transmission NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2364 of 3171

TRANSMISSION ASSEMBLY

MT-47

D

E

F

G

H

I

J

K

L

MA

B

MT

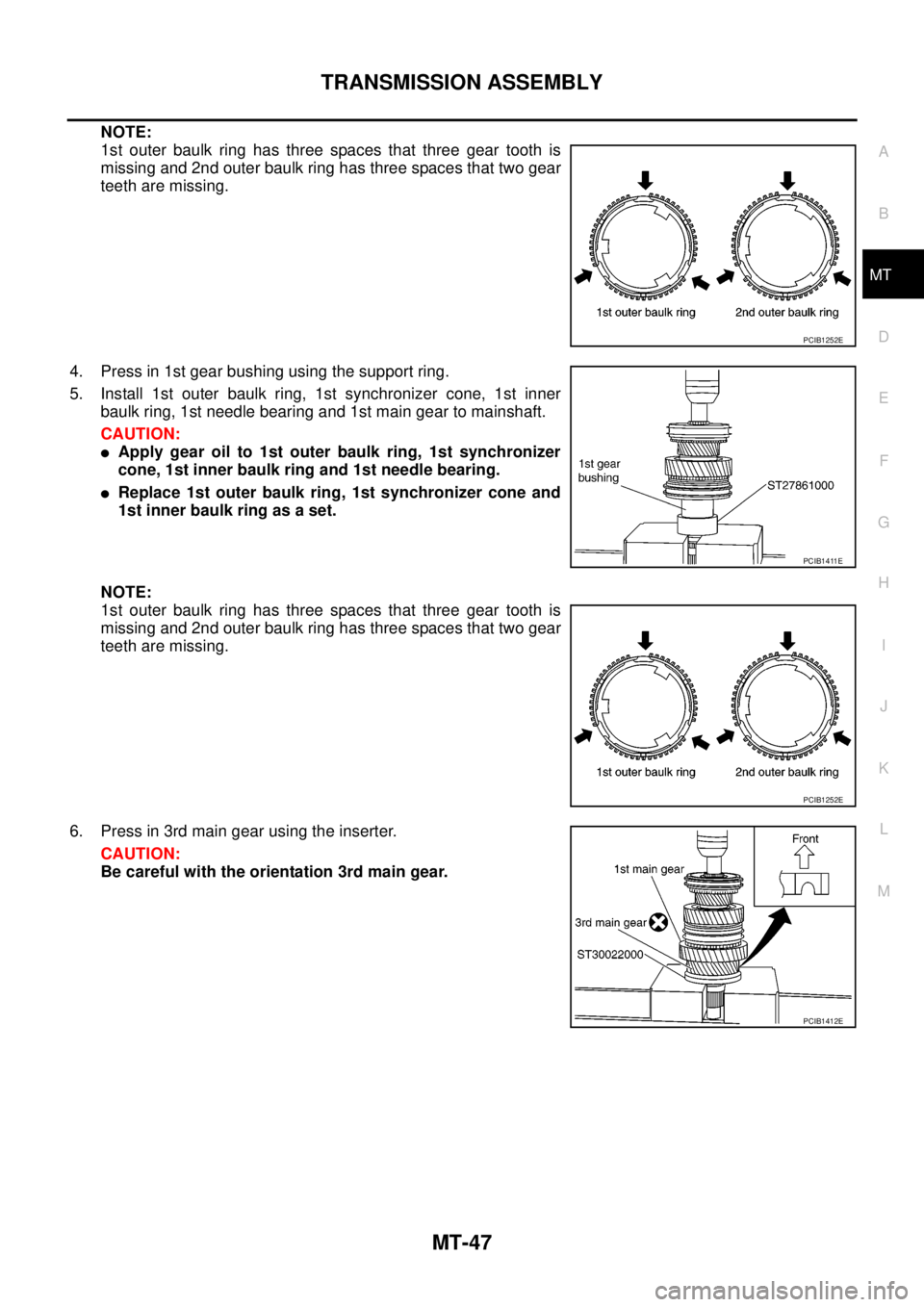

NOTE:

1st outer baulk ring has three spaces that three gear tooth is

missing and 2nd outer baulk ring has three spaces that two gear

teeth are missing.

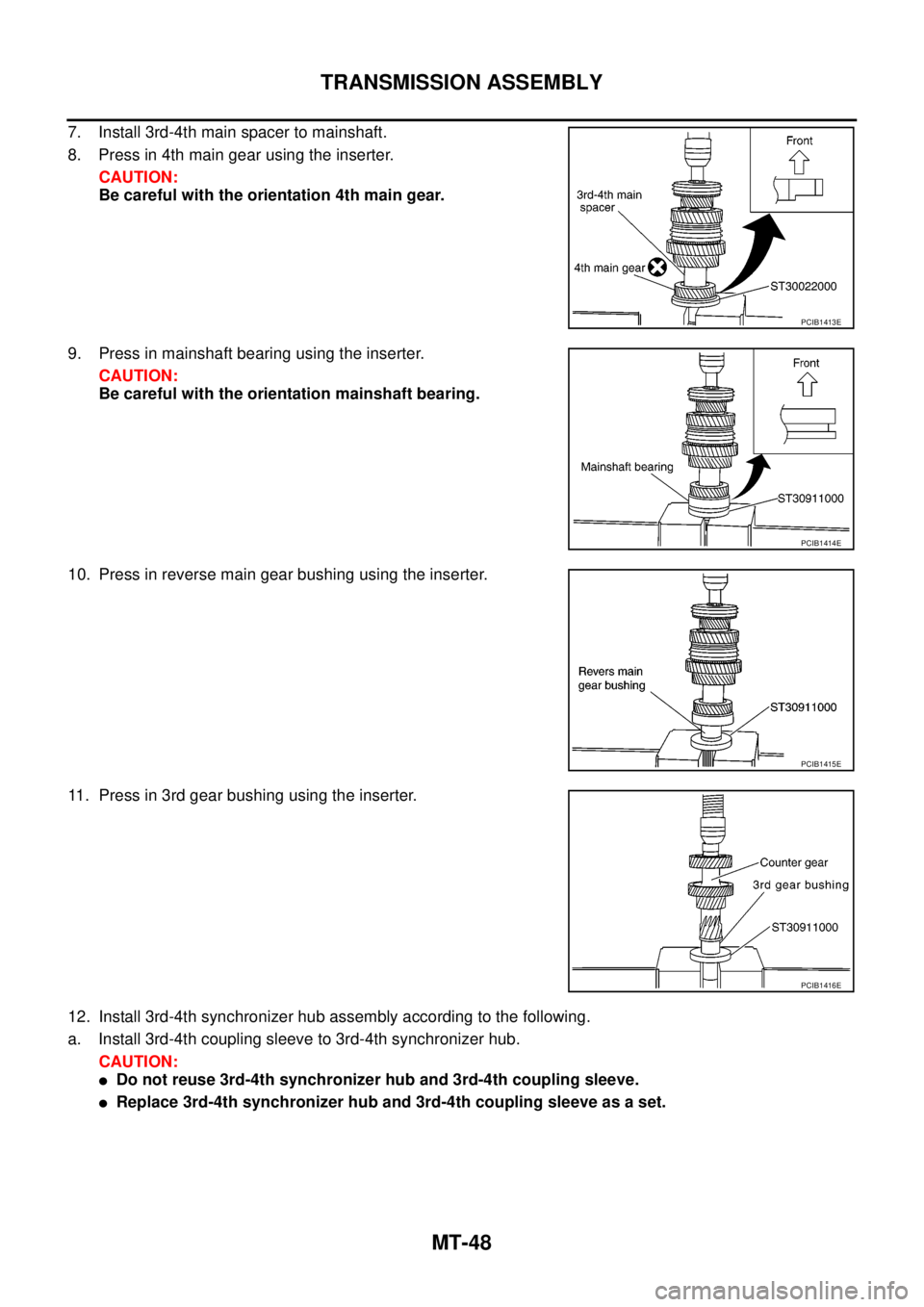

4. Press in 1st gear bushing using the support ring.

5. Install 1st outer baulk ring, 1st synchronizer cone, 1st inner

baulk ring, 1st needle bearing and 1st main gear to mainshaft.

CAUTION:

lApply gear oil to 1st outer baulk ring, 1st synchronizer

cone, 1st inner baulk ring and 1st needle bearing.

lReplace 1st outer baulk ring, 1st synchronizer cone and

1st inner baulk ring as a set.

NOTE:

1st outer baulk ring has three spaces that three gear tooth is

missing and 2nd outer baulk ring has three spaces that two gear

teeth are missing.

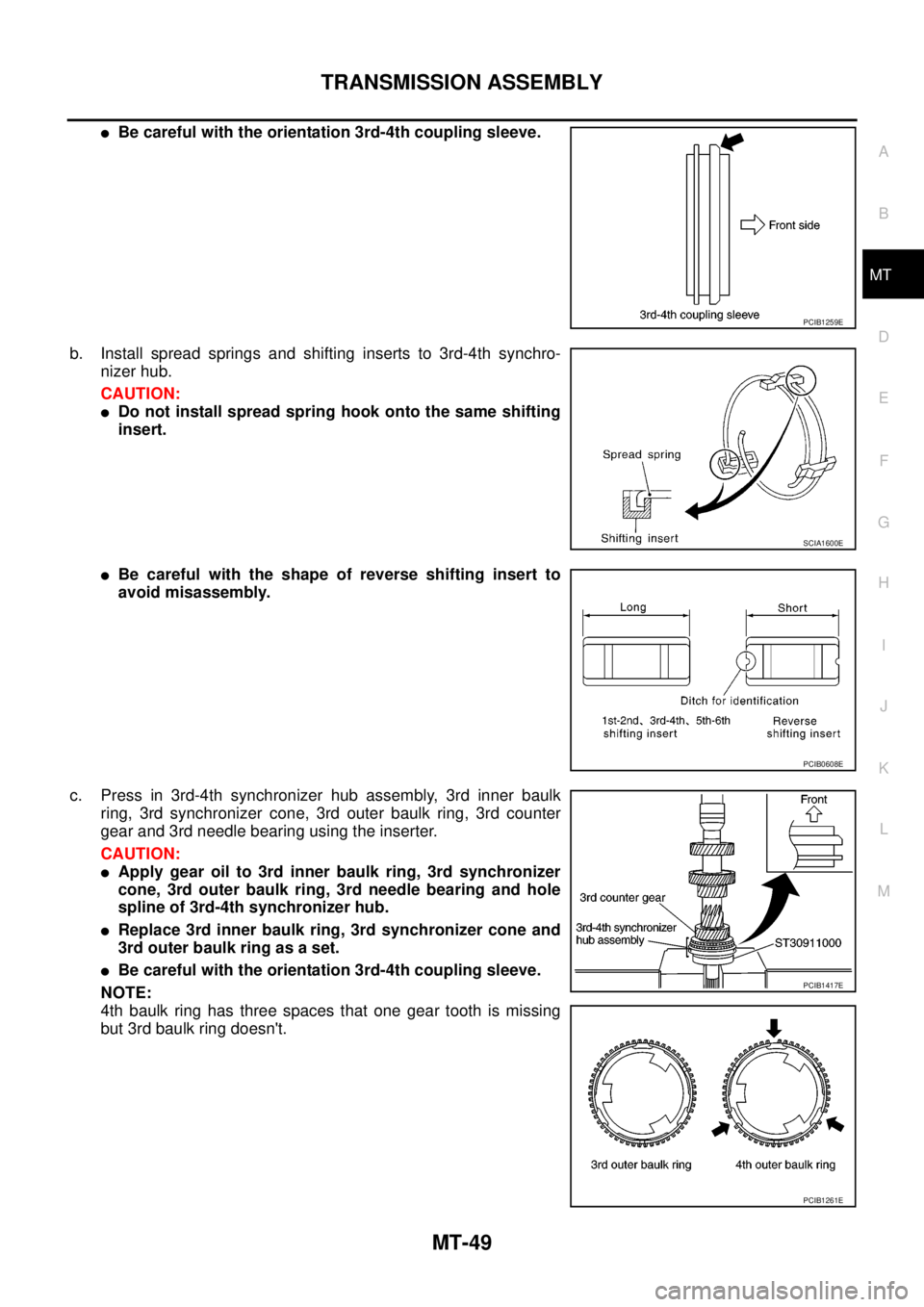

6. Press in 3rd main gear using the inserter.

CAUTION:

Be careful with the orientation 3rd main gear.

PCIB1252E

PCIB1411E

PCIB1252E

PCIB1412E

Page 2365 of 3171

MT-48

TRANSMISSION ASSEMBLY

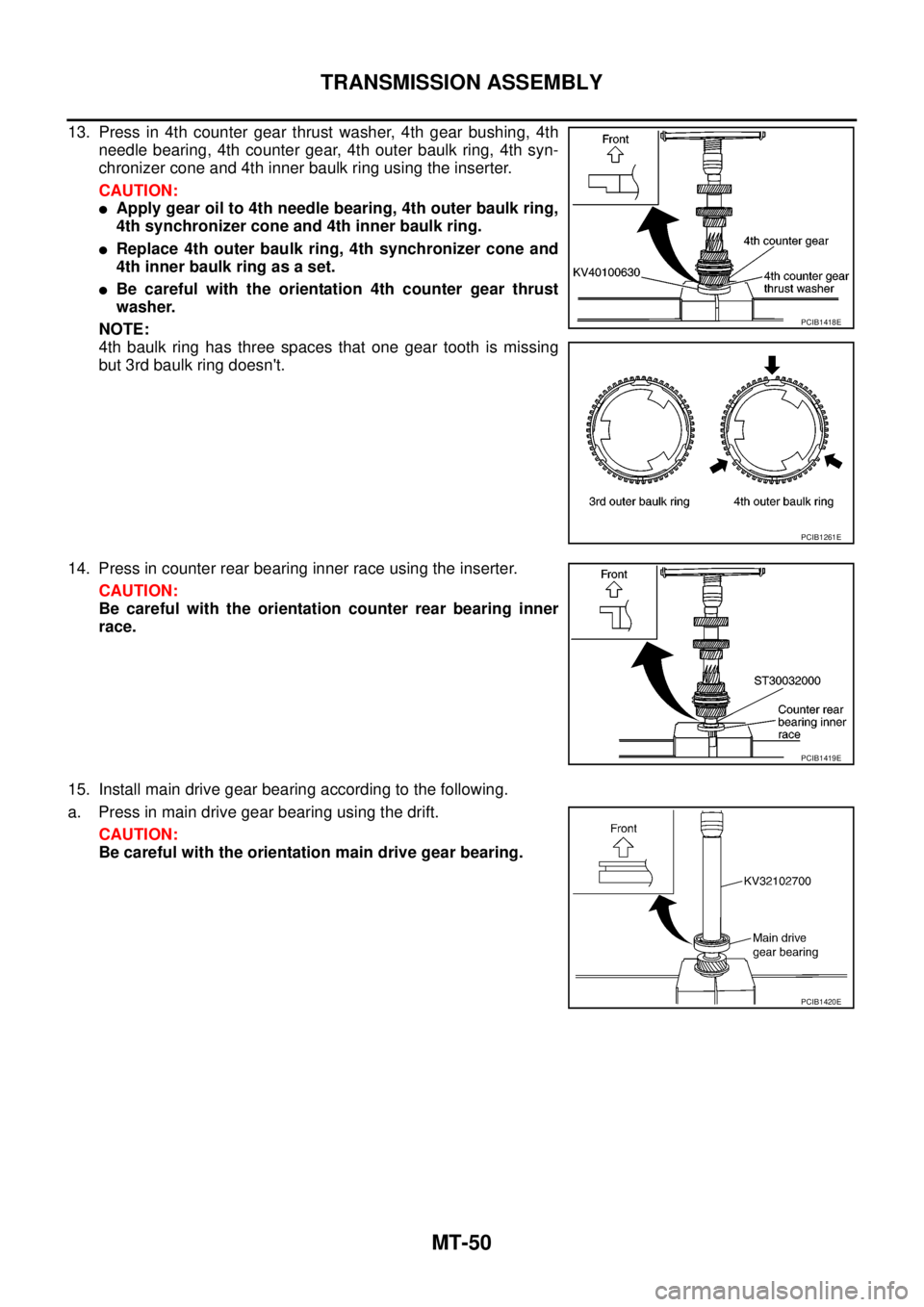

7. Install 3rd-4th main spacer to mainshaft.

8. Press in 4th main gear using the inserter.

CAUTION:

Be careful with the orientation 4th main gear.

9. Press in mainshaft bearing using the inserter.

CAUTION:

Be careful with the orientation mainshaft bearing.

10. Press in reverse main gear bushing using the inserter.

11. Press in 3rd gear bushing using the inserter.

12. Install 3rd-4th synchronizer hub assembly according to the following.

a. Install 3rd-4th coupling sleeve to 3rd-4th synchronizer hub.

CAUTION:

lDo not reuse 3rd-4th synchronizer hub and 3rd-4th coupling sleeve.

lReplace 3rd-4th synchronizer hub and 3rd-4th coupling sleeve as a set.

PCIB1413E

PCIB1414E

PCIB1415E

PCIB1416E

Page 2366 of 3171

TRANSMISSION ASSEMBLY

MT-49

D

E

F

G

H

I

J

K

L

MA

B

MT

lBe careful with the orientation 3rd-4th coupling sleeve.

b. Install spread springs and shifting inserts to 3rd-4th synchro-

nizer hub.

CAUTION:

lDo not install spread spring hook onto the same shifting

insert.

lBe careful with the shape of reverse shifting insert to

avoid misassembly.

c. Press in 3rd-4th synchronizer hub assembly, 3rd inner baulk

ring, 3rd synchronizer cone, 3rd outer baulk ring, 3rd counter

gear and 3rd needle bearing using the inserter.

CAUTION:

lApply gear oil to 3rd inner baulk ring, 3rd synchronizer

cone, 3rd outer baulk ring, 3rd needle bearing and hole

spline of 3rd-4th synchronizer hub.

lReplace 3rd inner baulk ring, 3rd synchronizer cone and

3rd outer baulk ring as a set.

lBe careful with the orientation 3rd-4th coupling sleeve.

NOTE:

4th baulk ring has three spaces that one gear tooth is missing

but 3rd baulk ring doesn't.

PCIB1259E

SCIA1600E

PCIB0608E

PCIB1417E

PCIB1261E

Page 2367 of 3171

MT-50

TRANSMISSION ASSEMBLY

13. Press in 4th counter gear thrust washer, 4th gear bushing, 4th

needle bearing, 4th counter gear, 4th outer baulk ring, 4th syn-

chronizer cone and 4th inner baulk ring using the inserter.

CAUTION:

lApply gear oil to 4th needle bearing, 4th outer baulk ring,

4th synchronizer cone and 4th inner baulk ring.

lReplace 4th outer baulk ring, 4th synchronizer cone and

4th inner baulk ring as a set.

lBe careful with the orientation 4th counter gear thrust

washer.

NOTE:

4th baulk ring has three spaces that one gear tooth is missing

but 3rd baulk ring doesn't.

14. Press in counter rear bearing inner race using the inserter.

CAUTION:

Be careful with the orientation counter rear bearing inner

race.

15. Install main drive gear bearing according to the following.

a. Press in main drive gear bearing using the drift.

CAUTION:

Be careful with the orientation main drive gear bearing.

PCIB1418E

PCIB1261E

PCIB1419E

PCIB1420E

Page 2368 of 3171

TRANSMISSION ASSEMBLY

MT-51

D

E

F

G

H

I

J

K

L

MA

B

MT

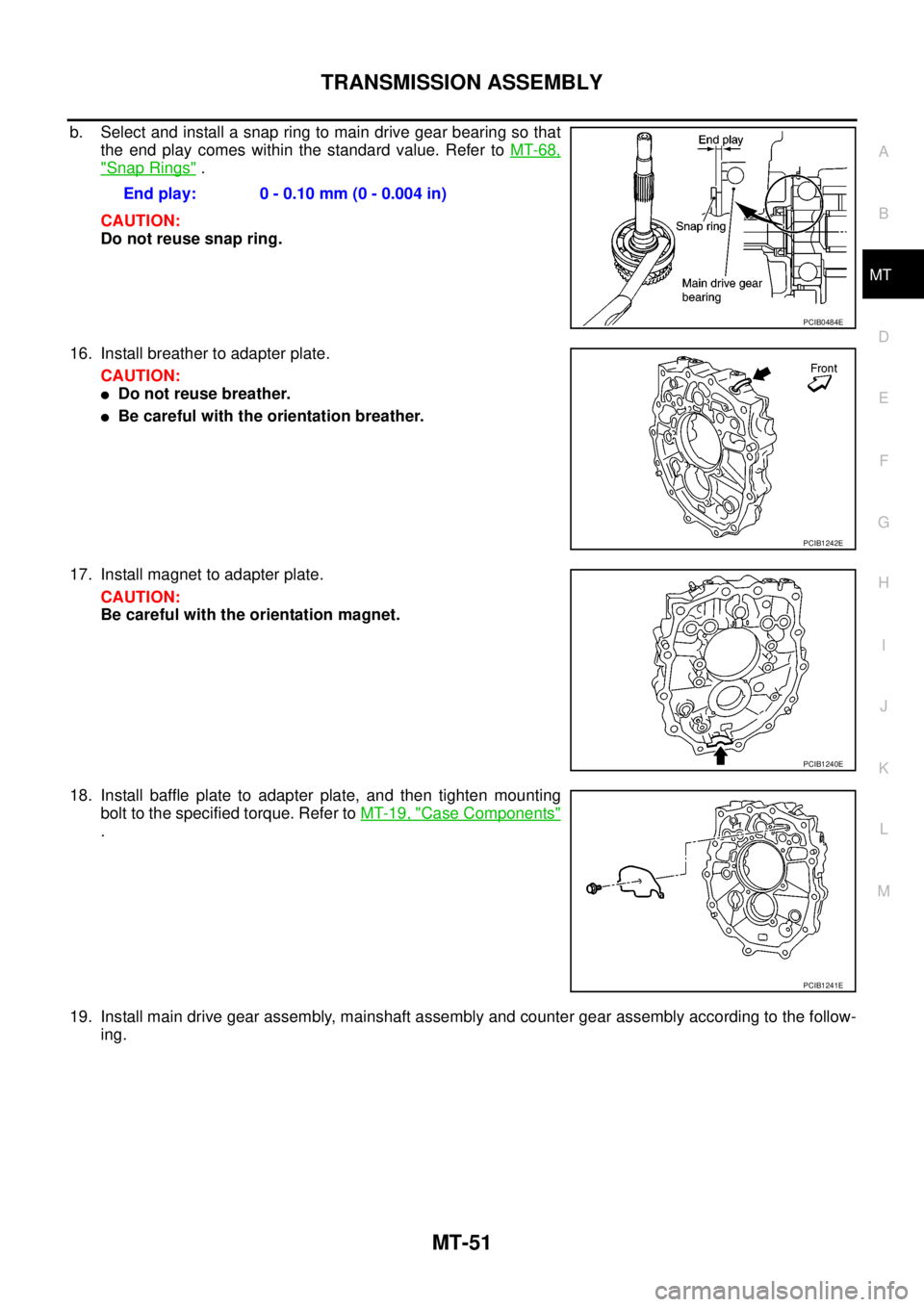

b. Selectandinstallasnapringtomaindrivegearbearingsothat

the end play comes within the standard value. Refer toMT-68,

"Snap Rings".

CAUTION:

Do not reuse snap ring.

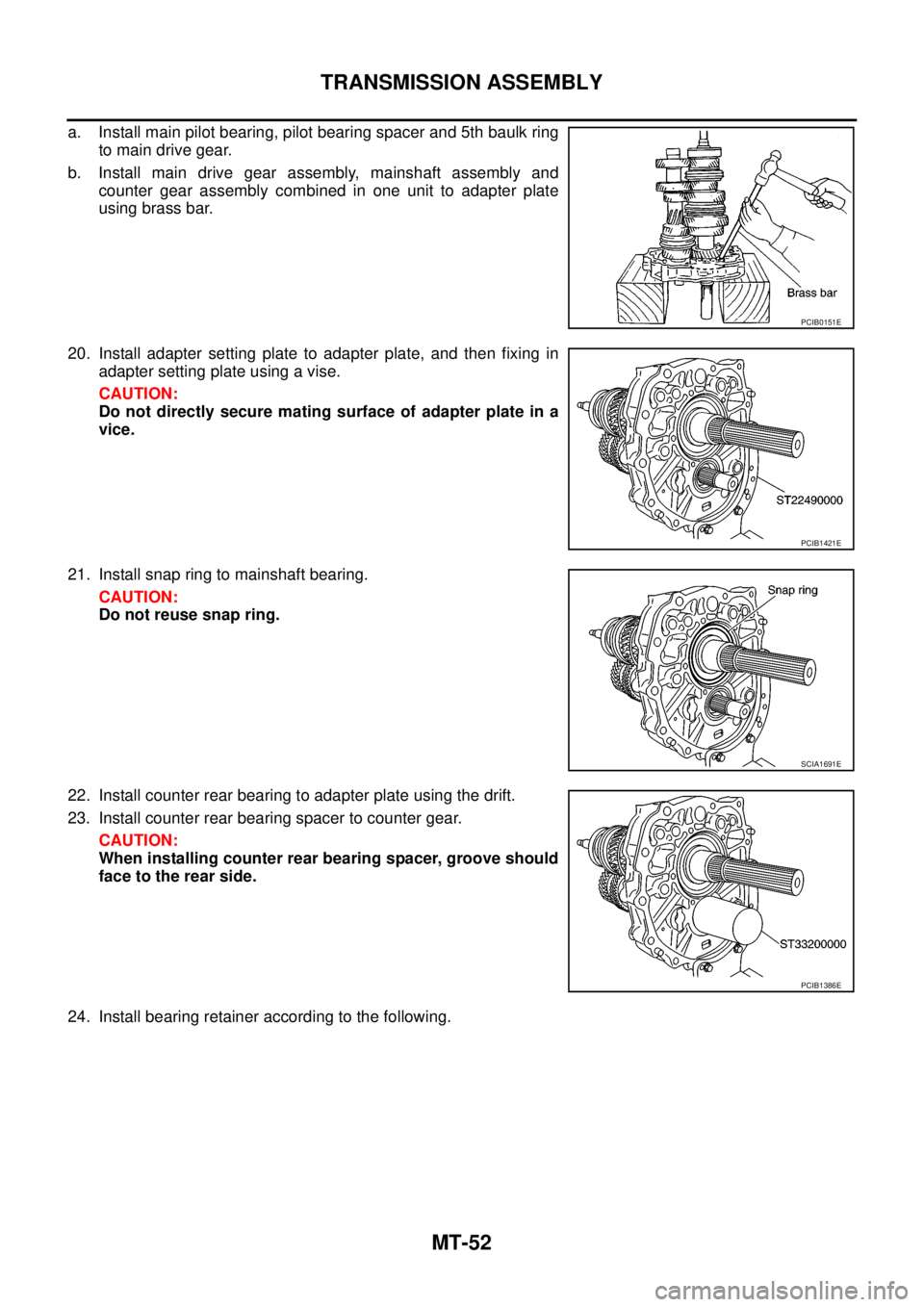

16. Install breather to adapter plate.

CAUTION:

lDo not reuse breather.

lBe careful with the orientation breather.

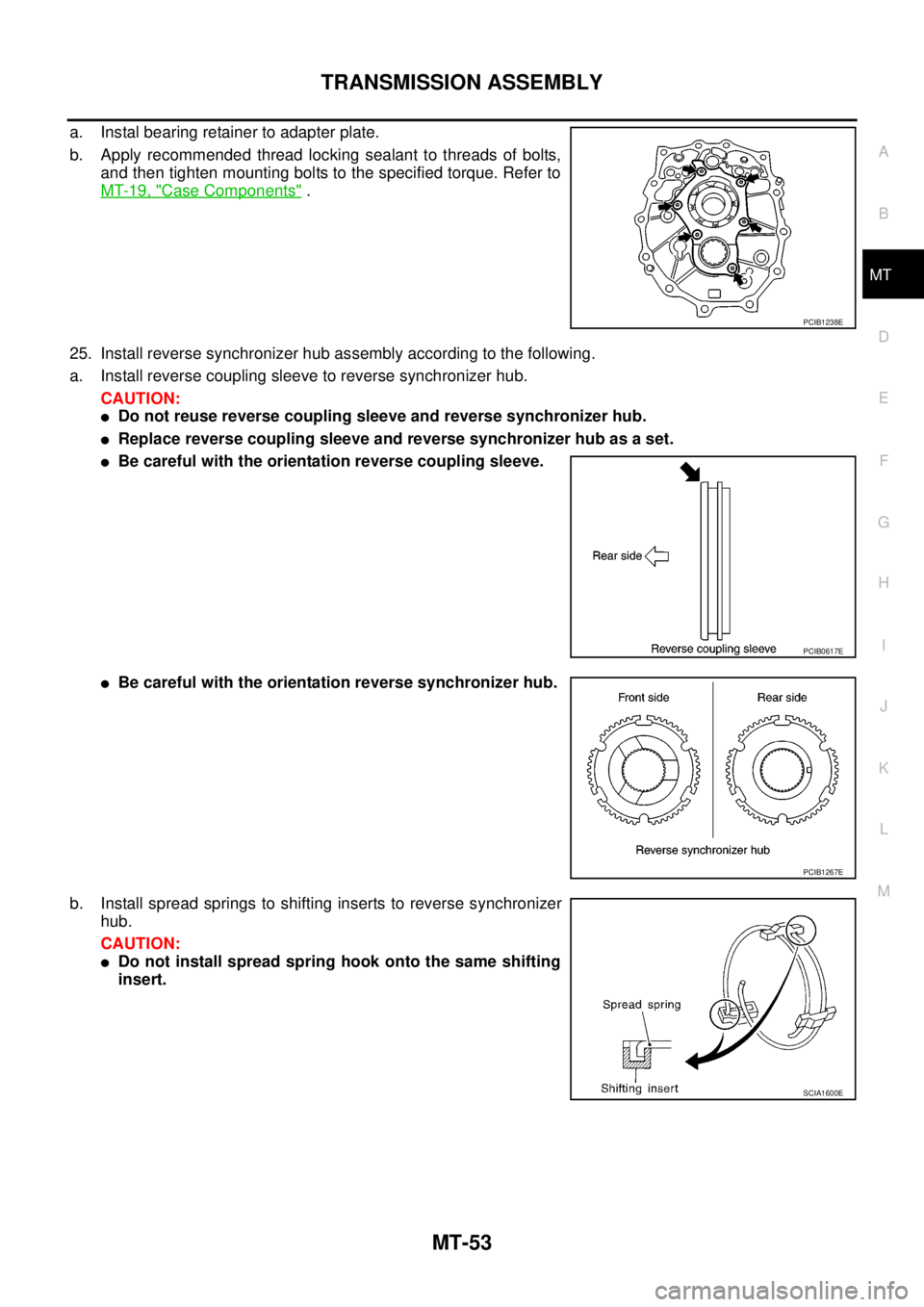

17. Install magnet to adapter plate.

CAUTION:

Be careful with the orientation magnet.

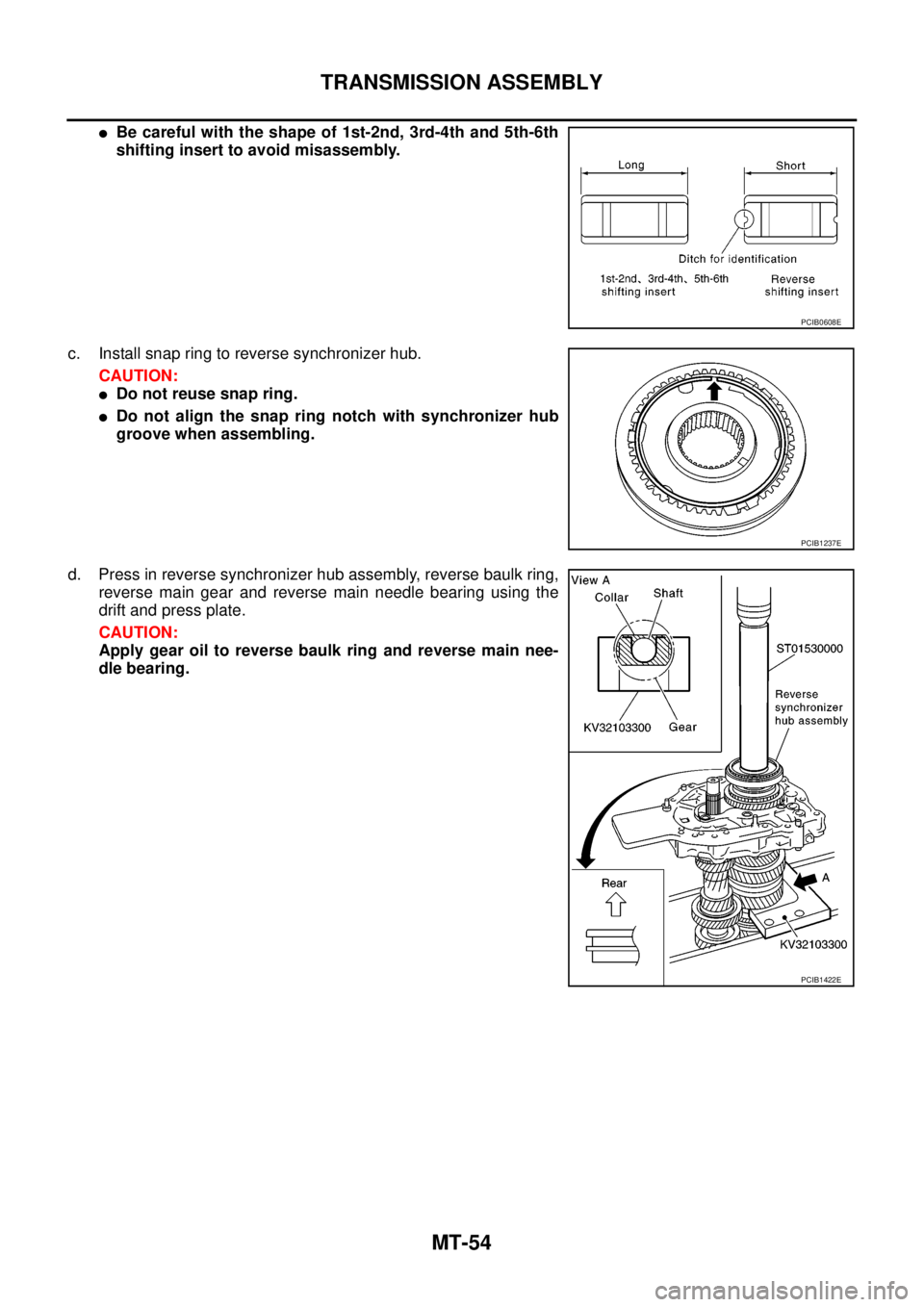

18. Install baffle plate to adapter plate, and then tighten mounting

bolt to the specified torque. Refer toMT-19, "

Case Components"

.

19. Install main drive gear assembly, mainshaft assembly and counter gear assembly according to the follow-

ing.End play: 0 - 0.10 mm (0 - 0.004 in)

PCIB0484E

PCIB1242E

PCIB1240E

PCIB1241E

Page 2369 of 3171

MT-52

TRANSMISSION ASSEMBLY

a. Install main pilot bearing, pilot bearing spacer and 5th baulk ring

to main drive gear.

b. Install main drive gear assembly, mainshaft assembly and

counter gear assembly combined in one unit to adapter plate

using brass bar.

20. Install adapter setting plate to adapter plate, and then fixing in

adapter setting plate using a vise.

CAUTION:

Do not directly secure mating surface of adapter plate in a

vice.

21. Install snap ring to mainshaft bearing.

CAUTION:

Do not reuse snap ring.

22. Install counter rear bearing to adapter plate using the drift.

23. Install counter rear bearing spacer to counter gear.

CAUTION:

When installing counter rear bearing spacer, groove should

face to the rear side.

24. Install bearing retainer according to the following.

PCIB0151E

PCIB1421E

SCIA1691E

PCIB1386E

Page 2370 of 3171

TRANSMISSION ASSEMBLY

MT-53

D

E

F

G

H

I

J

K

L

MA

B

MT

a. Instal bearing retainer to adapter plate.

b. Apply recommended thread locking sealant to threads of bolts,

and then tighten mounting bolts to the specified torque. Refer to

MT-19, "

Case Components".

25. Install reverse synchronizer hub assembly according to the following.

a. Install reverse coupling sleeve to reverse synchronizer hub.

CAUTION:

lDo not reuse reverse coupling sleeve and reverse synchronizer hub.

lReplace reverse coupling sleeve and reverse synchronizer hub as a set.

lBe careful with the orientation reverse coupling sleeve.

lBe careful with the orientation reverse synchronizer hub.

b. Install spread springs to shifting inserts to reverse synchronizer

hub.

CAUTION:

lDo not install spread spring hook onto the same shifting

insert.

PCIB1238E

PCIB0617E

PCIB1267E

SCIA1600E

Page 2371 of 3171

MT-54

TRANSMISSION ASSEMBLY

lBe careful with the shape of 1st-2nd, 3rd-4th and 5th-6th

shifting insert to avoid misassembly.

c. Install snap ring to reverse synchronizer hub.

CAUTION:

lDo not reuse snap ring.

lDo not align the snap ring notch with synchronizer hub

groove when assembling.

d. Press in reverse synchronizer hub assembly, reverse baulk ring,

reverse main gear and reverse main needle bearing using the

drift and press plate.

CAUTION:

Apply gear oil to reverse baulk ring and reverse main nee-

dle bearing.

PCIB0608E

PCIB1237E

PCIB1422E

Page 2372 of 3171

TRANSMISSION ASSEMBLY

MT-55

D

E

F

G

H

I

J

K

L

MA

B

MT

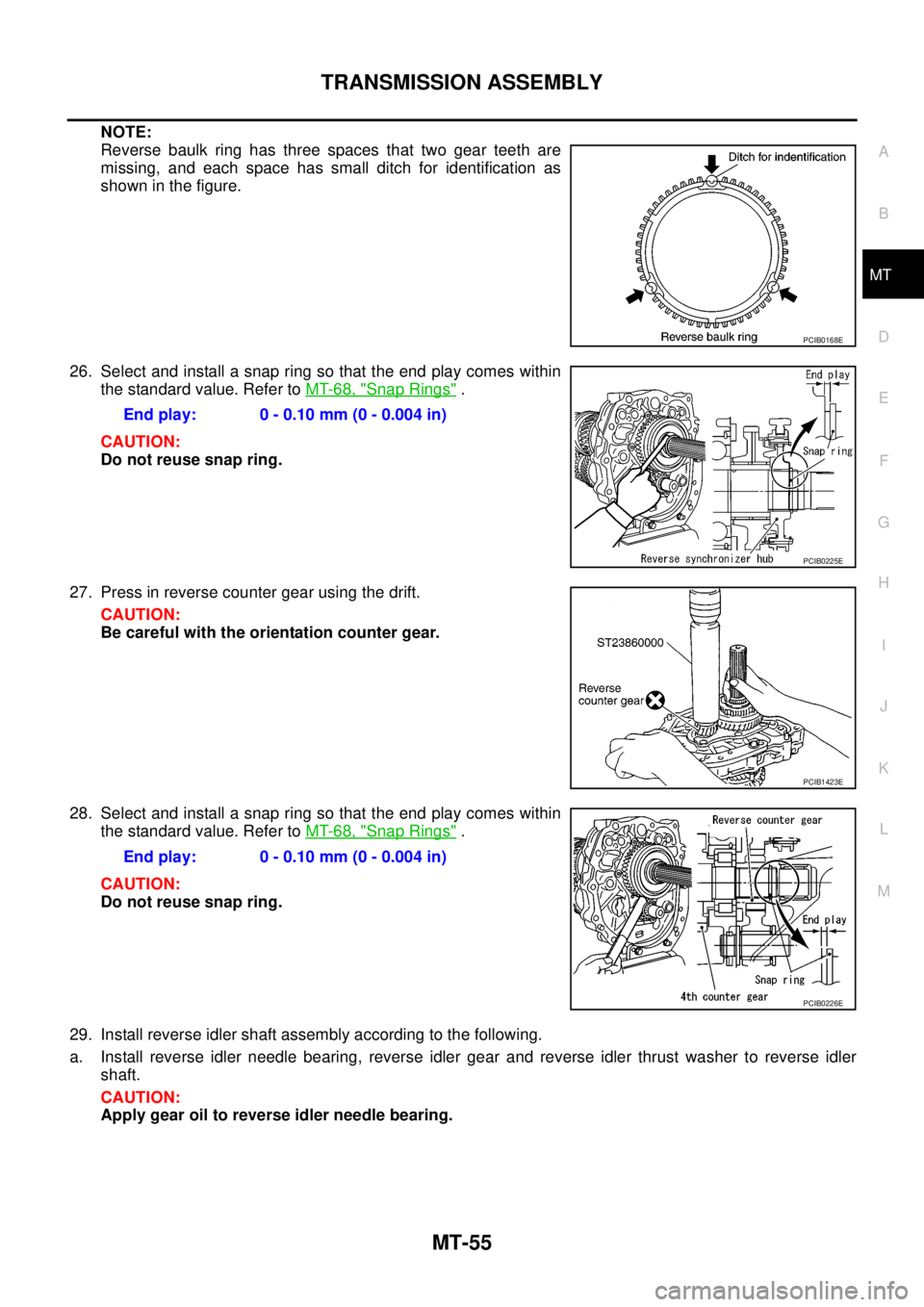

NOTE:

Reverse baulk ring has three spaces that two gear teeth are

missing, and each space has small ditch for identification as

showninthefigure.

26. Select and install a snap ring so that the end play comes within

the standard value. Refer toMT-68, "

Snap Rings".

CAUTION:

Do not reuse snap ring.

27. Press in reverse counter gear using the drift.

CAUTION:

Be careful with the orientation counter gear.

28. Select and install a snap ring so that the end play comes within

the standard value. Refer toMT-68, "

Snap Rings".

CAUTION:

Do not reuse snap ring.

29. Install reverse idler shaft assembly according to the following.

a. Install reverse idler needle bearing, reverse idler gear and reverse idler thrust washer to reverse idler

shaft.

CAUTION:

Apply gear oil to reverse idler needle bearing.

PCIB0168E

End play: 0 - 0.10 mm (0 - 0.004 in)

PCIB0225E

PCIB1423E

End play: 0 - 0.10 mm (0 - 0.004 in)

PCIB0226E

Page 2373 of 3171

MT-56

TRANSMISSION ASSEMBLY

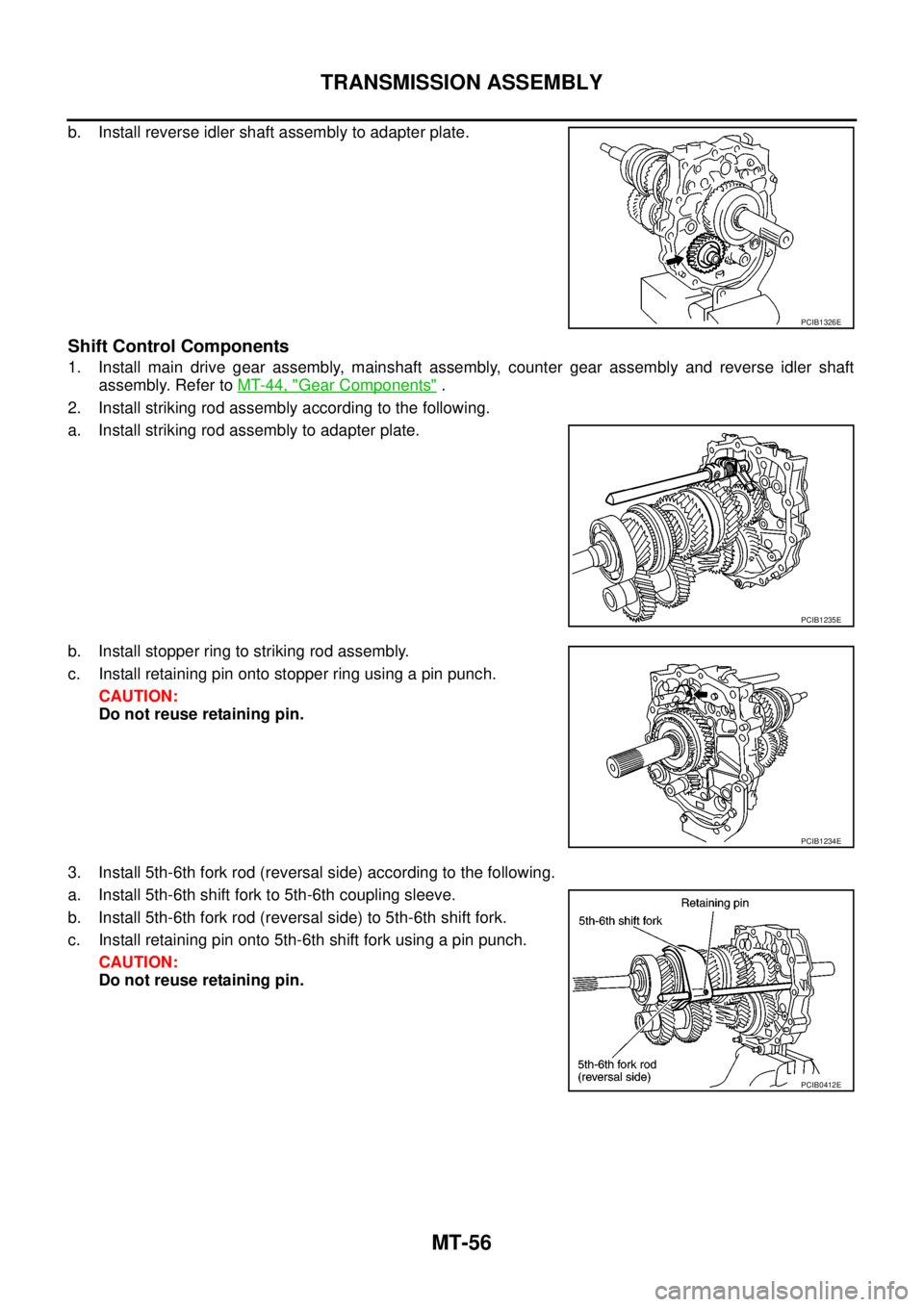

b. Install reverse idler shaft assembly to adapter plate.

Shift Control Components

1. Install main drive gear assembly, mainshaft assembly, counter gear assembly and reverse idler shaft

assembly. Refer toMT-44, "

Gear Components".

2. Install striking rod assembly according to the following.

a. Install striking rod assembly to adapter plate.

b. Install stopper ring to striking rod assembly.

c. Install retaining pin onto stopper ring using a pin punch.

CAUTION:

Do not reuse retaining pin.

3. Install 5th-6th fork rod (reversal side) according to the following.

a. Install 5th-6th shift fork to 5th-6th coupling sleeve.

b. Install 5th-6th fork rod (reversal side) to 5th-6th shift fork.

c. Install retaining pin onto 5th-6th shift fork using a pin punch.

CAUTION:

Do not reuse retaining pin.

PCIB1326E

PCIB1235E

PCIB1234E

PCIB0412E