engine oil NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2307 of 3171

MA-32

CHASSIS AND BODY MAINTENANCE

Changing Transfer Fluid

ELS001IR

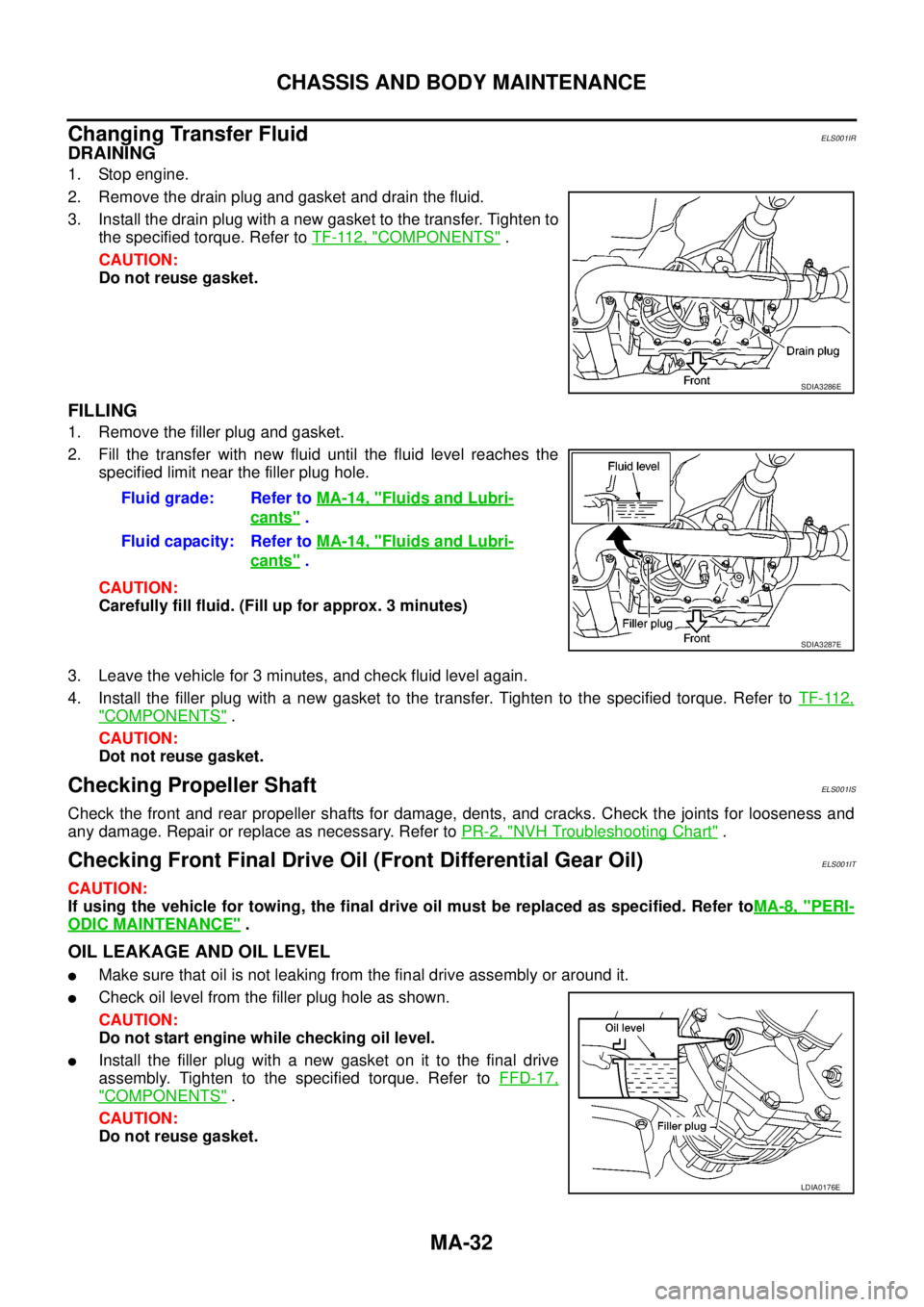

DRAINING

1. Stop engine.

2. Remove the drain plug and gasket and drain the fluid.

3. Install the drain plug with a new gasket to the transfer. Tighten to

the specified torque. Refer toTF-112, "

COMPONENTS".

CAUTION:

Do not reuse gasket.

FILLING

1. Remove the filler plug and gasket.

2. Fill the transfer with new fluid until the fluid level reaches the

specified limit near the filler plug hole.

CAUTION:

Carefully fill fluid. (Fill up for approx. 3 minutes)

3. Leave the vehicle for 3 minutes, and check fluid level again.

4. Install the filler plug with a new gasket to the transfer. Tighten to the specified torque. Refer toTF-112,

"COMPONENTS".

CAUTION:

Dot not reuse gasket.

Checking Propeller ShaftELS001IS

Check the front and rear propeller shafts for damage, dents, and cracks. Check the joints for looseness and

any damage. Repair or replace as necessary. Refer toPR-2, "

NVH Troubleshooting Chart".

Checking Front Final Drive Oil (Front Differential Gear Oil)ELS001IT

CAUTION:

If using the vehicle for towing, the final drive oil must be replaced as specified. Refer toMA-8, "

PERI-

ODIC MAINTENANCE".

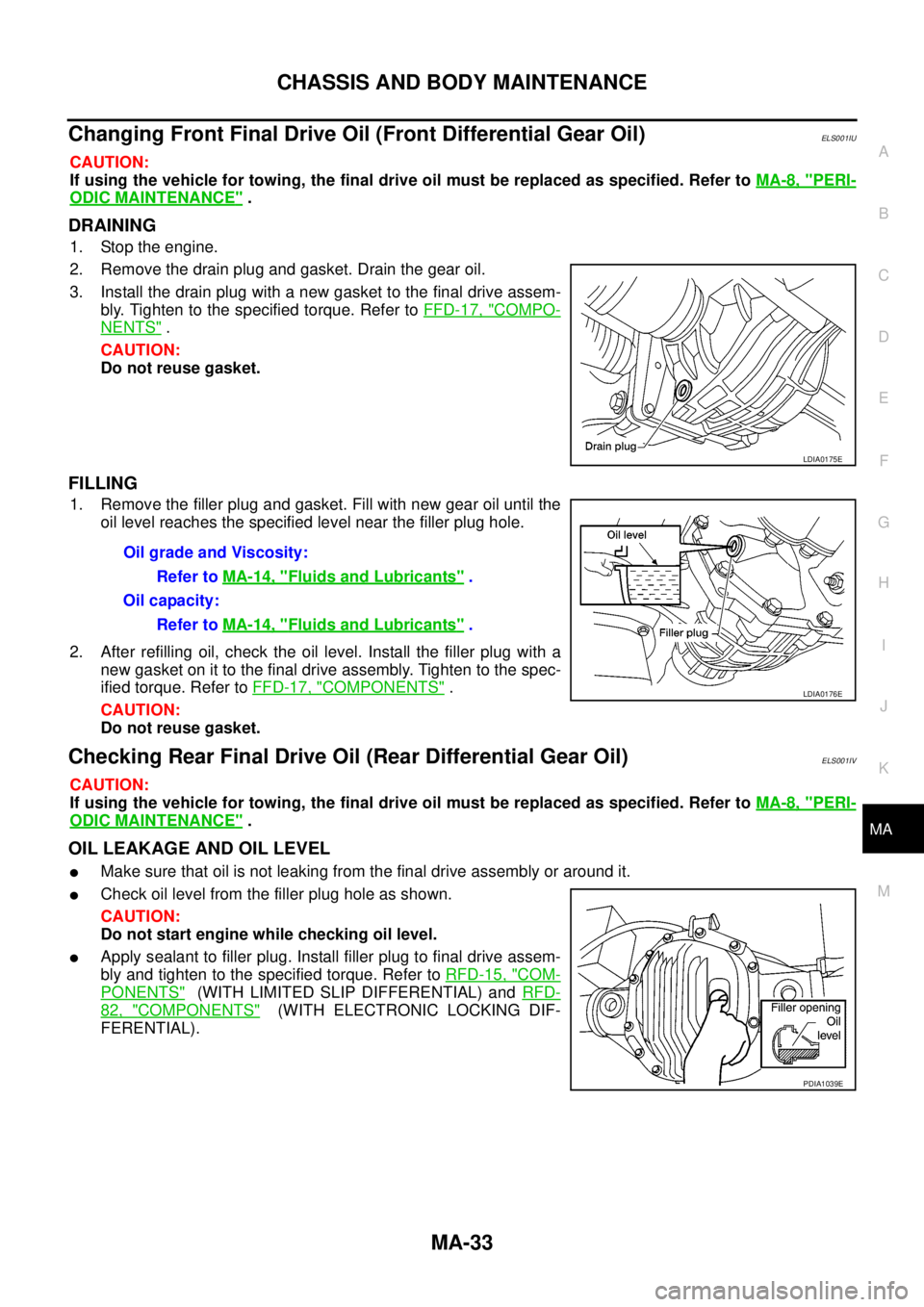

OIL LEAKAGE AND OIL LEVEL

lMake sure that oil is not leaking from the final drive assembly or around it.

lCheck oil level from the filler plug hole as shown.

CAUTION:

Do not start engine while checking oil level.

lInstall the filler plug with a new gasket on it to the final drive

assembly. Tighten to the specified torque. Refer toFFD-17,

"COMPONENTS".

CAUTION:

Do not reuse gasket.

SDIA3286E

Fluid grade: Refer toMA-14, "Fluids and Lubri-

cants".

Fluid capacity: Refer toMA-14, "

Fluids and Lubri-

cants".

SDIA3287E

LDIA0176E

Page 2308 of 3171

CHASSIS AND BODY MAINTENANCE

MA-33

C

D

E

F

G

H

I

J

K

MA

B

MA

Changing Front Final Drive Oil (Front Differential Gear Oil)ELS001IU

CAUTION:

If using the vehicle for towing, the final drive oil must be replaced as specified. Refer toMA-8, "

PERI-

ODIC MAINTENANCE".

DRAINING

1. Stop the engine.

2. Remove the drain plug and gasket. Drain the gear oil.

3. Install the drain plug with a new gasket to the final drive assem-

bly. Tighten to the specified torque. Refer toFFD-17, "

COMPO-

NENTS".

CAUTION:

Do not reuse gasket.

FILLING

1. Remove the filler plug and gasket. Fill with new gear oil until the

oil level reaches the specified level near the filler plug hole.

2. After refilling oil, check the oil level. Install the filler plug with a

new gasket on it to the final drive assembly. Tighten to the spec-

ified torque. Refer toFFD-17, "

COMPONENTS".

CAUTION:

Do not reuse gasket.

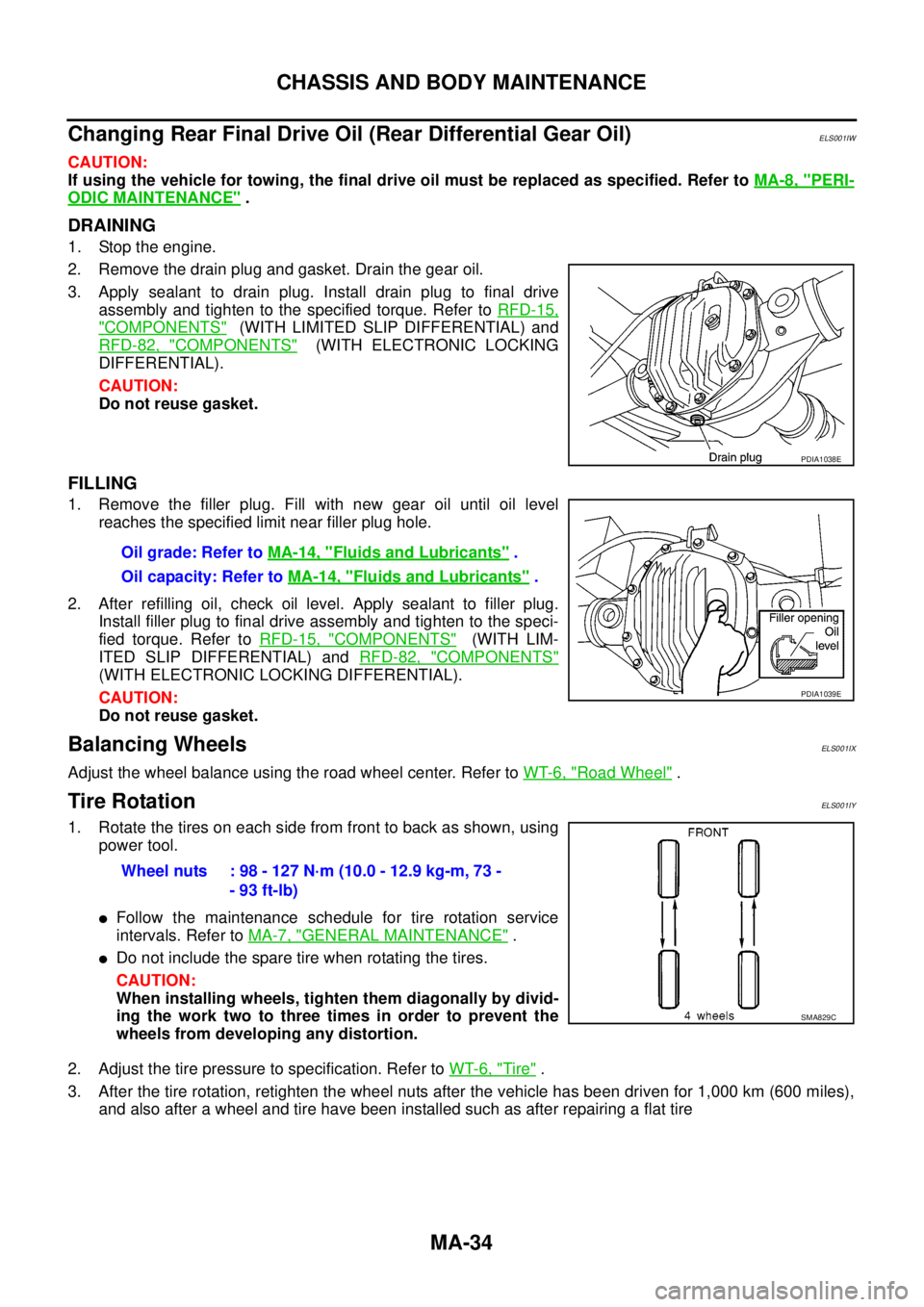

Checking Rear Final Drive Oil (Rear Differential Gear Oil)ELS001IV

CAUTION:

If using the vehicle for towing, the final drive oil must be replaced as specified. Refer toMA-8, "

PERI-

ODIC MAINTENANCE".

OIL LEAKAGE AND OIL LEVEL

lMake sure that oil is not leaking from the final drive assembly or around it.

lCheck oil level from the filler plug hole as shown.

CAUTION:

Do not start engine while checking oil level.

lApply sealant to filler plug. Install filler plug to final drive assem-

bly and tighten to the specified torque. Refer toRFD-15, "

COM-

PONENTS"(WITH LIMITED SLIP DIFFERENTIAL) andRFD-

82, "COMPONENTS"(WITH ELECTRONIC LOCKING DIF-

FERENTIAL).

LDIA0175E

OilgradeandViscosity:

Refer toMA-14, "

Fluids and Lubricants".

Oil capacity:

Refer toMA-14, "

Fluids and Lubricants".

LDIA0176E

PDIA1039E

Page 2309 of 3171

MA-34

CHASSIS AND BODY MAINTENANCE

Changing Rear Final Drive Oil (Rear Differential Gear Oil)

ELS001IW

CAUTION:

If using the vehicle for towing, the final drive oil must be replaced as specified. Refer toMA-8, "

PERI-

ODIC MAINTENANCE".

DRAINING

1. Stop the engine.

2. Remove the drain plug and gasket. Drain the gear oil.

3. Apply sealant to drain plug. Install drain plug to final drive

assembly and tighten to the specified torque. Refer toRFD-15,

"COMPONENTS"(WITH LIMITED SLIP DIFFERENTIAL) and

RFD-82, "

COMPONENTS"(WITH ELECTRONIC LOCKING

DIFFERENTIAL).

CAUTION:

Do not reuse gasket.

FILLING

1. Remove the filler plug. Fill with new gear oil until oil level

reaches the specified limit near filler plug hole.

2. After refilling oil, check oil level. Apply sealant to filler plug.

Install filler plug to final drive assembly and tighten to the speci-

fied torque. Refer toRFD-15, "

COMPONENTS"(WITH LIM-

ITED SLIP DIFFERENTIAL) andRFD-82, "

COMPONENTS"

(WITH ELECTRONIC LOCKING DIFFERENTIAL).

CAUTION:

Do not reuse gasket.

Balancing WheelsELS001IX

Adjust the wheel balance using the road wheel center. Refer toWT-6, "Road Wheel".

Tire RotationELS001IY

1. Rotate the tires on each side from front to back as shown, using

power tool.

lFollow the maintenance schedule for tire rotation service

intervals. Refer toMA-7, "

GENERAL MAINTENANCE".

lDo not include the spare tire when rotating the tires.

CAUTION:

When installing wheels, tighten them diagonally by divid-

ing the work two to three times in order to prevent the

wheels from developing any distortion.

2. Adjust the tire pressure to specification. Refer toWT-6, "

Tire".

3. After the tire rotation, retighten the wheel nuts after the vehicle has been driven for 1,000 km (600 miles),

and also after a wheel and tire have been installed such as after repairing a flat tire

PDIA1038E

Oil grade: Refer toMA-14, "Fluids and Lubricants".

Oil capacity: Refer toMA-14, "

Fluids and Lubricants".

PDIA1039E

Wheel nuts : 98 - 127 N·m (10.0 - 12.9 kg-m, 73 -

- 93 ft-lb)

SMA829C

Page 2312 of 3171

CHASSIS AND BODY MAINTENANCE

MA-37

C

D

E

F

G

H

I

J

K

MA

B

MA

LINING

lCheck for lining thickness.

Checking Steering Gear and LinkageELS001J3

STEERING GEAR

lCheck the steering gear housing for looseness, damage and oil

leakage as shown.

lCheck the steering column connections for looseness.

STEERING LINKAGE

lCheck the ball joint, dust cover and other component parts for looseness, wear, damage and grease leak-

age.

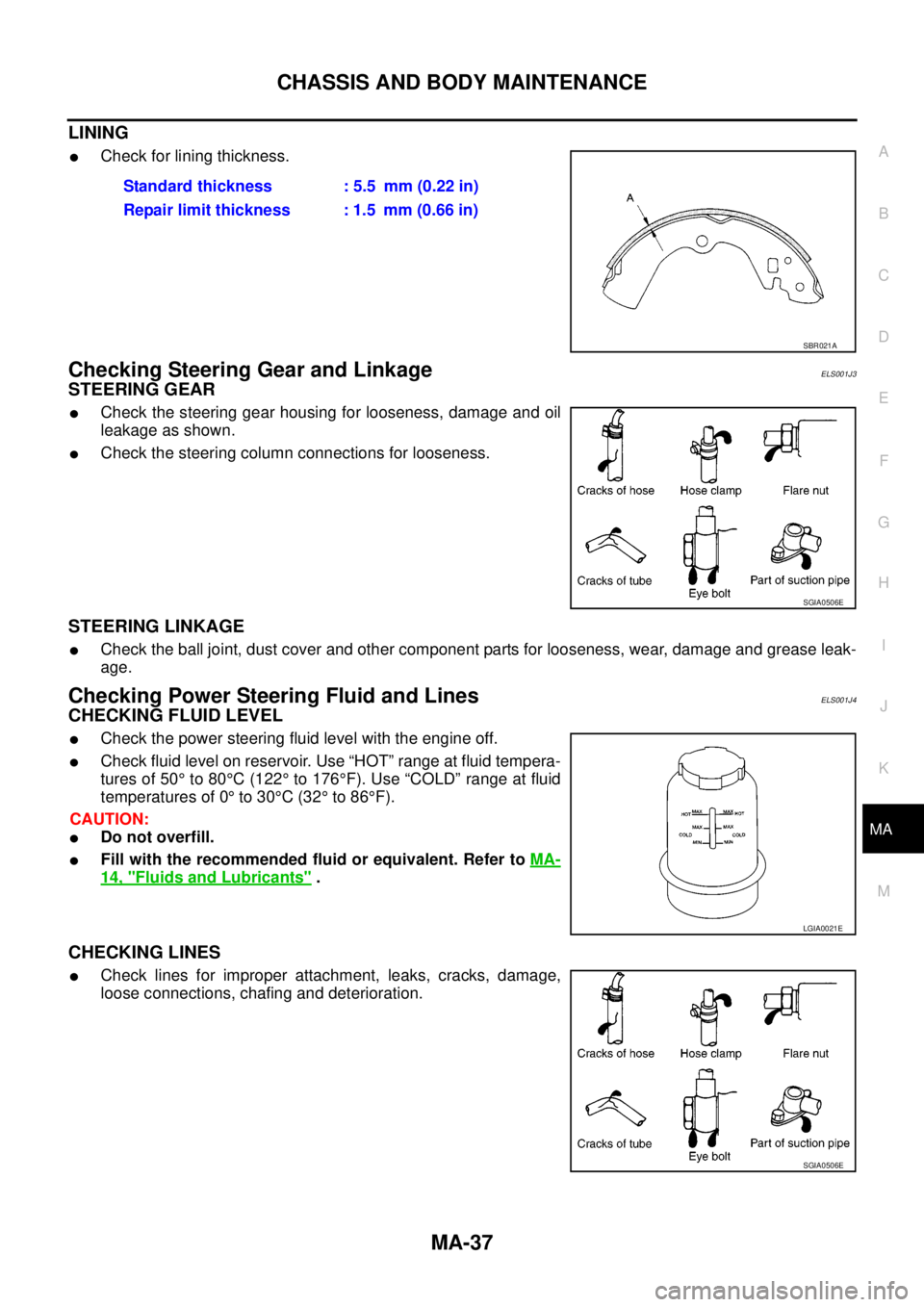

Checking Power Steering Fluid and LinesELS001J4

CHECKING FLUID LEVEL

lCheck the power steering fluid level with the engine off.

lCheck fluid level on reservoir. Use “HOT” range at fluid tempera-

tures of 50°to 80°C(122°to 176°F). Use “COLD” range at fluid

temperatures of 0°to 30°C(32°to 86°F).

CAUTION:

lDo not overfill.

lFill with the recommended fluid or equivalent. Refer toMA-

14, "Fluids and Lubricants".

CHECKING LINES

lCheck lines for improper attachment, leaks, cracks, damage,

loose connections, chafing and deterioration.Standard thickness : 5.5 mm (0.22 in)

Repair limit thickness : 1.5 mm (0.66 in)

SBR021A

SGIA0506E

LGIA0021E

SGIA0506E

Page 2316 of 3171

SERVICE DATA AND SPECIFICATIONS (SDS)

MA-41

C

D

E

F

G

H

I

J

K

MA

B

MA

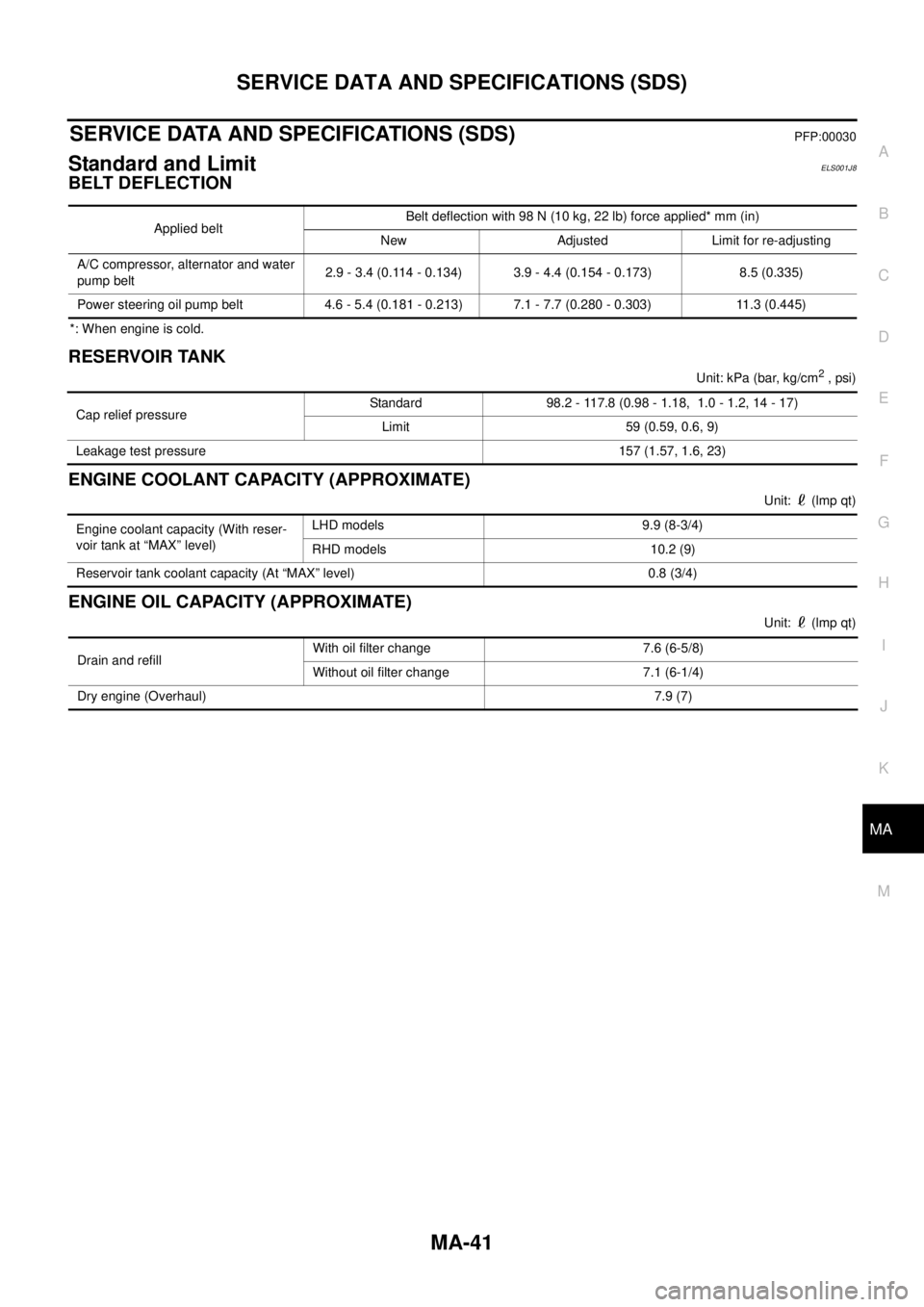

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

Standard and LimitELS001J8

BELT DEFLECTION

*: When engine is cold.

RESERVOIR TANK

Unit:kPa(bar,kg/cm2, psi)

ENGINE COOLANT CAPACITY (APPROXIMATE)

Unit: (lmp qt)

ENGINE OIL CAPACITY (APPROXIMATE)

Unit: (lmp qt) Applied beltBelt deflection with 98 N (10 kg, 22 lb) force applied* mm (in)

New Adjusted Limit for re-adjusting

A/C compressor, alternator and water

pump belt2.9 - 3.4 (0.114 - 0.134) 3.9 - 4.4 (0.154 - 0.173) 8.5 (0.335)

Power steering oil pump belt 4.6 - 5.4 (0.181 - 0.213) 7.1 - 7.7 (0.280 - 0.303) 11.3 (0.445)

Cap relief pressureStandard 98.2 - 117.8 (0.98 - 1.18, 1.0 - 1.2, 14 - 17)

Limit 59 (0.59, 0.6, 9)

Leakage test pressure 157 (1.57, 1.6, 23)

Engine coolant capacity (With reser-

voir tank at “MAX” level)LHD models 9.9 (8-3/4)

RHD models 10.2 (9)

Reservoir tank coolant capacity (At “MAX” level) 0.8 (3/4)

Drain and refillWith oil filter change 7.6 (6-5/8)

Without oil filter change 7.1 (6-1/4)

Dry engine (Overhaul)7.9 (7)

Page 2326 of 3171

M/T OIL

MT-9

D

E

F

G

H

I

J

K

L

MA

B

MT

M/T OILPFP:KLD20

Changing M/T OilECS00ID3

DRAINING

1. Start engine and let it run to warm up transmission.

2. Stop engine. Remove drain plug and gasket and then drain oil.

3. Set a gasket on drain plug and install it to transmission case. Tighten drain plug to the specified torque.

Refer toMT-19, "

Case Components".

CAUTION:

Do no reuse gasket.

FILLING

1. Remove filler plug and gasket. Fill with new oil until oil level reaches the specified limit near filler plug

mounting hole.

2. After refilling oil, check oil level. Set a gasket to filler plug, then install it to transmission case. Tighten filler

plug to the specified torque. Refer toMT-19, "

Case Components".

CAUTION:

Do no reuse gasket.

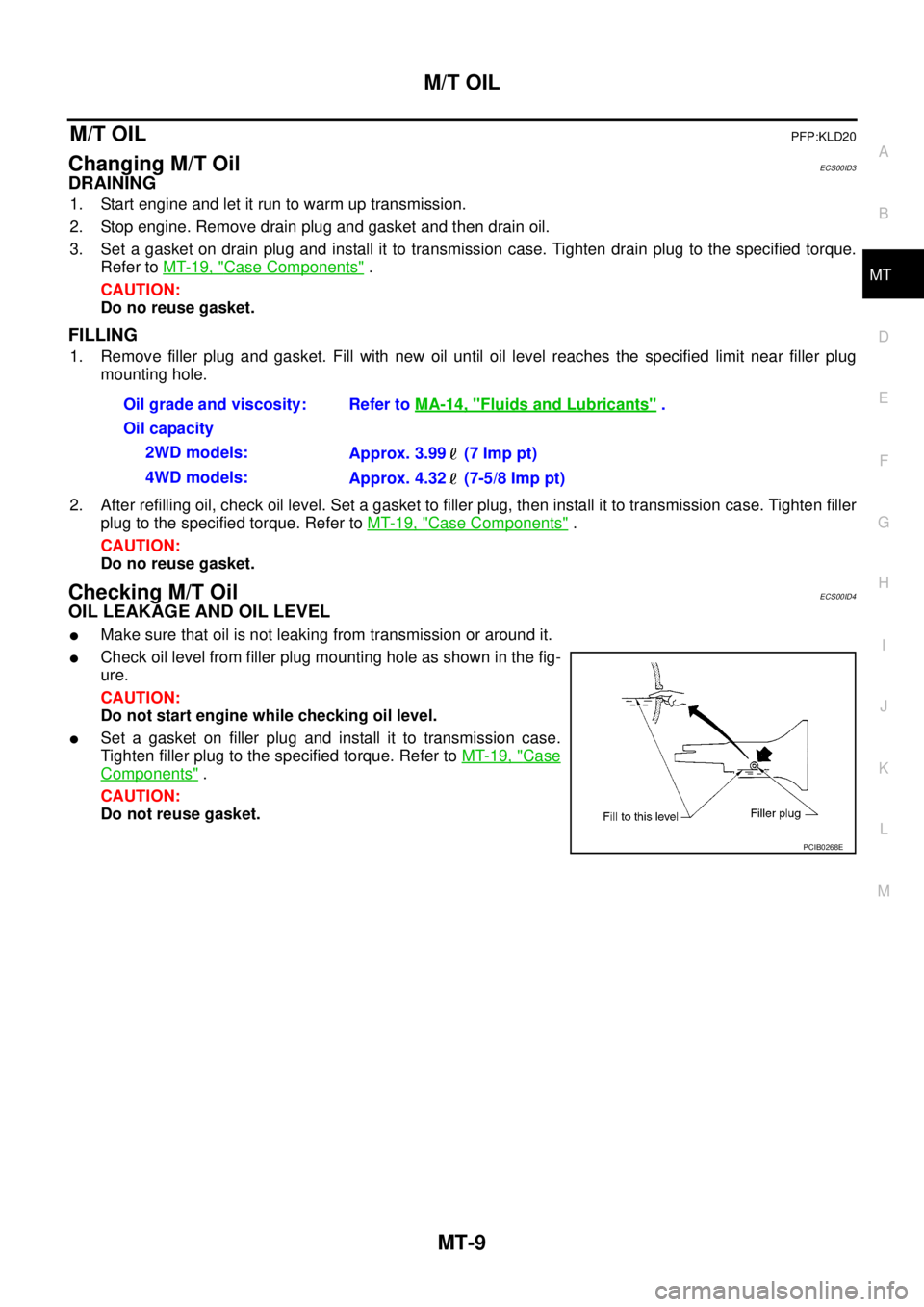

Checking M/T OilECS00ID4

OIL LEAKAGE AND OIL LEVEL

lMake sure that oil is not leaking from transmission or around it.

lCheck oil level from filler plug mounting hole as shown in the fig-

ure.

CAUTION:

Do not start engine while checking oil level.

lSet a gasket on filler plug and install it to transmission case.

Tighten filler plug to the specified torque. Refer toMT-19, "

Case

Components".

CAUTION:

Do not reuse gasket.Oil grade and viscosity: Refer toMA-14, "

Fluids and Lubricants".

Oil capacity

2WD models:

Approx. 3.99 (7 Imp pt)

4WD models:

Approx. 4.32 (7-5/8 Imp pt)

PCIB0268E

Page 2334 of 3171

TRANSMISSION ASSEMBLY

MT-17

D

E

F

G

H

I

J

K

L

MA

B

MT

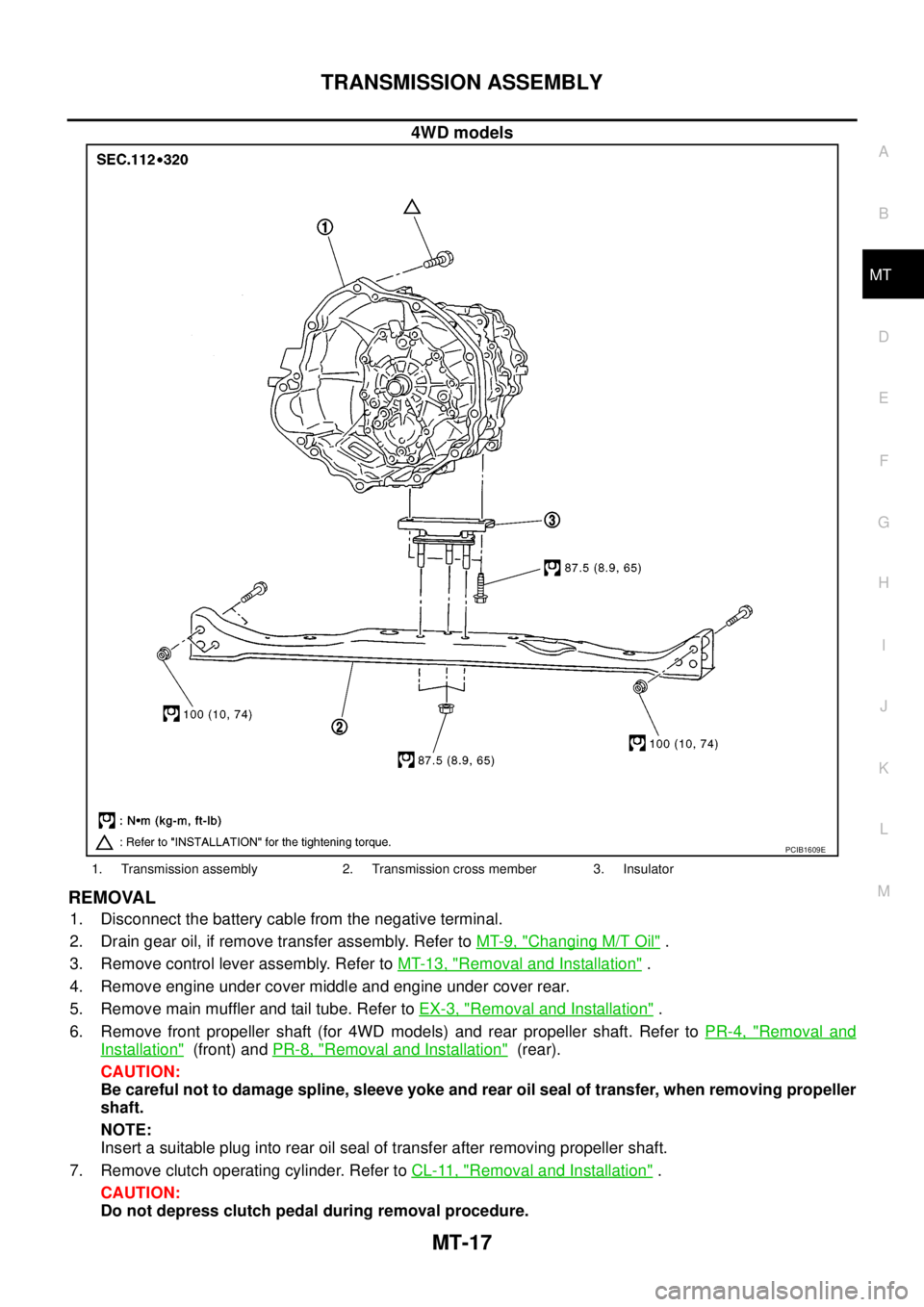

4WD models

REMOVAL

1. Disconnect the battery cable from the negative terminal.

2. Drain gear oil, if remove transfer assembly. Refer toMT-9, "

Changing M/T Oil".

3. Remove control lever assembly. Refer toMT-13, "

Removal and Installation".

4. Remove engine under cover middle and engine under cover rear.

5. Remove main muffler and tail tube. Refer toEX-3, "

Removal and Installation".

6. Remove front propeller shaft (for 4WD models) and rear propeller shaft. Refer toPR-4, "

Removal and

Installation"(front) andPR-8, "Removal and Installation"(rear).

CAUTION:

Be careful not to damage spline, sleeve yoke and rear oil seal of transfer, when removing propeller

shaft.

NOTE:

Insert a suitable plug into rear oil seal of transfer after removing propeller shaft.

7. Remove clutch operating cylinder. Refer toCL-11, "

Removal and Installation".

CAUTION:

Do not depress clutch pedal during removal procedure.

PCIB1609E

1. Transmission assembly 2. Transmission cross member 3. Insulator

Page 2384 of 3171

SERVICE DATA AND SPECIFICATIONS (SDS)

MT-67

D

E

F

G

H

I

J

K

L

MA

B

MT

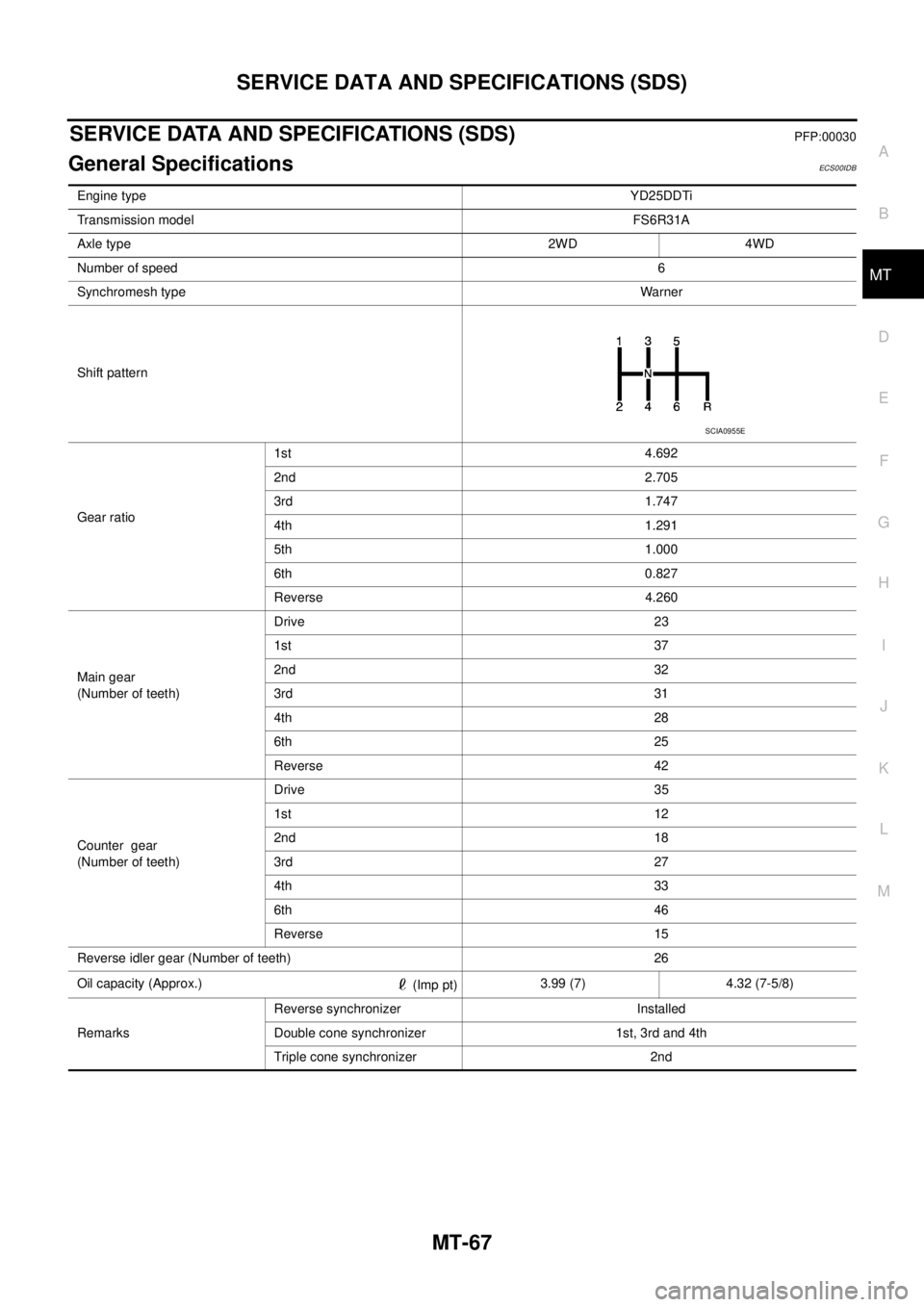

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

General SpecificationsECS00IDB

Engine typeYD25DDTi

Transmission modelFS6R31A

Axle type 2WD 4WD

Number of speed6

Synchromesh typeWarner

Shift pattern

Gear ratio1st 4.692

2nd 2.705

3rd 1.747

4th 1.291

5th 1.000

6th 0.827

Reverse 4.260

Main gear

(Number of teeth)Drive 23

1st 37

2nd 32

3rd 31

4th 28

6th 25

Reverse 42

Counter gear

(Number of teeth)Drive 35

1st 12

2nd 18

3rd 27

4th 33

6th 46

Reverse 15

Reverse idler gear (Number of teeth) 26

Oil capacity (Approx.)

(Imp pt)3.99 (7) 4.32 (7-5/8)

RemarksReverse synchronizer Installed

Double cone synchronizer 1st, 3rd and 4th

Triple cone synchronizer 2nd

SCIA0955E

Page 2492 of 3171

HEATER & COOLING UNIT ASSEMBLY

MTC-105

C

D

E

F

G

H

I

K

L

MA

B

MTC

Removal and InstallationEJS005GY

REMOVAL

1. Discharge the refrigerant from the A/C system. Refer toMTC-118, "Discharging Refrigerant".

2. Drain the coolant from the engine cooling system. Refer toCO-8, "

DRAINING ENGINE COOLANT".

3. Remove the cowl top extension. Refer toEI-20, "

Removal and Installation".

4. Remove the exhaust system. Refer toEX-3, "

Removal and Installation".

5. Disconnect the heater hoses from the heater core.

6. Disconnect the high/low pressure pipes from the expansion valve.

7. Move the two front seats to the rearmost position on the seat track.

8. Remove the instrument panel and console panel. Refer toIP-10, "

Removal and Installation".

9. Remove the steering column. Refer toPS-11, "

Removal and Installation".

10. Disconnect the instrument panel wire harness at the RH and LH in-line connector brackets, and the fuse

block (J/B) electrical connectors. Refer toPG-38, "

Harness Layout".

11. Disconnect the steering member from each side of the vehicle body.

12. Remove the heater and cooling unit assembly with it attached to the steering member, from the vehicle.

CAUTION:

Use care not to damage the seats and interior trim panels when removing the heater and cooling

unit assembly with it attached to the steering member.

13. Remove the heater and cooling unit assembly from the steering member.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

lReplace the O-ring of the low-pressure pipe and high-pressure pipe with a new one, and apply

compressor oil to it when installing it.

lAfter charging the refrigerant, check for leaks.

NOTE:

lFill the engine cooling system with the specified coolant mixture. Refer toCO-8, "REFILLING ENGINE

COOLANT".

lRecharge the A/C system. Refer toMTC-118, "Evacuating System and Charging Refrigerant".

Page 2509 of 3171

MTC-122

REFRIGERANT LINES

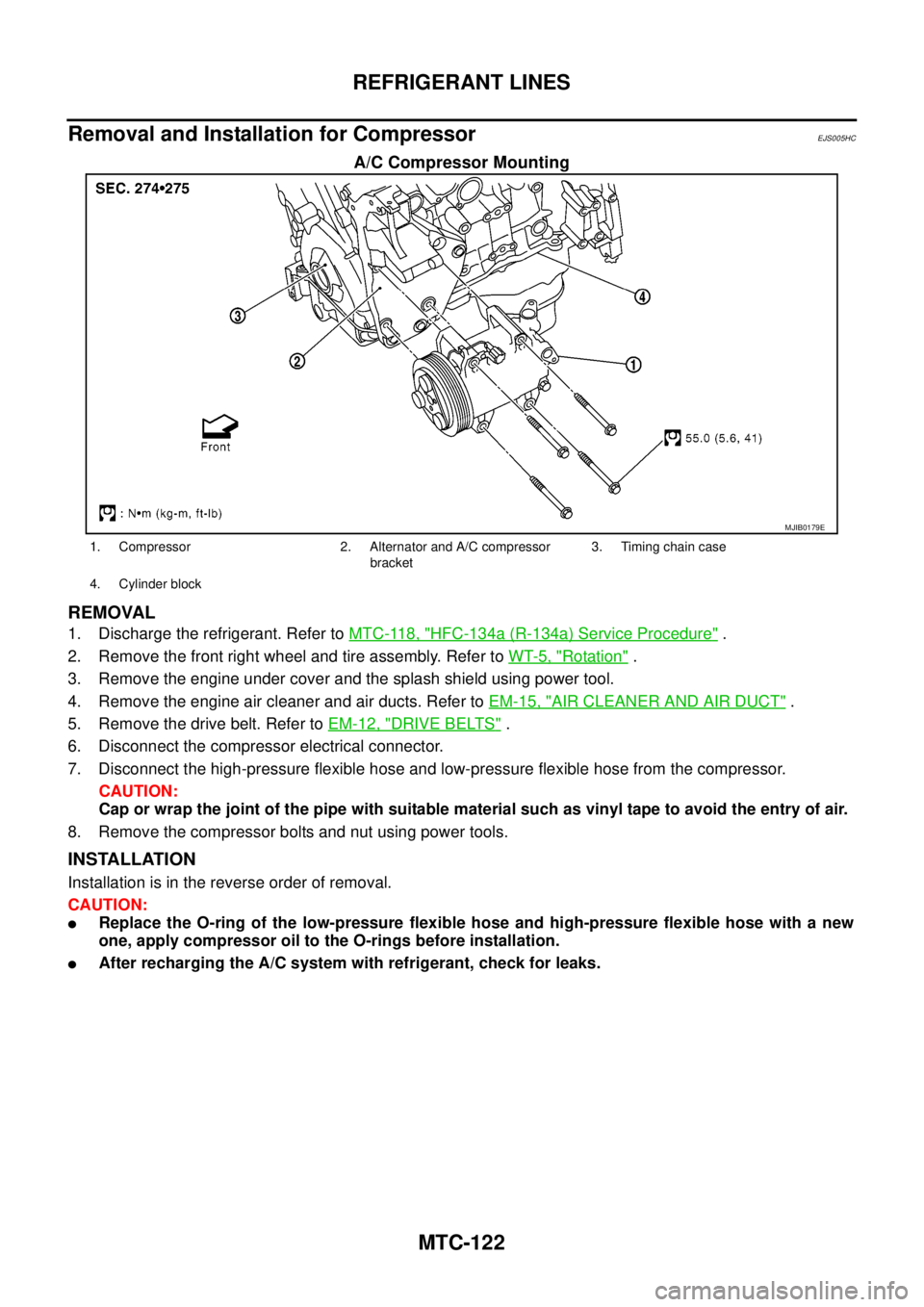

Removal and Installation for Compressor

EJS005HC

A/C Compressor Mounting

REMOVAL

1. Discharge the refrigerant. Refer toMTC-118, "HFC-134a (R-134a) Service Procedure".

2. Remove the front right wheel and tire assembly. Refer toWT-5, "

Rotation".

3. Remove the engine under cover and the splash shield using power tool.

4. Remove the engine air cleaner and air ducts. Refer toEM-15, "

AIR CLEANER AND AIR DUCT".

5. Remove the drive belt. Refer toEM-12, "

DRIVE BELTS".

6. Disconnect the compressor electrical connector.

7. Disconnect the high-pressure flexible hose and low-pressure flexible hose from the compressor.

CAUTION:

Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

8. Remove the compressor bolts and nut using power tools.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

lReplace the O-ring of the low-pressure flexible hose and high-pressure flexible hose with a new

one, apply compressor oil to the O-rings before installation.

lAfter recharging the A/C system with refrigerant, check for leaks.

MJIB0179E

1. Compressor 2. Alternator and A/C compressor

bracket3. Timing chain case

4. Cylinder block