NISSAN NAVARA 2005 Repair Workshop Manual

Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1471 of 3171

PRIMARY TIMING CHAIN

EM-89

C

D

E

F

G

H

I

J

K

L

MA

EM

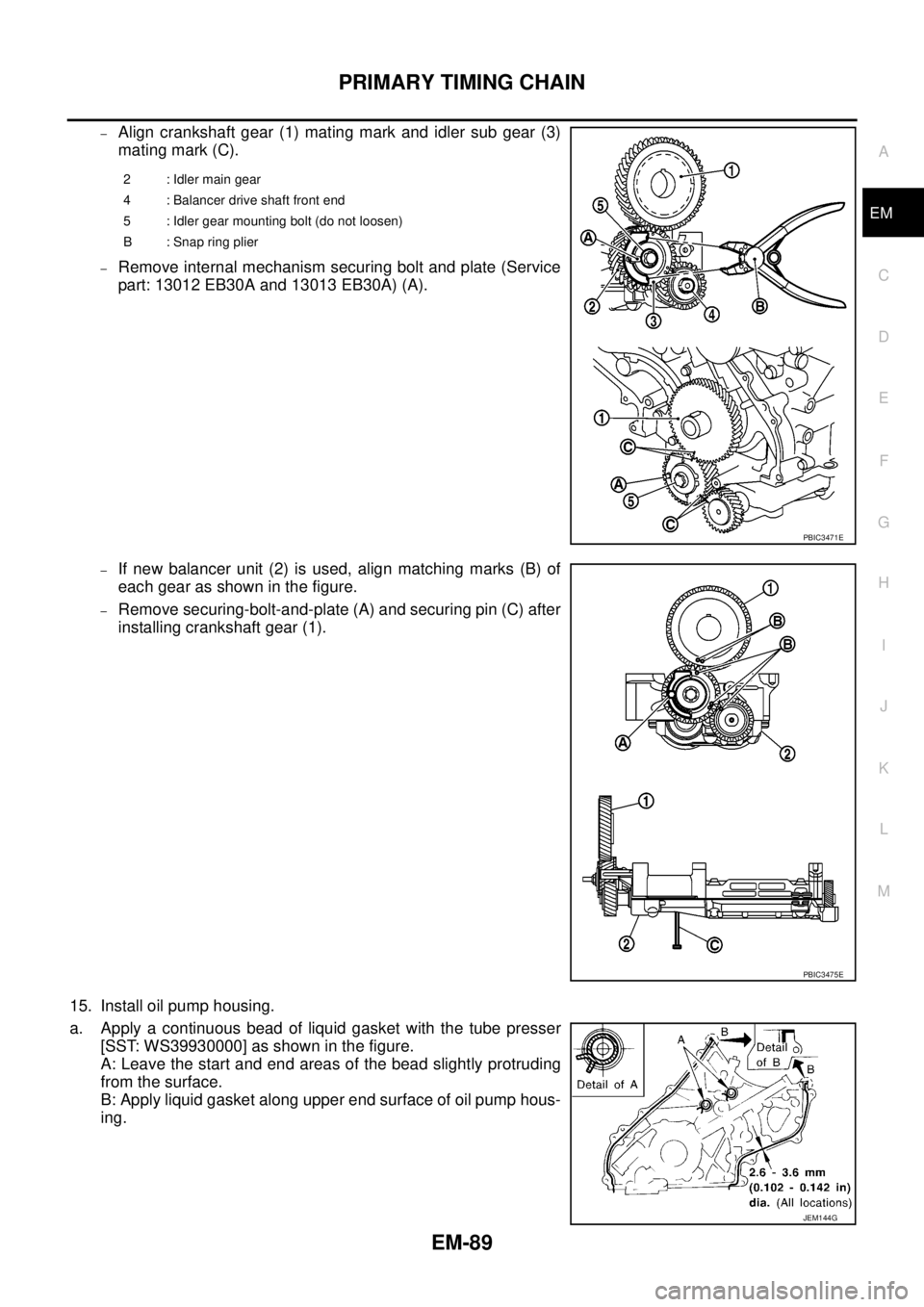

–Align crankshaft gear (1) mating mark and idler sub gear (3)

mating mark (C).

–Remove internal mechanism securing bolt and plate (Service

part: 13012 EB30A and 13013 EB30A) (A).

–If new balancer unit (2) is used, align matching marks (B) of

each gear as shown in the figure.

–Remove securing-bolt-and-plate (A) and securing pin (C) after

installing crankshaft gear (1).

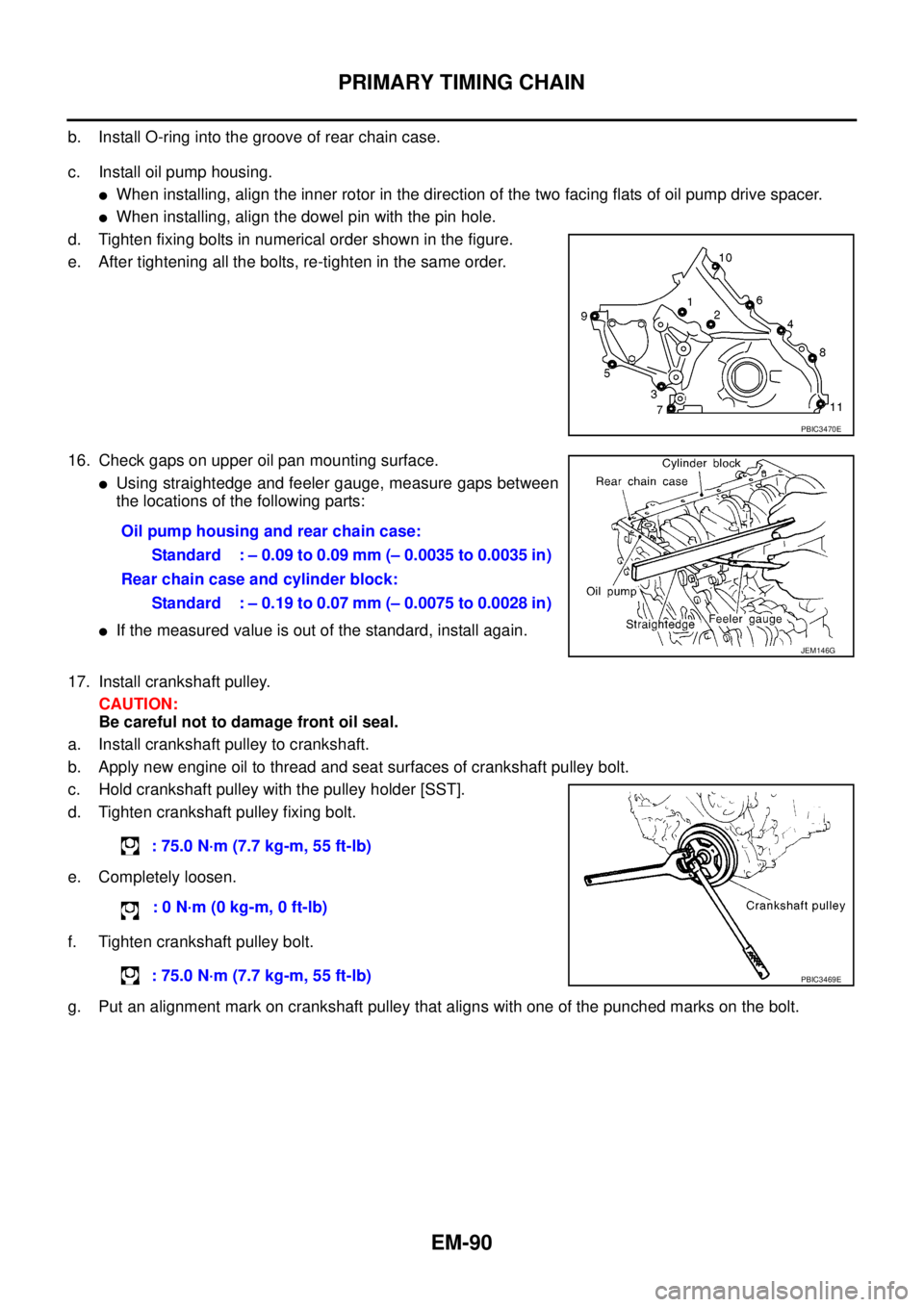

15. Install oil pump housing.

a. Apply a continuous bead of liquid gasket with the tube presser

[SST: WS39930000] as shown in the figure.

A: Leave the start and end areas of the bead slightly protruding

from the surface.

B: Apply liquid gasket along upper end surface of oil pump hous-

ing.

2 : Idler main gear

4 : Balancer drive shaft front end

5 : Idler gear mounting bolt (do not loosen)

B : Snap ring plier

PBIC3471E

PBIC3475E

JEM144G

Page 1472 of 3171

EM-90

PRIMARY TIMING CHAIN

b. Install O-ring into the groove of rear chain case.

c. Install oil pump housing.

lWhen installing, align the inner rotor in the direction of the two facing flats of oil pump drive spacer.

lWhen installing, align the dowel pin with the pin hole.

d. Tighten fixing bolts in numerical order shown in the figure.

e. After tightening all the bolts, re-tighten in the same order.

16. Check gaps on upper oil pan mounting surface.

lUsing straightedge and feeler gauge, measure gaps between

the locations of the following parts:

lIf the measured value is out of the standard, install again.

17. Install crankshaft pulley.

CAUTION:

Be careful not to damage front oil seal.

a. Install crankshaft pulley to crankshaft.

b. Apply new engine oil to thread and seat surfaces of crankshaft pulley bolt.

c. Hold crankshaft pulley with the pulley holder [SST].

d. Tighten crankshaft pulley fixing bolt.

e. Completely loosen.

f. Tighten crankshaft pulley bolt.

g. Put an alignment mark on crankshaft pulley that aligns with one of the punched marks on the bolt.

PBIC3470E

Oil pump housing and rear chain case:

Standard : – 0.09 to 0.09 mm (– 0.0035 to 0.0035 in)

Rear chain case and cylinder block:

Standard : – 0.19 to 0.07 mm (– 0.0075 to 0.0028 in)

JEM146G

: 75.0 N·m (7.7 kg-m, 55 ft-lb)

:0N·m(0kg-m,0ft-lb)

: 75.0 N·m (7.7 kg-m, 55 ft-lb)

PBIC3469E

Page 1473 of 3171

PRIMARY TIMING CHAIN

EM-91

C

D

E

F

G

H

I

J

K

L

MA

EM

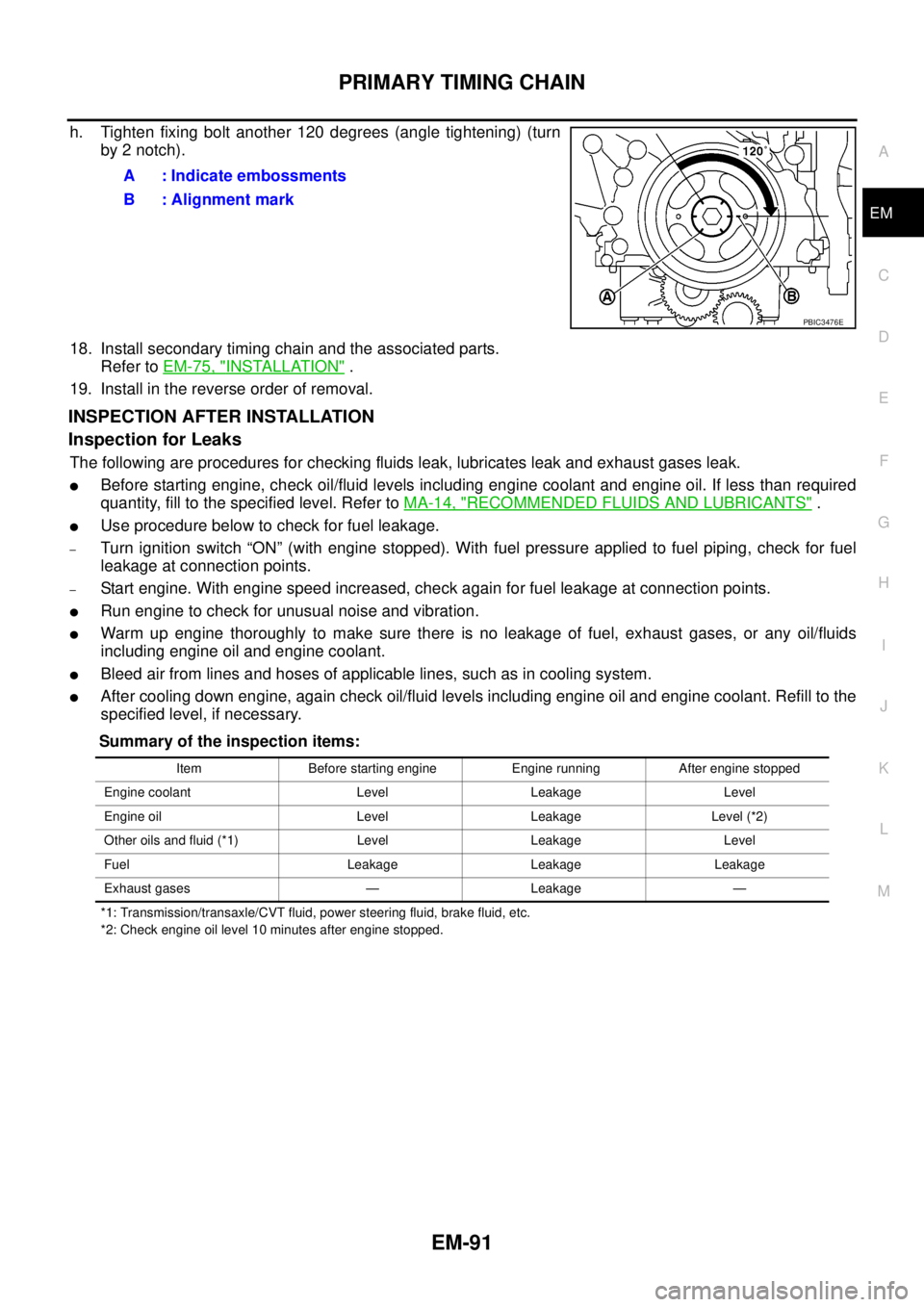

h. Tighten fixing bolt another 120 degrees (angle tightening) (turn

by 2 notch).

18. Install secondary timing chain and the associated parts.

Refer toEM-75, "

INSTALLATION".

19. Install in the reverse order of removal.

INSPECTION AFTER INSTALLATION

Inspection for Leaks

The following are procedures for checking fluids leak, lubricates leak and exhaust gases leak.

lBefore starting engine, check oil/fluid levels including engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer toMA-14, "

RECOMMENDED FLUIDS AND LUBRICANTS".

lUse procedure below to check for fuel leakage.

–Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel

leakage at connection points.

–Start engine. With engine speed increased, check again for fuel leakage at connection points.

lRun engine to check for unusual noise and vibration.

lWarm up engine thoroughly to make sure there is no leakage of fuel, exhaust gases, or any oil/fluids

including engine oil and engine coolant.

lBleed air from lines and hoses of applicable lines, such as in cooling system.

lAfter cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the

specified level, if necessary.

Summary of the inspection items:

*1: Transmission/transaxle/CVT fluid, power steering fluid, brake fluid, etc.

*2: Check engine oil level 10 minutes after engine stopped.

A : Indicate embossments

B : Alignment mark

PBIC3476E

Item Before starting engine Engine running After engine stopped

Engine coolant Level Leakage Level

Engine oil Level Leakage Level (*2)

Other oils and fluid (*1) Level Leakage Level

Fuel Leakage Leakage Leakage

Exhaust gases — Leakage —

Page 1474 of 3171

EM-92

CYLINDER HEAD

CYLINDER HEAD

PFP:11041

On-Vehicle ServiceEBS01E6A

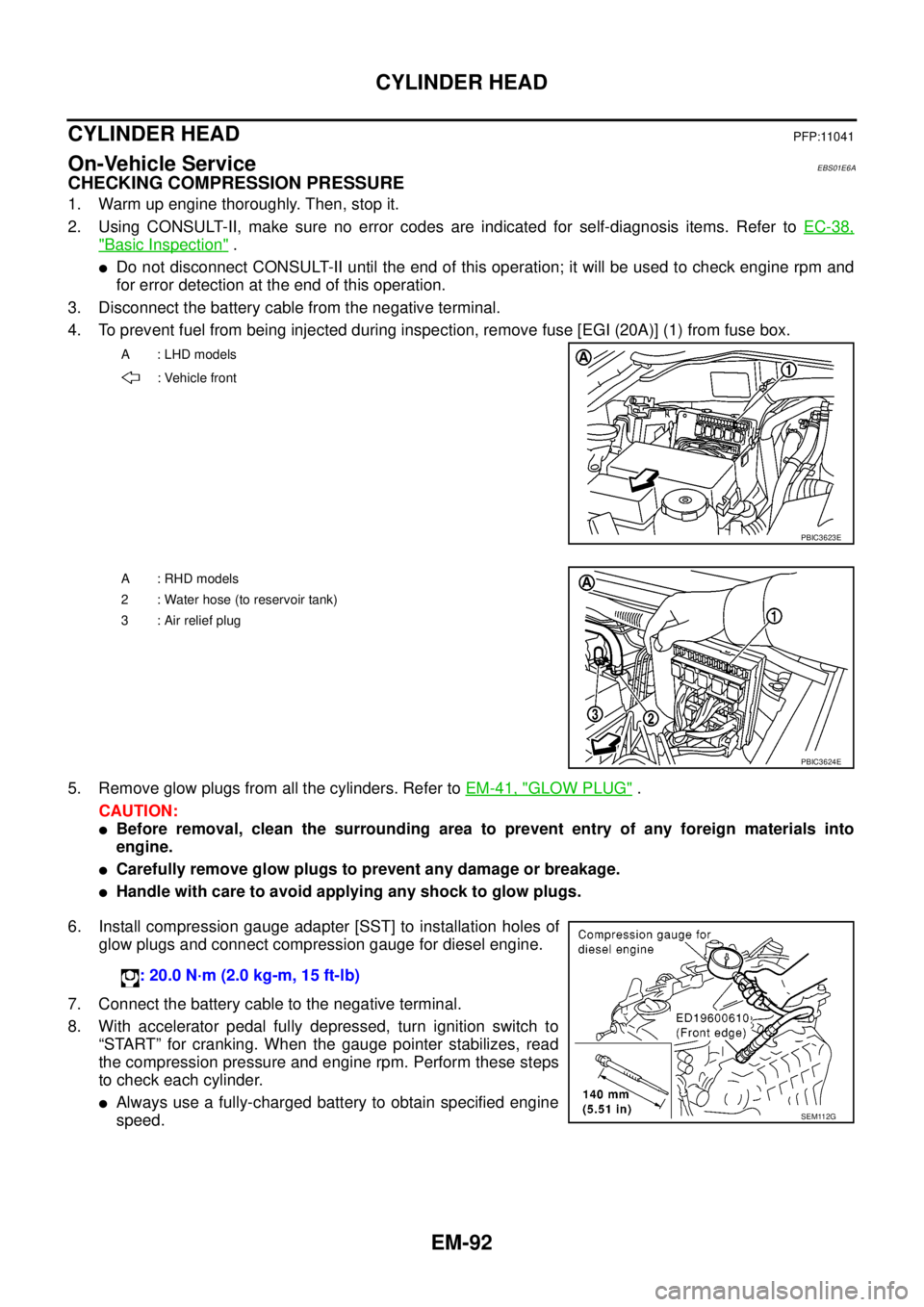

CHECKING COMPRESSION PRESSURE

1. Warm up engine thoroughly. Then, stop it.

2. Using CONSULT-II, make sure no error codes are indicated for self-diagnosis items. Refer toEC-38,

"Basic Inspection".

lDo not disconnect CONSULT-II until the end of this operation; it will be used to check engine rpm and

for error detection at the end of this operation.

3. Disconnect the battery cable from the negative terminal.

4. To prevent fuel from being injected during inspection, remove fuse [EGI (20A)] (1) from fuse box.

5. Remove glow plugs from all the cylinders. Refer toEM-41, "

GLOW PLUG".

CAUTION:

lBefore removal, clean the surrounding area to prevent entry of any foreign materials into

engine.

lCarefully remove glow plugs to prevent any damage or breakage.

lHandle with care to avoid applying any shock to glow plugs.

6. Install compression gauge adapter [SST] to installation holes of

glow plugs and connect compression gauge for diesel engine.

7. Connect the battery cable to the negative terminal.

8. With accelerator pedal fully depressed, turn ignition switch to

“START” for cranking. When the gauge pointer stabilizes, read

the compression pressure and engine rpm. Perform these steps

to check each cylinder.

lAlways use a fully-charged battery to obtain specified engine

speed.

A : LHD models

: Vehicle front

PBIC3623E

A : RHD models

2 : Water hose (to reservoir tank)

3:Airreliefplug

PBIC3624E

: 20.0 N·m (2.0 kg-m, 15 ft-lb)

SEM112G

Page 1475 of 3171

CYLINDER HEAD

EM-93

C

D

E

F

G

H

I

J

K

L

MA

EM

Compression pressure

Unit: kPa (bar, kg/cm2, psi)/rpm

lWhen engine rpm is out of the specified range, check the specific gravity of battery liquid. Measure

again under corrected conditions.

lIf engine rpm exceeds the limit, check valve clearance and combustion chamber components (valves,

valve seats, cylinder head gaskets, piston rings, pistons, cylinder bores, cylinder block upper and lower

surfaces) and measure again.

lIf compression pressure is low in some cylinders, apply engine oil from glow plug installation hole. Then

check pressure again.

–If compression pressure becomes normal after applying engine oil, piston ring may be worn or dam-

aged. Check piston ring for malfunction. If any, replace piston ring.

–If compression pressure is still low after applying engine oil, valve may be malfunctioning. Check valve

for malfunction. If contact malfunction is found, replace valve or valve seat.

lIf compression pressure in adjacent two cylinders is low after applying engine oil, pressure may be

leaking from gasket. In this case, replace cylinder head gasket.

9. Complete this operation as follows:

a. Turn the ignition switch to “OFF”.

b. Disconnect the battery cable from the negative terminal.

c. Install glow plug and install all the parts removed in step 4.

d. Install fuse [EGI (20A)].

e. Connect the battery cable to the negative terminal.

f. Using CONSULT-II make sure no DTC is indicated for items of self-diagnosis.

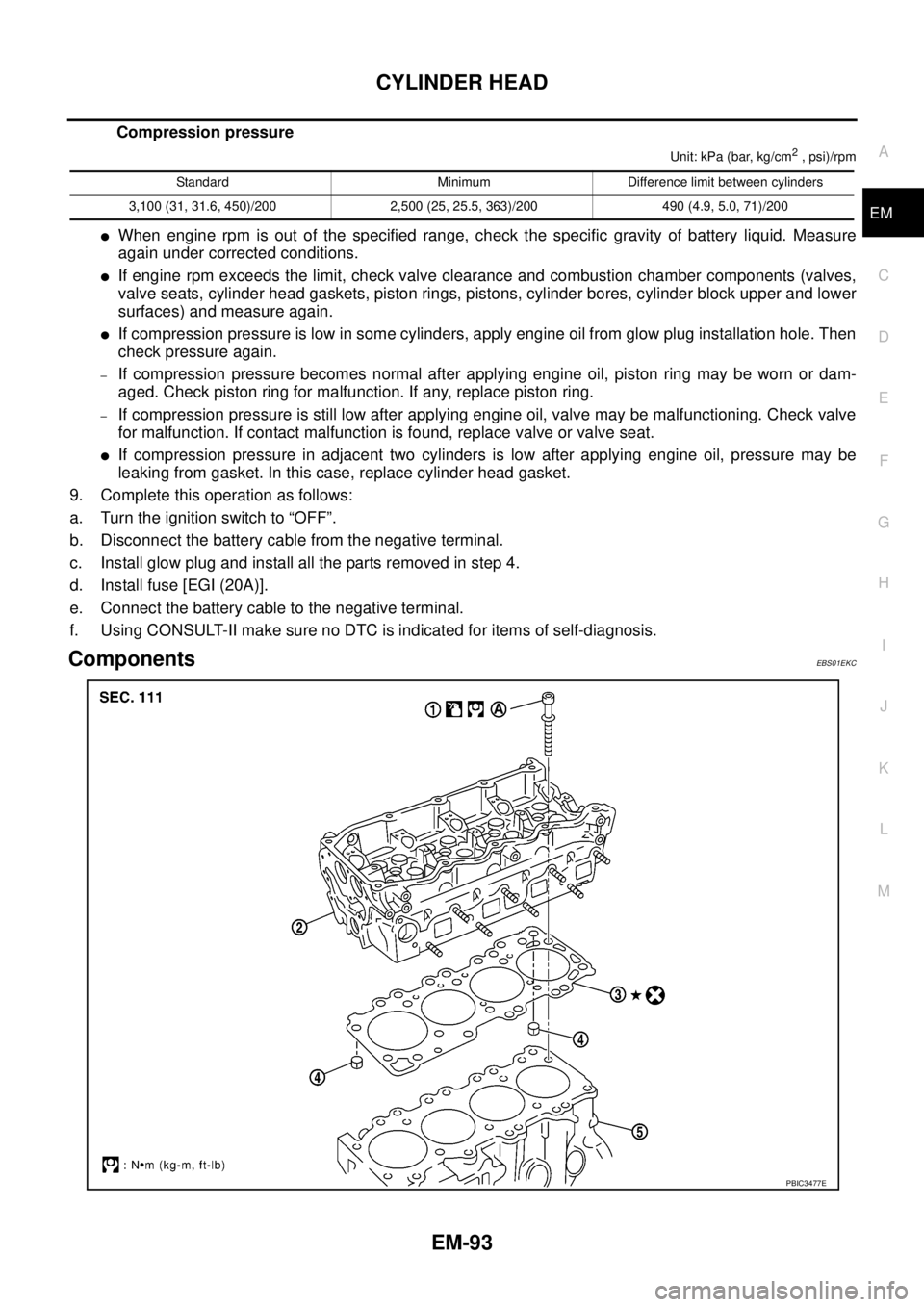

ComponentsEBS01EKC

Standard Minimum Difference limit between cylinders

3,100 (31, 31.6, 450)/200 2,500 (25, 25.5, 363)/200 490 (4.9, 5.0, 71)/200

PBIC3477E

Page 1476 of 3171

EM-94

CYLINDER HEAD

lRefer toGI-10, "Components"for symbol marks in the figure.

Removal and InstallationEBS01E6B

REMOVAL

1. Drain engine coolant. Refer toCO-7, "Changing Engine Coolant".

2. Remove the following:

lRocker cover (Refer toEM-56, "ROCKER COVER".)

lSpill tube and fuel injector (Refer toEM-44, "INJECTION TUBE AND FUEL INJECTOR".)

lIntake manifold (Refer toEM-20, "INTAKE MANIFOLD".)

lTurbocharger (Refer toEM-28, "TURBO CHARGER".)

lExhaust manifold (Refer toEM-34, "EXHAUST MANIFOLD".)

lSecondary timing chain (Refer toEM-73, "SECONDARY TIMING CHAIN".)

lCamshaft (Refer toEM-59, "CAMSHAFT".)

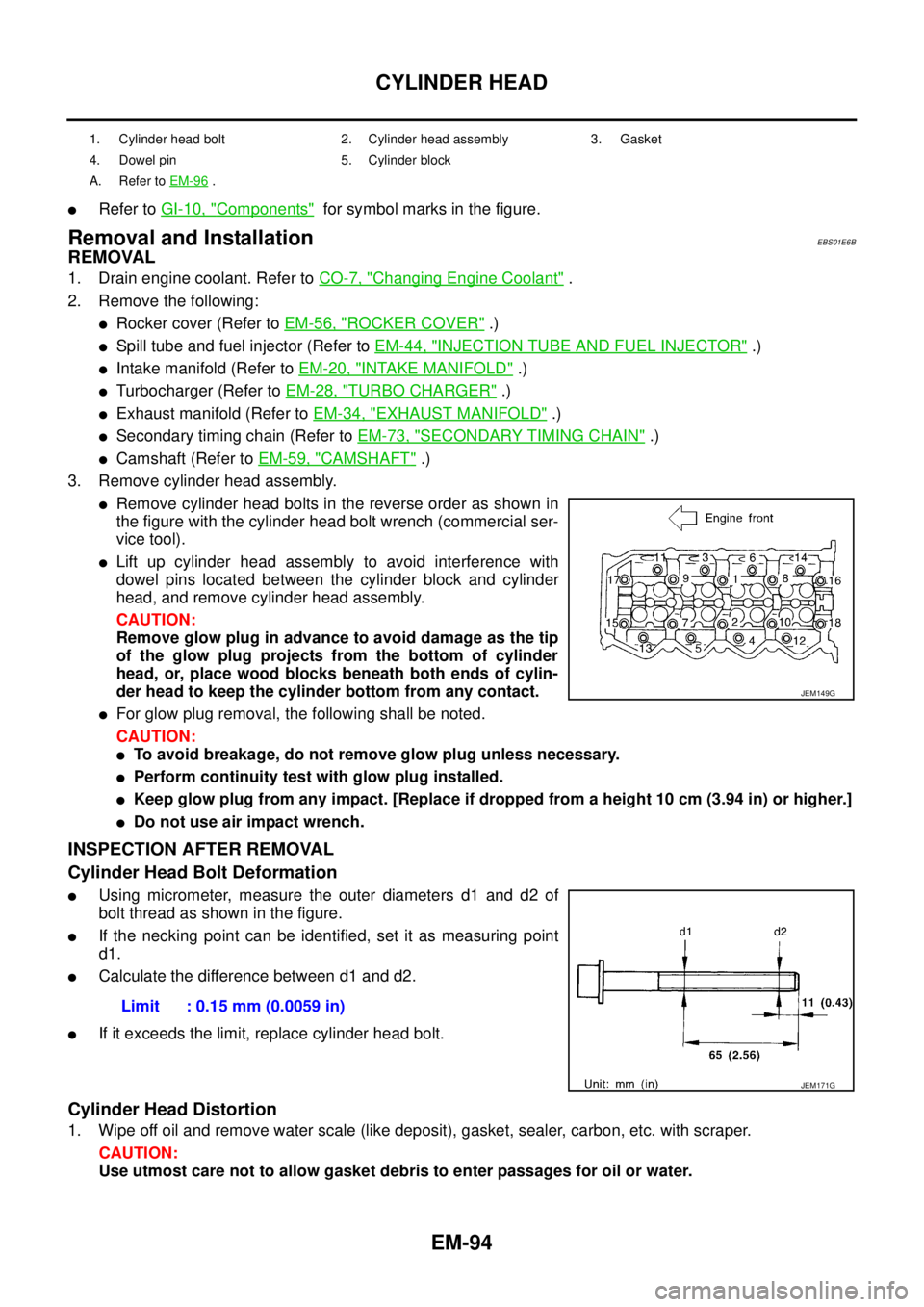

3. Remove cylinder head assembly.

lRemove cylinder head bolts in the reverse order as shown in

the figure with the cylinder head bolt wrench (commercial ser-

vice tool).

lLift up cylinder head assembly to avoid interference with

dowel pins located between the cylinder block and cylinder

head, and remove cylinder head assembly.

CAUTION:

Remove glow plug in advance to avoid damage as the tip

of the glow plug projects from the bottom of cylinder

head, or, place wood blocks beneath both ends of cylin-

der head to keep the cylinder bottom from any contact.

lFor glow plug removal, the following shall be noted.

CAUTION:

lTo avoid breakage, do not remove glow plug unless necessary.

lPerform continuity test with glow plug installed.

lKeep glow plug from any impact. [Replace if dropped from a height 10 cm (3.94 in) or higher.]

lDo not use air impact wrench.

INSPECTION AFTER REMOVAL

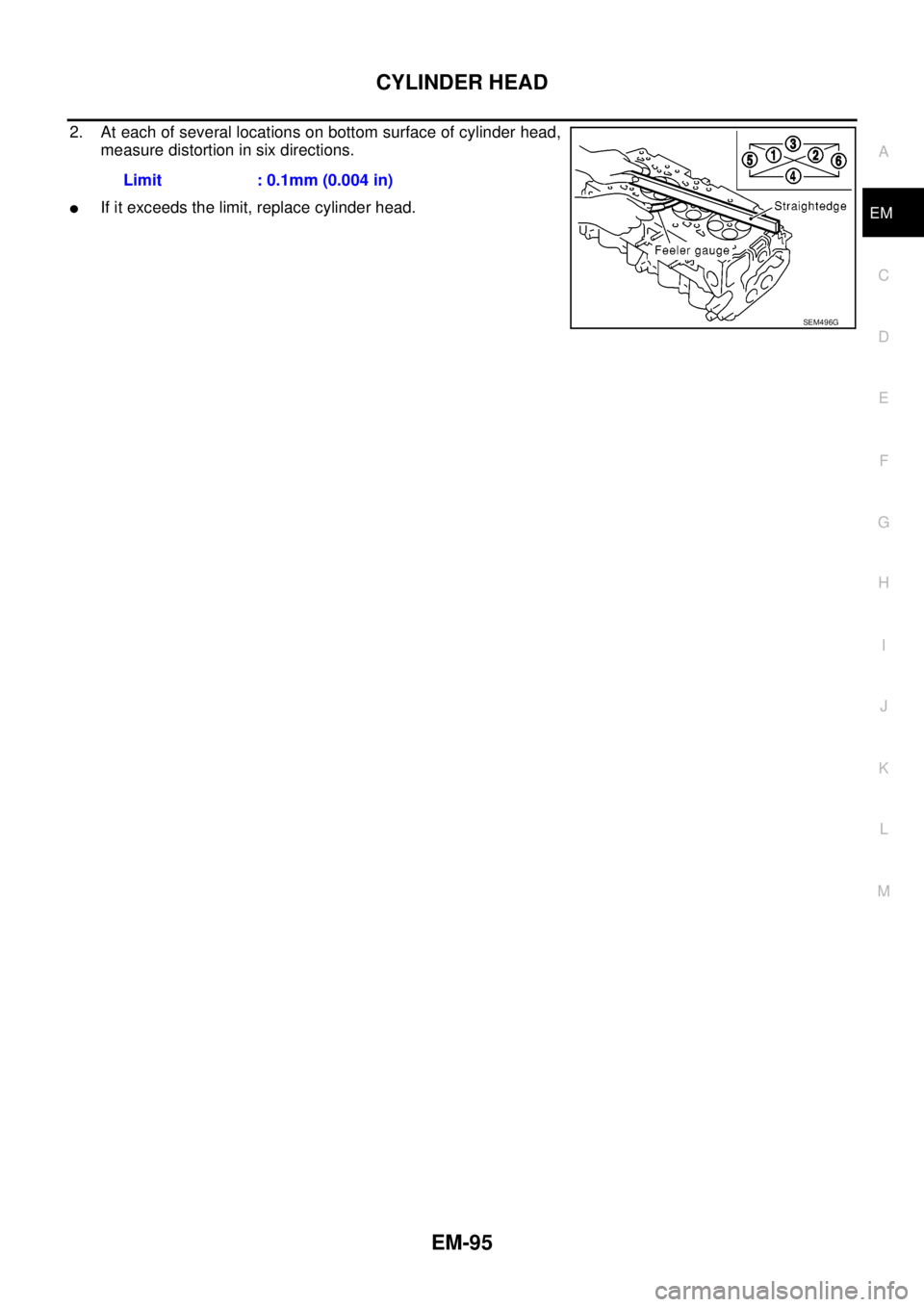

Cylinder Head Bolt Deformation

lUsing micrometer, measure the outer diameters d1 and d2 of

bolt thread as shown in the figure.

lIf the necking point can be identified, set it as measuring point

d1.

lCalculate the difference between d1 and d2.

lIf it exceeds the limit, replace cylinder head bolt.

Cylinder Head Distortion

1. Wipe off oil and remove water scale (like deposit), gasket, sealer, carbon, etc. with scraper.

CAUTION:

Use utmost care not to allow gasket debris to enter passages for oil or water.

1. Cylinder head bolt 2. Cylinder head assembly 3. Gasket

4. Dowel pin 5. Cylinder block

A. Refer toEM-96

.

JEM149G

Limit : 0.15 mm (0.0059 in)

JEM171G

Page 1477 of 3171

CYLINDER HEAD

EM-95

C

D

E

F

G

H

I

J

K

L

MA

EM

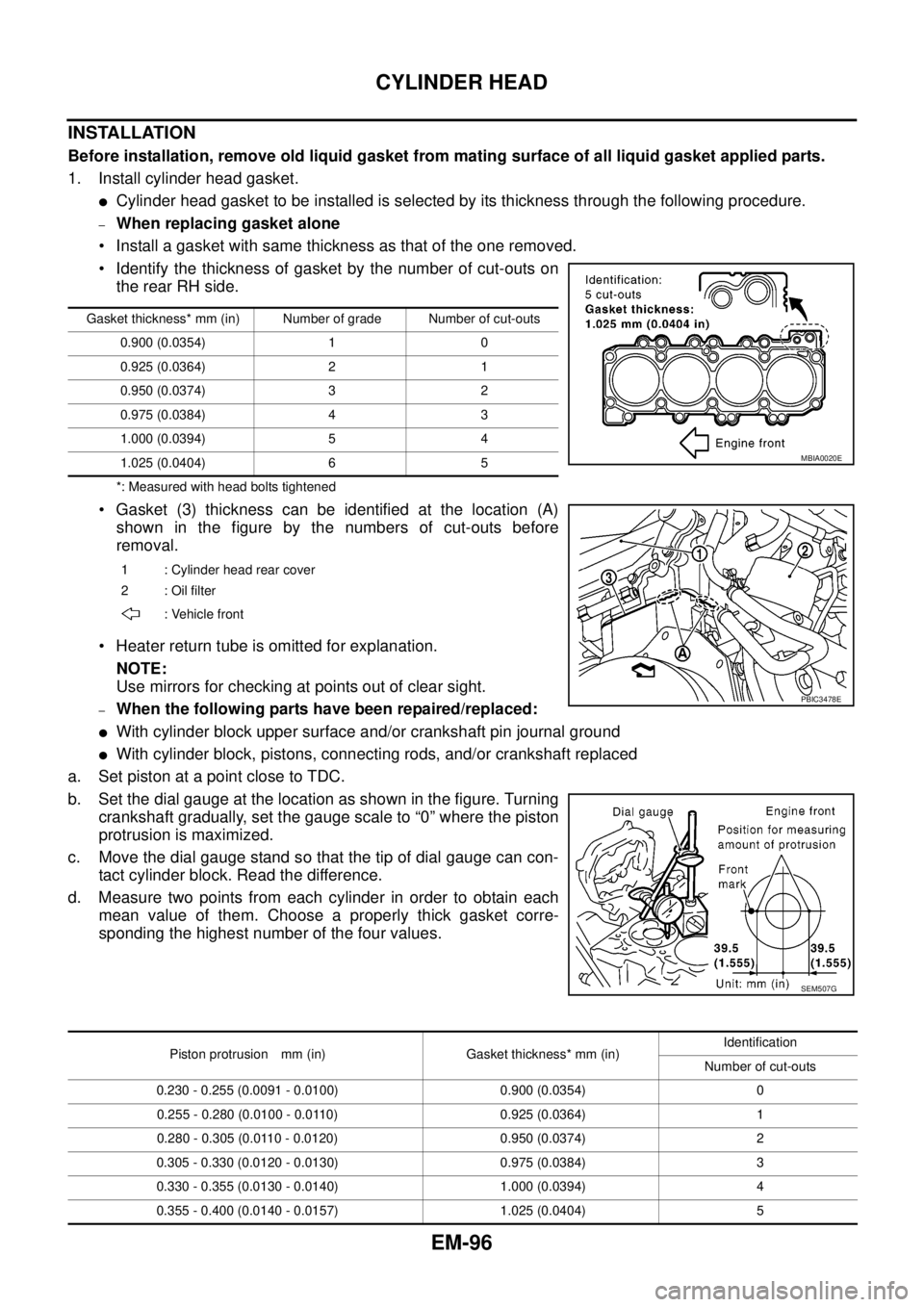

2. At each of several locations on bottom surface of cylinder head,

measure distortion in six directions.

lIf it exceeds the limit, replace cylinder head.Limit : 0.1mm (0.004 in)

SEM496G

Page 1478 of 3171

EM-96

CYLINDER HEAD

INSTALLATION

Before installation, remove old liquid gasket from mating surface of all liquid gasket applied parts.

1. Install cylinder head gasket.

lCylinder head gasket to be installed is selected by its thickness through the following procedure.

–When replacing gasket alone

• Install a gasket with same thickness as that of the one removed.

• Identify the thickness of gasket by the number of cut-outs on

the rear RH side.

*: Measured with head bolts tightened

• Gasket (3) thickness can be identified at the location (A)

shown in the figure by the numbers of cut-outs before

removal.

• Heater return tube is omitted for explanation.

NOTE:

Use mirrors for checking at points out of clear sight.

–When the following parts have been repaired/replaced:

lWith cylinder block upper surface and/or crankshaft pin journal ground

lWith cylinder block, pistons, connecting rods, and/or crankshaft replaced

a. Set piston at a point close to TDC.

b. Set the dial gauge at the location as shown in the figure. Turning

crankshaft gradually, set the gauge scale to “0” where the piston

protrusion is maximized.

c. Movethedialgaugestandsothatthetipofdialgaugecancon-

tact cylinder block. Read the difference.

d. Measure two points from each cylinder in order to obtain each

mean value of them. Choose a properly thick gasket corre-

sponding the highest number of the four values.

Gasket thickness* mm (in) Number of grade Number of cut-outs

0.900 (0.0354) 1 0

0.925 (0.0364) 2 1

0.950 (0.0374) 3 2

0.975 (0.0384) 4 3

1.000 (0.0394) 5 4

1.025 (0.0404) 6 5

1 : Cylinder head rear cover

2:Oilfilter

: Vehicle front

MBIA0020E

PBIC3478E

SEM507G

Piston protrusion mm (in) Gasket thickness* mm (in)Identification

Number of cut-outs

0.230 - 0.255 (0.0091 - 0.0100) 0.900 (0.0354) 0

0.255 - 0.280 (0.0100 - 0.0110) 0.925 (0.0364) 1

0.280 - 0.305 (0.0110 - 0.0120) 0.950 (0.0374) 2

0.305 - 0.330 (0.0120 - 0.0130) 0.975 (0.0384) 3

0.330 - 0.355 (0.0130 - 0.0140) 1.000 (0.0394) 4

0.355 - 0.400 (0.0140 - 0.0157) 1.025 (0.0404) 5

Page 1479 of 3171

CYLINDER HEAD

EM-97

C

D

E

F

G

H

I

J

K

L

MA

EM

*: Measured with head bolts tightened

e. If out of above protrusion, check replaced parts.

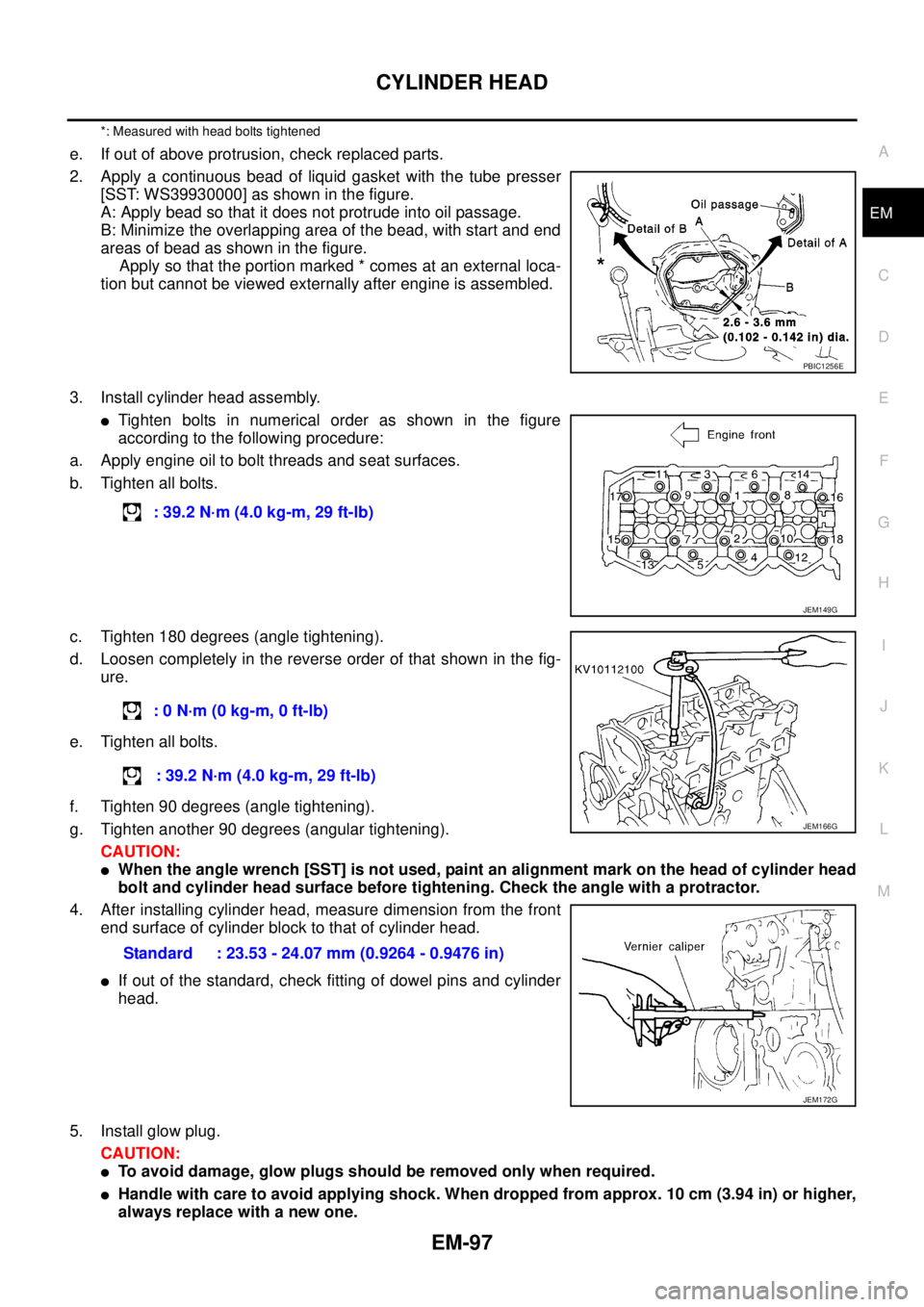

2. Apply a continuous bead of liquid gasket with the tube presser

[SST: WS39930000] as shown in the figure.

A: Apply bead so that it does not protrude into oil passage.

B: Minimize the overlapping area of the bead, with start and end

areas of bead as shown in the figure.

Apply so that the portion marked * comes at an external loca-

tion but cannot be viewed externally after engine is assembled.

3. Install cylinder head assembly.

lTighten bolts in numerical order as shown in the figure

according to the following procedure:

a. Apply engine oil to bolt threads and seat surfaces.

b. Tighten all bolts.

c. Tighten 180 degrees (angle tightening).

d. Loosen completely in the reverse order of that shown in the fig-

ure.

e. Tighten all bolts.

f. Tighten 90 degrees (angle tightening).

g. Tighten another 90 degrees (angular tightening).

CAUTION:

lWhen the angle wrench [SST] is not used, paint an alignment mark on the head of cylinder head

bolt and cylinder head surface before tightening. Check the angle with a protractor.

4. After installing cylinder head, measure dimension from the front

end surface of cylinder block to that of cylinder head.

lIf out of the standard, check fitting of dowel pins and cylinder

head.

5. Install glow plug.

CAUTION:

lTo avoid damage, glow plugs should be removed only when required.

lHandle with care to avoid applying shock. When dropped from approx. 10 cm (3.94 in) or higher,

always replace with a new one.

PBIC1256E

: 39.2 N·m (4.0 kg-m, 29 ft-lb)

JEM149G

:0N·m(0kg-m,0ft-lb)

: 39.2 N·m (4.0 kg-m, 29 ft-lb)

Standard : 23.53 - 24.07 mm (0.9264 - 0.9476 in)

JEM166G

JEM172G

Page 1480 of 3171

EM-98

CYLINDER HEAD

lBefore installing, remove carbon depositing on mounting hole of glow plug with a reamer.

6. Install engine coolant temperature sensor.

7. Install in the reverse order of removal.

INSPECTION AFTER INSTALLATION

Inspection for Leaks

The following are procedures for checking fluids leak, lubricates leak and exhaust gases leak.

lBefore starting engine, check oil/fluid levels including engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer toMA-14, "

RECOMMENDED FLUIDS AND LUBRICANTS".

lUse procedure below to check for fuel leakage.

–Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel

leakage at connection points.

–Start engine. With engine speed increased, check again for fuel leakage at connection points.

lRun engine to check for unusual noise and vibration.

lWarm up engine thoroughly to make sure there is no leakage of fuel, exhaust gases, or any oil/fluids

including engine oil and engine coolant.

lBleed air from lines and hoses of applicable lines, such as in cooling system.

lAfter cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the

specified level, if necessary.

Summary of the inspection items:

*1: Transmission/transaxle/CVT fluid, power steering fluid, brake fluid, etc.

*2: Check engine oil level 10 minutes after engine stopped.Item Before starting engine Engine running After engine stopped

Engine coolant Level Leakage Level

Engine oil Level Leakage Level (*2)

Other oils and fluid (*1) Level Leakage Level

Fuel Leakage Leakage Leakage

Exhaust gases — Leakage —