relay NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2615 of 3171

PG-86

FUSE AND RELAY BOX

Page 2705 of 3171

RFD-2

DIFFERENTIAL LOCK CONTROL UNIT ............ 42

DIFFERENTIAL LOCK MODE SWITCH ............. 42

DIFF LOCK INDICATOR LAMP ........................... 42

System Diagram ..................................................... 43

COMPONENTS FUNCTION DESCRIPTION ...... 43

CAN Communication .............................................. 43

SYSTEM DESCRIPTION .................................... 43

TROUBLE DIAGNOSIS ............................................ 44

Fail-safe Function ................................................... 44

How to Perform Trouble Diagnosis ......................... 44

BASIC CONCEPT ............................................... 44

Location of Electrical Parts ..................................... 45

Wiring Diagram — DIFLOC — ................................ 46

Trouble Diagnosis Chart for Symptoms .................. 48

Differential Lock Control Unit Input/Output Signal

Reference Values ................................................... 48

DIFFERENTIAL LOCK CONTROL UNIT

INSPECTION TABLE .......................................... 48

CONSULT-II Function (DIFF LOCK) ....................... 50

FUNCTION .......................................................... 50

CONSULT-II SETTING PROCEDURE ................ 50

SELF-DIAG RESULTS MODE ............................. 51

DATA MONITOR MODE ...................................... 53

TROUBLE DIAGNOSIS FOR SYSTEM .................... 54

Power Supply Circuit For Differential Lock Control

Unit ......................................................................... 54

CONSULT-II REFERENCE VALUE IN DATA

MONITOR MODE ................................................ 54

DIFFERENTIAL LOCK CONTROL UNIT TER-

MINALS AND REFERENCE VALUE ................... 54

DIAGNOSTIC PROCEDURE .............................. 55

Differential Lock Control Unit .................................. 56

DIAGNOSTIC PROCEDURE .............................. 56

Differential Lock Mode Switch ................................ 56

CONSULT-II REFERENCE VALUE IN DATA

MONITOR MODE ................................................ 56

DIFFERENTIAL LOCK CONTROL UNIT TER-

MINALS AND REFERENCE VALUE ................... 56

DIAGNOSTIC PROCEDURE .............................. 57

COMPONENT INSPECTION .............................. 59

Differential Lock Position Switch ............................. 60

CONSULT-II REFERENCE VALUE IN DATA

MONITOR MODE ................................................ 60

DIFFERENTIAL CONTROL UNIT TERMINALS

AND REFERENCE VALUE ................................. 60

DIAGNOSTIC PROCEDURE .............................. 61

COMPONENT INSPECTION .............................. 63

Differential Lock Solenoid Relay ............................. 63

CONSULT-II REFERENCE VALUE IN DATA

MONITOR MODE ................................................ 63DIAGNOSTIC PROCEDURE ............................... 63

Differential Lock Solenoid ....................................... 64

CONSULT-II REFERENCE VALUE IN DATA

MONITOR MODE ................................................ 64

DIFFERENTIAL LOCK CONTROL UNIT TER-

MINALS AND REFERENCE VALUE ................... 64

DIAGNOSTIC PROCEDURE ............................... 65

COMPONENT INSPECTION ............................... 68

ABS System ............................................................ 68

DIAGNOSTIC PROCEDURE ............................... 68

CAN Communication Line ....................................... 69

DIAGNOSTIC PROCEDURE ............................... 69

TROUBLE DIAGNOSIS FOR SYMPTOMS .............. 70

DIFF LOCK Indicator Lamp Does Not Turn ON ...... 70

DIAGNOSTIC PROCEDURE ............................... 70

DIFF LOCK Indicator Lamp Does Not Change ....... 73

DIAGNOSTIC PROCEDURE ............................... 73

DIFF LOCK Indicator Lamp Sometimes Flashes .... 74

DIAGNOSTIC PROCEDURE ............................... 74

DIFFERENTIAL LOCK CONTROL UNIT .................. 76

Removal and Installation ......................................... 76

REMOVAL ............................................................ 76

INSTALLATION .................................................... 76

FRONT OIL SEAL ..................................................... 77

Removal and Installation ......................................... 77

REMOVAL ............................................................ 77

INSTALLATION .................................................... 78

CARRIER COVER ..................................................... 80

Removal and Installation ......................................... 80

REMOVAL ............................................................ 80

INSTALLATION .................................................... 80

REAR FINAL DRIVE ASSEMBLY ............................. 81

Removal and Installation ......................................... 81

REMOVAL ............................................................ 81

INSTALLATION .................................................... 81

Disassembly and Assembly .................................... 82

COMPONENTS ................................................... 82

ASSEMBLY INSPECTION AND ADJUSTMENT...83

DISASSEMBLY .................................................... 86

INSPECTION AFTER DISASSEMBLY ................ 90

SELECTION ADJUSTING WASHERS ................ 90

ASSEMBLY .......................................................... 91

SERVICE DATA AND SPECIFICATIONS (SDS) ....100

General Specifications ..........................................100

Inspection and Adjustment ....................................100

PRELOAD TORQUE .........................................100

BACKLASH ........................................................100

COMPANION FLANGE RUNOUT .....................100

SELECTIVE PARTS ..........................................101

Page 2752 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSIS

RFD-49

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

Specifications Between Differential Lock Control Unit Terminals

DIFFERENTIAL LOCK CONTROL UNIT TERMINAL CONNE NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSIS

RFD-49

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

Specifications Between Differential Lock Control Unit Terminals

DIFFERENTIAL LOCK CONTROL UNIT TERMINAL CONNE](/img/5/57362/w960_57362-2751.png)

TROUBLE DIAGNOSIS

RFD-49

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

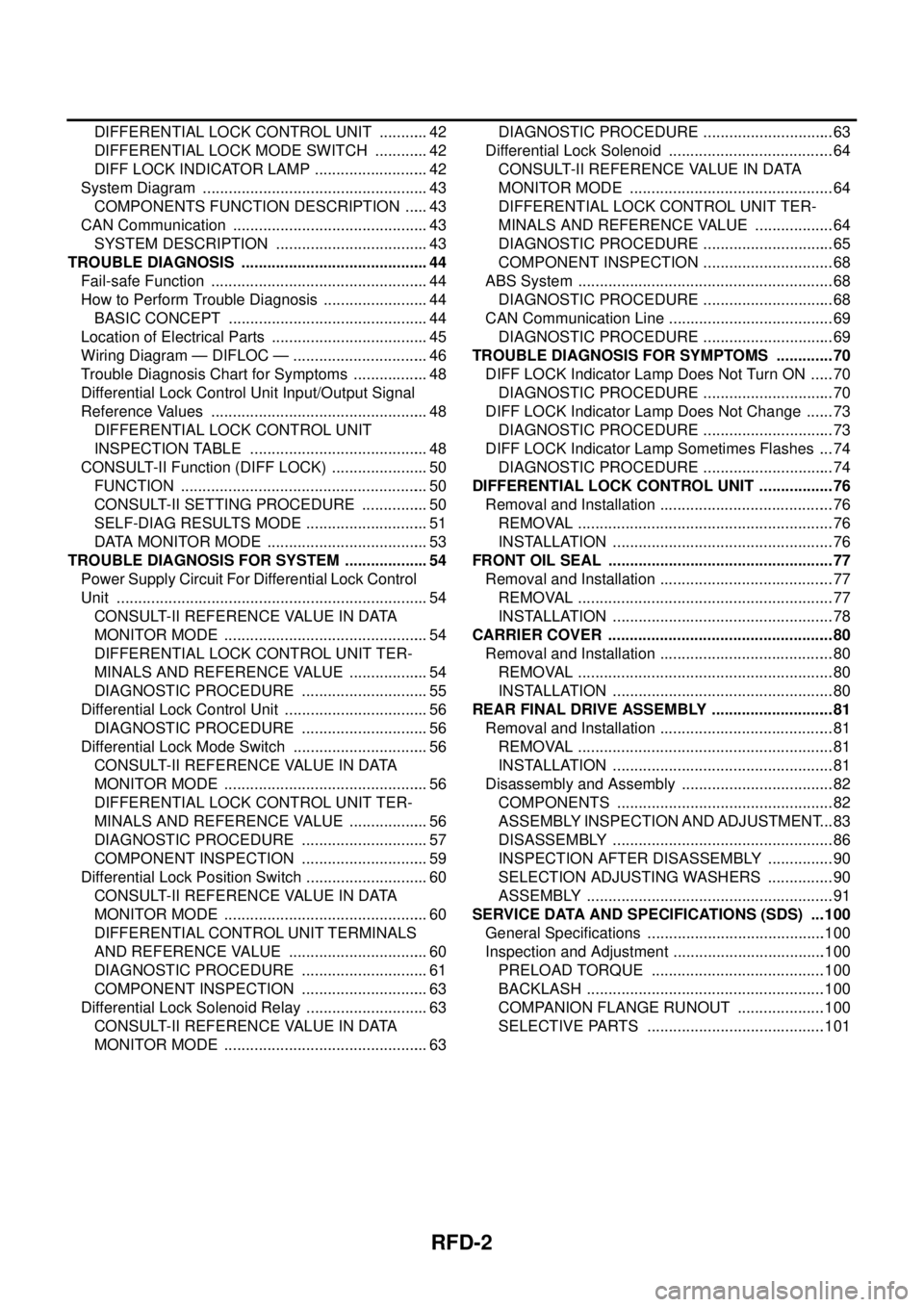

Specifications Between Differential Lock Control Unit Terminals

DIFFERENTIAL LOCK CONTROL UNIT TERMINAL CONNECTOR LAYOUT

Data are reference value and are measured between each terminal and ground.RELAY ON [ON/OFF]Operating condition of dif-

ferential lock solenoid

relay (integrated in differ-

ential lock control unit)

lVehicle stopped

lEngine running

l4WD shift switch: 4LODifferential lock mode

switch: ONON

Differential lock mode

switch: OFFOFF

RELAY MTR [ON/OFF]Control status of differen-

tial lock solenoid relay

(integrated in differential

lock control unit)

lVehicle stopped

lEngine running

l4WD shift switch: 4LODifferential lock mode

switch: ONON

Differential lock mode

switch: OFFOFF

SOL MTR [ON/OFF]Control status of differen-

tial lock solenoid

lVehicle stopped

lEngine running

l4WD shift switch: 4LODifferential lock mode

switch: ONON

Differential lock mode

switch: OFFOFF

IND MTR [ON/OFF]Control status of DIFF

LOCK indicator lampDIFF LOCK indicator lamp: ON ON

DIFF LOCK indicator lamp: OFF OFF

D-LOCK POS SW [ON/

OFF]Condition of differential

lock position switch

lVehicle stopped

lEngine running

l4WD shift switch: 4LODifferential lock mode

switch: ON

(DIFF LOCK indicator

lamp: ON)ON

Differential lock mode

switch: OFF

(DIFF LOCK indicator

lamp: OFF)OFF Monitor item [Unit] Content Condition Display value

SDIA2573E

TerminalWire

colorItem Condition Data (Approx.)

1 O Power supplyIgnition switch: ON Battery voltage

Ignition switch: OFF 0V

2 O Power supplyIgnition switch: ON Battery voltage

Ignition switch: OFF 0V

3 B Ground Always 0V

4 P CAN-L – –

5 L CAN-H – –

9YDifferential lock mode switch

(ON)Ignition switch: ONDifferential lock mode switch: ON Battery voltage

Differential lock mode switch: OFF 0V

10 B Ground Always 0V

Page 2755 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual RFD-52

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

TROUBLE DIAGNOSIS

CAUTION:

If “CAN COMM CIRCUIT [U1000]” is displayed with other DTCs, first perform the trouble diagnosis for CAN communication

line. NISSAN NAVARA 2005 Repair Workshop Manual RFD-52

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

TROUBLE DIAGNOSIS

CAUTION:

If “CAN COMM CIRCUIT [U1000]” is displayed with other DTCs, first perform the trouble diagnosis for CAN communication

line.](/img/5/57362/w960_57362-2754.png)

RFD-52

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

TROUBLE DIAGNOSIS

CAUTION:

If “CAN COMM CIRCUIT [U1000]” is displayed with other DTCs, first perform the trouble diagnosis for CAN communication

line.

How to Erase Self-diagnostic Results

1. Perform applicable inspection of malfunctioning item and then repair or replace.

2. Start engine and select “SELF-DIAG RESULTS” mode for “DIFF LOCK” with CONSULT-II.

3. Touch “ERASE” on CONSULT-II screen to erase DTC memory.

CAUTION:

If memory cannot be erased, perform diagnosis.

POSI SW ON

[P1839]When differential lock position switch is ON, rotation difference

occurs in wheel speed (rear wheel right and left).RFD-60, "Differential Lock Posi-

tion Switch"

RELAY

[P1844]Differential lock control unit detects as irregular by comparing target

value with monitor value.RFD-63, "Differential Lock Sole-

noid Relay",RFD-64, "Differen-

tial Lock Solenoid"

SOL CIRCUIT

[P1847]Malfunction is detected in differential lock control unit internal circuit.RFD-64, "Differential Lock Sole-

noid"

SOL DISCONNECT

[P1848]lDifferential lock solenoid internal circuit or harness is open.

lDifferential lock solenoid relay does not switch to ON position.RFD-64, "

Differential Lock Sole-

noid"

SOL SHORT

[P1849]Differential lock solenoid internal circuit or harness is shorted.RFD-64, "Differential Lock Sole-

noid"

SOL CURRENT

[P1850]Differential lock solenoid relay does not switch to OFF position.RFD-64, "Differential Lock Sole-

noid"

ABS SYSTEM

[C1203]Malfunction related to wheel sensor has been detected by ABS

actuator and electric unit (control unit).RFD-68, "ABS System"

CAN COMM CIRCUIT

[U1000]Malfunction has been detected from CAN communication line.RFD-69, "CAN Communication

Line"

NO DTC IS DETECTED.

FURTHER TESTING MAY

BE REQUIRED.No NG item has been detected. — Items (CONSULT-II screen

terms)Diagnostic item is detected when... Check item

Page 2756 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSIS

RFD-53

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

DATA MONITOR MODE

Operation Procedure

1. Perform “CONSULT-II SETTING PROCEDURE”. Refer toRFD-50, "CONSULT NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSIS

RFD-53

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

DATA MONITOR MODE

Operation Procedure

1. Perform “CONSULT-II SETTING PROCEDURE”. Refer toRFD-50, "CONSULT](/img/5/57362/w960_57362-2755.png)

TROUBLE DIAGNOSIS

RFD-53

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

DATA MONITOR MODE

Operation Procedure

1. Perform “CONSULT-II SETTING PROCEDURE”. Refer toRFD-50, "CONSULT-II SETTING PROCE-

DURE".

2. Touch “DATA MONITOR”.

3. Select from “SELECT MONITOR ITEM”, screen of data monitor mode is displayed.

NOTE:

When malfunction is detected, CONSULT-II performs REAL-TIME DIAGNOSIS.

Also, any malfunction detected while in this mode will be displayed at real time.

Display Item List

´: Standard –: Not applicable

Monitor item (Unit)SELECT MONITOR ITEM

Remarks

ECU INPUT

SIGNALSMAIN

SIGNALSSELECTION

FROM MENU

BATTERY VOLT [V]´´´Power supply voltage for differential lock

control unit.

4WD MODE [2H/4H/4Lo]´´´4WD shift switch signal status via CAN

communication line is displayed.

VHCL S/SEN-R [km/h] or [mph]´–´Wheel speed calculated by rear wheel

sensor right signal is displayed.

VHCL S/SEN-L [km/h] or [mph]´–´Wheel speed calculated by rear wheel

sensor left signal is displayed.

VHCL S/SEN-RL [km/h] or [mph]´´´Average value between wheel speed cal-

culated by rear wheel sensor right signal

and rear wheel sensor left signal is dis-

played.

D-LOCK SW SIG [ON/OFF]´´´Condition of differential lock mode switch

is displayed.

D-LOCK SIG [ON/OFF]´´´Control status of differential lock is dis-

played.

RELAY ON [ON/OFF]´´´Operating condition of differential lock

solenoid relay is displayed (integrated in

differential lock control unit).

RELAY MTR [ON/OFF]´´´Control status of differential lock solenoid

relay is displayed (integrated in differential

lock control unit).

SOL MTR [ON/OFF]´´´Control status of differential lock solenoid

is displayed.

IND MTR [ON/OFF]´´´Control status of DIFF LOCK indicator

lamp is displayed.

D-LOCK POS SW [ON/OFF]´´´Condition of differential lock position switch

is displayed.

Voltage [V] – –´The value measured by the voltage probe

is displayed.

Frequency [Hz] – –´

The value measured by the pulse probe is

displayed. DUTY-HI (high) [%] – –´

DUTY-LOW (low) [%] – –´

PLS WIDTH-HI [msec] – –´

PLS WIDTH-LOW [msec] – –´

Page 2766 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSIS FOR SYSTEM

RFD-63

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

COMPONENT INSPECTION

1. Turn ignition switch “OFF”.

2. Disconnect differential lock position s NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSIS FOR SYSTEM

RFD-63

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

COMPONENT INSPECTION

1. Turn ignition switch “OFF”.

2. Disconnect differential lock position s](/img/5/57362/w960_57362-2765.png)

TROUBLE DIAGNOSIS FOR SYSTEM

RFD-63

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

COMPONENT INSPECTION

1. Turn ignition switch “OFF”.

2. Disconnect differential lock position switch harness connector.

3. Remove differential lock position switch. Refer toRFD-45, "

Location of Electrical Parts".

4. Pull differential lock position switch and check continuity

between differential lock position switch harness connector ter-

minals.

5. If NG, replace differential lock position switch.

Differential Lock Solenoid RelayEDS003B5

CONSULT-II REFERENCE VALUE IN DATA MONITOR MODE

Data are reference value.

DIAGNOSTIC PROCEDURE

1.CHECK DIFFERENTIAL LOCK SOLENOID SYSTEM

Perform self-diagnosis. Refer toRFD-51, "

SELF-DIAG RESULTS MODE".

Is

“RELAY [P1844]”displayed?

YES >> Perform trouble diagnosis for differential lock solenoid. Refer toRFD-64, "Differential Lock Sole-

noid".

NO >> GO TO 2.

2.CHECK DIFFERENTIAL LOCK SOLENOID RELAY SIGNAL

With CONSULT-II

1. Start engine.

2. Select “DATA MONITOR” mode for “DIFF LOCK” with CONSULT-II.

3. Read out ON/OFF switching action of “RELAY ON”.

OK or NG

OK >> GO TO 4.

NG >> GO TO 3.

Terminal Condition Continuity

1-2Pull differential position switch Yes

Release Differential position switch No

SDIA3429E

Monitor item [Unit] Content Condition Display value

RELAY ON [ON/OFF]Operating condition of dif-

ferential lock solenoid

relay (integrated in differ-

ential lock control unit)

lVehicle stopped

lEngine running

l4WD shift switch: 4LODifferential lock mode

switch: ONON

Differential lock mode

switch: OFFOFF

Monitor item ConditionDisplay

value

RELAY ON

lVehicle stopped

lEngine running

l4WD shift

switch: 4LODifferential lock mode

switch: ONON

Differential lock mode

switch: OFFOFF

SDIA2642E

Page 2767 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual RFD-64

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

TROUBLE DIAGNOSIS FOR SYSTEM

3.CHECK DIFFERENTIAL LOCK CONTROL UNIT

Check differential lock control unit input/output signal. Refer toRFD-48, "

Differenti NISSAN NAVARA 2005 Repair Workshop Manual RFD-64

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

TROUBLE DIAGNOSIS FOR SYSTEM

3.CHECK DIFFERENTIAL LOCK CONTROL UNIT

Check differential lock control unit input/output signal. Refer toRFD-48, "

Differenti](/img/5/57362/w960_57362-2766.png)

RFD-64

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

TROUBLE DIAGNOSIS FOR SYSTEM

3.CHECK DIFFERENTIAL LOCK CONTROL UNIT

Check differential lock control unit input/output signal. Refer toRFD-48, "

Differential Lock Control Unit Input/

Output Signal Reference Values".

OK or NG

OK >> GO TO 4.

NG >> Check differential lock control unit pin terminals for damage or loose connection with harness con-

nector. If any item is damaged, repair or replace damaged parts.

4.CHECK DTC

Perform the self-diagnosis, after driving the vehicle for a while.

OK or NG

OK >>INSPECTION END

NG >> Replace differential lock control unit. Refer toRFD-76, "

Removal and Installation".

Differential Lock SolenoidEDS003B6

CONSULT-II REFERENCE VALUE IN DATA MONITOR MODE

Data are reference value.

DIFFERENTIAL LOCK CONTROL UNIT TERMINALS AND REFERENCE VALUE

Data are reference value and are measured between each terminal and ground.

CAUTION:

When using a circuit tester to measure voltage for inspection, be sure not to extend forcibly any connector terminals.Monitor item [Unit] Content Condition Display value

RELAY ON [ON/OFF]Operating condition of dif-

ferential lock solenoid

relay (integrated in differ-

ential lock control unit)

lVehicle stopped

lEngine running

l4WD shift switch: 4LODifferential lock mode

switch: ONON

Differential lock mode

switch: OFFOFF

RELAY MTR [ON/OFF]Control status of differen-

tial lock solenoid relay

(integrated in differential

lock control unit)

lVehicle stopped

lEngine running

l4WD shift switch: 4LODifferential lock mode

switch: ONON

Differential lock mode

switch: OFFOFF

SOL MTR [ON/OFF]Control status of differen-

tial lock solenoid

lVehicle stopped

lEngine running

l4WD shift switch: 4LODifferential lock mode

switch: ONON

Differential lock mode

switch: OFFOFF

Te r m i n a lWire

colorItem Condition Data (Approx.)

11 GR Differential lock solenoid (-)

lVehicle stopped

lEngine running

l4WD shift switch: 4LODifferential lock mode switch: ON 0V

Differential lock mode switch: OFF Battery voltage

12 L Differential lock solenoid (+)

lVehicle stopped

lEngine running

l4WD shift switch: 4LODifferential lock mode switch: ON 0V

Differential lock mode switch: OFF Battery voltage

Page 2768 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSIS FOR SYSTEM

RFD-65

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

DIAGNOSTIC PROCEDURE

1.CHECK DIFFERENTIAL SOLENOID SIGNAL

With CONSULT-II

1. Start engine.

2. Sele NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSIS FOR SYSTEM

RFD-65

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

DIAGNOSTIC PROCEDURE

1.CHECK DIFFERENTIAL SOLENOID SIGNAL

With CONSULT-II

1. Start engine.

2. Sele](/img/5/57362/w960_57362-2767.png)

TROUBLE DIAGNOSIS FOR SYSTEM

RFD-65

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

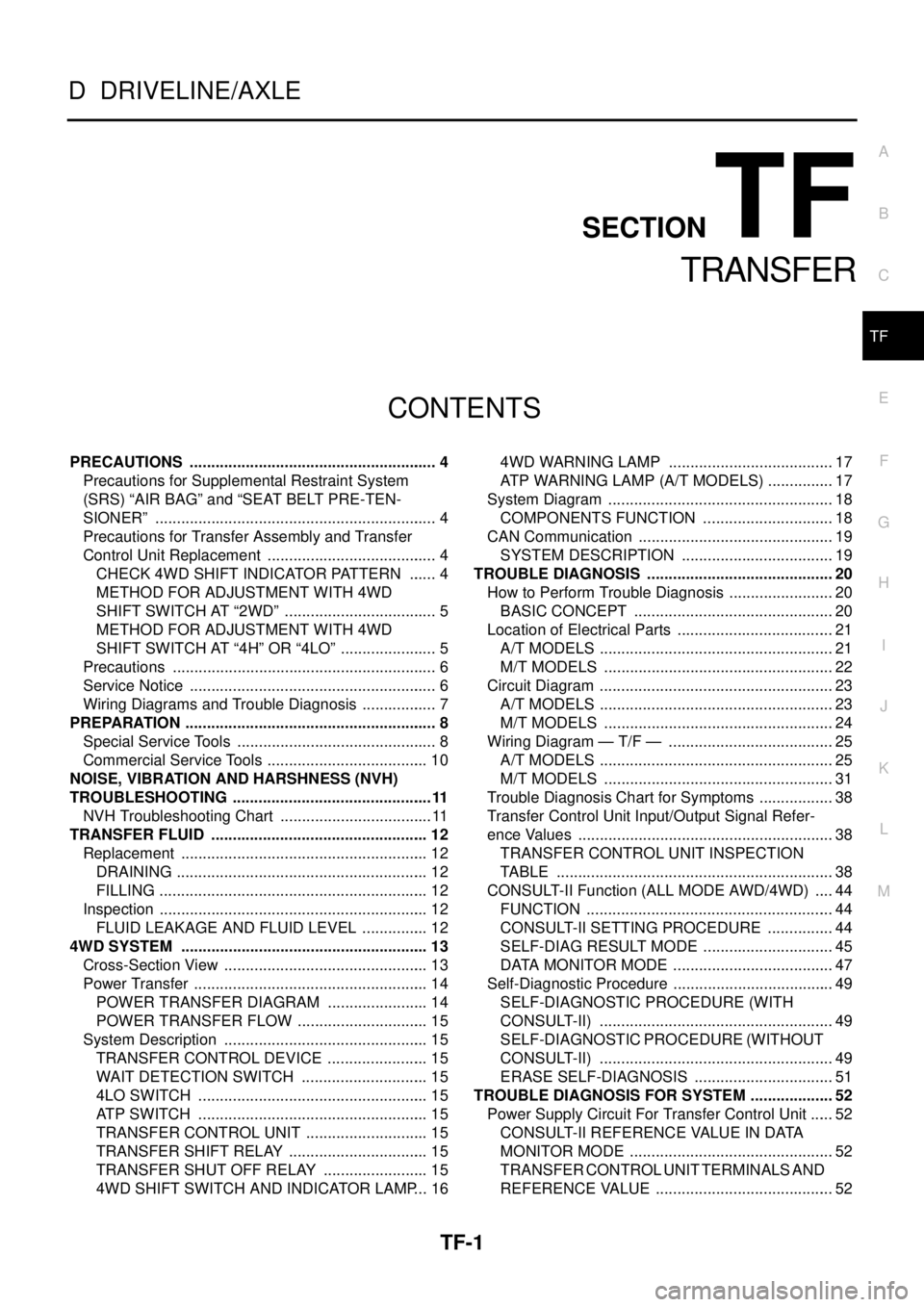

DIAGNOSTIC PROCEDURE

1.CHECK DIFFERENTIAL SOLENOID SIGNAL

With CONSULT-II

1. Start engine.

2. Select “DATA MONITOR” mode for “DIFF LOCK” with CONSULT-II.

3. Read out ON/OFF switching action of “RELAY ON”, “RELAY

MTR”, “SOL MTR”.

Without CONSULT-II

1. Start engine.

2. Check voltage between differential lock control unit harness

connector terminal and ground.

OK or NG

OK >> GO TO 6.

NG >> GO TO 2.

Monitor item ConditionDisplay

value

RELAY ON

lVehicle stopped

lEngine running

l4WD shift

switch: 4LODifferential lock mode

switch: ONON

Differential lock mode

switch: OFFOFF

RELAY MTRDifferential lock mode

switch: ONON

Differential lock mode

switch: OFFOFF

SOL MTRDifferential lock mode

switch: ONON

Differential lock mode

switch: OFFOFF

Connector Terminal ConditionData

(Approx.)

M10711 -

Ground

lVehicle stopped

lEngine running

l4WD shift switch: 4LODifferential

lock mode

switch: ON0V

Differential

lock mode

switch: OFFBattery

voltage

12 -

GroundDifferential

lock mode

switch: ON0V

Differential

lock mode

switch: OFFBattery

voltage

SDIA2539E

SDIA2565E

Page 2860 of 3171

STARTING SYSTEM

SC-27

C

D

E

F

G

H

I

J

L

MA

B

SC

STARTING SYSTEMPFP:00011

System DescriptionEKS00MZJ

A/T MODELS

Power is supplied at all times:

lto starter motor terminal 1 and

lthrough 40A fusible link (letterJ, located in the fuse and fusible link box)

lto ignition switch terminal 1.

with the ignition switch in the START position, power is supplied:

lfrom ignition switch terminal 5

lto IPDM E/R terminal 21.

With the ignition switch in the ON or START position, power is supplied to IPDM E/R CPU, and

the selector lever in the P or N position, power is supplied:

lthrough A/T assembly terminal 9

lto IPDM E/R terminal 48.

Ground is supplied at all times:

lto IPDM E/R terminals 38 and 59

lfrom body grounds E21, E41 and E61.

Then the starter relay is turned ON.

The IPDM E/R starter relay is energized and power is supplied:

lfrom terminal 19 of IPDM E/R

lto terminal 2 of the starter motor.

The starter motor plunger closes and provides a closed circuit between the battery and the starter motor. The

starter motor is grounded to the cylinder block. With power and ground supplied, the starter motor operates.

M/T MODELS

Power is supplied at all times:

lto starter motor terminal 1 and

lthrough 40A fusible link (letterJ, located in the fuse and fusible link box)

lto ignition switch terminal 1.

with the ignition switch in the START position, power is supplied:

lfrom ignition switch terminal 5

lto IPDM E/R terminal 21.

With the start signal is input to IPDM E/R CPU, power is supplied:

lthrough IPDM E/R terminal 14

lto IPDM E/R terminal 48.

Ground is supplied at all times:

lto IPDM E/R terminals 38 and 59

lfrom body grounds E21, E41 and E61.

Then the starter relay is turned ON.

The IPDM E/R starter relay is energized and power is supplied:

lfrom terminal 19 of IPDM E/R

lto terminal 2 of the starter motor.

The starter motor plunger closes and provides a closed circuit between the battery and the starter motor. The

starter motor is grounded to the cylinder block. With power and ground supplied, the starter motor operates.

Page 2968 of 3171

TF-1

TRANSFER

D DRIVELINE/AXLE

CONTENTS

C

E

F

G

H

I

J

K

L

M

SECTIONTF

A

B

TF

TRANSFER

PRECAUTIONS .......................................................... 4

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 4

Precautions for Transfer Assembly and Transfer

Control Unit Replacement ........................................ 4

CHECK 4WD SHIFT INDICATOR PATTERN ....... 4

METHOD FOR ADJUSTMENT WITH 4WD

SHIFT SWITCH AT “2WD” .................................... 5

METHOD FOR ADJUSTMENT WITH 4WD

SHIFT SWITCH AT “4H” OR “4LO” ....................... 5

Precautions .............................................................. 6

Service Notice .......................................................... 6

Wiring Diagrams and Trouble Diagnosis .................. 7

PREPARATION ........................................................... 8

Special Service Tools ............................................... 8

Commercial Service Tools ...................................... 10

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING ...............................................11

NVH Troubleshooting Chart .................................... 11

TRANSFER FLUID ................................................... 12

Replacement .......................................................... 12

DRAINING ........................................................... 12

FILLING ............................................................... 12

Inspection ............................................................... 12

FLUID LEAKAGE AND FLUID LEVEL ................ 12

4WD SYSTEM .......................................................... 13

Cross-Section View ................................................ 13

Power Transfer ....................................................... 14

POWER TRANSFER DIAGRAM ........................ 14

POWER TRANSFER FLOW ............................... 15

System Description ................................................ 15

TRANSFER CONTROL DEVICE ........................ 15

WAIT DETECTION SWITCH .............................. 15

4LO SWITCH ...................................................... 15

ATP SWITCH ...................................................... 15

TRANSFER CONTROL UNIT ............................. 15

TRANSFER SHIFT RELAY ................................. 15

TRANSFER SHUT OFF RELAY ......................... 15

4WD SHIFT SWITCH AND INDICATOR LAMP... 164WD WARNING LAMP ....................................... 17

ATP WARNING LAMP (A/T MODELS) ................ 17

System Diagram ..................................................... 18

COMPONENTS FUNCTION ............................... 18

CAN Communication .............................................. 19

SYSTEM DESCRIPTION .................................... 19

TROUBLE DIAGNOSIS ............................................ 20

How to Perform Trouble Diagnosis ......................... 20

BASIC CONCEPT ............................................... 20

Location of Electrical Parts ..................................... 21

A/T MODELS ....................................................... 21

M/T MODELS ...................................................... 22

Circuit Diagram ....................................................... 23

A/T MODELS ....................................................... 23

M/T MODELS ...................................................... 24

Wiring Diagram — T/F — ....................................... 25

A/T MODELS ....................................................... 25

M/T MODELS ...................................................... 31

Trouble Diagnosis Chart for Symptoms .................. 38

Transfer Control Unit Input/Output Signal Refer-

ence Values ............................................................ 38

TRANSFER CONTROL UNIT INSPECTION

TABLE ................................................................. 38

CONSULT-II Function (ALL MODE AWD/4WD) ..... 44

FUNCTION .......................................................... 44

CONSULT-II SETTING PROCEDURE ................ 44

SELF-DIAG RESULT MODE ............................... 45

DATA MONITOR MODE ...................................... 47

Self-Diagnostic Procedure ...................................... 49

SELF-DIAGNOSTIC PROCEDURE (WITH

CONSULT-II) ....................................................... 49

SELF-DIAGNOSTIC PROCEDURE (WITHOUT

CONSULT-II) ....................................................... 49

ERASE SELF-DIAGNOSIS ................................. 51

TROUBLE DIAGNOSIS FOR SYSTEM .................... 52

Power Supply Circuit For Transfer Control Unit ...... 52

CONSULT-II REFERENCE VALUE IN DATA

MONITOR MODE ................................................ 52

TRANSFER CONTROL UNIT TERMINALS AND

REFERENCE VALUE .......................................... 52