NISSAN NAVARA 2005 Repair Workshop Manual

Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1501 of 3171

CYLINDER BLOCK

EM-119

C

D

E

F

G

H

I

J

K

L

MA

EM

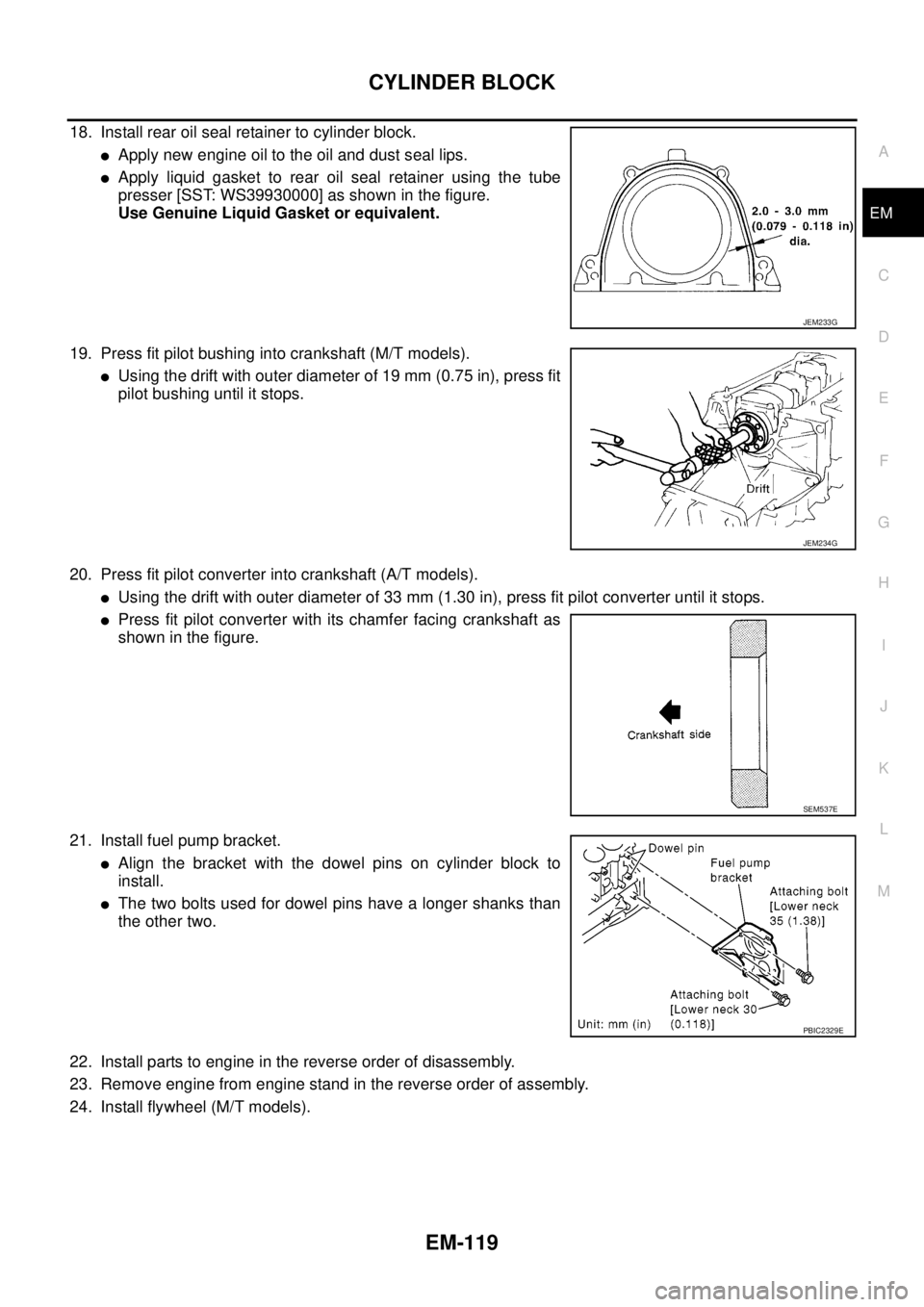

18. Install rear oil seal retainer to cylinder block.

lApply new engine oil to the oil and dust seal lips.

lApply liquid gasket to rear oil seal retainer using the tube

presser [SST: WS39930000] as shown in the figure.

Use Genuine Liquid Gasket or equivalent.

19. Press fit pilot bushing into crankshaft (M/T models).

lUsing the drift with outer diameter of 19 mm (0.75 in), press fit

pilot bushing until it stops.

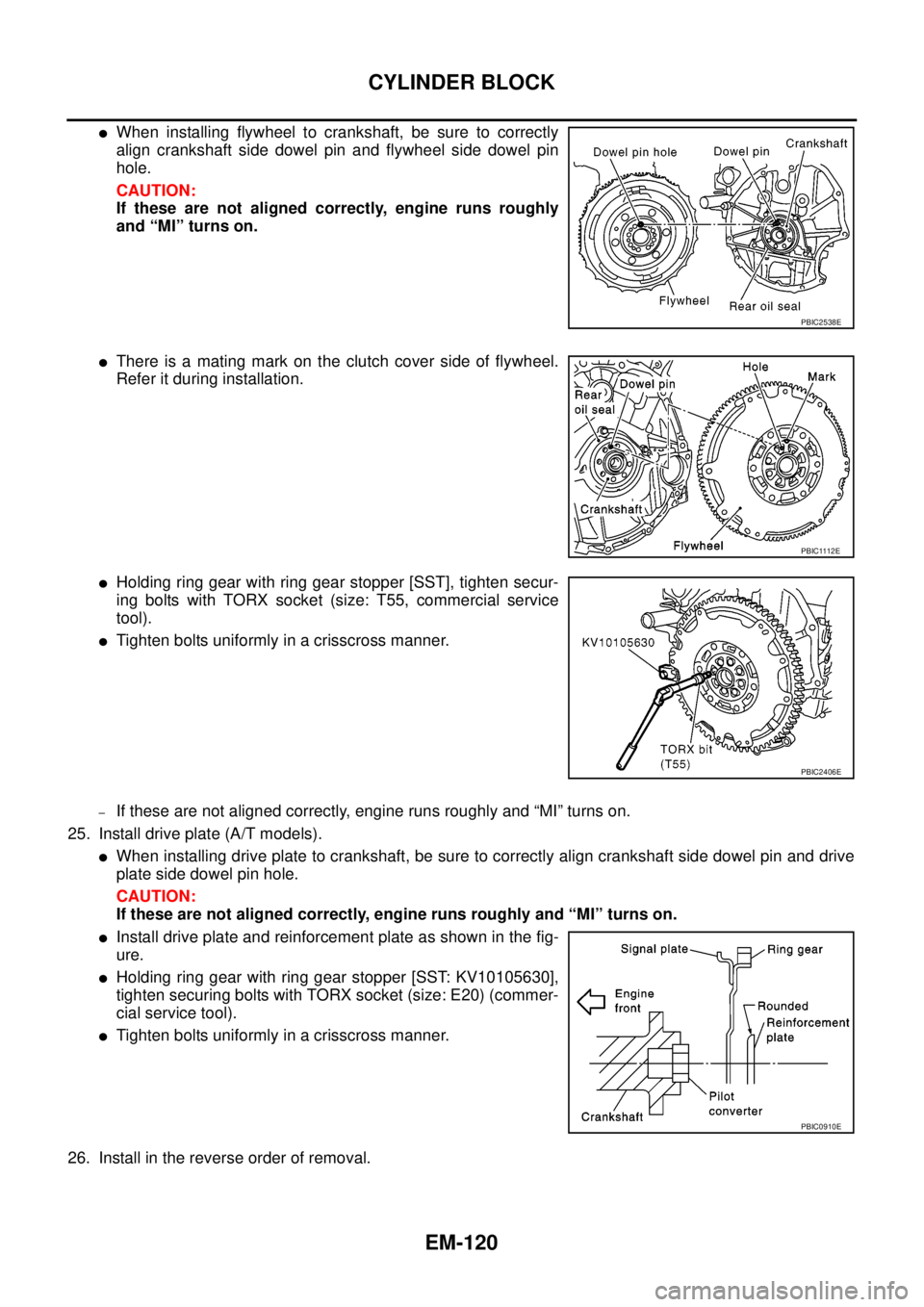

20. Press fit pilot converter into crankshaft (A/T models).

lUsing the drift with outer diameter of 33 mm (1.30 in), press fit pilot converter until it stops.

lPress fit pilot converter with its chamfer facing crankshaft as

showninthefigure.

21. Install fuel pump bracket.

lAlign the bracket with the dowel pins on cylinder block to

install.

lThe two bolts used for dowel pins have a longer shanks than

the other two.

22. Install parts to engine in the reverse order of disassembly.

23. Remove engine from engine stand in the reverse order of assembly.

24. Install flywheel (M/T models).

JEM233G

JEM234G

SEM537E

PBIC2329E

Page 1502 of 3171

EM-120

CYLINDER BLOCK

lWhen installing flywheel to crankshaft, be sure to correctly

align crankshaft side dowel pin and flywheel side dowel pin

hole.

CAUTION:

If these are not aligned correctly, engine runs roughly

and “MI” turns on.

lThere is a mating mark on the clutch cover side of flywheel.

Refer it during installation.

lHolding ring gear with ring gear stopper [SST], tighten secur-

ing bolts with TORX socket (size: T55, commercial service

tool).

lTighten bolts uniformly in a crisscross manner.

–If these are not aligned correctly, engine runs roughly and “MI” turns on.

25. Install drive plate (A/T models).

lWhen installing drive plate to crankshaft, be sure to correctly align crankshaft side dowel pin and drive

plate side dowel pin hole.

CAUTION:

If these are not aligned correctly, engine runs roughly and “MI” turns on.

lInstall drive plate and reinforcement plate as shown in the fig-

ure.

lHolding ring gear with ring gear stopper [SST: KV10105630],

tighten securing bolts with TORX socket (size: E20) (commer-

cial service tool).

lTighten bolts uniformly in a crisscross manner.

26. Install in the reverse order of removal.

PBIC2538E

PBIC1112E

PBIC2406E

PBIC0910E

Page 1503 of 3171

CYLINDER BLOCK

EM-121

C

D

E

F

G

H

I

J

K

L

MA

EM

How to Select Piston and BearingEBS01E6F

DESCRIPTION

lThe identification grade stamped on each part is the grade for the dimension measured in new condition.

This grade cannot apply to reused parts.

lFor reused or repaired parts, measure the dimension accurately. Determine the grade by comparing the

measurement with the values of each selection table.

lFor details of the measurement method of each part, the reuse standards and the selection method of the

selective fitting parts, refer to the text.

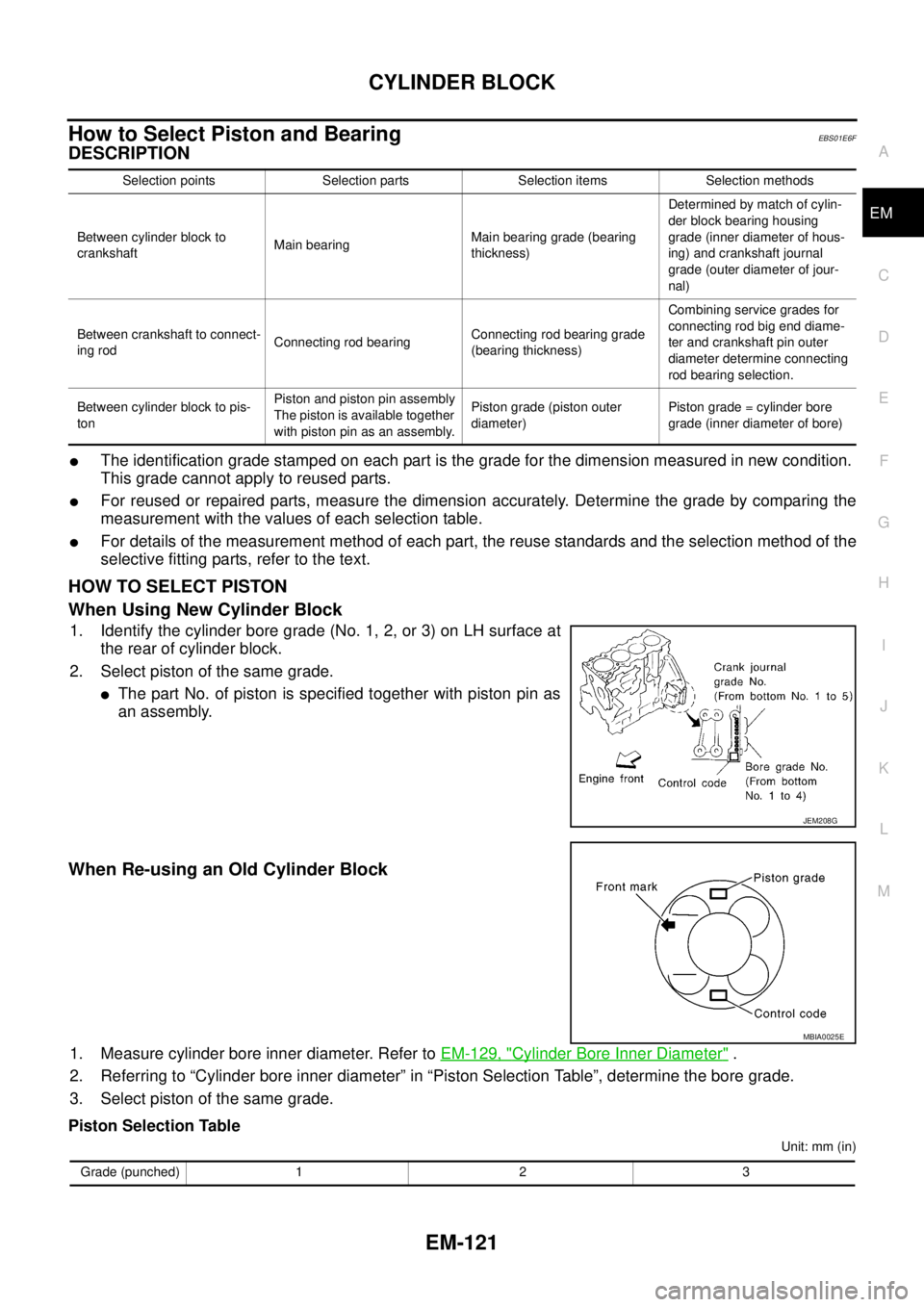

HOW TO SELECT PISTON

When Using New Cylinder Block

1. Identify the cylinder bore grade (No. 1, 2, or 3) on LH surface at

the rear of cylinder block.

2. Select piston of the same grade.

lThe part No. of piston is specified together with piston pin as

an assembly.

When Re-using an Old Cylinder Block

1. Measure cylinder bore inner diameter. Refer toEM-129, "Cylinder Bore Inner Diameter".

2. Referring to “Cylinder bore inner diameter” in “Piston Selection Table”, determine the bore grade.

3. Select piston of the same grade.

Piston Selection Table

Unit: mm (in) Selection points Selection parts Selection items Selection methods

Between cylinder block to

crankshaftMain bearingMain bearing grade (bearing

thickness)Determined by match of cylin-

der block bearing housing

grade (inner diameter of hous-

ing) and crankshaft journal

grade (outer diameter of jour-

nal)

Between crankshaft to connect-

ing rodConnecting rod bearingConnecting rod bearing grade

(bearing thickness)Combining service grades for

connecting rod big end diame-

ter and crankshaft pin outer

diameter determine connecting

rod bearing selection.

Between cylinder block to pis-

tonPiston and piston pin assembly

The piston is available together

with piston pin as an assembly.Piston grade (piston outer

diameter)Piston grade = cylinder bore

grade (inner diameter of bore)

JEM208G

MBIA0025E

Grade (punched) 1 2 3

Page 1504 of 3171

EM-122

CYLINDER BLOCK

NOTE:

Piston is available together with piston pin as an assembly.

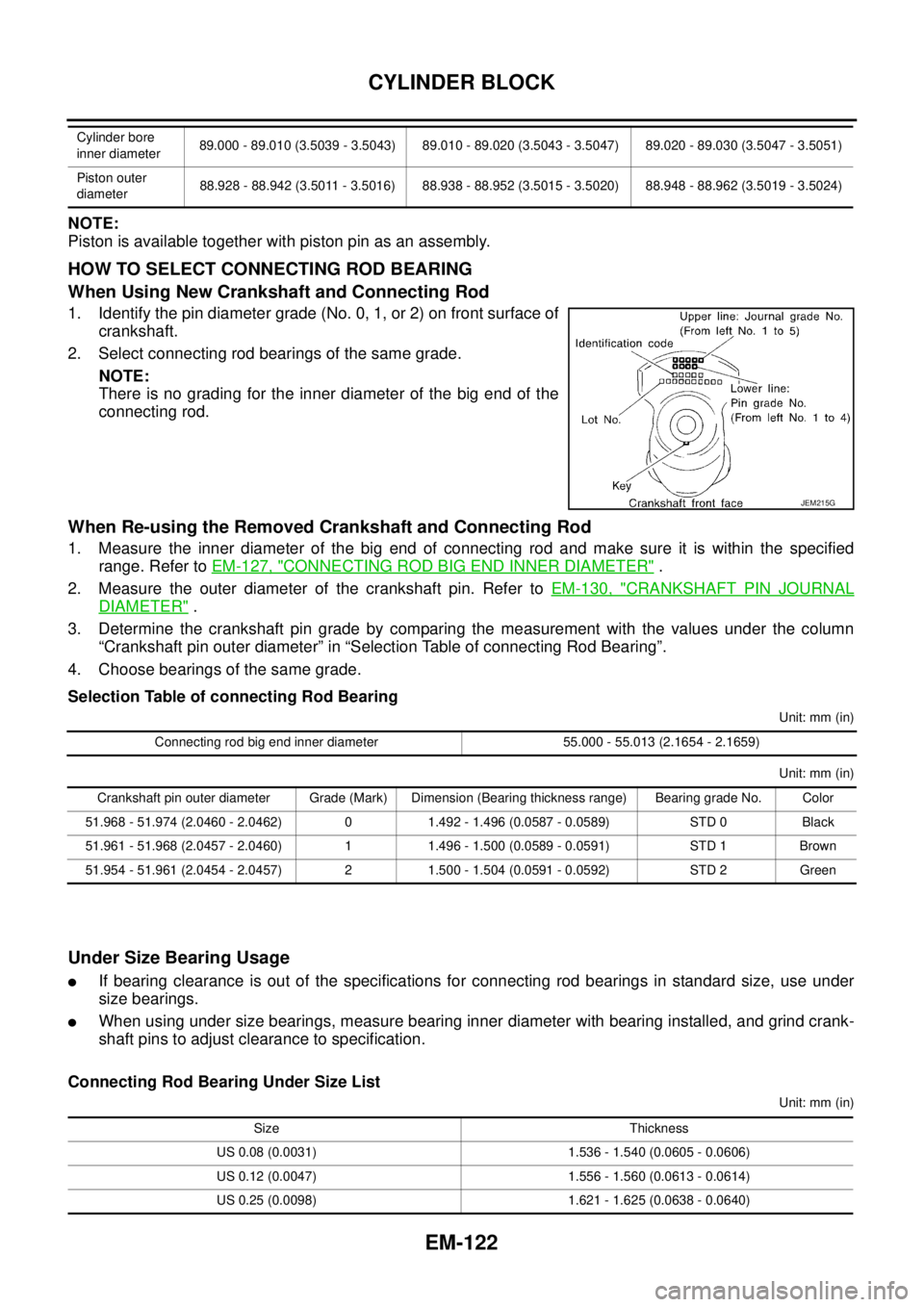

HOW TO SELECT CONNECTING ROD BEARING

When Using New Crankshaft and Connecting Rod

1. Identify the pin diameter grade (No. 0, 1, or 2) on front surface of

crankshaft.

2. Select connecting rod bearings of the same grade.

NOTE:

There is no grading for the inner diameter of the big end of the

connecting rod.

When Re-using the Removed Crankshaft and Connecting Rod

1. Measure the inner diameter of the big end of connecting rod and make sure it is within the specified

range. Refer toEM-127, "

CONNECTING ROD BIG END INNER DIAMETER".

2. Measure the outer diameter of the crankshaft pin. Refer toEM-130, "

CRANKSHAFT PIN JOURNAL

DIAMETER".

3. Determine the crankshaft pin grade by comparing the measurement with the values under the column

“Crankshaft pin outer diameter” in “Selection Table of connecting Rod Bearing”.

4. Choose bearings of the same grade.

Selection Table of connecting Rod Bearing

Unit: mm (in)

Unit: mm (in)

Under Size Bearing Usage

lIf bearing clearance is out of the specifications for connecting rod bearings in standard size, use under

size bearings.

lWhen using under size bearings, measure bearing inner diameter with bearing installed, and grind crank-

shaft pins to adjust clearance to specification.

Connecting Rod Bearing Under Size List

Unit: mm (in) Cylinder bore

inner diameter89.000 - 89.010 (3.5039 - 3.5043) 89.010 - 89.020 (3.5043 - 3.5047) 89.020 - 89.030 (3.5047 - 3.5051)

Piston outer

diameter88.928 - 88.942 (3.5011 - 3.5016) 88.938 - 88.952 (3.5015 - 3.5020) 88.948 - 88.962 (3.5019 - 3.5024)

JEM215G

Connecting rod big end inner diameter 55.000 - 55.013 (2.1654 - 2.1659)

Crankshaft pin outer diameter Grade (Mark) Dimension (Bearing thickness range) Bearing grade No. Color

51.968 - 51.974 (2.0460 - 2.0462) 0 1.492 - 1.496 (0.0587 - 0.0589) STD 0 Black

51.961 - 51.968 (2.0457 - 2.0460) 1 1.496 - 1.500 (0.0589 - 0.0591) STD 1 Brown

51.954 - 51.961 (2.0454 - 2.0457) 2 1.500 - 1.504 (0.0591 - 0.0592) STD 2 Green

Size Thickness

US 0.08 (0.0031) 1.536 - 1.540 (0.0605 - 0.0606)

US 0.12 (0.0047) 1.556 - 1.560 (0.0613 - 0.0614)

US 0.25 (0.0098) 1.621 - 1.625 (0.0638 - 0.0640)

Page 1505 of 3171

CYLINDER BLOCK

EM-123

C

D

E

F

G

H

I

J

K

L

MA

EM

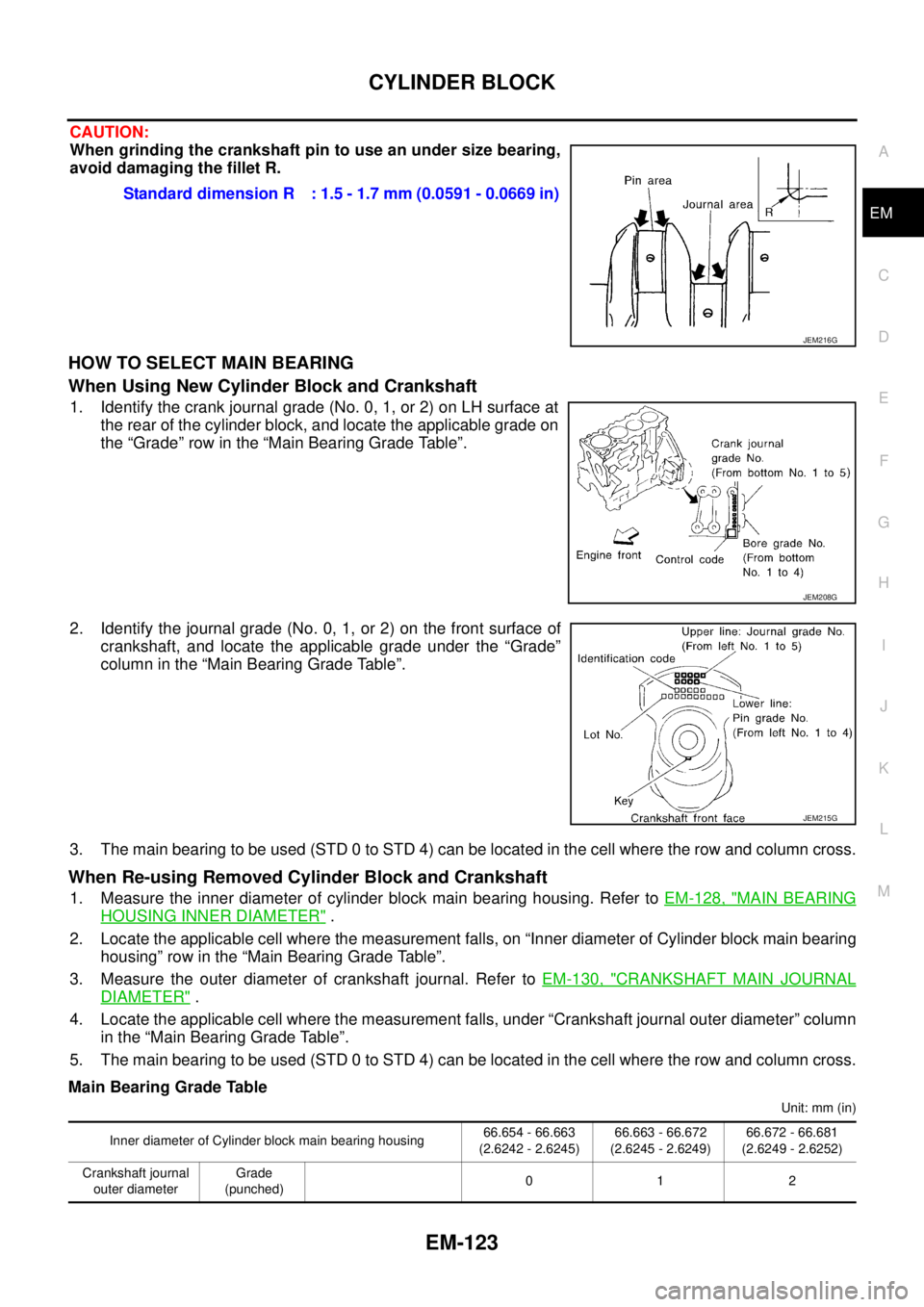

CAUTION:

When grinding the crankshaft pin to use an under size bearing,

avoid damaging the fillet R.

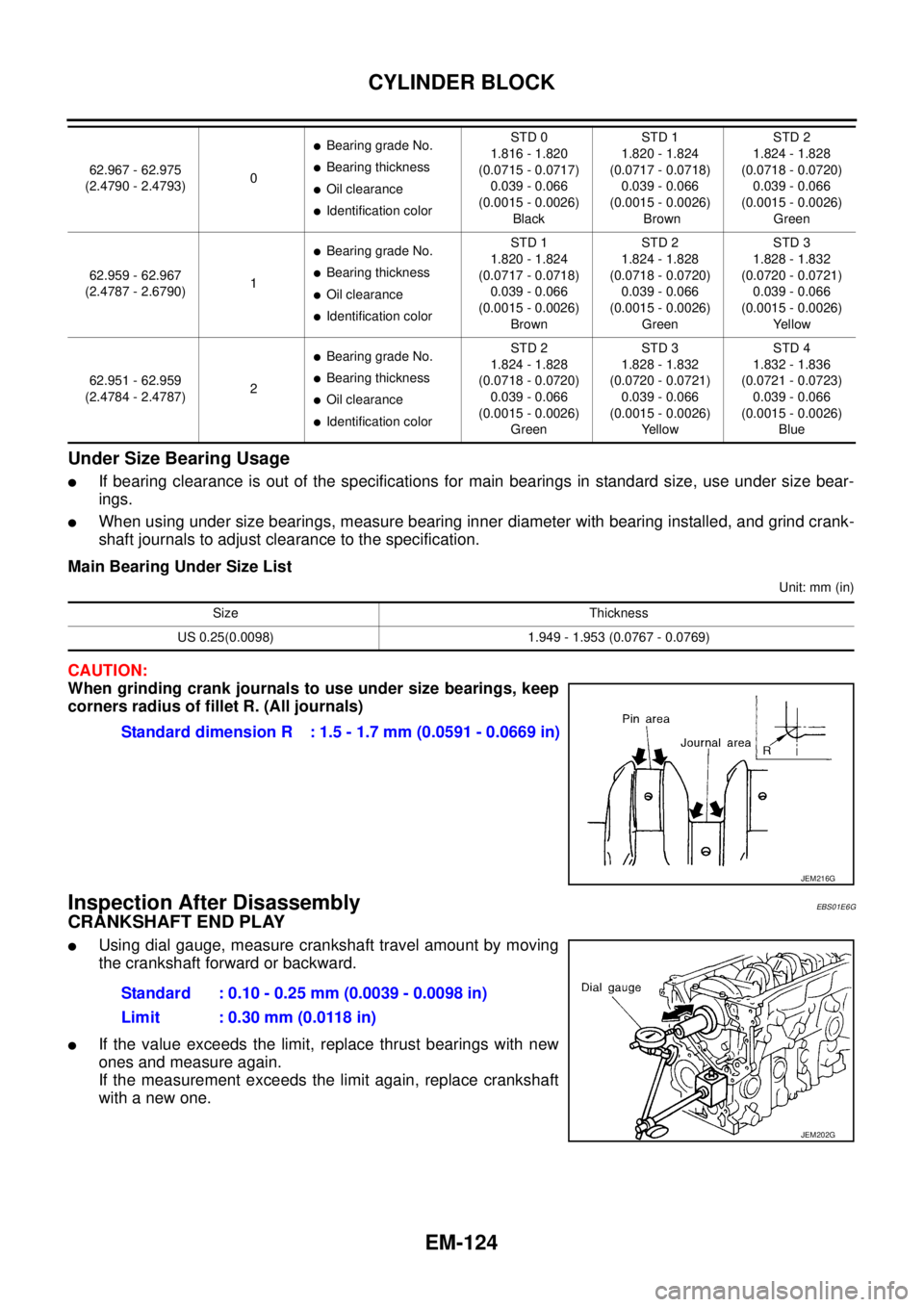

HOW TO SELECT MAIN BEARING

When Using New Cylinder Block and Crankshaft

1. Identify the crank journal grade (No. 0, 1, or 2) on LH surface at

the rear of the cylinder block, and locate the applicable grade on

the “Grade” row in the “Main Bearing Grade Table”.

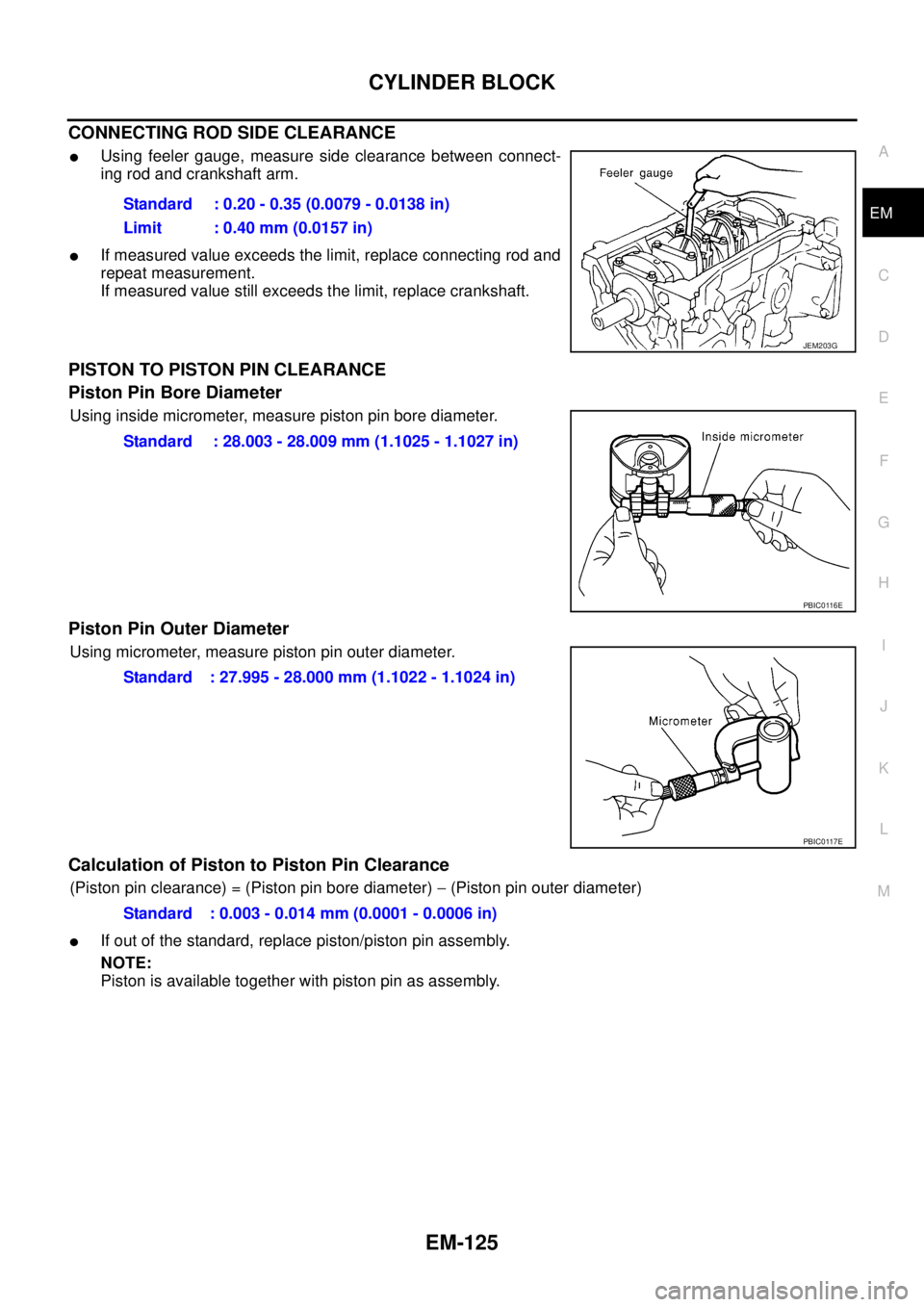

2. Identify the journal grade (No. 0, 1, or 2) on the front surface of

crankshaft, and locate the applicable grade under the “Grade”

column in the “Main Bearing Grade Table”.

3. The main bearing to be used (STD 0 to STD 4) can be located in the cell where the row and column cross.

When Re-using Removed Cylinder Block and Crankshaft

1. Measure the inner diameter of cylinder block main bearing housing. Refer toEM-128, "MAIN BEARING

HOUSING INNER DIAMETER".

2. Locate the applicable cell where the measurement falls, on “Inner diameter of Cylinder block main bearing

housing” row in the “Main Bearing Grade Table”.

3. Measure the outer diameter of crankshaft journal. Refer toEM-130, "

CRANKSHAFT MAIN JOURNAL

DIAMETER".

4. Locate the applicable cell where the measurement falls, under “Crankshaft journal outer diameter” column

in the “Main Bearing Grade Table”.

5. The main bearing to be used (STD 0 to STD 4) can be located in the cell where the row and column cross.

Main Bearing Grade Table

Unit: mm (in)

Standard dimension R : 1.5 - 1.7 mm (0.0591 - 0.0669 in)

JEM216G

JEM208G

JEM215G

Inner diameter of Cylinder block main bearing housing66.654 - 66.663

(2.6242 - 2.6245)66.663 - 66.672

(2.6245 - 2.6249)66.672 - 66.681

(2.6249 - 2.6252)

Crankshaft journal

outer diameterGrade

(punched)012

Page 1506 of 3171

EM-124

CYLINDER BLOCK

Under Size Bearing Usage

lIf bearing clearance is out of the specifications for main bearings in standard size, use under size bear-

ings.

lWhen using under size bearings, measure bearing inner diameter with bearing installed, and grind crank-

shaft journals to adjust clearance to the specification.

Main Bearing Under Size List

Unit: mm (in)

CAUTION:

When grinding crank journals to use under size bearings, keep

corners radius of fillet R. (All journals)

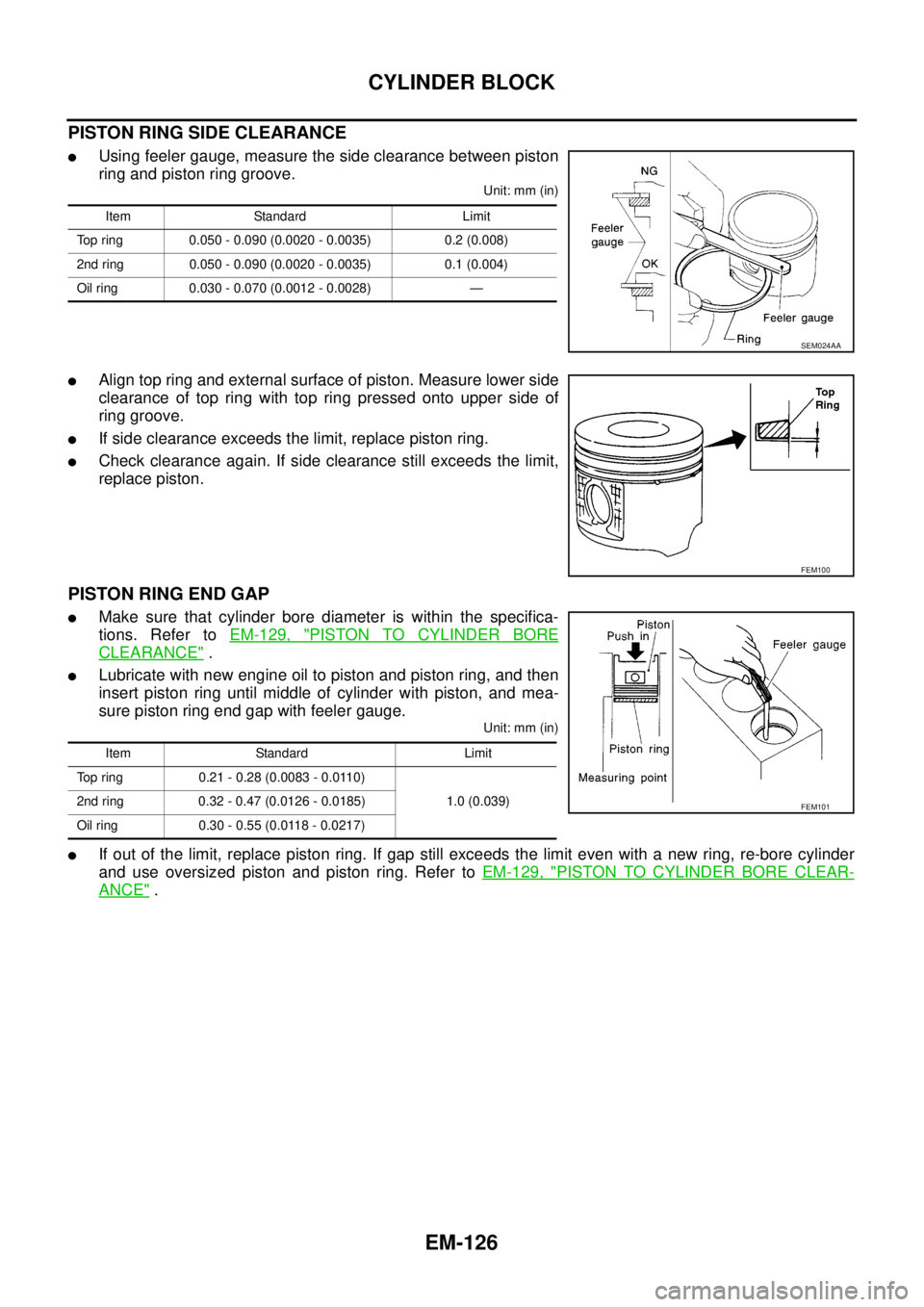

Inspection After DisassemblyEBS01E6G

CRANKSHAFT END PLAY

lUsing dial gauge, measure crankshaft travel amount by moving

the crankshaft forward or backward.

lIf the value exceeds the limit, replace thrust bearings with new

ones and measure again.

If the measurement exceeds the limit again, replace crankshaft

with a new one.

62.967 - 62.975

(2.4790 - 2.4793)0

lBearing grade No.

lBearing thickness

lOil clearance

lIdentification colorSTD 0

1.816 - 1.820

(0.0715 - 0.0717)

0.039 - 0.066

(0.0015 - 0.0026)

BlackSTD 1

1.820 - 1.824

(0.0717 - 0.0718)

0.039 - 0.066

(0.0015 - 0.0026)

BrownSTD 2

1.824 - 1.828

(0.0718 - 0.0720)

0.039 - 0.066

(0.0015 - 0.0026)

Green

62.959 - 62.967

(2.4787 - 2.6790)1

lBearing grade No.

lBearing thickness

lOil clearance

lIdentification colorSTD 1

1.820 - 1.824

(0.0717 - 0.0718)

0.039 - 0.066

(0.0015 - 0.0026)

BrownSTD 2

1.824 - 1.828

(0.0718 - 0.0720)

0.039 - 0.066

(0.0015 - 0.0026)

GreenSTD 3

1.828 - 1.832

(0.0720 - 0.0721)

0.039 - 0.066

(0.0015 - 0.0026)

Yellow

62.951 - 62.959

(2.4784 - 2.4787)2

lBearing grade No.

lBearing thickness

lOil clearance

lIdentification colorSTD 2

1.824 - 1.828

(0.0718 - 0.0720)

0.039 - 0.066

(0.0015 - 0.0026)

GreenSTD 3

1.828 - 1.832

(0.0720 - 0.0721)

0.039 - 0.066

(0.0015 - 0.0026)

YellowSTD 4

1.832 - 1.836

(0.0721 - 0.0723)

0.039 - 0.066

(0.0015 - 0.0026)

Blue

Size Thickness

US 0.25(0.0098) 1.949 - 1.953 (0.0767 - 0.0769)

Standard dimension R : 1.5 - 1.7 mm (0.0591 - 0.0669 in)

JEM216G

Standard : 0.10 - 0.25 mm (0.0039 - 0.0098 in)

Limit : 0.30 mm (0.0118 in)

JEM202G

Page 1507 of 3171

CYLINDER BLOCK

EM-125

C

D

E

F

G

H

I

J

K

L

MA

EM

CONNECTING ROD SIDE CLEARANCE

lUsing feeler gauge, measure side clearance between connect-

ing rod and crankshaft arm.

lIf measured value exceeds the limit, replace connecting rod and

repeat measurement.

If measured value still exceeds the limit, replace crankshaft.

PISTON TO PISTON PIN CLEARANCE

Piston Pin Bore Diameter

Using inside micrometer, measure piston pin bore diameter.

Piston Pin Outer Diameter

Using micrometer, measure piston pin outer diameter.

Calculation of Piston to Piston Pin Clearance

(Piston pin clearance) = (Piston pin bore diameter)-(Piston pin outer diameter)

lIf out of the standard, replace piston/piston pin assembly.

NOTE:

Piston is available together with piston pin as assembly.Standard : 0.20 - 0.35 (0.0079 - 0.0138 in)

Limit : 0.40 mm (0.0157 in)

JEM203G

Standard : 28.003 - 28.009 mm (1.1025 - 1.1027 in)

PBIC0116E

Standard : 27.995 - 28.000 mm (1.1022 - 1.1024 in)

PBIC0117E

Standard : 0.003 - 0.014 mm (0.0001 - 0.0006 in)

Page 1508 of 3171

EM-126

CYLINDER BLOCK

PISTON RING SIDE CLEARANCE

lUsing feeler gauge, measure the side clearance between piston

ringandpistonringgroove.

Unit: mm (in)

lAlign top ring and external surface of piston. Measure lower side

clearance of top ring with top ring pressed onto upper side of

ring groove.

lIf side clearance exceeds the limit, replace piston ring.

lCheck clearance again. If side clearance still exceeds the limit,

replace piston.

PISTON RING END GAP

lMake sure that cylinder bore diameter is within the specifica-

tions. Refer toEM-129, "

PISTON TO CYLINDER BORE

CLEARANCE".

lLubricate with new engine oil to piston and piston ring, and then

insert piston ring until middle of cylinder with piston, and mea-

sure piston ring end gap with feeler gauge.

Unit: mm (in)

lIf out of the limit, replace piston ring. If gap still exceeds the limit even with a new ring, re-bore cylinder

and use oversized piston and piston ring. Refer toEM-129, "

PISTON TO CYLINDER BORE CLEAR-

ANCE".

Item Standard Limit

Top ring 0.050 - 0.090 (0.0020 - 0.0035) 0.2 (0.008)

2nd ring 0.050 - 0.090 (0.0020 - 0.0035) 0.1 (0.004)

Oil ring 0.030 - 0.070 (0.0012 - 0.0028) —

SEM024AA

FEM100

Item Standard Limit

Top ring 0.21 - 0.28 (0.0083 - 0.0110)

1.0 (0.039) 2nd ring 0.32 - 0.47 (0.0126 - 0.0185)

Oil ring 0.30 - 0.55 (0.0118 - 0.0217)

FEM101

Page 1509 of 3171

CYLINDER BLOCK

EM-127

C

D

E

F

G

H

I

J

K

L

MA

EM

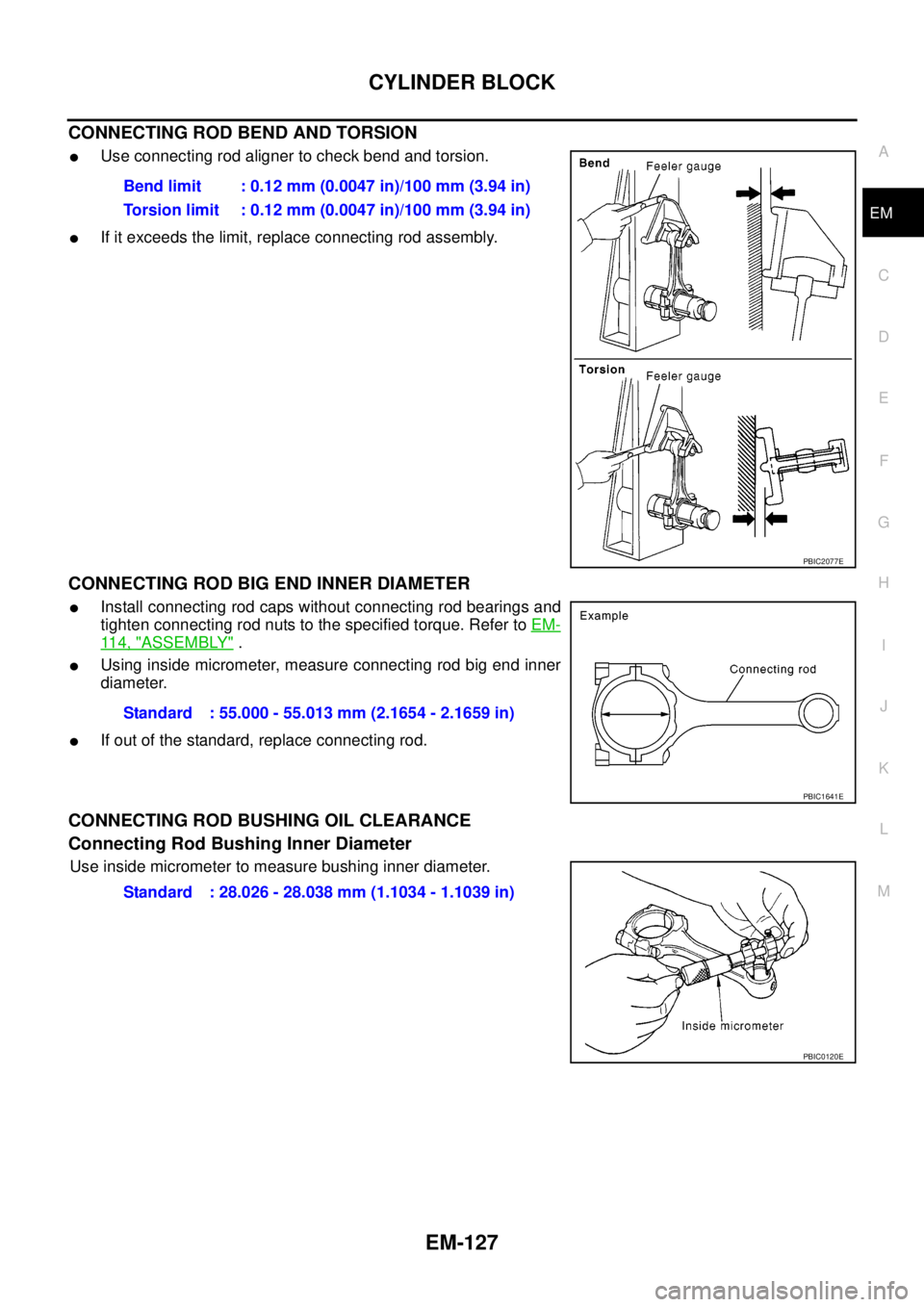

CONNECTING ROD BEND AND TORSION

lUse connecting rod aligner to check bend and torsion.

lIf it exceeds the limit, replace connecting rod assembly.

CONNECTING ROD BIG END INNER DIAMETER

lInstall connecting rod caps without connecting rod bearings and

tighten connecting rod nuts to the specified torque. Refer toEM-

11 4 , "ASSEMBLY".

lUsing inside micrometer, measure connecting rod big end inner

diameter.

lIf out of the standard, replace connecting rod.

CONNECTING ROD BUSHING OIL CLEARANCE

Connecting Rod Bushing Inner Diameter

Use inside micrometer to measure bushing inner diameter.Bend limit : 0.12 mm (0.0047 in)/100 mm (3.94 in)

Torsion limit : 0.12 mm (0.0047 in)/100 mm (3.94 in)

PBIC2077E

Standard : 55.000 - 55.013 mm (2.1654 - 2.1659 in)

PBIC1641E

Standard : 28.026 - 28.038 mm (1.1034 - 1.1039 in)

PBIC0120E

Page 1510 of 3171

EM-128

CYLINDER BLOCK

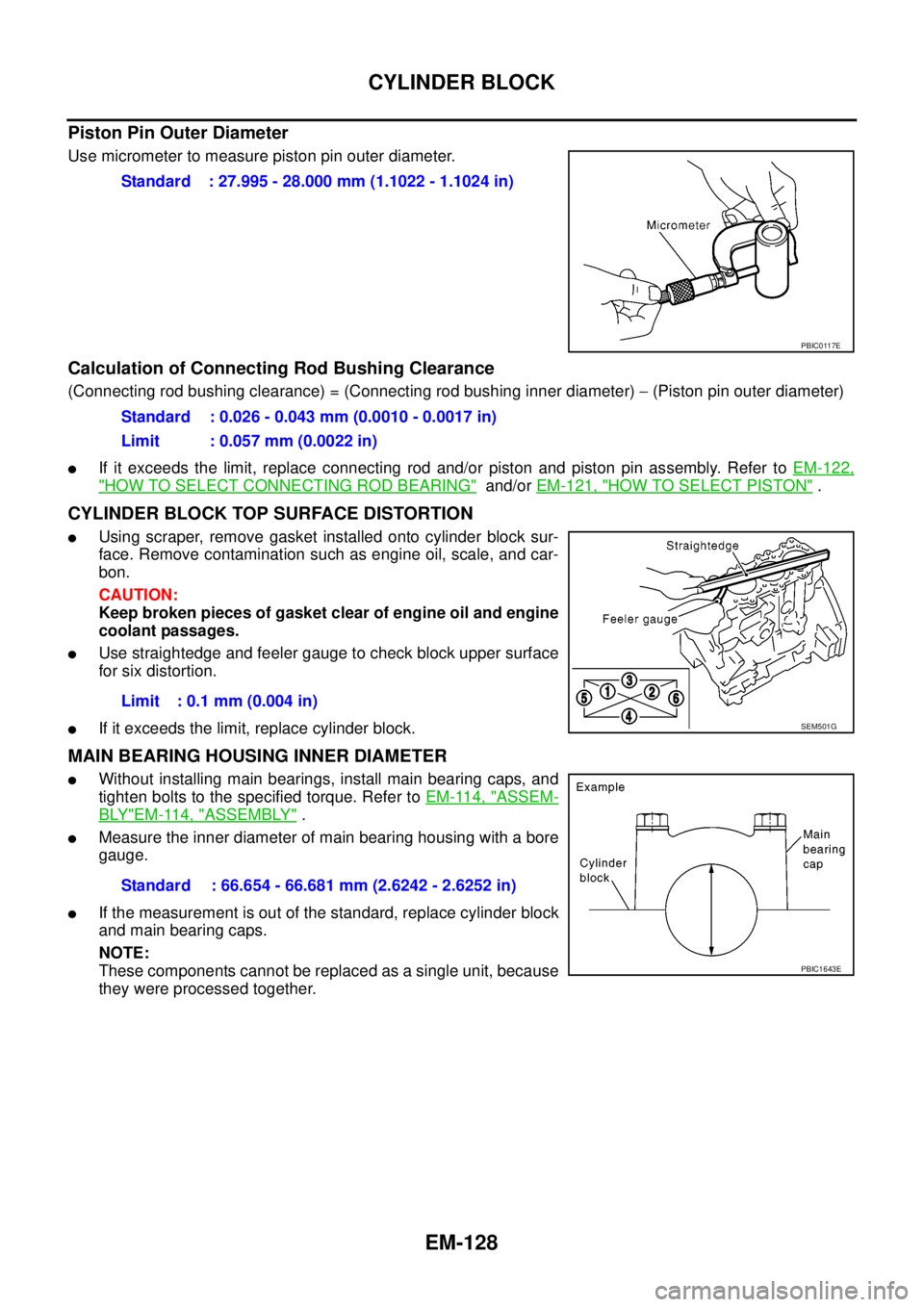

Piston Pin Outer Diameter

Use micrometer to measure piston pin outer diameter.

Calculation of Connecting Rod Bushing Clearance

(Connecting rod bushing clearance) = (Connecting rod bushing inner diameter)-(Piston pin outer diameter)

lIf it exceeds the limit, replace connecting rod and/or piston and piston pin assembly. Refer toEM-122,

"HOW TO SELECT CONNECTING ROD BEARING"and/orEM-121, "HOW TO SELECT PISTON".

CYLINDER BLOCK TOP SURFACE DISTORTION

lUsing scraper, remove gasket installed onto cylinder block sur-

face. Remove contamination such as engine oil, scale, and car-

bon.

CAUTION:

Keep broken pieces of gasket clear of engine oil and engine

coolant passages.

lUse straightedge and feeler gauge to check block upper surface

for six distortion.

lIf it exceeds the limit, replace cylinder block.

MAIN BEARING HOUSING INNER DIAMETER

lWithout installing main bearings, install main bearing caps, and

tighten bolts to the specified torque. Refer toEM-114, "

ASSEM-

BLY"EM-114, "ASSEMBLY".

lMeasure the inner diameter of main bearing housing with a bore

gauge.

lIf the measurement is out of the standard, replace cylinder block

andmainbearingcaps.

NOTE:

These components cannot be replaced as a single unit, because

they were processed together.Standard : 27.995 - 28.000 mm (1.1022 - 1.1024 in)

PBIC0117E

Standard : 0.026 - 0.043 mm (0.0010 - 0.0017 in)

Limit : 0.057 mm (0.0022 in)

Limit : 0.1 mm (0.004 in)

SEM501G

Standard : 66.654 - 66.681 mm (2.6242 - 2.6252 in)

PBIC1643E