light NISSAN NAVARA 2005 Repair User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 432 of 3171

ATC-98

TROUBLE DIAGNOSIS

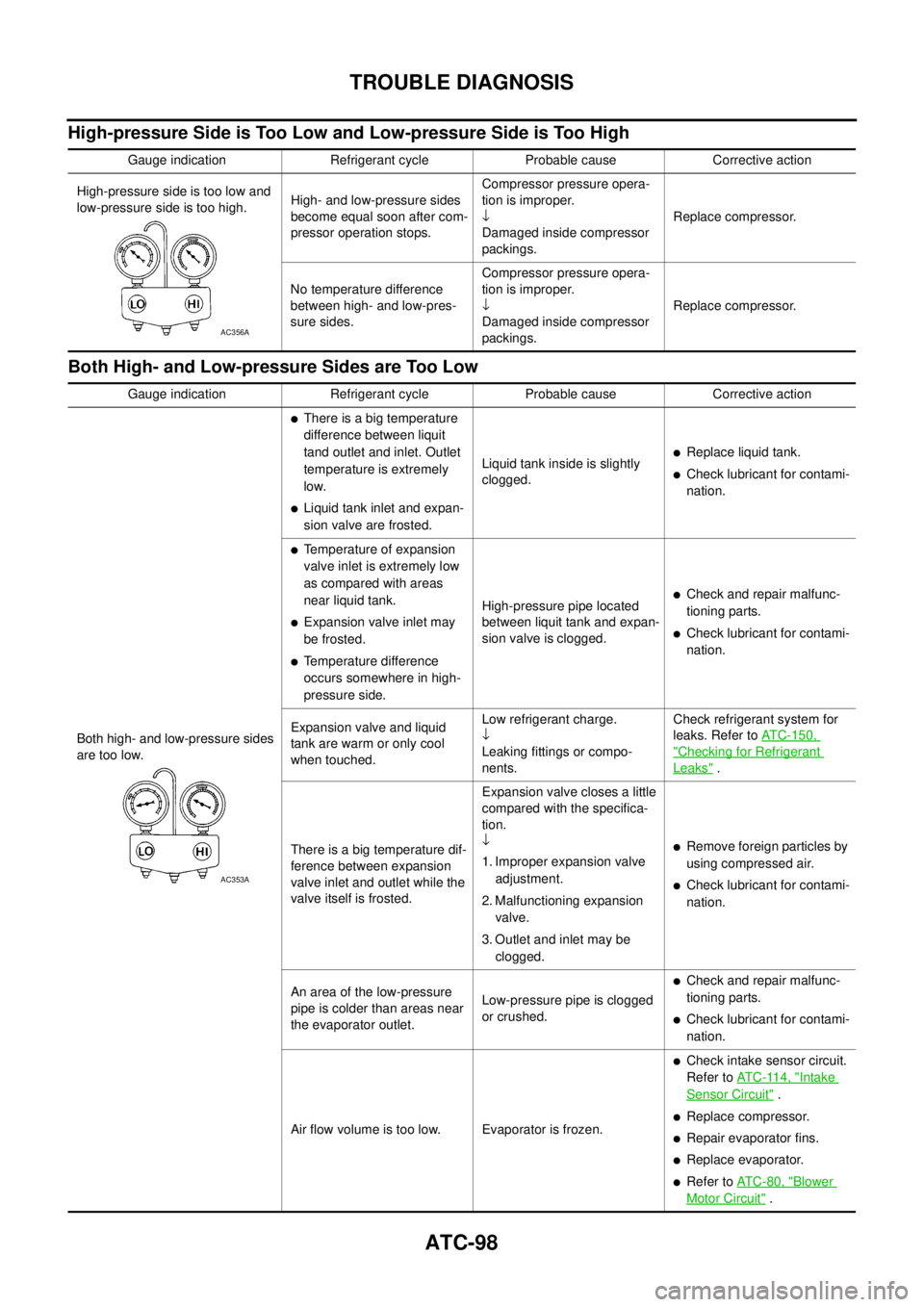

High-pressure Side is Too Low and Low-pressure Side is Too High

Both High- and Low-pressure Sides are Too Low

Gauge indication Refrigerant cycle Probable cause Corrective action

High-pressure side is too low and

low-pressure side is too high.High- and low-pressure sides

become equal soon after com-

pressor operation stops.Compressor pressure opera-

tion is improper.

¯

Damaged inside compressor

packings.Replace compressor.

No temperature difference

between high- and low-pres-

sure sides.Compressor pressure opera-

tion is improper.

¯

Damaged inside compressor

packings.Replace compressor.

AC356A

Gauge indication Refrigerant cycle Probable cause Corrective action

Both high- and low-pressure sides

are too low.

lThere is a big temperature

difference between liquit

tand outlet and inlet. Outlet

temperature is extremely

low.

lLiquid tank inlet and expan-

sion valve are frosted.Liquid tank inside is slightly

clogged.

lReplace liquid tank.

lCheck lubricant for contami-

nation.

lTemperature of expansion

valve inlet is extremely low

as compared with areas

near liquid tank.

lExpansion valve inlet may

be frosted.

lTemperature difference

occurs somewhere in high-

pressure side.High-pressure pipe located

between liquit tank and expan-

sion valve is clogged.

lCheck and repair malfunc-

tioning parts.

lCheck lubricant for contami-

nation.

Expansion valve and liquid

tank are warm or only cool

when touched.Low refrigerant charge.

¯

Leaking fittings or compo-

nents.Check refrigerant system for

leaks. Refer toATC-150,

"Checking for Refrigerant

Leaks".

There is a big temperature dif-

ference between expansion

valve inlet and outlet while the

valve itself is frosted.Expansion valve closes a little

compared with the specifica-

tion.

¯

1. Improper expansion valve

adjustment.

2. Malfunctioning expansion

valve.

3. Outlet and inlet may be

clogged.

lRemove foreign particles by

using compressed air.

lCheck lubricant for contami-

nation.

An area of the low-pressure

pipe is colder than areas near

the evaporator outlet.Low-pressure pipe is clogged

or crushed.

lCheck and repair malfunc-

tioning parts.

lCheck lubricant for contami-

nation.

Air flow volume is too low. Evaporator is frozen.

lCheck intake sensor circuit.

Refer toAT C - 11 4 , "

Intake

Sensor Circuit".

lReplace compressor.

lRepair evaporator fins.

lReplace evaporator.

lRefer toAT C - 8 0 , "Blower

Motor Circuit".

AC353A

Page 446 of 3171

ATC-112

TROUBLE DIAGNOSIS

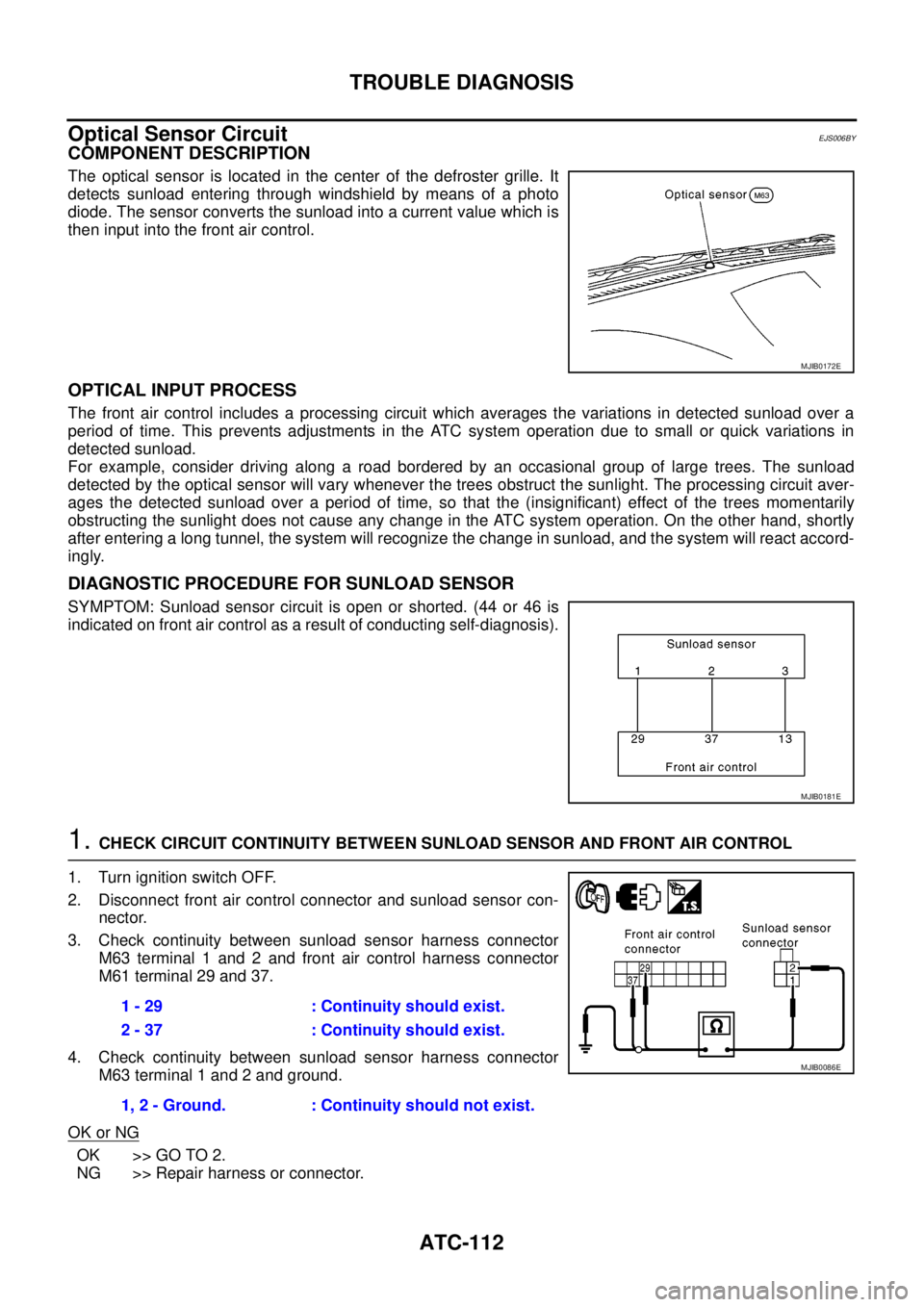

Optical Sensor Circuit

EJS006BY

COMPONENT DESCRIPTION

The optical sensor is located in the center of the defroster grille. It

detects sunload entering through windshield by means of a photo

diode. The sensor converts the sunload into a current value which is

then input into the front air control.

OPTICAL INPUT PROCESS

The front air control includes a processing circuit which averages the variations in detected sunload over a

period of time. This prevents adjustments in the ATC system operation due to small or quick variations in

detected sunload.

For example, consider driving along a road bordered by an occasional group of large trees. The sunload

detected by the optical sensor will vary whenever the trees obstruct the sunlight. The processing circuit aver-

ages the detected sunload over a period of time, so that the (insignificant) effect of the trees momentarily

obstructing the sunlight does not cause any change in the ATC system operation. On the other hand, shortly

after entering a long tunnel, the system will recognize the change in sunload, and the system will react accord-

ingly.

DIAGNOSTIC PROCEDURE FOR SUNLOAD SENSOR

SYMPTOM: Sunload sensor circuit is open or shorted. (44 or 46 is

indicated on front air control as a result of conducting self-diagnosis).

1.CHECK CIRCUIT CONTINUITY BETWEEN SUNLOAD SENSOR AND FRONT AIR CONTROL

1. Turn ignition switch OFF.

2. Disconnect front air control connector and sunload sensor con-

nector.

3. Check continuity between sunload sensor harness connector

M63 terminal 1 and 2 and front air control harness connector

M61 terminal 29 and 37.

4. Check continuity between sunload sensor harness connector

M63 terminal 1 and 2 and ground.

OK or NG

OK >> GO TO 2.

NG >> Repair harness or connector.

MJIB0172E

MJIB0181E

1 - 29 : Continuity should exist.

2 - 37 : Continuity should exist.

1, 2 - Ground. : Continuity should not exist.

MJIB0086E

Page 484 of 3171

ATC-150

REFRIGERANT LINES

CAUTION:

Replace the O-rings on the A/C low-pressure flexible A/C hose and the high-pressure A/C pipe with

new ones. Apply compressor oil to the O-rings for installation.

Removal and Installation for Expansion ValveEJS006CZ

REMOVAL

1. Discharge the refrigerant. Refer toATC-138, "HFC-134a (R-134a) Service Procedure".

2. Remove the heater and cooling unit assembly. Refer toATC-126, "

REMOVAL".

3. Remove the heater core and evaporator pipes grommet.

4. Remove the expansion valve.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

lReplace the O-rings on then expansion valve and the A/C refrigerant pipes with new ones, then

apply compressor oil to them for installation.

lAfter charging refrigerant, check for leaks.

Checking for Refrigerant LeaksEJS006D1

Perform a visual inspection of all refrigeration parts, fittings, hoses and components for signs of A/C lubricant

leakage, damage and corrosion. A/C lubricant leakage may indicate an area of refrigerant leakage. Allow

extra inspection time in these areas when using either an electronic refrigerant leak detector or fluorescent

dye leak detector.

If dye is observed, confirm the leak with an electronic refrigerant leak detector. It is possible a prior leak was

repaired and not properly cleaned.

When searching for leaks, do not stop when one leak is found but continue to check for additional leaks at all

system components and connections.

When searching for refrigerant leaks using an electronic leak detector, move the probe along the suspected

leak area at 1 to 2 inches per second and no further than 1/4 inch from the component.

CAUTION:

Moving the electronic leak detector probe slower and closer to the suspected leak area will improve

the chances of finding a leak.

Checking System for Leaks Using the Fluorescent Leak DetectorEJS006D2

1. Check A/C system for leaks using the UV lamp and safety goggles [SST: J-42220] in a low sunlight area

(area without windows preferable). Illuminate all components, fittings and lines. The dye will appear as a

bright green/yellow area at the point of leakage. Fluorescent dye observed at the evaporator drain open-

ing indicates an evaporator core assembly (tubes, core or expansion valve) leak.

2. If the suspected area is difficult to see, use an adjustable mirror or wipe the area with a clean shop rag or

cloth, with the UV lamp for dye residue.

3. After the leak is repaired, remove any residual dye using dye cleaner [SST: J-43872] to prevent future mis-

diagnosis.

4. Perform a system performance check and verify the leak repair with an approved electronic refrigerant

leak detector.

NOTE:

Other gases in the work area or substances on the A/C components, for example, anti-freeze, windshield

washer fluid, solvents and lubricants, may falsely trigger the leak detector. Make sure the surfaces to be

checked are clean.

Cleanwithadryclothorblowoffwithshopair.

Do not allow the sensor tip of the detector to contact with any substance. This can also cause false readings

and may damage the detector.Expansion valve bolts : 4 N·m (0.41 kg-m, 35 in-lb)

A/C refrigerant pipe to expansion valve bolt : Refer toATC-140, "

Components"

.

Page 522 of 3171

AV-34

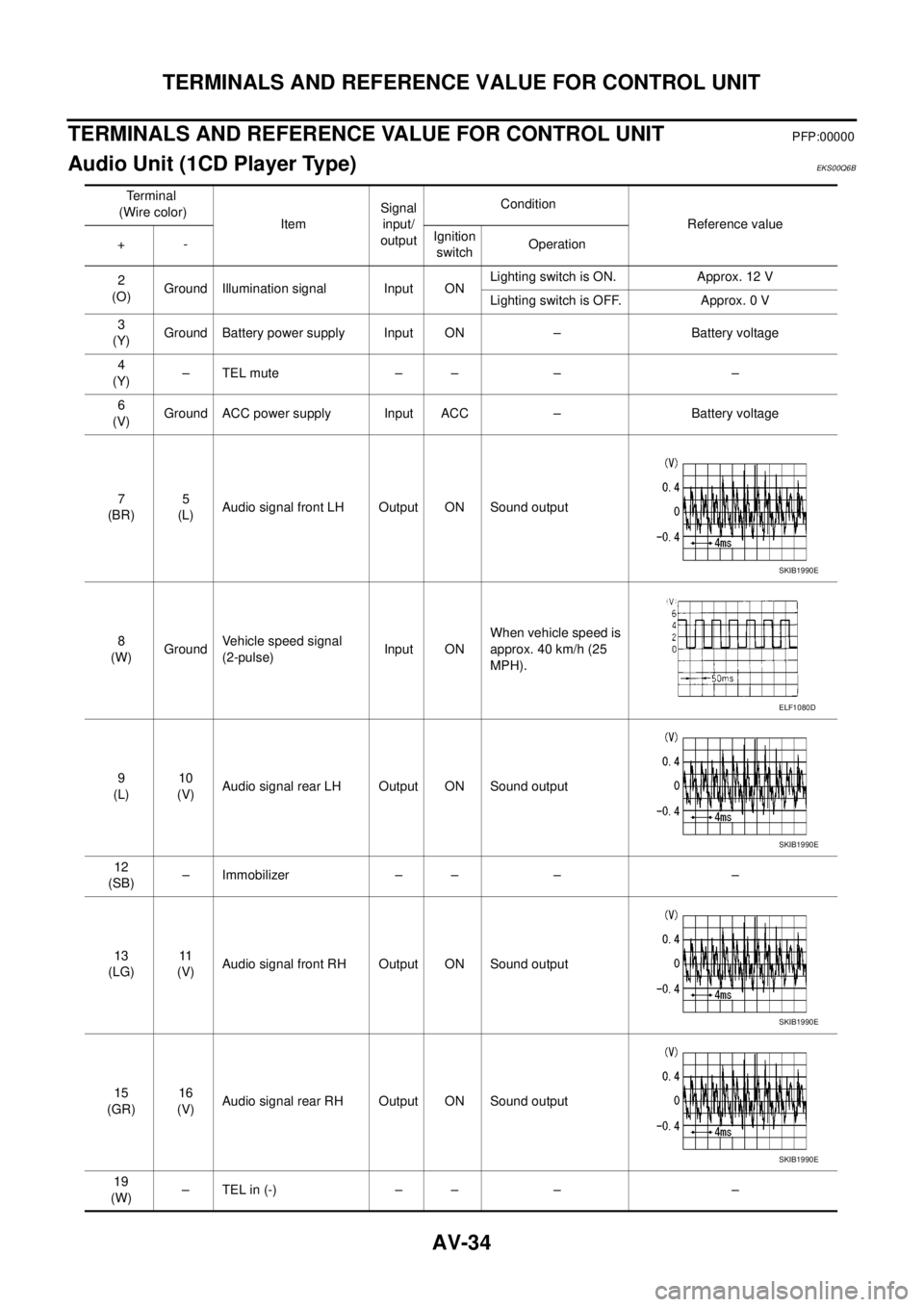

TERMINALS AND REFERENCE VALUE FOR CONTROL UNIT

TERMINALS AND REFERENCE VALUE FOR CONTROL UNIT

PFP:00000

Audio Unit (1CD Player Type)EKS00Q6B

Te r m i n a l

(Wire color)

ItemSignal

input/

outputCondition

Reference value

+-Ignition

switchOperation

2

(O)Ground Illumination signal Input ONLighting switch is ON. Approx. 12 V

Lighting switch is OFF. Approx. 0 V

3

(Y)Ground Battery power supply Input ON – Battery voltage

4

(Y)–TELmute – – – –

6

(V)Ground ACC power supply Input ACC – Battery voltage

7

(BR)5

(L)Audio signal front LH Output ON Sound output

8

(W)GroundVehicle speed signal

(2-pulse)Input ONWhen vehicle speed is

approx. 40 km/h (25

MPH).

9

(L)10

(V)Audio signal rear LH Output ON Sound output

12

(SB)– Immobilizer – – – –

13

(LG)11

(V)Audio signal front RH Output ON Sound output

15

(GR)16

(V)Audio signal rear RH Output ON Sound output

19

(W)–TELin(-) – – – –

SKIB1990E

ELF1080D

SKIB1990E

SKIB1990E

SKIB1990E

Page 523 of 3171

TERMINALS AND REFERENCE VALUE FOR CONTROL UNIT

AV-35

C

D

E

F

G

H

I

J

L

MA

B

AV

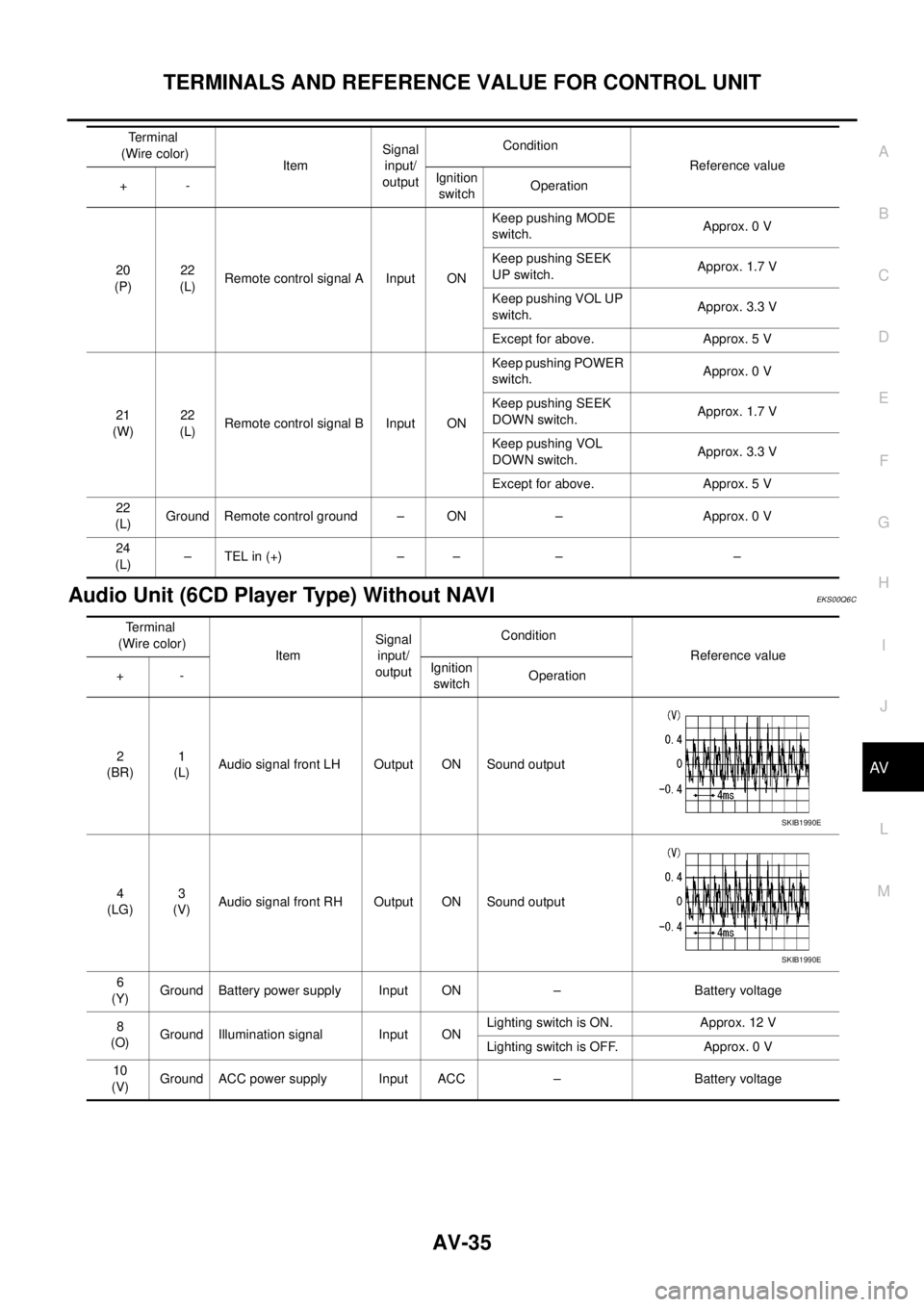

Audio Unit (6CD Player Type) Without NAVIEKS00Q6C

20

(P)22

(L)Remote control signal A Input ONKeep pushing MODE

switch.Approx. 0 V

Keep pushing SEEK

UP switch.Approx. 1.7 V

Keep pushing VOL UP

switch.Approx. 3.3 V

Except for above. Approx. 5 V

21

(W)22

(L)Remote control signal B Input ONKeep pushing POWER

switch.Approx. 0 V

Keep pushing SEEK

DOWN switch.Approx. 1.7 V

Keep pushing VOL

DOWN switch.Approx. 3.3 V

Except for above. Approx. 5 V

22

(L)Ground Remote control ground – ON – Approx. 0 V

24

(L)–TELin(+) – – – – Terminal

(Wire color)

ItemSignal

input/

outputCondition

Reference value

+-Ignition

switchOperation

Terminal

(Wire color)

ItemSignal

input/

outputCondition

Reference value

+-Ignition

switchOperation

2

(BR)1

(L)Audio signal front LH Output ON Sound output

4

(LG)3

(V)Audio signal front RH Output ON Sound output

6

(Y)Ground Battery power supply Input ON – Battery voltage

8

(O)Ground Illumination signal Input ONLighting switch is ON. Approx. 12 V

Lighting switch is OFF. Approx. 0 V

10

(V)Ground ACC power supply Input ACC – Battery voltage

SKIB1990E

SKIB1990E

Page 525 of 3171

TERMINALS AND REFERENCE VALUE FOR CONTROL UNIT

AV-37

C

D

E

F

G

H

I

J

L

MA

B

AV

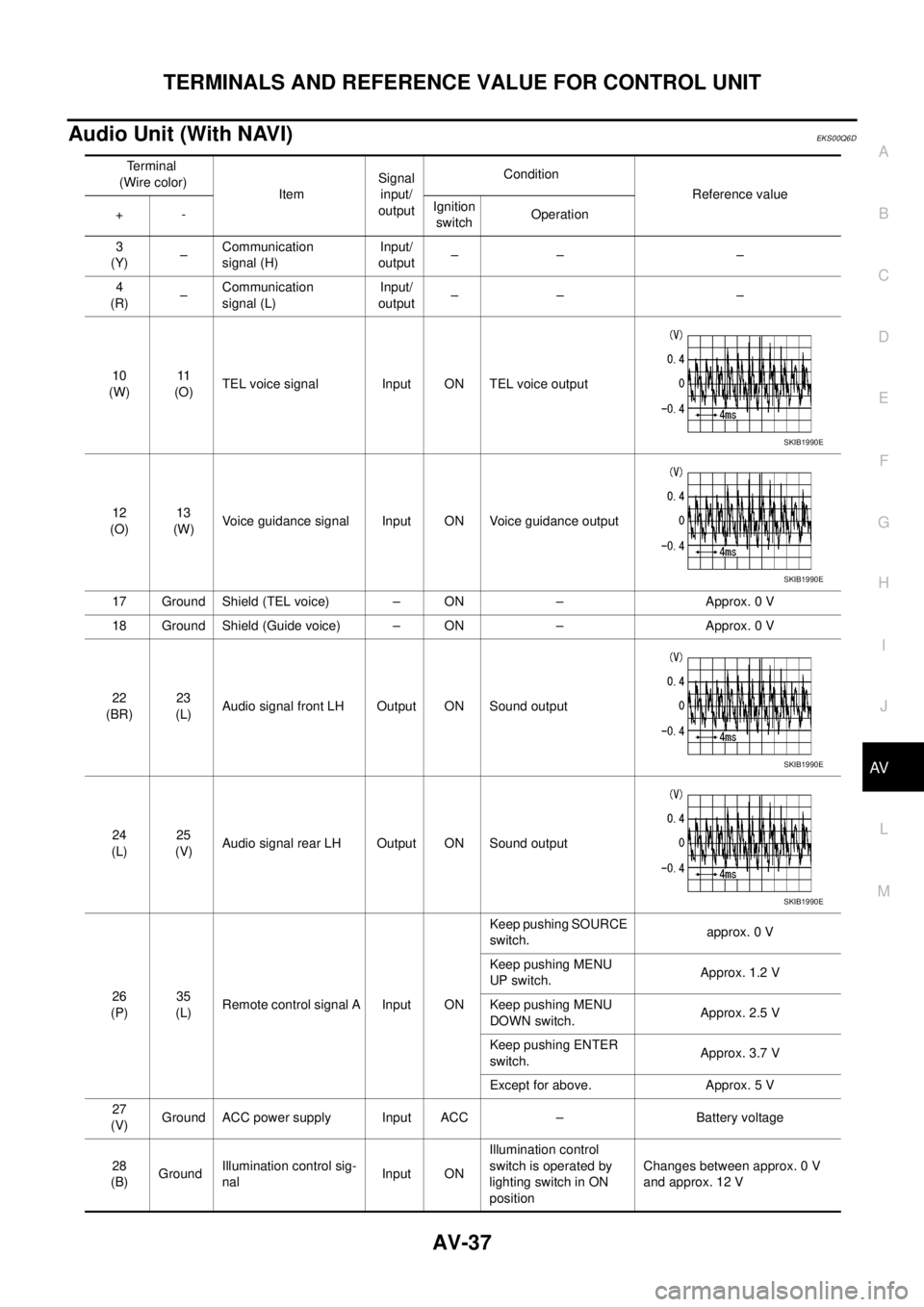

Audio Unit (With NAVI)EKS00Q6D

Terminal

(Wire color)

ItemSignal

input/

outputCondition

Reference value

+-Ignition

switchOperation

3

(Y)–Communication

signal (H)Input/

output–– –

4

(R)–Communication

signal (L)Input/

output–– –

10

(W)11

(O)TEL voice signal Input ON TEL voice output

12

(O)13

(W)Voice guidance signal Input ON Voice guidance output

17 Ground Shield (TEL voice) – ON – Approx. 0 V

18 Ground Shield (Guide voice) – ON – Approx. 0 V

22

(BR)23

(L)Audio signal front LH Output ON Sound output

24

(L)25

(V)Audio signal rear LH Output ON Sound output

26

(P)35

(L)Remote control signal A Input ONKeep pushing SOURCE

switch.approx. 0 V

Keep pushing MENU

UP switch.Approx. 1.2 V

Keep pushing MENU

DOWN switch.Approx. 2.5 V

Keep pushing ENTER

switch.Approx. 3.7 V

Except for above. Approx. 5 V

27

(V)Ground ACC power supply Input ACC – Battery voltage

28

(B)GroundIllumination control sig-

nalInput ONIllumination control

switch is operated by

lighting switch in ON

positionChanges between approx. 0 V

and approx. 12 V

SKIB1990E

SKIB1990E

SKIB1990E

SKIB1990E

Page 526 of 3171

AV-38

TERMINALS AND REFERENCE VALUE FOR CONTROL UNIT

NAVI Control Unit

EKS00Q6E

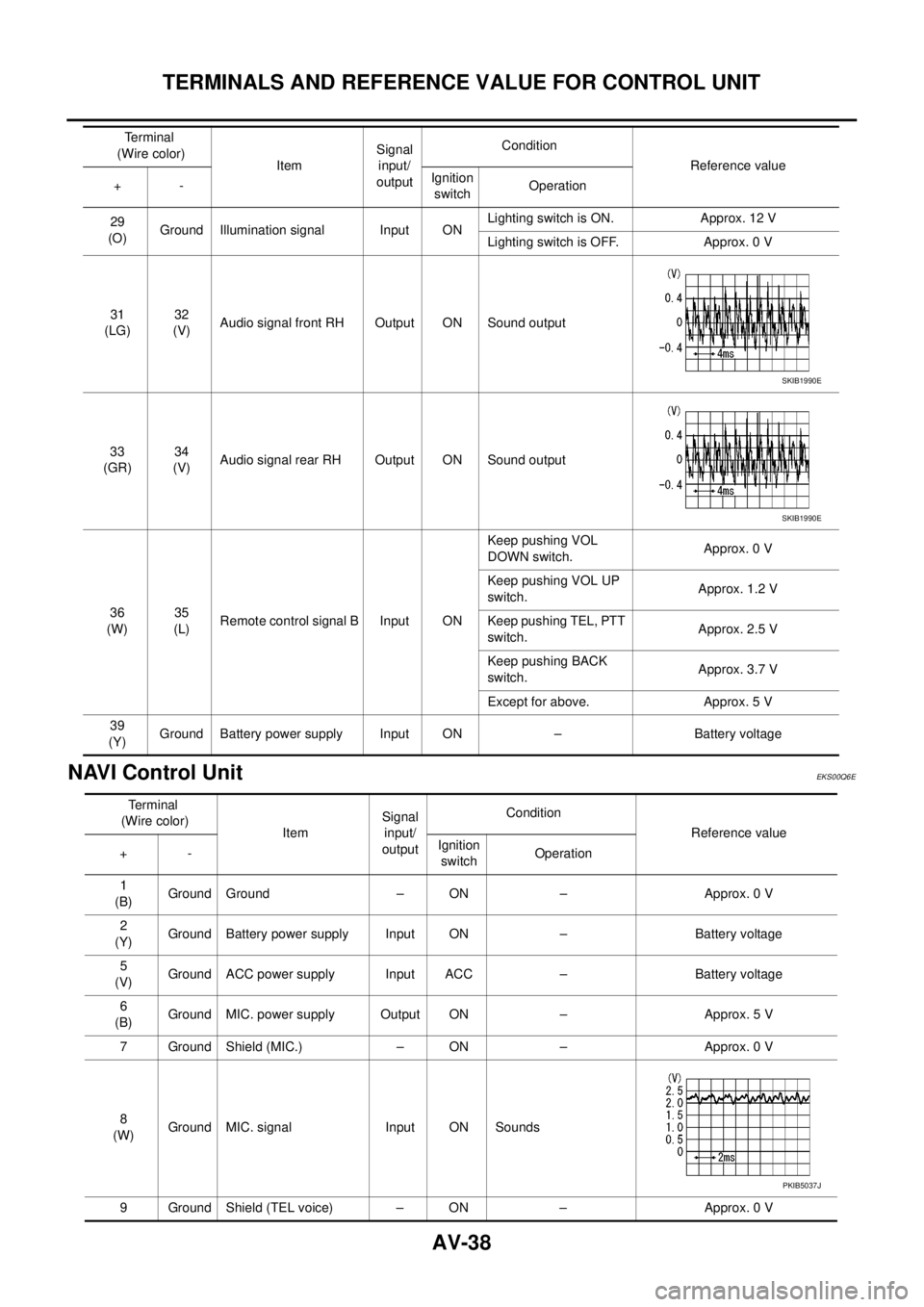

29

(O)Ground Illumination signal Input ONLighting switch is ON. Approx. 12 V

Lighting switch is OFF. Approx. 0 V

31

(LG)32

(V)Audio signal front RH Output ON Sound output

33

(GR)34

(V)Audio signal rear RH Output ON Sound output

36

(W)35

(L)Remote control signal B Input ONKeep pushing VOL

DOWN switch.Approx. 0 V

Keep pushing VOL UP

switch.Approx. 1.2 V

Keep pushing TEL, PTT

switch.Approx. 2.5 V

Keep pushing BACK

switch.Approx. 3.7 V

Except for above. Approx. 5 V

39

(Y)Ground Battery power supply Input ON – Battery voltage Terminal

(Wire color)

ItemSignal

input/

outputCondition

Reference value

+-Ignition

switchOperation

SKIB1990E

SKIB1990E

Terminal

(Wire color)

ItemSignal

input/

outputCondition

Reference value

+-Ignition

switchOperation

1

(B)Ground Ground – ON – Approx. 0 V

2

(Y)Ground Battery power supply Input ON – Battery voltage

5

(V)Ground ACC power supply Input ACC – Battery voltage

6

(B)Ground MIC. power supply Output ON – Approx. 5 V

7 Ground Shield (MIC.) – ON – Approx. 0 V

8

(W)Ground MIC. signal Input ON Sounds

9 Ground Shield (TEL voice) – ON – Approx. 0 V

PKIB5037J

Page 528 of 3171

AV-40

TERMINALS AND REFERENCE VALUE FOR CONTROL UNIT

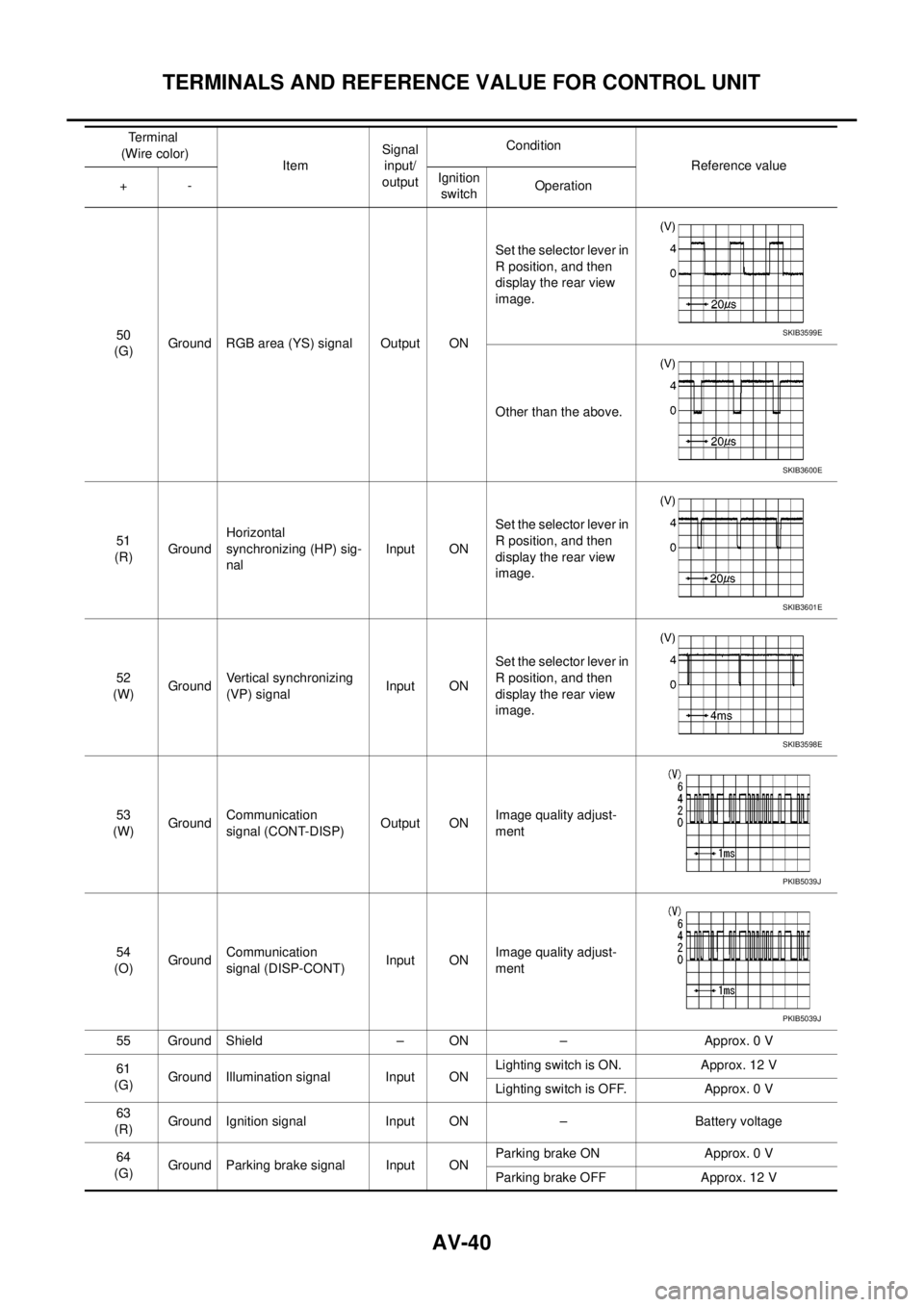

50

(G)Ground RGB area (YS) signal Output ONSet the selector lever in

R position, and then

display the rear view

image.

Other than the above.

51

(R)GroundHorizontal

synchronizing (HP) sig-

nalInput ONSet the selector lever in

R position, and then

display the rear view

image.

52

(W)GroundVertical synchronizing

(VP) signalInput ONSet the selector lever in

R position, and then

display the rear view

image.

53

(W)GroundCommunication

signal (CONT-DISP)Output ONImage quality adjust-

ment

54

(O)GroundCommunication

signal (DISP-CONT)Input ONImage quality adjust-

ment

55 Ground Shield – ON – Approx. 0 V

61

(G)Ground Illumination signal Input ONLighting switch is ON. Approx. 12 V

Lighting switch is OFF. Approx. 0 V

63

(R)Ground Ignition signal Input ON – Battery voltage

64

(G)Ground Parking brake signal Input ONParking brake ON Approx. 0 V

Parking brake OFF Approx. 12 V Terminal

(Wire color)

ItemSignal

input/

outputCondition

Reference value

+-Ignition

switchOperationSKIB3599E

SKIB3600E

SKIB3601E

SKIB3598E

PKIB5039J

PKIB5039J

Page 532 of 3171

AV-44

DIAGNOSIS SYSTEM

DIAGNOSIS SYSTEM

PFP:00000

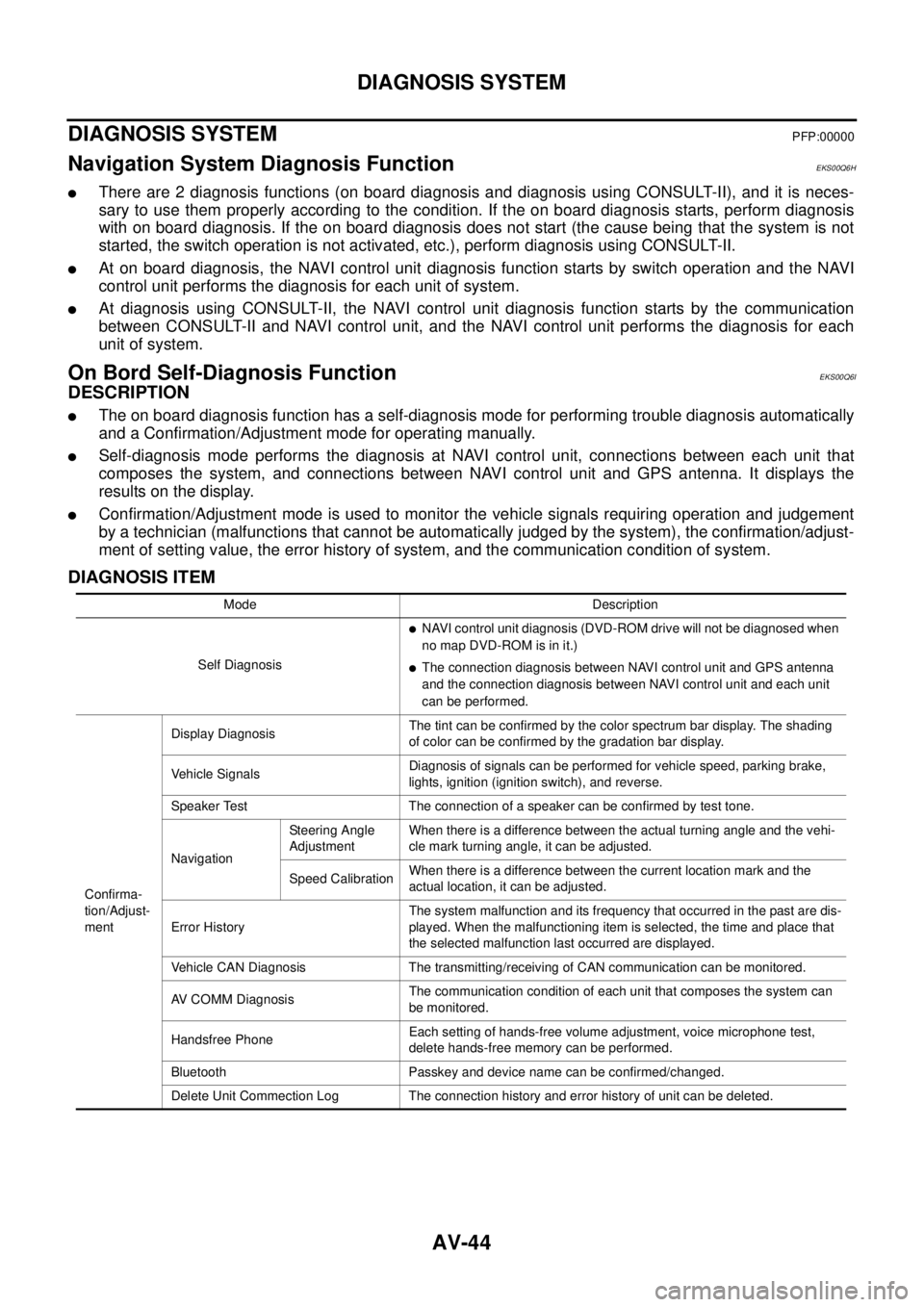

Navigation System Diagnosis FunctionEKS00Q6H

lThere are 2 diagnosis functions (on board diagnosis and diagnosis using CONSULT-II), and it is neces-

sary to use them properly according to the condition. If the on board diagnosis starts, perform diagnosis

with on board diagnosis. If the on board diagnosis does not start (the cause being that the system is not

started, the switch operation is not activated, etc.), perform diagnosis using CONSULT-II.

lAt on board diagnosis, the NAVI control unit diagnosis function starts by switch operation and the NAVI

control unit performs the diagnosis for each unit of system.

lAt diagnosis using CONSULT-II, the NAVI control unit diagnosis function starts by the communication

between CONSULT-II and NAVI control unit, and the NAVI control unit performs the diagnosis for each

unit of system.

On Bord Self-Diagnosis FunctionEKS00Q6I

DESCRIPTION

lThe on board diagnosis function has a self-diagnosis mode for performing trouble diagnosis automatically

and a Confirmation/Adjustment mode for operating manually.

lSelf-diagnosis mode performs the diagnosis at NAVI control unit, connections between each unit that

composes the system, and connections between NAVI control unit and GPS antenna. It displays the

results on the display.

lConfirmation/Adjustment mode is used to monitor the vehicle signals requiring operation and judgement

by a technician (malfunctions that cannot be automatically judged by the system), the confirmation/adjust-

ment of setting value, the error history of system, and the communication condition of system.

DIAGNOSIS ITEM

Mode Description

Self Diagnosis

lNAVI control unit diagnosis (DVD-ROM drive will not be diagnosed when

no map DVD-ROM is in it.)

lThe connection diagnosis between NAVI control unit and GPS antenna

and the connection diagnosis between NAVI control unit and each unit

can be performed.

Confirma-

tion/Adjust-

mentDisplay DiagnosisThe tint can be confirmed by the color spectrum bar display. The shading

of color can be confirmed by the gradation bar display.

Vehicle SignalsDiagnosis of signals can be performed for vehicle speed, parking brake,

lights, ignition (ignition switch), and reverse.

Speaker Test The connection of a speaker can be confirmed by test tone.

NavigationSteering Angle

AdjustmentWhen there is a difference between the actual turning angle and the vehi-

cle mark turning angle, it can be adjusted.

Speed CalibrationWhen there is a difference between the current location mark and the

actual location, it can be adjusted.

Error HistoryThe system malfunction and its frequency that occurred in the past are dis-

played. When the malfunctioning item is selected, the time and place that

the selected malfunction last occurred are displayed.

Vehicle CAN Diagnosis The transmitting/receiving of CAN communication can be monitored.

AV COMM DiagnosisThe communication condition of each unit that composes the system can

be monitored.

Handsfree PhoneEach setting of hands-free volume adjustment, voice microphone test,

delete hands-free memory can be performed.

Bluetooth Passkey and device name can be confirmed/changed.

Delete Unit Commection Log The connection history and error history of unit can be deleted.

Page 537 of 3171

DIAGNOSIS SYSTEM

AV-49

C

D

E

F

G

H

I

J

L

MA

B

AV

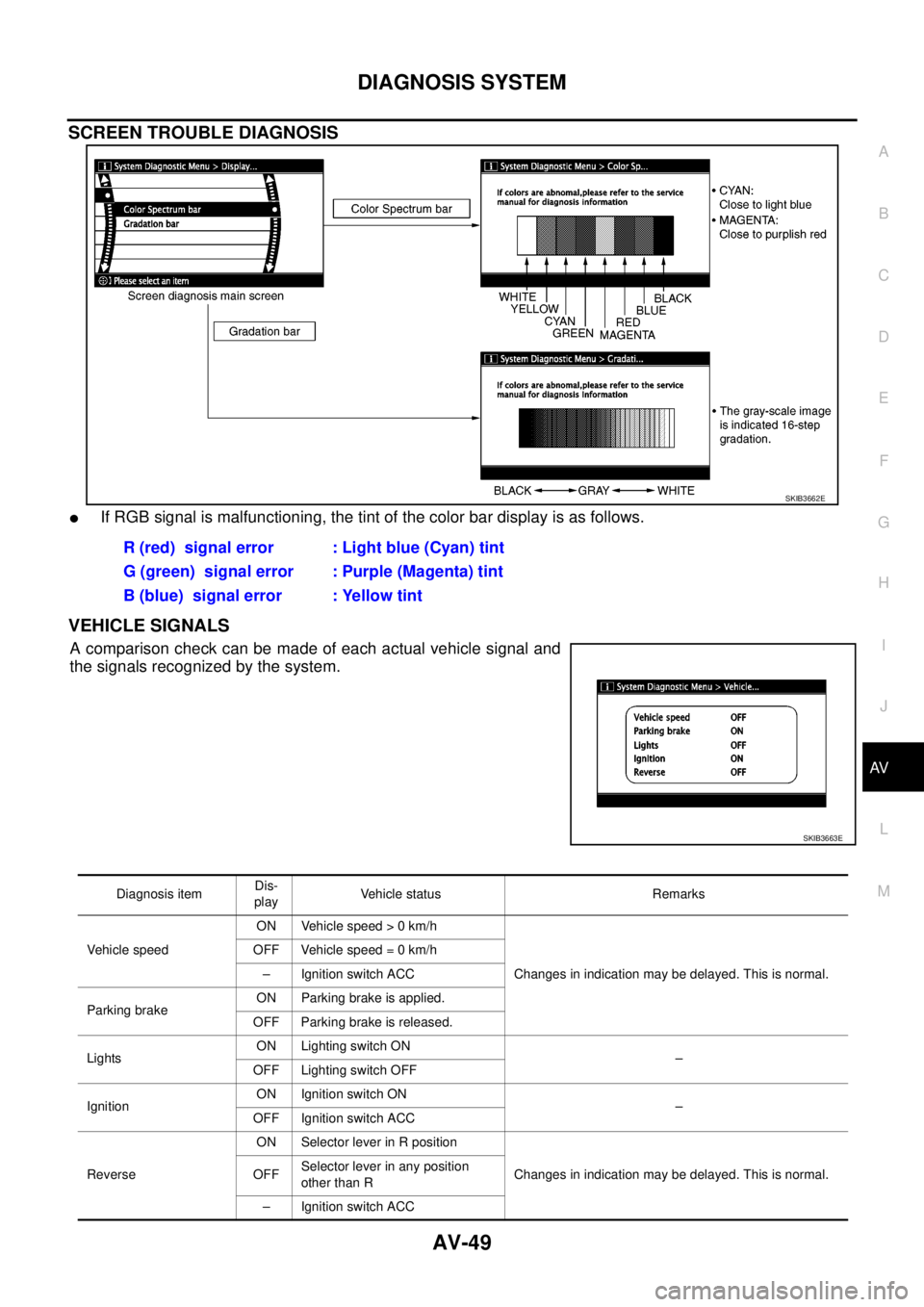

SCREEN TROUBLE DIAGNOSIS

lIf RGB signal is malfunctioning, the tint of the color bar display is as follows.

VEHICLE SIGNALS

Acomparisoncheckcanbemadeofeachactualvehiclesignaland

the signals recognized by the system.

SKIB3662E

R (red) signal error : Light blue (Cyan) tint

G (green) signal error : Purple (Magenta) tint

B (blue) signal error : Yellow tint

SKIB3663E

Diagnosis itemDis-

playVehicle status Remarks

Vehicle speedON Vehicle speed > 0 km/h

Changes in indication may be delayed. This is normal. OFF Vehicle speed = 0 km/h

– Ignition switch ACC

Parking brakeON Parking brake is applied.

OFF Parking brake is released.

LightsON Lighting switch ON

–

OFF Lighting switch OFF

IgnitionON Ignition switch ON

–

OFF Ignition switch ACC

ReverseON Selector lever in R position

Changes in indication may be delayed. This is normal. OFFSelector lever in any position

other than R

– Ignition switch ACC