key NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1675 of 3171

TOW TRUCK TOWING

GI-53

C

D

E

F

G

H

I

J

K

L

MB

GI

TOW TRUCK TOWINGPFP:00000

To w Tr u c k To w i n gEAS001DI

WARNING:

lNever get under the vehicle while it is supported only by the jack. Always use safety stands to

support the frame when you have to get under the vehicle.

lPlace wheel chocks at both front and back of the wheels on the ground.

CAUTION:

lAll applicable local laws regarding the towing operation must be obeyed.

lIt is necessary to use proper towing equipment to avoid possible damage during towing opera-

tion. Towing is in accordance with Towing Procedure Manual at dealer.

lAlways attach safety chains before towing.

lWhen towing, make sure that the transmission, steering system and powertrain are in good order.

If any unit is damaged, dollies must be used.

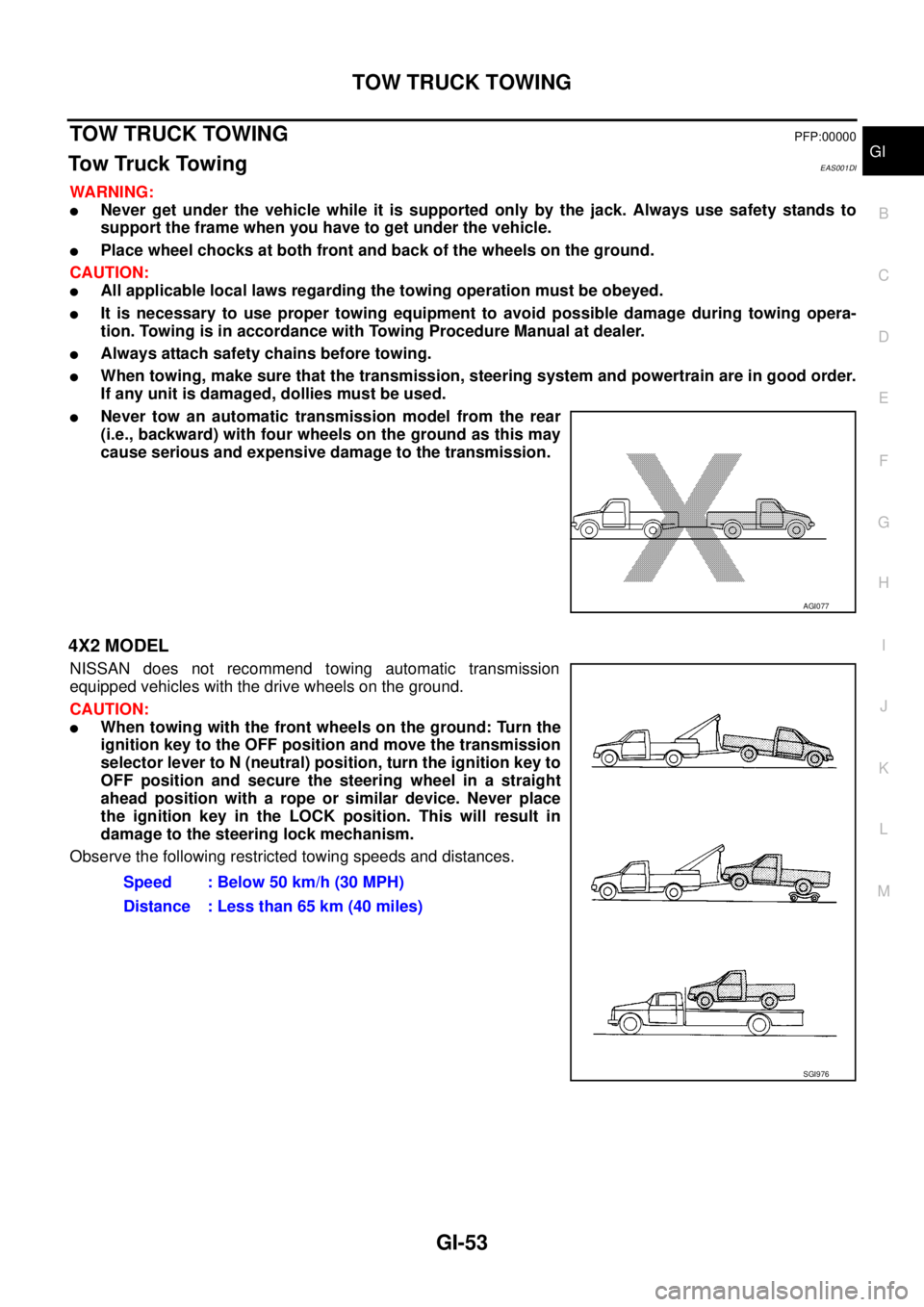

lNever tow an automatic transmission model from the rear

(i.e., backward) with four wheels on the ground as this may

cause serious and expensive damage to the transmission.

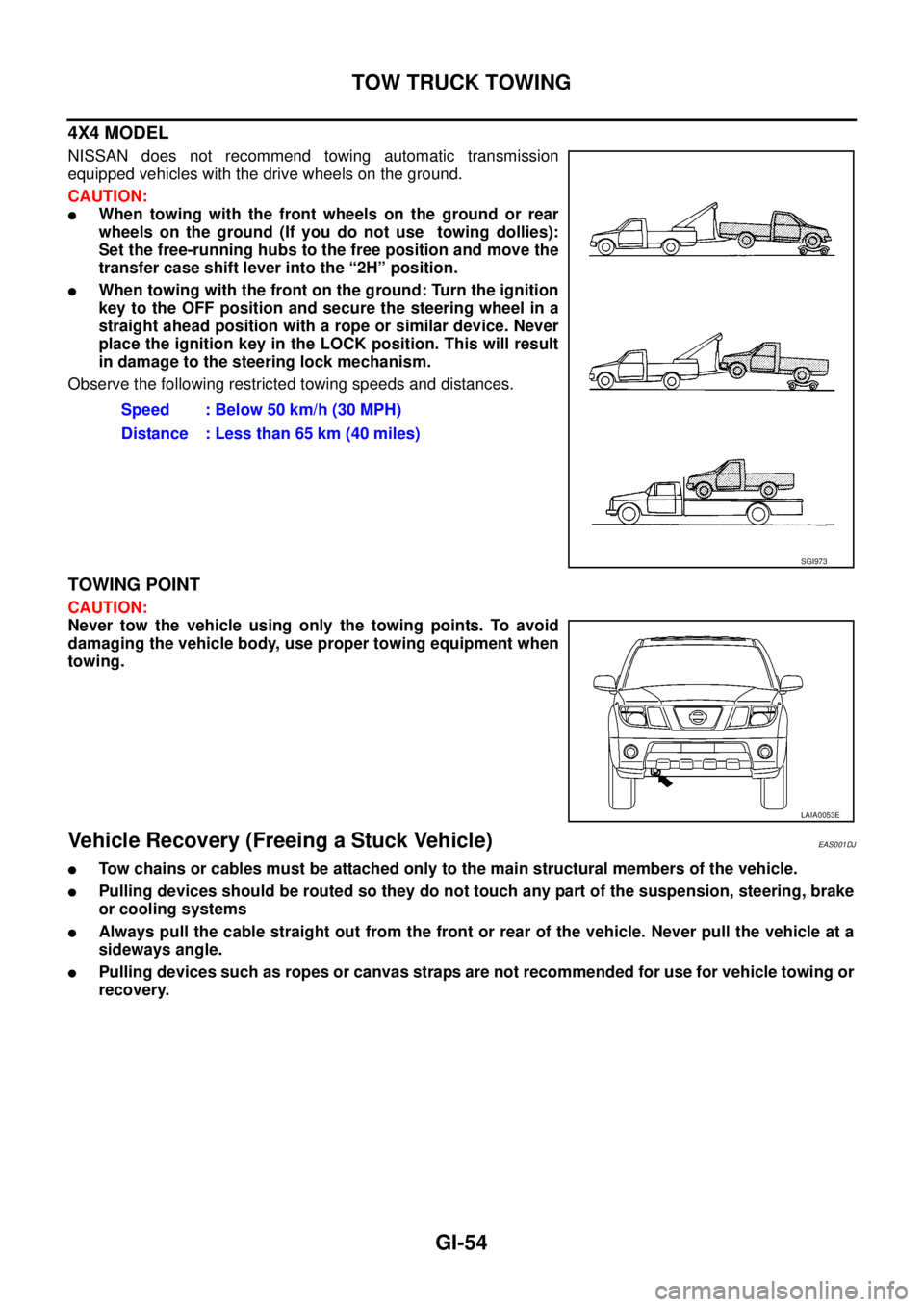

4X2 MODEL

NISSAN does not recommend towing automatic transmission

equipped vehicles with the drive wheels on the ground.

CAUTION:

lWhen towing with the front wheels on the ground: Turn the

ignition key to the OFF position and move the transmission

selector lever to N (neutral) position, turn the ignition key to

OFF position and secure the steering wheel in a straight

ahead position with a rope or similar device. Never place

the ignition key in the LOCK position. This will result in

damage to the steering lock mechanism.

Observe the following restricted towing speeds and distances.

AGI077

Speed : Below 50 km/h (30 MPH)

Distance : Less than 65 km (40 miles)

SGI976

Page 1676 of 3171

GI-54

TOW TRUCK TOWING

4X4 MODEL

NISSAN does not recommend towing automatic transmission

equipped vehicles with the drive wheels on the ground.

CAUTION:

lWhen towing with the front wheels on the ground or rear

wheels on the ground (If you do not use towing dollies):

Set the free-running hubs to the free position and move the

transfer case shift lever into the “2H” position.

lWhen towing with the front on the ground: Turn the ignition

key to the OFF position and secure the steering wheel in a

straight ahead position with a rope or similar device. Never

place the ignition key in the LOCK position. This will result

in damage to the steering lock mechanism.

Observe the following restricted towing speeds and distances.

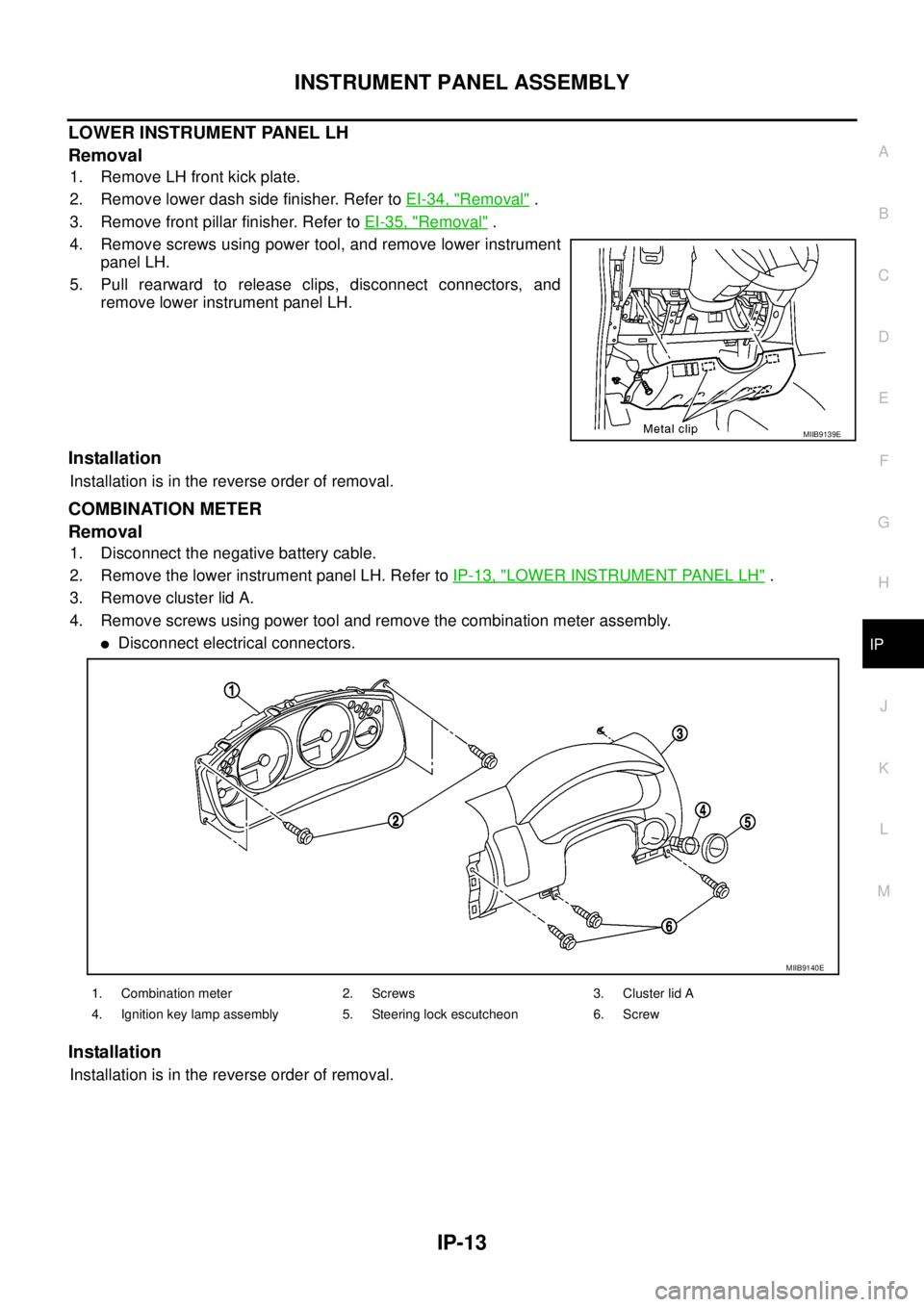

TOWING POINT

CAUTION:

Never tow the vehicle using only the towing points. To avoid

damaging the vehicle body, use proper towing equipment when

towing.

Vehicle Recovery (Freeing a Stuck Vehicle)EAS001DJ

lTow chains or cables must be attached only to the main structural members of the vehicle.

lPulling devices should be routed so they do not touch any part of the suspension, steering, brake

or cooling systems

lAlways pull the cable straight out from the front or rear of the vehicle. Never pull the vehicle at a

sideways angle.

lPulling devices such as ropes or canvas straps are not recommended for use for vehicle towing or

recovery.Speed : Below 50 km/h (30 MPH)

Distance : Less than 65 km (40 miles)

SGI973

LAIA0053E

Page 1757 of 3171

IDX-5

A

C

D

E

F

G

H

I

J

K

L B

IDX

ALPHABETICAL INDEX

HSEAT - Wiring diagram .......................SE-14,SE-17

I

IATS - Wiring diagram .....................................EC-100

Identification plate ...............................................GI-57

Idle speed ..........................................................EC-38

Ignition key hole illumination .............................LT-145

ILL - Wiring diagram .........................................LT-166

Illumination .......................................................LT-162

In vehicle sensor ...........................ATC-108,ATC-118

INJE/PW - Wiring diagram ...............................EC-284

INJECT - Wiring diagram .....EC-128,EC-240,EC-289

Injection nozzle .......EM-44,EC-123,EC-125,EC-237

Injector adjustment value ...................EC-271,EC-273

Injector adjustment value registration ................EC-25

Input clutch solenoid valve .................AT-132,AT-134

Instrument panel ..................................................IP-10

INT/V - Wiring diagram ....................................EC-315

Intake air control valve control solenoid valve .EC-314

Intake air temperature sensor ............................EC-98

Intake door control linkage adjustment ............ATC-79

Intake door motor ..........ATC-77,ATC-129,MTC-109

Intake manifold ..................................................EM-20

Intake sensor ..ATC-114,ATC-120,MTC-95,MTC-99

Interior .................................................................EI-33

Interior lamp ......................................................LT-145

Interior lamp on-off control ................................LT-145

IPDM (Intelligent power distribution module engine

room) .................................................................PG-14

ISO 15031-2 Terminology ..................................GI-61

J

Jacking points .....................................................GI-52

K

Key illumination ................................................LT-145

KEYLES - Wiring diagram ..................................BL-93

L

Leaf spring (rear) ..............................................RSU-7

Length (Dimensions) ..........................................GI-60

License lamp ....................................................LT-125

Lifting points .......................................................GI-52

Line pressure solenoid valve ...........................AT-114

Line pressure test (A/T) .....................................AT-44

Liquid gasket application ................EM-5,LU-2,CO-2

Location of electrical units .................................PG-71

Low coast brake solenoid valve ..........AT-152,AT-154

Lubricant (R134a) A/C ......................ATC-24,MTC-24

Lubricants ..........................................................MA-14

Lubrication circuit (engine) ..................................LU-4

Lubrication oil A/C ............................ATC-24,MTC-24

Lubrication-locks, hinges and hood latches .......MA-39

M

MAFS - Wiring diagram .....................................EC-94

Magnet clutch .ATC-87,ATC-143,MTC-79,MTC-123

MAIN - Wiring diagram ......................................EC-72

Main drive gear (M/T) ........................................MT-21

Mainshaft (M/T) ..................................................MT-21

Major overhaul (Final drive)FFD-17,RFD-15,RFD-82

Major overhaul (Transfer) ................................TF-112

Malfunction indicator (MI) ..................................EC-28

Map lamp ..........................................................LT-145

Mass air flow sensor (MAFS) .............................EC-92

Master cylinder (brake) ......................................BR-17

Master cylinder (clutch) ........................................CL-9

Meter .....................................................................DI-4

METER - Wiring diagram ....................................DI-10

MI & data link connectors circuit ......................EC-354

MIL/DL - Wiring diagram ..................................EC-354

Mode door control linkage adjustment ............ATC-65,

MTC-59

Mode door motor ............ATC-63,ATC-130,MTC-58,

MTC-110

Model variation ...................................................GI-56

Multiport fuel injection precautions .......................GI-6

N

NATS - Wiring diagram ....................................BL-173

NATS (Nissan anti-theft system) precautions .......GI-3

NVH troubleshooting (AX) .................................FAX-4

NVH troubleshooting (BR) ...................................BR-5

NVH troubleshooting (EM) ................................EM-10

NVH troubleshooting (Final drive) ........FFD-6,RFD-7,

RFD-39

NVH troubleshooting (M/T) ..................................MT-6

NVH troubleshooting (Propeller shaft) .................PR-2

NVH troubleshooting (ST) ....................................PS-5

NVH troubleshooting (Transfer) .........................TF-11

NVH troubleshooting (WT)NVH troubleshooting (WT) .

WT-2

O

Oil cooler (engine) .............................................LU-11

Oil filter .................................................................LU-8

Oil pan (engine) ................................................EM-36

Oil pressure (engine) ...........................................LU-5

Oil pump (A/T) .................................................AT-281

Oil pump (engine) ..............................................LU-14

Oil seal replacement (engine) ...........................EM-70

Oil seal replacement (front of final drive) ...........FFD-9

Oil seal replacement (side of final drive) ..........FFD-13

On board diagnostic system ..............................EC-27

Operating cylinder (clutch) .................................CL-11

Overheat ..........................................................EC-132

Oversize piston ...............................................EM-129

Page 1772 of 3171

INSTRUMENT PANEL ASSEMBLY

IP-13

C

D

E

F

G

H

J

K

L

MA

B

IP

LOWER INSTRUMENT PANEL LH

Removal

1. Remove LH front kick plate.

2. Remove lower dash side finisher. Refer toEI-34, "

Removal".

3. Remove front pillar finisher. Refer toEI-35, "

Removal".

4. Remove screws using power tool, and remove lower instrument

panel LH.

5. Pull rearward to release clips, disconnect connectors, and

remove lower instrument panel LH.

Installation

Installation is in the reverse order of removal.

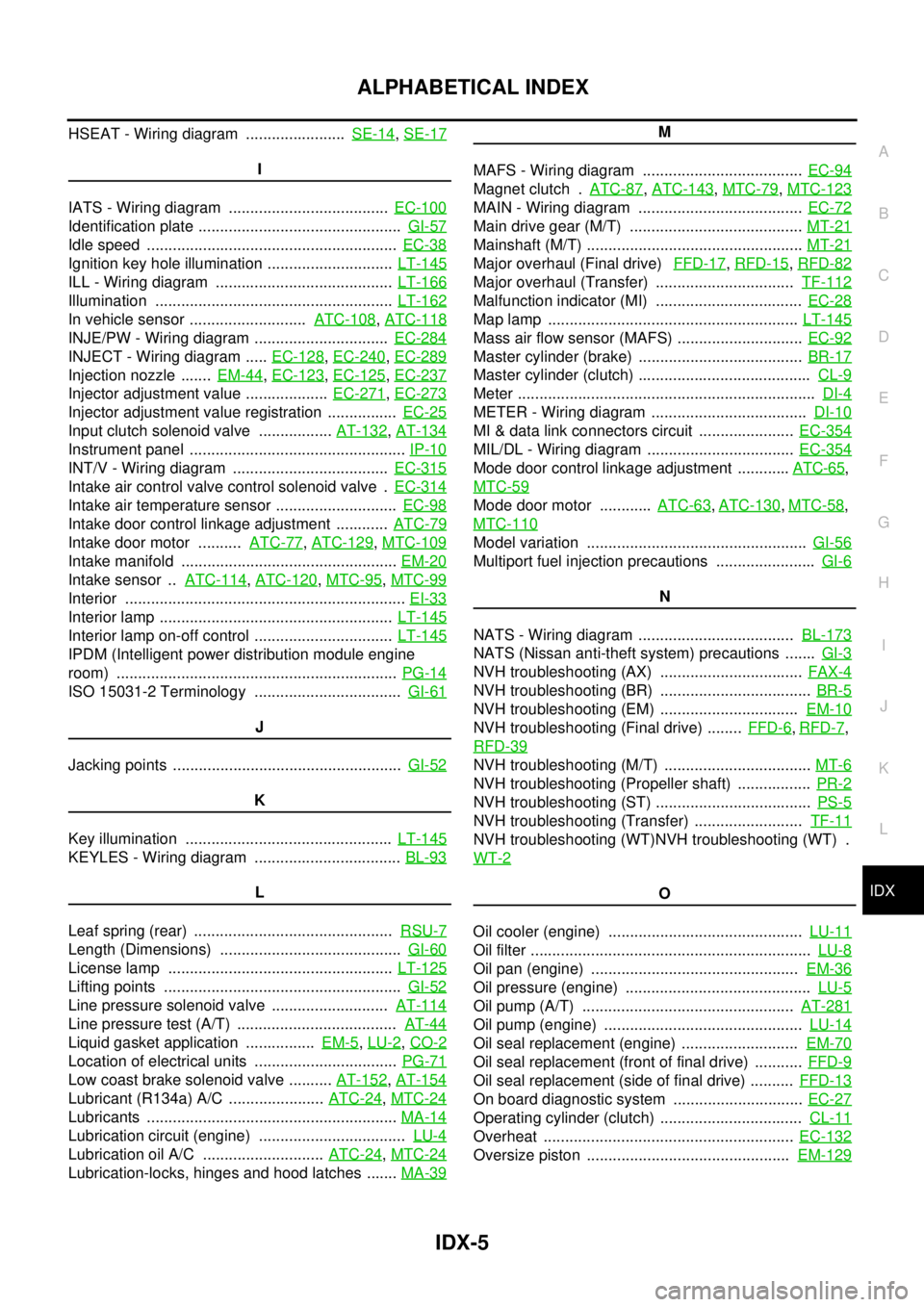

COMBINATION METER

Removal

1. Disconnect the negative battery cable.

2. Remove the lower instrument panel LH. Refer toIP-13, "

LOWER INSTRUMENT PANEL LH".

3. Remove cluster lid A.

4. Remove screws using power tool and remove the combination meter assembly.

lDisconnect electrical connectors.

Installation

Installation is in the reverse order of removal.

MIIB9139E

1. Combination meter 2. Screws 3. Cluster lid A

4. Ignition key lamp assembly 5. Steering lock escutcheon 6. Screw

MIIB9140E

Page 1788 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSES WORK FLOW

LAN-11

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

3. Confirm the unit name that “UNKWN” is displayed on the copy of “CAN DIAG SUPPORT MNTR” screen

of “A/T”, “HVAC”, � NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSES WORK FLOW

LAN-11

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

3. Confirm the unit name that “UNKWN” is displayed on the copy of “CAN DIAG SUPPORT MNTR” screen

of “A/T”, “HVAC”, �](/img/5/57362/w960_57362-1787.png)

TROUBLE DIAGNOSES WORK FLOW

LAN-11

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

3. Confirm the unit name that “UNKWN” is displayed on the copy of “CAN DIAG SUPPORT MNTR” screen

of “A/T”, “HVAC”, “BCM”, “ABS” and “IPDM E/R” as well as “ENGINE”. And then, put a check mark to the

check sheet table.

NOTE:

lFor “A/T”, “UNKWN” is displayed on “METER/M&A”, “ICC/e4WD” and “AWD/4WD”. But put a check

mark to “METER/M&A” because “UNKWN” is listed on the column of reception diagnosis of the check

sheet table.

lFor “HVAC”, “UNKWN” is not displayed. Do not put a check mark to it.

lFor “BCM”, “UNKWN” is displayed on “METER/M&A” and “I-KEY”. But put a check mark to “METER/

M&A” because “UNKWN” is listed on the column of reception diagnosis of the check sheet table.

lFor “ABS”, “UNKWN” is not displayed. Do not put a check mark to it.

lFor “IPDM E/R”, “UNKWN” is not displayed. Do not put a check mark to it.

PKIC2527E

Page 1796 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSES WORK FLOW

LAN-19

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

DESCRIPTION OF “CAN DIAG SUPPORT MNTR” SCREEN FOR FRONT AIR CONTROL

Display Results (Present)

lOK: Normal

lUNKWN: The diagnosed NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSES WORK FLOW

LAN-19

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

DESCRIPTION OF “CAN DIAG SUPPORT MNTR” SCREEN FOR FRONT AIR CONTROL

Display Results (Present)

lOK: Normal

lUNKWN: The diagnosed](/img/5/57362/w960_57362-1795.png)

TROUBLE DIAGNOSES WORK FLOW

LAN-19

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

DESCRIPTION OF “CAN DIAG SUPPORT MNTR” SCREEN FOR FRONT AIR CONTROL

Display Results (Present)

lOK: Normal

lUNKWN: The diagnosed unit does not transmit or receive the applicable data normally.

l–: There is no received unit or the unit is not in the condition that reception diagnosis is performed.

Display Results (Past)

lOK: Normal

l0: There is malfunction now.

l1 ~ 39: Displays when it is normal at present and finds malfunction in the past. It increases like 0®1®2...38®39 after returning to the

normal condition whenever IGN OFF®ON. If it is over 39, it is fixed to 39 until the self-diagnostic results are erased. It returns to 0

when malfunction is detected again in the process.

l–: Undiagnosed

PKIC2531E

“SELECT SYSTEM”

screen“CAN DIAG SUPPORT

MNTR” screenDescription Present Past

HVACTRANSMIT DIAG Make sure of normal transmission. OK/UNKWN/–

OK/0/1~39/– ECM Make sure of normal reception from ECM. OK/UNKWN/–

TCM TCM is not diagnosed. –

BCM/SEC Make sure of normal reception from BCM. OK/UNKWN/–

VDC/TCS/ABSMake sure of normal reception from ABS actua-

tor and electric unit (control unit).OK/UNKWN/–

IPDM E/R Make sure of normal reception from IPDM E/R. OK/UNKWN/–

DISPLAY DISPLAY is not diagnosed. –

I-KEY I-KEY is not diagnosed. –

EPS EPS is not diagnosed. –

AWD/4WD AWD/4WD is not diagnosed. –

e4WD e4WD is not diagnosed. –

ICC ICC is not diagnosed. –

LANE KEEP LANE KEEP is not diagnosed. –

TIRE-P TIRE-P is not diagnosed. –

Page 1797 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual LAN-20

[CAN]

TROUBLE DIAGNOSES WORK FLOW

DESCRIPTION OF “CAN DIAG SUPPORT MNTR” SCREEN

FOR BCM

Display Results (Present)

lOK: Normal

lNG: Malfunction

lUNKWN: The diagnosed unit does not transmit o NISSAN NAVARA 2005 Repair Workshop Manual LAN-20

[CAN]

TROUBLE DIAGNOSES WORK FLOW

DESCRIPTION OF “CAN DIAG SUPPORT MNTR” SCREEN

FOR BCM

Display Results (Present)

lOK: Normal

lNG: Malfunction

lUNKWN: The diagnosed unit does not transmit o](/img/5/57362/w960_57362-1796.png)

LAN-20

[CAN]

TROUBLE DIAGNOSES WORK FLOW

DESCRIPTION OF “CAN DIAG SUPPORT MNTR” SCREEN

FOR BCM

Display Results (Present)

lOK: Normal

lNG: Malfunction

lUNKWN: The diagnosed unit does not transmit or receive the applicable data normally.

PKIC2532E

“SELECT SYSTEM”

screen“CAN DIAG SUPPORT

MNTR” screenDescription Present

BCMINITIAL DIAG Make sure that microcomputer in ECU works normally. OK/NG

TRANSMIT DIAG Make sure of normal transmission. OK/UNKWN

ECM Make sure of normal reception from ECM. OK/UNKWN

IPDM E/R Make sure of normal reception from IPDM E/R. OK/UNKWN

METER/M&A Make sure of normal reception from combination meter. OK/UNKWN

I-KEY I-KEY is not diagnosed. UNKWN

Page 2085 of 3171

LT-2

AUTO LIGHT SYSTEM ............................................. 49

Component Parts and Harness Connector Location... 49

System Description ................................................. 49

OUTLINE ............................................................. 49

COMBINATION SWITCH READING FUNCTION... 50

CAN Communication System Description .............. 50

Major Components and Functions .......................... 50

Schematic ............................................................... 51

Wiring Diagram — AUTO/L — ................................ 52

Terminals and Reference Values for BCM .............. 56

Terminals and Reference Values for IPDM E/R ...... 57

How to Proceed With Trouble Diagnosis ................ 57

Preliminary Check .................................................. 58

SETTING CHANGE FUNCTIONS ....................... 58

CHECK POWER SUPPLY AND GROUND CIR-

CUIT .................................................................... 58

CONSULT-II Function (BCM) .................................. 59

CONSULT-II OPERATION ................................... 59

WORK SUPPORT ............................................... 60

DATA MONITOR .................................................. 60

ACTIVE TEST ..................................................... 61

Trouble Diagnosis Chart by Symptom .................... 62

Lighting Switch Inspection ...................................... 62

Light and Rain Sensor System Inspection .............. 63

Removal and Installation of Light and Rain Sensor... 65

REMOVAL ........................................................... 65

INSTALLATION .................................................... 65

HEADLAMP AIMING CONTROL (MANUAL) ........... 66

Schematic ............................................................... 66

Wiring Diagram — H/AIM — ................................... 67

Removal and Installation ........................................ 70

Switch Circuit Inspection ........................................ 70

FRONT FOG LAMP .................................................. 71

Component Parts and Harness Connector Location... 71

System Description ................................................. 71

OUTLINE ............................................................. 71

COMBINATION SWITCH READING FUNCTION... 72

CAN Communication System Description .............. 72

Schematic ............................................................... 73

Wiring Diagram — F/FOG — .................................. 74

Terminals and Reference Values for BCM .............. 77

Terminals and Reference Values for IPDM E/R ...... 77

How to Proceed With Trouble Diagnosis ................ 78

Preliminary Check .................................................. 78

CHECK POWER SUPPLY AND GROUND CIR-

CUIT .................................................................... 78

CONSULT-II Functions (BCM) ................................ 79

CONSULT-II Functions (IPDM E/R) ........................ 79

Front Fog Lamps Do Not Illuminate (Both Sides) ... 80

Front Fog Lamp Does Not Illuminate (One Side) ... 82

Front Fog Lamp Indicator Lamp Does Not Illuminate... 83

Front Fog Lamps Do Not Turn OFF ........................ 84

Aiming Adjustment .................................................. 85

Bulb Replacement .................................................. 86

Removal and Installation of Front Fog Lamp .......... 86

REMOVAL ........................................................... 86

INSTALLATION .................................................... 86

REAR FOG LAMP ..................................................... 87

Component Parts and Harness Connector Location... 87System Description ................................................. 87

OUTLINE ............................................................. 87

COMBINATION SWITCH READING FUNCTION... 88

CAN Communication System Description .............. 88

CAN Communication Unit ....................................... 88

Wiring Diagram — R/FOG — .................................. 89

Terminals and Reference Values for BCM .............. 91

How to Proceed With Trouble Diagnosis ................ 91

Preliminary Check ................................................... 92

CHECK POWER SUPPLY AND GROUND CIR-

CUIT ..................................................................... 92

CONSULT-II Functions (BCM) ................................ 93

Rear Fog Lamp Does Not Operate ......................... 93

Rear Fog Lamp Indicator Lamp Does Not Illuminate... 95

Rear Fog Lamp Does Not Turn OFF ....................... 96

Bulb Replacement ................................................... 96

Removal and Installation ......................................... 96

TURN SIGNAL AND HAZARD WARNING LAMPS... 97

Component Parts and Harness Connector Location... 97

System Description ................................................. 97

OUTLINE ............................................................. 97

TURN SIGNAL OPERATION ............................... 97

HAZARD LAMP OPERATION ............................. 98

REMOTE KEYLESS ENTRY SYSTEM OPERA-

TION .................................................................... 99

COMBINATION SWITCH READING FUNCTION... 99

CAN Communication System Description .............. 99

Wiring Diagram — TURN — .................................100

Terminals and Reference Values for BCM ............102

How to Proceed With Trouble Diagnosis ..............103

Preliminary Check .................................................103

CHECK POWER SUPPLY AND GROUND CIR-

CUIT ...................................................................103

CONSULT-II Function (BCM) ................................105

CONSULT-II OPERATION .................................105

DATA MONITOR ................................................106

ACTIVE TEST ....................................................106

Turn Signal Lamp Does Not Operate ....................107

Hazard Warning Lamp Does Not Operate But Turn

Signal Lamps Operate ..........................................109

Turn Signal Indicator Lamp Does Not Operate .....110

Bulb Replacement (Front Turn Signal Lamp) ........ 111

Bulb Replacement (Rear Turn Signal Lamp) ........ 111

Bulb Replacement (Side Turn Signal Lamp) ......... 111

Removal and Installation of Front Turn Signal Lamp. 111

Removal and Installation of Rear Turn Signal Lamp. 111

Removal and Installation of Side Turn Signal Lamp. 111

REMOVAL .......................................................... 111

INSTALLATION .................................................. 111

LIGHTING AND TURN SIGNAL SWITCH ..............112

Removal and Installation .......................................112

REMOVAL ..........................................................112

INSTALLATION ..................................................112

HAZARD SWITCH ...................................................113

Removal and Installation .......................................113

REMOVAL ..........................................................113

INSTALLATION ..................................................113

COMBINATION SWITCH ........................................114

Wiring Diagram — COMBSW — ..........................114

Page 2182 of 3171

TURN SIGNAL AND HAZARD WARNING LAMPS

LT-99

C

D

E

F

G

H

I

J

L

MA

B

LT

lto front combination lamp RH terminal 1

lto side turn signal lamp RH terminal 1 and

lto rear combination lamp RH terminal 2.

Ground is supplied

lto front combination lamp RH and LH terminals 2

lto side turn signal lamp RH and LH terminals 2 and

lto rear combination lamp RH and LH terminals 3

lthrough ground E21, E41 and E61.

The BCM also supplies input to combination meter terminals 11 and 12 through the CAN communication. This

input is processed by unified meter control unit in combination meter, which in turn supplies ground to the left

and right turn signal indicator lamps.

With power and input supplied, BCM controls flashing of hazard warning lamps.

REMOTE KEYLESS ENTRY SYSTEM OPERATION

Refer toBL-89, "MULTI-REMOTE CONTROL SYSTEM".

COMBINATION SWITCH READING FUNCTION

Refer toBCS-3, "COMBINATION SWITCH READING FUNCTION".

CAN Communication System DescriptionEKS00P87

Refer toLAN-23, "CAN COMMUNICATION".

Page 2228 of 3171

INTERIOR ROOM LAMP

LT-145

C

D

E

F

G

H

I

J

L

MA

B

LT

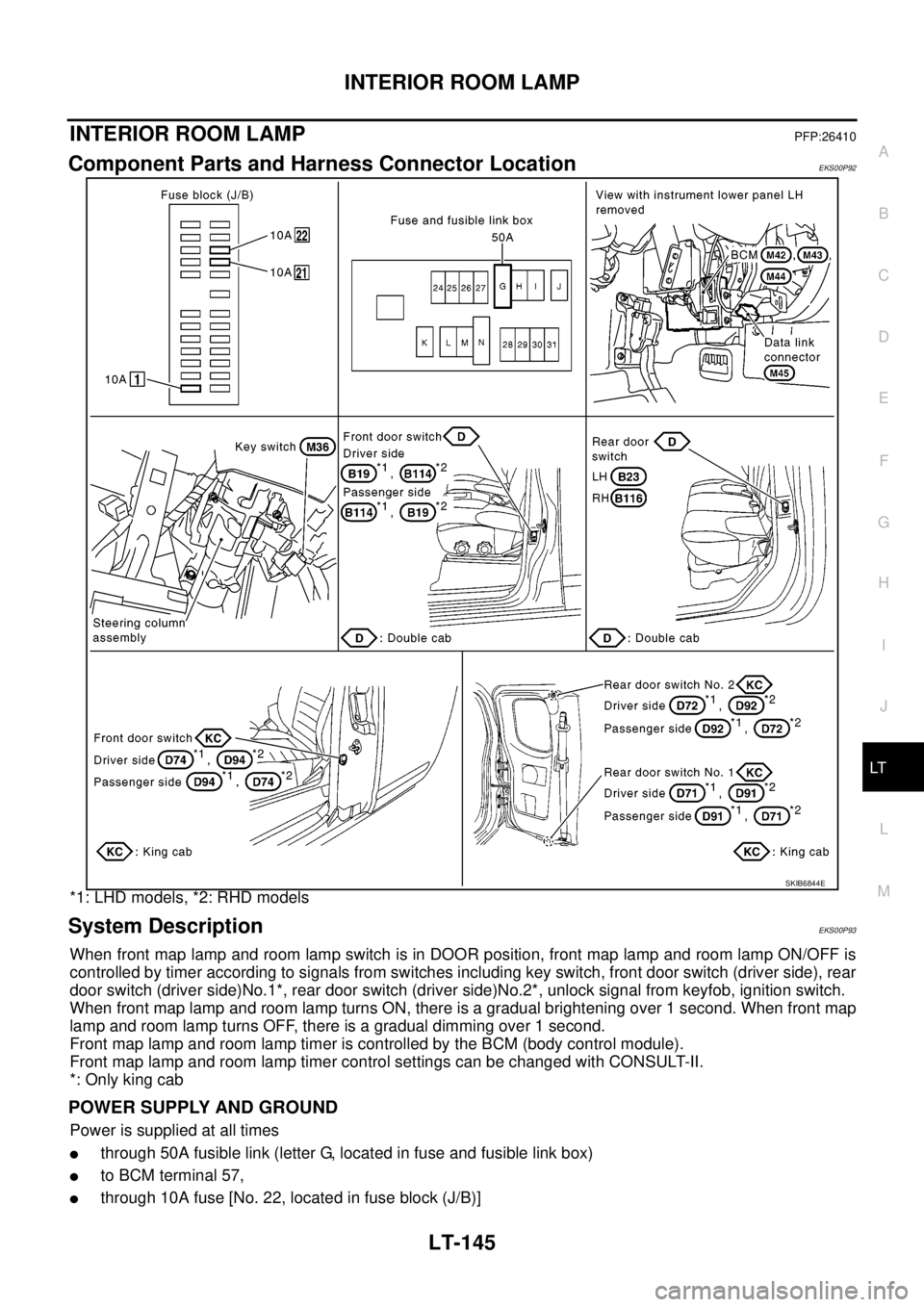

INTERIOR ROOM LAMPPFP:26410

Component Parts and Harness Connector LocationEKS00P92

*1: LHD models, *2: RHD models

System DescriptionEKS00P93

When front map lamp and room lamp switch is in DOOR position, front map lamp and room lamp ON/OFF is

controlled by timer according to signals from switches including key switch, front door switch (driver side), rear

door switch (driver side)No.1*, rear door switch (driver side)No.2*, unlock signal from keyfob, ignition switch.

When front map lamp and room lamp turns ON, there is a gradual brightening over 1 second. When front map

lamp and room lamp turns OFF, there is a gradual dimming over 1 second.

Front map lamp and room lamp timer is controlled by the BCM (body control module).

Front map lamp and room lamp timer control settings can be changed with CONSULT-II.

*: Only king cab

POWER SUPPLY AND GROUND

Power is supplied at all times

lthrough 50A fusible link (letter G, located in fuse and fusible link box)

lto BCM terminal 57,

lthrough 10A fuse [No. 22, located in fuse block (J/B)]

SKIB6844E