engine oil NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2665 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual RAX-2

[M226]

PRECAUTIONS

[M226]PRECAUTIONSPFP:00001

PrecautionsEDS003HT

lWhen installing the rubber bushings, the final tightening must be done under unladen condition and with

the tires on level grou NISSAN NAVARA 2005 Repair Workshop Manual RAX-2

[M226]

PRECAUTIONS

[M226]PRECAUTIONSPFP:00001

PrecautionsEDS003HT

lWhen installing the rubber bushings, the final tightening must be done under unladen condition and with

the tires on level grou](/img/5/57362/w960_57362-2664.png)

RAX-2

[M226]

PRECAUTIONS

[M226]PRECAUTIONSPFP:00001

PrecautionsEDS003HT

lWhen installing the rubber bushings, the final tightening must be done under unladen condition and with

the tires on level ground. Oil will shorten the life of the rubber bushings, so wipe off any spilled oil immedi-

ately.

lUnladen condition means the fuel tank, engine coolant and lubricants are at the full secification. The

spare tire, jack, hand tools, and mats are in their designated positions.

lLock nuts are not reusable. Always use new lock nuts for installation. New lock nuts are pre-oiled, do not

apply any additional lubrication.

Page 2706 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual PRECAUTIONS

RFD-3

[WITH LIMITED SLIP DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

[WITH LIMITED SLIP DIFFERENTIAL]PRECAUTIONSPFP:00001

Limited Slip Differential (LSD) Performance JudgementEDS003IG

lInspec NISSAN NAVARA 2005 Repair Workshop Manual PRECAUTIONS

RFD-3

[WITH LIMITED SLIP DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

[WITH LIMITED SLIP DIFFERENTIAL]PRECAUTIONSPFP:00001

Limited Slip Differential (LSD) Performance JudgementEDS003IG

lInspec](/img/5/57362/w960_57362-2705.png)

PRECAUTIONS

RFD-3

[WITH LIMITED SLIP DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

[WITH LIMITED SLIP DIFFERENTIAL]PRECAUTIONSPFP:00001

Limited Slip Differential (LSD) Performance JudgementEDS003IG

lInspection is required when detecting any noise or malfunction while driving or turning. Improper condition

of oil or differential case assembly is suspected. Refer toRFD-3, "

METHOD FOR TROUBLESHOOTING"

.

METHOD FOR TROUBLESHOOTING

1. Check differential gear oil level and differential gear oil leakage. Refer toRFD-9, "Checking Differential

Gear Oil".

2. Changing differential gear oil. Refer toRFD-9, "

Changing Differential Gear Oil".

3. Start engine. Drive for 10 min.

4. Again changing differential gear oil. Refer toRFD-9, "

Changing Differential Gear Oil".

5. Start engine. Drive for 10 min. Check if any noise or improper oil condition is detected.

lIf OK, check differential gear oil level and differential gear oil leakage. Refer toRFD-9, "Checking Differ-

ential Gear Oil".

lIf NG, replace differential case assembly after checking each part of final drive. Refer toRFD-15, "Dis-

assembly and Assembly".

Service Notice or PrecautionsEDS0038Z

lCheck for the correct installation status prior to removal or disassembly. If matching marks are required,

be certain they do not interfere with the function of the parts when applied.

lOverhaul should be done in a clean work area, it is preferable to work in dust proof area.

lBefore disassembly completely remove sand and mud from the exterior of the unit, preventing them from

entering into the unit during disassembly or assembly.

lCheck appearance of the disassembled parts for damage, deformation, and unusual wear. Replace them

with new ones if necessary.

lGaskets, seals and O-rings should be replaced any time the unit is disassembled.

lIn principle, tighten bolts or nuts gradually in several steps working diagonally from inside to outside. If

tightening sequence is specified, observe it.

lClean and flush the parts sufficiently and blow-dry them.

lBe careful not to damage sliding surfaces and mating surfaces.

lWhen applying sealant, remove the old sealant from the mounting surface; then remove any moisture, oil,

and foreign materials from the application and mounting surfaces.

lAlways use shop paper for cleaning the inside of components.

lAvoid using cotton gloves or shop rags to prevent entering of lint.

lDuring assembly, observe the specified tightening torque, and apply new differential gear oil, petroleum

jelly, or multi-purpose grease as specified.

Page 2712 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual DIFFERENTIAL GEAR OIL

RFD-9

[WITH LIMITED SLIP DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

DIFFERENTIAL GEAR OILPFP:KLD30

Changing Differential Gear OilEDS00394

DRAINING

1. Stop engine.

2. Remove drain p NISSAN NAVARA 2005 Repair Workshop Manual DIFFERENTIAL GEAR OIL

RFD-9

[WITH LIMITED SLIP DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

DIFFERENTIAL GEAR OILPFP:KLD30

Changing Differential Gear OilEDS00394

DRAINING

1. Stop engine.

2. Remove drain p](/img/5/57362/w960_57362-2711.png)

DIFFERENTIAL GEAR OIL

RFD-9

[WITH LIMITED SLIP DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

DIFFERENTIAL GEAR OILPFP:KLD30

Changing Differential Gear OilEDS00394

DRAINING

1. Stop engine.

2. Remove drain plug and drain gear oil.

3. Apply sealant to drain plug. Install drain plug to final drive

assembly and tighten to the specified torque. Refer toRFD-15,

"COMPONENTS".

FILLING

1. Remove filler plug. Fill with new gear oil until oil level reaches

the specified limit near filler plug hole.

2. After refilling oil, check oil level. Apply sealant to filler plug.

Install filler plug to final drive assembly and tighten to the speci-

fied torque. Refer toRFD-15, "

COMPONENTS".

Checking Differential Gear OilEDS00395

OIL LEAKAGE AND OIL LEVEL

1. Make sure that gear oil is not leaking from final drive assembly or around it.

2. Check oil level from filler plug hole as shown.

CAUTION:

Do not start engine while checking oil level.

3. Apply sealant to filler plug. Install filler plug to final drive assem-

bly and tighten to the specified torque. Refer toRFD-15, "

COM-

PONENTS".

PDIA1038E

OilgradeandViscosity:

Refer toMA-14, "

Fluids and Lubricants".

Oil capacity:

Approx. 2.01 (3-1/2pt)

PDIA1039E

PDIA1039E

Page 2743 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual RFD-40

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

DIFFERENTIAL GEAR OIL

DIFFERENTIAL GEAR OIL

PFP:KLD30

Changing Differential Gear OilEDS003AN

DRAINING

1. Stop engine.

2. Remove drain plug and drain gear NISSAN NAVARA 2005 Repair Workshop Manual RFD-40

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

DIFFERENTIAL GEAR OIL

DIFFERENTIAL GEAR OIL

PFP:KLD30

Changing Differential Gear OilEDS003AN

DRAINING

1. Stop engine.

2. Remove drain plug and drain gear](/img/5/57362/w960_57362-2742.png)

RFD-40

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

DIFFERENTIAL GEAR OIL

DIFFERENTIAL GEAR OIL

PFP:KLD30

Changing Differential Gear OilEDS003AN

DRAINING

1. Stop engine.

2. Remove drain plug and drain gear oil.

3. Apply sealant to drain plug. Install drain plug to final drive

assembly and tighten to the specified torque. Refer toRFD-82,

"COMPONENTS".

FILLING

1. Remove filler plug. Fill with new gear oil until oil level reaches

the specified limit near filler plug hole.

2. After refilling oil, check oil level. Apply sealant to filler plug.

Install filler plug to final drive assembly and tighten to the speci-

fied torque. Refer toRFD-82, "

COMPONENTS".

Checking Differential Gear OilEDS003AO

OIL LEAKAGE AND OIL LEVEL

1. Make sure that gear oil is not leaking from final drive assembly or around it.

2. Check oil level from filler plug hole as shown.

CAUTION:

Do not start engine while checking oil level.

3. Apply sealant to filler plug. Install filler plug to final drive assem-

bly and tighten to the specified torque. Refer toRFD-82, "

COM-

PONENTS".

PDIA1038E

Oil grade and Viscosity:

Refer toMA-14, "

Fluids and Lubricants".

Oil capacity:

Approx. 2.01 (3-1/2pt)

PDIA1039E

PDIA1039E

Page 2807 of 3171

RSU-2

PRECAUTIONS

PRECAUTIONS

PFP:00001

PrecautionsEES002JD

lWhen installing rubber parts, final tightening must be carried out under unladen condition* with

tires on ground.

*Fuel, radiator coolant, and engine oil are full. Spare tire, jack, hand tools, and mats are in their

designated positions. Oil will shorten the life of rubber bushings, so wipe off any spilled oil imme-

diately.

lLock nuts are not reusable. Always use new lock nuts for installation. New lock nuts are pre-oiled,

do not apply any additional lubrication.

Page 2810 of 3171

REAR SUSPENSION ASSEMBLY

RSU-5

C

D

F

G

H

I

J

K

L

MA

B

RSU

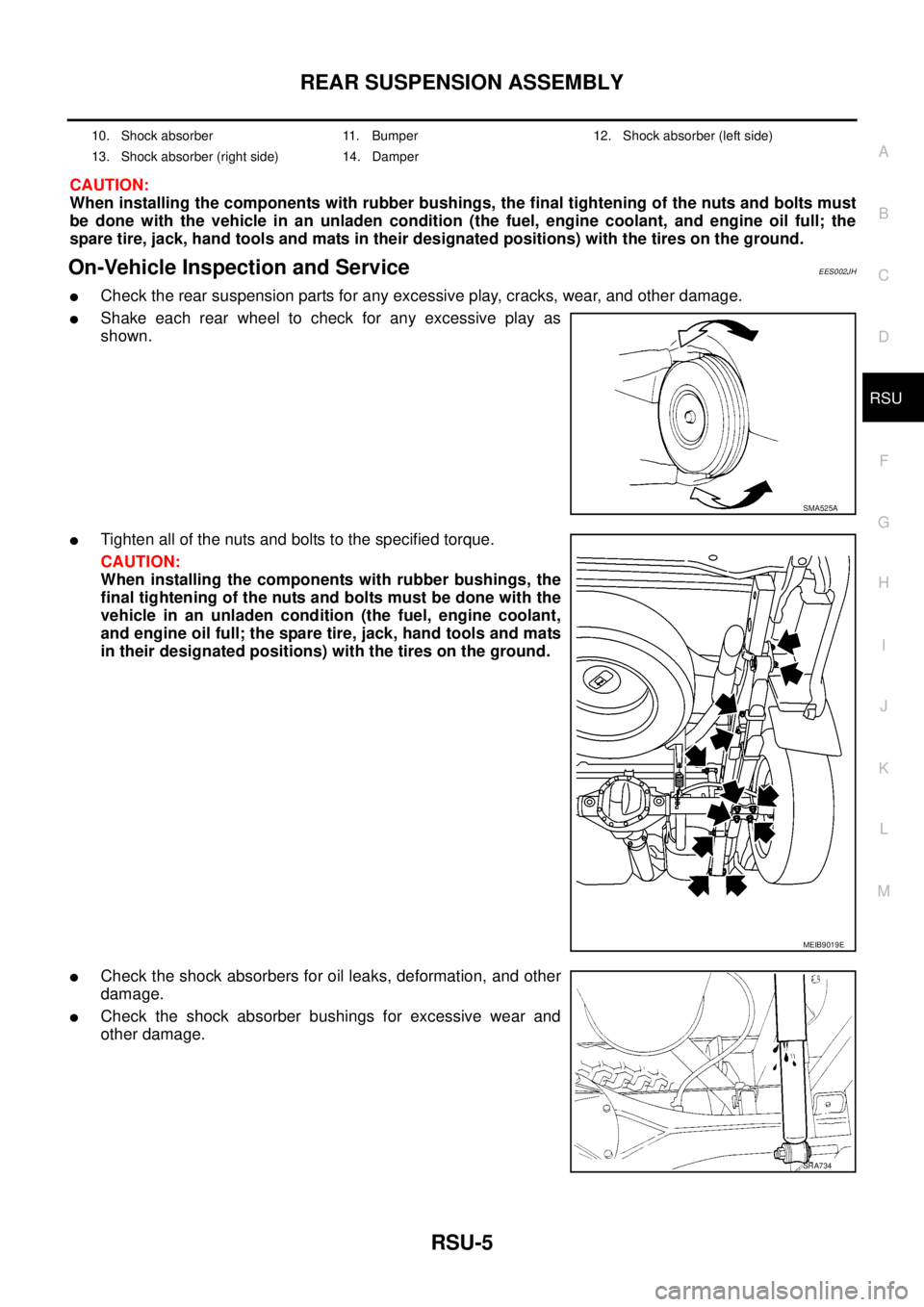

CAUTION:

When installing the components with rubber bushings, the final tightening of the nuts and bolts must

be done with the vehicle in an unladen condition (the fuel, engine coolant, and engine oil full; the

spare tire, jack, hand tools and mats in their designated positions) with the tires on the ground.

On-Vehicle Inspection and ServiceEES002JH

lCheck the rear suspension parts for any excessive play, cracks, wear, and other damage.

lShake each rear wheel to check for any excessive play as

shown.

lTighten all of the nuts and bolts to the specified torque.

CAUTION:

When installing the components with rubber bushings, the

final tightening of the nuts and bolts must be done with the

vehicle in an unladen condition (the fuel, engine coolant,

and engine oil full; the spare tire, jack, hand tools and mats

in their designated positions) with the tires on the ground.

lCheck the shock absorbers for oil leaks, deformation, and other

damage.

lCheck the shock absorber bushings for excessive wear and

other damage.

10. Shock absorber 11. Bumper 12. Shock absorber (left side)

13. Shock absorber (right side) 14. Damper

SMA525A

MEIB9019E

SRA734

Page 2813 of 3171

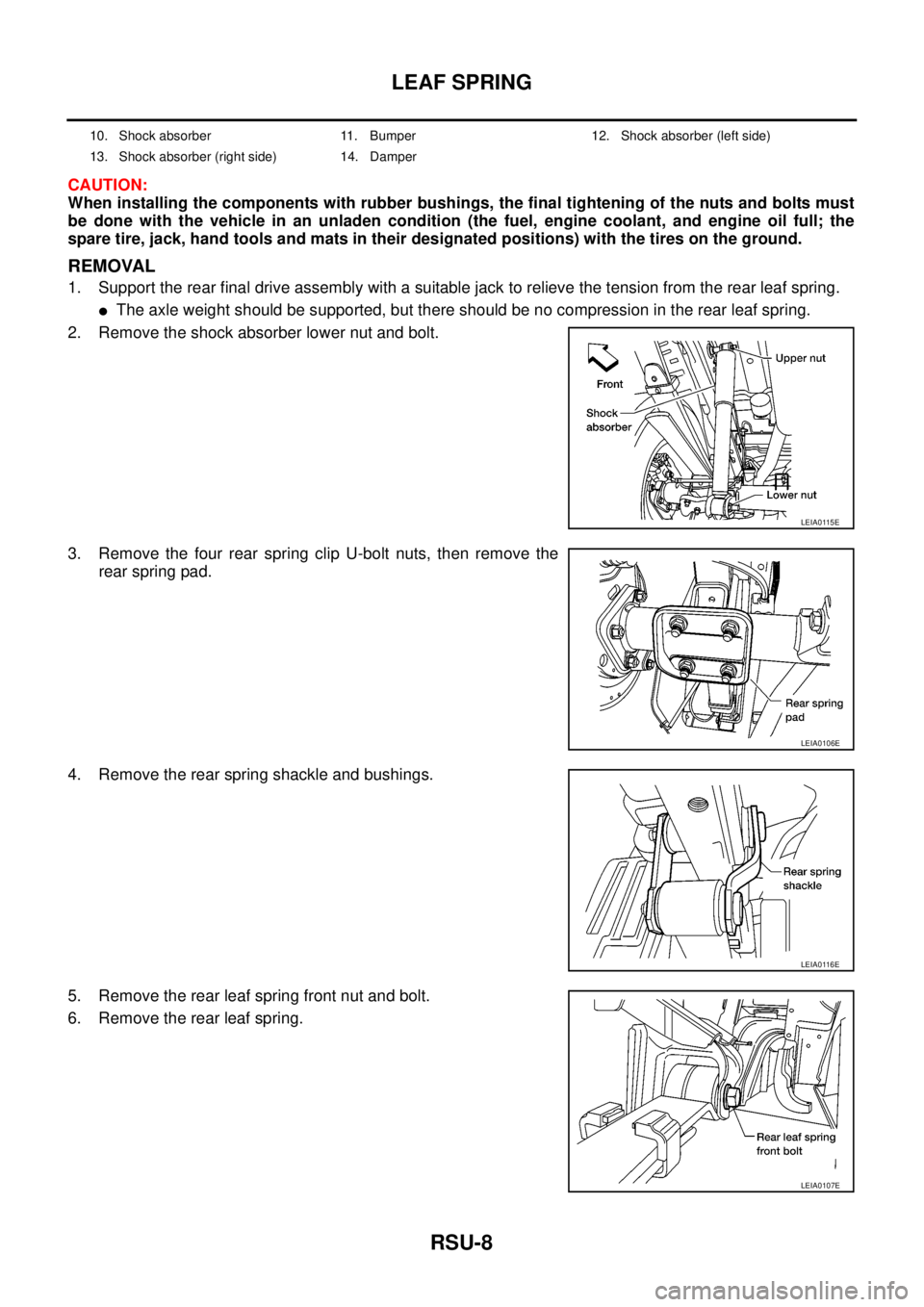

RSU-8

LEAF SPRING

CAUTION:

When installing the components with rubber bushings, the final tightening of the nuts and bolts must

be done with the vehicle in an unladen condition (the fuel, engine coolant, and engine oil full; the

spare tire, jack, hand tools and mats in their designated positions) with the tires on the ground.

REMOVAL

1. Support the rear final drive assembly with a suitable jack to relieve the tension from the rear leaf spring.

lThe axle weight should be supported, but there should be no compression in the rear leaf spring.

2. Remove the shock absorber lower nut and bolt.

3. Remove the four rear spring clip U-bolt nuts, then remove the

rear spring pad.

4. Remove the rear spring shackle and bushings.

5. Remove the rear leaf spring front nut and bolt.

6. Remove the rear leaf spring.

10. Shock absorber 11. Bumper 12. Shock absorber (left side)

13. Shock absorber (right side) 14. Damper

LEIA0115E

LEIA0106E

LEIA0116E

LEIA0107E

Page 2815 of 3171

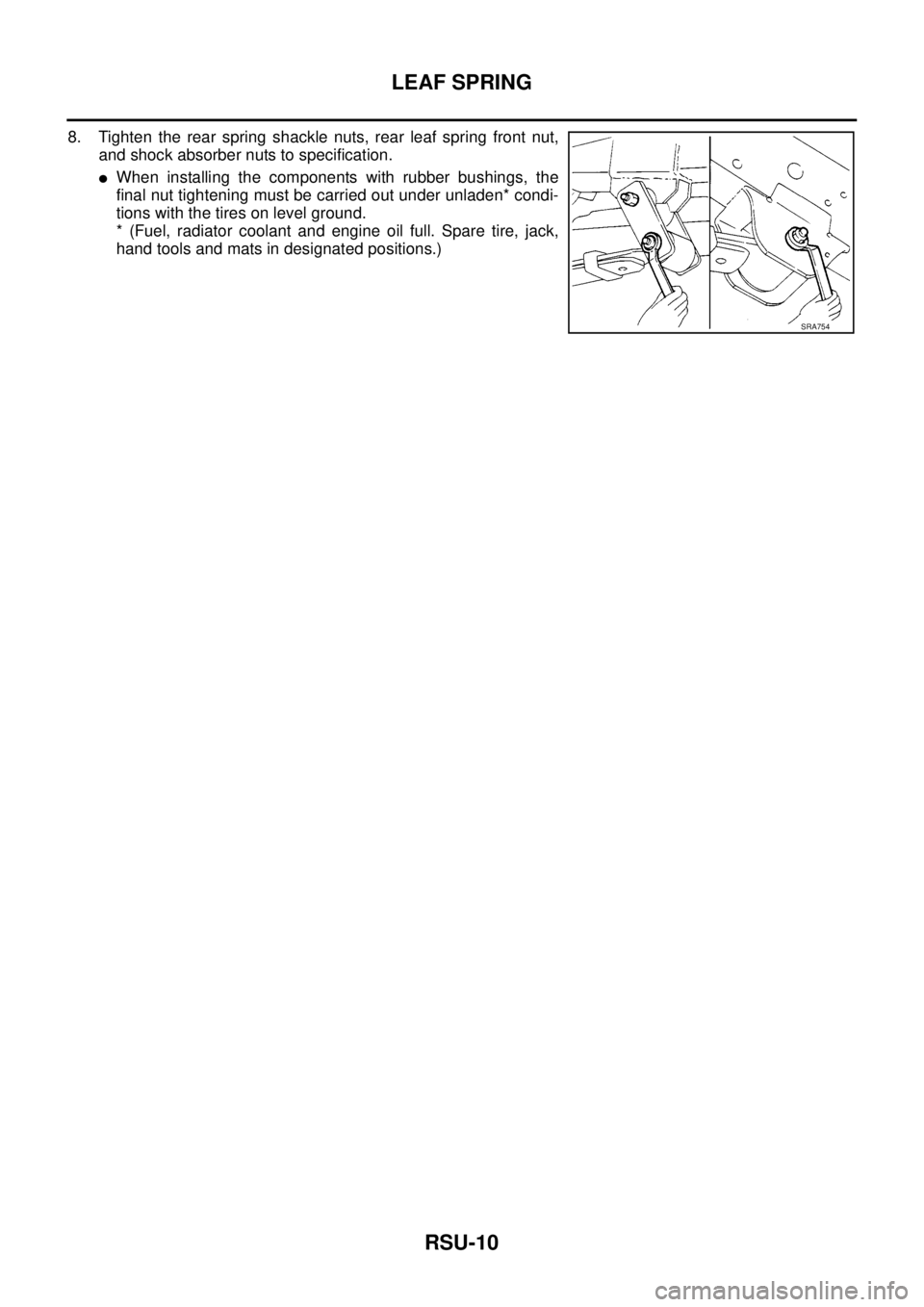

RSU-10

LEAF SPRING

8. Tighten the rear spring shackle nuts, rear leaf spring front nut,

and shock absorber nuts to specification.

lWhen installing the components with rubber bushings, the

final nut tightening must be carried out under unladen* condi-

tions with the tires on level ground.

* (Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.)

SRA754

Page 2816 of 3171

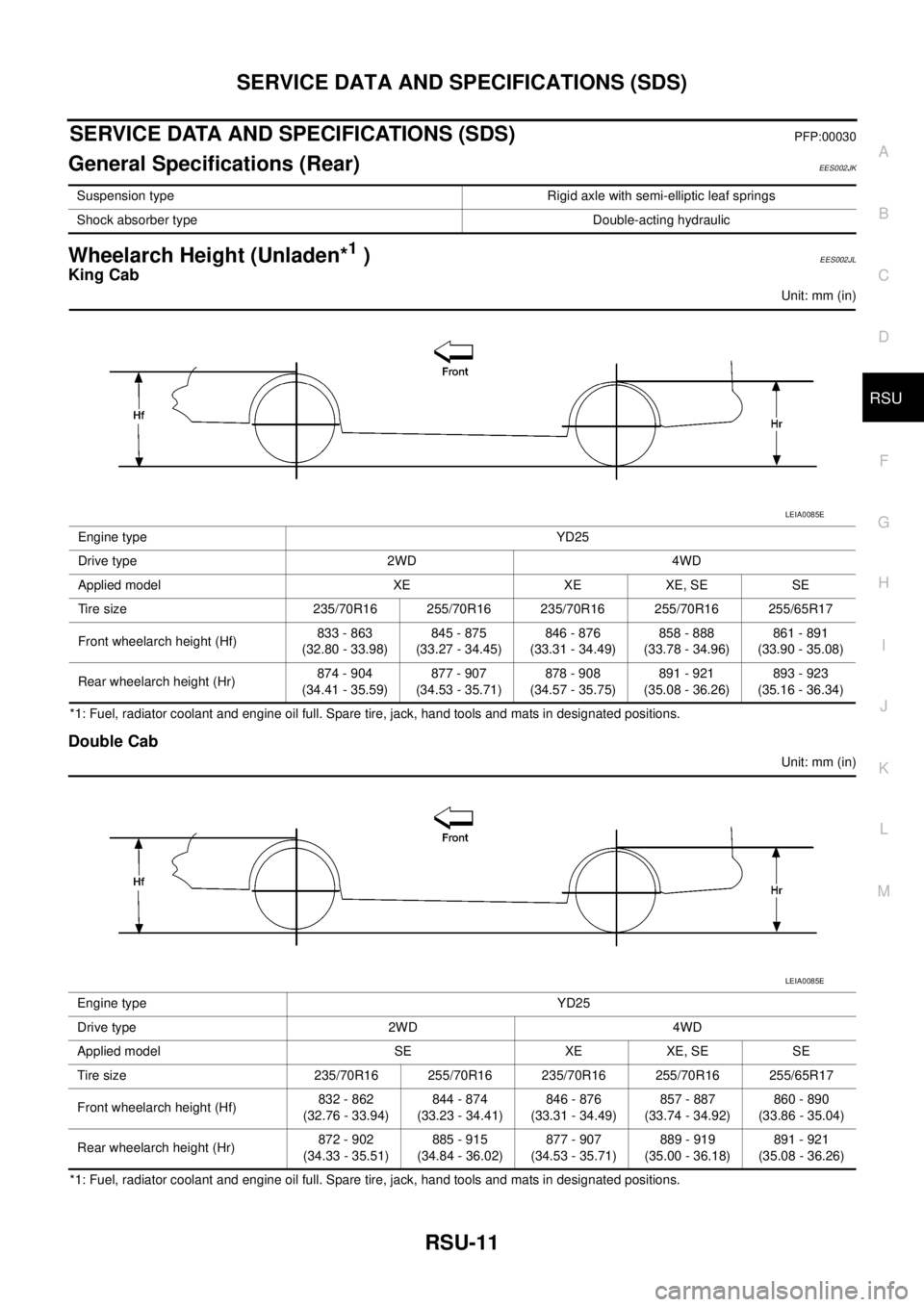

SERVICE DATA AND SPECIFICATIONS (SDS)

RSU-11

C

D

F

G

H

I

J

K

L

MA

B

RSU

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

General Specifications (Rear)EES002JK

Wheelarch Height (Unladen*1)EES002JL

King Cab

Unit: mm (in)

*1: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

Double Cab

Unit: mm (in)

*1: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.Suspension type Rigid axle with semi-elliptic leaf springs

Shock absorber type Double-acting hydraulic

Engine type YD25

Drive type 2WD 4WD

Applied model XE XE XE, SE SE

Tire size 235/70R16 255/70R16 235/70R16 255/70R16 255/65R17

Front wheelarch height (Hf)833 - 863

(32.80 - 33.98)845 - 875

(33.27 - 34.45)846 - 876

(33.31 - 34.49)858 - 888

(33.78 - 34.96)861 - 891

(33.90 - 35.08)

Rear wheelarch height (Hr)874 - 904

(34.41 - 35.59)877 - 907

(34.53 - 35.71)878 - 908

(34.57 - 35.75)891 - 921

(35.08 - 36.26)893 - 923

(35.16 - 36.34)

LEIA0085E

Engine type YD25

Drive type 2WD 4WD

Applied model SE XE XE, SE SE

Tire size 235/70R16 255/70R16 235/70R16 255/70R16 255/65R17

Front wheelarch height (Hf)832 - 862

(32.76 - 33.94)844 - 874

(33.23 - 34.41)846 - 876

(33.31 - 34.49)857 - 887

(33.74 - 34.92)860 - 890

(33.86 - 35.04)

Rear wheelarch height (Hr)872 - 902

(34.33 - 35.51)885 - 915

(34.84 - 36.02)877 - 907

(34.53 - 35.71)889 - 919

(35.00 - 36.18)891 - 921

(35.08 - 36.26)

LEIA0085E

Page 2870 of 3171

SERVICE DATA AND SPECIFICATIONS (SDS)

SC-37

C

D

E

F

G

H

I

J

L

MA

B

SC

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

BatteryEKS00MZT

StarterEKS00MZU

AlternatorEKS00MZV

Applied modelYD25 engine

TypeL3/760L

Capacity V-AH12-75

Ty p eM8T76071ZE

MITSUBISHI

Reduction

Applied modelYD25 engine

System voltage V12

No-loadTerminal voltage V 11.0

Current A Less than 145

Revolution rpm More than 3,400

Minimum diameter of commutator mm (in) 31.4 (1.236)

Minimum length of brush mm (in) 11.0 (0.433)

Brush spring tension N (kg, lb)26.7 - 36.1

(2.72 - 3.68, 6.0 - 8.12)

Clearance between bearing metal and armature shaft mm (in) —

Clearance “ ” between pinion front edge and pinion stopper mm (in)—

Movement “ ” in height of pinion assembly mm (in)0 (0, 0)

TypeA3TJ0781 A3TG2681ZE

MITSUBISHI

Applied modelYD25 engine

LHD models RHD models

Nominal rating V-A 12-150 12-130

Ground polarityNegative

Minimum revolutions under no-load

(When 13.5V is applied) rpmLess than 1,000

Hot output current (When 13.5V is applied) A/rpmMore than 35/1,300

More than 105/2,500

More than 136/5,000More than 33/1,300

More than 105/2,500

More than 122/5,000

Regulated output voltage V 14.1 - 14.7

Minimum length of brush mm (in) More than 5.0 (0.197)

Brush spring pressure N (g, oz.)4.1 - 5.3

(418 - 520, 14.74 - 18.34)4.8 - 6.0

(490 - 610, 17.28 - 21.51)

Slip ring minimum diameter mm (in) More than 22.1 (0.870)

Rotor coil resistance at 20°(68°F)W1.6 - 2.0 1.7 - 2.1