ECU NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2641 of 3171

PS-14

POWER STEERING GEAR AND LINKAGE

POWER STEERING GEAR AND LINKAGE

PFP:49001

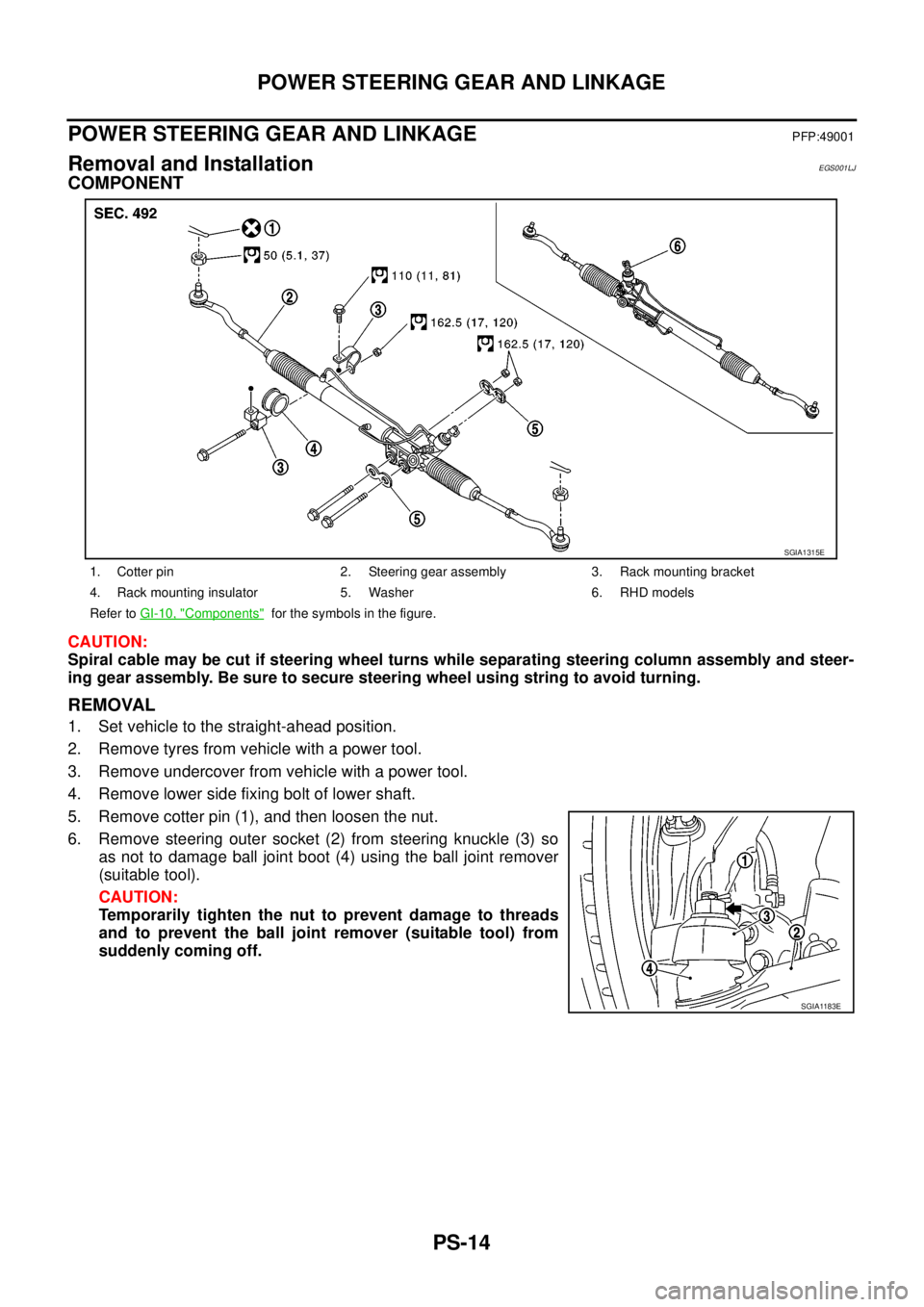

Removal and InstallationEGS001LJ

COMPONENT

CAUTION:

Spiral cable may be cut if steering wheel turns while separating steering column assembly and steer-

ing gear assembly. Be sure to secure steering wheel using string to avoid turning.

REMOVAL

1. Set vehicle to the straight-ahead position.

2. Remove tyres from vehicle with a power tool.

3. Remove undercover from vehicle with a power tool.

4. Remove lower side fixing bolt of lower shaft.

5. Remove cotter pin (1), and then loosen the nut.

6. Remove steering outer socket (2) from steering knuckle (3) so

as not to damage ball joint boot (4) using the ball joint remover

(suitable tool).

CAUTION:

Temporarily tighten the nut to prevent damage to threads

and to prevent the ball joint remover (suitable tool) from

suddenly coming off.

1. Cotter pin 2. Steering gear assembly 3. Rack mounting bracket

4. Rack mounting insulator 5. Washer 6. RHD models

Refer toGI-10, "

Components"for the symbols in the figure.

SGIA1315E

SGIA1183E

Page 2643 of 3171

PS-16

POWER STEERING GEAR AND LINKAGE

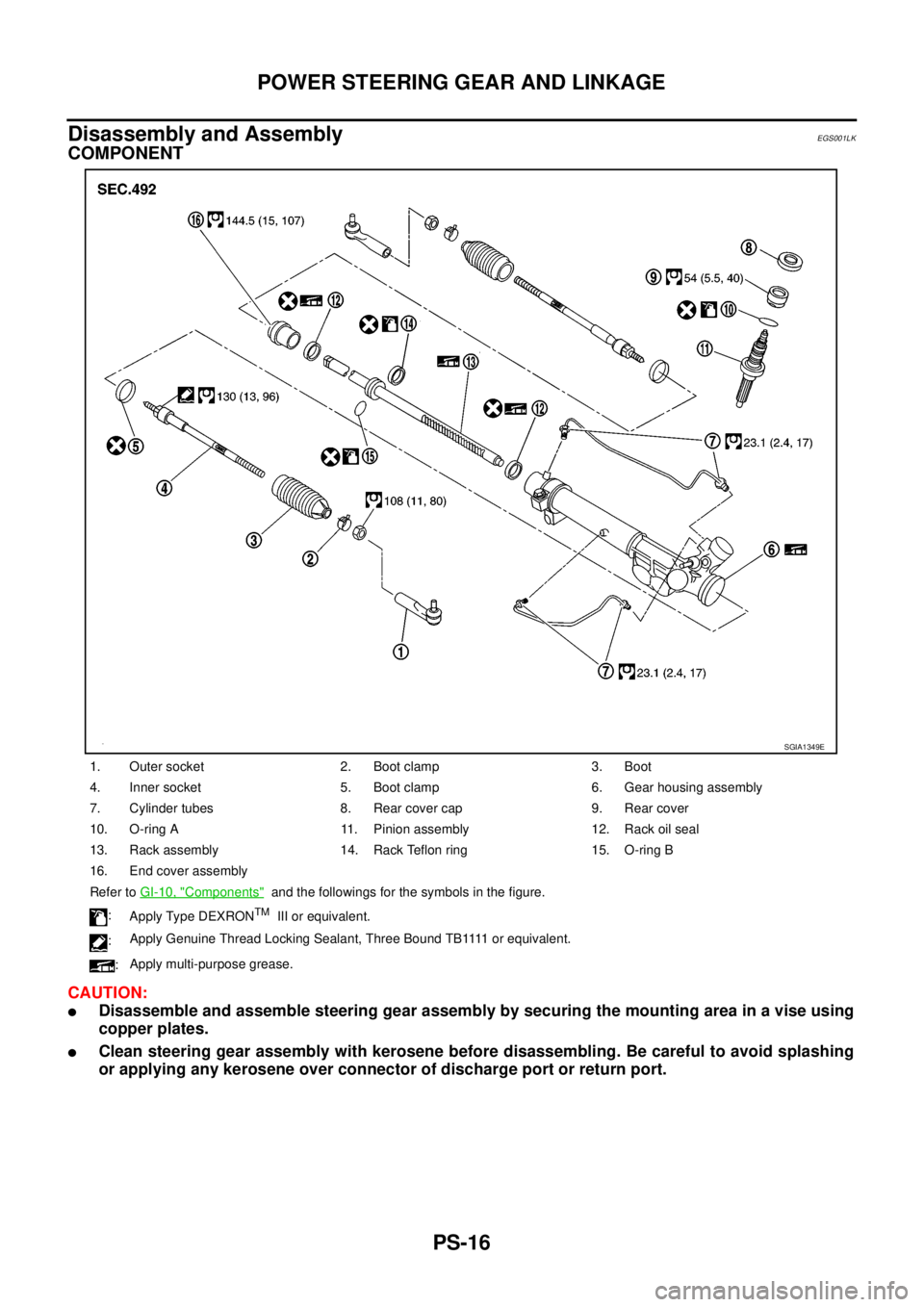

Disassembly and Assembly

EGS001LK

COMPONENT

CAUTION:

lDisassemble and assemble steering gear assembly by securing the mounting area in a vise using

copper plates.

lClean steering gear assembly with kerosene before disassembling. Be careful to avoid splashing

or applying any kerosene over connector of discharge port or return port.

1. Outer socket 2. Boot clamp 3. Boot

4. Inner socket 5. Boot clamp 6. Gear housing assembly

7. Cylinder tubes 8. Rear cover cap 9. Rear cover

10. O-ring A 11. Pinion assembly 12. Rack oil seal

13. Rack assembly 14. Rack Teflon ring 15. O-ring B

16. End cover assembly

Refer toGI-10, "

Components"and the followings for the symbols in the figure.

:

Apply Type DEXRON

TMIII or equivalent.

:A p p l y G e n u i n e T h r e a d L o c k i n g S e a l a n t , T h r e e B o u n d T B 1111 o r e q u i v a l e n t .

:Apply multi-purpose grease.

SGIA1349E

Page 2654 of 3171

POWER STEERING OIL PUMP

PS-27

C

D

E

F

H

I

J

K

L

MA

B

PS

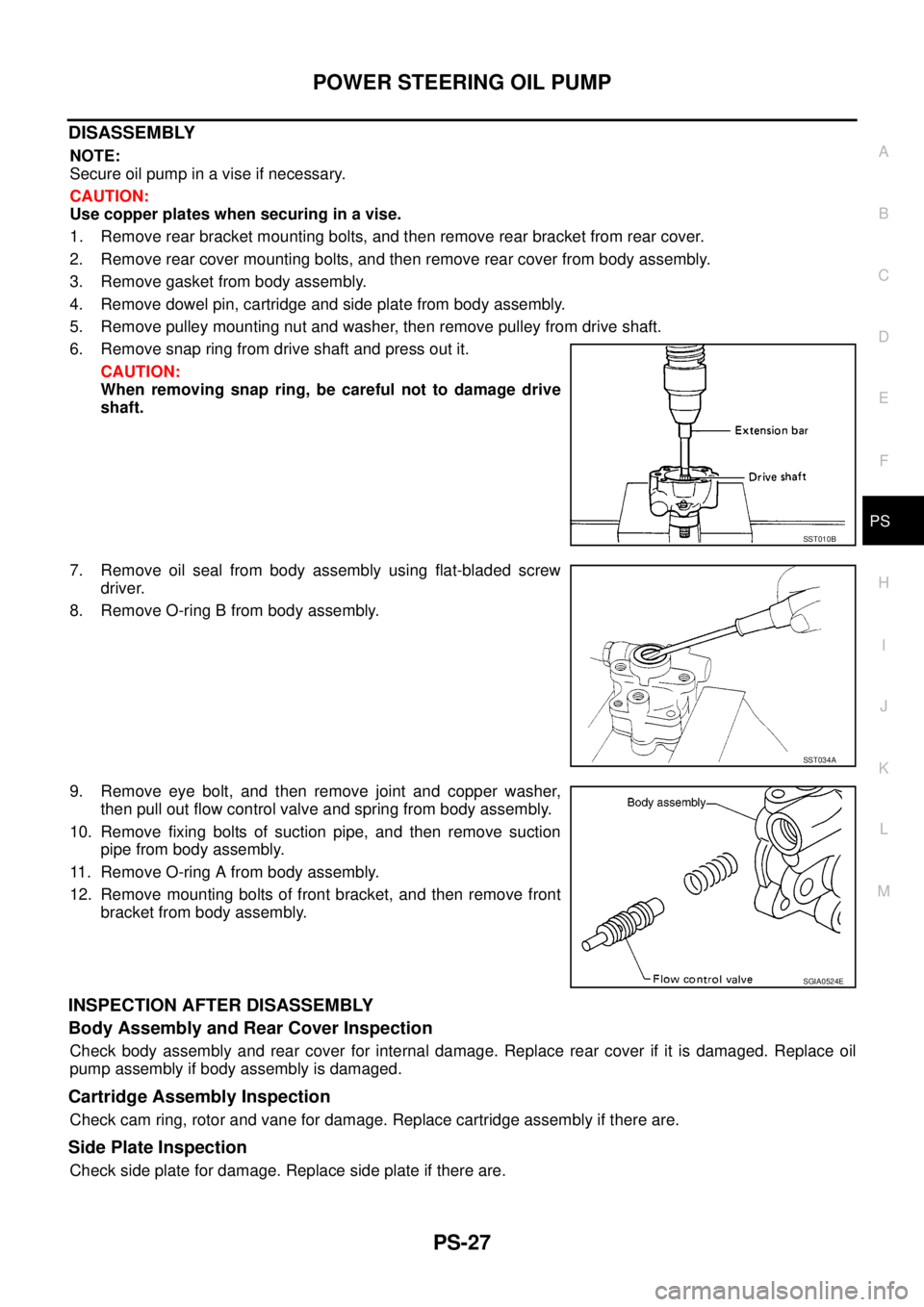

DISASSEMBLY

NOTE:

Secure oil pump in a vise if necessary.

CAUTION:

Use copper plates when securing in a vise.

1. Remove rear bracket mounting bolts, and then remove rear bracket from rear cover.

2. Remove rear cover mounting bolts, and then remove rear cover from body assembly.

3. Remove gasket from body assembly.

4. Remove dowel pin, cartridge and side plate from body assembly.

5. Remove pulley mounting nut and washer, then remove pulley from drive shaft.

6. Remove snap ring from drive shaft and press out it.

CAUTION:

When removing snap ring, be careful not to damage drive

shaft.

7. Remove oil seal from body assembly using flat-bladed screw

driver.

8. Remove O-ring B from body assembly.

9. Remove eye bolt, and then remove joint and copper washer,

then pull out flow control valve and spring from body assembly.

10. Remove fixing bolts of suction pipe, and then remove suction

pipe from body assembly.

11. Remove O-ring A from body assembly.

12. Remove mounting bolts of front bracket, and then remove front

bracket from body assembly.

INSPECTION AFTER DISASSEMBLY

Body Assembly and Rear Cover Inspection

Check body assembly and rear cover for internal damage. Replace rear cover if it is damaged. Replace oil

pump assembly if body assembly is damaged.

Cartridge Assembly Inspection

Check cam ring, rotor and vane for damage. Replace cartridge assembly if there are.

Side Plate Inspection

Check side plate for damage. Replace side plate if there are.

SST010B

SST034A

SGIA0524E

Page 2655 of 3171

PS-28

POWER STEERING OIL PUMP

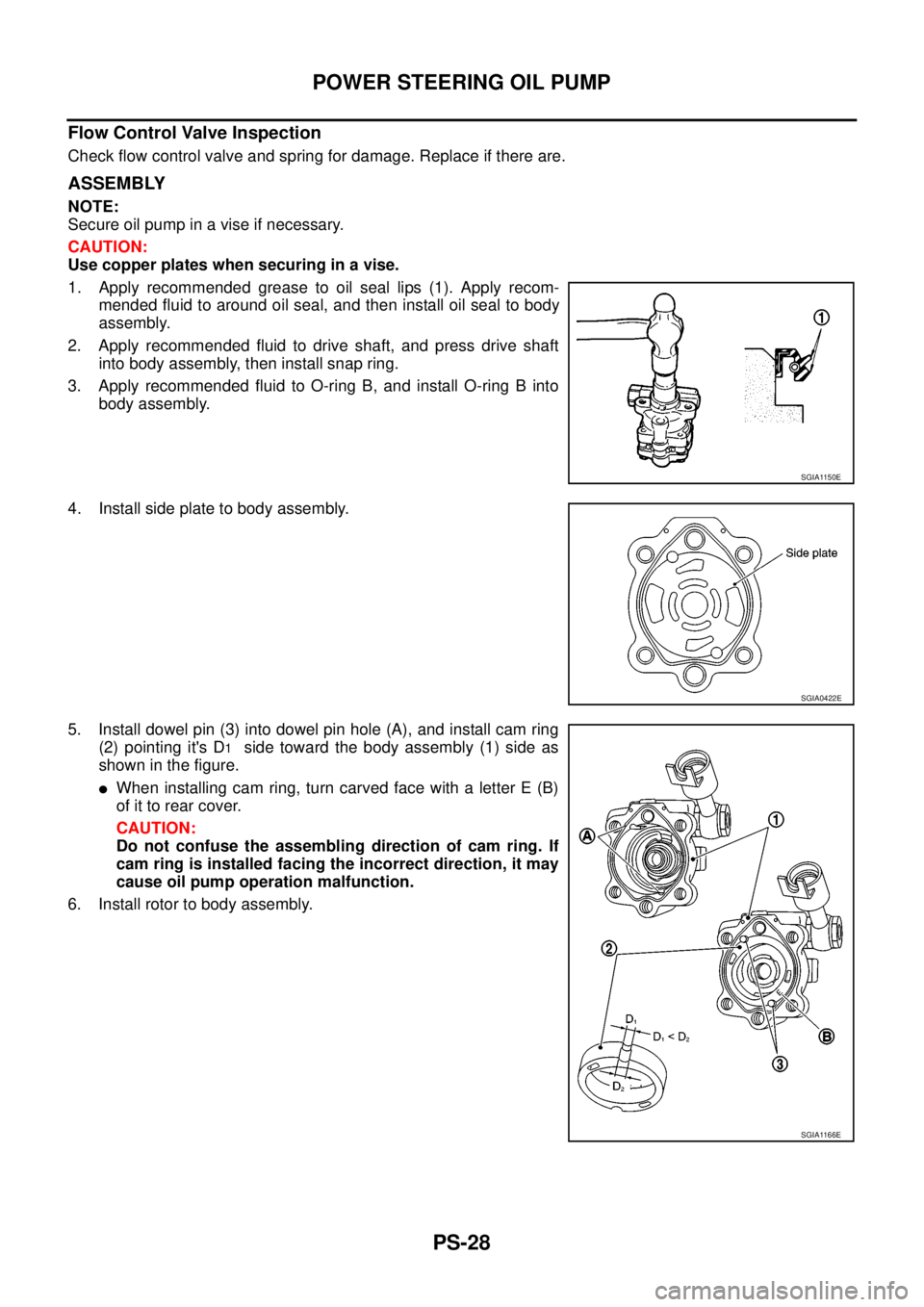

Flow Control Valve Inspection

Check flow control valve and spring for damage. Replace if there are.

ASSEMBLY

NOTE:

Secureoilpumpinaviseifnecessary.

CAUTION:

Use copper plates when securing in a vise.

1. Apply recommended grease to oil seal lips (1). Apply recom-

mended fluid to around oil seal, and then install oil seal to body

assembly.

2. Apply recommended fluid to drive shaft, and press drive shaft

into body assembly, then install snap ring.

3. Apply recommended fluid to O-ring B, and install O-ring B into

body assembly.

4. Install side plate to body assembly.

5. Install dowel pin (3) into dowel pin hole (A), and install cam ring

(2) pointing it's D

1side toward the body assembly (1) side as

showninthefigure.

lWhen installing cam ring, turn carved face with a letter E (B)

of it to rear cover.

CAUTION:

Do not confuse the assembling direction of cam ring. If

cam ring is installed facing the incorrect direction, it may

cause oil pump operation malfunction.

6. Install rotor to body assembly.

SGIA1150E

SGIA0422E

SGIA1166E

Page 2657 of 3171

PS-30

HYDRAULIC LINE

HYDRAULIC LINE

PFP:49721

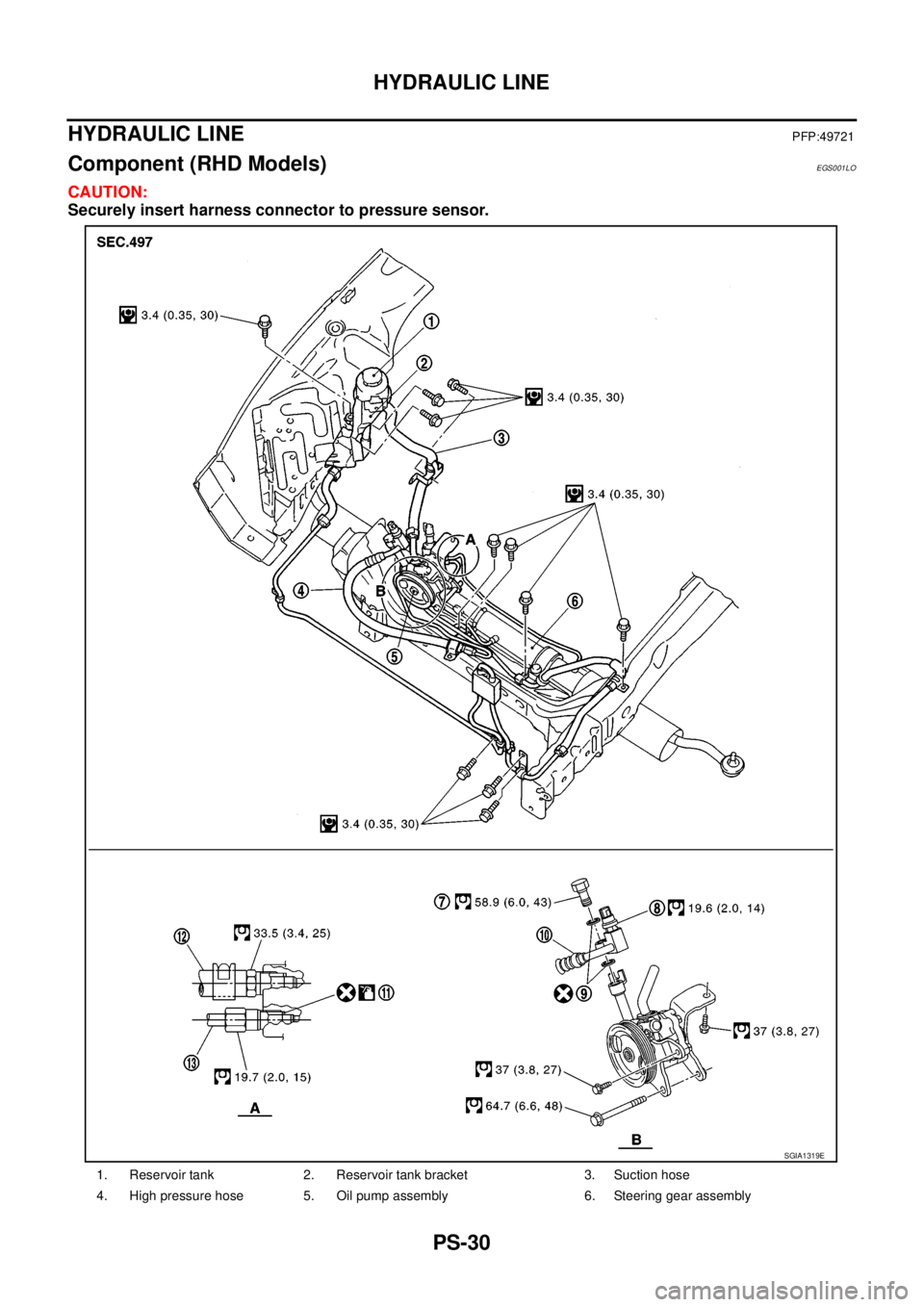

Component (RHD Models)EGS001LO

CAUTION:

Securely insert harness connector to pressure sensor.

1. Reservoir tank 2. Reservoir tank bracket 3. Suction hose

4. High pressure hose 5. Oil pump assembly 6. Steering gear assembly

SGIA1319E

Page 2659 of 3171

PS-32

HYDRAULIC LINE

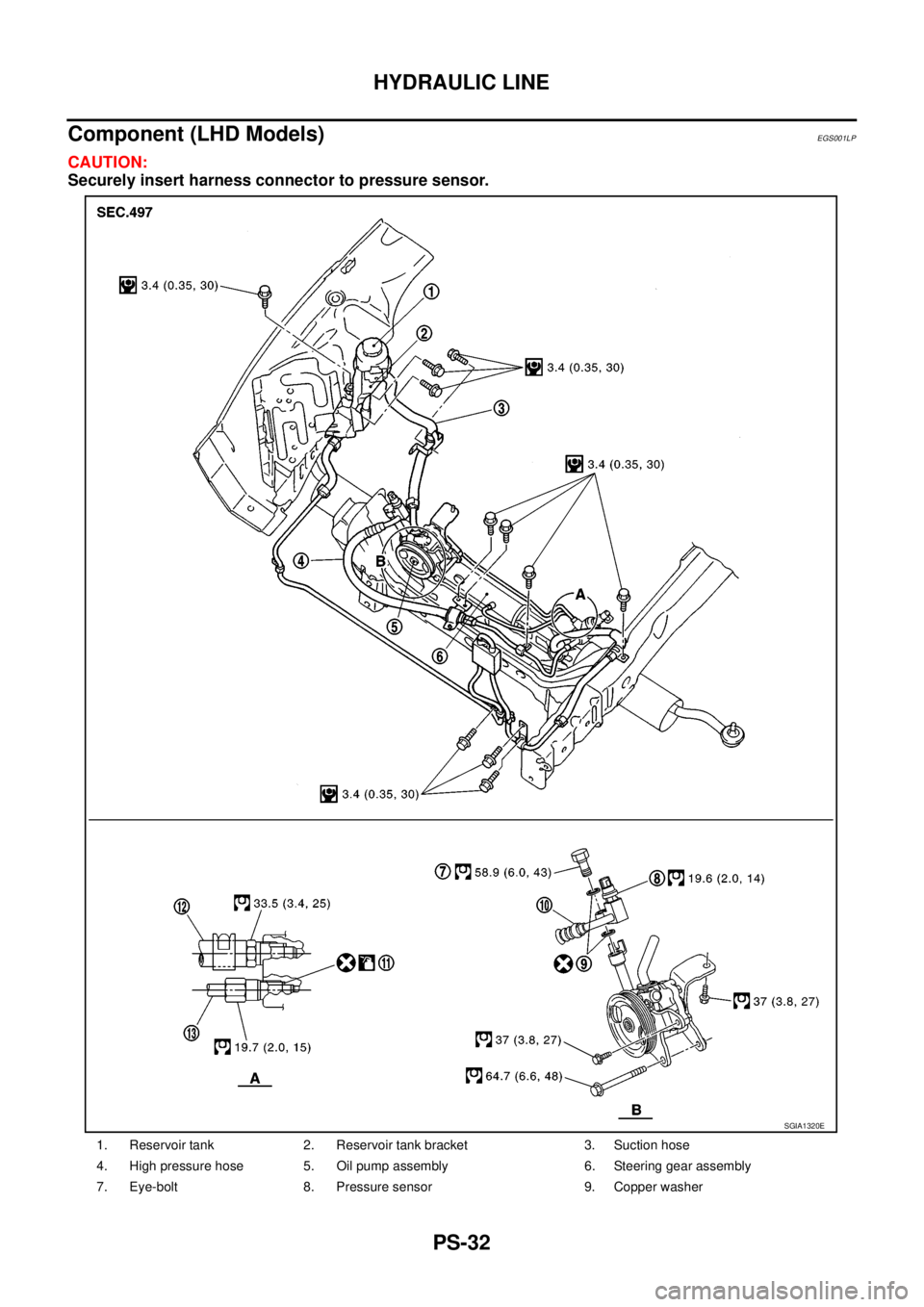

Component (LHD Models)

EGS001LP

CAUTION:

Securely insert harness connector to pressure sensor.

1. Reservoir tank 2. Reservoir tank bracket 3. Suction hose

4. High pressure hose 5. Oil pump assembly 6. Steering gear assembly

7. Eye-bolt 8. Pressure sensor 9. Copper washer

SGIA1320E

Page 2660 of 3171

HYDRAULIC LINE

PS-33

C

D

E

F

H

I

J

K

L

MA

B

PS

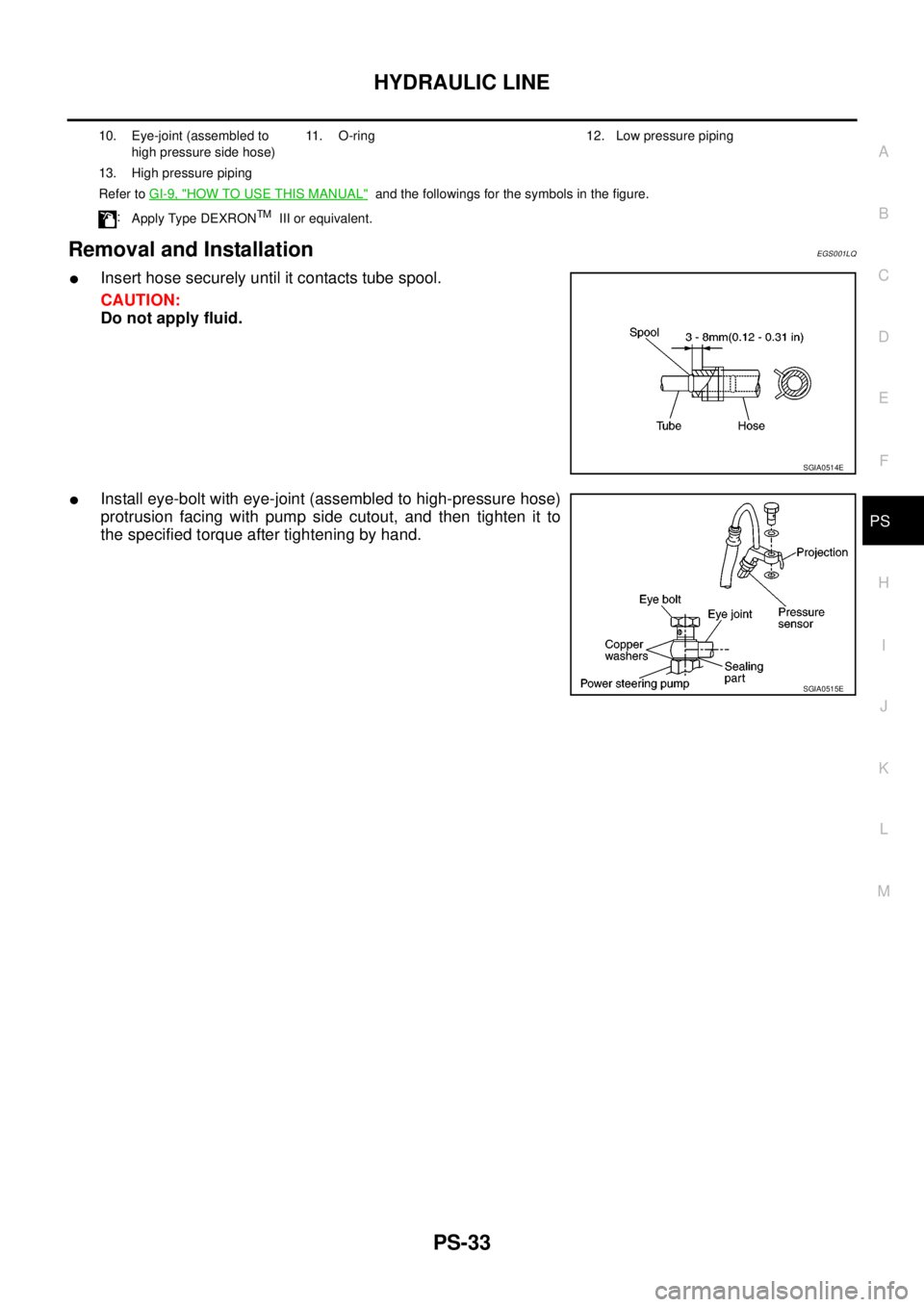

Removal and InstallationEGS001LQ

lInsert hose securely until it contacts tube spool.

CAUTION:

Do not apply fluid.

lInstall eye-bolt with eye-joint (assembled to high-pressure hose)

protrusion facing with pump side cutout, and then tighten it to

the specified torque after tightening by hand.

10. Eye-joint (assembled to

high pressure side hose)11. O-ring 12. Low pressure piping

13. High pressure piping

Refer toGI-9, "

HOW TO USE THIS MANUAL"and the followings for the symbols in the figure.

:

Apply Type DEXRON

TMIII or equivalent.

SGIA0514E

SGIA0515E

Page 2671 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual RAX-8

[M226]

AXLE SHAFT

REMOVAL

1. Remove the wheel.

2. Remove the rear brake drum. Refer toBR-31, "

Removal and Installation of Drum Brake Assembly".

3. Remove four lock nuts and spring washers secur NISSAN NAVARA 2005 Repair Workshop Manual RAX-8

[M226]

AXLE SHAFT

REMOVAL

1. Remove the wheel.

2. Remove the rear brake drum. Refer toBR-31, "

Removal and Installation of Drum Brake Assembly".

3. Remove four lock nuts and spring washers secur](/img/5/57362/w960_57362-2670.png)

RAX-8

[M226]

AXLE SHAFT

REMOVAL

1. Remove the wheel.

2. Remove the rear brake drum. Refer toBR-31, "

Removal and Installation of Drum Brake Assembly".

3. Remove four lock nuts and spring washers securing the axle

shaft retainer to the rear axle case.

4. Using a wire, suspend the baffle plate to the sub frame.

NOTE:

Brake hose and brake cable do not need to be disconnected from the baffle plate and wheel cylinder.

CAUTION:

lBe careful not to deform brake tube.

lDo not bend the parking brake cable.

lWhile removing drum, never depress brake pedal because the piston will pop out.

5. Remove the axle shaft assembly from the rear axle case as

shown.

6. Using a puller remove the bearing cup from the rear axle case.

CAUTION:

lThe axle shaft bearing cup may stay in place in the axle

shaft housing. Remove the cup carefully so as not to

damage the inner surface of the axle shaft housing.

7. Usingapuller,removetheaxleshaftguideandoilsealfromthe

rear axle case.

NOTE:

Rear final drive oil will spill while removing the oil seal. Use a drain pan under the rear axle case to drain

oil.

10. Baffle plate 11. Bearing cup 12. Axle shaft guide

13. Oil seal 14. Breather 15. Rear axle case

LDIA0112E

WDIA0182E

Tool number : ST33290001

Tool number : ST33290001

MDIB9050E

Page 2672 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual AXLE SHAFT

RAX-9

[M226]

C

E

F

G

H

I

J

K

L

MA

B

RAX

INSPECTION AFTER REMOVAL

Axle Shaft Bearing and Cup

lCheck that the axle shaft bearing and cup roll freely and are free from noise, cracks, pitting a NISSAN NAVARA 2005 Repair Workshop Manual AXLE SHAFT

RAX-9

[M226]

C

E

F

G

H

I

J

K

L

MA

B

RAX

INSPECTION AFTER REMOVAL

Axle Shaft Bearing and Cup

lCheck that the axle shaft bearing and cup roll freely and are free from noise, cracks, pitting a](/img/5/57362/w960_57362-2671.png)

AXLE SHAFT

RAX-9

[M226]

C

E

F

G

H

I

J

K

L

MA

B

RAX

INSPECTION AFTER REMOVAL

Axle Shaft Bearing and Cup

lCheck that the axle shaft bearing and cup roll freely and are free from noise, cracks, pitting and wear.

Replace if necessary.

Axle Shaft Retainer

lCheck for deformation and cracks. Replace if necessary.

Rear Axle Case

lCheck the exterior and inner machined surfaces for deformation and cracks. Replace if necessary.

INSTALLATION

Installation is in the reverse order of removal.

When installing pay attention to following points:

lInstall a new shaft guide and a new oil seal into the rear axle case.

CAUTION:

lDo not reuse the axle oil seal. The axle oil seal must be replaced every time the axle shaft assem-

bly is removed from the axle shaft housing.

lWhen installing oil seals, apply multi-purpsose grease to oil seal lips.

lInstall four new lock nuts to secure the axle shaft assembly to the rear axle case, and tighten lock nuts to

the specified torque. Refer toRAX-7, "

Removal and Installation".

lReinstall the rear brake drum. Refer toBR-31, "Removal and Installation of Drum Brake Assembly".

lAdjust the differential gear oil level.

Refer toRFD-9, "

DIFFERENTIAL GEAR OIL", for M226 without LD.

Refer toRFD-9, "

DIFFERENTIAL GEAR OIL", for M226 with LD.

lReinstall the wheel. Refer toWT-5, "Rotation".

DISASSEMBLY

1. Remove the ABS sensor rotor. Refer toBRC-39, "SENSOR ROTOR".

2. Remove the snap ring from the axle shaft using a suitable snap ring pliers.

3. Secure the axle shaft in a suitable vise as shown, and use a

brass hammer to remove studs (4) from the axle shaft retainer.

CAUTION:

lMount the axle shaft using a soft jaw vise to avoid dam-

aging the axle shaft retainer.

MDIB9051E

Page 2682 of 3171

SQUEAK AND RATTLE TROUBLE DIAGNOSES

RF-5

C

D

E

F

G

H

J

K

L

MA

B

RF

DUPLICATE THE NOISE AND TEST DRIVE

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or location of the noise. This information can be used to

duplicate the same conditions when you confirm the repair.

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following:

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle “twist”.

5) At idle, apply engine load (electrical load, half-clutch on M/T models, drive position on A/T models).

6) Raisethevehicleonahoistandhitatirewitharubberhammer.

lDrive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

lIf it is difficult to duplicate the noise, drive the vehicle slowly on an undulating or rough road to stress the

vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, check ASIST for Technical Service Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, follow the procedure to repair the noise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area. To help pinpoint the source of the noise, use a listening tool

(Engine Ear or mechanics stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by:

lremoving the components in the area that you suspect the noise is coming from.

Do not use too much force when removing clips and fasteners, otherwise clips and fastener can be broken

or lost during the repair, resulting in the creation of new noise.

ltapping or pushing/pulling the component that you suspect is causing the noise.

Do not tap or push/pull the component with excessive force, otherwise the noise will be eliminated only

temporarily.

lfeeling for a vibration with your hand by touching the component(s) that you suspect is (are) causing the

noise.

lplacing a piece of paper between components that you suspect are causing the noise.

llooking for loose components and contact marks.

Refer toRF-6, "

Generic Squeak and Rattle Troubleshooting".

REPAIR THE CAUSE

lIf the cause is a loose component, tighten the component securely.

lIf the cause is insufficient clearance between components:

–separate components by repositioning or loosening and retightening the component, if possible.

–insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or ure-

thane tape are available through your authorized Nissan Parts Department.

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

NOTE:

Always check with the Parts Department for the latest parts information.

Each item can be ordered separately as needed.

URETHANE PADS [1.5 mm (0.059 in) thick]

Insulates connectors, harness, etc.

76268-9E005: 100´135 mm (3.94´5.31 in)/76884-71L01: 60´85 mm (2.36´3.35 in)/76884-71L02: 15´

25 mm (0.59´0.98 in)

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

73982-9E000: 45 mm (1.77 in) thick, 50´50 mm (1.97´1.97 in)/73982-50Y00: 10 mm (0.39 in) thick, 50

´50 mm (1.97´1.97 in)

INSULATOR (Light foam block)

80845-71L00: 30 mm (1.18 in) thick, 30´50 mm (1.18´1.97 in)