relay NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2245 of 3171

LT-162

ILLUMINATION

ILLUMINATION

PFP:27545

System DescriptionEKS00P8V

Control of the illumination lamps operation is dependent upon the position of the lighting switch (combination

switch). When the lighting switch is placed in the 1ST position, 2ND position or AUTO position (headlamp is

ON) the BCM (body control module) receives input signal requesting the illumination lamps to illuminate. This

input signal is communicated to the IPDM E/R (intelligent power distribution module engine room) through the

CAN communication. The CPU (central processing unit) of the IPDM E/R controls the tail lamp relay coil. This

relay, when energized, directs power to the illumination lamps, which then illuminate.

Power is supplied at all times

lto ignition relay (located in IPDM E/R) and

lto tail lamp relay (located in IPDM E/R), from battery directly,

lthrough 50A fusible link (letter G, located in fuse and fusible link box)

lto BCM terminal 57,

lthrough 20A fuse (No. 52, located in IPDM E/R) and

lthrough 20A fuse (No. 53, located in IPDM E/R)

lto CPU (located in IPDM E/R),

lthrough 10A fuse [No.19, located in fuse block (J/B)]

lto combination meter terminal 3.

With the ignition switch in the ON or START position, power is supplied

lto ignition relay (located in IPDM E/R),

lthrough 10A fuse [No. 1, located in fuse block (J/B)]

lto BCM terminal 3,

lthrough 10A fuse [No. 14, located in fuse block (J/B)]

lto combination meter 16.

Ground is supplied

lto BCM terminal 55 and

lto combination meter terminal 23

lthrough grounds M21, M80 and M83,

lto IPDM E/R terminals 38 and 59

lthrough grounds E21, E41 and E61.

ILLUMINATION OPERATION BY LIGHTING SWITCH

With the lighting switch in the 1ST position, 2ND position or AUTO position (headlamp is ON), the BCM

receives input signal requesting the illumination lamps to illuminate. This input signal is communicated to the

IPDM E/R through the CAN communication. The CPU of the IPDM E/R controls the tail lamp relay coil, which,

when energized, directs power

lthrough 10A fuse (No. 37, located in IPDM E/R)

lthrough IPDM E/R terminal 57

lto hazard switch (illumination) terminal 3

lto 4WD shift switch (illumination) terminal 7 (with 4-wheel drive)

lto front air control (illumination) terminal 8

lto audio unit (illumination) terminal 2 (1CD player)

lto audio unit (illumination) terminal 8 (6CD player)

lto AV switch (illumination) terminal 3 (with NAVI)

lto audio unit (illumination) terminal 29 (with NAVI)

lto glove box lamp terminal 1

lto A/T device (illumination) terminal 3 (with A/T)

lto heat up switch (illumination) terminal 5

lto DIFF LOCK switch (illumination) terminal 4 (with DIFF LOCK)

lto heated seat switch (driver side) (illumination) terminal 5 (with heated seats)

lto heated seat switch (passenger side) (illumination) terminal 5 (with heated seats)

Page 2407 of 3171

MTC-20

REFRIGERATION SYSTEM

REFRIGERATION SYSTEM

PFP:KA990

Refrigerant CycleEJS0062E

REFRIGERANT FLOW

The refrigerant flows in the standard pattern, that is, through the compressor, the condenser with liquid tank,

through the evaporator, and back to the compressor. The refrigerant evaporation through the evaporator is

controlled by an externally equalized expansion valve, located inside the evaporator case.

FREEZE PROTECTION

Under usual operating conditions, when the A/C is switched ON, the compressor runs continuously, and the

evaporator pressure, and therefore, temperature is controlled by the V-6 variable displacement compressor to

prevent freeze up.

Refrigerant System ProtectionEJS005FT

REFRIGERANT PRESSURE SENSOR

The refrigerant system is protected against excessively high or low pressures by the refrigerant pressure sen-

sor, located on the condenser. If the system pressure rises above or falls below the specifications, the refriger-

ant pressure sensor detects the pressure inside the refrigerant line and sends a voltage signal to the ECM.

The ECM de-energizes the A/C relay to disengage the magnetic compressor clutch when pressure on the high

pressure side detected by refrigerant pressure sensor is over about 2,746 kPa (28 kg/cm

2, 398 psi), or below

about 120 kPa (1.22 kg/cm

2,17.4psi).

Page 2414 of 3171

AIR CONDITIONER CONTROL

MTC-27

C

D

E

F

G

H

I

K

L

MA

B

MTC

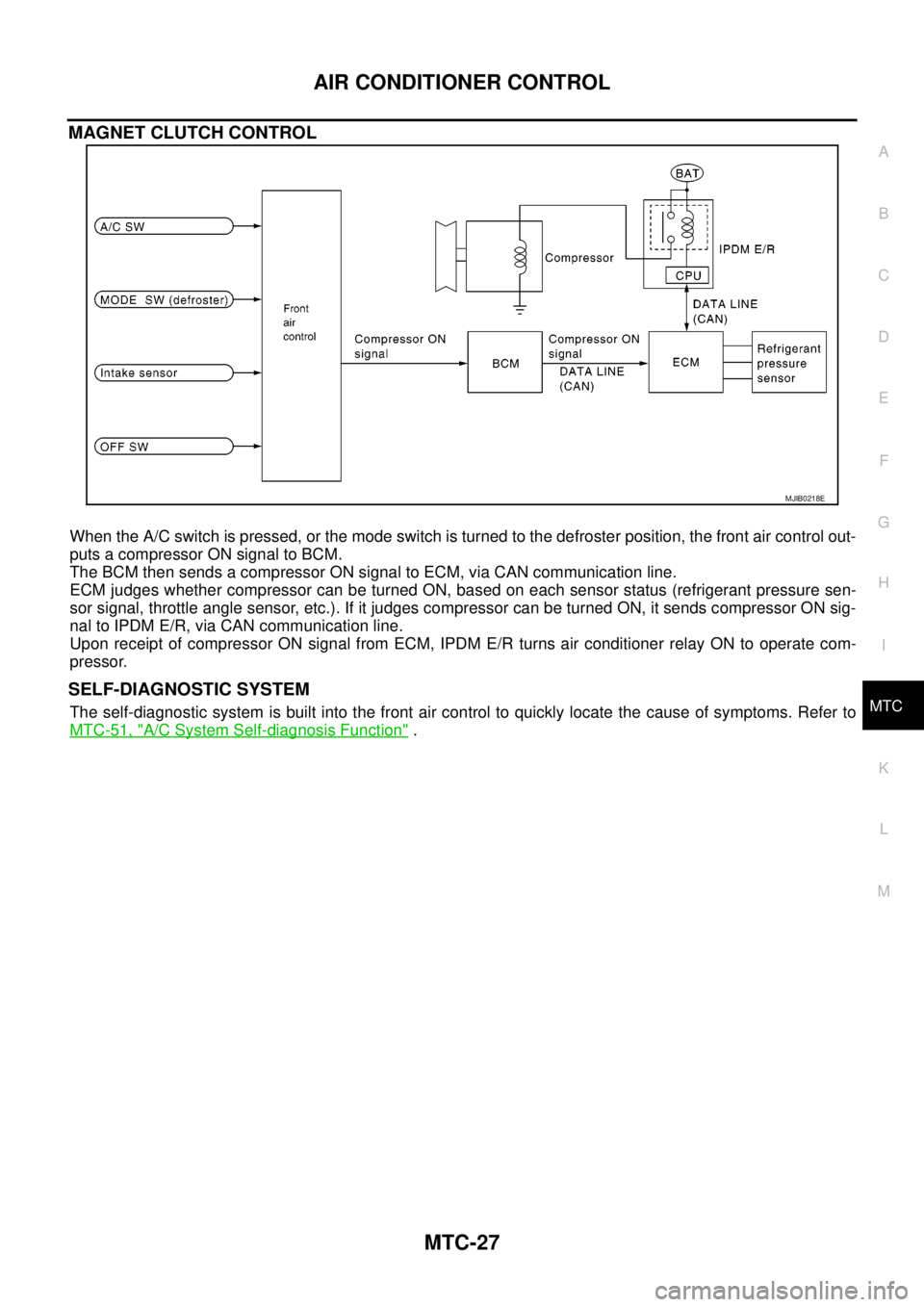

MAGNET CLUTCH CONTROL

When the A/C switch is pressed, or the mode switch is turned to the defroster position, the front air control out-

puts a compressor ON signal to BCM.

The BCM then sends a compressor ON signal to ECM, via CAN communication line.

ECM judges whether compressor can be turned ON, based on each sensor status (refrigerant pressure sen-

sor signal, throttle angle sensor, etc.). If it judges compressor can be turned ON, it sends compressor ON sig-

nal to IPDM E/R, via CAN communication line.

Upon receipt of compressor ON signal from ECM, IPDM E/R turns air conditioner relay ON to operate com-

pressor.

SELF-DIAGNOSTIC SYSTEM

The self-diagnostic system is built into the front air control to quickly locate the cause of symptoms. Refer to

MTC-51, "

A/C System Self-diagnosis Function".

MJIB0218E

Page 2437 of 3171

MTC-50

TROUBLE DIAGNOSIS

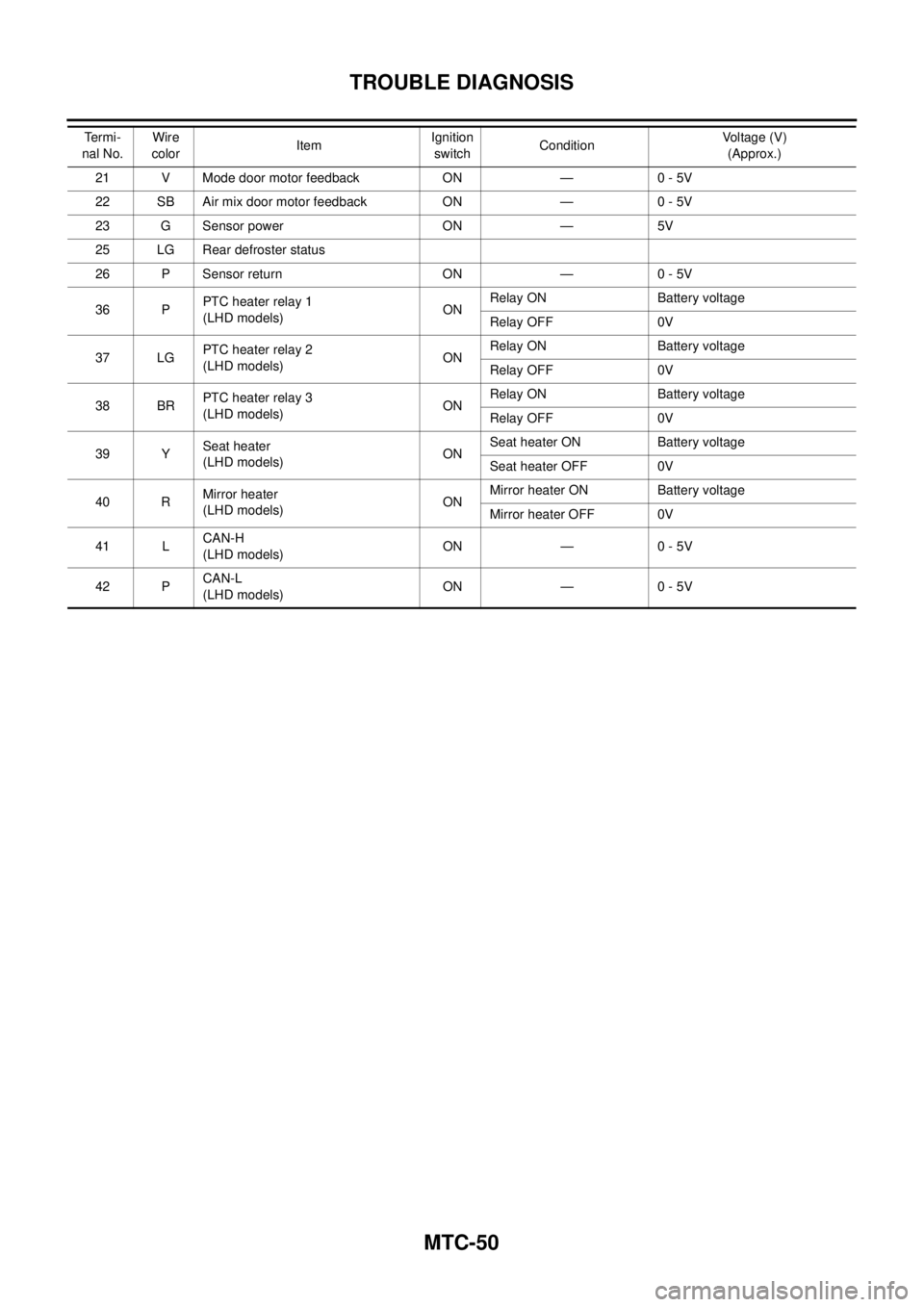

21 V Mode door motor feedback ON — 0 - 5V

22 SB Air mix door motor feedback ON — 0 - 5V

23 G Sensor power ON — 5V

25 LG Rear defroster status

26 P Sensor return ON — 0 - 5V

36 PPTC heater relay 1

(LHD models)ONRelay ON Battery voltage

Relay OFF 0V

37 LGPTC heater relay 2

(LHD models)ONRelay ON Battery voltage

Relay OFF 0V

38 BRPTC heater relay 3

(LHD models)ONRelay ON Battery voltage

Relay OFF 0V

39 YSeat heater

(LHD models)ONSeat heater ON Battery voltage

Seat heater OFF 0V

40 RMirror heater

(LHD models)ONMirror heater ON Battery voltage

Mirror heater OFF 0V

41 LCAN-H

(LHD models)ON — 0 - 5V

42 PCAN-L

(LHD models)ON — 0 - 5V Te r m i -

nal No.Wire

colorItemIgnition

switchConditionVoltage (V)

(Approx.)

Page 2459 of 3171

MTC-72

TROUBLE DIAGNOSIS

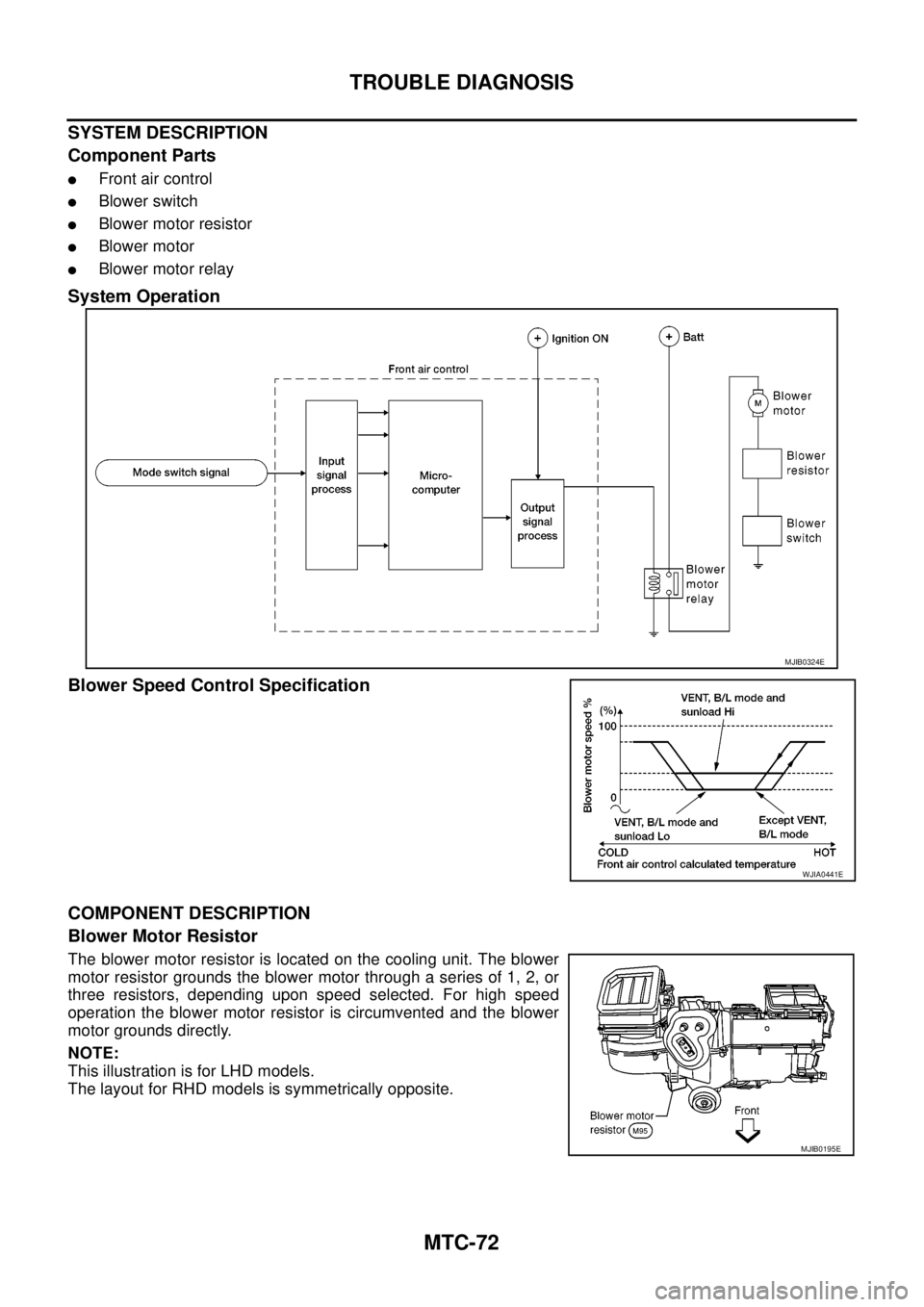

SYSTEM DESCRIPTION

Component Parts

lFront air control

lBlower switch

lBlower motor resistor

lBlower motor

lBlower motor relay

System Operation

Blower Speed Control Specification

COMPONENT DESCRIPTION

Blower Motor Resistor

The blower motor resistor is located on the cooling unit. The blower

motor resistor grounds the blower motor through a series of 1, 2, or

three resistors, depending upon speed selected. For high speed

operation the blower motor resistor is circumvented and the blower

motor grounds directly.

NOTE:

This illustration is for LHD models.

The layout for RHD models is symmetrically opposite.

MJIB0324E

WJIA0441E

MJIB0195E

Page 2461 of 3171

MTC-74

TROUBLE DIAGNOSIS

4.CHECK BLOWER MOTOR RELAY

Refer toMTC-77, "

Blower Motor Relay".

OK or NG

OK >> GO TO 5.

NG >> Replace blower motor relay.

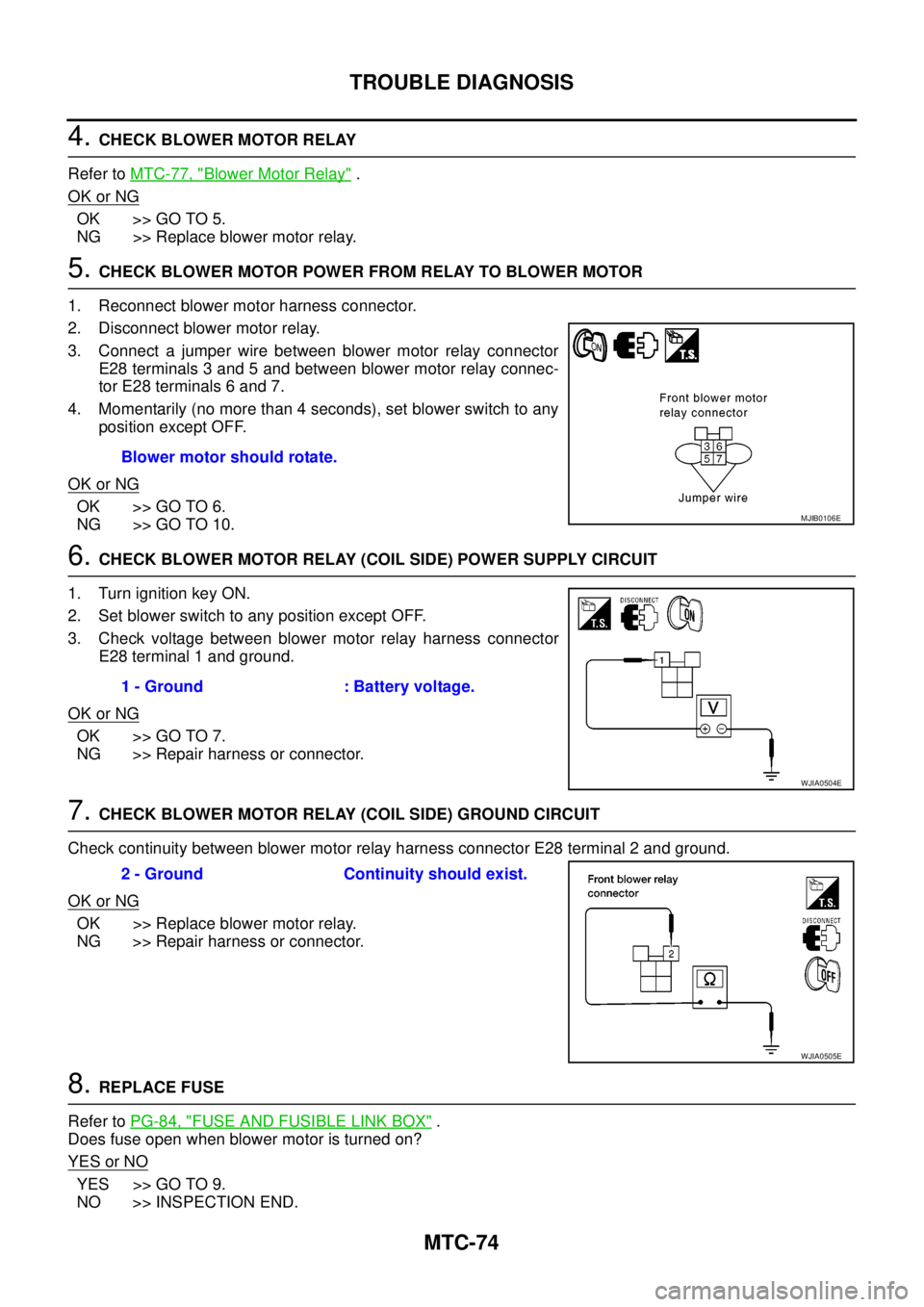

5.CHECK BLOWER MOTOR POWER FROM RELAY TO BLOWER MOTOR

1. Reconnect blower motor harness connector.

2. Disconnect blower motor relay.

3. Connect a jumper wire between blower motor relay connector

E28 terminals 3 and 5 and between blower motor relay connec-

tor E28 terminals 6 and 7.

4. Momentarily (no more than 4 seconds), set blower switch to any

position except OFF.

OK or NG

OK >> GO TO 6.

NG >> GO TO 10.

6.CHECK BLOWER MOTOR RELAY (COIL SIDE) POWER SUPPLY CIRCUIT

1. Turn ignition key ON.

2. Set blower switch to any position except OFF.

3. Check voltage between blower motor relay harness connector

E28 terminal 1 and ground.

OK or NG

OK >> GO TO 7.

NG >> Repair harness or connector.

7.CHECK BLOWER MOTOR RELAY (COIL SIDE) GROUND CIRCUIT

Check continuity between blower motor relay harness connector E28 terminal 2 and ground.

OK or NG

OK >> Replace blower motor relay.

NG >> Repair harness or connector.

8.REPLACE FUSE

Refer toPG-84, "

FUSE AND FUSIBLE LINK BOX".

Does fuse open when blower motor is turned on?

YESorNO

YES >> GO TO 9.

NO >> INSPECTION END.Blower motor should rotate.

MJIB0106E

1 - Ground : Battery voltage.

WJIA0504E

2 - Ground Continuity should exist.

WJIA0505E

Page 2462 of 3171

TROUBLE DIAGNOSIS

MTC-75

C

D

E

F

G

H

I

K

L

MA

B

MTC

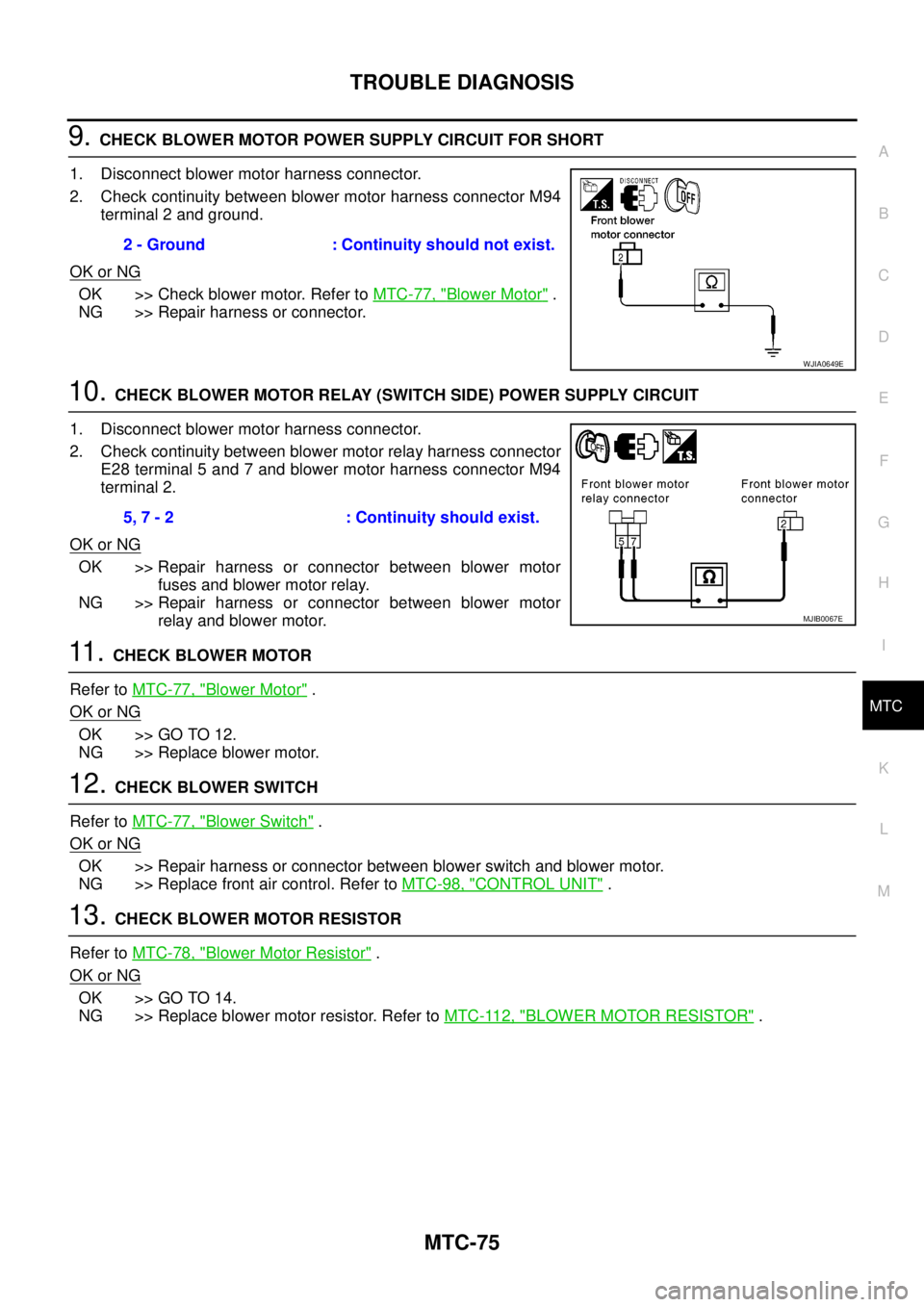

9.CHECK BLOWER MOTOR POWER SUPPLY CIRCUIT FOR SHORT

1. Disconnect blower motor harness connector.

2. Check continuity between blower motor harness connector M94

terminal 2 and ground.

OK or NG

OK >> Check blower motor. Refer toMTC-77, "Blower Motor".

NG >> Repair harness or connector.

10.CHECK BLOWER MOTOR RELAY (SWITCH SIDE) POWER SUPPLY CIRCUIT

1. Disconnect blower motor harness connector.

2. Check continuity between blower motor relay harness connector

E28 terminal 5 and 7 and blower motor harness connector M94

terminal 2.

OK or NG

OK >> Repair harness or connector between blower motor

fuses and blower motor relay.

NG >> Repair harness or connector between blower motor

relay and blower motor.

11 .CHECK BLOWER MOTOR

Refer toMTC-77, "

Blower Motor".

OK or NG

OK >> GO TO 12.

NG >> Replace blower motor.

12.CHECK BLOWER SWITCH

Refer toMTC-77, "

Blower Switch".

OK or NG

OK >> Repair harness or connector between blower switch and blower motor.

NG >> Replace front air control. Refer toMTC-98, "

CONTROL UNIT".

13.CHECK BLOWER MOTOR RESISTOR

Refer toMTC-78, "

Blower Motor Resistor".

OK or NG

OK >> GO TO 14.

NG >> Replace blower motor resistor. Refer toMTC-112, "

BLOWER MOTOR RESISTOR". 2 - Ground : Continuity should not exist.

WJIA0649E

5, 7 - 2 : Continuity should exist.

MJIB0067E

Page 2464 of 3171

TROUBLE DIAGNOSIS

MTC-77

C

D

E

F

G

H

I

K

L

MA

B

MTC

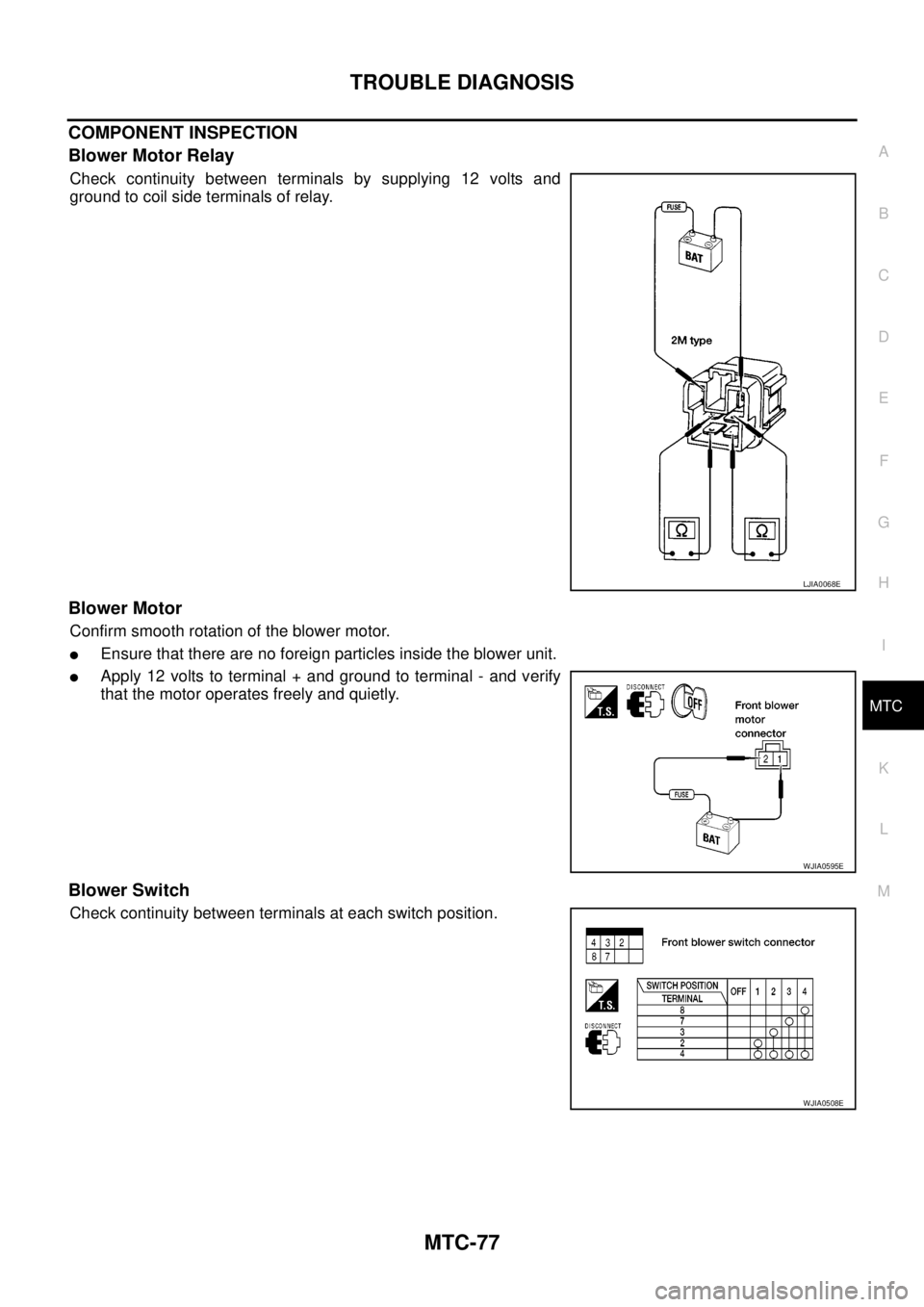

COMPONENT INSPECTION

Blower Motor Relay

Check continuity between terminals by supplying 12 volts and

ground to coil side terminals of relay.

Blower Motor

Confirm smooth rotation of the blower motor.

lEnsure that there are no foreign particles inside the blower unit.

lApply 12 volts to terminal + and ground to terminal - and verify

that the motor operates freely and quietly.

Blower Switch

Check continuity between terminals at each switch position.

LJIA0068E

WJIA0595E

WJIA0508E

Page 2530 of 3171

PG-1

POWER SUPPLY, GROUND & CIRCUIT ELEMENTS

K ELECTRICAL

CONTENTS

C

D

E

F

G

H

I

J

L

M

SECTIONPG

A

B

PG

POWER SUPPLY, GROUND & CIRCUIT ELEMENTS

PRECAUTIONS .......................................................... 3

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 3

Wiring Diagrams and Trouble Diagnosis .................. 3

POWER SUPPLY ROUTING CIRCUIT ...................... 4

Schematic ................................................................ 4

Wiring Diagram — POWER — ................................. 5

BATTERY POWER SUPPLY — IGNITION SW.

IN ANY POSITION ................................................ 5

ACCESSORY POWER SUPPLY — IGNITION

SW. IN ACC OR ON ............................................ 10

IGNITION POWER SUPPLY — IGNITION SW.

IN ON ................................................................... 11

IGNITION POWER SUPPLY — IGNITION SW.

IN ON AND/OR START ....................................... 12

IPDM E/R (INTELLIGENT POWER DISTRIBUTION

MODULE ENGINE ROOM) ...................................... 14

System Description ................................................ 14

SYSTEMS CONTROLLED BY IPDM E/R ........... 14

CAN COMMUNICATION LINE CONTROL ......... 14

IPDM E/R STATUS CONTROL ........................... 15

CAN Communication System Description .............. 15

Function of Detecting Ignition Relay Malfunction ... 15

CONSULT-II Function (IPDM E/R) ......................... 16

CONSULT-II BASIC OPERATION ...................... 16

SELF-DIAGNOSTIC RESULTS .......................... 17

DATA MONITOR ................................................. 17

CAN DIAG SUPPORT MNTR ............................. 18

ACTIVE TEST ..................................................... 18

Auto Active Test ..................................................... 19

DESCRIPTION .................................................... 19

OPERATION PROCEDURE ............................... 19

INSPECTION IN AUTO ACTIVE TEST MODE... 20

Schematic .............................................................. 22

IPDM E/R Terminal Arrangement ........................... 23

Check IPDM E/R Power Supply and Ground Circuit... 24Inspection with CONSULT-II (Self-Diagnosis) ........ 25

Removal and Installation of IPDM E/R ................... 26

REMOVAL ........................................................... 26

INSTALLATION ................................................... 26

GROUND CIRCUIT ................................................... 27

Ground Distribution ................................................. 27

MAIN HARNESS ................................................. 27

ENGINE ROOM HARNESS ................................ 30

ENGINE CONTROL HARNESS .......................... 34

BODY HARNESS (LH SIDE) .............................. 35

BODY HARNESS (RH SIDE) .............................. 36

DEFOGGER CABLE ........................................... 37

HARNESS ................................................................. 38

Harness Layout ...................................................... 38

HOW TO READ HARNESS LAYOUT ................. 38

OUTLINE/DOUBLE CAB MODELS .................... 39

OUTLINE/KING CAB MODELS .......................... 40

MAIN HARNESS/LHD MODELS ......................... 41

MAIN HARNESS/RHD MODELS ........................ 44

ENGINE ROOM HARNESS/LHD MODELS ........ 47

ENGINE ROOM HARNESS/RHD MODELS ....... 49

ENGINE CONTROL HARNESS .......................... 51

CHASSIS HARNESS .......................................... 53

BODY HARNESS (LH SIDE)/DOUBLE CAB

MODELS ............................................................. 54

BODY HARNESS (RH SIDE)/DOUBLE CAB

MODELS ............................................................. 56

BODY HARNESS (LH SIDE)/KING CAB MOD-

ELS ...................................................................... 58

BODY HARNESS (RH SIDE)/KING CAB MOD-

ELS ...................................................................... 60

ROOM LAMP HARNESS .................................... 62

FRONT DOOR LH HARNESS/LHD MODELS .... 63

FRONT DOOR RH HARNESS/LHD MODELS ... 63

FRONT DOOR LH HARNESS/RHD MODELS ... 64

FRONT DOOR RH HARNESS/RHD MODELS ... 64

REAR DOOR LH HARNESS/DOUBLE CAB

MODELS ............................................................. 65

REAR DOOR RH HARNESS/DOUBLE CAB

MODELS ............................................................. 65

Page 2531 of 3171

PG-2

REAR DOOR LH HARNESS/KING CAB MOD-

ELS ...................................................................... 66

REAR DOOR RH HARNESS/KING CAB MOD-

ELS ...................................................................... 66

TAIL HARNESS ................................................... 67

Wiring Diagram Codes (Cell Codes) ....................... 68

ELECTRICAL UNITS LOCATION ............................. 71

Electrical Units Location ......................................... 71

ENGINE COMPARTMENT .................................. 71

PASSENGER COMPARTMENT .......................... 72

Fuse ........................................................................ 74

Fusible Link ............................................................ 74

Circuit Breaker (Built Into BCM) ............................. 74

HARNESS CONNECTOR ......................................... 75

Description .............................................................. 75

HARNESS CONNECTOR (TAB-LOCKING

TYPE) .................................................................. 75

HARNESS CONNECTOR (SLIDE-LOCKINGTYPE) .................................................................. 76

HARNESS CONNECTOR (DIRECT-CONNECT

SRS COMPONENT TYPE) .................................. 77

ELECTRICAL UNITS ................................................ 78

Terminal Arrangement ............................................. 78

STANDARDIZED RELAY .......................................... 79

Description .............................................................. 79

NORMAL OPEN, NORMAL CLOSED AND

MIXED TYPE RELAYS ........................................ 79

TYPE OF STANDARDIZED RELAYS .................. 79

SUPER MULTIPLE JUNCTION (SMJ) ...................... 81

Terminal Arrangement ............................................. 81

FUSE BLOCK - JUNCTION BOX (J/B) .................... 83

Terminal Arrangement ............................................. 83

FUSE AND FUSIBLE LINK BOX .............................. 84

Terminal Arrangement ............................................. 84

FUSE AND RELAY BOX ........................................... 85

Terminal Arrangement ............................................. 85