engine oil NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2263 of 3171

LU-6

ENGINE OIL

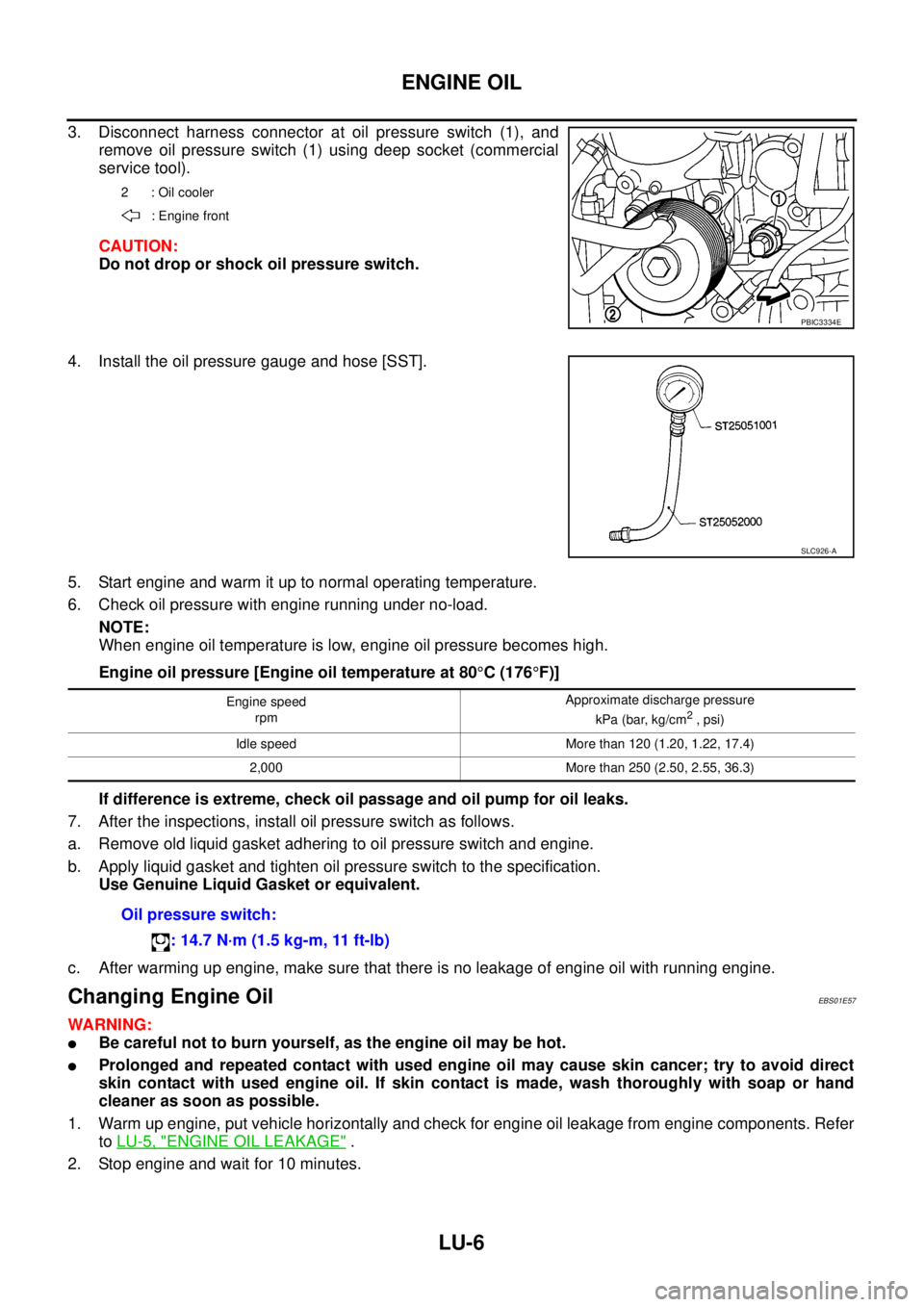

3. Disconnect harness connector at oil pressure switch (1), and

remove oil pressure switch (1) using deep socket (commercial

service tool).

CAUTION:

Do not drop or shock oil pressure switch.

4. Install the oil pressure gauge and hose [SST].

5. Start engine and warm it up to normal operating temperature.

6. Check oil pressure with engine running under no-load.

NOTE:

When engine oil temperature is low, engine oil pressure becomes high.

Engine oil pressure [Engine oil temperature at 80°C(176°F)]

If difference is extreme, check oil passage and oil pump for oil leaks.

7. After the inspections, install oil pressure switch as follows.

a. Remove old liquid gasket adhering to oil pressure switch and engine.

b. Apply liquid gasket and tighten oil pressure switch to the specification.

Use Genuine Liquid Gasket or equivalent.

c. After warming up engine, make sure that there is no leakage of engine oil with running engine.

Changing Engine OilEBS01E57

WARNING:

lBe careful not to burn yourself, as the engine oil may be hot.

lProlonged and repeated contact with used engine oil may cause skin cancer; try to avoid direct

skin contact with used engine oil. If skin contact is made, wash thoroughly with soap or hand

cleaner as soon as possible.

1. Warm up engine, put vehicle horizontally and check for engine oil leakage from engine components. Refer

toLU-5, "

ENGINE OIL LEAKAGE".

2. Stop engine and wait for 10 minutes.

2 : Oil cooler

: Engine front

PBIC3334E

SLC926-A

Engine speed

rpmApproximate discharge pressure

kPa (bar, kg/cm2, psi)

Idle speed More than 120 (1.20, 1.22, 17.4)

2,000 More than 250 (2.50, 2.55, 36.3)

Oil pressure switch:

: 14.7 N·m (1.5 kg-m, 11 ft-lb)

Page 2264 of 3171

ENGINE OIL

LU-7

C

D

E

F

G

H

I

J

K

L

MA

LU

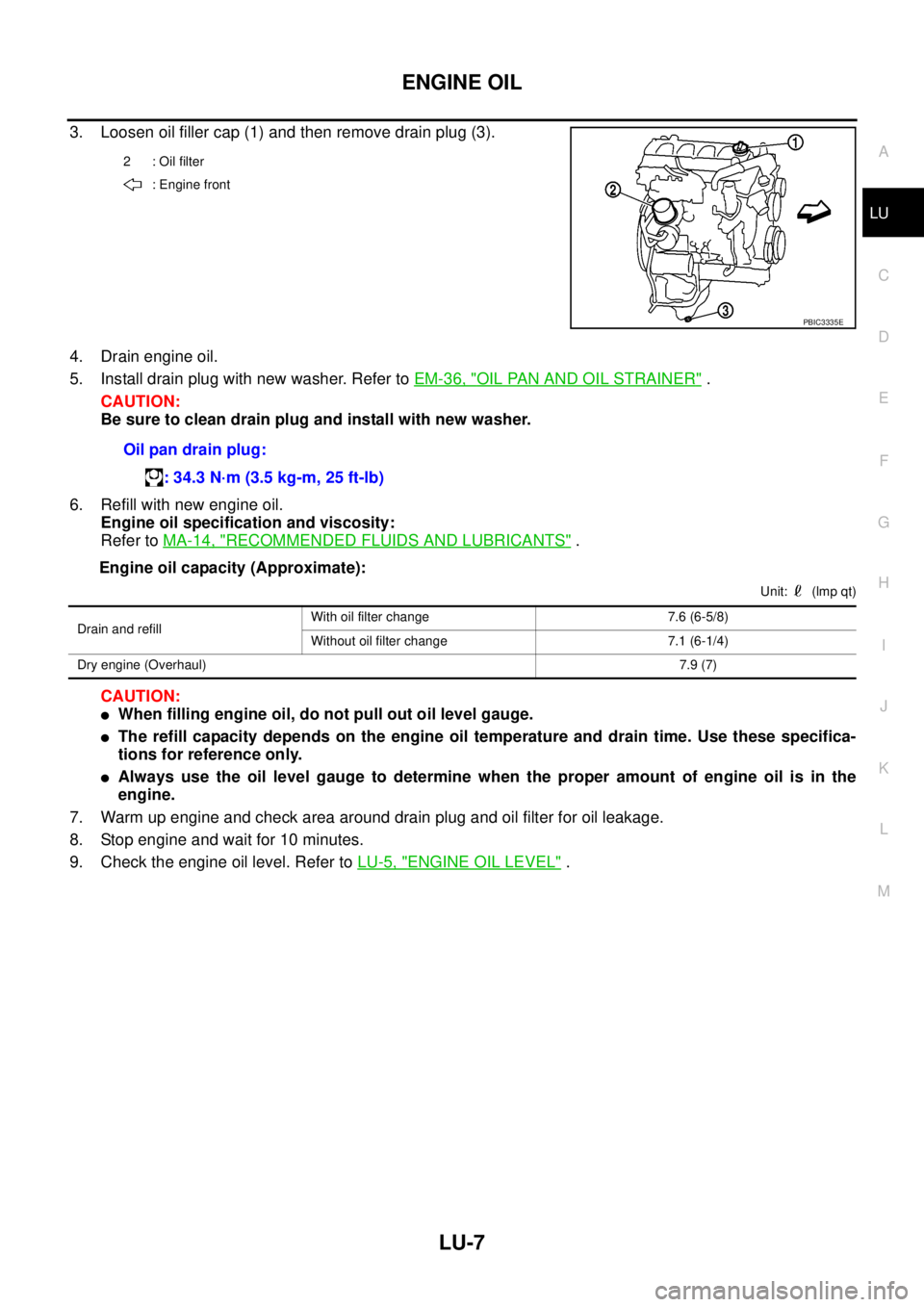

3. Loosen oil filler cap (1) and then remove drain plug (3).

4. Drain engine oil.

5. Install drain plug with new washer. Refer toEM-36, "

OIL PAN AND OIL STRAINER".

CAUTION:

Be sure to clean drain plug and install with new washer.

6. Refill with new engine oil.

Engine oil specification and viscosity:

Refer toMA-14, "

RECOMMENDED FLUIDS AND LUBRICANTS".

Engine oil capacity (Approximate):

Unit: (lmp qt)

CAUTION:

lWhen filling engine oil, do not pull out oil level gauge.

lThe refill capacity depends on the engine oil temperature and drain time. Use these specifica-

tions for reference only.

lAlways use the oil level gauge to determine when the proper amount of engine oil is in the

engine.

7. Warm up engine and check area around drain plug and oil filter for oil leakage.

8. Stop engine and wait for 10 minutes.

9. Check the engine oil level. Refer toLU-5, "

ENGINE OIL LEVEL".

2 : Oil filter

: Engine front

PBIC3335E

Oil pan drain plug:

: 34.3 N·m (3.5 kg-m, 25 ft-lb)

Drain and refillWith oil filter change 7.6 (6-5/8)

Without oil filter change 7.1 (6-1/4)

Dry engine (Overhaul)7.9 (7)

Page 2265 of 3171

LU-8

OIL FILTER

OIL FILTER

PFP:15208

Removal and InstallationEBS01E58

REMOVAL

1. Remove engine undercover middle.

2. Place a pan to catch the engine oil under the lower part of drain hose outlet before removing oil filter.

3. Using the oil filter wrench, remove oil filter.

CAUTION:

lBe careful not to get burned when engine and engine oil are hot.

lWhen removing, prepare a shop cloth to absorb any engine oil leakage or spillage.

lDo not allow engine oil to adhere to drive belts.

lCompletely wipe off any engine oil that adhere to engine and vehicle.

lOil filter is provided with a relief valve. Use Genuine Nissan Oil Filter or equivalent.

INSTALLATION

1. Remove foreign materials adhering to the oil filter installation surface.

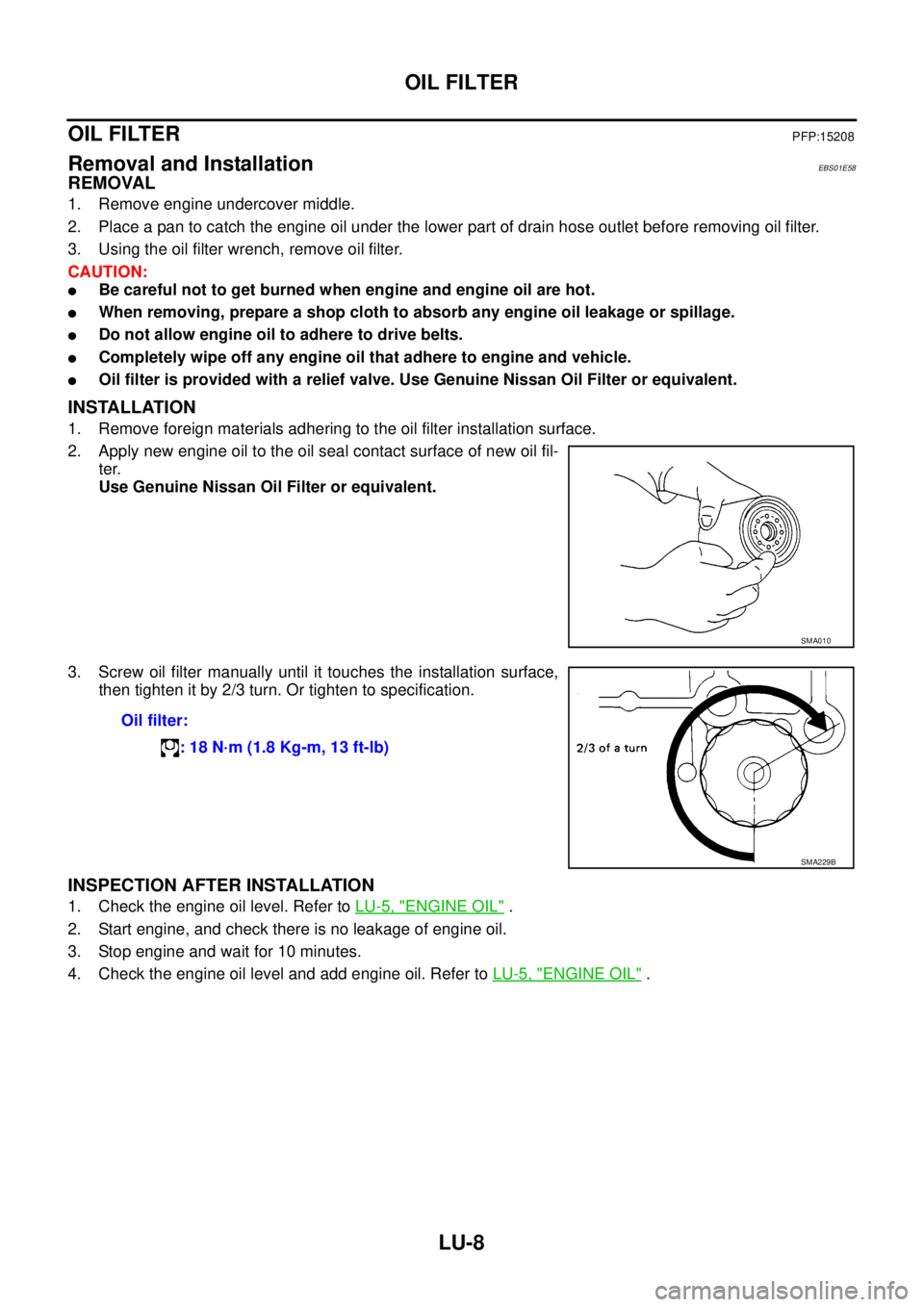

2. Apply new engine oil to the oil seal contact surface of new oil fil-

ter.

Use Genuine Nissan Oil Filter or equivalent.

3. Screw oil filter manually until it touches the installation surface,

then tighten it by 2/3 turn. Or tighten to specification.

INSPECTION AFTER INSTALLATION

1. Check the engine oil level. Refer toLU-5, "ENGINE OIL".

2. Start engine, and check there is no leakage of engine oil.

3. Stop engine and wait for 10 minutes.

4. Check the engine oil level and add engine oil. Refer toLU-5, "

ENGINE OIL".

SMA010

Oil filter:

: 18 N·m (1.8 Kg-m, 13 ft-lb)

SMA229B

Page 2267 of 3171

LU-10

OIL FILTER BRACKET

INSTALLATION

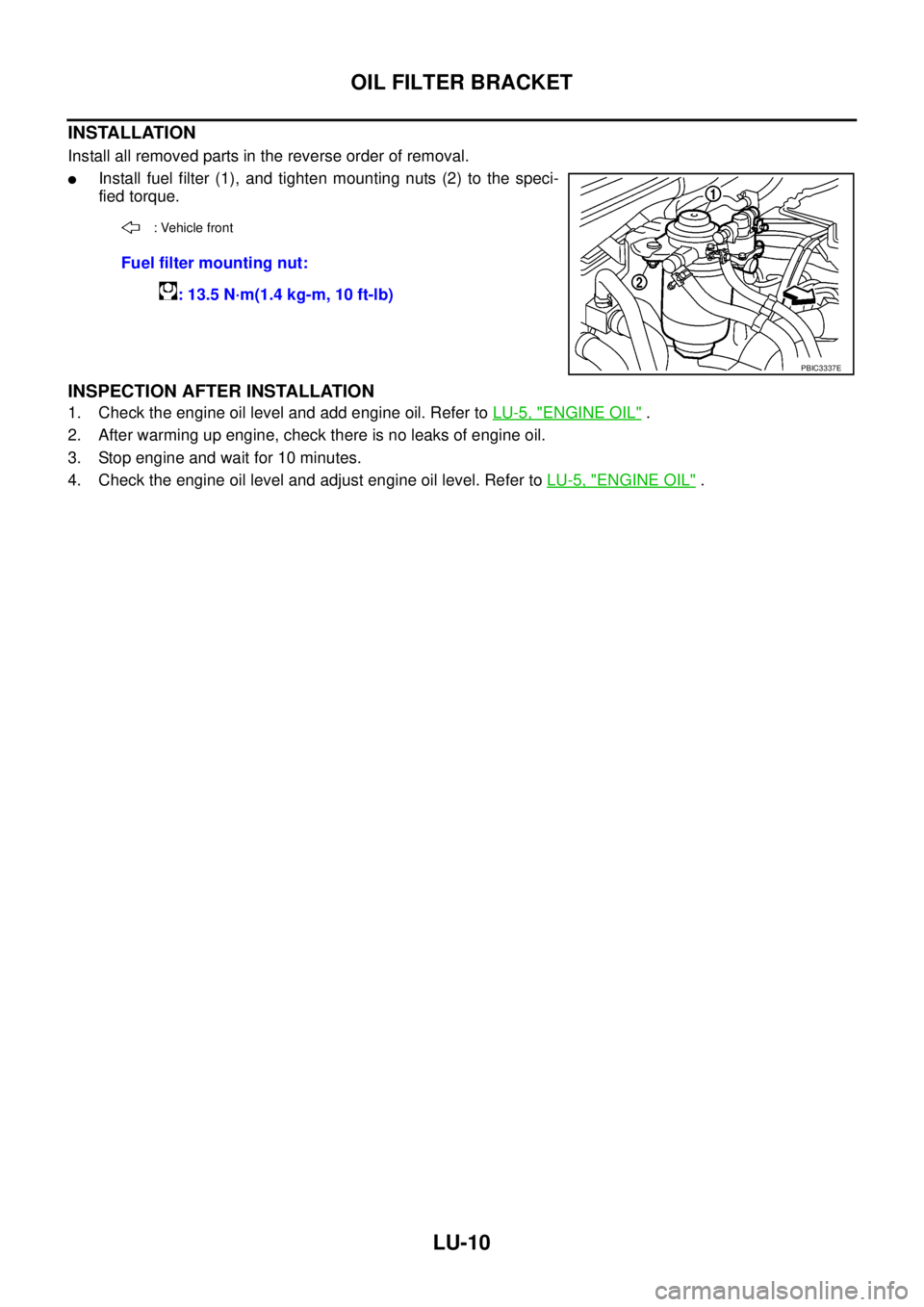

Install all removed parts in the reverse order of removal.

lInstall fuel filter (1), and tighten mounting nuts (2) to the speci-

fied torque.

INSPECTION AFTER INSTALLATION

1. Check the engine oil level and add engine oil. Refer toLU-5, "ENGINE OIL".

2. After warming up engine, check there is no leaks of engine oil.

3. Stop engine and wait for 10 minutes.

4. Check the engine oil level and adjust engine oil level. Refer toLU-5, "

ENGINE OIL".

: Vehicle front

Fuel filter mounting nut:

: 13.5 N·m(1.4 kg-m, 10 ft-lb)

PBIC3337E

Page 2268 of 3171

OIL COOLER

LU-11

C

D

E

F

G

H

I

J

K

L

MA

LU

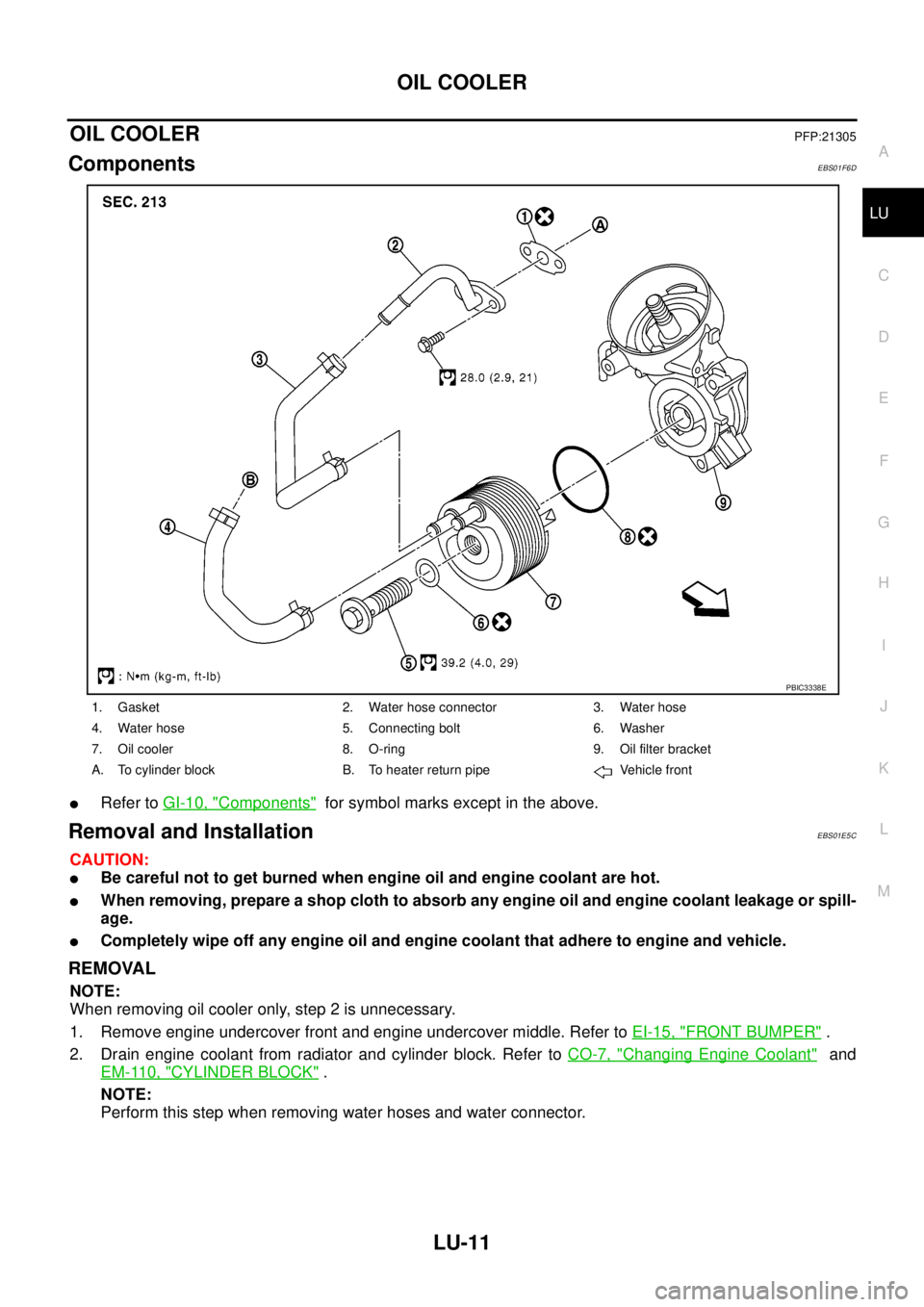

OIL COOLERPFP:21305

ComponentsEBS01F6D

lRefer toGI-10, "Components"for symbol marks except in the above.

Removal and InstallationEBS01E5C

CAUTION:

lBe careful not to get burned when engine oil and engine coolant are hot.

lWhen removing, prepare a shop cloth to absorb any engine oil and engine coolant leakage or spill-

age.

lCompletely wipe off any engine oil and engine coolant that adhere to engine and vehicle.

REMOVAL

NOTE:

When removing oil cooler only, step 2 is unnecessary.

1. Remove engine undercover front and engine undercover middle. Refer toEI-15, "

FRONT BUMPER".

2. Drain engine coolant from radiator and cylinder block. Refer toCO-7, "

Changing Engine Coolant"and

EM-110, "

CYLINDER BLOCK".

NOTE:

Perform this step when removing water hoses and water connector.

1. Gasket 2. Water hose connector 3. Water hose

4. Water hose 5. Connecting bolt 6. Washer

7. Oil cooler 8. O-ring 9. Oil filter bracket

A. To cylinder block B. To heater return pipe Vehicle front

PBIC3338E

Page 2269 of 3171

LU-12

OIL COOLER

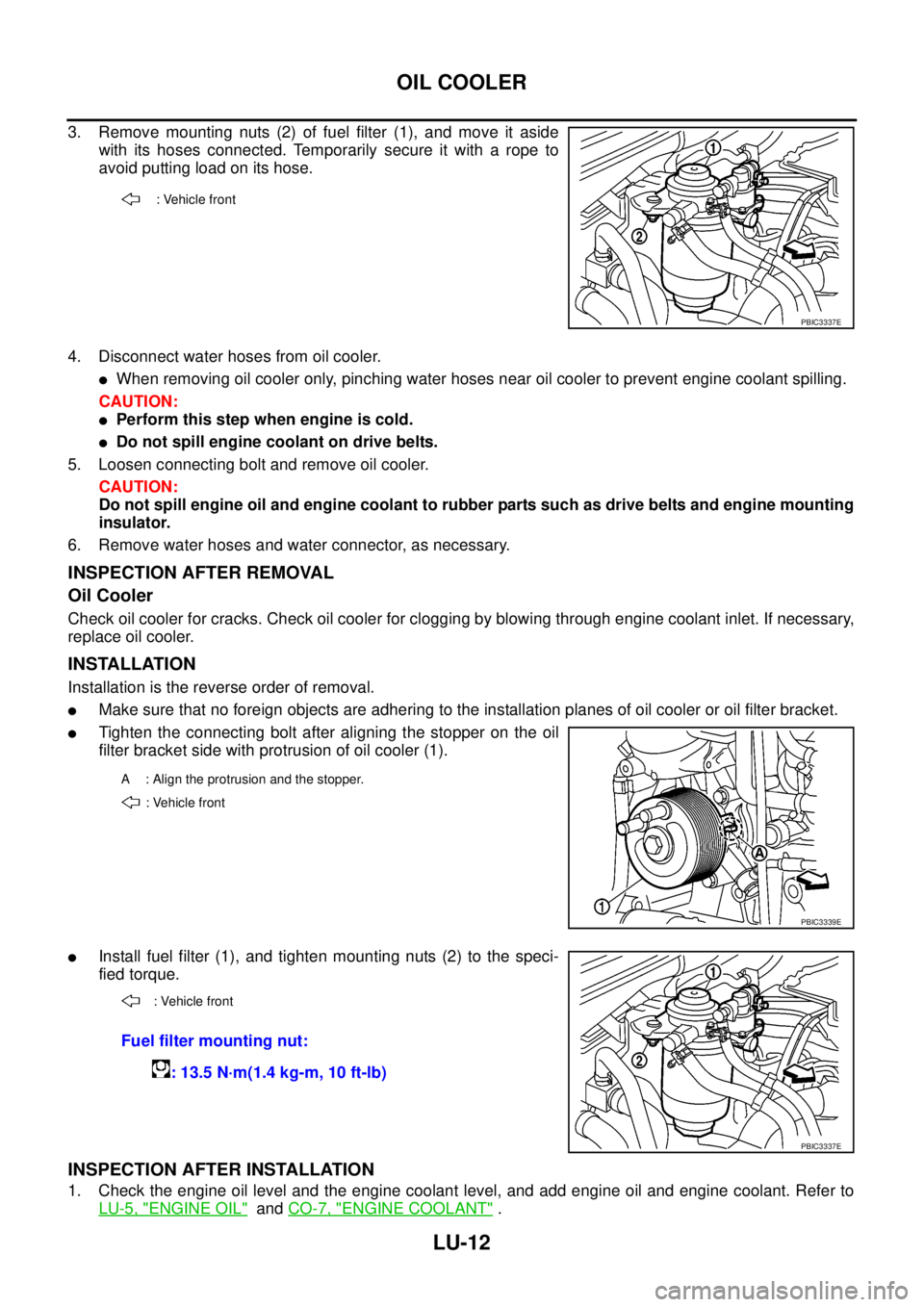

3. Remove mounting nuts (2) of fuel filter (1), and move it aside

with its hoses connected. Temporarily secure it with a rope to

avoid putting load on its hose.

4. Disconnect water hoses from oil cooler.

lWhen removing oil cooler only, pinching water hoses near oil cooler to prevent engine coolant spilling.

CAUTION:

lPerform this step when engine is cold.

lDo not spill engine coolant on drive belts.

5. Loosen connecting bolt and remove oil cooler.

CAUTION:

Do not spill engine oil and engine coolant to rubber parts such as drive belts and engine mounting

insulator.

6. Remove water hoses and water connector, as necessary.

INSPECTION AFTER REMOVAL

Oil Cooler

Check oil cooler for cracks. Check oil cooler for clogging by blowing through engine coolant inlet. If necessary,

replace oil cooler.

INSTALLATION

Installation is the reverse order of removal.

lMake sure that no foreign objects are adhering to the installation planes of oil cooler or oil filter bracket.

lTighten the connecting bolt after aligning the stopper on the oil

filter bracket side with protrusion of oil cooler (1).

lInstall fuel filter (1), and tighten mounting nuts (2) to the speci-

fied torque.

INSPECTION AFTER INSTALLATION

1. Check the engine oil level and the engine coolant level, and add engine oil and engine coolant. Refer to

LU-5, "

ENGINE OIL"andCO-7, "ENGINE COOLANT".

: Vehicle front

PBIC3337E

A : Align the protrusion and the stopper.

: Vehicle front

PBIC3339E

: Vehicle front

Fuel filter mounting nut:

: 13.5 N·m(1.4 kg-m, 10 ft-lb)

PBIC3337E

Page 2270 of 3171

OIL COOLER

LU-13

C

D

E

F

G

H

I

J

K

L

MA

LU

2. Start engine, and make sure that there is no leaks of engine oil or engine coolant.

3. Stop engine and wait for 10 minutes.

4. Check the engine oil level and the engine coolant level again. Refer toLU-5, "

ENGINE OIL"andCO-7,

"ENGINE COOLANT".

Page 2271 of 3171

LU-14

OIL PUMP

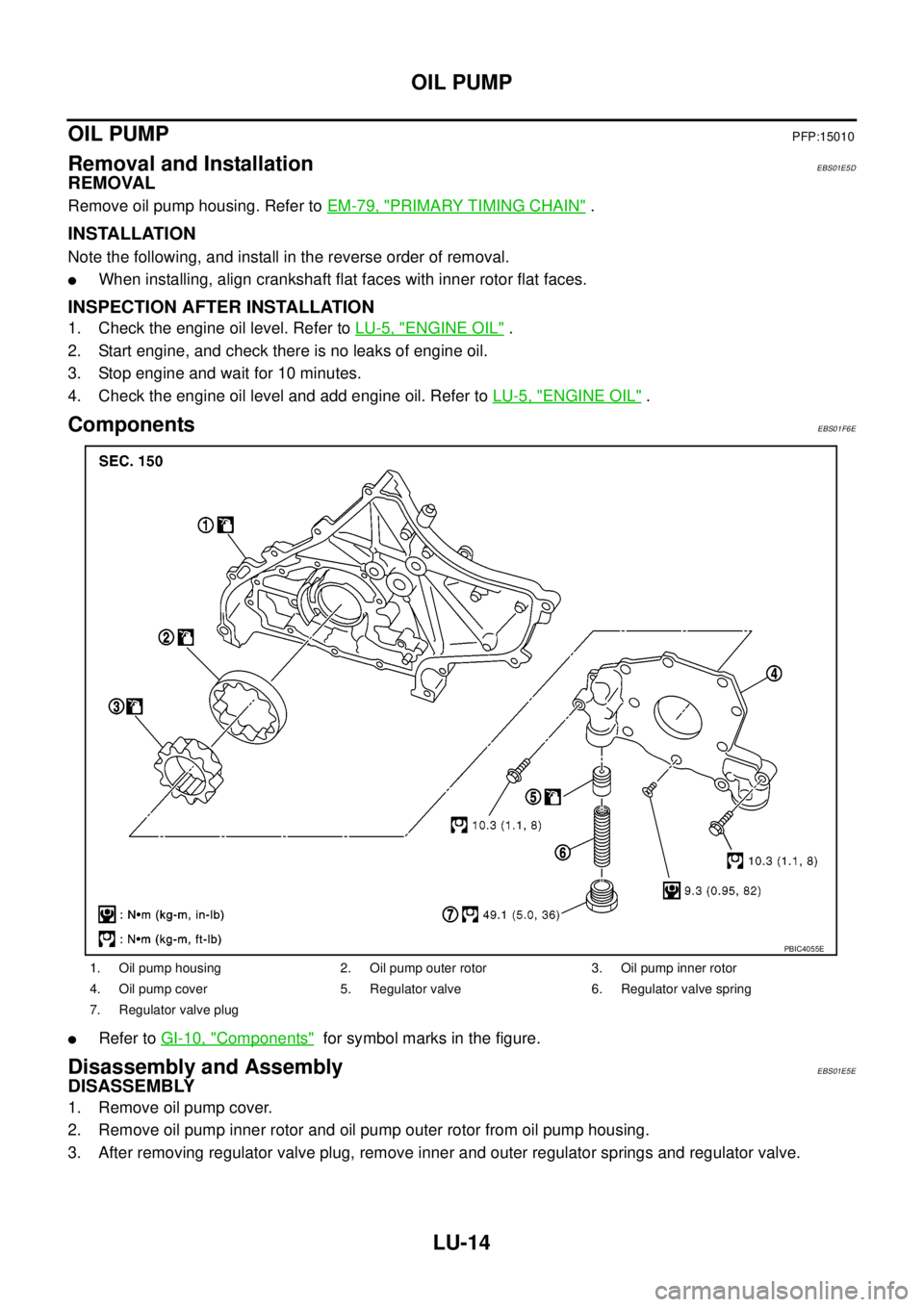

OIL PUMP

PFP:15010

Removal and InstallationEBS01E5D

REMOVAL

Remove oil pump housing. Refer toEM-79, "PRIMARY TIMING CHAIN".

INSTALLATION

Note the following, and install in the reverse order of removal.

lWhen installing, align crankshaft flat faces with inner rotor flat faces.

INSPECTION AFTER INSTALLATION

1. Check the engine oil level. Refer toLU-5, "ENGINE OIL".

2. Start engine, and check there is no leaks of engine oil.

3. Stop engine and wait for 10 minutes.

4. Check the engine oil level and add engine oil. Refer toLU-5, "

ENGINE OIL".

ComponentsEBS01F6E

lRefer toGI-10, "Components"for symbol marks in the figure.

Disassembly and AssemblyEBS01E5E

DISASSEMBLY

1. Remove oil pump cover.

2. Remove oil pump inner rotor and oil pump outer rotor from oil pump housing.

3. After removing regulator valve plug, remove inner and outer regulator springs and regulator valve.

1. Oil pump housing 2. Oil pump outer rotor 3. Oil pump inner rotor

4. Oil pump cover 5. Regulator valve 6. Regulator valve spring

7. Regulator valve plug

PBIC4055E

Page 2273 of 3171

LU-16

OIL PUMP

• If measured/calculated values are out of the standard, replace oil pump assembly.

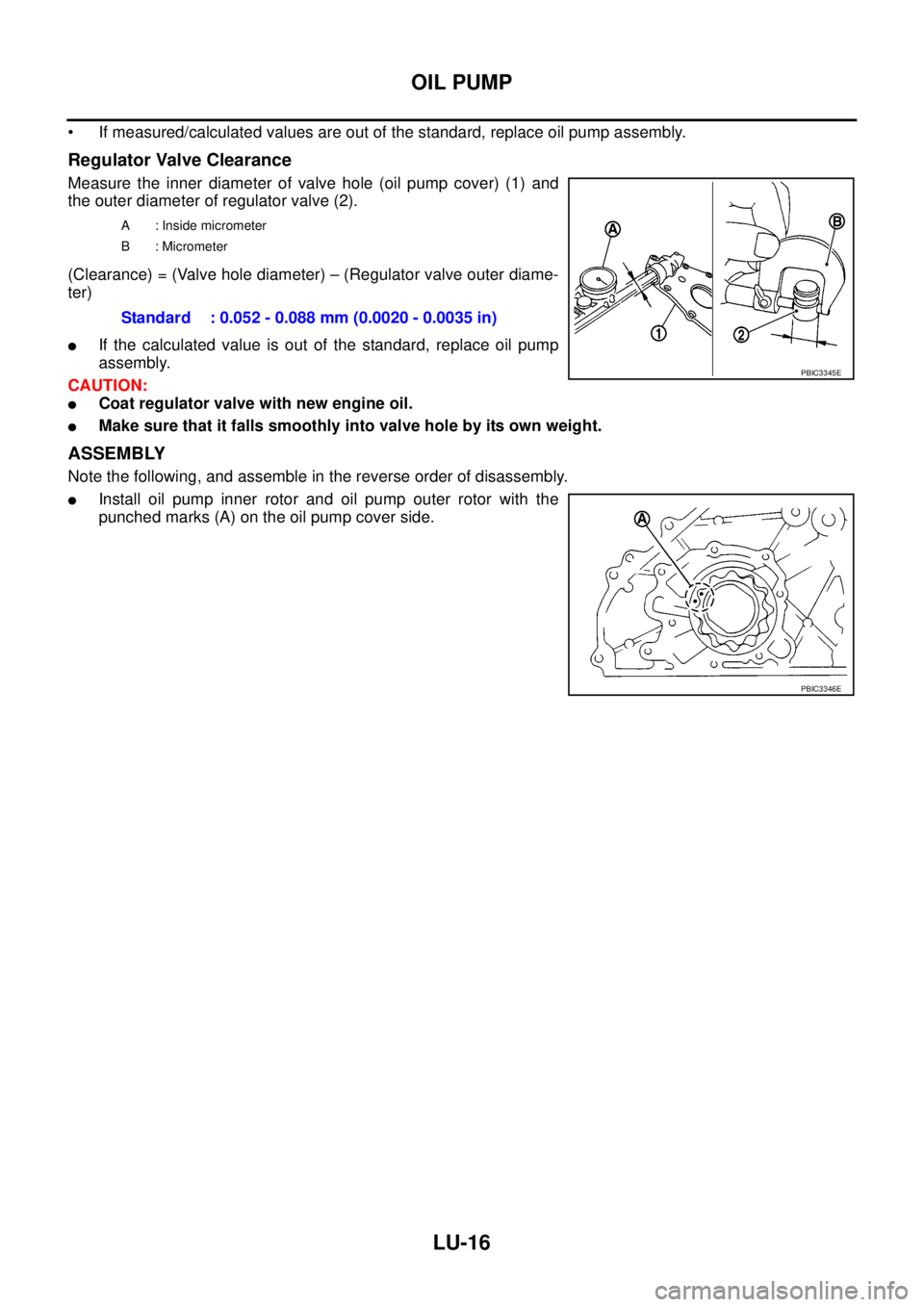

Regulator Valve Clearance

Measure the inner diameter of valve hole (oil pump cover) (1) and

the outer diameter of regulator valve (2).

(Clearance) = (Valve hole diameter) – (Regulator valve outer diame-

ter)

lIf the calculated value is out of the standard, replace oil pump

assembly.

CAUTION:

lCoat regulator valve with new engine oil.

lMake sure that it falls smoothly into valve hole by its own weight.

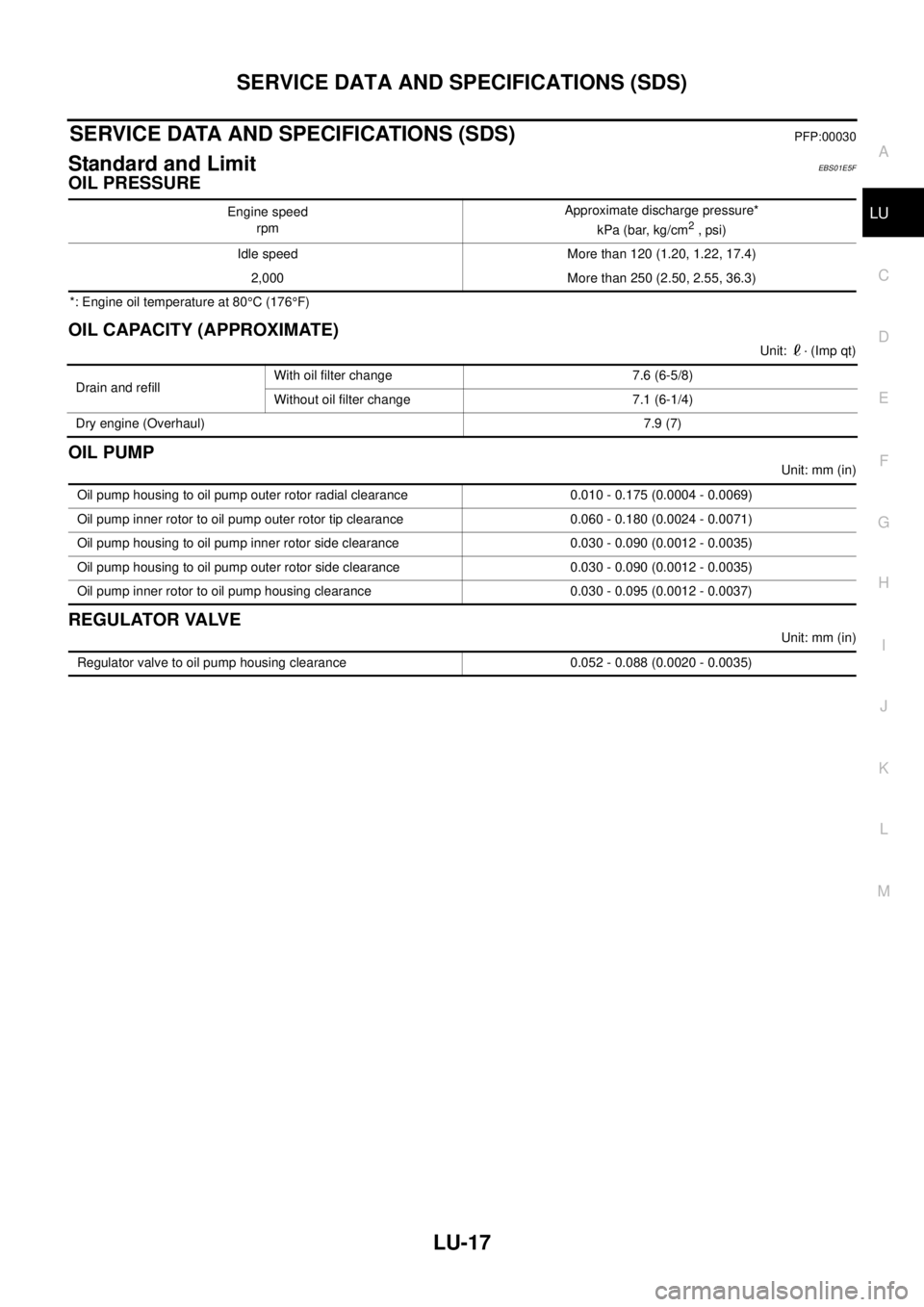

ASSEMBLY

Note the following, and assemble in the reverse order of disassembly.

lInstall oil pump inner rotor and oil pump outer rotor with the

punched marks (A) on the oil pump cover side.

A : Inside micrometer

B : Micrometer

Standard : 0.052 - 0.088 mm (0.0020 - 0.0035 in)

PBIC3345E

PBIC3346E

Page 2274 of 3171

SERVICE DATA AND SPECIFICATIONS (SDS)

LU-17

C

D

E

F

G

H

I

J

K

L

MA

LU

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

Standard and LimitEBS01E5F

OIL PRESSURE

*: Engine oil temperature at 80°C (176°F)

OIL CAPACITY (APPROXIMATE)

Unit: · (Imp qt)

OIL PUMP

Unit: mm (in)

REGULATOR VALVE

Unit: mm (in) Engine speed

rpmApproximate discharge pressure*

kPa (bar, kg/cm

2, psi)

Idle speed More than 120 (1.20, 1.22, 17.4)

2,000 More than 250 (2.50, 2.55, 36.3)

Drain and refillWith oil filter change 7.6 (6-5/8)

Without oil filter change 7.1 (6-1/4)

Dry engine (Overhaul)7.9 (7)

Oil pump housing to oil pump outer rotor radial clearance 0.010 - 0.175 (0.0004 - 0.0069)

Oil pump inner rotor to oil pump outer rotor tip clearance 0.060 - 0.180 (0.0024 - 0.0071)

Oil pump housing to oil pump inner rotor side clearance 0.030 - 0.090 (0.0012 - 0.0035)

Oil pump housing to oil pump outer rotor side clearance 0.030 - 0.090 (0.0012 - 0.0035)

Oil pump inner rotor to oil pump housing clearance 0.030 - 0.095 (0.0012 - 0.0037)

Regulator valve to oil pump housing clearance 0.052 - 0.088 (0.0020 - 0.0035)