drain bolt NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 19 of 3171

A/T FLUID

AT-11

D

E

F

G

H

I

J

K

L

MA

B

AT

A/T FLUIDPFP:KLE40

Changing A/T FluidECS00FWD

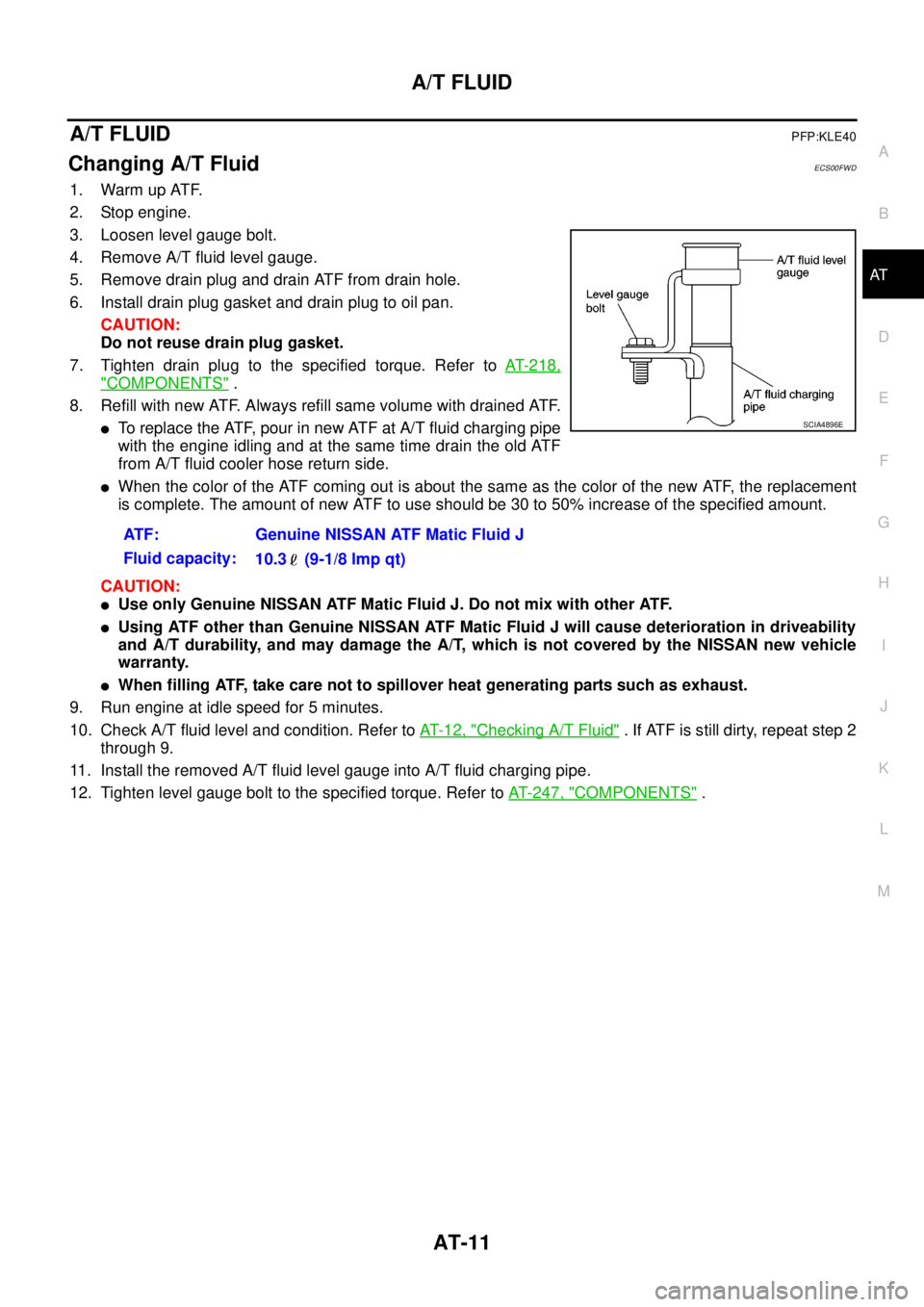

1. Warm up ATF.

2. Stop engine.

3. Loosen level gauge bolt.

4. Remove A/T fluid level gauge.

5. Remove drain plug and drain ATF from drain hole.

6. Install drain plug gasket and drain plug to oil pan.

CAUTION:

Do not reuse drain plug gasket.

7. Tighten drain plug to the specified torque. Refer toAT-218,

"COMPONENTS".

8. Refill with new ATF. Always refill same volume with drained ATF.

lTo replace the ATF, pour in new ATF at A/T fluid charging pipe

with the engine idling and at the same time drain the old ATF

from A/T fluid cooler hose return side.

lWhen the color of the ATF coming out is about the same as the color of the new ATF, the replacement

is complete. The amount of new ATF to use should be 30 to 50% increase of the specified amount.

CAUTION:

lUse only Genuine NISSAN ATF Matic Fluid J. Do not mix with other ATF.

lUsing ATF other than Genuine NISSAN ATF Matic Fluid J will cause deterioration in driveability

and A/T durability, and may damage the A/T, which is not covered by the NISSAN new vehicle

warranty.

lWhen filling ATF, take care not to spillover heat generating parts such as exhaust.

9. Run engine at idle speed for 5 minutes.

10. Check A/T fluid level and condition. Refer toAT-12, "

Checking A/T Fluid". If ATF is still dirty, repeat step 2

through 9.

11. Install the removed A/T fluid level gauge into A/T fluid charging pipe.

12. Tighten level gauge bolt to the specified torque. Refer toAT- 2 4 7 , "

COMPONENTS". ATF: Genuine NISSAN ATF Matic Fluid J

Fluid capacity:

10.3 (9-1/8 lmp qt)

SCIA4896E

Page 226 of 3171

AT-218

ON-VEHICLE SERVICE

ON-VEHICLE SERVICE

PFP:00000

Control Valve With TCM and A/T Fluid Temperature Sensor 2ECS00G36

COMPONENTS

1. A/T 2. Snap ring 3. Sub-harness

4. Control valve with TCM 5. Bracket 6. A/T fluid temperature sensor 2

7. Oil pan gasket 8. Oil pan 9. Magnet

10. Drain plug 11. Drain plug gasket 12. Oil pan mounting bolt

13. Terminal cord assembly 14. O-ring

SCIA5478E

Page 234 of 3171

AT-226

ON-VEHICLE SERVICE

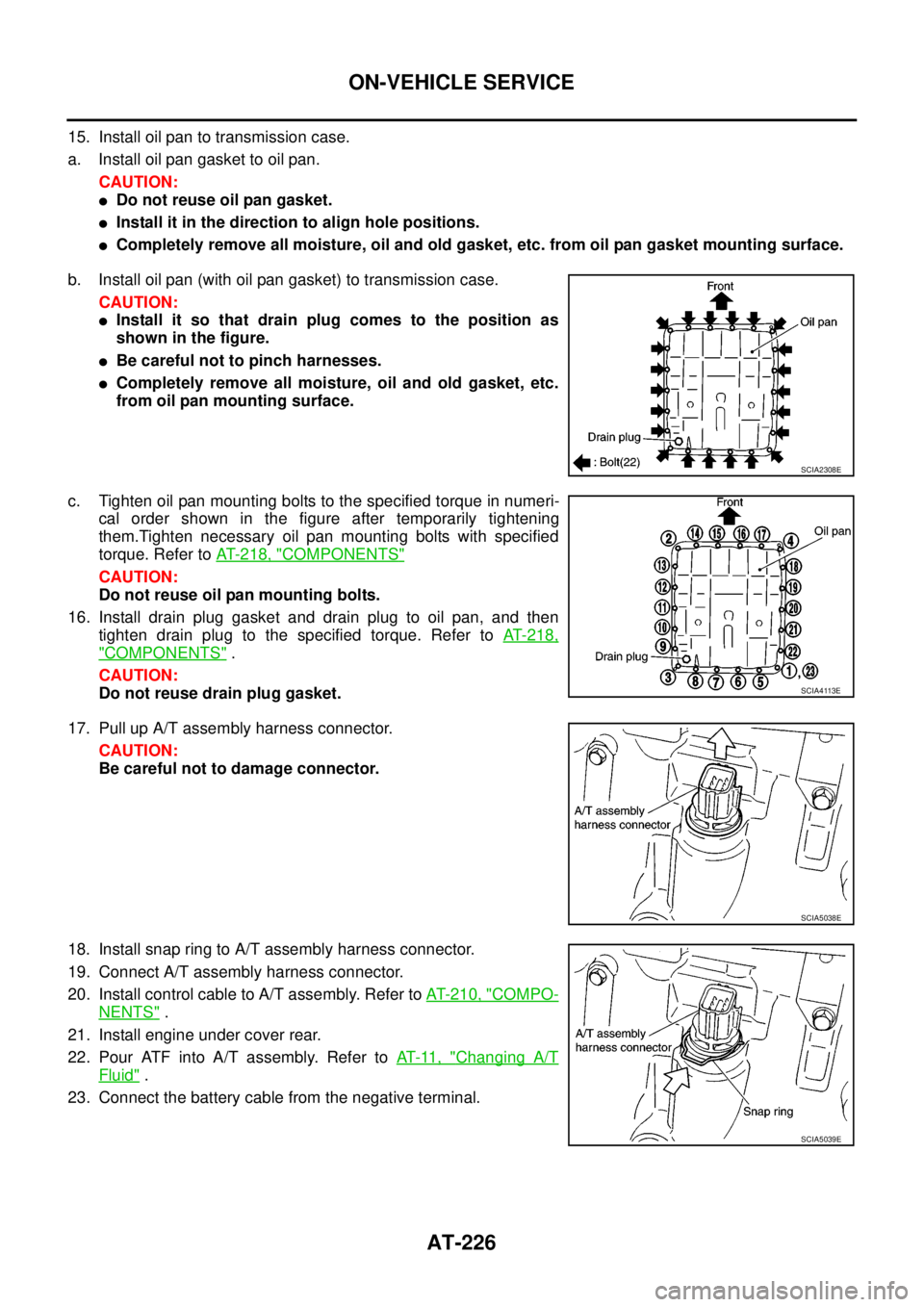

15. Install oil pan to transmission case.

a. Install oil pan gasket to oil pan.

CAUTION:

lDo not reuse oil pan gasket.

lInstall it in the direction to align hole positions.

lCompletely remove all moisture, oil and old gasket, etc. from oil pan gasket mounting surface.

b. Install oil pan (with oil pan gasket) to transmission case.

CAUTION:

lInstall it so that drain plug comes to the position as

shown in the figure.

lBe careful not to pinch harnesses.

lCompletely remove all moisture, oil and old gasket, etc.

from oil pan mounting surface.

c. Tighten oil pan mounting bolts to the specified torque in numeri-

cal order shown in the figure after temporarily tightening

them.Tighten necessary oil pan mounting bolts with specified

torque. Refer toAT- 2 1 8 , "

COMPONENTS"

CAUTION:

Do not reuse oil pan mounting bolts.

16. Install drain plug gasket and drain plug to oil pan, and then

tighten drain plug to the specified torque. Refer toAT-218,

"COMPONENTS".

CAUTION:

Do not reuse drain plug gasket.

17. Pull up A/T assembly harness connector.

CAUTION:

Be careful not to damage connector.

18. Install snap ring to A/T assembly harness connector.

19. Connect A/T assembly harness connector.

20. Install control cable to A/T assembly. Refer toAT- 2 1 0 , "

COMPO-

NENTS".

21. Install engine under cover rear.

22. Pour ATF into A/T assembly. Refer toAT-11, "

Changing A/T

Fluid".

23. Connect the battery cable from the negative terminal.

SCIA2308E

SCIA4113E

SCIA5038E

SCIA5039E

Page 237 of 3171

ON-VEHICLE SERVICE

AT-229

D

E

F

G

H

I

J

K

L

MA

B

AT

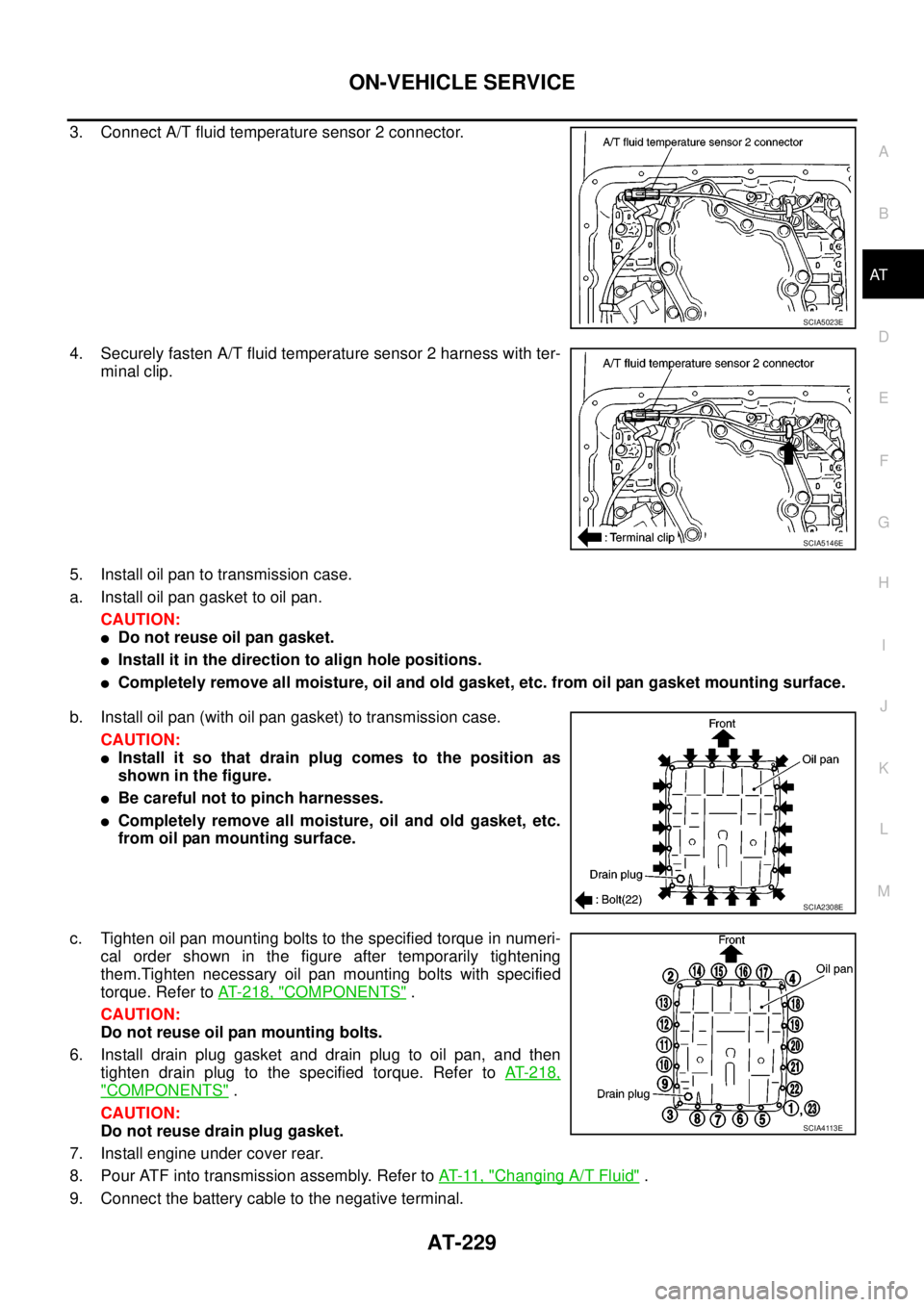

3. Connect A/T fluid temperature sensor 2 connector.

4. Securely fasten A/T fluid temperature sensor 2 harness with ter-

minal clip.

5. Install oil pan to transmission case.

a. Install oil pan gasket to oil pan.

CAUTION:

lDo not reuse oil pan gasket.

lInstall it in the direction to align hole positions.

lCompletely remove all moisture, oil and old gasket, etc. from oil pan gasket mounting surface.

b. Install oil pan (with oil pan gasket) to transmission case.

CAUTION:

lInstall it so that drain plug comes to the position as

shown in the figure.

lBe careful not to pinch harnesses.

lCompletely remove all moisture, oil and old gasket, etc.

from oil pan mounting surface.

c. Tighten oil pan mounting bolts to the specified torque in numeri-

cal order shown in the figure after temporarily tightening

them.Tighten necessary oil pan mounting bolts with specified

torque. Refer toAT- 2 1 8 , "

COMPONENTS".

CAUTION:

Do not reuse oil pan mounting bolts.

6. Install drain plug gasket and drain plug to oil pan, and then

tighten drain plug to the specified torque. Refer toAT-218,

"COMPONENTS".

CAUTION:

Do not reuse drain plug gasket.

7. Install engine under cover rear.

8. Pour ATF into transmission assembly. Refer toAT-11, "

Changing A/T Fluid".

9. Connect the battery cable to the negative terminal.

SCIA5023E

SCIA5146E

SCIA2308E

SCIA4113E

Page 238 of 3171

AT-230

ON-VEHICLE SERVICE

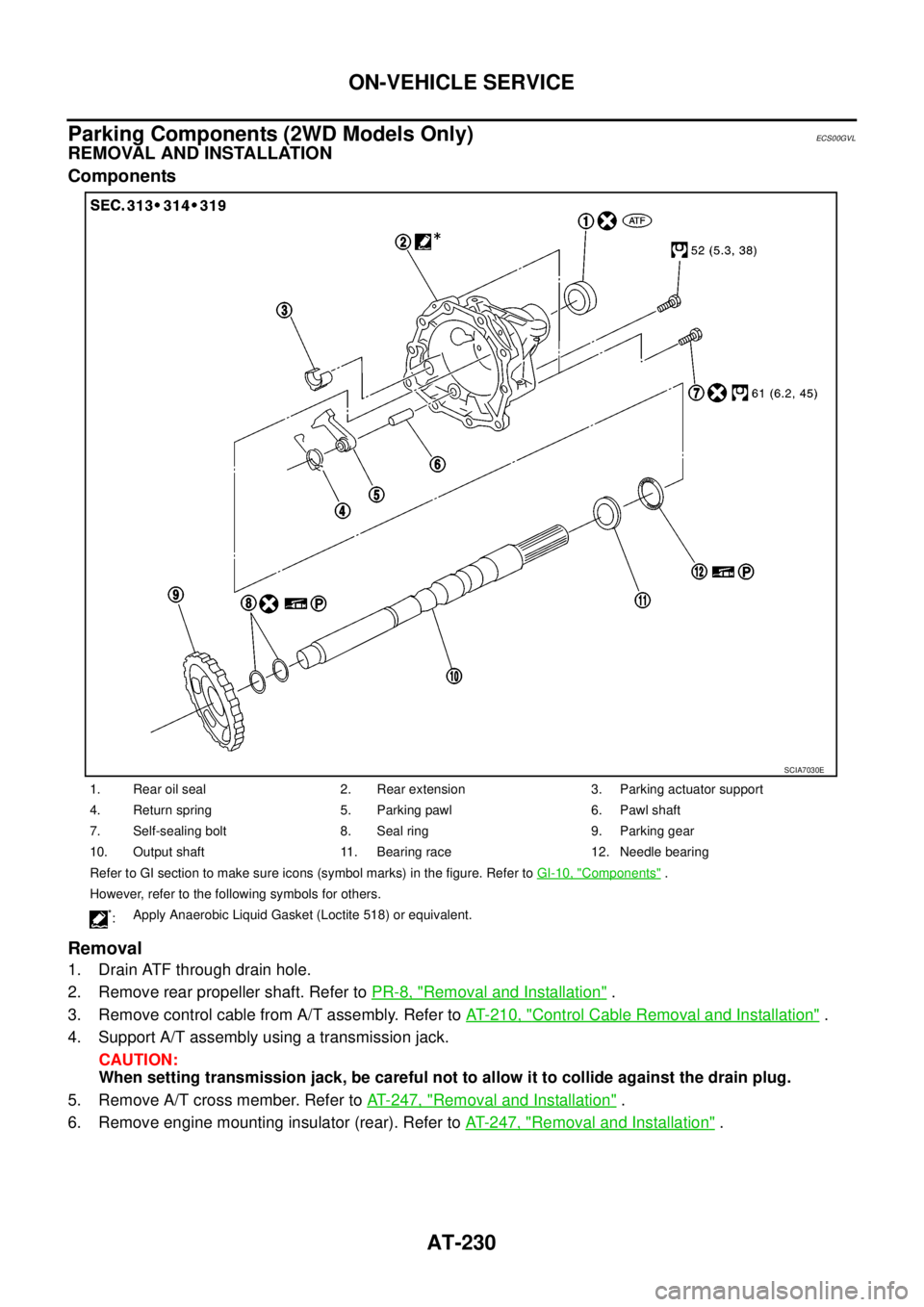

Parking Components (2WD Models Only)

ECS00GVL

REMOVAL AND INSTALLATION

Components

Removal

1. Drain ATF through drain hole.

2. Remove rear propeller shaft. Refer toPR-8, "

Removal and Installation".

3. Remove control cable from A/T assembly. Refer toAT- 2 1 0 , "

Control Cable Removal and Installation".

4. Support A/T assembly using a transmission jack.

CAUTION:

When setting transmission jack, be careful not to allow it to collide against the drain plug.

5. Remove A/T cross member. Refer toAT- 2 4 7 , "

Removal and Installation".

6. Remove engine mounting insulator (rear). Refer toAT- 2 4 7 , "

Removal and Installation".

1. Rear oil seal 2. Rear extension 3. Parking actuator support

4. Return spring 5. Parking pawl 6. Pawl shaft

7. Self-sealing bolt 8. Seal ring 9. Parking gear

10. Output shaft 11. Bearing race 12. Needle bearing

Refer to GI section to make sure icons (symbol marks) in the figure. Refer toGI-10, "

Components".

However, refer to the following symbols for others.

*:Apply Anaerobic Liquid Gasket (Loctite 518) or equivalent.

SCIA7030E

Page 244 of 3171

AT-236

ON-VEHICLE SERVICE

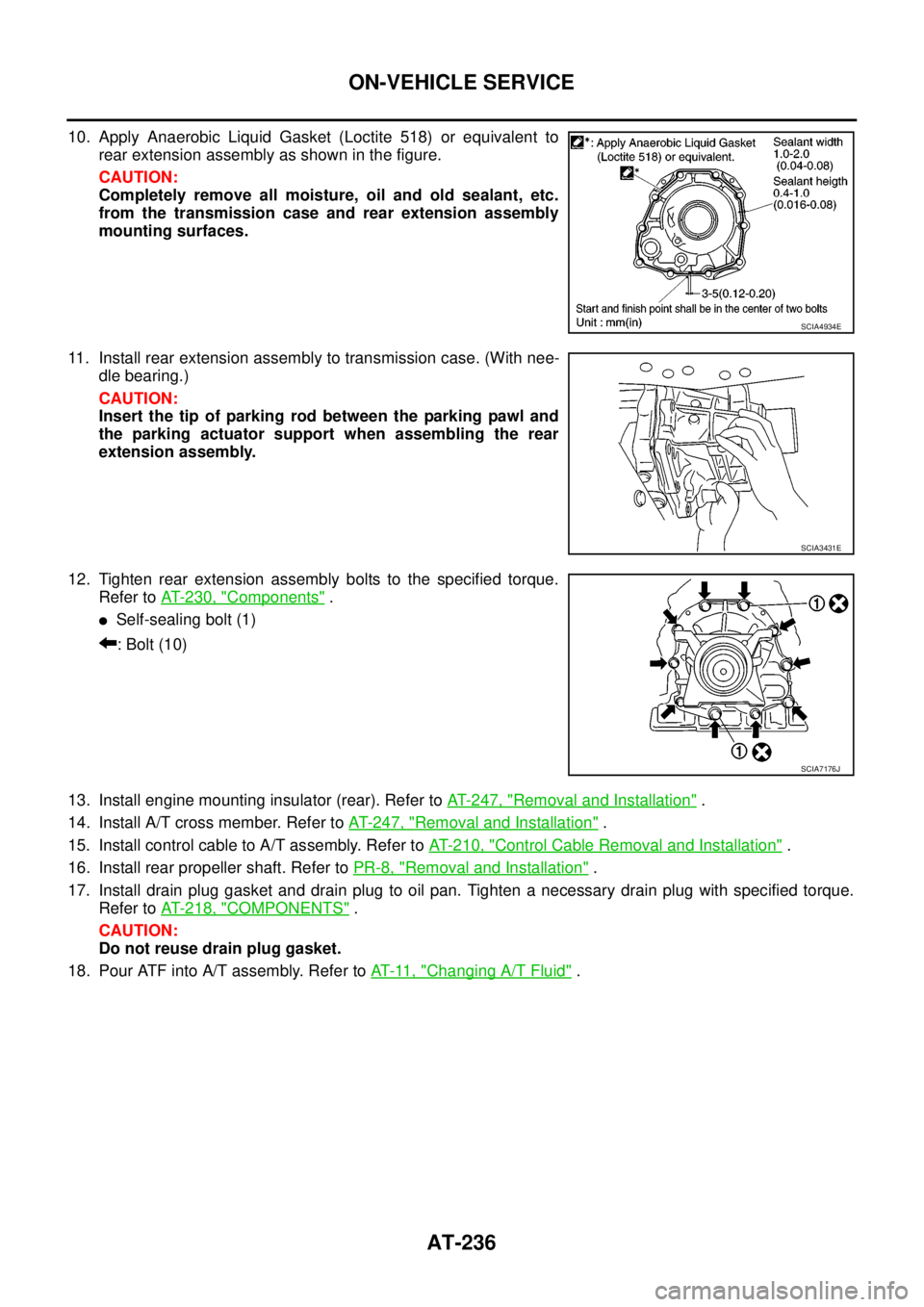

10. Apply Anaerobic Liquid Gasket (Loctite 518) or equivalent to

rear extension assembly as shown in the figure.

CAUTION:

Completely remove all moisture, oil and old sealant, etc.

from the transmission case and rear extension assembly

mounting surfaces.

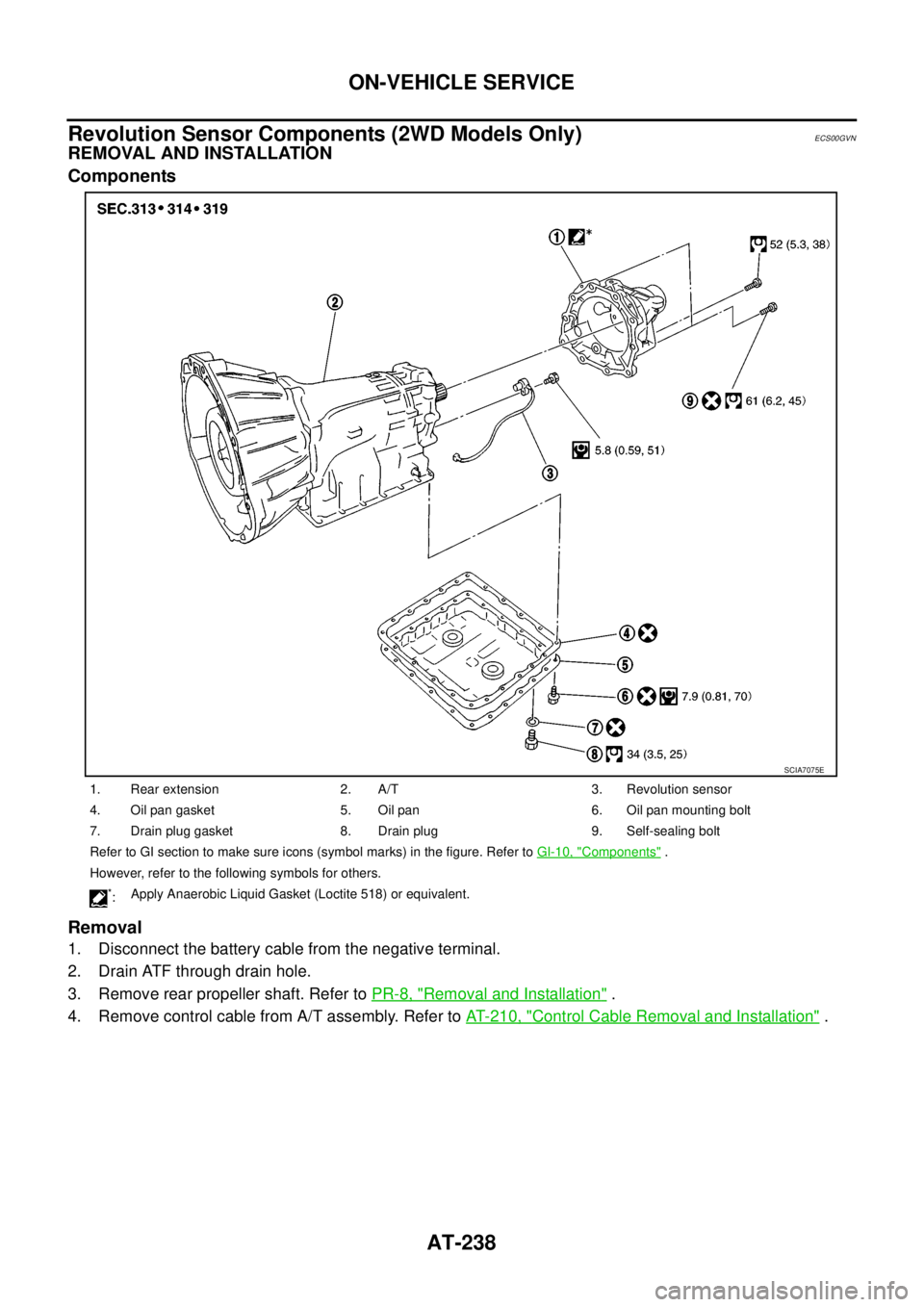

11. Install rear extension assembly to transmission case. (With nee-

dle bearing.)

CAUTION:

Insert the tip of parking rod between the parking pawl and

the parking actuator support when assembling the rear

extension assembly.

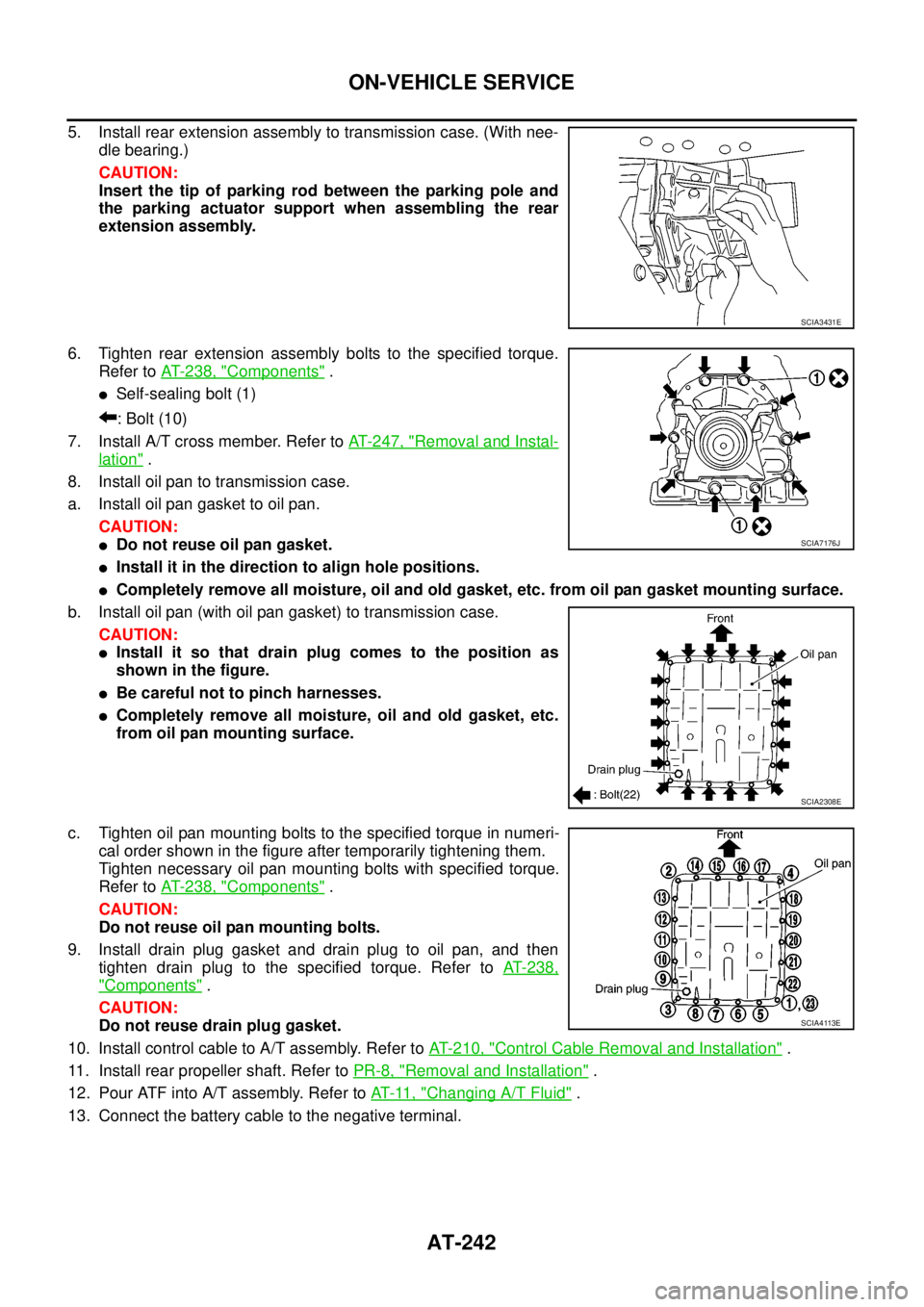

12. Tighten rear extension assembly bolts to the specified torque.

Refer toAT- 2 3 0 , "

Components".

lSelf-sealing bolt (1)

:Bolt(10)

13. Install engine mounting insulator (rear). Refer toAT- 2 4 7 , "

Removal and Installation".

14. Install A/T cross member. Refer toAT- 2 4 7 , "

Removal and Installation".

15. Install control cable to A/T assembly. Refer toAT- 2 1 0 , "

Control Cable Removal and Installation".

16. Install rear propeller shaft. Refer toPR-8, "

Removal and Installation".

17. Install drain plug gasket and drain plug to oil pan. Tighten a necessary drain plug with specified torque.

Refer toAT- 2 1 8 , "

COMPONENTS".

CAUTION:

Do not reuse drain plug gasket.

18. Pour ATF into A/T assembly. Refer toAT-11, "

Changing A/T Fluid".

SCIA4934E

SCIA3431E

SCIA7176J

Page 246 of 3171

AT-238

ON-VEHICLE SERVICE

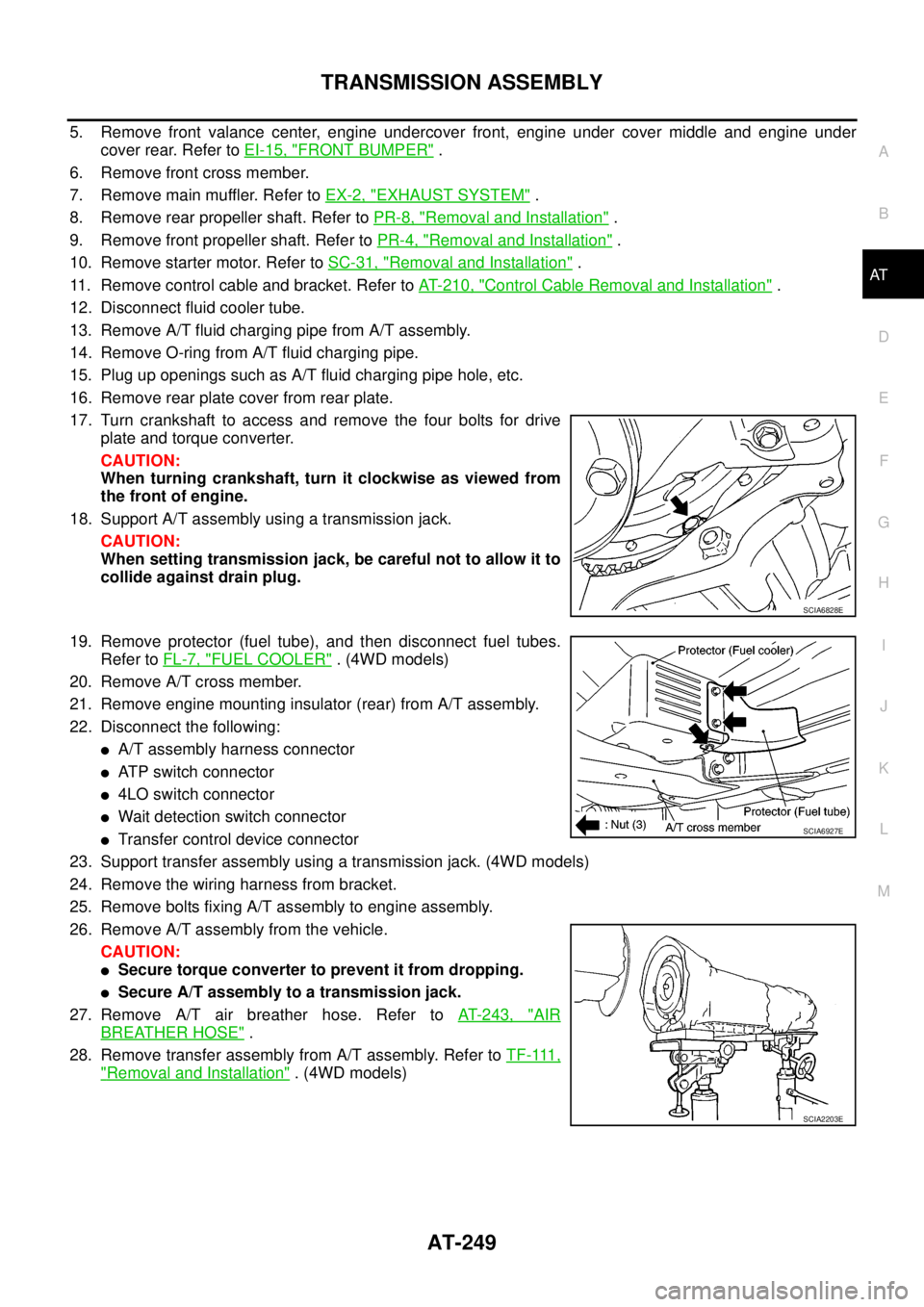

Revolution Sensor Components (2WD Models Only)

ECS00GVN

REMOVAL AND INSTALLATION

Components

Removal

1. Disconnect the battery cable from the negative terminal.

2. Drain ATF through drain hole.

3. Remove rear propeller shaft. Refer toPR-8, "

Removal and Installation".

4. Remove control cable from A/T assembly. Refer toAT- 2 1 0 , "

Control Cable Removal and Installation".

1. Rear extension 2. A/T 3. Revolution sensor

4. Oil pan gasket 5. Oil pan 6. Oil pan mounting bolt

7. Drain plug gasket 8. Drain plug 9. Self-sealing bolt

Refer to GI section to make sure icons (symbol marks) in the figure. Refer toGI-10, "

Components".

However, refer to the following symbols for others.

*:Apply Anaerobic Liquid Gasket (Loctite 518) or equivalent.

SCIA7075E

Page 250 of 3171

AT-242

ON-VEHICLE SERVICE

5. Install rear extension assembly to transmission case. (With nee-

dle bearing.)

CAUTION:

Insert the tip of parking rod between the parking pole and

the parking actuator support when assembling the rear

extension assembly.

6. Tighten rear extension assembly bolts to the specified torque.

Refer toAT- 2 3 8 , "

Components".

lSelf-sealing bolt (1)

:Bolt(10)

7. Install A/T cross member. Refer toAT- 2 4 7 , "

Removal and Instal-

lation".

8. Install oil pan to transmission case.

a. Install oil pan gasket to oil pan.

CAUTION:

lDo not reuse oil pan gasket.

lInstall it in the direction to align hole positions.

lCompletely remove all moisture, oil and old gasket, etc. from oil pan gasket mounting surface.

b. Install oil pan (with oil pan gasket) to transmission case.

CAUTION:

lInstall it so that drain plug comes to the position as

shown in the figure.

lBe careful not to pinch harnesses.

lCompletely remove all moisture, oil and old gasket, etc.

from oil pan mounting surface.

c. Tighten oil pan mounting bolts to the specified torque in numeri-

cal order shown in the figure after temporarily tightening them.

Tighten necessary oil pan mounting bolts with specified torque.

Refer toAT- 2 3 8 , "

Components".

CAUTION:

Do not reuse oil pan mounting bolts.

9. Install drain plug gasket and drain plug to oil pan, and then

tighten drain plug to the specified torque. Refer toAT-238,

"Components".

CAUTION:

Do not reuse drain plug gasket.

10. Install control cable to A/T assembly. Refer toAT- 2 1 0 , "

Control Cable Removal and Installation".

11. Install rear propeller shaft. Refer toPR-8, "

Removal and Installation".

12. Pour ATF into A/T assembly. Refer toAT-11, "

Changing A/T Fluid".

13. Connect the battery cable to the negative terminal.

SCIA3431E

SCIA7176J

SCIA2308E

SCIA4113E

Page 257 of 3171

TRANSMISSION ASSEMBLY

AT-249

D

E

F

G

H

I

J

K

L

MA

B

AT

5. Remove front valance center, engine undercover front, engine under cover middle and engine under

coverrear.RefertoEI-15, "

FRONT BUMPER".

6. Remove front cross member.

7. Remove main muffler. Refer toEX-2, "

EXHAUST SYSTEM".

8. Remove rear propeller shaft. Refer toPR-8, "

Removal and Installation".

9. Remove front propeller shaft. Refer toPR-4, "

Removal and Installation".

10. Remove starter motor. Refer toSC-31, "

Removal and Installation".

11. Remove control cable and bracket. Refer toAT- 2 1 0 , "

Control Cable Removal and Installation".

12. Disconnect fluid cooler tube.

13. Remove A/T fluid charging pipe from A/T assembly.

14. Remove O-ring from A/T fluid charging pipe.

15. Plug up openings such as A/T fluid charging pipe hole, etc.

16. Remove rear plate cover from rear plate.

17. Turn crankshaft to access and remove the four bolts for drive

plate and torque converter.

CAUTION:

When turning crankshaft, turn it clockwise as viewed from

the front of engine.

18. Support A/T assembly using a transmission jack.

CAUTION:

When setting transmission jack, be careful not to allow it to

collide against drain plug.

19. Remove protector (fuel tube), and then disconnect fuel tubes.

Refer toFL-7, "

FUEL COOLER". (4WD models)

20. Remove A/T cross member.

21. Remove engine mounting insulator (rear) from A/T assembly.

22. Disconnect the following:

lA/T assembly harness connector

lATP switch connector

l4LO switch connector

lWait detection switch connector

lTransfer control device connector

23. Support transfer assembly using a transmission jack. (4WD models)

24. Remove the wiring harness from bracket.

25. Remove bolts fixing A/T assembly to engine assembly.

26. Remove A/T assembly from the vehicle.

CAUTION:

lSecure torque converter to prevent it from dropping.

lSecure A/T assembly to a transmission jack.

27. Remove A/T air breather hose. Refer toAT- 2 4 3 , "

AIR

BREATHER HOSE".

28. Remove transfer assembly from A/T assembly. Refer toT F - 111 ,

"Removal and Installation". (4WD models)

SCIA6828E

SCIA6927E

SCIA2203E

Page 264 of 3171

AT-256

OVERHAUL

7. Pawl shaft 8. Seal ring 9. Needle bearing

10. Revolution sensor 11. Parking gear 12. Output shaft

13. Bearing race 14. Needle bearing 15. Manual plate

16. Parking rod 17. Manual shaft oil seal 18. Manual shaft

19. O-ring 20. Band servo anchor end pin 21. Detent spring

22. Spacer 23. Seal ring 24. Snap ring

25. Return spring 26. O-ring 27. Servo assembly

28. Snap ring 29. Sub-harness 30. Control valve with TCM

31. Bracket 32. A/T fluid temperature sensor 2 33. Oil pan

34. Magnet 35. Drain plug 36. Drain plug gasket

37. Oil pan mounting bolt 38. Oil pan gasket 39. Terminal cord assembly

40. O-ring 41. Retaining pin 42. Transmission case

Refer to GI section to make sure icons (symbol marks) in the figure. Refer toGI-10, "

Components".

However, refer to the following symbols for others.

*:Apply Anaerobic Liquid Gasket (Loctite 518) or equivalent.