instrument panel NISSAN NAVARA 2005 Repair User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 469 of 3171

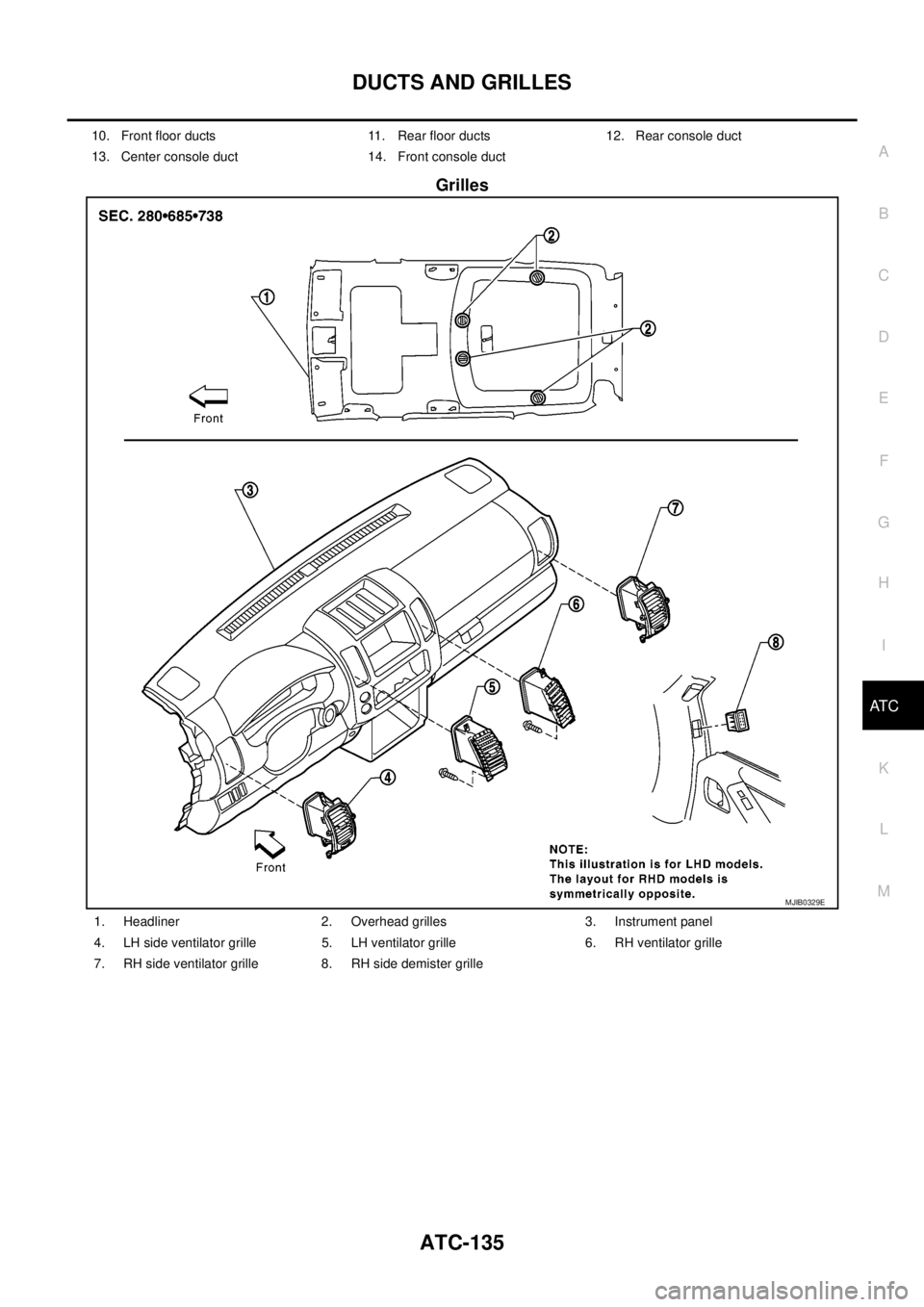

DUCTS AND GRILLES

ATC-135

C

D

E

F

G

H

I

K

L

MA

B

AT C

Grilles

10. Front floor ducts 11. Rear floor ducts 12. Rear console duct

13. Center console duct 14. Front console duct

MJIB0329E

1. Headliner 2. Overhead grilles 3. Instrument panel

4. LH side ventilator grille 5. LH ventilator grille 6. RH ventilator grille

7. RH side ventilator grille 8. RH side demister grille

Page 470 of 3171

ATC-136

DUCTS AND GRILLES

Removal and Installation

EJS006CK

CONSOLE DUCTS AND CONSOLE GRILLE

Removal

The center console must be removed and disassembled to remove the console ducts and the console grille.

Refer toIP-16, "

CENTER CONSOLE".

Installation

Installation is in the reverse order of removal.

DEFROSTER NOZZLE

Removal

1. Remove the instrument panel trim. Refer toIP-10, "Removal and Installation".

2. Remove the defroster nozzle.

Installation

Installation is in the reverse order of removal.

RH AND LH SIDE DEMISTER DUCT

Removal

1. Remove the instrument panel trim. Refer toIP-10, "Removal and Installation".

2. Remove the center console. Refer toIP-16, "

CENTER CONSOLE".

3. Remove the RH or LH side demister duct.

Installation

Installation is in the reverse order of removal.

RH AND LH VENTILATOR DUCT

Removal

1. Remove the instrument panel trim. Refer toIP-10, "Removal and Installation".

2. Remove the center console. Refer toIP-16, "

CENTER CONSOLE".

3. Remove the RH or LH ventilator duct.

Installation

Installation is in the reverse order of removal.

CENTER VENTILATOR DUCT

Removal

1. Remove the heater and cooling unit assembly. Refer toATC-126, "REMOVAL".

2. Remove the center console. Refer toIP-16, "

CENTER CONSOLE".

3. Remove the defroster nozzle.

4. Remove the RH and LH ventilator ducts.

5. Remove the RH and LH side demister ducts.

6. Remove the center ventilator duct.

Installation

Installation is in the reverse order of removal.

FLOOR CONNECTOR DUCT

Removal

1. Remove the heater and cooling unit assembly. Refer toATC-126, "REMOVAL".

2. Remove the center console. Refer toIP-16, "

CENTER CONSOLE".

3. Remove the floor connector duct.

Installation

Installation is in the reverse order of removal.

Page 561 of 3171

REMOVAL AND INSTALLATION

AV-73

C

D

E

F

G

H

I

J

L

MA

B

AV

REMOVAL AND INSTALLATIONPFP:00000

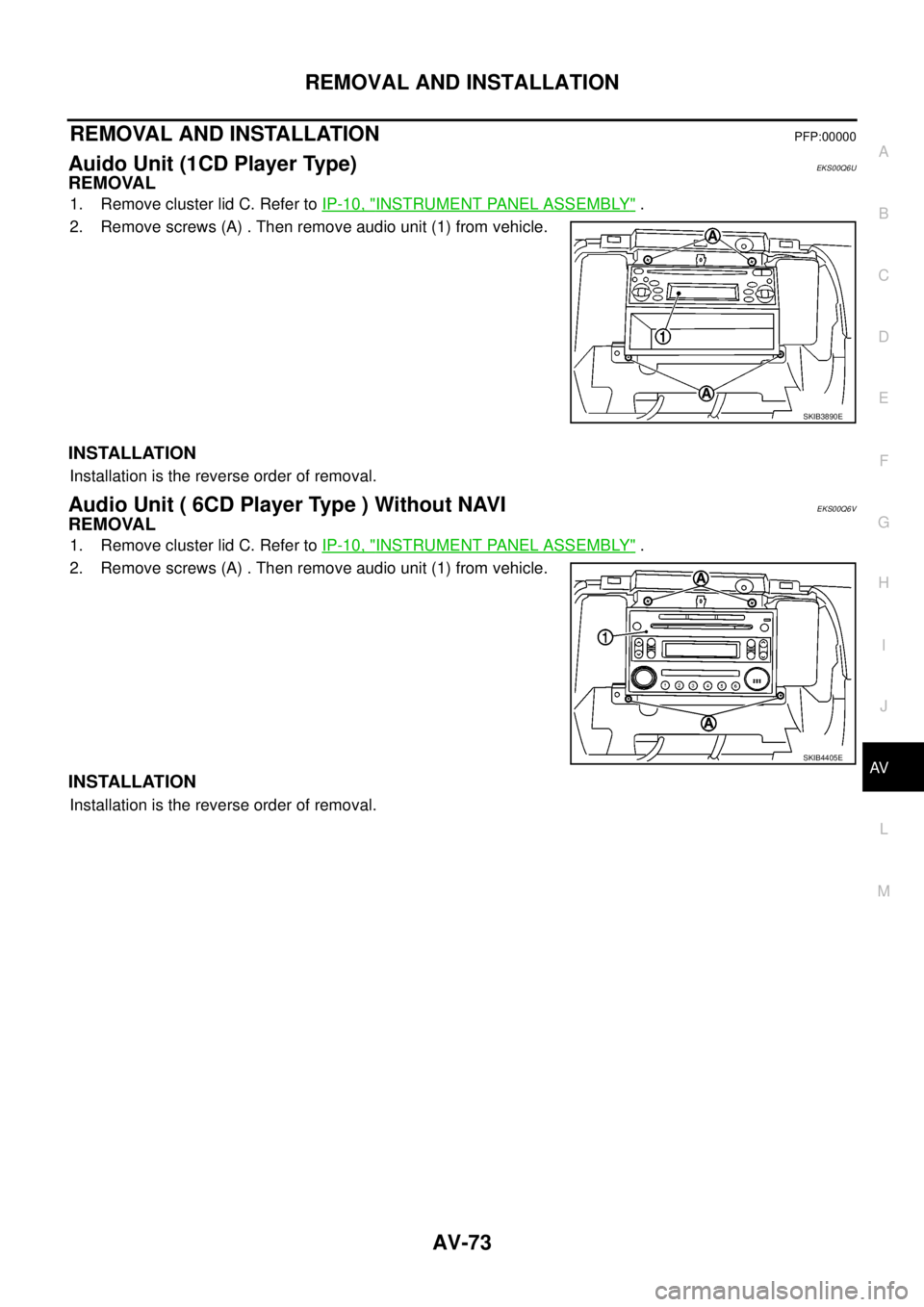

Auido Unit (1CD Player Type)EKS00Q6U

REMOVAL

1. Remove cluster lid C. Refer toIP-10, "INSTRUMENT PANEL ASSEMBLY".

2. Remove screws (A) . Then remove audio unit (1) from vehicle.

INSTALLATION

Installation is the reverse order of removal.

Audio Unit ( 6CD Player Type ) Without NAVIEKS00Q6V

REMOVAL

1. Remove cluster lid C. Refer toIP-10, "INSTRUMENT PANEL ASSEMBLY".

2. Remove screws (A) . Then remove audio unit (1) from vehicle.

INSTALLATION

Installation is the reverse order of removal.

SKIB3890E

SKIB4405E

Page 562 of 3171

AV-74

REMOVAL AND INSTALLATION

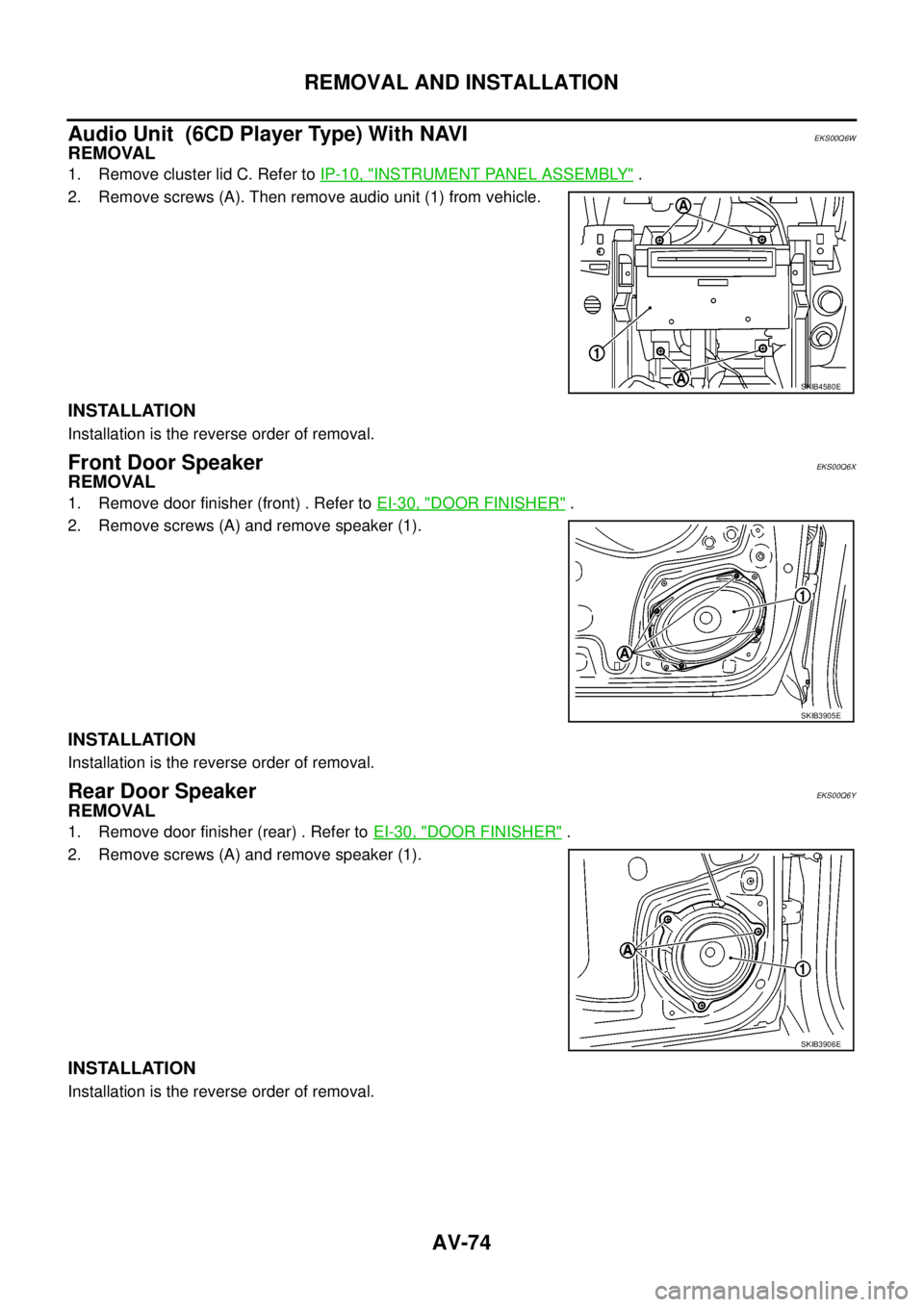

Audio Unit (6CD Player Type) With NAVI

EKS00Q6W

REMOVAL

1. Remove cluster lid C. Refer toIP-10, "INSTRUMENT PANEL ASSEMBLY".

2. Remove screws (A). Then remove audio unit (1) from vehicle.

INSTALLATION

Installation is the reverse order of removal.

Front Door SpeakerEKS00Q6X

REMOVAL

1. Remove door finisher (front) . Refer toEI-30, "DOOR FINISHER".

2. Remove screws (A) and remove speaker (1).

INSTALLATION

Installation is the reverse order of removal.

Rear Door SpeakerEKS00Q6Y

REMOVAL

1. Remove door finisher (rear) . Refer toEI-30, "DOOR FINISHER".

2. Remove screws (A) and remove speaker (1).

INSTALLATION

Installation is the reverse order of removal.

SKIB4580E

SKIB3905E

SKIB3906E

Page 565 of 3171

REMOVAL AND INSTALLATION

AV-77

C

D

E

F

G

H

I

J

L

MA

B

AV

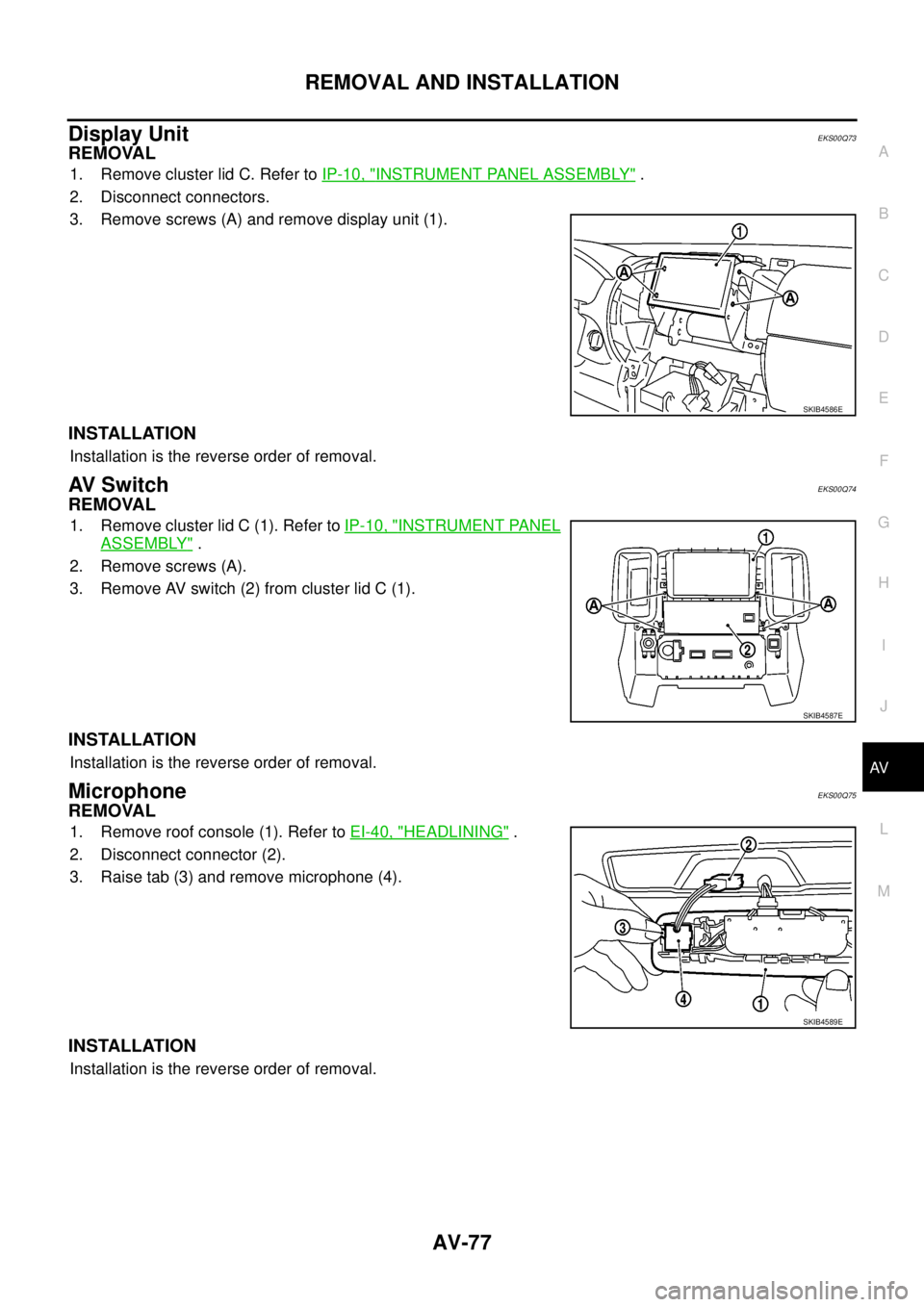

Display UnitEKS00Q73

REMOVAL

1. Remove cluster lid C. Refer toIP-10, "INSTRUMENT PANEL ASSEMBLY".

2. Disconnect connectors.

3. Remove screws (A) and remove display unit (1).

INSTALLATION

Installation is the reverse order of removal.

AV S w i t c hEKS00Q74

REMOVAL

1. Remove cluster lid C (1). Refer toIP-10, "INSTRUMENT PANEL

ASSEMBLY".

2. Remove screws (A).

3. Remove AV switch (2) from cluster lid C (1).

INSTALLATION

Installation is the reverse order of removal.

MicrophoneEKS00Q75

REMOVAL

1. Remove roof console (1). Refer toEI-40, "HEADLINING".

2. Disconnect connector (2).

3. Raise tab (3) and remove microphone (4).

INSTALLATION

Installation is the reverse order of removal.

SKIB4586E

SKIB4587E

SKIB4589E

Page 583 of 3171

BCM (BODY CONTROL MODULE)

BCS-17

C

D

E

F

G

H

I

J

L

MA

B

BCS

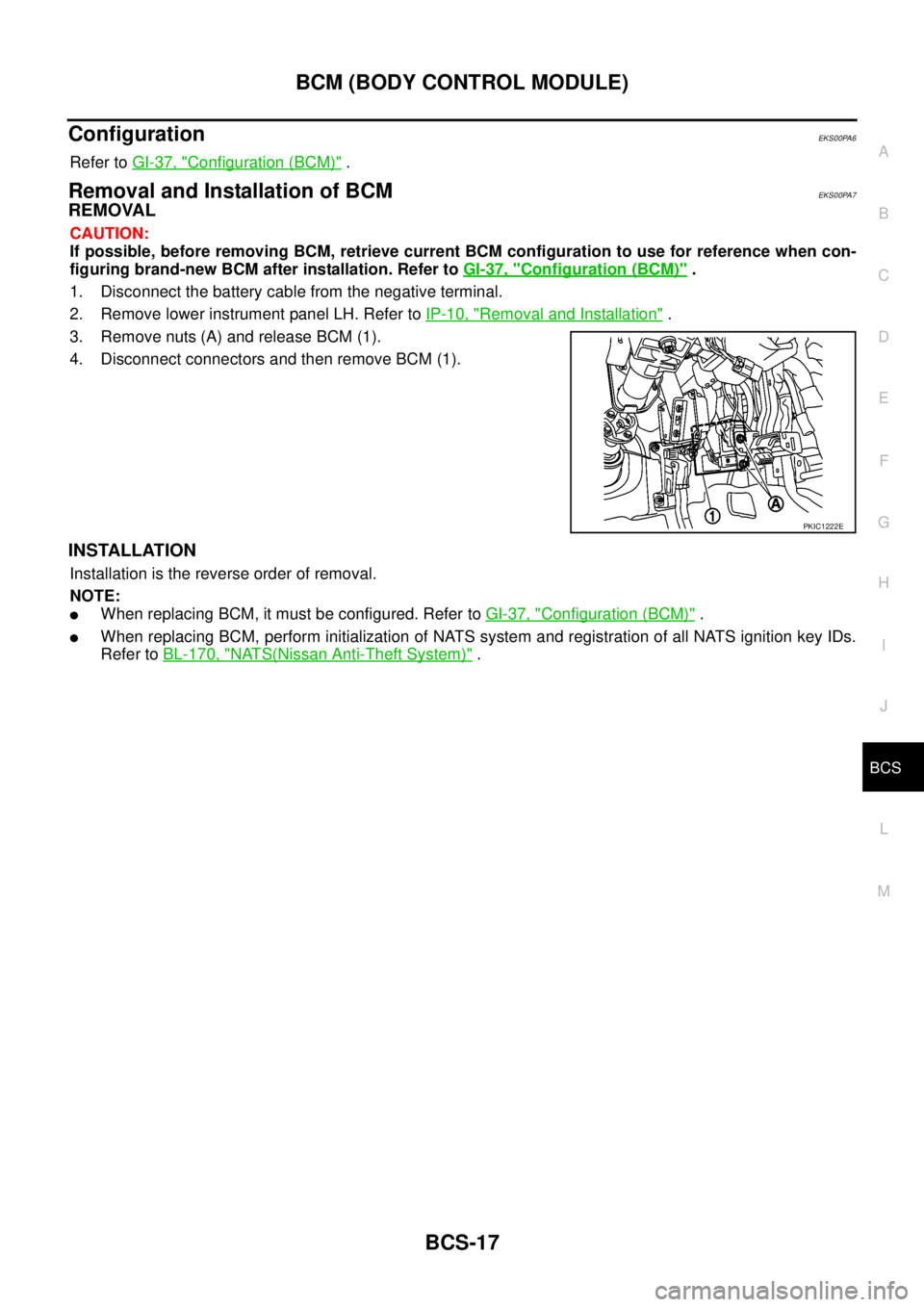

ConfigurationEKS00PA6

Refer toGI-37, "Configuration (BCM)".

Removal and Installation of BCMEKS00PA7

REMOVAL

CAUTION:

If possible, before removing BCM, retrieve current BCM configuration to use for reference when con-

figuring brand-new BCM after installation. Refer toGI-37, "

Configuration (BCM)".

1. Disconnect the battery cable from the negative terminal.

2. Remove lower instrument panel LH. Refer toIP-10, "

Removal and Installation".

3. Remove nuts (A) and release BCM (1).

4. Disconnect connectors and then remove BCM (1).

INSTALLATION

Installation is the reverse order of removal.

NOTE:

lWhen replacing BCM, it must be configured. Refer toGI-37, "Configuration (BCM)".

lWhen replacing BCM, perform initialization of NATS system and registration of all NATS ignition key IDs.

Refer toBL-170, "

NATS(Nissan Anti-Theft System)".

PKIC1222E

Page 585 of 3171

BL-1

BODY, LOCK & SECURITY SYSTEM

IBODY

CONTENTS

C

D

E

F

G

H

J

K

L

M

SECTIONBL

A

B

BL

BODY, LOCK & SECURITY SYSTEM

PRECAUTIONS .......................................................... 4

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 4

Precautions for procedures with out cowl top cover..... 4

Precautions for Work ................................................ 4

Wiring Diagrams and Trouble Diagnosis .................. 4

PREPARATION ........................................................... 5

Commercial Service Tools ........................................ 5

SQUEAK AND RATTLE TROUBLE DIAGNOSES..... 6

Work Flow ................................................................ 6

CUSTOMER INTERVIEW ..................................... 6

DUPLICATE THE NOISE AND TEST DRIVE ....... 7

CHECK RELATED SERVICE BULLETINS ........... 7

LOCATE THE NOISE AND IDENTIFY THE

ROOT CAUSE ...................................................... 7

REPAIR THE CAUSE ........................................... 7

CONFIRM THE REPAIR ....................................... 8

Generic Squeak and Rattle Troubleshooting ........... 8

INSTRUMENT PANEL .......................................... 8

CENTER CONSOLE ............................................. 8

DOORS ................................................................. 8

TRUNK .................................................................. 9

SUNROOF/HEADLINING ..................................... 9

SEATS ................................................................... 9

UNDERHOOD ....................................................... 9

Diagnostic Worksheet ............................................ 10

HOOD ....................................................................... 12

Fitting Adjustment .................................................. 12

LONGITUDINAL AND LATERAL CLEARANCE

ADJUSTMENT .................................................... 13

FRONT END HEIGHT ADJUSTMENT ............... 13

SURFACE HEIGHT ADJUSTMENT ................... 13

Removal and Installation of Hood Assembly .......... 14

REMOVAL ........................................................... 14

INSTALLATION ................................................... 14

Removal and Installation of Hood Hinge ................ 15

REMOVAL ........................................................... 15

INSTALLATION ................................................... 15

Removal and Installation of Hood Lock Control ..... 15REMOVAL ........................................................... 15

INSTALLATION ................................................... 16

Hood Lock Control Inspection ................................ 17

RADIATOR CORE SUPPORT .................................. 18

Removal and Installation ........................................ 18

REMOVAL ........................................................... 18

INSTALLATION ................................................... 19

FRONT FENDER ...................................................... 20

Removal and Installation ........................................ 20

REMOVAL ........................................................... 20

INSTALLATION ................................................... 20

POWER DOOR LOCK SYSTEM .............................. 21

Component Parts and Harness Connector Location... 21

KING CAB ........................................................... 21

DOUBLE CAB ..................................................... 22

System Description ................................................. 23

OUTLINE ............................................................. 24

CAN Communication System Description .............. 25

CAN Communication Unit ....................................... 25

Schematic ............................................................... 26

Wiring Diagram —D/LOCK— ................................. 27

Terminals and Reference Value for BCM ............... 34

CONSULT-II Function (BCM) ................................. 35

CONSULT-II BASIC OPERATION PROCEDURE

... 35

CONSULT-II APPLICATION ITEMS .................... 36

Work Flow ............................................................... 37

Trouble Diagnoses Chart by Symptom ................... 37

Check Power Supply and Ground Circuit ............... 37

Check Door Switch ................................................. 39

CHECK DOOR SWITCH (DOUBLE CAB) .......... 39

CHECK DOOR SWITCH (KING CAB) ................ 41

Check Key Switch ................................................... 43

Check Door Key Cylinder Switch (LHD Model Only)... 45

Check Front Door Lock Actuator (Driver Side) ....... 48

Check Front Door Lock Actuator (Passenger Side)... 49

Check Front Door Lock Actuator Switch ................. 50

Check Rear Door Lock Actuator LH (Double Cab

Model) ..................................................................... 50

Check Rear Door Lock Actuator RH (Double Cab

Page 592 of 3171

BL-8

SQUEAK AND RATTLE TROUBLE DIAGNOSES

FELT CLOTHTAPE

Used to insulate where movement does not occur. Ideal for instrument panel applications.

68370-4B000: 15´25 mm (0.59´0.98 in) pad/68239-13E00: 5 mm (0.20 in) wide tape roll

The following materials, not available through NISSAN Parts Department, can also be used to repair squeaks

and rattles.

UHMW(TEFLON) TAPE

Insulates where slight movement is present. Ideal for instrument panel applications.

SILICONE GREASE

Used in place of UHMW tape that will be visible or not fit.

Note: Will only last a few months.

SILICONE SPRAY

Use when grease cannot be applied.

DUCT TAPE

Use to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle TroubleshootingEIS00DI3

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. Cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicon spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or rattle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation procedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the areas with felt cloth tape or insulator foam blocks to

repair the noise.

Page 605 of 3171

POWERDOORLOCKSYSTEM

BL-21

C

D

E

F

G

H

J

K

L

MA

B

BL

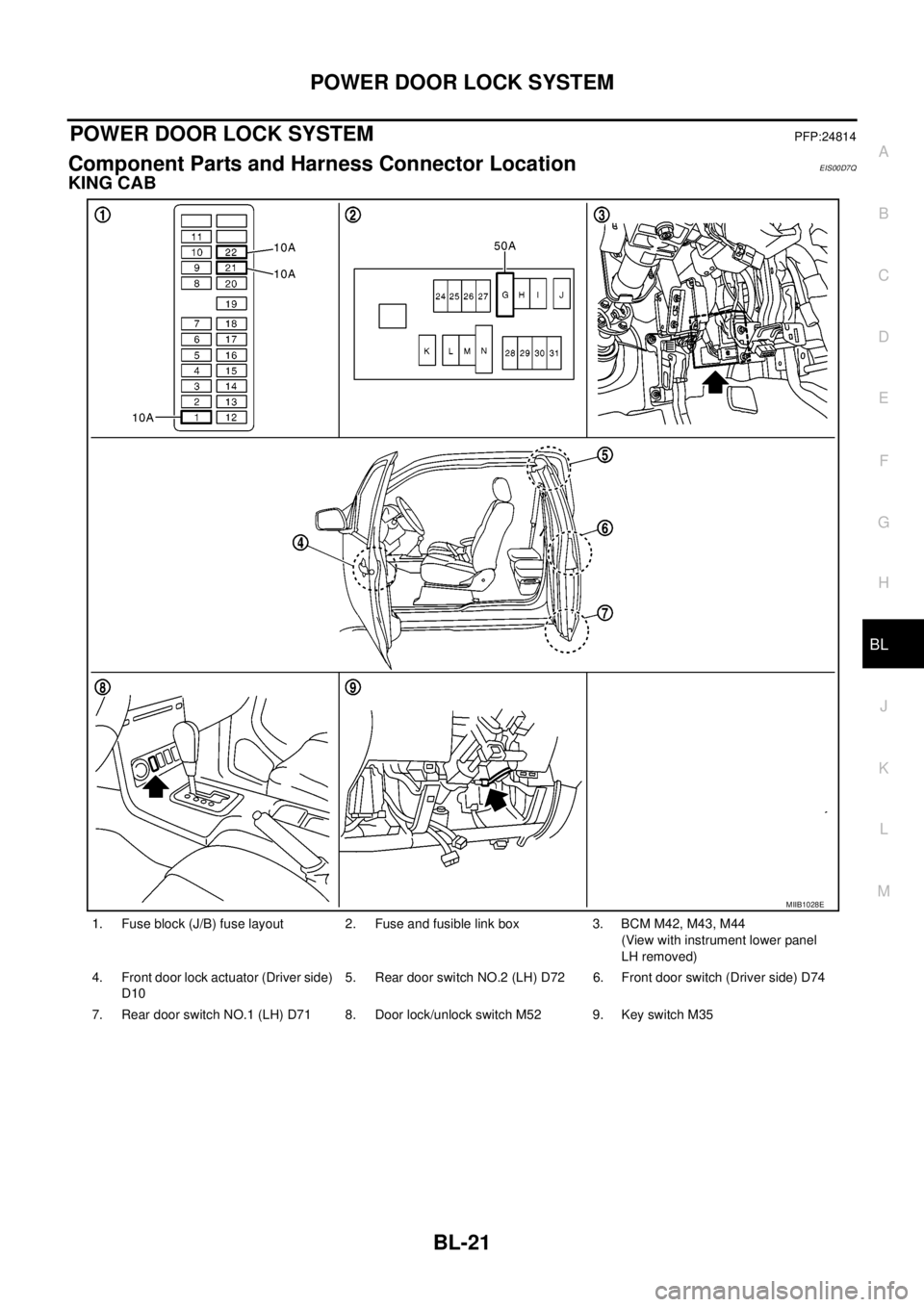

POWER DOOR LOCK SYSTEMPFP:24814

Component Parts and Harness Connector LocationEIS00D7Q

KING CAB

1. Fuse block (J/B) fuse layout 2. Fuse and fusible link box 3. BCM M42, M43, M44

(View with instrument lower panel

LH removed)

4. Front door lock actuator (Driver side)

D105. Rear door switch NO.2 (LH) D72 6. Front door switch (Driver side) D74

7. Rear door switch NO.1 (LH) D71 8. Door lock/unlock switch M52 9. Key switch M35

MIIB1028E

Page 606 of 3171

BL-22

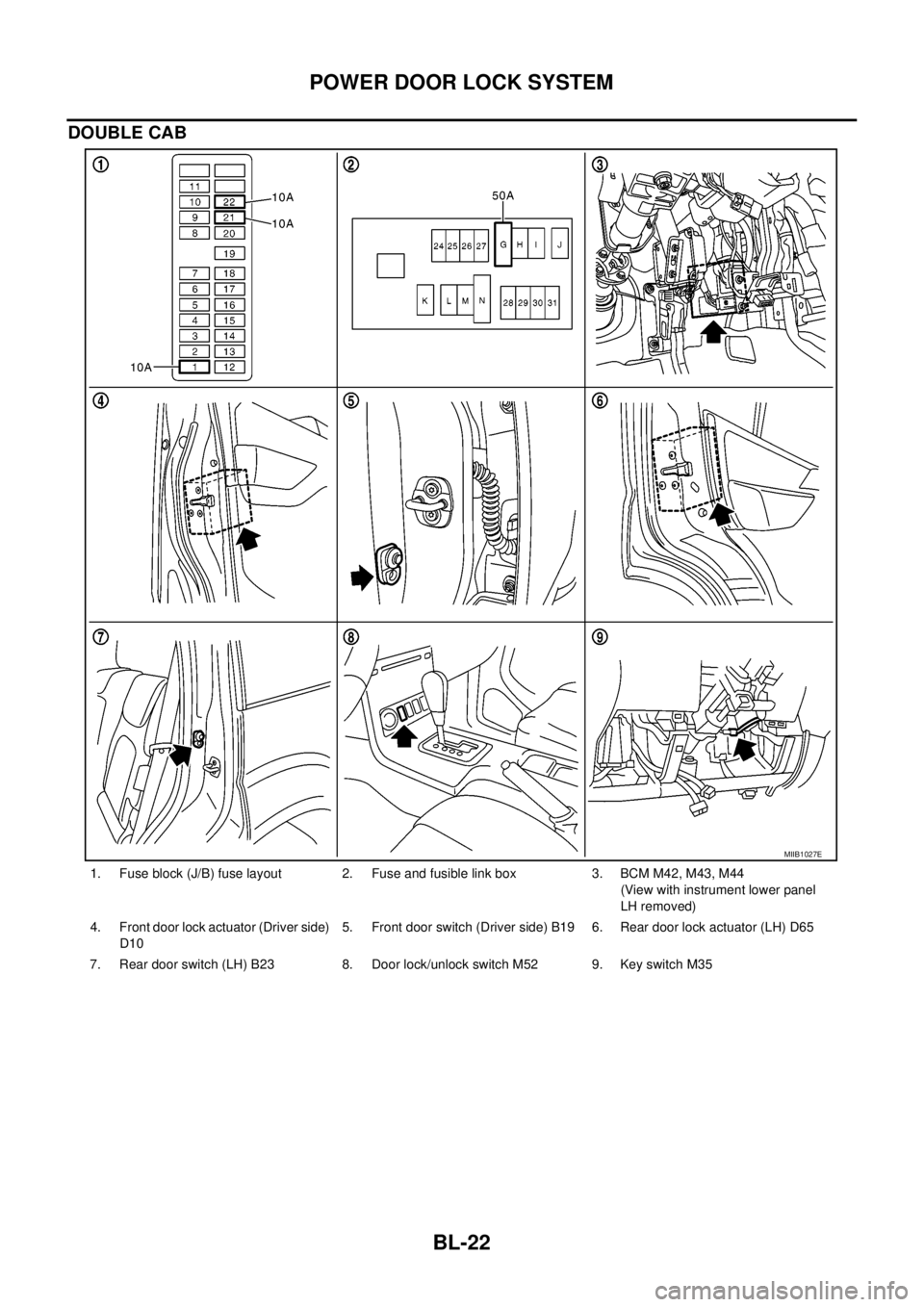

POWER DOOR LOCK SYSTEM

DOUBLE CAB

1. Fuse block (J/B) fuse layout 2. Fuse and fusible link box 3. BCM M42, M43, M44

(View with instrument lower panel

LH removed)

4. Front door lock actuator (Driver side)

D105. Front door switch (Driver side) B19 6. Rear door lock actuator (LH) D65

7. Rear door switch (LH) B23 8. Door lock/unlock switch M52 9. Key switch M35

MIIB1027E