belt NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2961 of 3171

SRS-52

DISPOSAL OF AIR BAG MODULE AND SEAT BELT PRE-TENSIONER

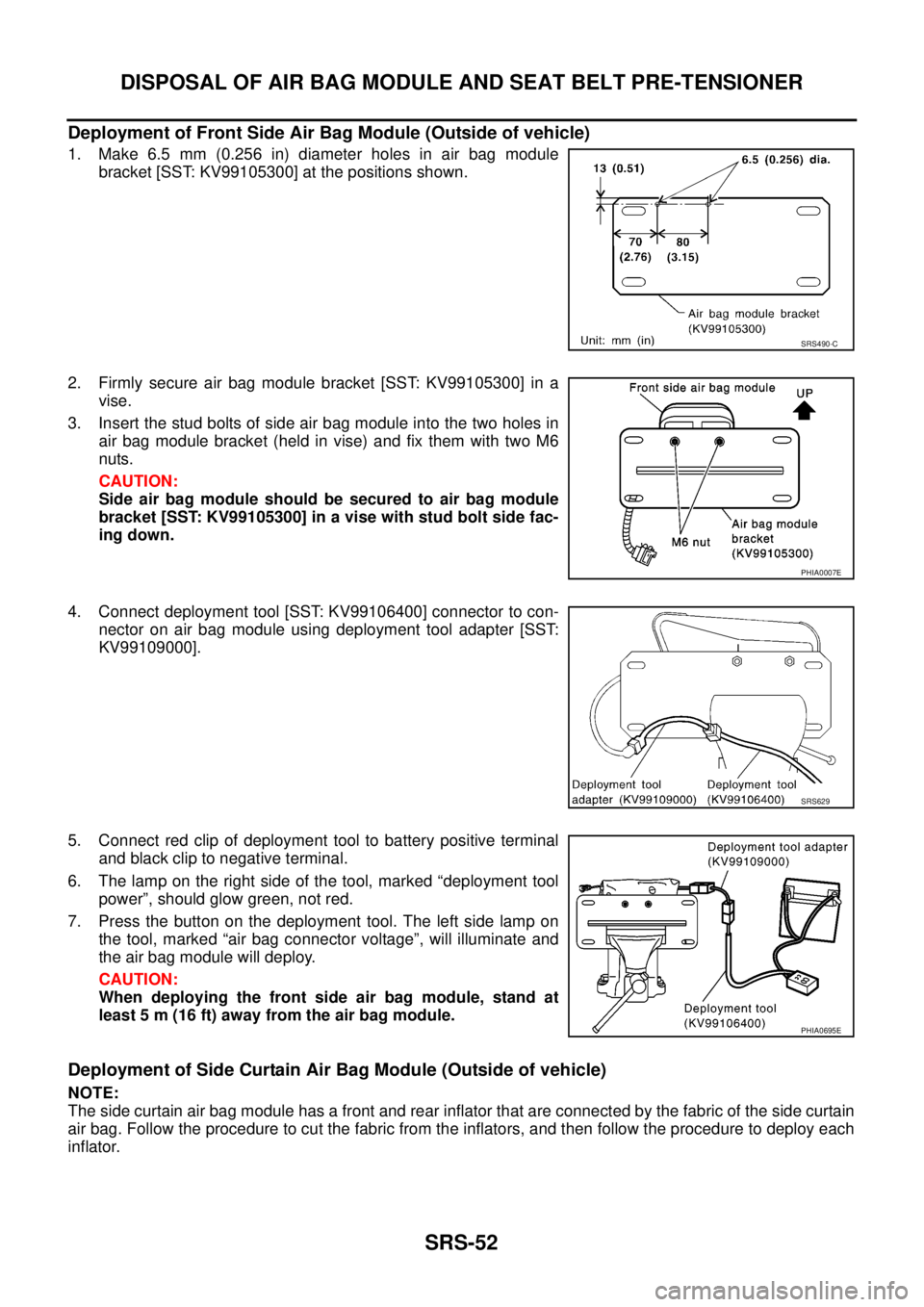

Deployment of Front Side Air Bag Module (Outside of vehicle)

1. Make 6.5 mm (0.256 in) diameter holes in air bag module

bracket [SST: KV99105300] at the positions shown.

2. Firmly secure air bag module bracket [SST: KV99105300] in a

vise.

3. Insert the stud bolts of side air bag module into the two holes in

air bag module bracket (held in vise) and fix them with two M6

nuts.

CAUTION:

Side air bag module should be secured to air bag module

bracket [SST: KV99105300] in a vise with stud bolt side fac-

ing down.

4. Connect deployment tool [SST: KV99106400] connector to con-

nector on air bag module using deployment tool adapter [SST:

KV99109000].

5. Connect red clip of deployment tool to battery positive terminal

and black clip to negative terminal.

6. The lamp on the right side of the tool, marked “deployment tool

power”, should glow green, not red.

7. Press the button on the deployment tool. The left side lamp on

the tool, marked “air bag connector voltage”, will illuminate and

the air bag module will deploy.

CAUTION:

When deploying the front side air bag module, stand at

least 5 m (16 ft) away from the air bag module.

Deployment of Side Curtain Air Bag Module (Outside of vehicle)

NOTE:

The side curtain air bag module has a front and rear inflator that are connected by the fabric of the side curtain

air bag. Follow the procedure to cut the fabric from the inflators, and then follow the procedure to deploy each

inflator.

SRS490-C

PHIA0007E

SRS629

PHIA0695E

Page 2962 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual DISPOSAL OF AIR BAG MODULE AND SEAT BELT PRE-TENSIONER

SRS-53

C

D

E

F

G

I

J

K

L

MA

B

SRS

1. Cut the inflator from side curtain air bag module.

2. Connect deployment tool [SST: KV99106400] to the infla NISSAN NAVARA 2005 Repair Workshop Manual DISPOSAL OF AIR BAG MODULE AND SEAT BELT PRE-TENSIONER

SRS-53

C

D

E

F

G

I

J

K

L

MA

B

SRS

1. Cut the inflator from side curtain air bag module.

2. Connect deployment tool [SST: KV99106400] to the infla](/img/5/57362/w960_57362-2961.png)

DISPOSAL OF AIR BAG MODULE AND SEAT BELT PRE-TENSIONER

SRS-53

C

D

E

F

G

I

J

K

L

MA

B

SRS

1. Cut the inflator from side curtain air bag module.

2. Connect deployment tool [SST: KV99106400] to the inflator

using deployment tool adapter [SST: KV99110500].

3. Put the inflator connected with the deployment tool [SST:

KV99106400] into a tire without a wheel.

4. Put the tire with the inflator onto another tire without wheel. Add

an additional tire without a wheel and then a tire mounted on a

wheel on top.

CAUTION:

Tie all tires together with a strap in order to keep them

standing.

5. Connect red clip of deployment tool to battery positive terminal

and black clip to negative terminal.

6. The lamp on the right side of the tool, marked “deployment tool

power”, should glow green, not red.

7. Press the button on the deployment tool. The left side lamp on

the tool, marked “air bag connector voltage”, will illuminate and the air bag module will deploy.

CAUTION:

When deploying the side curtain air bag module, stand at least 5 m (16 ft) away from the side cur-

tain air bag module.

8. Repeat this procedure to deploy the second inflator.

SHIA0198E

PHIA0568E

PHIA0011E

PHIA0555E

Page 2963 of 3171

SRS-54

DISPOSAL OF AIR BAG MODULE AND SEAT BELT PRE-TENSIONER

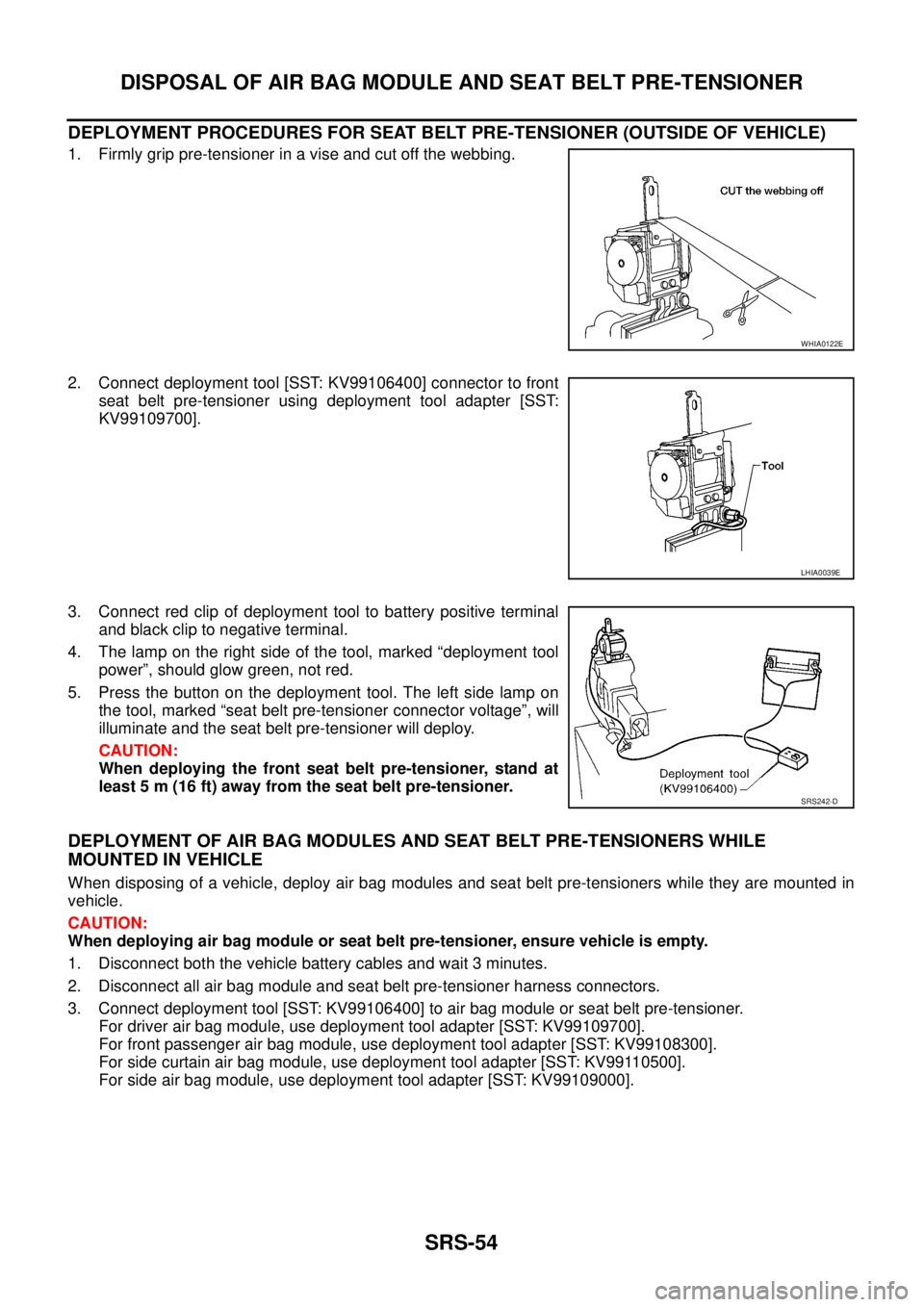

DEPLOYMENT PROCEDURES FOR SEAT BELT PRE-TENSIONER (OUTSIDE OF VEHICLE)

1. Firmly grip pre-tensioner in a vise and cut off the webbing.

2. Connect deployment tool [SST: KV99106400] connector to front

seat belt pre-tensioner using deployment tool adapter [SST:

KV99109700].

3. Connect red clip of deployment tool to battery positive terminal

and black clip to negative terminal.

4. The lamp on the right side of the tool, marked “deployment tool

power”, should glow green, not red.

5. Press the button on the deployment tool. The left side lamp on

the tool, marked “seat belt pre-tensioner connector voltage”, will

illuminate and the seat belt pre-tensioner will deploy.

CAUTION:

When deploying the front seat belt pre-tensioner, stand at

least 5 m (16 ft) away from the seat belt pre-tensioner.

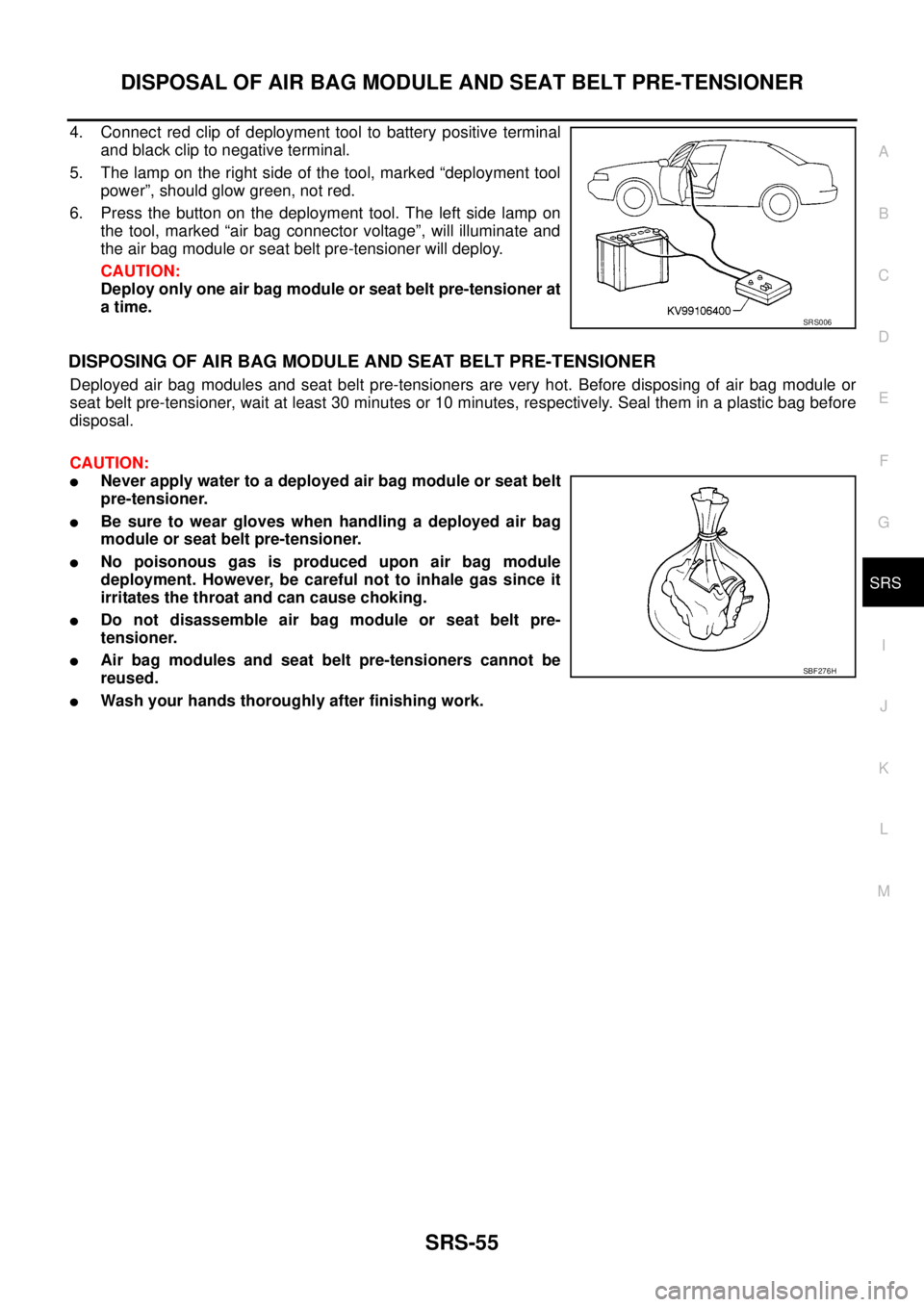

DEPLOYMENT OF AIR BAG MODULES AND SEAT BELT PRE-TENSIONERS WHILE

MOUNTED IN VEHICLE

When disposing of a vehicle, deploy air bag modules and seat belt pre-tensioners while they are mounted in

vehicle.

CAUTION:

When deploying air bag module or seat belt pre-tensioner, ensure vehicle is empty.

1. Disconnect both the vehicle battery cables and wait 3 minutes.

2. Disconnect all air bag module and seat belt pre-tensioner harness connectors.

3. Connect deployment tool [SST: KV99106400] to air bag module or seat belt pre-tensioner.

For driver air bag module, use deployment tool adapter [SST: KV99109700].

For front passenger air bag module, use deployment tool adapter [SST: KV99108300].

For side curtain air bag module, use deployment tool adapter [SST: KV99110500].

For side air bag module, use deployment tool adapter [SST: KV99109000].

WHIA0122E

LHIA0039E

SRS242-D

Page 2964 of 3171

DISPOSAL OF AIR BAG MODULE AND SEAT BELT PRE-TENSIONER

SRS-55

C

D

E

F

G

I

J

K

L

MA

B

SRS

4. Connect red clip of deployment tool to battery positive terminal

and black clip to negative terminal.

5. The lamp on the right side of the tool, marked “deployment tool

power”, should glow green, not red.

6. Press the button on the deployment tool. The left side lamp on

the tool, marked “air bag connector voltage”, will illuminate and

the air bag module or seat belt pre-tensioner will deploy.

CAUTION:

Deploy only one air bag module or seat belt pre-tensioner at

atime.

DISPOSING OF AIR BAG MODULE AND SEAT BELT PRE-TENSIONER

Deployed air bag modules and seat belt pre-tensioners are very hot. Before disposing of air bag module or

seat belt pre-tensioner, wait at least 30 minutes or 10 minutes, respectively. Seal them in a plastic bag before

disposal.

CAUTION:

lNever apply water to a deployed air bag module or seat belt

pre-tensioner.

lBe sure to wear gloves when handling a deployed air bag

module or seat belt pre-tensioner.

lNo poisonous gas is produced upon air bag module

deployment. However, be careful not to inhale gas since it

irritates the throat and can cause choking.

lDo not disassemble air bag module or seat belt pre-

tensioner.

lAir bag modules and seat belt pre-tensioners cannot be

reused.

lWash your hands thoroughly after finishing work.

SRS006

SBF276H

Page 2965 of 3171

SRS-56

COLLISION DIAGNOSIS

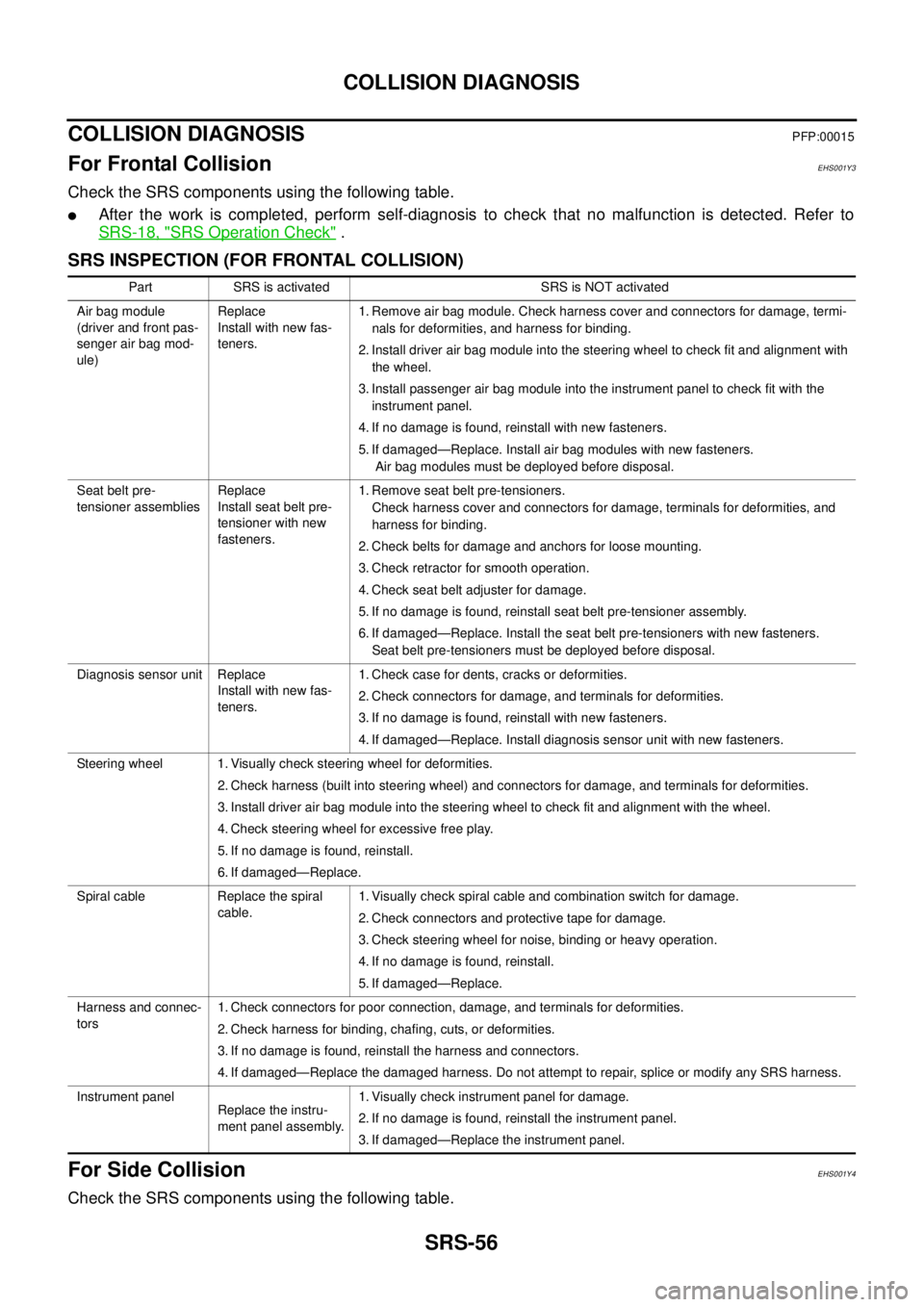

COLLISION DIAGNOSIS

PFP:00015

For Frontal CollisionEHS001Y3

Check the SRS components using the following table.

lAfter the work is completed, perform self-diagnosis to check that no malfunction is detected. Refer to

SRS-18, "

SRS Operation Check".

SRS INSPECTION (FOR FRONTAL COLLISION)

For Side CollisionEHS001Y4

Check the SRS components using the following table.

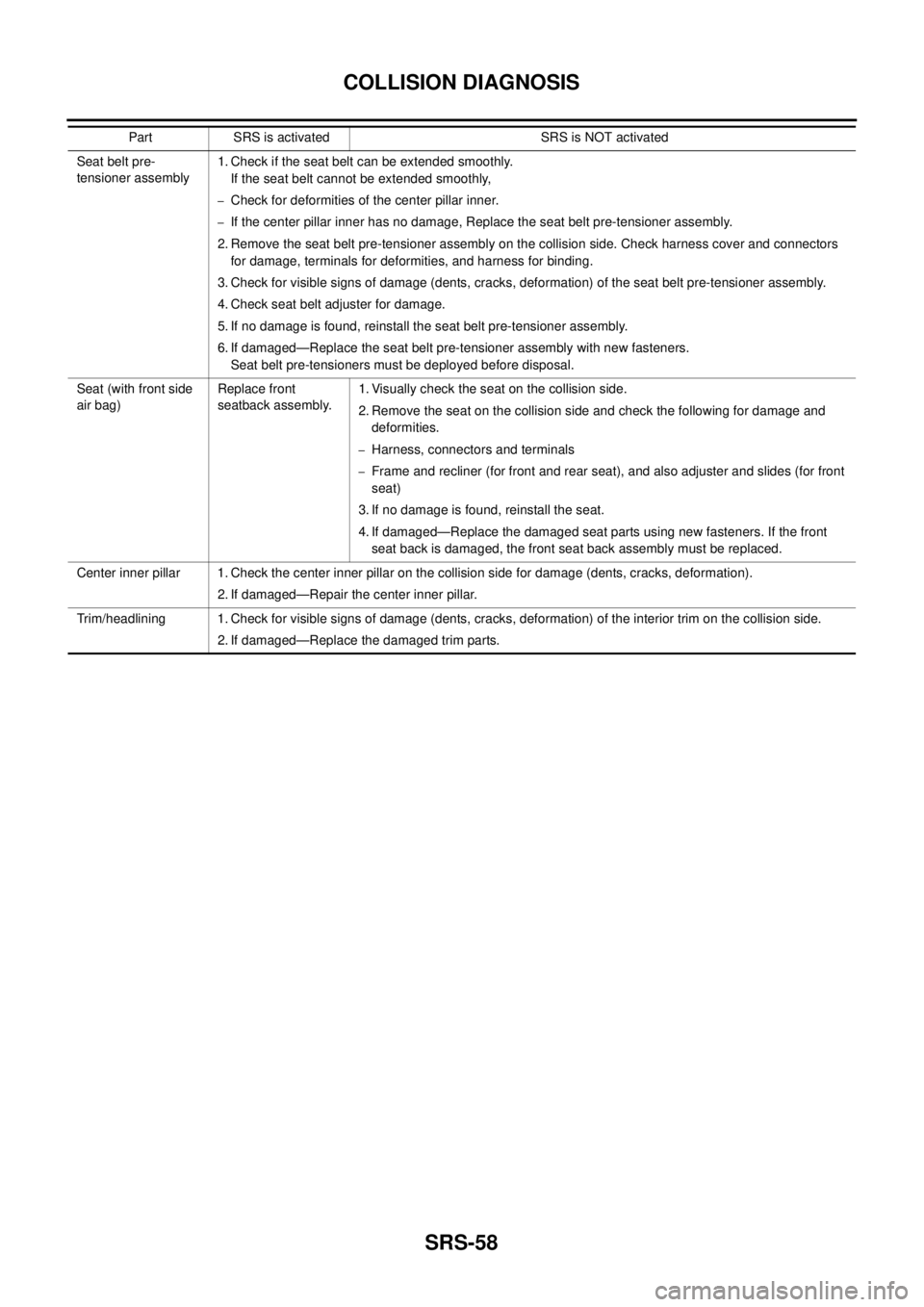

Part SRS is activated SRS is NOT activated

Air bag module

(driver and front pas-

senger air bag mod-

ule)Replace

Install with new fas-

teners.1. Remove air bag module. Check harness cover and connectors for damage, termi-

nals for deformities, and harness for binding.

2. Install driver air bag module into the steering wheel to check fit and alignment with

the wheel.

3. Install passenger air bag module into the instrument panel to check fit with the

instrument panel.

4. If no damage is found, reinstall with new fasteners.

5. If damaged—Replace. Install air bag modules with new fasteners.

Air bag modules must be deployed before disposal.

Seat belt pre-

tensioner assembliesReplace

Install seat belt pre-

tensioner with new

fasteners.1. Remove seat belt pre-tensioners.

Check harness cover and connectors for damage, terminals for deformities, and

harness for binding.

2. Check belts for damage and anchors for loose mounting.

3. Check retractor for smooth operation.

4. Check seat belt adjuster for damage.

5. If no damage is found, reinstall seat belt pre-tensioner assembly.

6. If damaged—Replace. Install the seat belt pre-tensioners with new fasteners.

Seat belt pre-tensioners must be deployed before disposal.

Diagnosis sensor unit Replace

Install with new fas-

teners.1. Check case for dents, cracks or deformities.

2. Check connectors for damage, and terminals for deformities.

3. If no damage is found, reinstall with new fasteners.

4. If damaged—Replace. Install diagnosis sensor unit with new fasteners.

Steering wheel 1. Visually check steering wheel for deformities.

2. Check harness (built into steering wheel) and connectors for damage, and terminals for deformities.

3. Install driver air bag module into the steering wheel to check fit and alignment with the wheel.

4. Check steering wheel for excessive free play.

5. If no damage is found, reinstall.

6. If damaged—Replace.

Spiral cable Replace the spiral

cable.1. Visually check spiral cable and combination switch for damage.

2. Check connectors and protective tape for damage.

3. Check steering wheel for noise, binding or heavy operation.

4. If no damage is found, reinstall.

5. If damaged—Replace.

Harness and connec-

tors1. Check connectors for poor connection, damage, and terminals for deformities.

2. Check harness for binding, chafing, cuts, or deformities.

3. If no damage is found, reinstall the harness and connectors.

4. If damaged—Replace the damaged harness. Do not attempt to repair, splice or modify any SRS harness.

Instrument panel

Replace the instru-

ment panel assembly.1. Visually check instrument panel for damage.

2. If no damage is found, reinstall the instrument panel.

3. If damaged—Replace the instrument panel.

Page 2967 of 3171

SRS-58

COLLISION DIAGNOSIS

Seat belt pre-

tensioner assembly1. Check if the seat belt can be extended smoothly.

If the seat belt cannot be extended smoothly,

–Check for deformities of the center pillar inner.

–If the center pillar inner has no damage, Replace the seat belt pre-tensioner assembly.

2. Remove the seat belt pre-tensioner assembly on the collision side. Check harness cover and connectors

for damage, terminals for deformities, and harness for binding.

3. Check for visible signs of damage (dents, cracks, deformation) of the seat belt pre-tensioner assembly.

4. Check seat belt adjuster for damage.

5. If no damage is found, reinstall the seat belt pre-tensioner assembly.

6. If damaged—Replace the seat belt pre-tensioner assembly with new fasteners.

Seat belt pre-tensioners must be deployed before disposal.

Seat (with front side

air bag)Replace front

seatback assembly.1. Visually check the seat on the collision side.

2. Remove the seat on the collision side and check the following for damage and

deformities.

–Harness, connectors and terminals

–Frame and recliner (for front and rear seat), and also adjuster and slides (for front

seat)

3. If no damage is found, reinstall the seat.

4. If damaged—Replace the damaged seat parts using new fasteners. If the front

seat back is damaged, the front seat back assembly must be replaced.

Center inner pillar 1. Check the center inner pillar on the collision side for damage (dents, cracks, deformation).

2. If damaged—Repair the center inner pillar.

Trim/headlining 1. Check for visible signs of damage (dents, cracks, deformation) of the interior trim on the collision side.

2. If damaged—Replace the damaged trim parts. Part SRS is activated SRS is NOT activated

Page 2968 of 3171

TF-1

TRANSFER

D DRIVELINE/AXLE

CONTENTS

C

E

F

G

H

I

J

K

L

M

SECTIONTF

A

B

TF

TRANSFER

PRECAUTIONS .......................................................... 4

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 4

Precautions for Transfer Assembly and Transfer

Control Unit Replacement ........................................ 4

CHECK 4WD SHIFT INDICATOR PATTERN ....... 4

METHOD FOR ADJUSTMENT WITH 4WD

SHIFT SWITCH AT “2WD” .................................... 5

METHOD FOR ADJUSTMENT WITH 4WD

SHIFT SWITCH AT “4H” OR “4LO” ....................... 5

Precautions .............................................................. 6

Service Notice .......................................................... 6

Wiring Diagrams and Trouble Diagnosis .................. 7

PREPARATION ........................................................... 8

Special Service Tools ............................................... 8

Commercial Service Tools ...................................... 10

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING ...............................................11

NVH Troubleshooting Chart .................................... 11

TRANSFER FLUID ................................................... 12

Replacement .......................................................... 12

DRAINING ........................................................... 12

FILLING ............................................................... 12

Inspection ............................................................... 12

FLUID LEAKAGE AND FLUID LEVEL ................ 12

4WD SYSTEM .......................................................... 13

Cross-Section View ................................................ 13

Power Transfer ....................................................... 14

POWER TRANSFER DIAGRAM ........................ 14

POWER TRANSFER FLOW ............................... 15

System Description ................................................ 15

TRANSFER CONTROL DEVICE ........................ 15

WAIT DETECTION SWITCH .............................. 15

4LO SWITCH ...................................................... 15

ATP SWITCH ...................................................... 15

TRANSFER CONTROL UNIT ............................. 15

TRANSFER SHIFT RELAY ................................. 15

TRANSFER SHUT OFF RELAY ......................... 15

4WD SHIFT SWITCH AND INDICATOR LAMP... 164WD WARNING LAMP ....................................... 17

ATP WARNING LAMP (A/T MODELS) ................ 17

System Diagram ..................................................... 18

COMPONENTS FUNCTION ............................... 18

CAN Communication .............................................. 19

SYSTEM DESCRIPTION .................................... 19

TROUBLE DIAGNOSIS ............................................ 20

How to Perform Trouble Diagnosis ......................... 20

BASIC CONCEPT ............................................... 20

Location of Electrical Parts ..................................... 21

A/T MODELS ....................................................... 21

M/T MODELS ...................................................... 22

Circuit Diagram ....................................................... 23

A/T MODELS ....................................................... 23

M/T MODELS ...................................................... 24

Wiring Diagram — T/F — ....................................... 25

A/T MODELS ....................................................... 25

M/T MODELS ...................................................... 31

Trouble Diagnosis Chart for Symptoms .................. 38

Transfer Control Unit Input/Output Signal Refer-

ence Values ............................................................ 38

TRANSFER CONTROL UNIT INSPECTION

TABLE ................................................................. 38

CONSULT-II Function (ALL MODE AWD/4WD) ..... 44

FUNCTION .......................................................... 44

CONSULT-II SETTING PROCEDURE ................ 44

SELF-DIAG RESULT MODE ............................... 45

DATA MONITOR MODE ...................................... 47

Self-Diagnostic Procedure ...................................... 49

SELF-DIAGNOSTIC PROCEDURE (WITH

CONSULT-II) ....................................................... 49

SELF-DIAGNOSTIC PROCEDURE (WITHOUT

CONSULT-II) ....................................................... 49

ERASE SELF-DIAGNOSIS ................................. 51

TROUBLE DIAGNOSIS FOR SYSTEM .................... 52

Power Supply Circuit For Transfer Control Unit ...... 52

CONSULT-II REFERENCE VALUE IN DATA

MONITOR MODE ................................................ 52

TRANSFER CONTROL UNIT TERMINALS AND

REFERENCE VALUE .......................................... 52

Page 2971 of 3171

TF-4

PRECAUTIONS

PRECAUTIONS

PFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EDS003ID

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

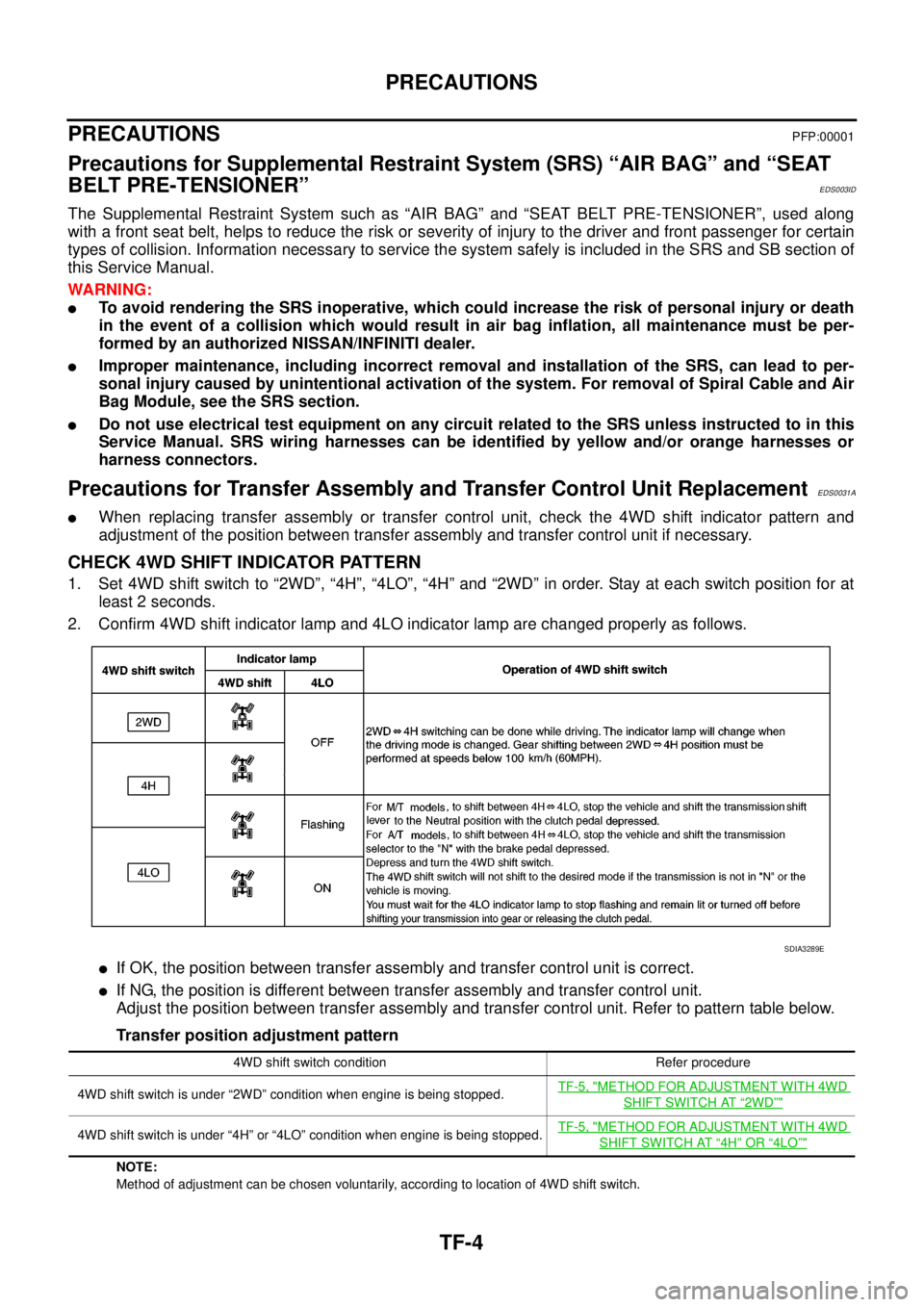

Precautions for Transfer Assembly and Transfer Control Unit ReplacementEDS0031A

lWhen replacing transfer assembly or transfer control unit, check the 4WD shift indicator pattern and

adjustment of the position between transfer assembly and transfer control unit if necessary.

CHECK 4WD SHIFT INDICATOR PATTERN

1. Set 4WD shift switch to “2WD”, “4H”, “4LO”, “4H” and “2WD” in order. Stay at each switch position for at

least 2 seconds.

2. Confirm 4WD shift indicator lamp and 4LO indicator lamp are changed properly as follows.

lIf OK, the position between transfer assembly and transfer control unit is correct.

lIf NG, the position is different between transfer assembly and transfer control unit.

Adjust the position between transfer assembly and transfer control unit. Refer to pattern table below.

Transfer position adjustment pattern

NOTE:

Method of adjustment can be chosen voluntarily, according to location of 4WD shift switch.

SDIA3289E

4WD shift switch condition Refer procedure

4WD shift switch is under “2WD” condition when engine is being stopped.TF-5, "

METHOD FOR ADJUSTMENT WITH 4WD

SHIFT SWITCH AT“2WD”"

4WD shift switch is under “4H” or “4LO” condition when engine is being stopped.TF-5, "METHOD FOR ADJUSTMENT WITH 4WD

SHIFT SWITCH AT“4H”OR“4LO”"

Page 3112 of 3171

WW-1

WIPER, WASHER & HORN

K ELECTRICAL

CONTENTS

C

D

E

F

G

H

I

J

L

M

SECTIONWW

A

B

WW

WIPER, WASHER & HORN

PRECAUTION ............................................................ 3

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 3

Wiring Diagrams and Trouble Diagnosis .................. 3

FRONT WIPER AND WASHER SYSTEM .................. 4

Components Parts and Harness Connector Loca-

tion ........................................................................... 4

System Description .................................................. 4

LOW SPEED WIPER OPERATION ...................... 5

HI SPEED WIPER OPERATION ........................... 5

INTERMITTENT OPERATION .............................. 6

AUTO STOP OPERATION .................................... 6

FRONT WASHER OPERATION ........................... 6

MIST OPERATION ................................................ 7

FAIL-SAFE FUNCTION ......................................... 7

COMBINATION SWITCH READING FUNCTION..... 8

CAN Communication System Description .............. 10

Schematic ............................................................... 11

Wiring Diagram — WIPER — ................................ 12

Terminals and Reference Values for BCM ............. 15

Terminals and Reference Values for IPDM E/R ..... 16

How To Proceed With Trouble Diagnosis ............... 16

Preliminary Inspection ............................................ 16

INSPECTION FOR POWER SUPPLY AND

GROUND CIRCUIT ............................................. 16

CONSULT-II Function (BCM) ................................. 18

CONSULT-II OPERATION .................................. 18

WORK SUPPORT ............................................... 19

DATA MONITOR ................................................. 19

ACTIVE TEST ..................................................... 20

CONSULT-II Function (IPDM E/R) ......................... 21

CONSULT-II OPERATION .................................. 21

DATA MONITOR ................................................. 22

ACTIVE TEST ..................................................... 22

Front Wiper Does Not Operate in Rain (Front Wiper

Switch Turned to INT Position) ............................... 23

Front Wiper Does Not Operate .............................. 25

Front Wiper Does Not Return to Stop Position (After

Front Wiper for 10 Seconds, They Stop for 20 sec-onds, and After Repeating the Operations Five

Times, They Become Inoperative) .......................... 28

Only Front Wiper LO Does Not Operate ................. 29

Only Front Wiper HI Does Not Operate .................. 31

Only Front Wiper INT Does Not Operate ................ 32

Front Wiper Intermittent Operation Switch Position

Cannot Be Adjusted ................................................ 33

Front Wiper Interval Time Is Not Controlled by Vehi-

cle Speed ................................................................ 33

Wipers Do Not Wipe When Front Washer Operates... 33

Removal and Installation of Front Wiper Arms,

Adjustment of Wiper Arms Stop Location ............... 34

REMOVAL ........................................................... 34

INSTALLATION ................................................... 34

Removal and Installation of Wiper Motor and Link-

age .......................................................................... 35

REMOVAL ........................................................... 35

INSTALLATION ................................................... 35

Washer Nozzle Adjustment .................................... 36

Washer Tube Layout .............................................. 36

Removal and Installation of Wiper and Washer

Switch ..................................................................... 36

REMOVAL ........................................................... 36

INSTALLATION ................................................... 36

Removal and Installation of Front Washer Tank ..... 37

REMOVAL ........................................................... 37

INSTALLATION ................................................... 37

Removal and Installation of Front Washer Motor ... 38

REMOVAL ........................................................... 38

INSTALLATION ................................................... 38

Removal and Installation of Washer Fluid Level Sen-

sor ........................................................................... 38

REMOVAL ........................................................... 38

INSTALLATION ................................................... 38

HEADLAMP WASHER ............................................. 39

Components Parts and Harness Connector Loca-

tion .......................................................................... 39

System Description ................................................. 39

OUTLINE ............................................................. 40

HEADLAMP WASHER OPERATION .................. 40

Page 3114 of 3171

PRECAUTION

WW-3

C

D

E

F

G

H

I

J

L

MA

B

WW

PRECAUTIONPFP:00011

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EKS00N1N

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Wiring Diagrams and Trouble DiagnosisEKS00L9V

When you read wiring diagrams, refer to the following:

lRefer toGI-15, "HowtoReadWiringDiagrams".

lRefer toPG-4, "POWER SUPPLY ROUTING CIRCUIT".

When you perform trouble diagnosis, refer to the following:

lRefer toGI-11, "How to Follow Trouble Diagnoses".

lRefer toGI-24, "How to Perform Efficient Diagnosis for an Electrical Incident".