ECU NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2878 of 3171

SQUEAK AND RATTLE TROUBLE DIAGNOSES

SE-7

C

D

E

F

G

H

J

K

L

MA

B

SE

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid dumpers out of adjustment

2. Trunk lid striker out of adjustment

3. Trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sunvisor shaft shaking in the holder

3. Front or rear windshield touching headlining and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

SEATS

When isolating seat noise it's important to note the position the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. Rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of these incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Page 2911 of 3171

SRS-2

DIAGNOSIS SENSOR UNIT ..................................... 48

Removal and Installation ........................................ 48

REMOVAL ........................................................... 48

INSTALLATION .................................................... 48

ECU DISCRIMINATED NO. ................................. 48

DISPOSAL OF AIR BAG MODULE AND SEAT BELT

PRE-TENSIONER ..................................................... 49

Caution for Air Bag Module and Seat Belt Pre-

tensioner ................................................................. 49

CHECKING DEPLOYMENT TOOL ..................... 49

DEPLOYMENT PROCEDURES FOR AIR BAG

MODULE (OUTSIDE OF VEHICLE) ................... 50

DEPLOYMENT PROCEDURES FOR SEAT

BELT PRE-TENSIONER (OUTSIDE OF VEHI-

CLE) .................................................................... 54

DEPLOYMENT OF AIR BAG MODULES ANDSEAT BELT PRE-TENSIONERS WHILE

MOUNTED IN VEHICLE ...................................... 54

DISPOSING OF AIR BAG MODULE AND SEAT

BELT PRE-TENSIONER ...................................... 55

COLLISION DIAGNOSIS .......................................... 56

For Frontal Collision ................................................ 56

SRS INSPECTION (FOR FRONTAL COLLI-

SION) ................................................................... 56

For Side Collision .................................................... 56

WHEN SRS IS ACTIVATED IN THE SIDE COL-

LISION ................................................................. 57

WHEN SRS IS NOT ACTIVATED IN THE SIDE

COLLISION .......................................................... 57

SRS INSPECTION (FOR SIDE COLLISION) ...... 57

Page 2916 of 3171

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

SRS-7

C

D

E

F

G

I

J

K

L

MA

B

SRS

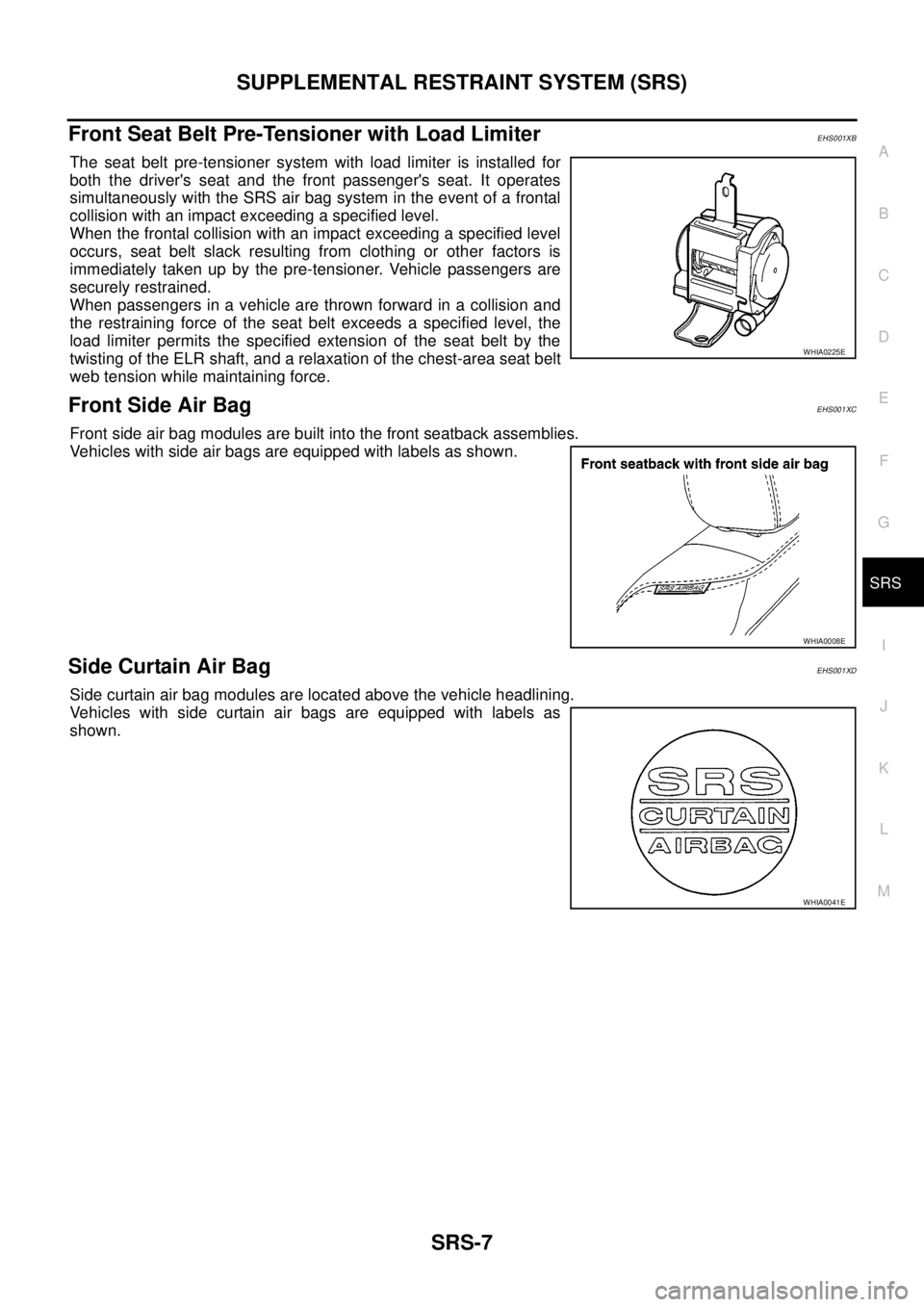

Front Seat Belt Pre-Tensioner with Load LimiterEHS001XB

The seat belt pre-tensioner system with load limiter is installed for

both the driver's seat and the front passenger's seat. It operates

simultaneously with the SRS air bag system in the event of a frontal

collision with an impact exceeding a specified level.

When the frontal collision with an impact exceeding a specified level

occurs, seat belt slack resulting from clothing or other factors is

immediately taken up by the pre-tensioner. Vehicle passengers are

securely restrained.

When passengers in a vehicle are thrown forward in a collision and

the restraining force of the seat belt exceeds a specified level, the

load limiter permits the specified extension of the seat belt by the

twisting of the ELR shaft, and a relaxation of the chest-area seat belt

web tension while maintaining force.

Front Side Air BagEHS001XC

Front side air bag modules are built into the front seatback assemblies.

Vehicles with side air bags are equipped with labels as shown.

Side Curtain Air BagEHS001XD

Side curtain air bag modules are located above the vehicle headlining.

Vehicles with side curtain air bags are equipped with labels as

shown.

WHIA0225E

WHIA0008E

WHIA0041E

Page 2925 of 3171

SRS-16

TROUBLE DIAGNOSIS

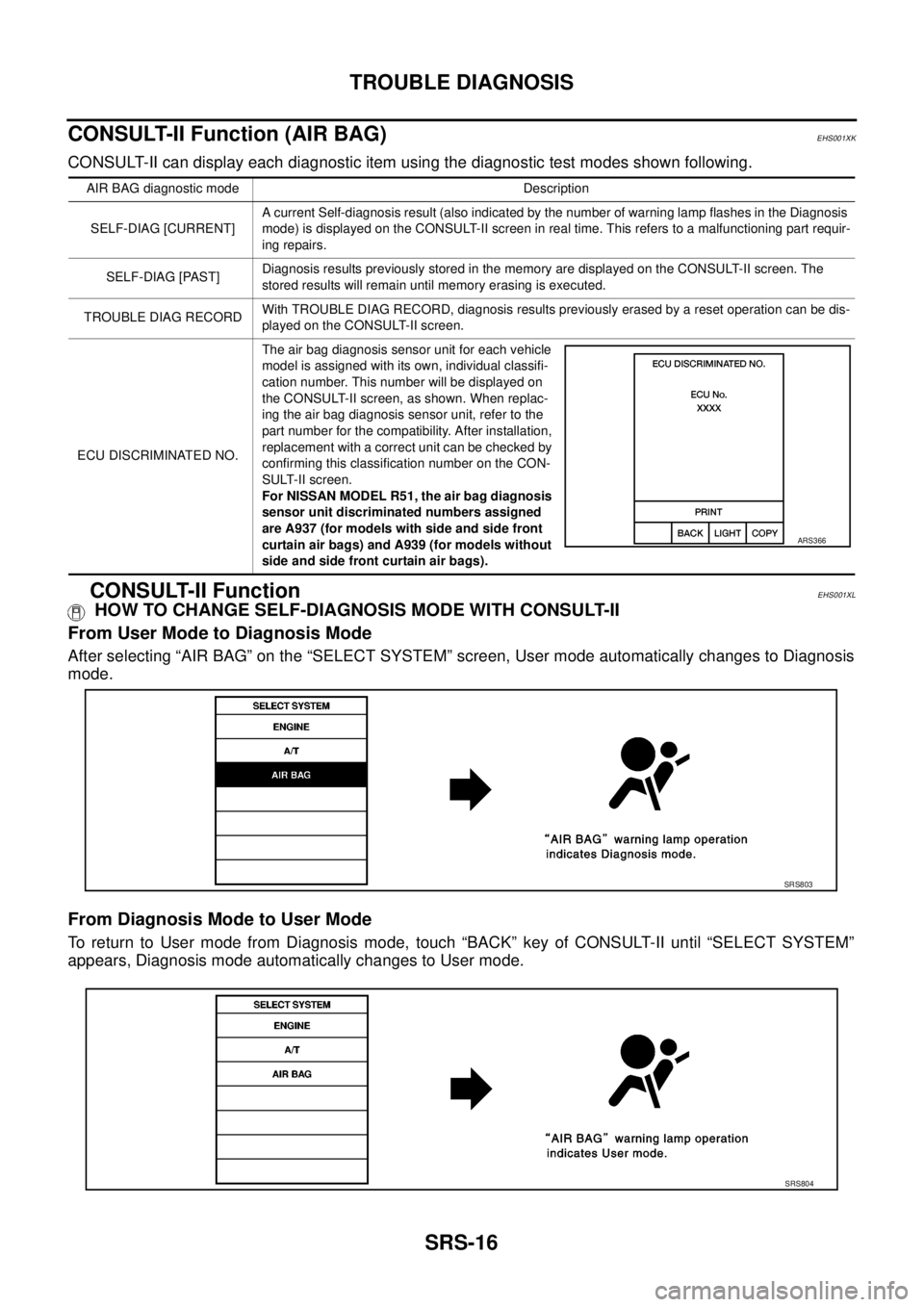

CONSULT-II Function (AIR BAG)

EHS001XK

CONSULT-II can display each diagnostic item using the diagnostic test modes shown following.

CONSULT-II FunctionEHS001XL

HOW TO CHANGE SELF-DIAGNOSIS MODE WITH CONSULT-II

From User Mode to Diagnosis Mode

After selecting “AIR BAG” on the “SELECT SYSTEM” screen, User mode automatically changes to Diagnosis

mode.

From Diagnosis Mode to User Mode

To return to User mode from Diagnosis mode, touch “BACK” key of CONSULT-II until “SELECT SYSTEM”

appears, Diagnosis mode automatically changes to User mode.

AIR BAG diagnostic mode Description

SELF-DIAG [CURRENT]A current Self-diagnosis result (also indicated by the number of warning lamp flashes in the Diagnosis

mode) is displayed on the CONSULT-II screen in real time. This refers to a malfunctioning part requir-

ing repairs.

SELF-DIAG [PAST]Diagnosis results previously stored in the memory are displayed on the CONSULT-II screen. The

stored results will remain until memory erasing is executed.

TROUBLE DIAG RECORDWith TROUBLE DIAG RECORD, diagnosis results previously erased by a reset operation can be dis-

played on the CONSULT-II screen.

ECU DISCRIMINATED NO.The air bag diagnosis sensor unit for each vehicle

model is assigned with its own, individual classifi-

cation number. This number will be displayed on

the CONSULT-II screen, as shown. When replac-

ing the air bag diagnosis sensor unit, refer to the

part number for the compatibility. After installation,

replacement with a correct unit can be checked by

confirming this classification number on the CON-

SULT-II screen.

For NISSAN MODEL R51, the air bag diagnosis

sensor unit discriminated numbers assigned

are A937 (for models with side and side front

curtain air bags) and A939 (for models without

side and side front curtain air bags).

ARS366

SRS803

SRS804

Page 2951 of 3171

SRS-42

FRONT PASSENGER AIR BAG MODULE

lBefore servicing SRS, turn the ignition switch off, disconnect both battery cables and wait at least

3 minutes.

lAlways work from the side of or under front passenger air bag module.

lAfter the work is completed, perform self-diagnosis to check that no malfunction is detected.

Refer toSRS-18, "

SRS Operation Check".

1. Locate the yellow and orange direct-connect passenger air bag module harness connectors.

2. Use wire cutters to cut back both previously used direct-connect passenger air bag module harness con-

nectors from the vehicle wiring harness approximately 50 mm (1.9 in) from the connectors.

3. Remove approximately 150 mm (5.9 in) of the vehicle harness covering from the cut end.

4. Slide a piece of dual-wall heat shrink tubing (provided in the pas-

senger air bag service kit) onto each wire of the previously used

vehicle wiring harness.

5. Fold each wire back and insert into the end of the heat shrink

tubing so that the end of the wire is approximately centered in

the heat shrink tubing.

6. Use a heat gun to shrink the heat shrink tubing and seal the wire.

7. Use electrical tape to secure the modified circuits to the outside of the wiring harness.

8. Locate the front passenger air bag service replacement connec-

tor that is taped back to the main harness. Unwrap the tape to

access the yellow service replacement connector and remove

the dust cover from the connector.

LHIA0017E

WHIA0062E

MHIB0108E

Page 2952 of 3171

FRONT SIDE AIR BAG MODULE

SRS-43

C

D

E

F

G

I

J

K

L

MA

B

SRS

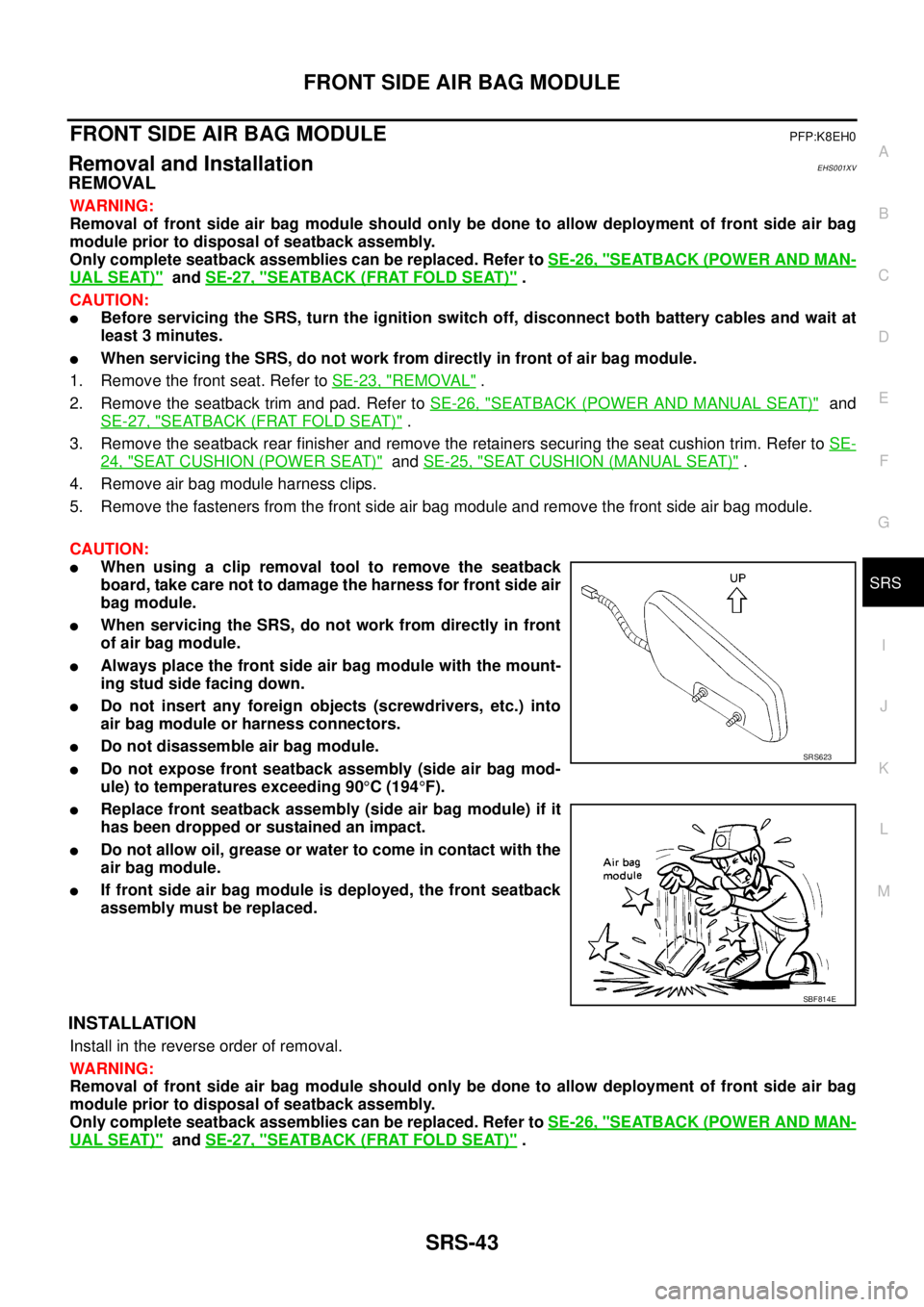

FRONT SIDE AIR BAG MODULEPFP:K8EH0

Removal and InstallationEHS001XV

REMOVAL

WARNING:

Removal of front side air bag module should only be done to allow deployment of front side air bag

module prior to disposal of seatback assembly.

Only complete seatback assemblies can be replaced. Refer toSE-26, "

SEATBACK (POWER AND MAN-

UAL SEAT)"andSE-27, "SEATBACK (FRAT FOLD SEAT)".

CAUTION:

lBefore servicing the SRS, turn the ignition switch off, disconnect both battery cables and wait at

least 3 minutes.

lWhen servicing the SRS, do not work from directly in front of air bag module.

1. Remove the front seat. Refer toSE-23, "

REMOVAL".

2. Remove the seatback trim and pad. Refer toSE-26, "

SEATBACK (POWER AND MANUAL SEAT)"and

SE-27, "

SEATBACK (FRAT FOLD SEAT)".

3. Remove the seatback rear finisher and remove the retainers securing the seat cushion trim. Refer toSE-

24, "SEAT CUSHION (POWER SEAT)"andSE-25, "SEAT CUSHION (MANUAL SEAT)".

4. Remove air bag module harness clips.

5. Remove the fasteners from the front side air bag module and remove the front side air bag module.

CAUTION:

lWhen using a clip removal tool to remove the seatback

board, take care not to damage the harness for front side air

bag module.

lWhen servicing the SRS, do not work from directly in front

of air bag module.

lAlways place the front side air bag module with the mount-

ing stud side facing down.

lDo not insert any foreign objects (screwdrivers, etc.) into

air bag module or harness connectors.

lDo not disassemble air bag module.

lDo not expose front seatback assembly (side air bag mod-

ule) to temperatures exceeding 90°C(194°F).

lReplace front seatback assembly (side air bag module) if it

has been dropped or sustained an impact.

lDo not allow oil, grease or water to come in contact with the

air bag module.

lIf front side air bag module is deployed, the front seatback

assembly must be replaced.

INSTALLATION

Install in the reverse order of removal.

WARNING:

Removal of front side air bag module should only be done to allow deployment of front side air bag

module prior to disposal of seatback assembly.

Only complete seatback assemblies can be replaced. Refer toSE-26, "

SEATBACK (POWER AND MAN-

UAL SEAT)"andSE-27, "SEATBACK (FRAT FOLD SEAT)".

SRS623

SBF814E

Page 2957 of 3171

SRS-48

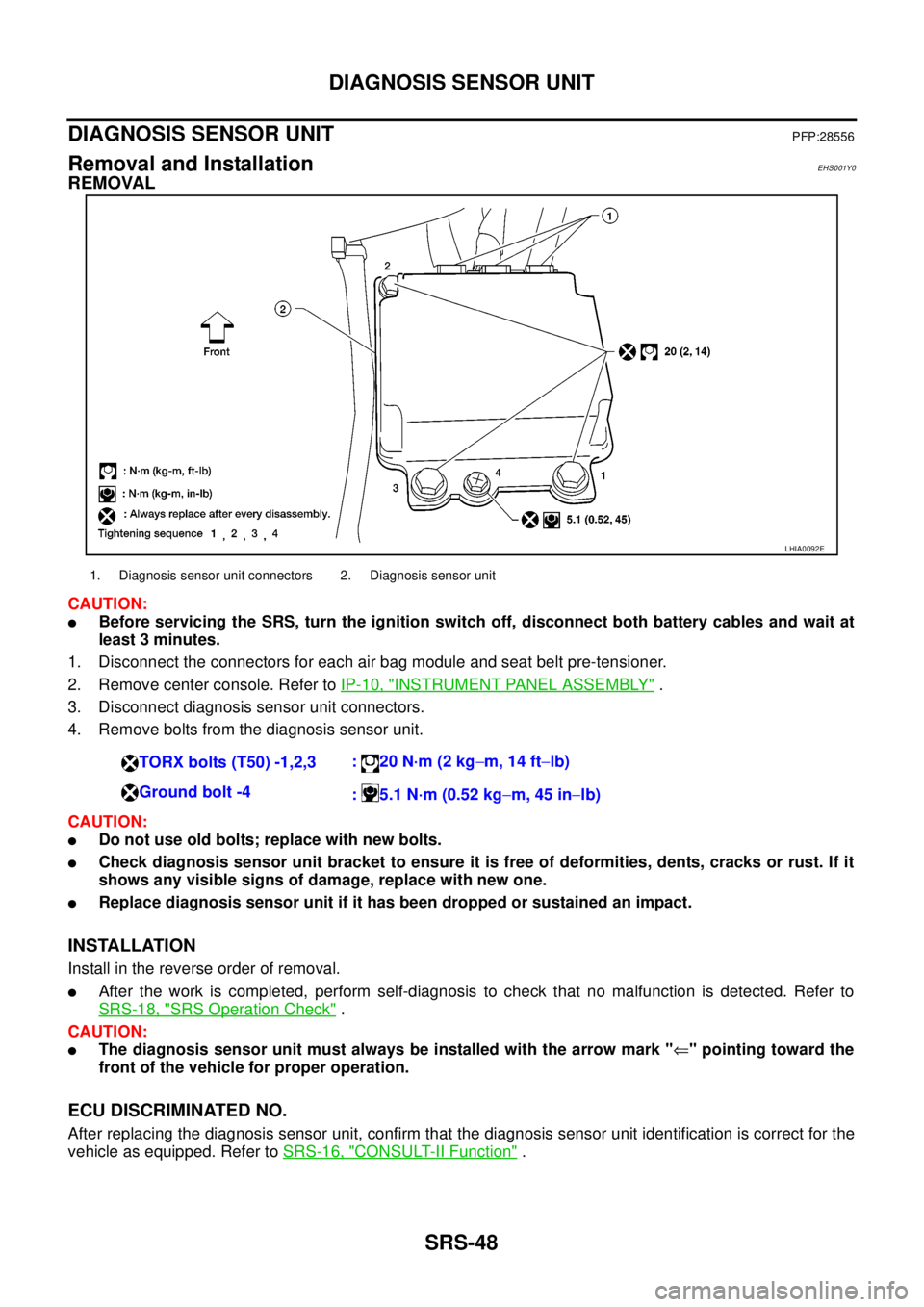

DIAGNOSIS SENSOR UNIT

DIAGNOSIS SENSOR UNIT

PFP:28556

Removal and InstallationEHS001Y0

REMOVAL

CAUTION:

lBefore servicing the SRS, turn the ignition switch off, disconnect both battery cables and wait at

least 3 minutes.

1. Disconnect the connectors for each air bag module and seat belt pre-tensioner.

2. Remove center console. Refer toIP-10, "

INSTRUMENT PANEL ASSEMBLY".

3. Disconnect diagnosis sensor unit connectors.

4. Remove bolts from the diagnosis sensor unit.

CAUTION:

lDo not use old bolts; replace with new bolts.

lCheck diagnosis sensor unit bracket to ensure it is free of deformities, dents, cracks or rust. If it

shows any visible signs of damage, replace with new one.

lReplace diagnosis sensor unit if it has been dropped or sustained an impact.

INSTALLATION

Install in the reverse order of removal.

lAfter the work is completed, perform self-diagnosis to check that no malfunction is detected. Refer to

SRS-18, "

SRS Operation Check".

CAUTION:

lThe diagnosis sensor unit must always be installed with the arrow mark "Ü" pointing toward the

front of the vehicle for proper operation.

ECU DISCRIMINATED NO.

After replacing the diagnosis sensor unit, confirm that the diagnosis sensor unit identification is correct for the

vehicle as equipped. Refer toSRS-16, "

CONSULT-II Function".

LHIA0092E

1. Diagnosis sensor unit connectors 2. Diagnosis sensor unit

TORX bolts (T50) -1,2,3:20N·m(2kg-m, 14 ft-lb)

Ground bolt -4

: 5.1 N·m (0.52 kg-m, 45 in-lb)

Page 2959 of 3171

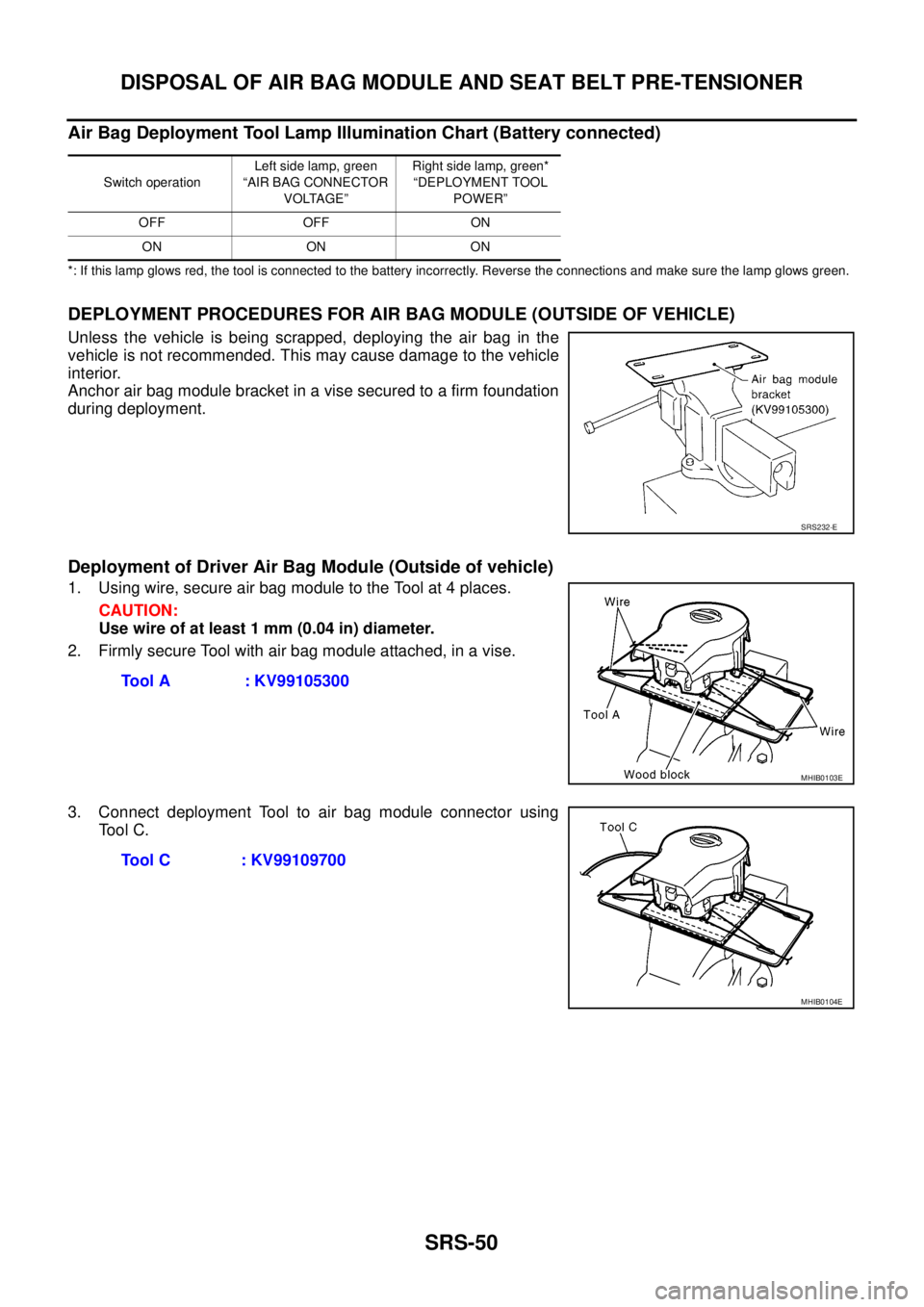

SRS-50

DISPOSAL OF AIR BAG MODULE AND SEAT BELT PRE-TENSIONER

Air Bag Deployment Tool Lamp Illumination Chart (Battery connected)

*: If this lamp glows red, the tool is connected to the battery incorrectly. Reverse the connections and make sure the lamp glows green.

DEPLOYMENT PROCEDURES FOR AIR BAG MODULE (OUTSIDE OF VEHICLE)

Unless the vehicle is being scrapped, deploying the air bag in the

vehicle is not recommended. This may cause damage to the vehicle

interior.

Anchor air bag module bracket in a vise secured to a firm foundation

during deployment.

Deployment of Driver Air Bag Module (Outside of vehicle)

1. Using wire, secure air bag module to the Tool at 4 places.

CAUTION:

Use wire of at least 1 mm (0.04 in) diameter.

2. Firmly secure Tool with air bag module attached, in a vise.

3. Connect deployment Tool to air bag module connector using

To o l C .

Switch operationLeft side lamp, green

“AIR BAG CONNECTOR

VOLTAGE”Right side lamp, green*

“DEPLOYMENT TOOL

POWER”

OFF OFF ON

ON ON ON

SRS232-E

Tool A : KV99105300

MHIB0103E

Tool C : KV99109700

MHIB0104E

Page 2960 of 3171

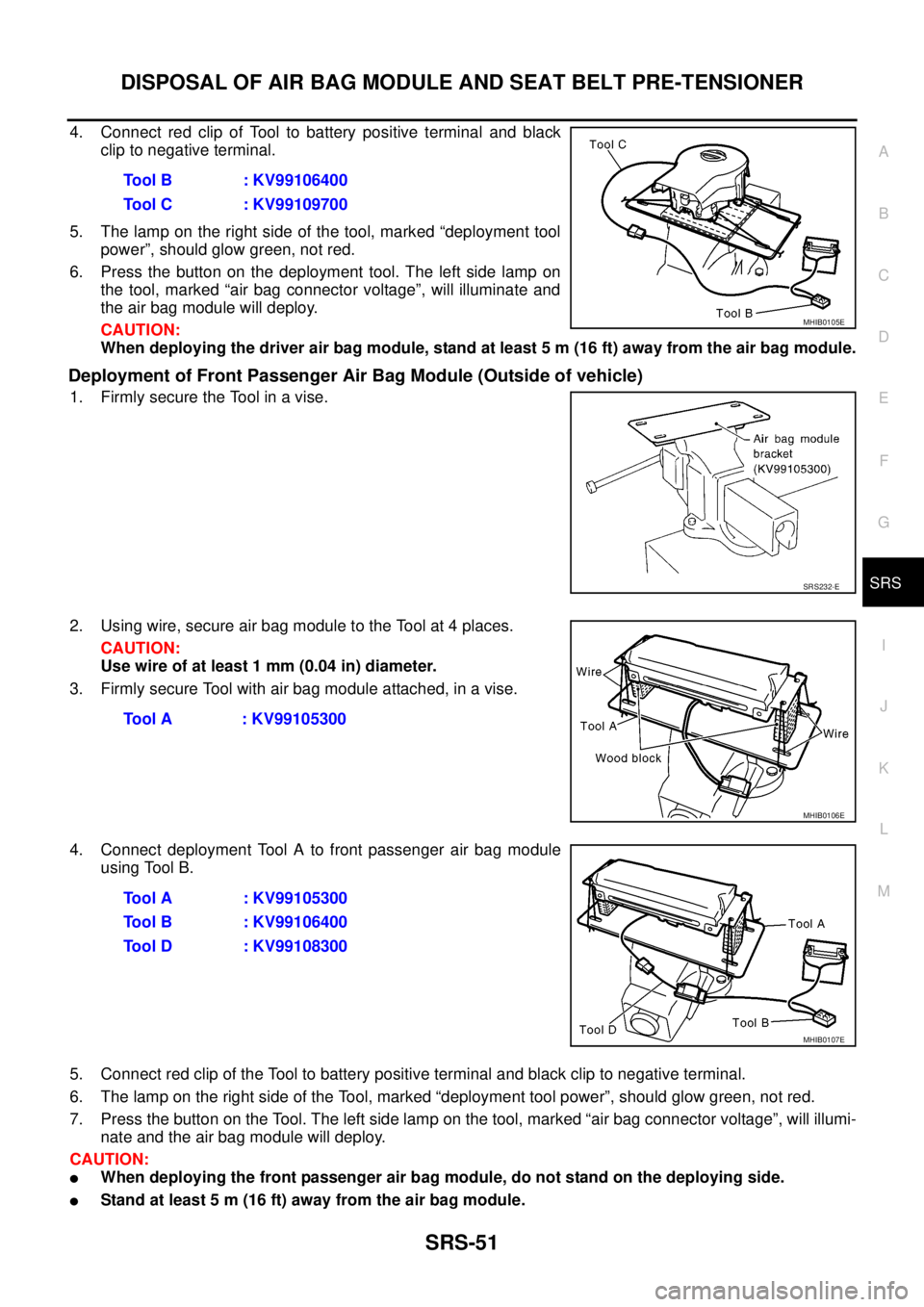

DISPOSAL OF AIR BAG MODULE AND SEAT BELT PRE-TENSIONER

SRS-51

C

D

E

F

G

I

J

K

L

MA

B

SRS

4. Connect red clip of Tool to battery positive terminal and black

clip to negative terminal.

5. The lamp on the right side of the tool, marked “deployment tool

power”, should glow green, not red.

6. Press the button on the deployment tool. The left side lamp on

the tool, marked “air bag connector voltage”, will illuminate and

the air bag module will deploy.

CAUTION:

When deploying the driver air bag module, stand at least 5 m (16 ft) away from the air bag module.

Deployment of Front Passenger Air Bag Module (Outside of vehicle)

1. Firmly secure the Tool in a vise.

2. Using wire, secure air bag module to the Tool at 4 places.

CAUTION:

Usewireofatleast1mm(0.04in)diameter.

3. Firmly secure Tool with air bag module attached, in a vise.

4. Connect deployment Tool A to front passenger air bag module

using Tool B.

5. Connect red clip of the Tool to battery positive terminal and black clip to negative terminal.

6. The lamp on the right side of the Tool, marked “deployment tool power”, should glow green, not red.

7. Press the button on the Tool. The left side lamp on the tool, marked “air bag connector voltage”, will illumi-

nate and the air bag module will deploy.

CAUTION:

lWhen deploying the front passenger air bag module, do not stand on the deploying side.

lStand at least 5 m (16 ft) away from the air bag module.Tool B : KV99106400

Tool C : KV99109700

MHIB0105E

SRS232-E

Tool A : KV99105300

MHIB0106E

Tool A : KV99105300

Tool B : KV99106400

Tool D : KV99108300

MHIB0107E

Page 2961 of 3171

SRS-52

DISPOSAL OF AIR BAG MODULE AND SEAT BELT PRE-TENSIONER

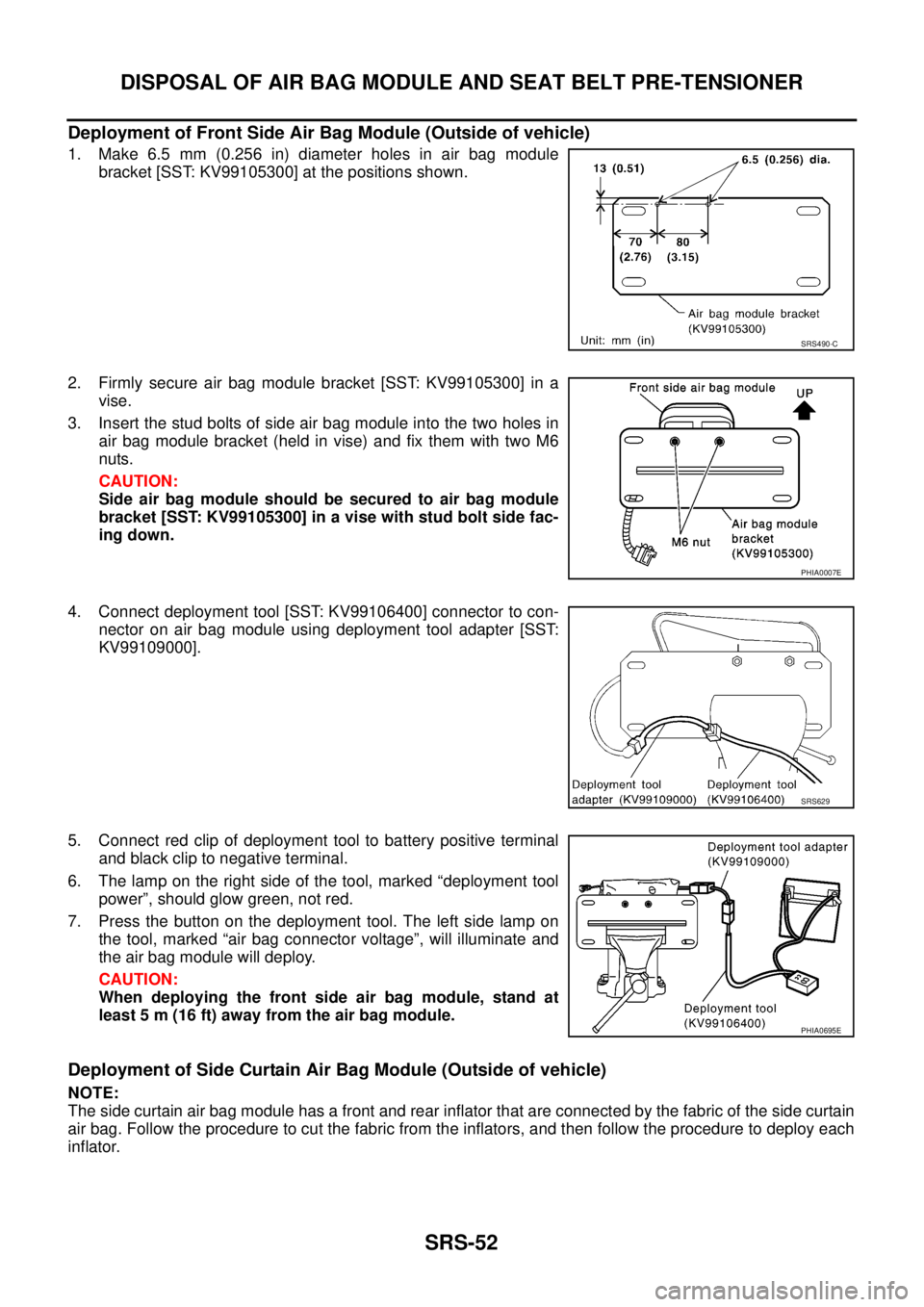

Deployment of Front Side Air Bag Module (Outside of vehicle)

1. Make 6.5 mm (0.256 in) diameter holes in air bag module

bracket [SST: KV99105300] at the positions shown.

2. Firmly secure air bag module bracket [SST: KV99105300] in a

vise.

3. Insert the stud bolts of side air bag module into the two holes in

air bag module bracket (held in vise) and fix them with two M6

nuts.

CAUTION:

Side air bag module should be secured to air bag module

bracket [SST: KV99105300] in a vise with stud bolt side fac-

ing down.

4. Connect deployment tool [SST: KV99106400] connector to con-

nector on air bag module using deployment tool adapter [SST:

KV99109000].

5. Connect red clip of deployment tool to battery positive terminal

and black clip to negative terminal.

6. The lamp on the right side of the tool, marked “deployment tool

power”, should glow green, not red.

7. Press the button on the deployment tool. The left side lamp on

the tool, marked “air bag connector voltage”, will illuminate and

the air bag module will deploy.

CAUTION:

When deploying the front side air bag module, stand at

least 5 m (16 ft) away from the air bag module.

Deployment of Side Curtain Air Bag Module (Outside of vehicle)

NOTE:

The side curtain air bag module has a front and rear inflator that are connected by the fabric of the side curtain

air bag. Follow the procedure to cut the fabric from the inflators, and then follow the procedure to deploy each

inflator.

SRS490-C

PHIA0007E

SRS629

PHIA0695E