NISSAN NAVARA 2005 Repair Workshop Manual

Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1671 of 3171

CONSULT-II CHECKING SYSTEM

GI-49

C

D

E

F

G

H

I

J

K

L

MB

GI

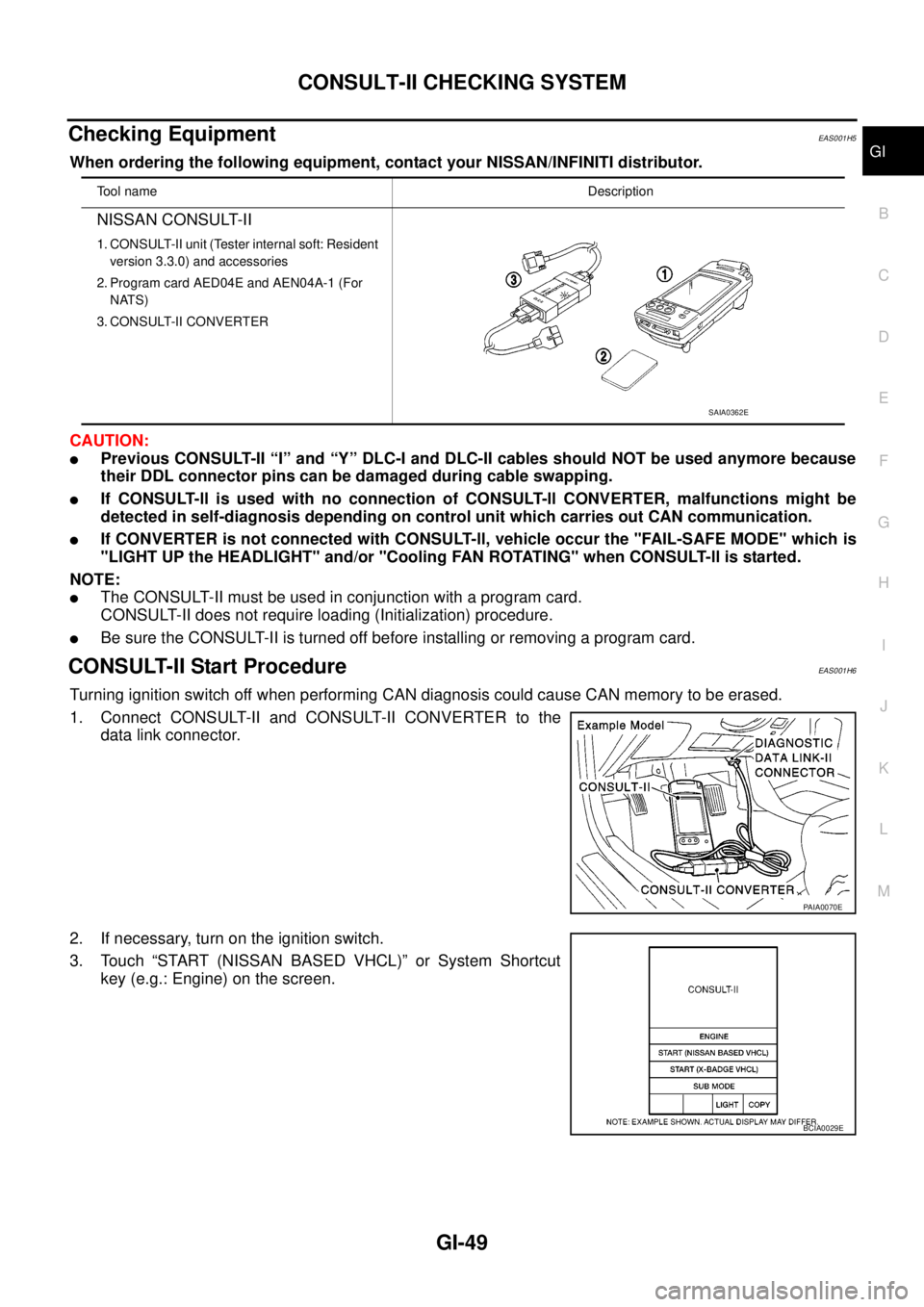

Checking EquipmentEAS001H5

When ordering the following equipment, contact your NISSAN/INFINITI distributor.

CAUTION:

lPrevious CONSULT-II “I” and “Y” DLC-I and DLC-II cables should NOT be used anymore because

their DDL connector pins can be damaged during cable swapping.

lIf CONSULT-ll is used with no connection of CONSULT-ll CONVERTER, malfunctions might be

detected in self-diagnosis depending on control unit which carries out CAN communication.

lIf CONVERTER is not connected with CONSULT-ll, vehicle occur the "FAIL-SAFE MODE" which is

"LIGHT UP the HEADLIGHT" and/or "Cooling FAN ROTATING" when CONSULT-ll is started.

NOTE:

lThe CONSULT-II must be used in conjunction with a program card.

CONSULT-II does not require loading (Initialization) procedure.

lBe sure the CONSULT-II is turned off before installing or removing a program card.

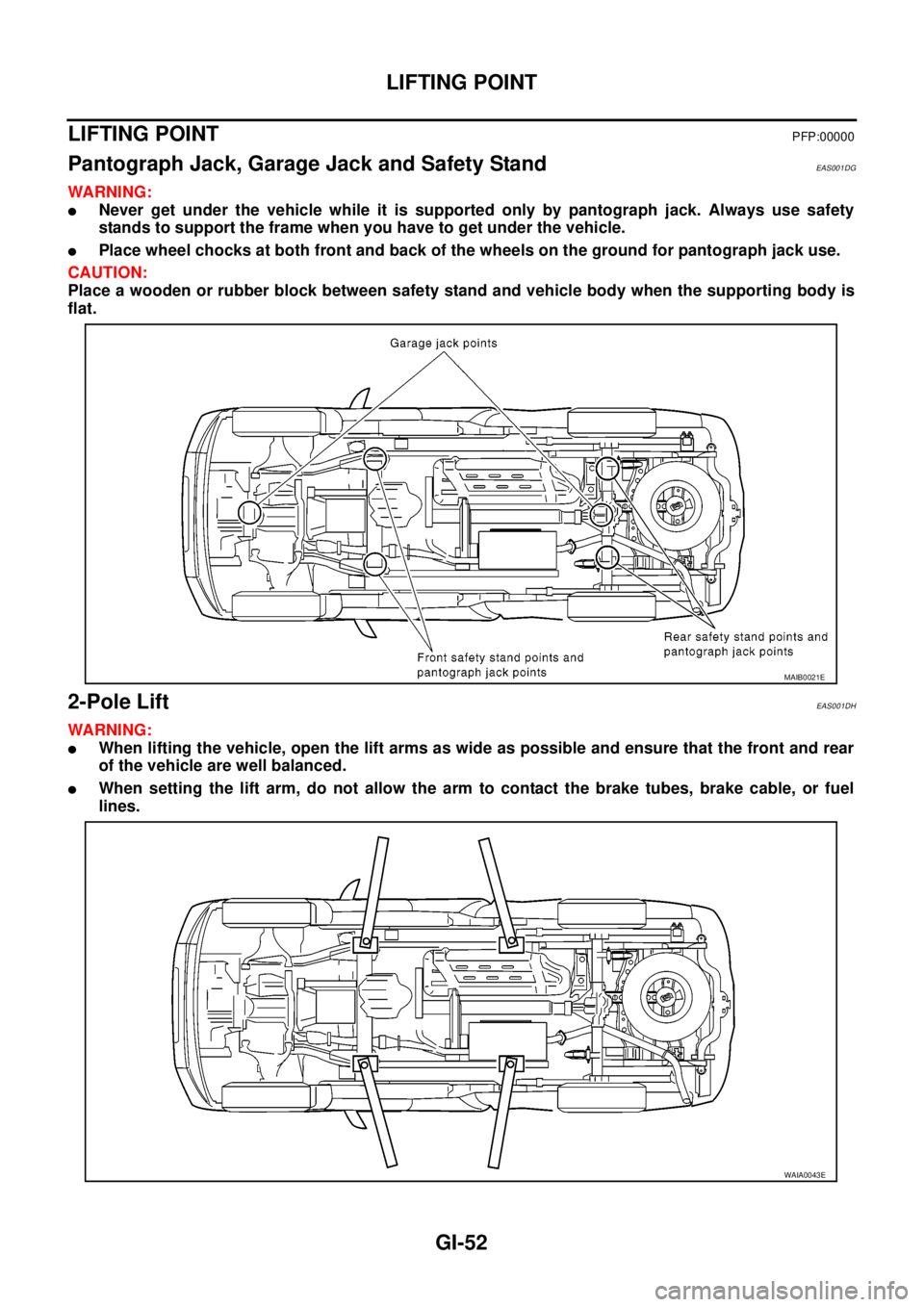

CONSULT-II Start ProcedureEAS001H6

Turning ignition switch off when performing CAN diagnosis could cause CAN memory to be erased.

1. Connect CONSULT-II and CONSULT-II CONVERTER to the

data link connector.

2. If necessary, turn on the ignition switch.

3. Touch “START (NISSAN BASED VHCL)” or System Shortcut

key (e.g.: Engine) on the screen.

Tool nameDescription

NISSAN CONSULT-II

1. CONSULT-II unit (Tester internal soft: Resident

version 3.3.0) and accessories

2. Program card AED04E and AEN04A-1 (For

NATS)

3. CONSULT-II CONVERTER

SAIA0362E

PAIA0070E

BCIA0029E

Page 1672 of 3171

GI-50

CONSULT-II CHECKING SYSTEM

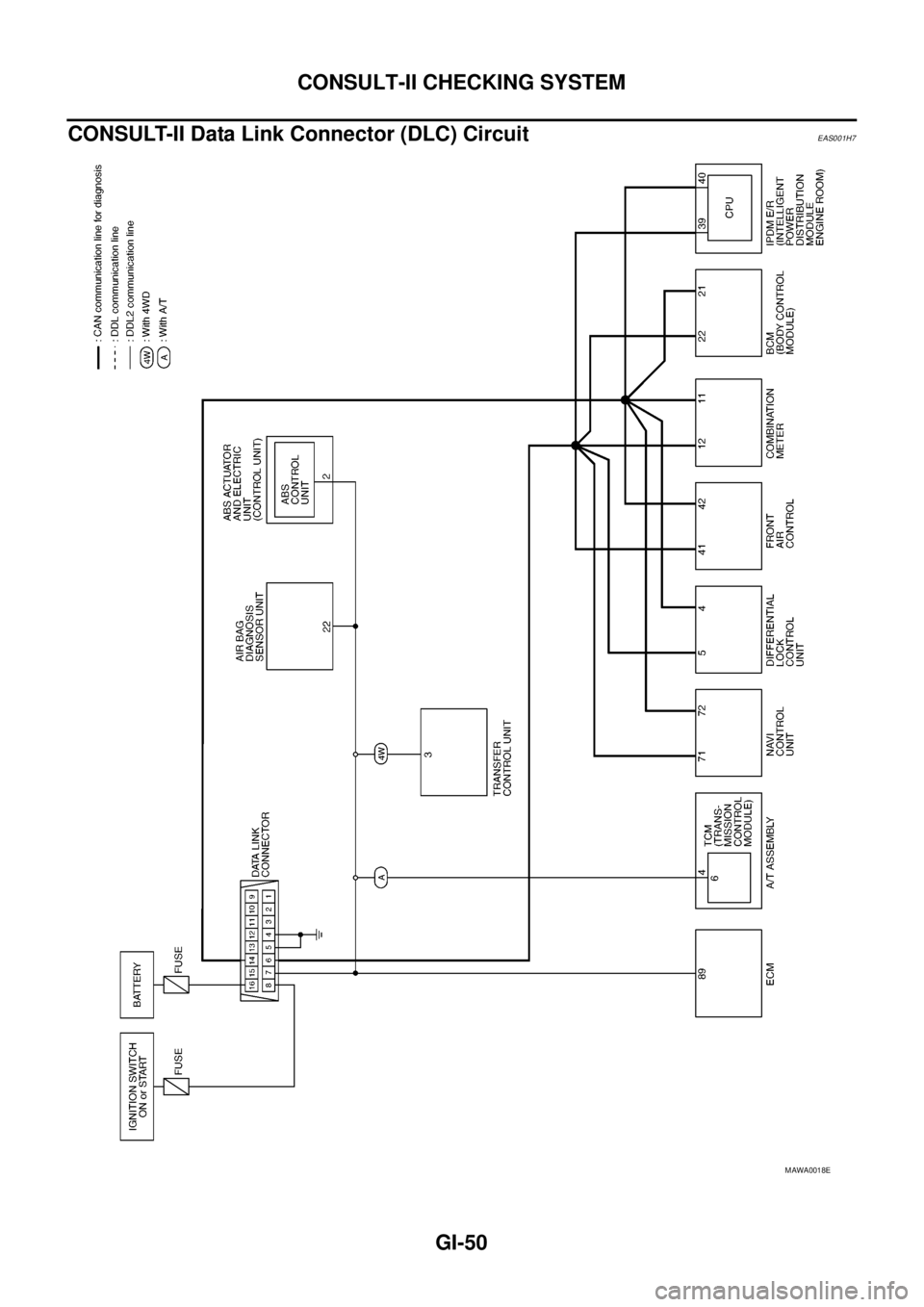

CONSULT-II Data Link Connector (DLC) Circuit

EAS001H7

MAWA0018E

Page 1673 of 3171

CONSULT-II CHECKING SYSTEM

GI-51

C

D

E

F

G

H

I

J

K

L

MB

GI

INSPECTION PROCEDURE

If the CONSULT-II cannot diagnose the system properly, check the following items.

NOTE:

The DDL1 and DDL2 circuits from DLC pins 12, 13, 14 and 15 may be connected to more than one system. A

short in a DDL circuit connected to a control unit in one system may affect CONSULT-II access to other sys-

tems.

Symptom Check item

CONSULT-II cannot access

any system.

lCONSULT-II DLC power supply circuit (Terminal 8) and ground circuit (Terminal 4) (For detailed

circuit, refer to “MIL & Data Link Connectors Wiring Diagram” in EC section.)

lCONSULT-II DLC cable and CONSULT-II CONVERTER.

CONSULT-II cannot access

individual system. (Other sys-

tems can be accessed.)

lCONSULT-II program card (Check the appropriate CONSULT-II program card for the system.

Refer to "Checking Equipment".)

lPower supply and ground circuit for the control unit of the system (For detailed circuit, refer to wir-

ing diagram for each system.)

lOpen or short circuit between the system and CONSULT-II DLC (For detailed circuit, refer to wiring

diagram for each system.)

lOpen or short circuit CAN communication. Refer toLAN-3, "Precautions When Using CONSULT-

II"

Page 1674 of 3171

GI-52

LIFTING POINT

LIFTING POINT

PFP:00000

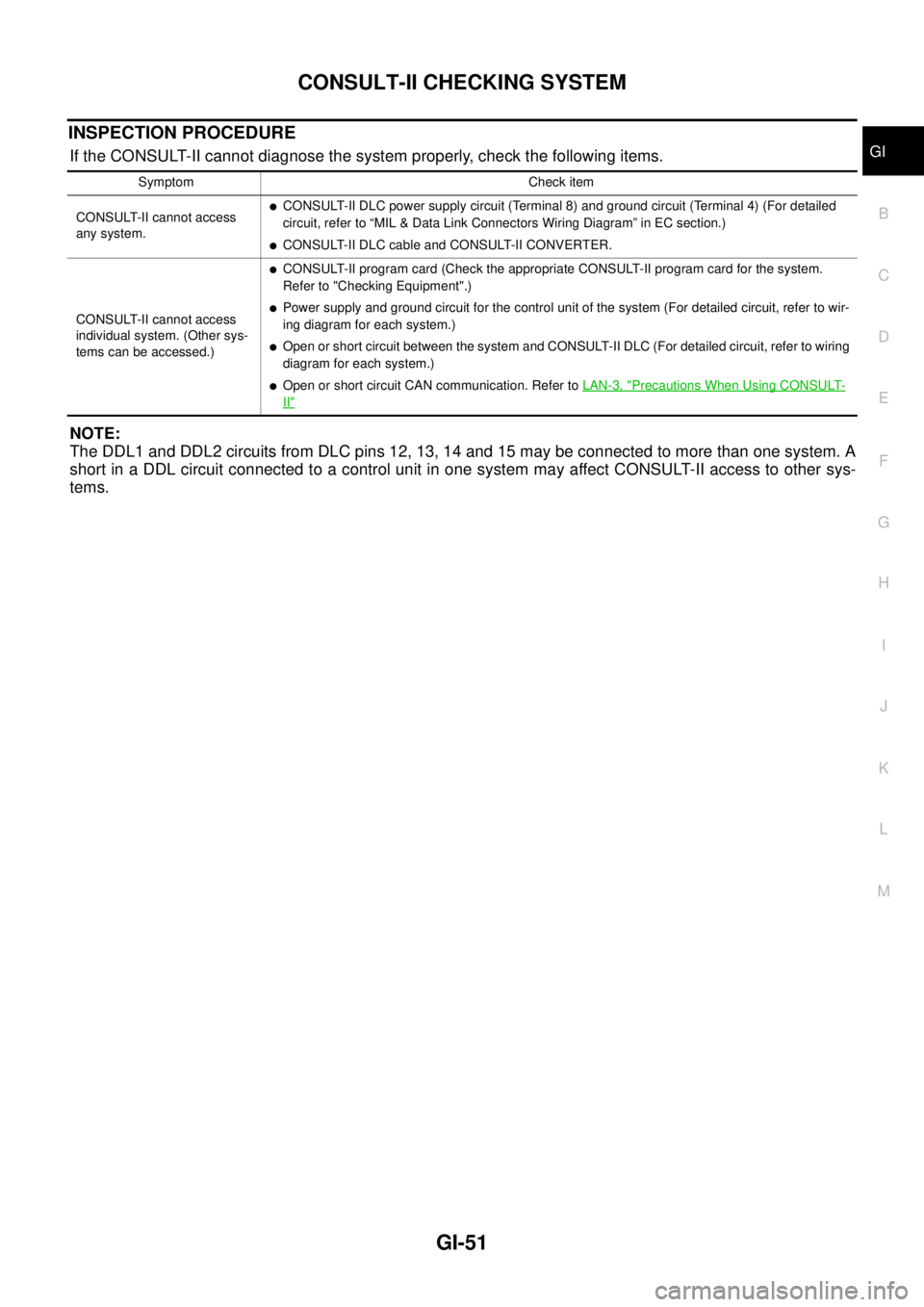

Pantograph Jack, Garage Jack and Safety StandEAS001DG

WARNING:

lNever get under the vehicle while it is supported only by pantograph jack. Always use safety

stands to support the frame when you have to get under the vehicle.

lPlace wheel chocks at both front and back of the wheels on the ground for pantograph jack use.

CAUTION:

Place a wooden or rubber block between safety stand and vehicle body when the supporting body is

flat.

2-Pole LiftEAS001DH

WARNING:

lWhen lifting the vehicle, open the lift arms as wide as possible and ensure that the front and rear

of the vehicle are well balanced.

lWhen setting the lift arm, do not allow the arm to contact the brake tubes, brake cable, or fuel

lines.

MAIB0021E

WAIA0043E

Page 1675 of 3171

TOW TRUCK TOWING

GI-53

C

D

E

F

G

H

I

J

K

L

MB

GI

TOW TRUCK TOWINGPFP:00000

To w Tr u c k To w i n gEAS001DI

WARNING:

lNever get under the vehicle while it is supported only by the jack. Always use safety stands to

support the frame when you have to get under the vehicle.

lPlace wheel chocks at both front and back of the wheels on the ground.

CAUTION:

lAll applicable local laws regarding the towing operation must be obeyed.

lIt is necessary to use proper towing equipment to avoid possible damage during towing opera-

tion. Towing is in accordance with Towing Procedure Manual at dealer.

lAlways attach safety chains before towing.

lWhen towing, make sure that the transmission, steering system and powertrain are in good order.

If any unit is damaged, dollies must be used.

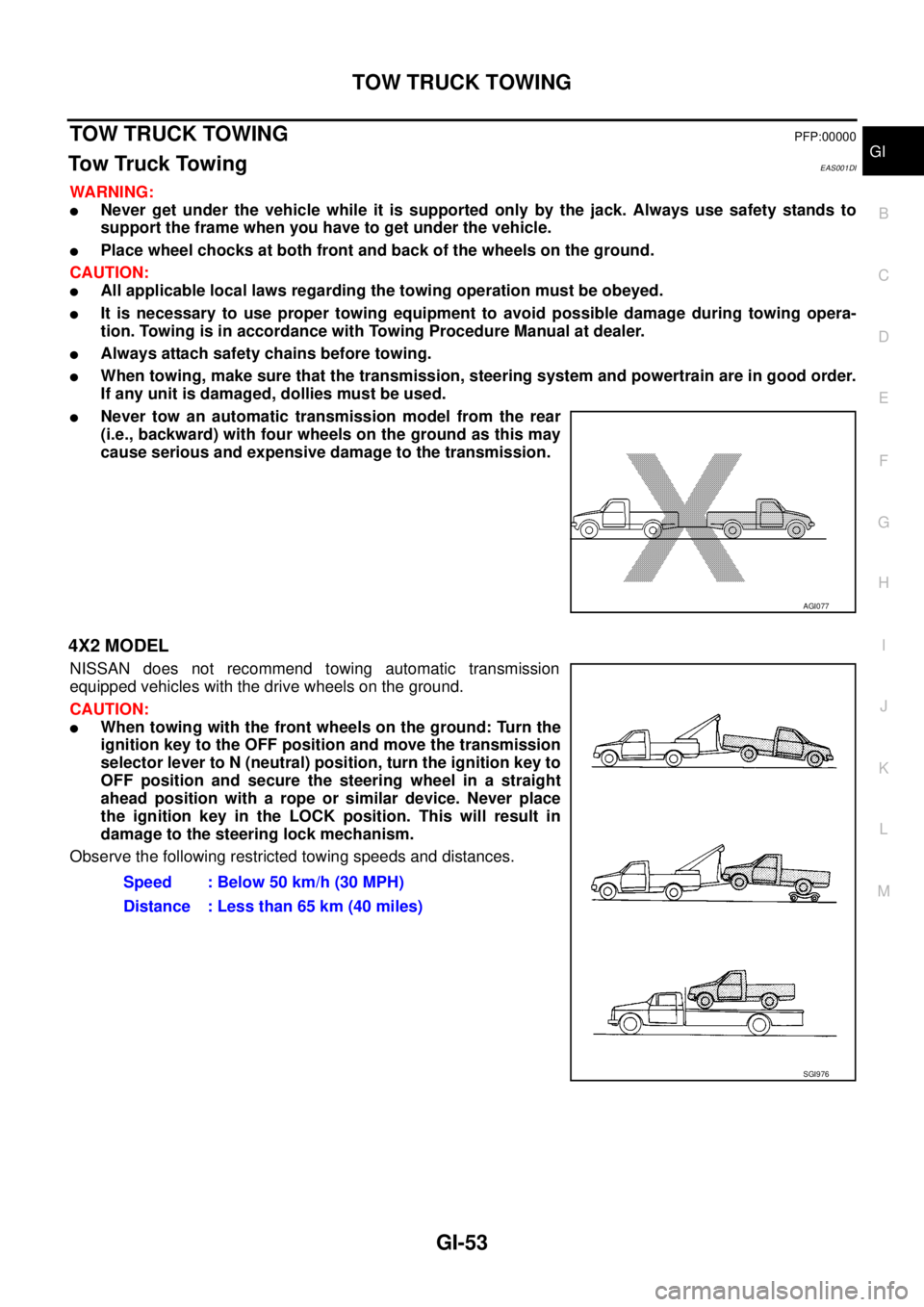

lNever tow an automatic transmission model from the rear

(i.e., backward) with four wheels on the ground as this may

cause serious and expensive damage to the transmission.

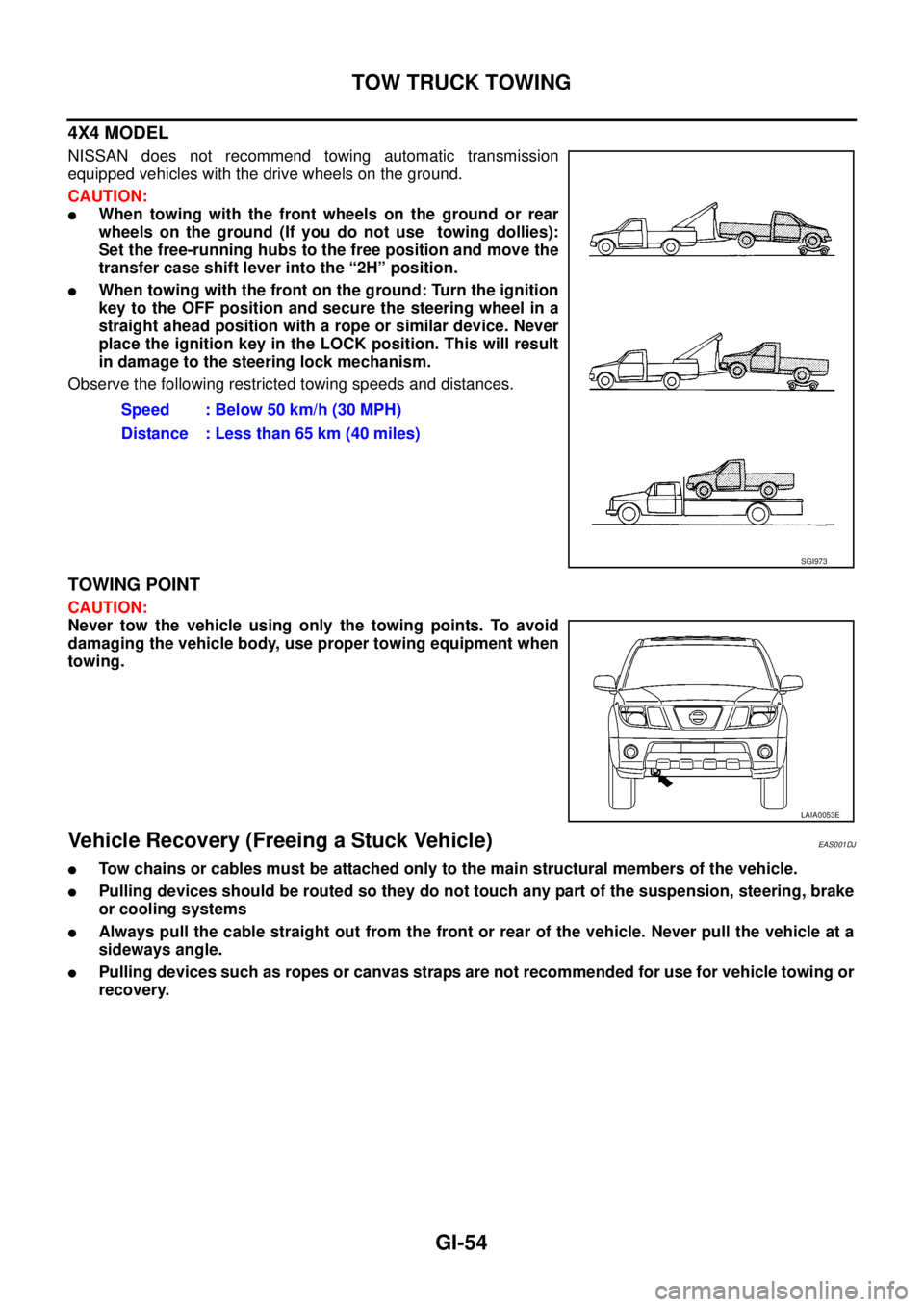

4X2 MODEL

NISSAN does not recommend towing automatic transmission

equipped vehicles with the drive wheels on the ground.

CAUTION:

lWhen towing with the front wheels on the ground: Turn the

ignition key to the OFF position and move the transmission

selector lever to N (neutral) position, turn the ignition key to

OFF position and secure the steering wheel in a straight

ahead position with a rope or similar device. Never place

the ignition key in the LOCK position. This will result in

damage to the steering lock mechanism.

Observe the following restricted towing speeds and distances.

AGI077

Speed : Below 50 km/h (30 MPH)

Distance : Less than 65 km (40 miles)

SGI976

Page 1676 of 3171

GI-54

TOW TRUCK TOWING

4X4 MODEL

NISSAN does not recommend towing automatic transmission

equipped vehicles with the drive wheels on the ground.

CAUTION:

lWhen towing with the front wheels on the ground or rear

wheels on the ground (If you do not use towing dollies):

Set the free-running hubs to the free position and move the

transfer case shift lever into the “2H” position.

lWhen towing with the front on the ground: Turn the ignition

key to the OFF position and secure the steering wheel in a

straight ahead position with a rope or similar device. Never

place the ignition key in the LOCK position. This will result

in damage to the steering lock mechanism.

Observe the following restricted towing speeds and distances.

TOWING POINT

CAUTION:

Never tow the vehicle using only the towing points. To avoid

damaging the vehicle body, use proper towing equipment when

towing.

Vehicle Recovery (Freeing a Stuck Vehicle)EAS001DJ

lTow chains or cables must be attached only to the main structural members of the vehicle.

lPulling devices should be routed so they do not touch any part of the suspension, steering, brake

or cooling systems

lAlways pull the cable straight out from the front or rear of the vehicle. Never pull the vehicle at a

sideways angle.

lPulling devices such as ropes or canvas straps are not recommended for use for vehicle towing or

recovery.Speed : Below 50 km/h (30 MPH)

Distance : Less than 65 km (40 miles)

SGI973

LAIA0053E

Page 1677 of 3171

TIGHTENING TORQUE OF STANDARD BOLTS

GI-55

C

D

E

F

G

H

I

J

K

L

MB

GI

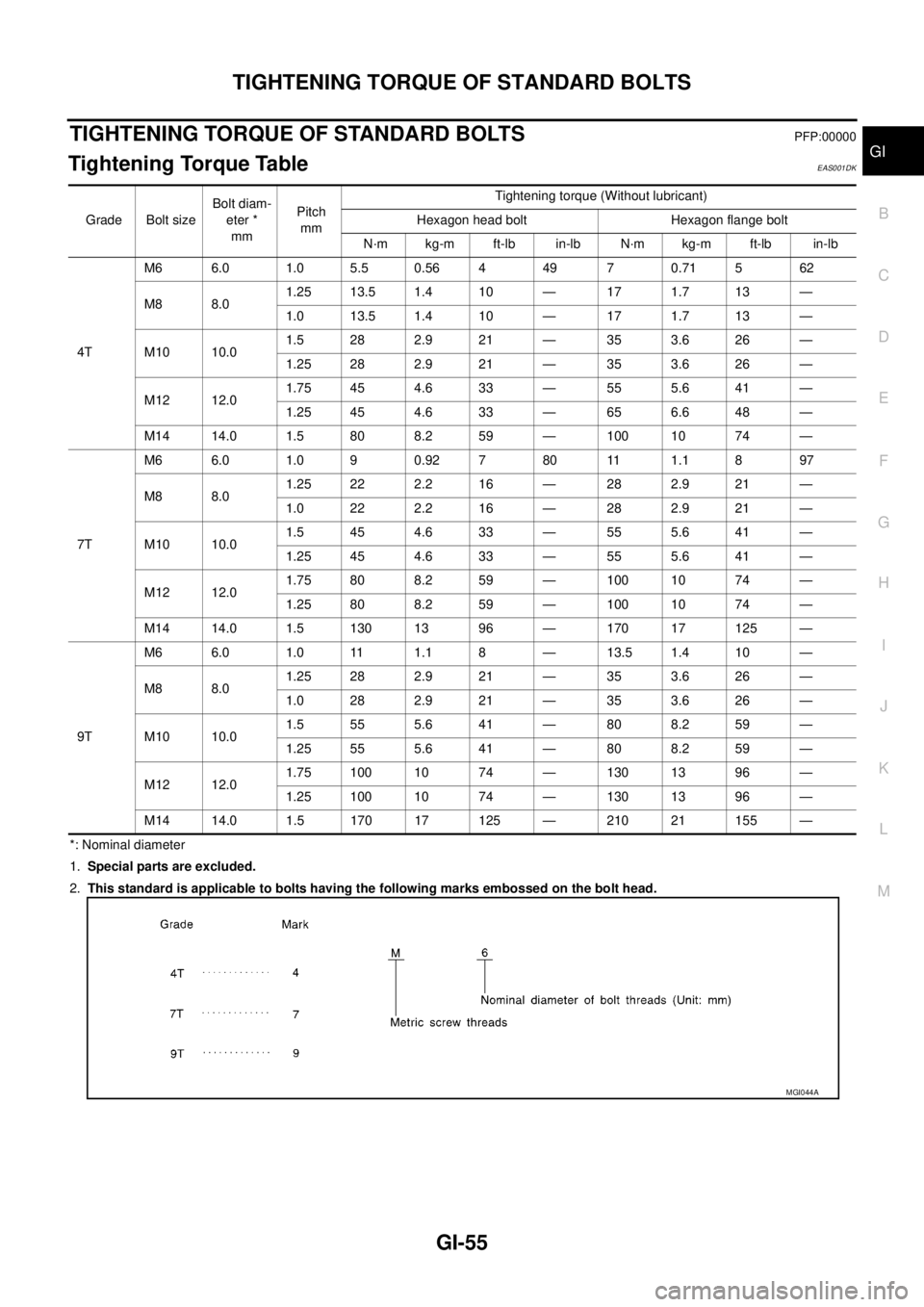

TIGHTENING TORQUE OF STANDARD BOLTSPFP:00000

Tightening Torque TableEAS001DK

*: Nominal diameter

1.Special parts are excluded.

2.This standard is applicable to bolts having the following marks embossed on the bolt head. Grade Bolt sizeBolt diam-

eter *

mmPitch

mmTightening torque (Without lubricant)

Hexagon head bolt Hexagon flange bolt

N·m kg-m ft-lb in-lb N·m kg-m ft-lb in-lb

4TM6 6.0 1.0 5.5 0.56 4 49 7 0.71 5 62

M8 8.01.25 13.5 1.4 10 — 17 1.7 13 —

1.0 13.5 1.4 10 — 17 1.7 13 —

M10 10.01.5282.921— 353.626—

1.25 28 2.9 21 — 35 3.6 26 —

M12 12.01.75 45 4.6 33 — 55 5.6 41 —

1.25 45 4.6 33 — 65 6.6 48 —

M14 14.0 1.5 80 8.2 59 — 100 10 74 —

7TM6 6.0 1.0 9 0.92 7 80 11 1.1 8 97

M8 8.01.25 22 2.2 16 — 28 2.9 21 —

1.0222.216— 282.921—

M10 10.01.5454.633— 555.641—

1.25 45 4.6 33 — 55 5.6 41 —

M12 12.01.75 80 8.2 59 — 100 10 74 —

1.25 80 8.2 59 — 100 10 74 —

M14 14.0 1.5 130 13 96 — 170 17 125 —

9TM6 6.0 1.0 11 1.1 8 — 13.5 1.4 10 —

M8 8.01.25 28 2.9 21 — 35 3.6 26 —

1.0282.921— 353.626—

M10 10.01.5555.641— 808.259—

1.25 55 5.6 41 — 80 8.2 59 —

M12 12.01.75 100 10 74 — 130 13 96 —

1.25 100 10 74 — 130 13 96 —

M14 14.0 1.5 170 17 125 — 210 21 155 —

MGI044A

Page 1678 of 3171

GI-56

IDENTIFICATION INFORMATION

IDENTIFICATION INFORMATION

PFP:00010

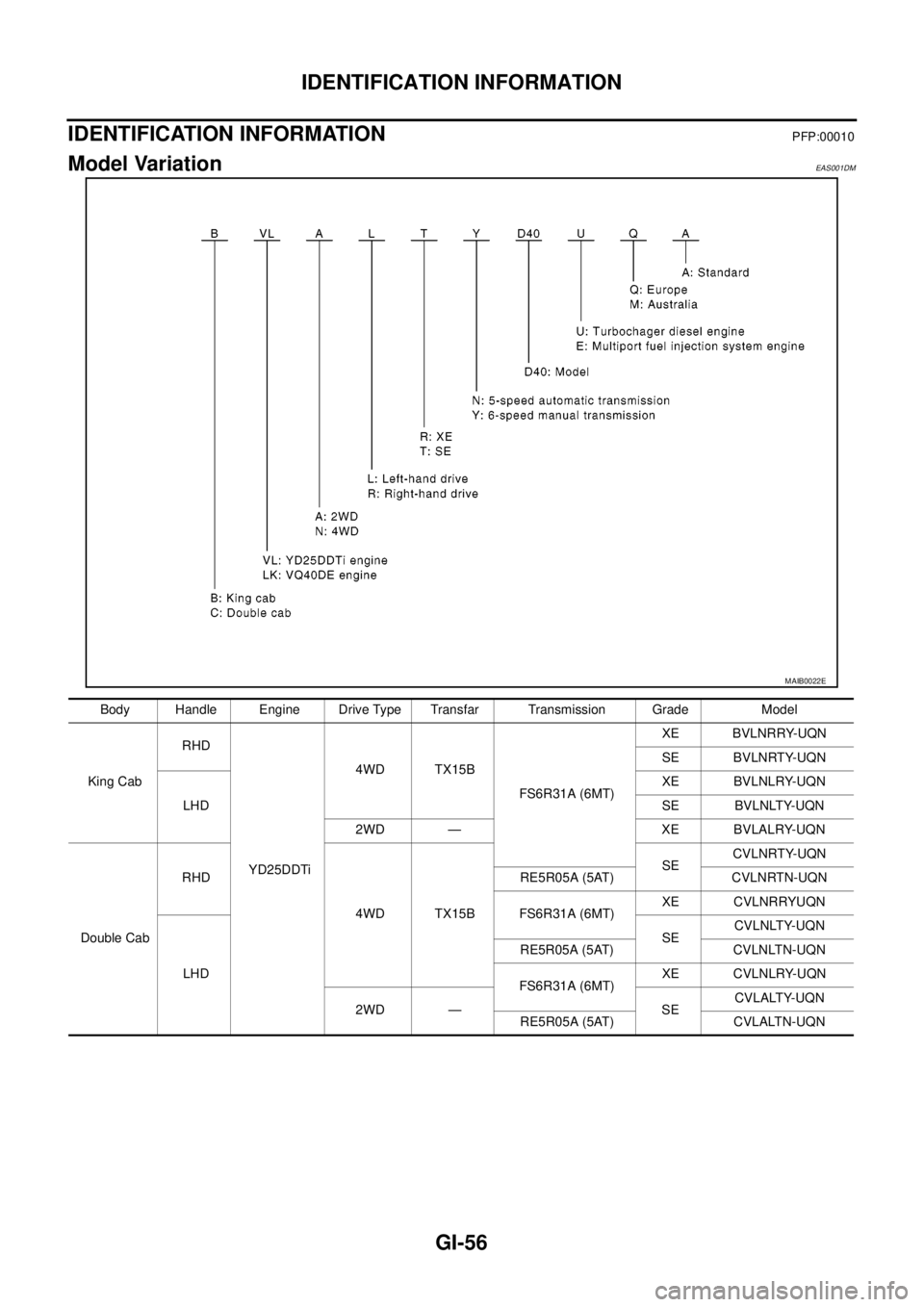

Model VariationEAS001DM

MAIB0022E

Body Handle Engine Drive Type Transfar Transmission Grade Model

King CabRHD

YD25DDTi4WD TX15B

FS6R31A (6MT)XE BVLNRRY-UQN

SE BVLNRTY-UQN

LHDXE BVLNLRY-UQN

SE BVLNLTY-UQN

2WD — XE BVLALRY-UQN

Double CabRHD

4WD TX15BSECVLNRTY-UQN

RE5R05A (5AT) CVLNRTN-UQN

FS6R31A (6MT)XE CVLNRRYUQN

LHDSECVLNLTY-UQN

RE5R05A (5AT) CVLNLTN-UQN

FS6R31A (6MT)XE CVLNLRY-UQN

2WD — SECVLALTY-UQN

RE5R05A (5AT) CVLALTN-UQN

Page 1679 of 3171

IDENTIFICATION INFORMATION

GI-57

C

D

E

F

G

H

I

J

K

L

MB

GI

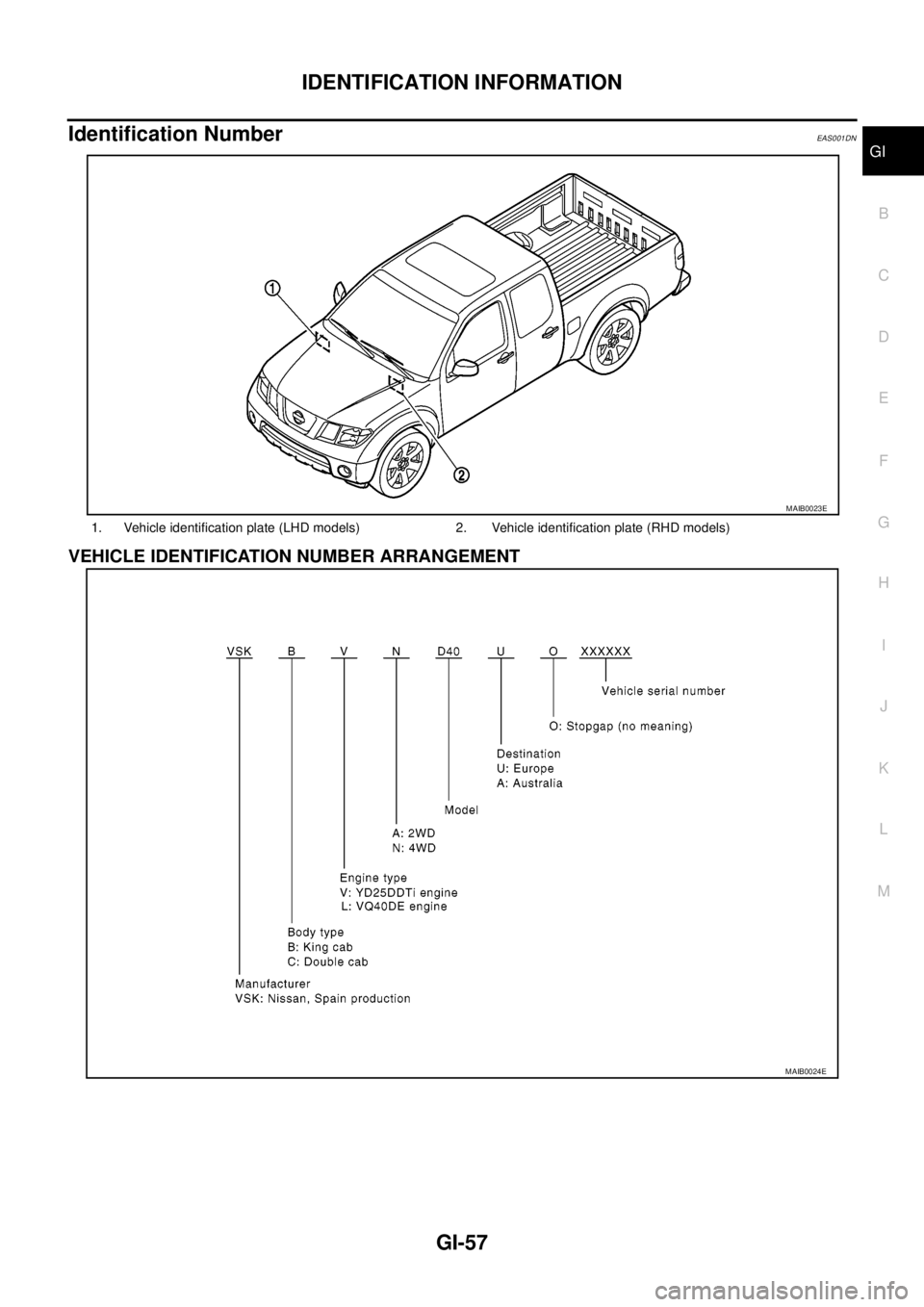

Identification NumberEAS001DN

VEHICLE IDENTIFICATION NUMBER ARRANGEMENT

1. Vehicle identification plate (LHD models) 2. Vehicle identification plate (RHD models)

MAIB0023E

MAIB0024E

Page 1680 of 3171

GI-58

IDENTIFICATION INFORMATION

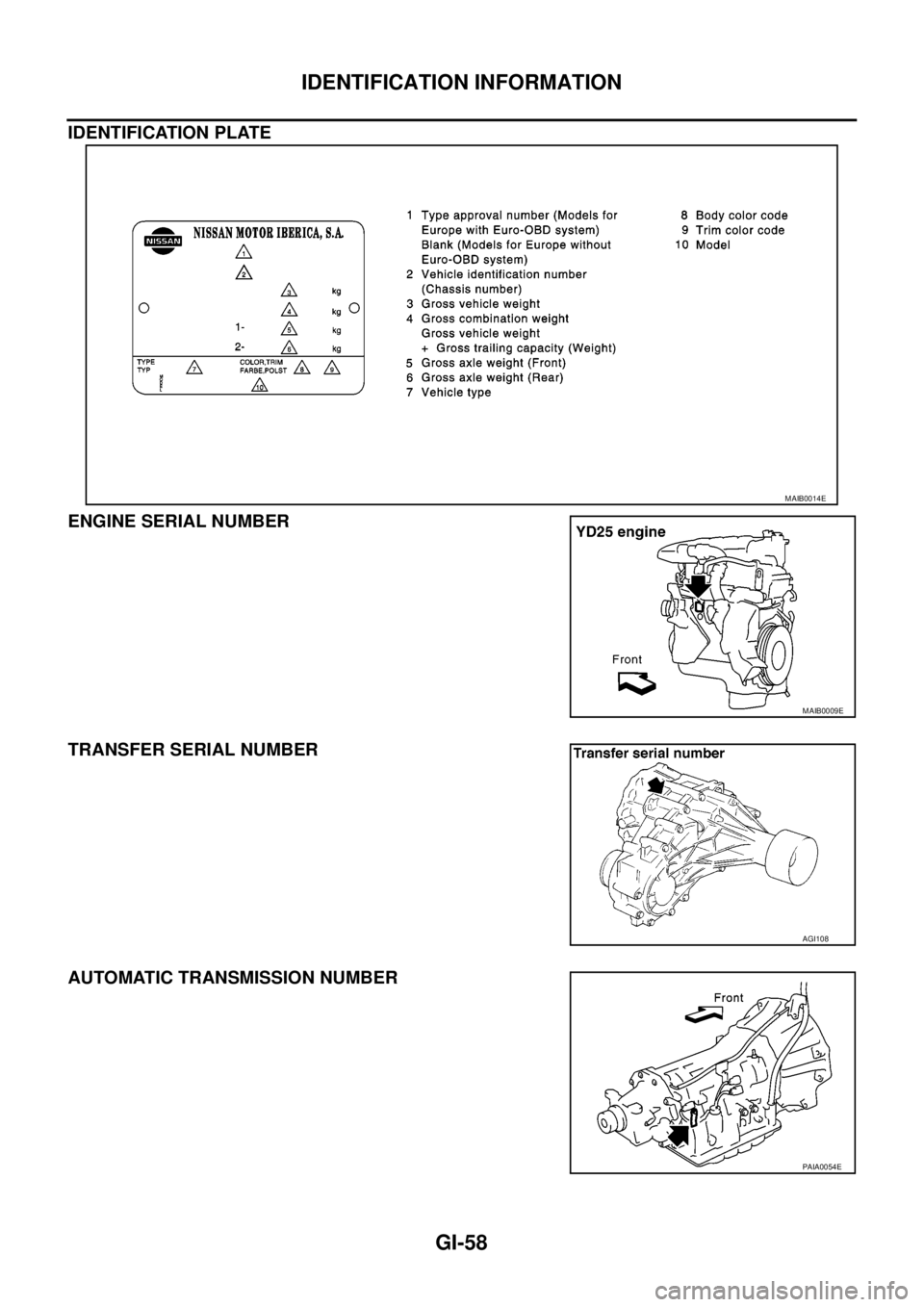

IDENTIFICATION PLATE

ENGINE SERIAL NUMBER

TRANSFER SERIAL NUMBER

AUTOMATIC TRANSMISSION NUMBER

MAIB0014E

MAIB0009E

AGI108

PAIA0054E