light NISSAN NAVARA 2005 Repair Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 591 of 3171

SQUEAK AND RATTLE TROUBLE DIAGNOSES

BL-7

C

D

E

F

G

H

J

K

L

MA

B

BL

DUPLICATE THE NOISE AND TEST DRIVE

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or location of the noise. This information can be used to

duplicate the same conditions when you confirm the repair.

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following:

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle “twist”.

5) At idle, apply engine load (electrical load, half-clutch on M/T models, drive position on A/T models).

6) Raisethevehicleonahoistandhitatirewitharubberhammer.

lDrive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

lIf it is difficult to duplicate the noise, drive the vehicle slowly on an undulating or rough road to stress the

vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, check ASIST for Technical Service Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, follow the procedure to repair the noise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area. To help pinpoint the source of the noise, use a listening tool

(Engine Ear or mechanics stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by:

lremoving the components in the area that you suspect the noise is coming from.

Do not use too much force when removing clips and fasteners, otherwise clips and fastener can be broken

or lost during the repair, resulting in the creation of new noise.

ltapping or pushing/pulling the component that you suspect is causing the noise.

Do not tap or push/pull the component with excessive force, otherwise the noise will be eliminated only

temporarily.

lfeeling for a vibration with your hand by touching the component(s) that you suspect is (are) causing the

noise.

lplacing a piece of paper between components that you suspect are causing the noise.

llooking for loose components and contact marks.

Refer toBL-8, "

Generic Squeak and Rattle Troubleshooting".

REPAIR THE CAUSE

lIf the cause is a loose component, tighten the component securely.

lIf the cause is insufficient clearance between components:

–separate components by repositioning or loosening and retightening the component, if possible.

–insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or ure-

thane tape are available through your authorized Nissan Parts Department.

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

NOTE:

Always check with the Parts Department for the latest parts information.

Each item can be ordered separately as needed.

URETHANE PADS [1.5 mm (0.059 in) thick]

Insulates connectors, harness, etc.

76268-9E005: 100´135 mm (3.94´5.31 in)/76884-71L01: 60´85 mm (2.36´3.35 in)/76884-71L02: 15´

25 mm (0.59´0.98 in)

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

73982-9E000: 45 mm (1.77 in) thick, 50´50 mm (1.97´1.97 in)/73982-50Y00: 10 mm (0.39 in) thick, 50

´50 mm (1.97´1.97 in)

INSULATOR (Light foam block)

80845-71L00: 30 mm (1.18 in) thick, 30´50 mm (1.18´1.97 in)

Page 592 of 3171

BL-8

SQUEAK AND RATTLE TROUBLE DIAGNOSES

FELT CLOTHTAPE

Used to insulate where movement does not occur. Ideal for instrument panel applications.

68370-4B000: 15´25 mm (0.59´0.98 in) pad/68239-13E00: 5 mm (0.20 in) wide tape roll

The following materials, not available through NISSAN Parts Department, can also be used to repair squeaks

and rattles.

UHMW(TEFLON) TAPE

Insulates where slight movement is present. Ideal for instrument panel applications.

SILICONE GREASE

Used in place of UHMW tape that will be visible or not fit.

Note: Will only last a few months.

SILICONE SPRAY

Use when grease cannot be applied.

DUCT TAPE

Use to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle TroubleshootingEIS00DI3

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. Cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicon spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or rattle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation procedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the areas with felt cloth tape or insulator foam blocks to

repair the noise.

Page 593 of 3171

SQUEAK AND RATTLE TROUBLE DIAGNOSES

BL-9

C

D

E

F

G

H

J

K

L

MA

B

BL

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid dumpers out of adjustment

2. Trunk lid striker out of adjustment

3. Trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sunvisor shaft shaking in the holder

3. Front or rear windshield touching headlining and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

SEATS

When isolating seat noise it's important to note the position the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. Rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of these incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Page 755 of 3171

NATS(NISSAN ANTI-THEFT SYSTEM)

BL-171

C

D

E

F

G

H

J

K

L

MA

B

BL

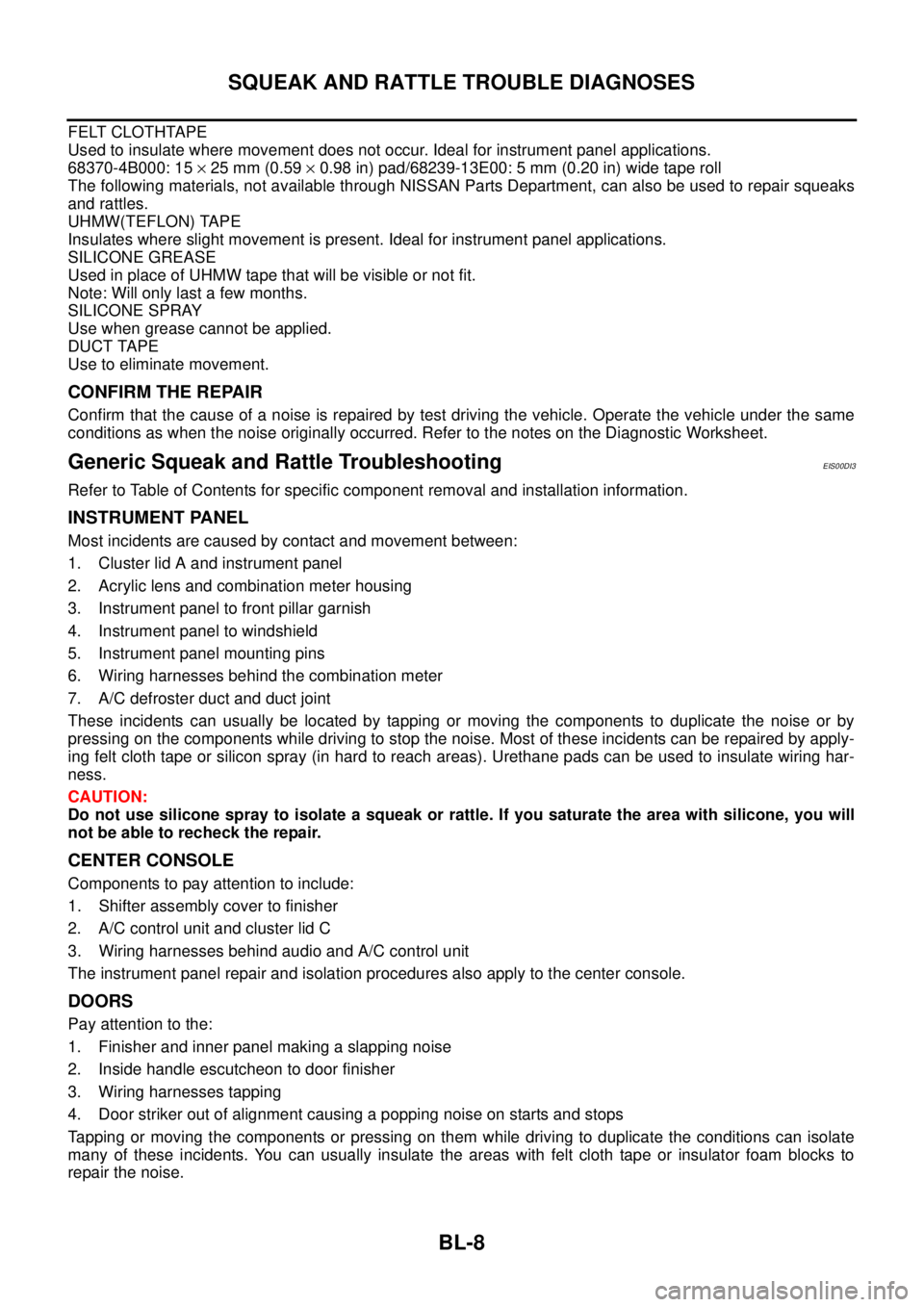

System DescriptionEIS00DAP

NATS (Nissan Anti-Theft System) has the following immobilizer functions:

lSince only NATS ignition keys, whose ID No. s have been registered into the ECM and IMMU of NATS,

allow the engine to run, a vehicle operation without a registered key in NATS is prevented by NATS.

That is to say, NATS will immobilize the engine if someone tries to start it without the registered key of

NATS.

lThis version of NATS has dongle unit to improve its anti-theft performance (RHD models). Dongle unit has

its own ID which is registered into NATS IMMU. So if dongle unit is replaced, initialization must be per-

formed.

lWhen malfunction of dongle unit is detected:

The security indicator lamp illuminates for about 15 minutes after ignition switch is turned to ON.

–When dongle unit has a malfunction and the indicator lamp is illuminated, engine cannot be started. How-

ever engine can be started only one time when security indicator lamp turns off in about 15 minutes after

ignition switch is turned to ON.

lAll of the originally supplied ignition key IDs have been NATS registered in NATS.

If the vehicle owner requests, a maximum of four key IDs can be registered into the NATS components.

lThe security indicator blinks when the ignition switch is in “OFF” or “ACC” position. Therefore, NATS

warns outsiders that the vehicle is equipped with the anti-theft system.

lWhen NATS detects malfunction, the security indicator lamp lights up as follows.

lNATS trouble diagnoses, system initialization and additional registration of other NATS ignition key IDs

must be performed using CONSULT-II hardware and CONSULT-II NATS software.

Regarding the procedures of NATS initialization and NATS ignition key ID registration, refer to CONSULT-

II operation manual, NATS.

lWhen servicing a malfunction of the NATS (indicated by lighting up of Security Indicator Lamp) or

registering another NATS ignition key ID no., it may be necessary to re-register original key identi-

fication. Therefore, be sure to receive ALL KEYS from vehicle owner.

Condition IGN ON andWith dongle Without dongle

Security indicator Security indicator

NATS malfunction (except dongle unit) is

detected1. 6 times blinking

2. Staying ON after ignition switch is turned ON.Staying ON

Only malfunction of dongle unit is

detected.Staying ON for about 15 minutes after ignition

switch is turned ON.—

Malfunction of NATS and engine related

parts are detected.1. 6 times blinking

2. Staying ON after ignition switch is turned ON.Staying ON

Only engine related part malfunction is

detected.——

Just after initialization of NATS 6 times blinking —

Page 762 of 3171

BL-178

NATS(NISSAN ANTI-THEFT SYSTEM)

Trouble Diagnoses

EIS00DB0

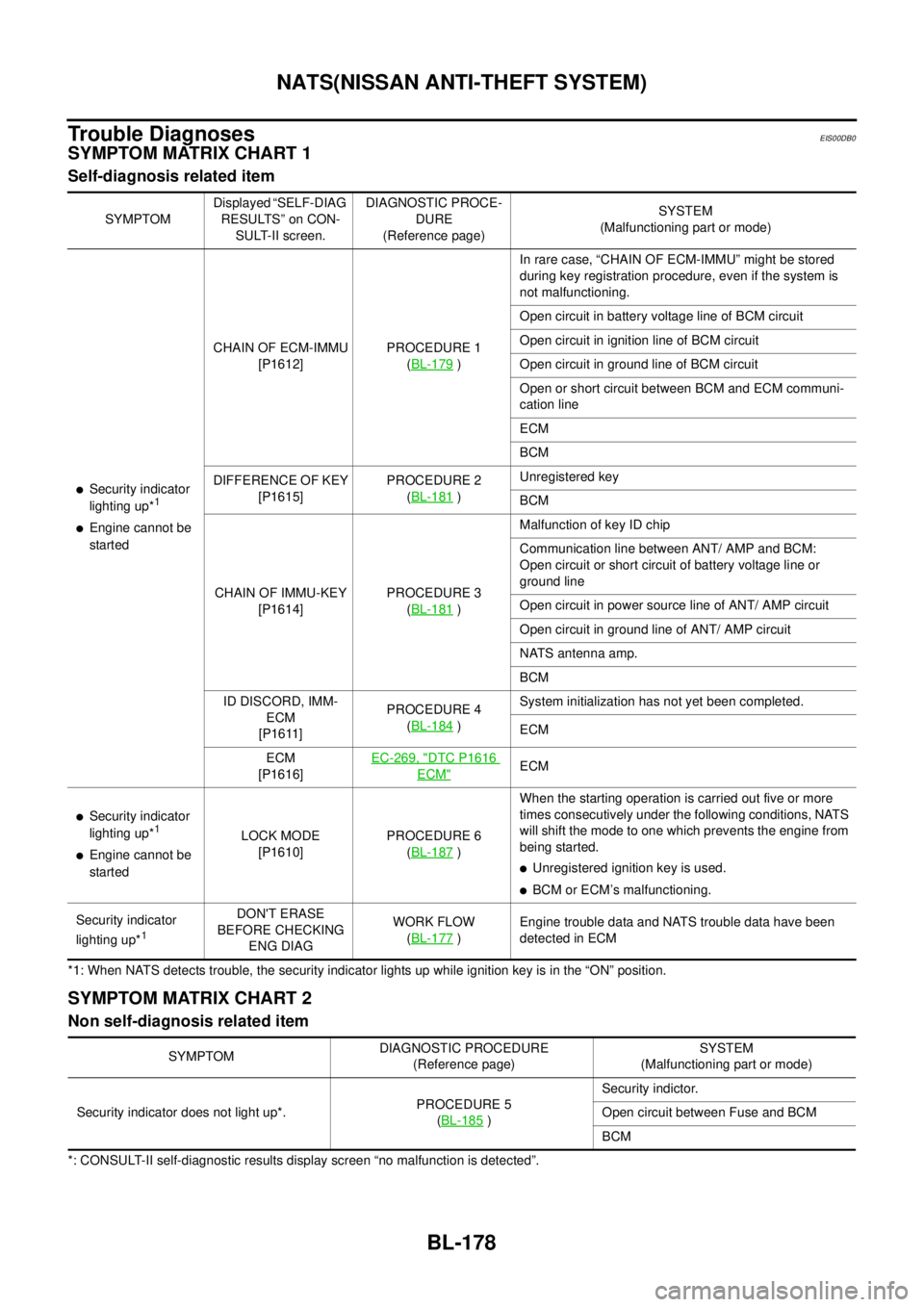

SYMPTOM MATRIX CHART 1

Self-diagnosis related item

*1: When NATS detects trouble, the security indicator lights up while ignition key is in the “ON” position.

SYMPTOM MATRIX CHART 2

Non self-diagnosis related item

*: CONSULT-II self-diagnostic results display screen “no malfunction is detected”.SYMPTOMDisplayed “SELF-DIAG

RESULTS” on CON-

SULT-II screen.DIAGNOSTIC PROCE-

DURE

(Reference page)SYSTEM

(Malfunctioning part or mode)

lSecurity indicator

lighting up*1

lEngine cannot be

startedCHAIN OF ECM-IMMU

[P1612]PROCEDURE 1

(BL-179

)In rare case, “CHAIN OF ECM-IMMU” might be stored

during key registration procedure, even if the system is

not malfunctioning.

Open circuit in battery voltage line of BCM circuit

Open circuit in ignition line of BCM circuit

Open circuit in ground line of BCM circuit

Open or short circuit between BCM and ECM communi-

cation line

ECM

BCM

DIFFERENCE OF KEY

[P1615]PROCEDURE 2

(BL-181

)Unregistered key

BCM

CHAIN OF IMMU-KEY

[P1614]PROCEDURE 3

(BL-181

)Malfunction of key ID chip

Communication line between ANT/ AMP and BCM:

Open circuit or short circuit of battery voltage line or

ground line

Open circuit in power source line of ANT/ AMP circuit

Open circuit in ground line of ANT/ AMP circuit

NATS antenna amp.

BCM

ID DISCORD, IMM-

ECM

[P1611]PROCEDURE 4

(BL-184

)System initialization has not yet been completed.

ECM

ECM

[P1616]EC-269, "

DTC P1616

ECM"ECM

lSecurity indicator

lighting up*1

lEngine cannot be

startedLOCK MODE

[P1610]PROCEDURE 6

(BL-187)When the starting operation is carried out five or more

times consecutively under the following conditions, NATS

will shift the mode to one which prevents the engine from

being started.

lUnregistered ignition key is used.

lBCM or ECM’s malfunctioning.

Security indicator

lighting up*

1

DON'T ERASE

BEFORE CHECKING

ENG DIAGWORK FLOW

(BL-177

)Engine trouble data and NATS trouble data have been

detected in ECM

SYMPTOMDIAGNOSTIC PROCEDURE

(Reference page)SYSTEM

(Malfunctioning part or mode)

Security indicator does not light up*.PROCEDURE 5

(BL-185

)Security indictor.

Open circuit between Fuse and BCM

BCM

Page 769 of 3171

NATS(NISSAN ANTI-THEFT SYSTEM)

BL-185

C

D

E

F

G

H

J

K

L

MA

B

BL

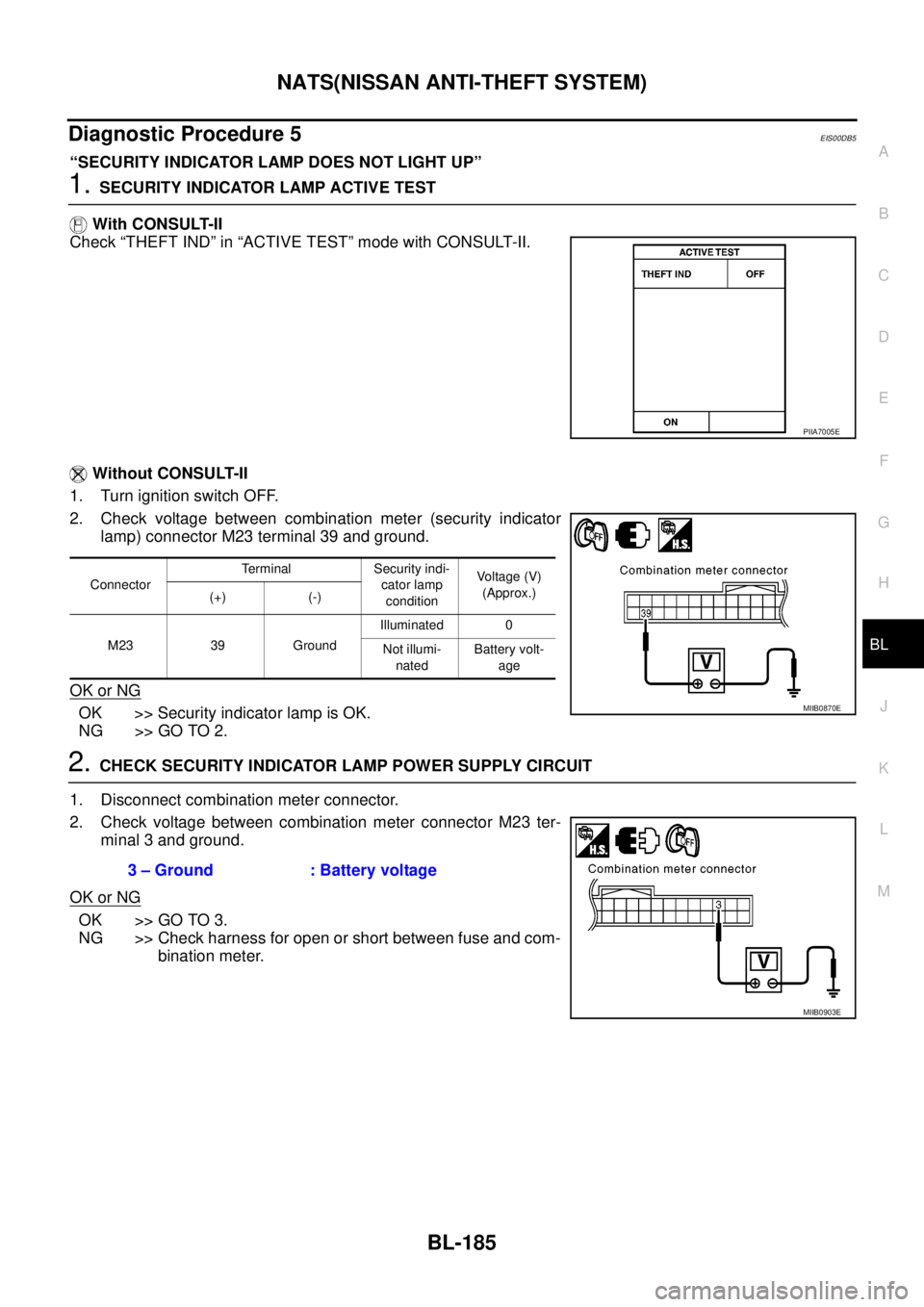

Diagnostic Procedure 5EIS00DB5

“SECURITY INDICATOR LAMP DOES NOT LIGHT UP”

1.SECURITY INDICATOR LAMP ACTIVE TEST

With CONSULT-II

Check “THEFT IND” in “ACTIVE TEST” mode with CONSULT-II.

Without CONSULT-II

1. Turn ignition switch OFF.

2. Check voltage between combination meter (security indicator

lamp) connector M23 terminal 39 and ground.

OK or NG

OK >> Security indicator lamp is OK.

NG >> GO TO 2.

2.CHECK SECURITY INDICATOR LAMP POWER SUPPLY CIRCUIT

1. Disconnect combination meter connector.

2. Check voltage between combination meter connector M23 ter-

minal 3 and ground.

OK or NG

OK >> GO TO 3.

NG >> Check harness for open or short between fuse and com-

bination meter.

PIIA7005E

ConnectorTerminal Security indi-

cator lamp

conditionVoltage (V)

(Approx.)

(+) (-)

M23 39 GroundIlluminated 0

Not illumi-

natedBattery volt-

age

MIIB0870E

3 – Ground : Battery voltage

MIIB0903E

Page 827 of 3171

![NISSAN NAVARA 2005 Repair Owners Guide SYSTEM DESCRIPTION

BRC-5

[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

SYSTEM DESCRIPTIONPFP:00000

System DiagramEFS005TJ

FunctionsEFS005TK

ABS

lThe Anti-Lock Brake System is a function that detects wheel revoluti NISSAN NAVARA 2005 Repair Owners Guide SYSTEM DESCRIPTION

BRC-5

[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

SYSTEM DESCRIPTIONPFP:00000

System DiagramEFS005TJ

FunctionsEFS005TK

ABS

lThe Anti-Lock Brake System is a function that detects wheel revoluti](/img/5/57362/w960_57362-826.png)

SYSTEM DESCRIPTION

BRC-5

[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

SYSTEM DESCRIPTIONPFP:00000

System DiagramEFS005TJ

FunctionsEFS005TK

ABS

lThe Anti-Lock Brake System is a function that detects wheel revolution while braking, and it improves

handling stability during sudden braking by electrically preventing 4 wheels lock. Maneuverability is also

improved for avoiding obstacles.

lElectrical system diagnosis by CONSULT-II is available.

EBD

lElectronic Brake Distributor is a function that detects subtle slippages between the front and rear tyre dur-

ing braking, and it improves handling stability by electrically controlling the brake fluid pressure which

results in reduced rear tyre slippage.

lElectrical system diagnosis by CONSULT-II is available.

Operation That Is Not “System Error”EFS005TL

ABS

lWhen starting engine or just after starting vehicle, brake pedal may vibrate or the motor operating noise

may be heard from engine room. This is a normal states of the operation check.

lDuring ABS operation, brake pedal lightly vibrates and a mechanical noise may be heard. This is normal.

lStopping distance may be longer than that of vehicles without ABS when vehicle drives on rough, gravel,

or snow-covered (fresh, deep snow) roads.

Fail-Safe FunctionEFS005TM

ABS, EBD SYSTEM

In case of electrical malfunction with ABS, ABS warning lamp will turn on. In case of electrical incidents with

EBD, brake warning lamp and ABS warning lamp will turn on. Simultaneously, ABS become one of following

conditions of Fail-Safe function.

1. For ABS malfunction, only EBD is activated and condition of vehicle is same condition of vehicles without

ABS system.

NOTE:

ABS self-diagnosis sound may be heard.That is a normal condition because a self-diagnosis for “Ignition

switch ON” and “The first starting” are being performed.

2. For EBD malfunction, EBD and ABS become inoperative, and condition of vehicle is same as condition of

vehicles without ABS, EBD system.

SFIA3001E

Page 845 of 3171

![NISSAN NAVARA 2005 Repair Owners Guide TROUBLE DIAGNOSIS

BRC-23

[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

For Fast and Accurate DiagnosisEFS005TX

PRECAUTIONS FOR DIAGNOSIS

lBefore performing diagnosis, always read precautions. Refer toBRC-17, "CONS NISSAN NAVARA 2005 Repair Owners Guide TROUBLE DIAGNOSIS

BRC-23

[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

For Fast and Accurate DiagnosisEFS005TX

PRECAUTIONS FOR DIAGNOSIS

lBefore performing diagnosis, always read precautions. Refer toBRC-17, "CONS](/img/5/57362/w960_57362-844.png)

TROUBLE DIAGNOSIS

BRC-23

[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

For Fast and Accurate DiagnosisEFS005TX

PRECAUTIONS FOR DIAGNOSIS

lBefore performing diagnosis, always read precautions. Refer toBRC-17, "CONSULT- II Functions".

lAfter diagnosis is finished, be sure to erase memory. Refer toBRC-18, "ERASE MEMORY".

lWhen checking continuity and voltage between units, be sure to check for disconnection, looseness,

bend, or collapse of connector terminals. If any malfunction is found, repair or replace connector termi-

nals.

lFor intermittent symptoms, possible cause is malfunction in harness, harness connector, or terminals.

Move harness, harness connector, and terminals to check for poor connections.

lIf a circuit tester is used for check, be careful not to forcibly extend any connector terminal.

lABS system electrically controls brake operation and engine output. Following symptoms may be caused

by normal operations:

Basic InspectionEFS005TY

BASIC INSPECTION 1 BRAKE FLUID LEVEL, LEAKS, AND BRAKE PADS

1. Check fluid level in the brake reservoir tank. If fluid level is low, refill brake fluid.

2. Check brake tube and around ABS actuator and electric unit (control unit) for leaks. If leakage or seepage

is found, check the following items.

lIf ABS actuator and electric unit (control unit) connection is loose, tighten brake tube to the specified

torque and re-conduct the leak inspection to make sure there are no leakage.

lIf there is damage to the connection flare nut or ABS actuator and electric unit (control unit) screw,

replace the damaged part and re-conduct the leak inspection to make sure there are no leakage.

lIf there is leakage or seepage at any location other than ABS actuator and electric unit (control unit)

connection, wipe away leakage or seepage with clean cloth. Then inspect again and confirm than there

is on leakage.

lIf there is leakage from ABS actuator and electric unit (control unit), wipe away leakage or seepage with

clean cloth. Then inspect again. If there is leakage or seepage, replace ABS actuator and electric unit

(control unit).

CAUTION:

ABS actuator and electric unit (control unit) body cannot be disassembled.

3. Check brake pad degree of wear. Refer toBR-24, "

PAD WEAR INSPECTION"in “Front Disc Brake” and

BR-32, "

Lining Thickness Inspection"in “Rear Drum Brake”.

BASIC INSPECTION 2 POWER SYSTEM TERMINAL LOOSENESS AND BATTERY INSPECTION

Make sure battery positive cable, negative cable and ground connection are not loose. In addition, check the

battery voltage to make sure it has not dropped and alternator is normal.

Symptom Symptom description Result

Motor operation noiseThis is noise of motor inside ABS actuator and electric unit (control unit). Slight

noise may occur during ABS operation.

Normal

Just after engine starts, motor operating noise may be heard. This is a normal

status of the system operation check.

System operation check noiseWhen engine starts, slight “click” noise may be heard from engine compart-

ment. This is normal and is part of system operation check.Normal

ABS operation

(Longer stopping distance)When driving on roads with a low coefficient of friction, such as snowy roads

or gravel roads, the stopping distance is sometimes longer for vehicles

equipped with ABS. Therefore, when driving on such roads, drive at a suffi-

ciently reduced speed to be safe.Normal

Page 857 of 3171

![NISSAN NAVARA 2005 Repair Owners Guide TROUBLE DIAGNOSIS

BRC-35

[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Symptom 4: ABS Function Does Not OperateEFS005UB

CAUTION:

ABS does not operate when speed is 10 km/h (6 MPH) or lower.

1.CHECK ABS WARNING LAM NISSAN NAVARA 2005 Repair Owners Guide TROUBLE DIAGNOSIS

BRC-35

[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Symptom 4: ABS Function Does Not OperateEFS005UB

CAUTION:

ABS does not operate when speed is 10 km/h (6 MPH) or lower.

1.CHECK ABS WARNING LAM](/img/5/57362/w960_57362-856.png)

TROUBLE DIAGNOSIS

BRC-35

[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Symptom 4: ABS Function Does Not OperateEFS005UB

CAUTION:

ABS does not operate when speed is 10 km/h (6 MPH) or lower.

1.CHECK ABS WARNING LAMP DISPLAY

Make sure that the ABS warning lamp is turned off after the ignition switch is turned ON or when driving.

OK or NG

OK >> GO TO procedure 3 “CHECK WHEEL SENSOR AND SENSOR ROTOR” of symptom1. Refer to

BRC-33, "

Symptom 1: Excessive ABS Function Operation Frequency".

NG >> Perform self-diagnosis. Refer toBRC-18, "

Self-Diagnosis".

Symptom 5: Pedal Vibration or ABS Operation Sound OccursEFS005UC

CAUTION:

Under the following conditions, ABS is activated and vibration is felt when brake pedal is lightly

depressed (just place a foot on it). However, this is normal.

lWhen shifting gears

lWhen driving on slippery road

lDuring cornering at high speed

lWhen passing over bumps or grooves [at approximately 50 mm (1.97 in) or more]

lWhen pulling away just after starting engine [at approximately 10 km/h (6 MPH) or more]

1.SYMPTOM CHECK 1

Check if there is pedal vibration or operation noise when the engine is started.

Do symptoms occur?

YES >> GO TO 2.

NO >> Perform self-diagnosis. Refer toBRC-18, "

Self-Diagnosis".

2.SYMPTOM CHECK 2

Check symptoms when electrical component (headlamps, etc.) switches are operated.

Do symptoms occur?

YES >> Check if there is a radio, antenna, antenna lead wire, or wiring close to the control unit. If there is,

move it farther away.

NO >> GO TO procedure 3²CHECK WHEEL SENSOR AND SENSOR ROTOR²of symptom 1. Refer to

BRC-33, "

Symptom 1: Excessive ABS Function Operation Frequency".

Symptom 6: ABS Warning Lamp Indication Is Not NormalEFS005UD

NOTE:

Lighting condition of ABS warning lamp refer toBRC-24, "

BASIC INSPECTION 3 ABS WARNING LAMP AND

BRAKE WARNING LAMP INSPECTION".

1.CHECK COMBINATION METER INDICATION

Check the combination meter indication and operation. Refer toDI-13, "

Self-Diagnosis Mode of Combination

Meter".

OK or NG

OK >> GO TO 2.

NG >> Combination meter is malfunctioning. Check combination meter. Refer toDI-4, "

COMBINATION

METERS".

Page 886 of 3171

CO-2

PRECAUTIONS

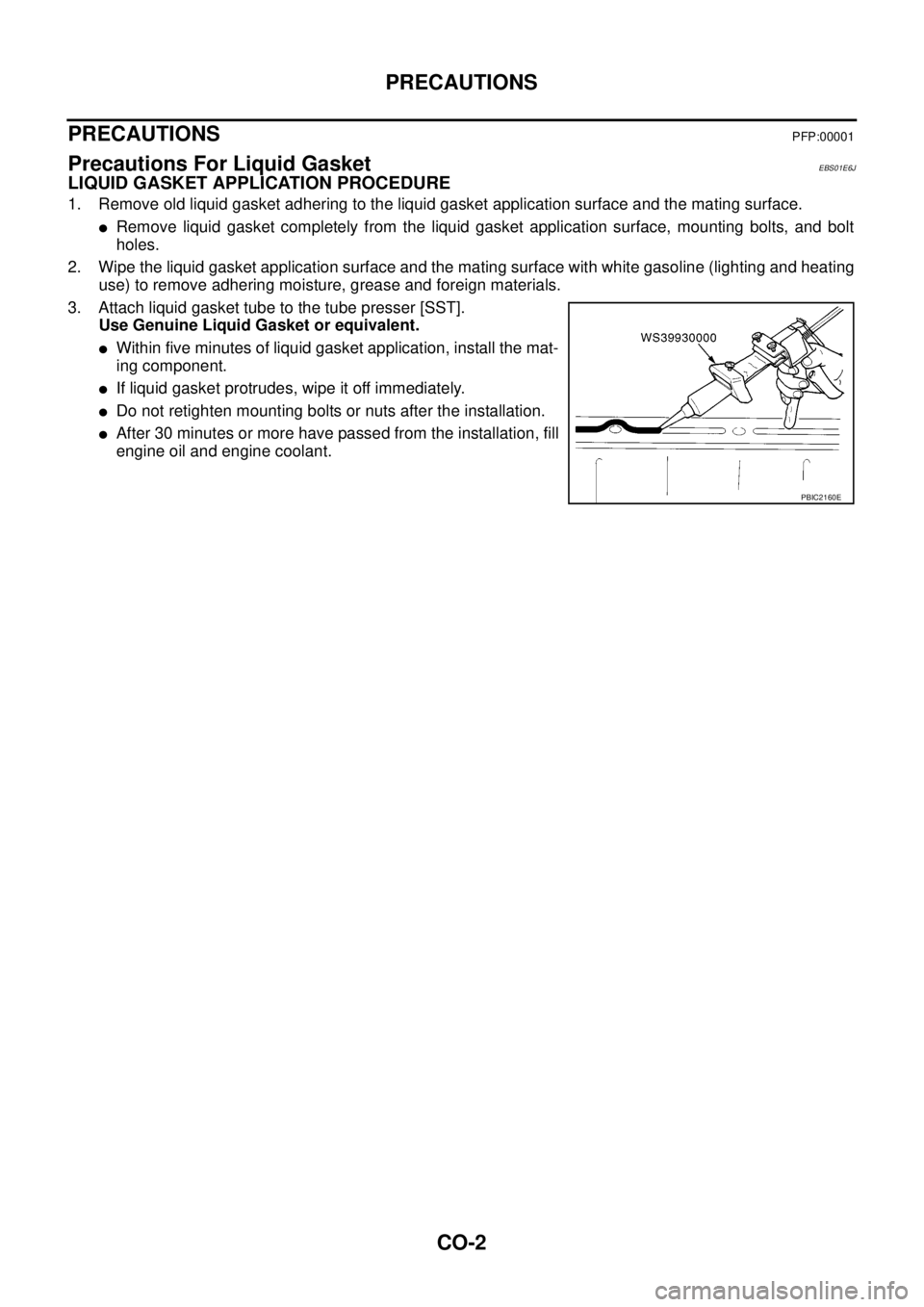

PRECAUTIONS

PFP:00001

Precautions For Liquid GasketEBS01E6J

LIQUID GASKET APPLICATION PROCEDURE

1. Remove old liquid gasket adhering to the liquid gasket application surface and the mating surface.

lRemove liquid gasket completely from the liquid gasket application surface, mounting bolts, and bolt

holes.

2. Wipe the liquid gasket application surface and the mating surface with white gasoline (lighting and heating

use) to remove adhering moisture, grease and foreign materials.

3. Attach liquid gasket tube to the tube presser [SST].

Use Genuine Liquid Gasket or equivalent.

lWithin five minutes of liquid gasket application, install the mat-

ing component.

lIf liquid gasket protrudes, wipe it off immediately.

lDo not retighten mounting bolts or nuts after the installation.

lAfter 30 minutes or more have passed from the installation, fill

engine oil and engine coolant.

PBIC2160E