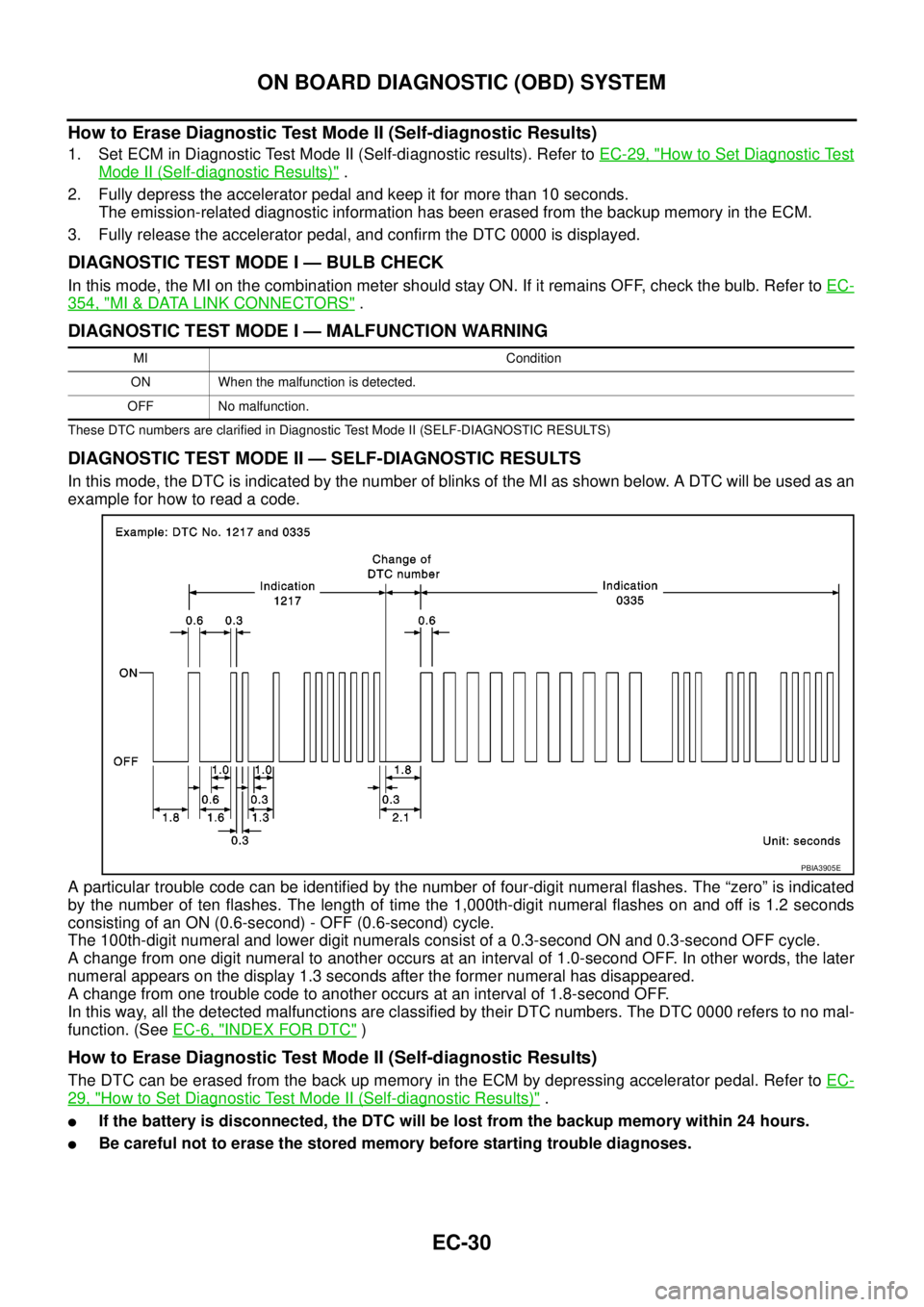

DIAGNOSTIC TEST MODE II — SELF-DIAGNOSTIC RESULTS

In this mode, the DTC is indicated by the number of blinks of the MI as shown below. A DTC will be used as an

example for how to read a code.

A particular trouble code can be identified by the number of four-digit numeral flashes. The “zero” is indicated

by the number of ten flashes. The length of time the 1,000th-digit numeral flashes on and off is 1.2 seconds

consisting of an ON (0.6-second) - OFF (0.6-second) cycle.

The 100th-digit numeral and lower digit numerals consist of a 0.3-second ON and 0.3-second OFF cycle.

A change from one digit numeral to another occurs at an interval of 1.0-second OFF. In other words, the later

numeral appears on the display 1.3 seconds after the former numeral has disappeared.

A change from one trouble code to another occurs at an interval of 1.8-second OFF.

In this way, all the detected malfunctions are classified by their DTC numbers. The DTC 0000 refers to no mal-

function. (SeeEC-6, "

INDEX FOR DTC")

How to Erase Diagnostic Test Mode II (Self-diagnostic Results)

The DTC can be erased from the back up memory in the ECM by depressing accelerator pedal. Refer toEC-

29, "How to Set Diagnostic Test Mode II (Self-diagnostic Results)".

lIf the battery is disconnected, the DTC will be lost from the backup memory within 24 hours.

lBe careful not to erase the stored memory before starting trouble diagnoses.

MI Condition

ON When the malfunction is detected.

OFF No malfunction.

PBIA3905E

Page 1017 of 3171

TROUBLE DIAGNOSIS

EC-37

C

D

E

F

G

H

I

J

K

L

MA

EC

DTC Inspection Priority ChartEBS01KCU

If some DTCs are displayed at the same time, perform inspections one by one based on the following priority

chart.

NOTE:

If DTC U1000 is displayed with other DTC, first perform the trouble diagnosis for DTC U1000. Refer to

EC-79, "

DTC U1000 CAN COMMUNICATION LINE".

Priority Detected items (DTC)

1

lU1000 CAN communication line

lP0016 Crankshaft position - camshaft position correlation

lP0102 P0103 Mass air flow sensor

lP0112 P0113 Intake air temperature sensor

lP0117 P0118 Engine coolant temperature sensor

lP0122 P0123 P0222 P0223 P2135 Accelerator pedal position sensor

lP0182 P0183 Fuel pump temperature sensor

lP0192 P0193 Fuel rail pressure sensor

lP0237 P0238 Turbocharger boost sensor

lP0335 P0336 Crankshaft position sensor

lP0340 P0341 Camshaft position sensor

lP0563 Battery voltage

lP0605 P0606 P1616 ECM

lP0642 P0643 P0652 P0653 Sensor power supply

lP1610 - P1615 NATS

lP1622 P1623 Injector adjustment value

lP2228 P2229 Barometric pressure sensor

2

lP0089 P0628 P0629 P1272 - P1275 Fuel pump

lP0200 - P0204 P1268 - P1271 P2146 - P2149 Fuel injector

lP0686 ECM relay

3

lP0088 P0093 Fuel system

lP0217 Engine over temperature (OVERHEAT)

lP0234 Turbocharger system

lP0501 P0502 P0503 ASCD vehicle speed sensor

lP0504 ASCD brake switch

lP0580 P0581 ASCD steering switch

Page 1020 of 3171

EC-40

TROUBLE DIAGNOSIS

8.CHECK IDLE SPEED AGAIN

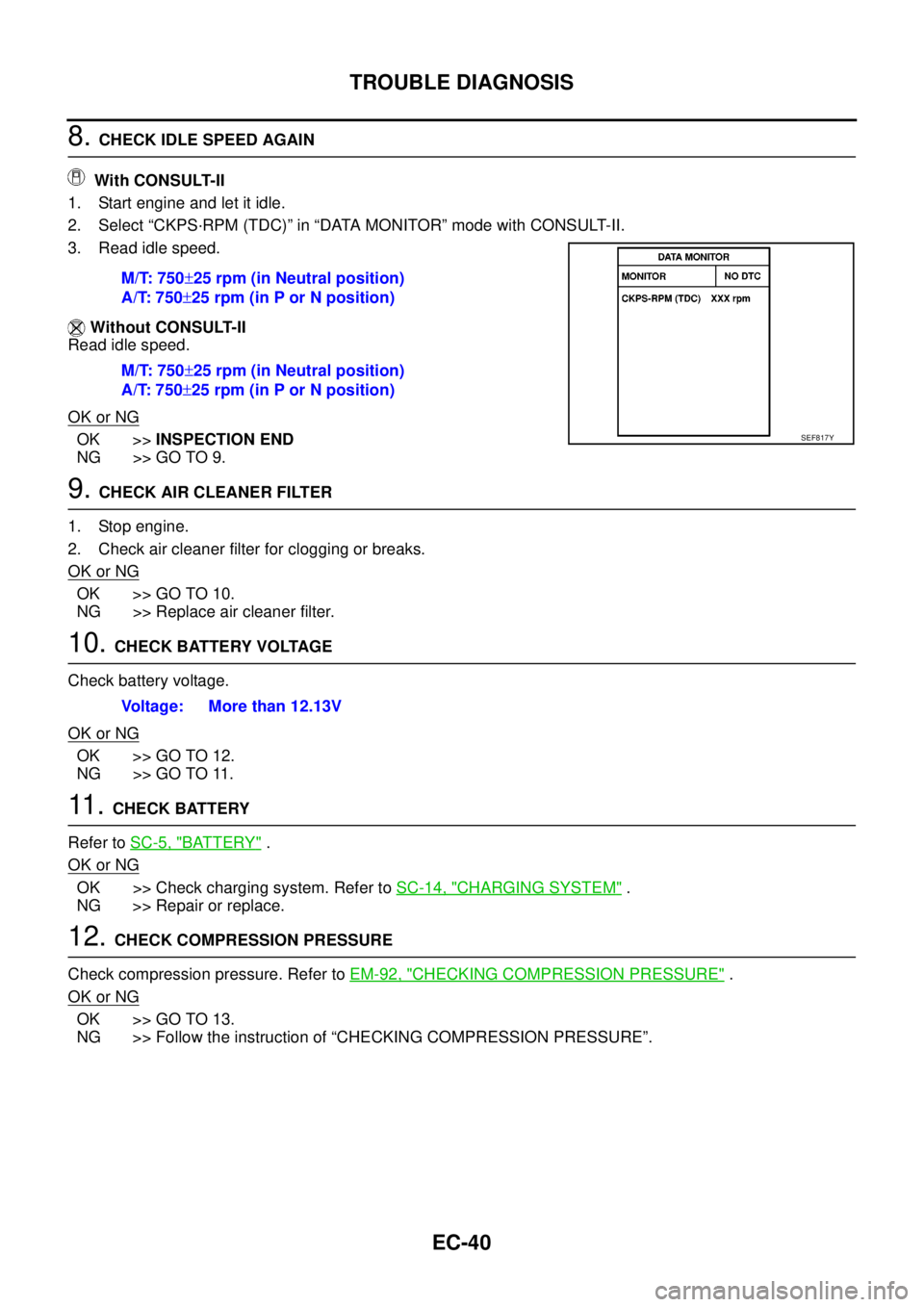

With CONSULT-II

1. Start engine and let it idle.

2. Select “CKPS·RPM (TDC)” in “DATA MONITOR” mode with CONSULT-II.

3. Read idle speed.

Without CONSULT-II

Read idle speed.

OK or NG

OK >>INSPECTION END

NG >> GO TO 9.

9.CHECK AIR CLEANER FILTER

1. Stop engine.

2. Check air cleaner filter for clogging or breaks.

OK or NG

OK >> GO TO 10.

NG >> Replace air cleaner filter.

10.CHECK BATTERY VOLTAGE

Check battery voltage.

OK or NG

OK >> GO TO 12.

NG >> GO TO 11.

11 .CHECK BATTERY

Refer toSC-5, "

BATTERY".

OK or NG

OK >> Check charging system. Refer toSC-14, "CHARGING SYSTEM".

NG >> Repair or replace.

12.CHECK COMPRESSION PRESSURE

Check compression pressure. Refer toEM-92, "

CHECKING COMPRESSION PRESSURE".

OK or NG

OK >> GO TO 13.

NG >> Follow the instruction of “CHECKING COMPRESSION PRESSURE”.M/T: 750±25 rpm (in Neutral position)

A/T: 750±25 rpm (in P or N position)

M/T: 750±25 rpm (in Neutral position)

A/T: 750±25 rpm (in P or N position)

SEF817Y

Voltage: More than 12.13V

Page 1024 of 3171

EC-44

TROUBLE DIAGNOSIS

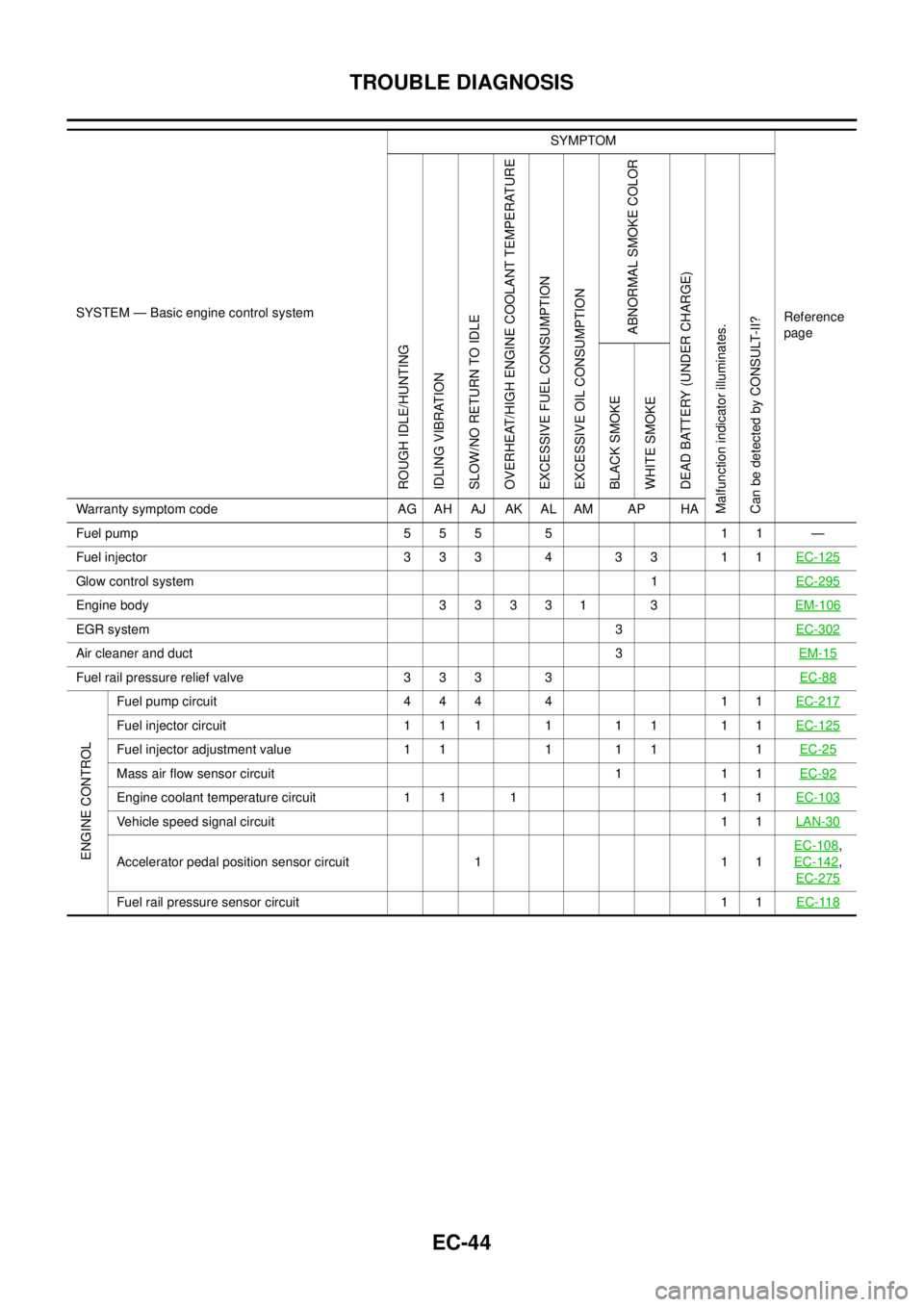

SYSTEM — Basic engine control systemSYMPTOM

Reference

page

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEAT/HIGH ENGINE COOLANT TEMPERATURE

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

ABNORMAL SMOKE COLOR

DEAD BATTERY (UNDER CHARGE)

Malfunction indicator illuminates.

Can be detected by CONSULT-II?BLACK SMOKE

WHITE SMOKE

Warranty symptom code AG AH AJ AK AL AM AP HA

Fuel pump 5 5 5 5 1 1 —

Fuel injector 3 3 3 4 3 3 1 1EC-125

Glow control system1EC-295

Engine body 3 3 3 3 1 3EM-106

EGR system3EC-302

Air cleaner and duct3EM-15

Fuel rail pressure relief valve 3 3 3 3EC-88

ENGINE CONTROL

Fuel pump circuit 4 4 4 4 1 1EC-217

Fuel injector circuit 1 1 1 1 1 1 1 1EC-125

Fuel injector adjustment value 1 1 1 1 1 1EC-25

Mass air flow sensor circuit 1 1 1EC-92

Engine coolant temperature circuit 1 1 1 1 1EC-103

Vehicle speed signal circuit11LAN-30

Accelerator pedal position sensor circuit 1 1 1EC-108

,

EC-142

,

EC-275

Fuel rail pressure sensor circuit11EC-118