key NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2229 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual LT-146

INTERIOR ROOM LAMP

lto key switch terminal 2,

lthrough 10A fuse [No. 21, located in fuse block (J/B)]

lto BCM terminal 41.

When key is inserted in key switch, power is supplied

lthrough the key NISSAN NAVARA 2005 Repair Workshop Manual LT-146

INTERIOR ROOM LAMP

lto key switch terminal 2,

lthrough 10A fuse [No. 21, located in fuse block (J/B)]

lto BCM terminal 41.

When key is inserted in key switch, power is supplied

lthrough the key](/img/5/57362/w960_57362-2228.png)

LT-146

INTERIOR ROOM LAMP

lto key switch terminal 2,

lthrough 10A fuse [No. 21, located in fuse block (J/B)]

lto BCM terminal 41.

When key is inserted in key switch, power is supplied

lthrough the key switch terminal 1

lto BCM terminal 5.

With ignition switch in the ON or START position, power is supplied

lthrough 10A fuse [No. 1, located in fuse and block (J/B)]

lto BCM terminal 3.

Ground is supplied

lto BCM terminal 55

lthrough grounds M21, M80 and M83.

When front driver side door is opened, ground is supplied (double cab)

lto BCM terminal 15

lthrough front door switch driver side terminal 2

lthrough case ground of front door switch driver side.

When front passenger side door is opened, ground is supplied (double cab)

lto BCM terminal 14

lthrough front door switch passenger side terminal 2

lthrough case ground of front door switch passenger side.

When rear door LH is opened, ground is supplied (double cab)

lto BCM terminal 16

lthrough rear door switch LH terminal 2

lthrough case ground of rear door switch LH.

When rear door RH is opened, ground is supplied (double cab)

lto BCM terminal 12

lthrough rear door switch RH terminal 2

lthrough case ground of rear door switch RH.

When front driver side door is opened, ground is supplied (king cab)

lto BCM terminal 15

lthrough front door switch (driver side) terminal 2

lthrough front door switch (driver side) terminal 3

lthrough grounds B9 and B25 (LHD models)

lthrough grounds B106 and B121 (RHD models).

When front passenger side door is opened, ground is supplied (king cab)

lto BCM terminal 14

lthrough front door switch (passenger side) terminal 2

lthrough front door switch (passenger side) terminal 3

lthrough grounds B9 and B25 (LHD models)

lthrough grounds B106 and B121 (RHD models).

When rear door (driver side) is opened, ground is supplied (king cab)

lto BCM terminal 15

lthrough rear door switch (driver side) No.1 and No.2 terminals 1

lthrough rear door switch (driver side) No.1 and No.2 terminals 2

lthrough grounds B9 and B25 (LHD models)

lthrough grounds B106 and B121 (RHD models).

When rear door (passenger side) is opened, ground is supplied (king cab)

lto BCM terminal 14

lthrough rear door switch (passenger side) No.1 and No.2 terminals 1

Page 2230 of 3171

INTERIOR ROOM LAMP

LT-147

C

D

E

F

G

H

I

J

L

MA

B

LT

lthrough rear door switch (passenger side) No.1 and No.2 terminals 2

lthrough grounds B9 and B25 (LHD models)

lthrough grounds B106 and B121 (RHD models).

When a signal is received by BCM, power is supplied

lthrough BCM terminal 42

lto key ring lamp terminal 1

lto front map lamp terminal 1 and

lto room lamp terminal 2.

SWITCH OPERATION

When front map lamp switch is ON, ground is supplied

lto front map lamp terminal 2

lthrough grounds M21, M80 and M83.

When room lamp switch is ON, ground is supplied through room lamp case ground.

ROOM LAMP TIMER OPERATION

When lamp switch is in DOOR position, and when all conditions below are met, BCM performs timer control

(maximum 30 seconds) for interior room lamp and map lamp ON/OFF.

Power is supplied

lthrough 10A fuse [No. 22, located in fuse block (J/B)]

lto key switch terminal 2.

Key is removed from ignition key cylinder (key switch OFF), power will not be supplied to BCM terminal 5.

At the time that driver's door is opened, BCM detects that driver's door is unlocked. It determines that room

lamp timer operation conditions are met, and turns the interior room lamps ON for 30 seconds.

Key is in ignition key cylinder (key switch ON), power is supplied

lthrough key switch terminal 1

lto BCM terminal 5.

When key is removed from key switch (key switch OFF), power supply to BCM terminal 5 is terminated. BCM

detects that key has been removed, determines that room lamp timer conditions are met, and turns the interior

room lamps ON for 30 seconds.

When driver's door opens®closes, and the key is not inserted in the key switch (key switch OFF), BCM ter-

minal 15 changes between 0V (door open)®12V (door closed). The BCM determines that conditions for

room lamp operation are met and turns the room lamp ON for 30 seconds.

Timer control is canceled under the following conditions.

lDriver's door is opened [front door switch (driver side)].

lIgnition switch ON.

lKeyfob

INTERIOR LAMP BATTERY SAVER CONTROL

If interior lamp is left ON, it will not be turned off even when door is closed.

BCM turns off interior lamp automatically to save battery 30 minutes after ignition switch is turned off.

BCM controls interior lamps listed below:

lFront map lamp

lRoom lamp

lKey ring lamp

After lamps turn OFF by the battery saver system, the lamps illuminate again when

lsignal received from keyfob or key cylinder is locked or unlocked,

ldoor is opened or closed,

lkey is removed from ignition key cylinder or inserted in ignition key cylinder.

Interior lamp battery saver control period can be changed by the function setting of CONSULT-II. Refer toLT-

158, "WORK SUPPORT".

Page 2237 of 3171

LT-154

INTERIOR ROOM LAMP

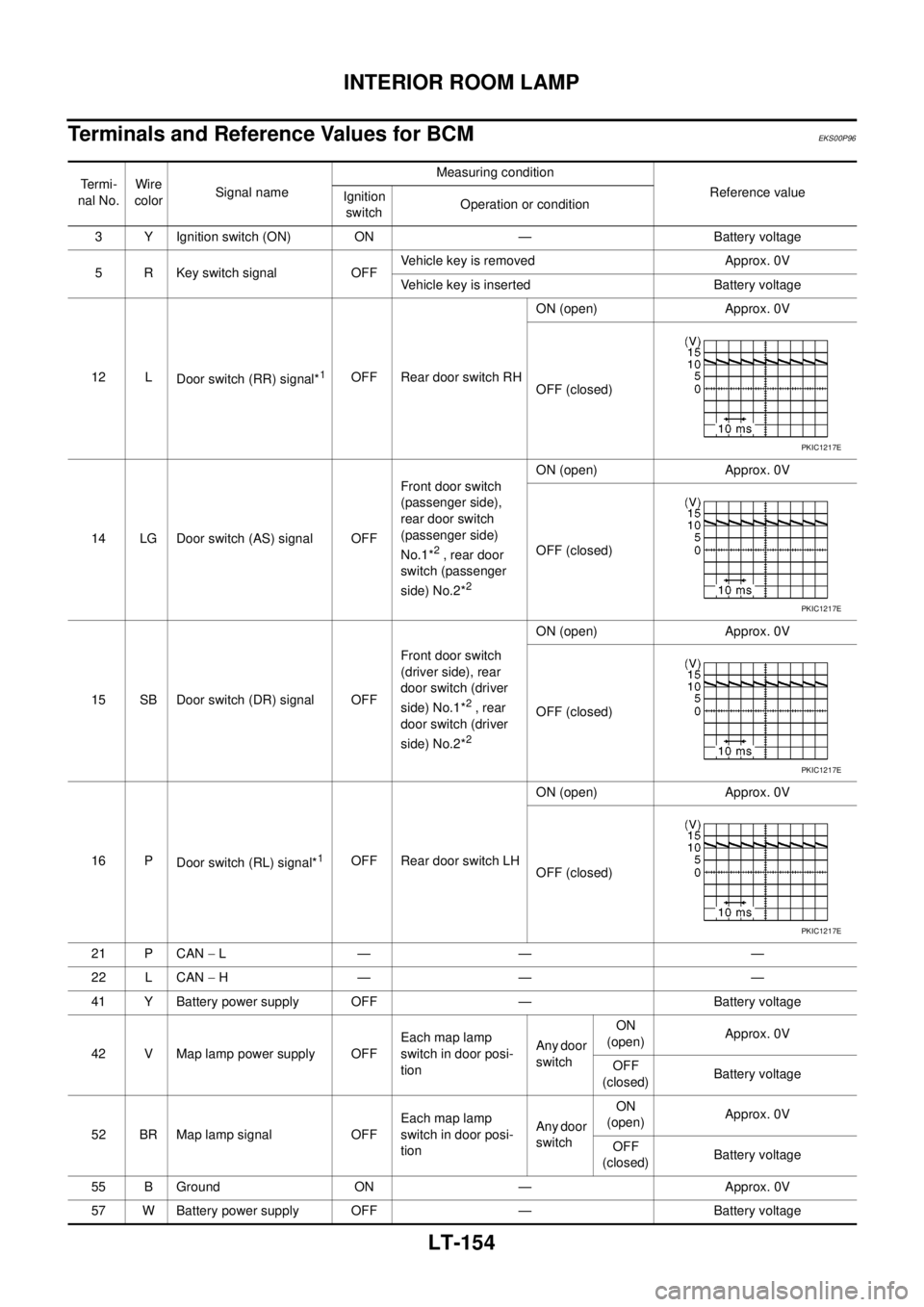

Terminals and Reference Values for BCM

EKS00P96

Te r m i -

nal No.Wire

colorSignal nameMeasuring condition

Reference value

Ignition

switchOperation or condition

3 Y Ignition switch (ON) ON — Battery voltage

5 R Key switch signal OFFVehicle key is removed Approx. 0V

Vehicle key is inserted Battery voltage

12 L

Door switch (RR) signal*

1OFF Rear door switch RHON (open) Approx. 0V

OFF (closed)

14 LG Door switch (AS) signal OFFFront door switch

(passenger side),

rear door switch

(passenger side)

No.1*

2, rear door

switch (passenger

side) No.2*

2

ON (open) Approx. 0V

OFF (closed)

15 SB Door switch (DR) signal OFFFront door switch

(driver side), rear

door switch (driver

side) No.1*

2, rear

door switch (driver

side) No.2*

2

ON (open) Approx. 0V

OFF (closed)

16 P

Door switch (RL) signal*

1OFF Rear door switch LHON (open) Approx. 0V

OFF (closed)

21 P CAN-L— — —

22 L CAN-H— — —

41 Y Battery power supply OFF — Battery voltage

42 V Map lamp power supply OFFEach map lamp

switch in door posi-

tionAny door

switchON

(open)Approx. 0V

OFF

(closed)Battery voltage

52 BR Map lamp signal OFFEach map lamp

switch in door posi-

tionAny door

switchON

(open)Approx. 0V

OFF

(closed)Battery voltage

55 B Ground ON — Approx. 0V

57 W Battery power supply OFF — Battery voltage

PKIC1217E

PKIC1217E

PKIC1217E

PKIC1217E

Page 2241 of 3171

LT-158

INTERIOR ROOM LAMP

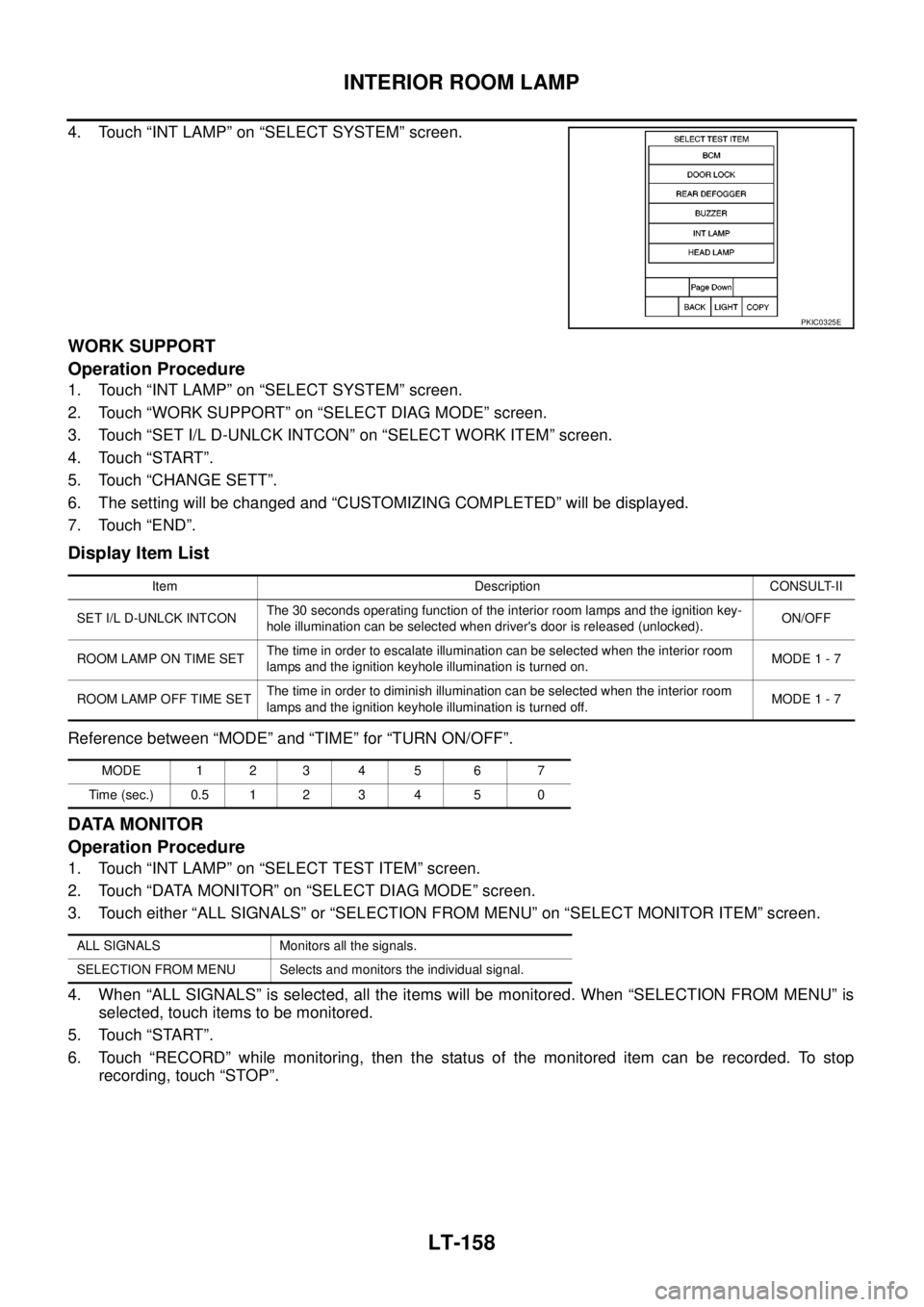

4. Touch “INT LAMP” on “SELECT SYSTEM” screen.

WORK SUPPORT

Operation Procedure

1. Touch “INT LAMP” on “SELECT SYSTEM” screen.

2. Touch “WORK SUPPORT” on “SELECT DIAG MODE” screen.

3. Touch “SET I/L D-UNLCK INTCON” on “SELECT WORK ITEM” screen.

4. Touch “START”.

5. Touch “CHANGE SETT”.

6. The setting will be changed and “CUSTOMIZING COMPLETED” will be displayed.

7. Touch “END”.

Display Item List

Reference between “MODE” and “TIME” for “TURN ON/OFF”.

DATA MONITOR

Operation Procedure

1. Touch “INT LAMP” on “SELECT TEST ITEM” screen.

2. Touch “DATA MONITOR” on “SELECT DIAG MODE” screen.

3. Touch either “ALL SIGNALS” or “SELECTION FROM MENU” on “SELECT MONITOR ITEM” screen.

4. When “ALL SIGNALS” is selected, all the items will be monitored. When “SELECTION FROM MENU” is

selected, touch items to be monitored.

5. Touch “START”.

6. Touch “RECORD” while monitoring, then the status of the monitored item can be recorded. To stop

recording, touch “STOP”.

PKIC0325E

Item Description CONSULT-II

SET I/L D-UNLCK INTCONThe 30 seconds operating function of the interior room lamps and the ignition key-

hole illumination can be selected when driver's door is released (unlocked).ON/OFF

ROOM LAMP ON TIME SETThe time in order to escalate illumination can be selected when the interior room

lamps and the ignition keyhole illumination is turned on.MODE 1 - 7

ROOM LAMP OFF TIME SETThe time in order to diminish illumination can be selected when the interior room

lamps and the ignition keyhole illumination is turned off.MODE 1 - 7

MODE 1 2 3 4 5 6 7

Time (sec.) 0.5 1 2 3 4 5 0

ALL SIGNALS Monitors all the signals.

SELECTION FROM MENU Selects and monitors the individual signal.

Page 2242 of 3171

INTERIOR ROOM LAMP

LT-159

C

D

E

F

G

H

I

J

L

MA

B

LT

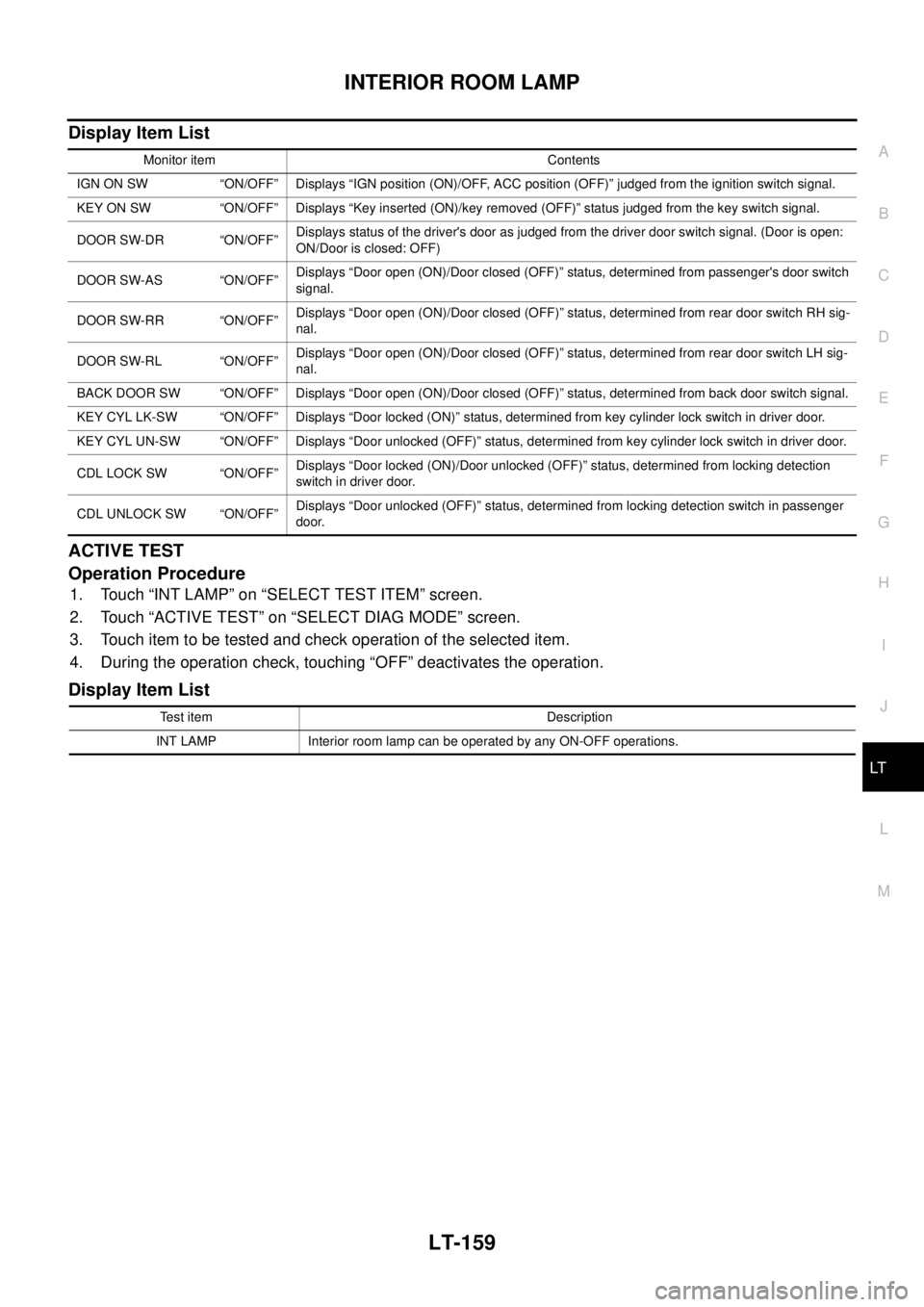

Display Item List

ACTIVE TEST

Operation Procedure

1. Touch “INT LAMP” on “SELECT TEST ITEM” screen.

2. Touch “ACTIVE TEST” on “SELECT DIAG MODE” screen.

3. Touch item to be tested and check operation of the selected item.

4. During the operation check, touching “OFF” deactivates the operation.

Display Item List

Monitor item Contents

IGN ON SW “ON/OFF” Displays “IGN position (ON)/OFF, ACC position (OFF)” judged from the ignition switch signal.

KEY ON SW “ON/OFF” Displays “Key inserted (ON)/key removed (OFF)” status judged from the key switch signal.

DOOR SW-DR “ON/OFF”Displays status of the driver's door as judged from the driver door switch signal. (Door is open:

ON/Door is closed: OFF)

DOOR SW-AS “ON/OFF”Displays “Door open (ON)/Door closed (OFF)” status, determined from passenger's door switch

signal.

DOOR SW-RR “ON/OFF”Displays “Door open (ON)/Door closed (OFF)” status, determined from rear door switch RH sig-

nal.

DOOR SW-RL “ON/OFF”Displays “Door open (ON)/Door closed (OFF)” status, determined from rear door switch LH sig-

nal.

BACK DOOR SW “ON/OFF” Displays “Door open (ON)/Door closed (OFF)” status, determined from back door switch signal.

KEY CYL LK-SW “ON/OFF” Displays “Door locked (ON)” status, determined from key cylinder lock switch in driver door.

KEY CYL UN-SW “ON/OFF” Displays “Door unlocked (OFF)” status, determined from key cylinder lock switch in driver door.

CDL LOCK SW “ON/OFF”Displays “Door locked (ON)/Door unlocked (OFF)” status, determined from locking detection

switch in driver door.

CDL UNLOCK SW “ON/OFF”Displays “Door unlocked (OFF)” status, determined from locking detection switch in passenger

door.

Test item Description

INT LAMP Interior room lamp can be operated by any ON-OFF operations.

Page 2280 of 3171

DESCRIPTION

MA-5

C

D

E

F

G

H

I

J

K

MA

B

MA

DESCRIPTIONPFP:00000

Pre-Delivery Inspection ItemsELS001K2

Shown below are Pre-delivery Inspection Items required for the new vehicle. It is recommended that

necessary items other than those listed here be added, paying due regard to the conditions in each

country.

Perform applicable items on each model. Consult text of this section for specifications.

Install vehicle protection kit

Fit all accessories ordered (if applicable) (e.g. towbar, audio, navigation, air conditioner, styling kit)

UNDER HOOD — engine off

Check coolant level and cooling system for leaks

Charge battery and check terminals for condition

Check drive belts tension

Check fuel filter for water or dust (diesel only) and fuel system for leaks

Check engine oil level and for oil leaks

Check brake and clutch fluid levels and fluid lines for leaks

Check and top up washer reservoirs

Check power steering fluid level and fluid lines for leaks (if applicable)

Check air conditioning system for gas leaks (if applicable)

ON INSIDE AND OUTSIDE

Install transit fuse if removed for vehicle storage

Check instruments, gauges, lamps, horn and accessories for operation

Check wipers and washers for operation and adjustment

Check interior and door mirrors and sun visors for operation

Set radio code and set clock

Check parking brake adjustment

Check clutch pedal adjustment

Check steering lock operation

Check seat adjusters and seat belts for operation

Check all windows for operation and alignment

Check mouldings, trim and fittings for fit and alignment

Check weatherstrips for fit and adhesion

Check hood, trunk lid, door panels and fuel lid for fit and alignment

Check latches, keys, remote key, door locks and remote trunk lid and fuel lid release for operation

Check wheel nut torques

Check tyre pressure (incl. spare tyre)

Check tool kit and jack for operation

Check automatic transmission/transaxle starter inhibitor (if applicable)

Check sunroof for operation and alignment (if applicable)

UNDER BODY

Check manual transmission/transaxle, differential and transfer box for oil level and oil leaks

Tighten bolts and nuts steering linkage and gear box, axle/suspension parts, propeller and exhaust system

Check brake and clutch lines, and oil/fluid reservoirs for leaks

Remove front suspension spacer blocks (if applicable)

Check body mounting torque (if applicable)

Page 2461 of 3171

MTC-74

TROUBLE DIAGNOSIS

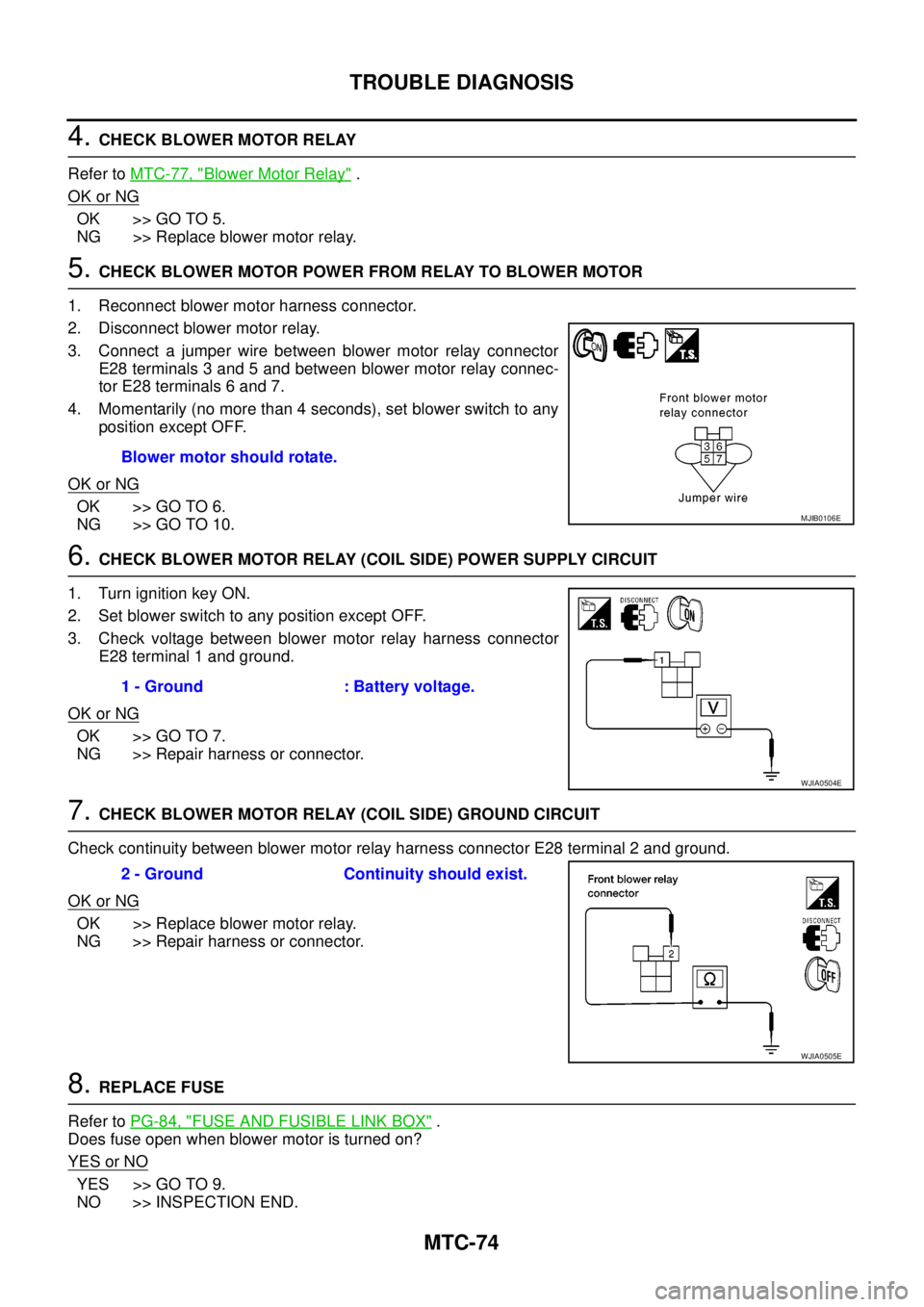

4.CHECK BLOWER MOTOR RELAY

Refer toMTC-77, "

Blower Motor Relay".

OK or NG

OK >> GO TO 5.

NG >> Replace blower motor relay.

5.CHECK BLOWER MOTOR POWER FROM RELAY TO BLOWER MOTOR

1. Reconnect blower motor harness connector.

2. Disconnect blower motor relay.

3. Connect a jumper wire between blower motor relay connector

E28 terminals 3 and 5 and between blower motor relay connec-

tor E28 terminals 6 and 7.

4. Momentarily (no more than 4 seconds), set blower switch to any

position except OFF.

OK or NG

OK >> GO TO 6.

NG >> GO TO 10.

6.CHECK BLOWER MOTOR RELAY (COIL SIDE) POWER SUPPLY CIRCUIT

1. Turn ignition key ON.

2. Set blower switch to any position except OFF.

3. Check voltage between blower motor relay harness connector

E28 terminal 1 and ground.

OK or NG

OK >> GO TO 7.

NG >> Repair harness or connector.

7.CHECK BLOWER MOTOR RELAY (COIL SIDE) GROUND CIRCUIT

Check continuity between blower motor relay harness connector E28 terminal 2 and ground.

OK or NG

OK >> Replace blower motor relay.

NG >> Repair harness or connector.

8.REPLACE FUSE

Refer toPG-84, "

FUSE AND FUSIBLE LINK BOX".

Does fuse open when blower motor is turned on?

YESorNO

YES >> GO TO 9.

NO >> INSPECTION END.Blower motor should rotate.

MJIB0106E

1 - Ground : Battery voltage.

WJIA0504E

2 - Ground Continuity should exist.

WJIA0505E

Page 2598 of 3171

HARNESS

PG-69

C

D

E

F

G

H

I

J

L

MA

B

PG

FTS EC Fuel Pump Temperature Sensor

GLOW EC Glow Control System

H/AIM LT Headlamp Aiming Control System

H/LAMP LT Headlamp

HEATUP EC Heat Up Switch

HLC WW Headlamp Washer

HORN WW Horn

HSEAT SE Heated Seat

I/KEY BL Intelligent Key System

I/MIRR GW Inside Mirror (Auto Anti-dazzling Mirror)

IATS EC Intake Air Temperature Sensor

ILL LT Illumination

INJ/PW EC Fuel Injector Power Supply

INJECT EC Fuel Injector

INT/L LT Room and Map Lamps

INT/V EC Intake Air Control Valve Control Solenoid Valve

MAFS EC Mass Air Flow Sensor

MAIN AT Main Power Supply and Ground Circuit

MAIN EC Main Power Supply and Ground Circuit

METER DI Speedometer, Tachometer, Temp. and Fuel Gauges

MIL/DL EC Malfunction Indicator Lamp, Data Link Connector

MIRROR GW Door Mirror

MMSW AT Manual Mode Switch

MULTI BL Multi-remote Control System

NATS BL NATS (Nissan Anti-Theft System)

NAVI AV Navigation System

NONDTC AT NON-detective Items

P/SCKT WW Power Socket

PHONE AV Telephone

PNP/SW AT Park/Neutral Position Switch

PNP/SW EC Park/Neutral Position Switch

POWER PG Power Supply Routing

R/FOG LT Rear Fog Lamp

RP/SEN EC Refrigerant Pressure Sensor

S/LOCK BL Power Door Lock — Super Lock

S/SIG EC Start Signal

SEAT SE Power Seat

SHIFT AT A/T Shift Lock System

SROOF RF Sunroof

SRS SRS Supplemental Restraint System

START SC Starting System

STOP/L LT Stop Lamp

STSIG AT Start Signal Circuit

T/F TF TransferCode Section Wiring Diagram Name

Page 2603 of 3171

PG-74

ELECTRICAL UNITS LOCATION

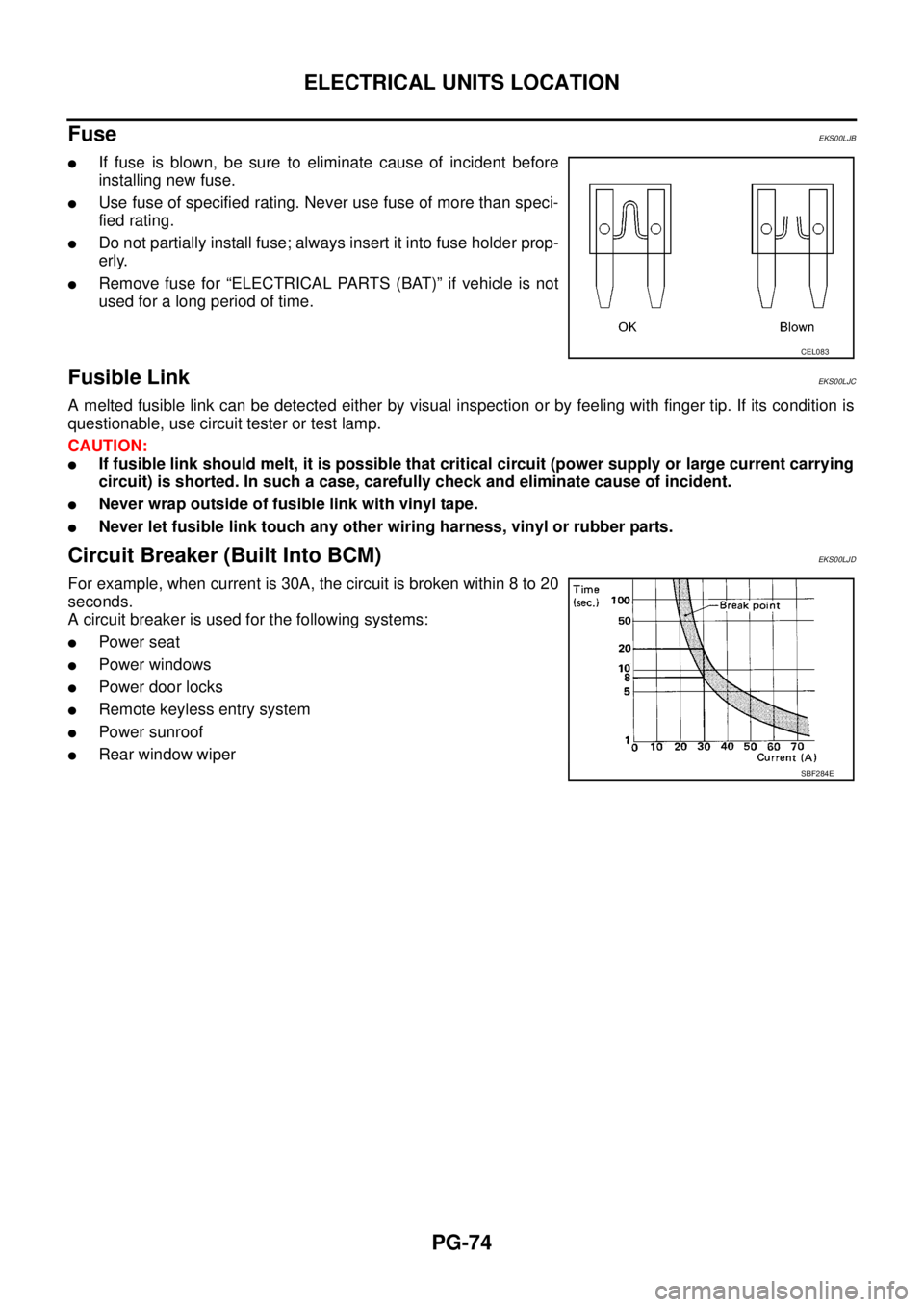

Fuse

EKS00LJB

lIf fuse is blown, be sure to eliminate cause of incident before

installing new fuse.

lUse fuse of specified rating. Never use fuse of more than speci-

fied rating.

lDo not partially install fuse; always insert it into fuse holder prop-

erly.

lRemove fuse for “ELECTRICAL PARTS (BAT)” if vehicle is not

used for a long period of time.

Fusible LinkEKS00LJC

A melted fusible link can be detected either by visual inspection or by feeling with finger tip. If its condition is

questionable, use circuit tester or test lamp.

CAUTION:

lIf fusible link should melt, it is possible that critical circuit (power supply or large current carrying

circuit) is shorted. In such a case, carefully check and eliminate cause of incident.

lNever wrap outside of fusible link with vinyl tape.

lNever let fusible link touch any other wiring harness, vinyl or rubber parts.

Circuit Breaker (Built Into BCM)EKS00LJD

For example, when current is 30A, the circuit is broken within 8 to 20

seconds.

A circuit breaker is used for the following systems:

lPower seat

lPower windows

lPowerdoorlocks

lRemote keyless entry system

lPower sunroof

lRear window wiper

CEL083

SBF284E

Page 2854 of 3171

CHARGING SYSTEM

SC-21

C

D

E

F

G

H

I

J

L

MA

B

SC

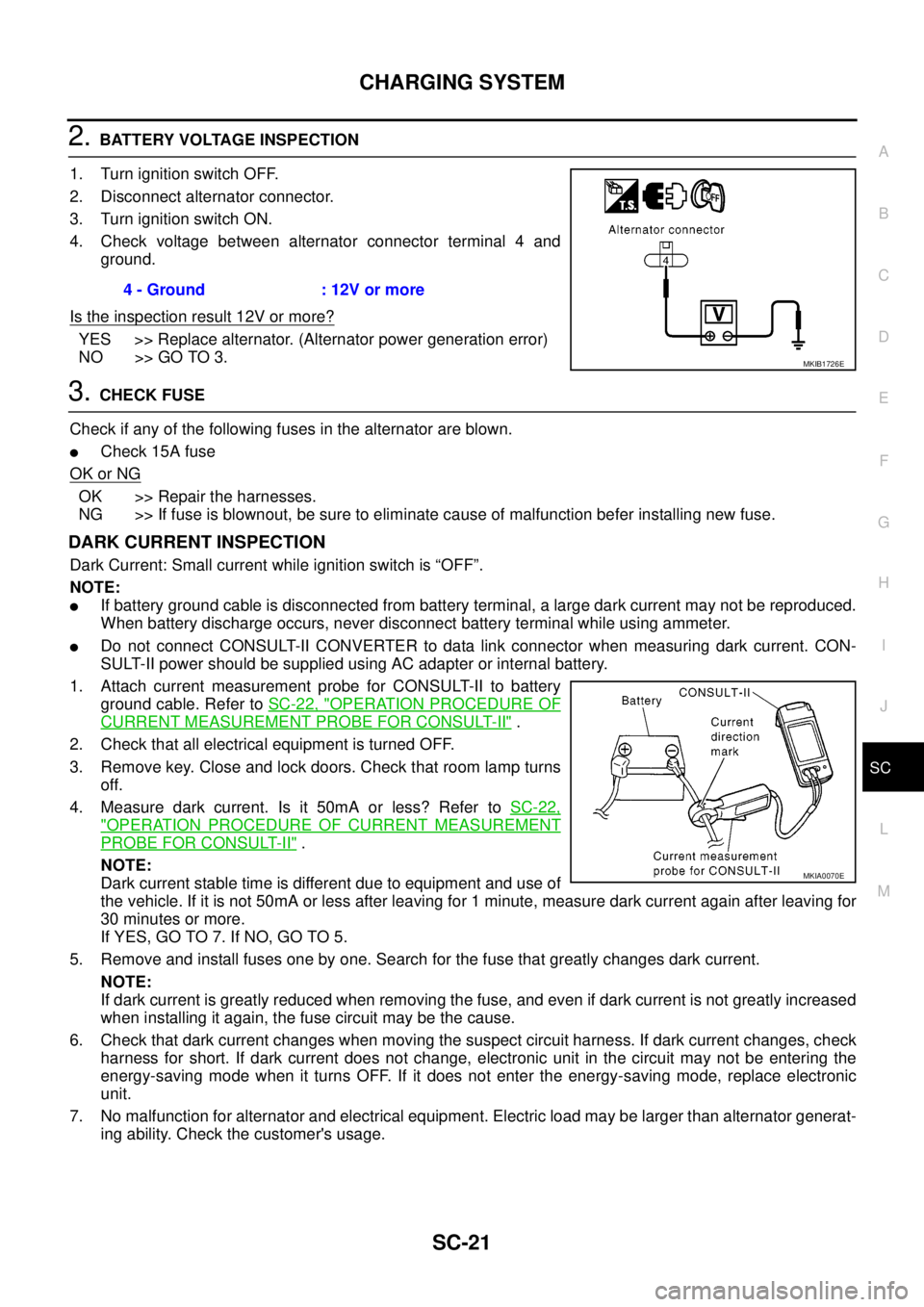

2.BATTERY VOLTAGE INSPECTION

1. Turn ignition switch OFF.

2. Disconnect alternator connector.

3. Turn ignition switch ON.

4. Check voltage between alternator connector terminal 4 and

ground.

Is the inspection result 12V or more?

YES >> Replace alternator. (Alternator power generation error)

NO >> GO TO 3.

3.CHECK FUSE

Check if any of the following fuses in the alternator are blown.

lCheck 15A fuse

OK or NG

OK >> Repair the harnesses.

NG >> If fuse is blownout, be sure to eliminate cause of malfunction befer installing new fuse.

DARK CURRENT INSPECTION

Dark Current: Small current while ignition switch is “OFF”.

NOTE:

lIf battery ground cable is disconnected from battery terminal, a large dark current may not be reproduced.

When battery discharge occurs, never disconnect battery terminal while using ammeter.

lDo not connect CONSULT-II CONVERTER to data link connector when measuring dark current. CON-

SULT-II power should be supplied using AC adapter or internal battery.

1. Attach current measurement probe for CONSULT-II to battery

ground cable. Refer toSC-22, "

OPERATION PROCEDURE OF

CURRENT MEASUREMENT PROBE FOR CONSULT-II".

2. Check that all electrical equipment is turned OFF.

3. Remove key. Close and lock doors. Check that room lamp turns

off.

4. Measure dark current. Is it 50mA or less? Refer toSC-22,

"OPERATION PROCEDURE OF CURRENT MEASUREMENT

PROBE FOR CONSULT-II".

NOTE:

Dark current stable time is different due to equipment and use of

the vehicle. If it is not 50mA or less after leaving for 1 minute, measure dark current again after leaving for

30 minutes or more.

If YES, GO TO 7. If NO, GO TO 5.

5. Remove and install fuses one by one. Search for the fuse that greatly changes dark current.

NOTE:

If dark current is greatly reduced when removing the fuse, and even if dark current is not greatly increased

when installing it again, the fuse circuit may be the cause.

6. Check that dark current changes when moving the suspect circuit harness. If dark current changes, check

harness for short. If dark current does not change, electronic unit in the circuit may not be entering the

energy-saving mode when it turns OFF. If it does not enter the energy-saving mode, replace electronic

unit.

7. No malfunction for alternator and electrical equipment. Electric load may be larger than alternator generat-

ing ability. Check the customer's usage.4 - Ground : 12V or more

MKIB1726E

MKIA0070E