transmission NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2384 of 3171

SERVICE DATA AND SPECIFICATIONS (SDS)

MT-67

D

E

F

G

H

I

J

K

L

MA

B

MT

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

General SpecificationsECS00IDB

Engine typeYD25DDTi

Transmission modelFS6R31A

Axle type 2WD 4WD

Number of speed6

Synchromesh typeWarner

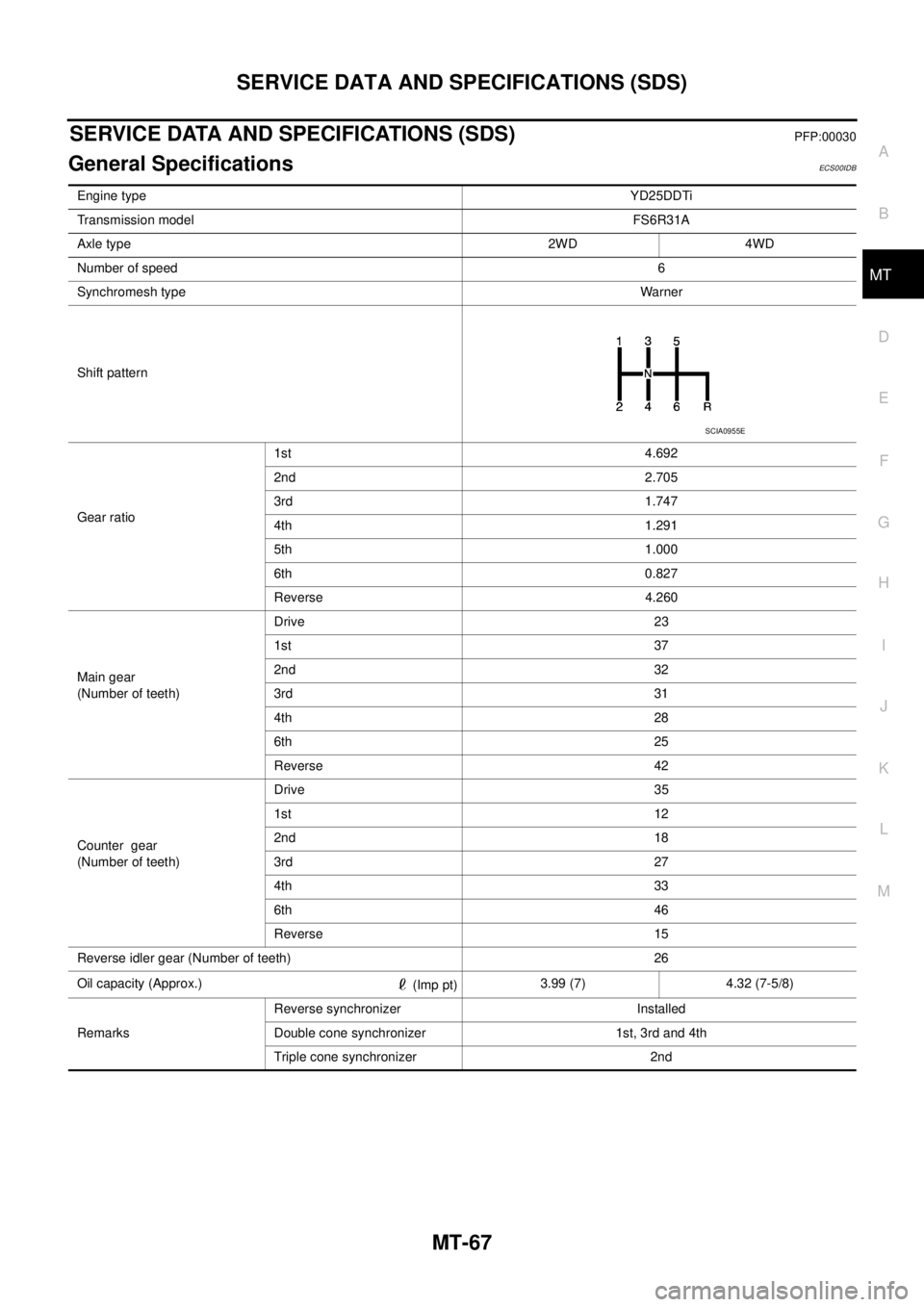

Shift pattern

Gear ratio1st 4.692

2nd 2.705

3rd 1.747

4th 1.291

5th 1.000

6th 0.827

Reverse 4.260

Main gear

(Number of teeth)Drive 23

1st 37

2nd 32

3rd 31

4th 28

6th 25

Reverse 42

Counter gear

(Number of teeth)Drive 35

1st 12

2nd 18

3rd 27

4th 33

6th 46

Reverse 15

Reverse idler gear (Number of teeth) 26

Oil capacity (Approx.)

(Imp pt)3.99 (7) 4.32 (7-5/8)

RemarksReverse synchronizer Installed

Double cone synchronizer 1st, 3rd and 4th

Triple cone synchronizer 2nd

SCIA0955E

Page 2546 of 3171

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PG-17

C

D

E

F

G

H

I

J

L

MA

B

PG

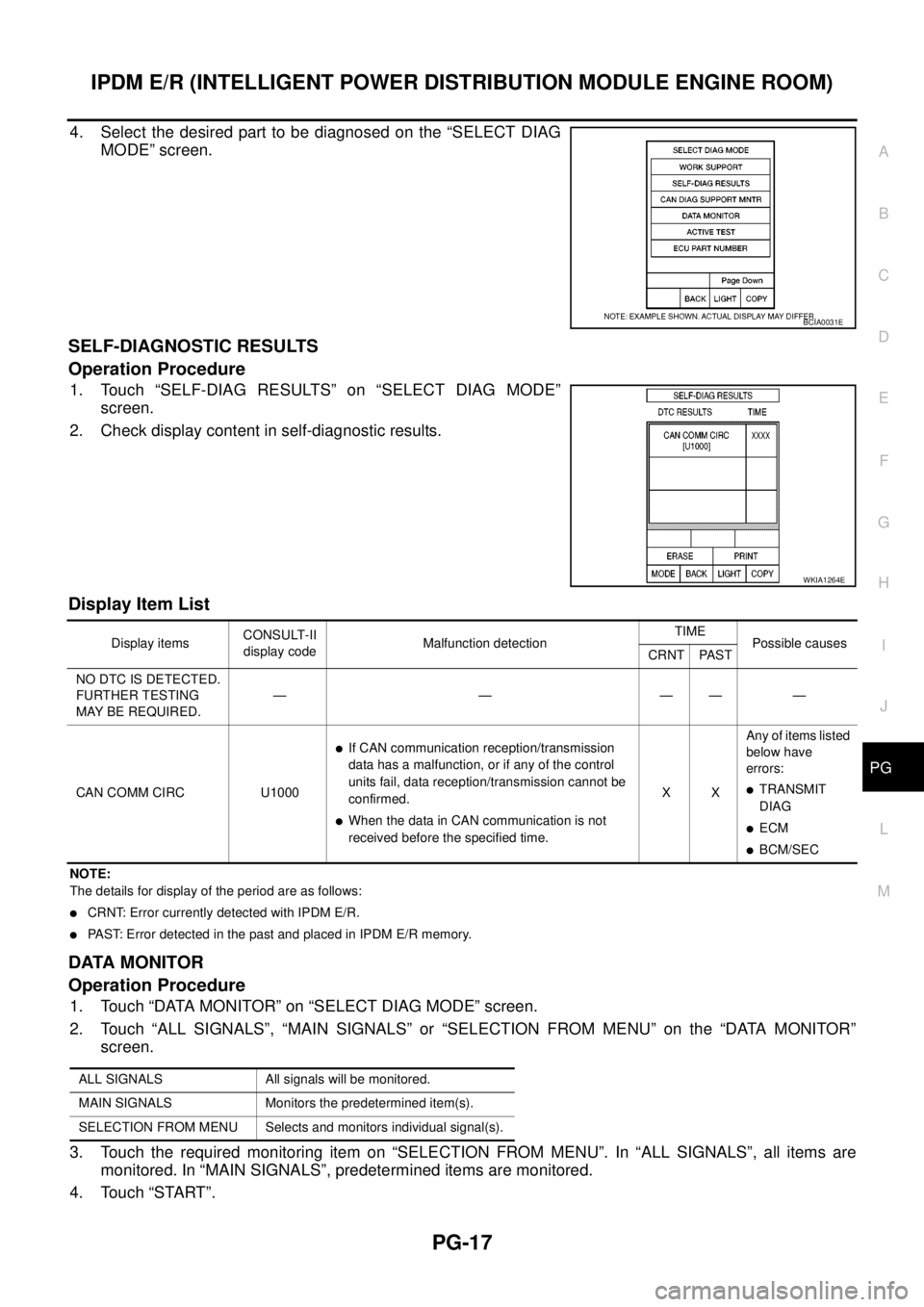

4. Select the desired part to be diagnosed on the “SELECT DIAG

MODE” screen.

SELF-DIAGNOSTIC RESULTS

Operation Procedure

1. Touch “SELF-DIAG RESULTS” on “SELECT DIAG MODE”

screen.

2. Check display content in self-diagnostic results.

Display Item List

NOTE:

The details for display of the period are as follows:

lCRNT: Error currently detected with IPDM E/R.

lPAST: Error detected in the past and placed in IPDM E/R memory.

DATA MONITOR

Operation Procedure

1. Touch “DATA MONITOR” on “SELECT DIAG MODE” screen.

2. Touch “ALL SIGNALS”, “MAIN SIGNALS” or “SELECTION FROM MENU” on the “DATA MONITOR”

screen.

3. Touch the required monitoring item on “SELECTION FROM MENU”. In “ALL SIGNALS”, all items are

monitored. In “MAIN SIGNALS”, predetermined items are monitored.

4. Touch “START”.

BCIA0031E

WKIA1264E

Display itemsCONSULT-II

display codeMalfunction detectionTIME

Possible causes

CRNT PAST

NO DTC IS DETECTED.

FURTHER TESTING

MAYBEREQUIRED.—————

CAN COMM CIRC U1000

lIf CAN communication reception/transmission

data has a malfunction, or if any of the control

units fail, data reception/transmission cannot be

confirmed.

lWhen the data in CAN communication is not

received before the specified time.XXAny of items listed

below have

errors:

lTRANSMIT

DIAG

lECM

lBCM/SEC

ALL SIGNALS All signals will be monitored.

MAIN SIGNALS Monitors the predetermined item(s).

SELECTION FROM MENU Selects and monitors individual signal(s).

Page 2627 of 3171

PR-12

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

PFP:00030

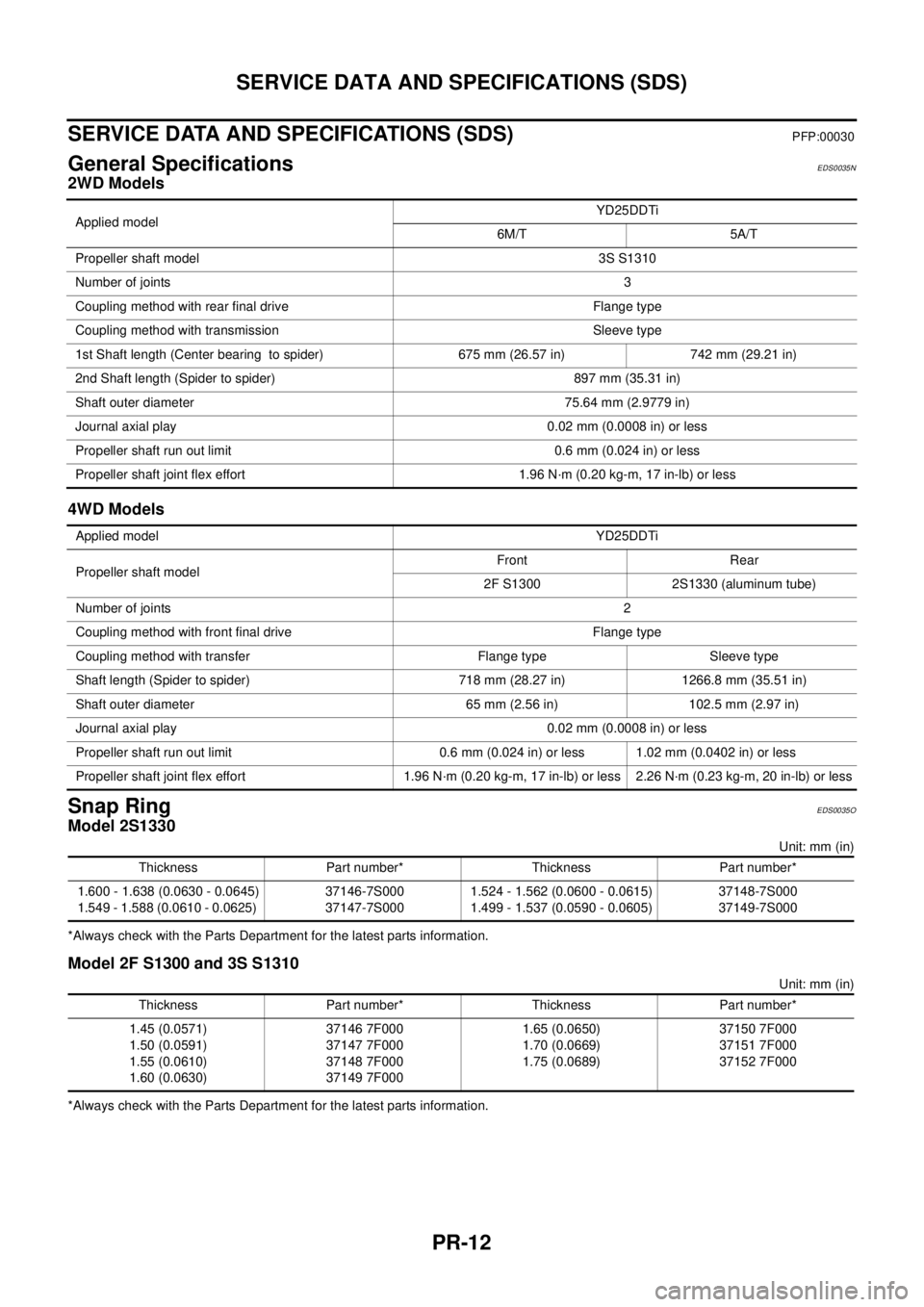

General SpecificationsEDS0035N

2WD Models

4WD Models

Snap RingEDS0035O

Model 2S1330

Unit: mm (in)

*Always check with the Parts Department for the latest parts information.

Model 2F S1300 and 3S S1310

Unit: mm (in)

*Always check with the Parts Department for the latest parts information.Applied modelYD25DDTi

6M/T 5A/T

Propeller shaft model 3S S1310

Number of joints3

Coupling method with rear final drive Flange type

Coupling method with transmission Sleeve type

1st Shaft length (Center bearing to spider) 675 mm (26.57 in) 742 mm (29.21 in)

2nd Shaft length (Spider to spider) 897 mm (35.31 in)

Shaft outer diameter 75.64 mm (2.9779 in)

Journal axial play 0.02 mm (0.0008 in) or less

Propeller shaft run out limit 0.6 mm (0.024 in) or less

Propeller shaft joint flex effort 1.96 N·m (0.20 kg-m, 17 in-lb) or less

Applied modelYD25DDTi

Propeller shaft modelFront Rear

2F S1300 2S1330 (aluminum tube)

Number of joints2

Coupling method with front final drive Flange type

Coupling method with transfer Flange type Sleeve type

Shaft length (Spider to spider) 718 mm (28.27 in) 1266.8 mm (35.51 in)

Shaft outer diameter 65 mm (2.56 in) 102.5 mm (2.97 in)

Journal axial play 0.02 mm (0.0008 in) or less

Propeller shaft run out limit 0.6 mm (0.024 in) or less 1.02 mm (0.0402 in) or less

Propeller shaft joint flex effort 1.96 N·m (0.20 kg-m, 17 in-lb) or less 2.26 N·m (0.23 kg-m, 20 in-lb) or less

Thickness Part number* Thickness Part number*

1.600 - 1.638 (0.0630 - 0.0645)

1.549 - 1.588 (0.0610 - 0.0625)37146-7S000

37147-7S0001.524 - 1.562 (0.0600 - 0.0615)

1.499 - 1.537 (0.0590 - 0.0605)37148-7S000

37149-7S000

Thickness Part number* Thickness Part number*

1.45 (0.0571)

1.50 (0.0591)

1.55 (0.0610)

1.60 (0.0630)37146 7F000

37147 7F000

37148 7F000

37149 7F0001.65 (0.0650)

1.70 (0.0669)

1.75 (0.0689)37150 7F000

37151 7F000

37152 7F000

Page 2690 of 3171

SUNROOF

RF-13

C

D

E

F

G

H

J

K

L

MA

B

RF

CAN Communication System DescriptionEIS00D4X

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

CAN Communication UnitEIS00D4Y

Refer toLAN-30, "CAN Communication Unit".

Page 2717 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual RFD-14

[WITH LIMITED SLIP DIFFERENTIAL]

REAR FINAL DRIVE ASSEMBLY

REAR FINAL DRIVE ASSEMBLY

PFP:38300

Removal and InstallationEDS00398

REMOVAL

1. Remove the rear propeller shaft. Refer toPR-8, "Remova NISSAN NAVARA 2005 Repair Workshop Manual RFD-14

[WITH LIMITED SLIP DIFFERENTIAL]

REAR FINAL DRIVE ASSEMBLY

REAR FINAL DRIVE ASSEMBLY

PFP:38300

Removal and InstallationEDS00398

REMOVAL

1. Remove the rear propeller shaft. Refer toPR-8, "Remova](/img/5/57362/w960_57362-2716.png)

RFD-14

[WITH LIMITED SLIP DIFFERENTIAL]

REAR FINAL DRIVE ASSEMBLY

REAR FINAL DRIVE ASSEMBLY

PFP:38300

Removal and InstallationEDS00398

REMOVAL

1. Remove the rear propeller shaft. Refer toPR-8, "Removal and Installation".

lPlug rear end of transmission or transfer.

2. Remove the axle shafts and back plate and torque members. Refer toRAX-7, "

Removal and Installation".

3. Disconnect the following components from the rear final drive.

lABS sensor wire harness

lRear cable (LH) and rear cable (RH)

lBrake hoses and brake tube

CAUTION:

Position the wire harness, cable and hoses away from the final drive assembly. Failure to do so

may result in components being damaged during rear axle assembly removal.

4. Support the rear final drive using a suitable jack.

5. Remove rear shock absorber lower bolts. Refer toRSU-6, "

Removal and Installation".

6. Remove leaf spring U-bolt nuts. Refer toRSU-7, "

Removal and Installation".

WARNING:

Support the rear final drive assembly using suitable jack before removing leaf spring U-bolt nuts.

7. Remove rear final drive assembly using suitable jack.

INSTALLATION

Installation is the reverse order of removal.

lWhen oil leaks while removing rear final drive assembly, check oil level after the installation. Refer to

RFD-9, "

Checking Differential Gear Oil".

lRefill brake fluid and bleed the air from the brake system. Refer toBR-11, "Bleeding Brake System".

Page 2746 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual DIFFERENTIAL LOCK SYSTEM

RFD-43

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

System DiagramEDS003AS

COMPONENTS FUNCTION DESCRIPTION

CAN CommunicationEDS003AT

SYSTEM DESCRIPTION

CA NISSAN NAVARA 2005 Repair Workshop Manual DIFFERENTIAL LOCK SYSTEM

RFD-43

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

System DiagramEDS003AS

COMPONENTS FUNCTION DESCRIPTION

CAN CommunicationEDS003AT

SYSTEM DESCRIPTION

CA](/img/5/57362/w960_57362-2745.png)

DIFFERENTIAL LOCK SYSTEM

RFD-43

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

System DiagramEDS003AS

COMPONENTS FUNCTION DESCRIPTION

CAN CommunicationEDS003AT

SYSTEM DESCRIPTION

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

For details, refer toDI-65, "

CAN Communication Unit".

SDIA2500E

Component parts Function

Differential lock control unit

lControls differential lock solenoid and switches differential lock/unlock.

lAs a fail-safe function, differential lock disengages, if malfunction is detected in differential lock

system.

Differential lock solenoid Controls pressure plate by current from differential lock control unit.

Differential lock position switch Detects that differential is lock or unlock condition.

Differential lock mode switch Able to select differential lock or unlock.

DIFF LOCK indicator lamp Illuminates that differential is in lock or lock standby condition.

ABS actuator and electric unit

(control unit)Transmits the following signals via CAN communication to differential lock control unit.

lVehicle speed signal

Transfer control unitTransmits the following signal via CAN communication to differential lock control unit.

l4WD shift switch signal

Page 2784 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual REAR FINAL DRIVE ASSEMBLY

RFD-81

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

REAR FINAL DRIVE ASSEMBLYPFP:38300

Removal and InstallationEDS003BF

REMOVAL

1. Remove the rear propel NISSAN NAVARA 2005 Repair Workshop Manual REAR FINAL DRIVE ASSEMBLY

RFD-81

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

REAR FINAL DRIVE ASSEMBLYPFP:38300

Removal and InstallationEDS003BF

REMOVAL

1. Remove the rear propel](/img/5/57362/w960_57362-2783.png)

REAR FINAL DRIVE ASSEMBLY

RFD-81

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

REAR FINAL DRIVE ASSEMBLYPFP:38300

Removal and InstallationEDS003BF

REMOVAL

1. Remove the rear propeller shaft. Refer toPR-8, "Removal and Installation".

lPlug rear end of transmission or transfer.

2. Remove the axle shafts and back plate and torque members. Refer toRAX-7, "

Removal and Installation".

3. Disconnect the following components from the rear final drive.

lABS sensor wire harness

lRear cable (LH) and rear cable (RH)

lBrake hoses and brake tube

lDifferential lock position switch harness connector

lDifferential lock solenoid harness connector

CAUTION:

Position the wire harness, cable and hoses away from the final drive assembly. Failure to do so

may result in components being damaged during rear axle assembly removal.

4. Support the rear final drive using a suitable jack.

5. Remove rear shock absorber lower bolts. Refer toRSU-6, "

Removal and Installation".

6. Remove leaf spring U-bolt nuts. Refer toRSU-7, "

Removal and Installation".

WARNING:

Support the rear final drive assembly using suitable jack before removing leaf spring U-bolt nuts.

7. Remove rear final drive assembly using suitable jack.

INSTALLATION

Installation is the reverse order of removal.

lWhen oil leaks while removing rear final drive assembly, check oil level after the installation. Refer to

RFD-40, "

Checking Differential Gear Oil".

lRefill brake fluid and bleed the air from the brake system. Refer toBR-11, "Bleeding Brake System".

lAfter the installation, check DIFF LOCK indicator lamp. Refer toRFD-33, "Precautions for Differential

Case Assembly and Differential Lock Control Unit Replacement".

Page 2864 of 3171

STARTING SYSTEM

SC-31

C

D

E

F

G

H

I

J

L

MA

B

SC

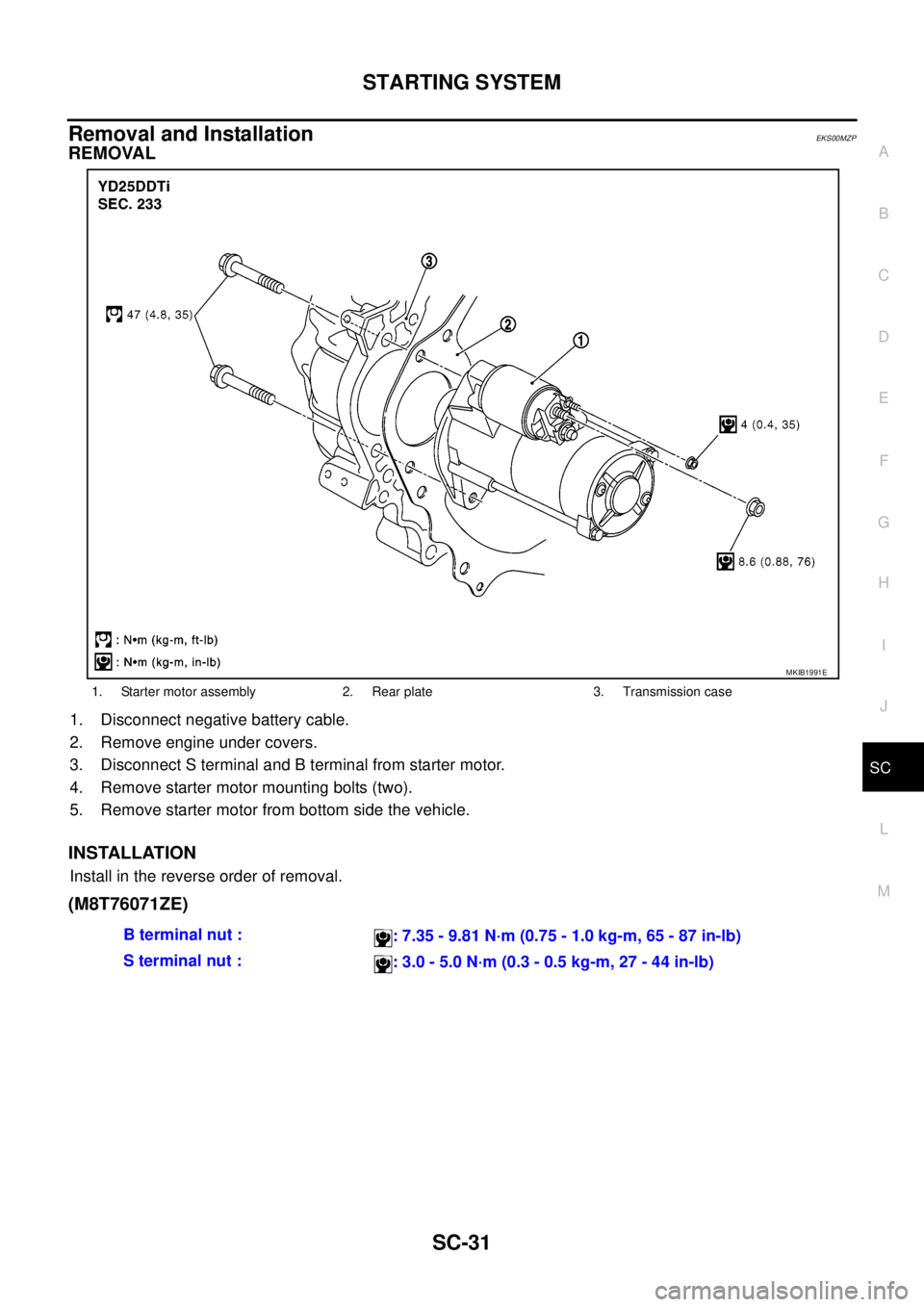

Removal and InstallationEKS00MZP

REMOVAL

1. Disconnect negative battery cable.

2. Remove engine under covers.

3. Disconnect S terminal and B terminal from starter motor.

4. Remove starter motor mounting bolts (two).

5. Remove starter motor from bottom side the vehicle.

INSTALLATION

Install in the reverse order of removal.

(M8T76071ZE)

1. Starter motor assembly 2. Rear plate 3. Transmission case

MKIB1991E

B terminal nut :

: 7.35 - 9.81 N·m (0.75 - 1.0 kg-m, 65 - 87 in-lb)

S terminal nut :

:3.0-5.0N·m(0.3-0.5kg-m,27-44in-lb)

Page 2985 of 3171

TF-18

4WD SYSTEM

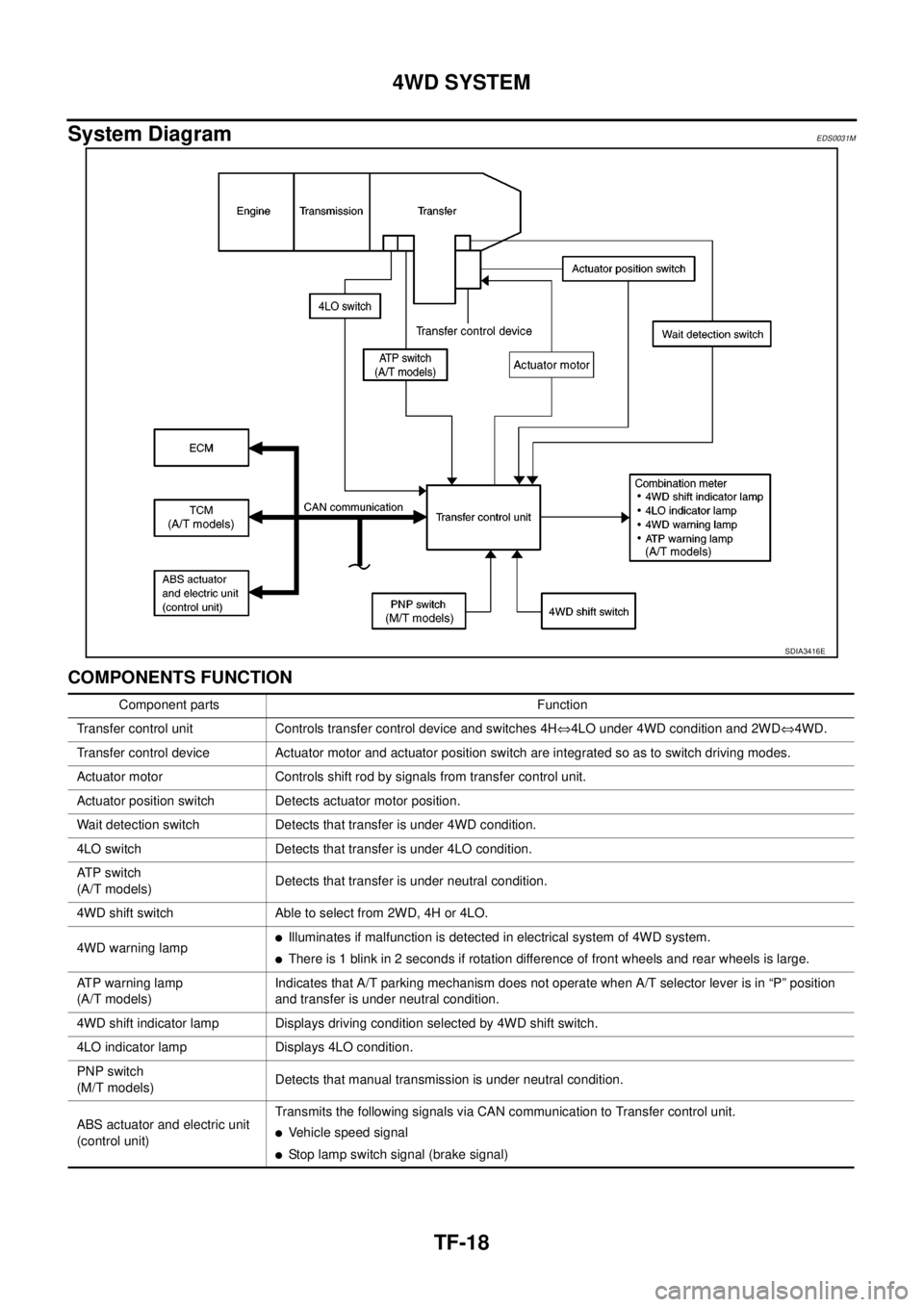

System Diagram

EDS0031M

COMPONENTS FUNCTION

SDIA3416E

Component parts Function

Transfer control unit Controls transfer control device and switches 4HÛ4LO under 4WD condition and 2WDÛ4WD.

Transfer control device Actuator motor and actuator position switch are integrated so as to switch driving modes.

Actuator motor Controls shift rod by signals from transfer control unit.

Actuator position switch Detects actuator motor position.

Wait detection switch Detects that transfer is under 4WD condition.

4LO switch Detects that transfer is under 4LO condition.

AT P s w i t c h

(A/T models)Detects that transfer is under neutral condition.

4WD shift switch Able to select from 2WD, 4H or 4LO.

4WD warning lamp

lIlluminates if malfunction is detected in electrical system of 4WD system.

lThere is 1 blink in 2 seconds if rotation difference of front wheels and rear wheels is large.

ATP warning lamp

(A/T models)Indicates that A/T parking mechanism does not operate when A/T selector lever is in “P” position

and transfer is under neutral condition.

4WD shift indicator lamp Displays driving condition selected by 4WD shift switch.

4LO indicator lamp Displays 4LO condition.

PNP switch

(M/T models)Detects that manual transmission is under neutral condition.

ABS actuator and electric unit

(control unit)Transmits the following signals via CAN communication to Transfer control unit.

lVehicle speed signal

lStop lamp switch signal (brake signal)

Page 2986 of 3171

4WD SYSTEM

TF-19

C

E

F

G

H

I

J

K

L

MA

B

TF

CAN CommunicationEDS0031N

SYSTEM DESCRIPTION

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

For details, refer toLAN-23, "

CAN COMMUNICATION".

TCM

(A/T models)Transmits the following signal via CAN communication to Transfer control unit.lOutput shaft revolution signal

lA/T position indicator signal (PNP switch signal)

ECMTransmits engine speed signal via CAN communication to Transfer control unit.

lEngine speed signal Component parts Function