low beam NISSAN NAVARA 2005 Repair User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2111 of 3171

LT-28

HEADLAMP -CONVENTIONAL TYPE-

Aiming Adjustment

EKS00P7Y

For details, refer to the regulations in your state.

Before performing aiming adjustment, check the following.

1. Ensure all tires are inflated to correct pressure.

2. Place vehicle and screen on level surface.

3. Ensure there is no load in vehicle other than the driver (or equivalent weight placed in driver's position).

Coolant and engine oil filled to correct level, and fuel tank full.

4. Confirm spare tire, jack and tools are properly stowed.

LOW BEAM AND HIGH BEAM

NOTE:

Aim each headlamp individually and ensure other headlamp beam pattern is blocked from screen.

1. Turn headlamp low beam ON.

2. Use adjusting screws to perform aiming adjustment.

lFirst tighten the adjusting screw all the way and then make adjustment by loosening the screw.

If the vehicle front body has been repaired and/or the headlamp assembly has been replaced, check

aiming. Use the aiming chart shown in the figure.

PKIC1216E

Page 2112 of 3171

HEADLAMP -CONVENTIONAL TYPE-

LT-29

C

D

E

F

G

H

I

J

L

MA

B

LT

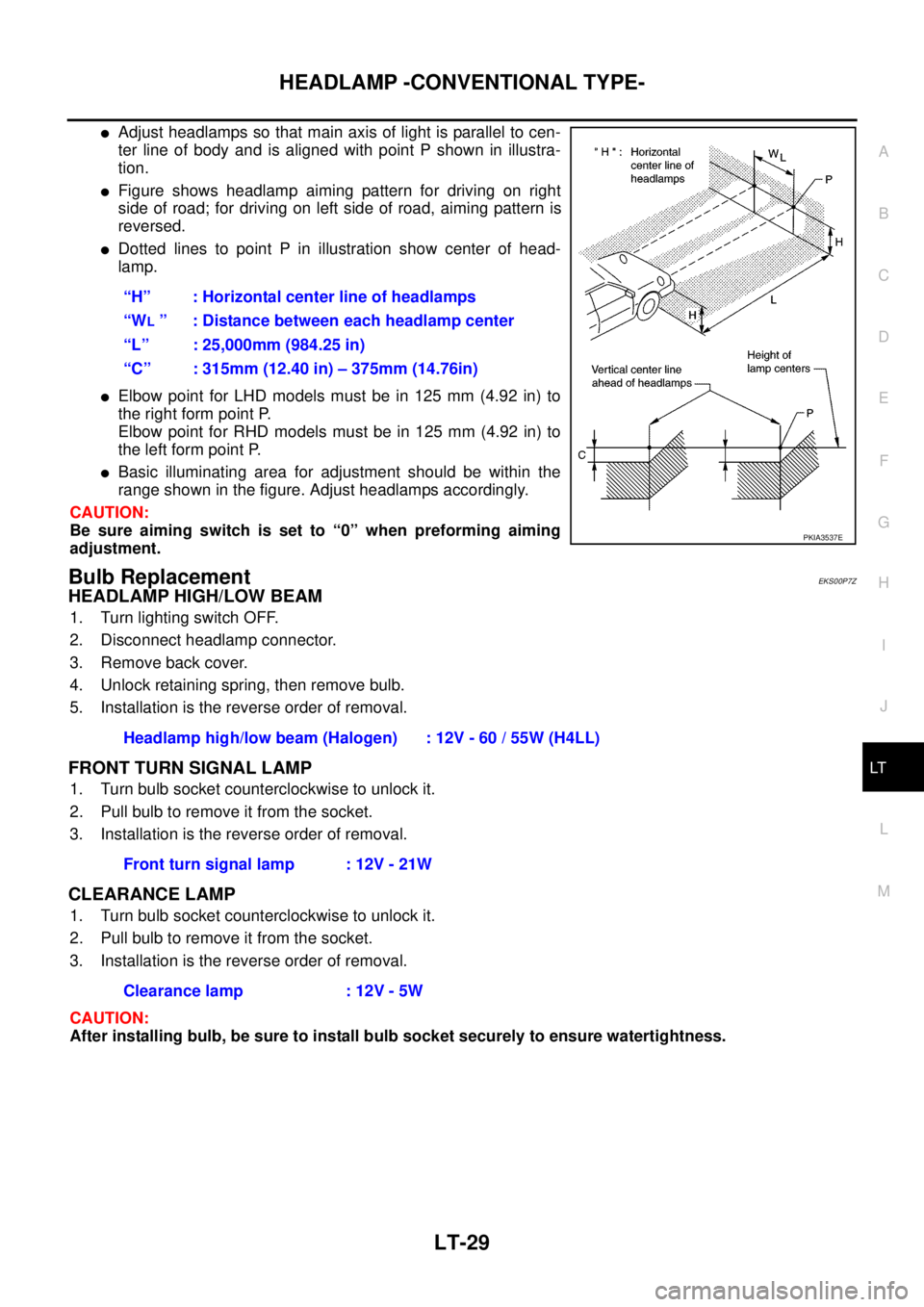

lAdjust headlamps so that main axis of light is parallel to cen-

ter line of body and is aligned with point P shown in illustra-

tion.

lFigure shows headlamp aiming pattern for driving on right

side of road; for driving on left side of road, aiming pattern is

reversed.

lDotted lines to point P in illustration show center of head-

lamp.

lElbow point for LHD models must be in 125 mm (4.92 in) to

the right form point P.

Elbow point for RHD models must be in 125 mm (4.92 in) to

the left form point P.

lBasic illuminating area for adjustment should be within the

range shown in the figure. Adjust headlamps accordingly.

CAUTION:

Be sure aiming switch is set to “0” when preforming aiming

adjustment.

Bulb ReplacementEKS00P7Z

HEADLAMP HIGH/LOW BEAM

1. Turn lighting switch OFF.

2. Disconnect headlamp connector.

3. Remove back cover.

4. Unlock retaining spring, then remove bulb.

5. Installation is the reverse order of removal.

FRONT TURN SIGNAL LAMP

1. Turn bulb socket counterclockwise to unlock it.

2. Pull bulb to remove it from the socket.

3. Installation is the reverse order of removal.

CLEARANCE LAMP

1. Turn bulb socket counterclockwise to unlock it.

2. Pull bulb to remove it from the socket.

3. Installation is the reverse order of removal.

CAUTION:

After installing bulb, be sure to install bulb socket securely to ensure watertightness.“H” : Horizontal center line of headlamps

“W

L” : Distance between each headlamp center

“L” : 25,000mm (984.25 in)

“C” : 315mm (12.40 in) – 375mm (14.76in)

PKIA3537E

Headlamp high/low beam (Halogen) : 12V - 60 / 55W (H4LL)

Front turn signal lamp : 12V - 21W

Clearance lamp : 12V - 5W

Page 2114 of 3171

HEADLAMP - DAYTIME LIGHT SYSTEM -

LT-31

C

D

E

F

G

H

I

J

L

MA

B

LT

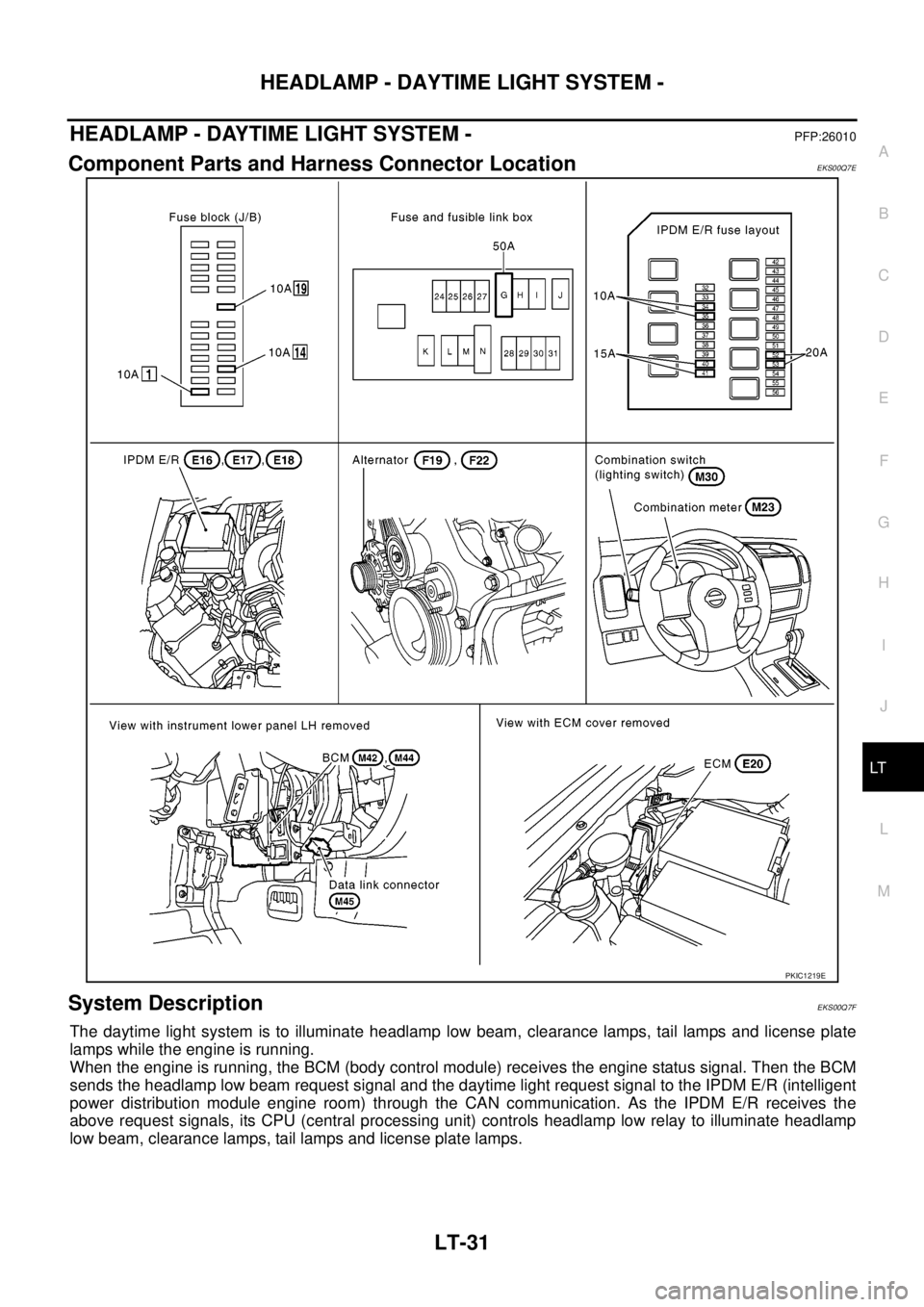

HEADLAMP - DAYTIME LIGHT SYSTEM -PFP:26010

Component Parts and Harness Connector LocationEKS00Q7E

System DescriptionEKS00Q7F

The daytime light system is to illuminate headlamp low beam, clearance lamps, tail lamps and license plate

lamps while the engine is running.

When the engine is running, the BCM (body control module) receives the engine status signal. Then the BCM

sends the headlamp low beam request signal and the daytime light request signal to the IPDM E/R (intelligent

power distribution module engine room) through the CAN communication. As the IPDM E/R receives the

above request signals, its CPU (central processing unit) controls headlamp low relay to illuminate headlamp

low beam, clearance lamps, tail lamps and license plate lamps.

PKIC1219E

Page 2115 of 3171

LT-32

HEADLAMP - DAYTIME LIGHT SYSTEM -

OUTLINE

Power is supplied at all times

lto ignition relay (located in IPDM E/R)

lto headlamp high relay (located in IPDM E/R) and

lto headlamp low relay (located in IPDM E/R), from battery directly,

lthrough 50A fusible link (letter G, located in fuse and fusible link box)

lto BCM terminal 57,

lthrough 20A fuse (No. 52, located in IPDM E/R) and

lthrough 20A fuse (No. 53, located in IPDM E/R)

lto CPU (located in IPDM E/R),

lthrough 10A fuse [No. 19, located in fuse block (J/B)]

lto combination meter terminal 3.

With the ignition switch in the ON or START position, power is supplied

lto ignition relay (located in IPDM E/R),

lthrough 10A fuse [No. 1, located in fuse block (J/B)]

lto BCM terminal 3,

lthrough 10A fuse [No. 14, located in fuse block (J/B)]

lto combination meter terminal 16.

Ground is supplied at all times

lto BCM terminal 55 and

lto combination meter terminal 23

lthrough grounds M21, M80 and M83,

lto IPDM E/R terminals 38 and 59

lthrough grounds E21, E41 and E61.

DAYTIME LIGHT OPERATION

With the lighting switch in the OFF position and engine running, the BCM receives input signal requesting

headlamp low beam, clearance lamp, license plate lamp, and tail lamp to illuminate. This input signal is com-

municated to the IPDM E/R through the CAN communication. The CPU located in the IPDM E/R controls

headlamp low relay.

lthrough 15A fuse (No. 41, located in IPDM E/R)

lthrough IPDM E/R terminal 54

lto front combination lamp RH terminal 1,

lthrough 15A fuse (No. 40, located in IPDM E/R)

lthrough IPDM E/R terminal 52

lto front combination lamp LH terminal 1.

Ground is supplied at all times

lto front combination lamp RH and LH terminals 3

lthrough grounds E21, E41 and E61.

With power and ground supplied, the headlamp low beam, clearance, license plate and tail lamps illuminate.

Page 2129 of 3171

LT-46

HEADLAMP - DAYTIME LIGHT SYSTEM -

4. Select the desired part to be diagnosed on “SELECT DIAG

MODE” screen.

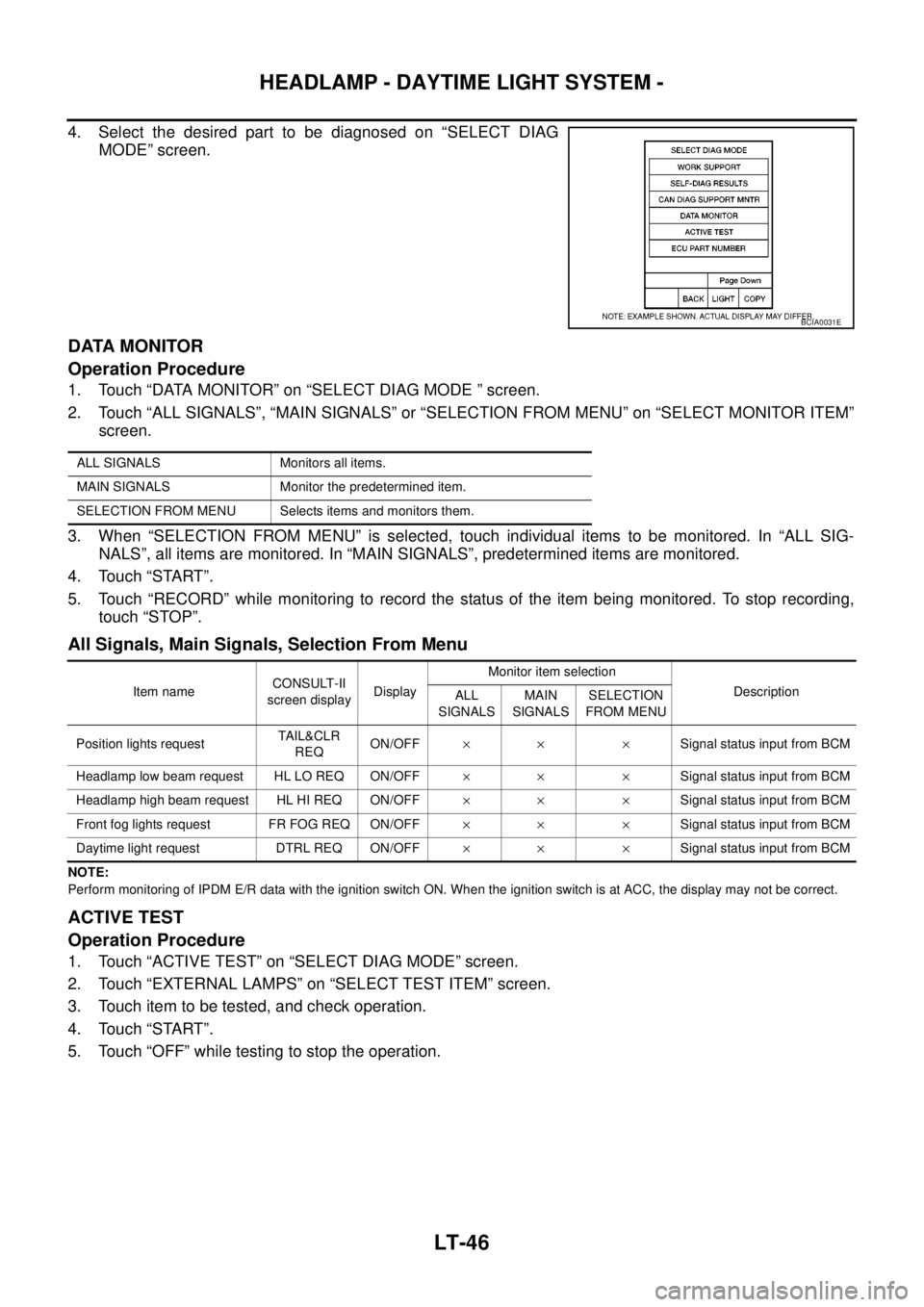

DATA MONITOR

Operation Procedure

1. Touch “DATA MONITOR” on “SELECT DIAG MODE ” screen.

2. Touch “ALL SIGNALS”, “MAIN SIGNALS” or “SELECTION FROM MENU” on “SELECT MONITOR ITEM”

screen.

3. When “SELECTION FROM MENU” is selected, touch individual items to be monitored. In “ALL SIG-

NALS”, all items are monitored. In “MAIN SIGNALS”, predetermined items are monitored.

4. Touch “START”.

5. Touch “RECORD” while monitoring to record the status of the item being monitored. To stop recording,

touch “STOP”.

All Signals, Main Signals, Selection From Menu

NOTE:

Perform monitoring of IPDM E/R data with the ignition switch ON. When the ignition switch is at ACC, the display may not be correct.

ACTIVE TEST

Operation Procedure

1. Touch “ACTIVE TEST” on “SELECT DIAG MODE” screen.

2. Touch “EXTERNAL LAMPS” on “SELECT TEST ITEM” screen.

3. Touch item to be tested, and check operation.

4. Touch “START”.

5. Touch “OFF” while testing to stop the operation.

BCIA0031E

ALL SIGNALS Monitors all items.

MAIN SIGNALS Monitor the predetermined item.

SELECTION FROM MENU Selects items and monitors them.

Item nameCONSULT-II

screen displayDisplayMonitor item selection

Description

ALL

SIGNALSMAIN

SIGNALSSELECTION

FROM MENU

Position lights requestTA I L & C L R

REQON/OFF´´ ´Signal status input from BCM

Headlamp low beam request HL LO REQ ON/OFF´´ ´Signal status input from BCM

Headlamp high beam request HL HI REQ ON/OFF´´ ´Signal status input from BCM

Front fog lights request FR FOG REQ ON/OFF´´ ´Signal status input from BCM

Daytime light request DTRL REQ ON/OFF´´ ´Signal status input from BCM

Page 2130 of 3171

HEADLAMP - DAYTIME LIGHT SYSTEM -

LT-47

C

D

E

F

G

H

I

J

L

MA

B

LT

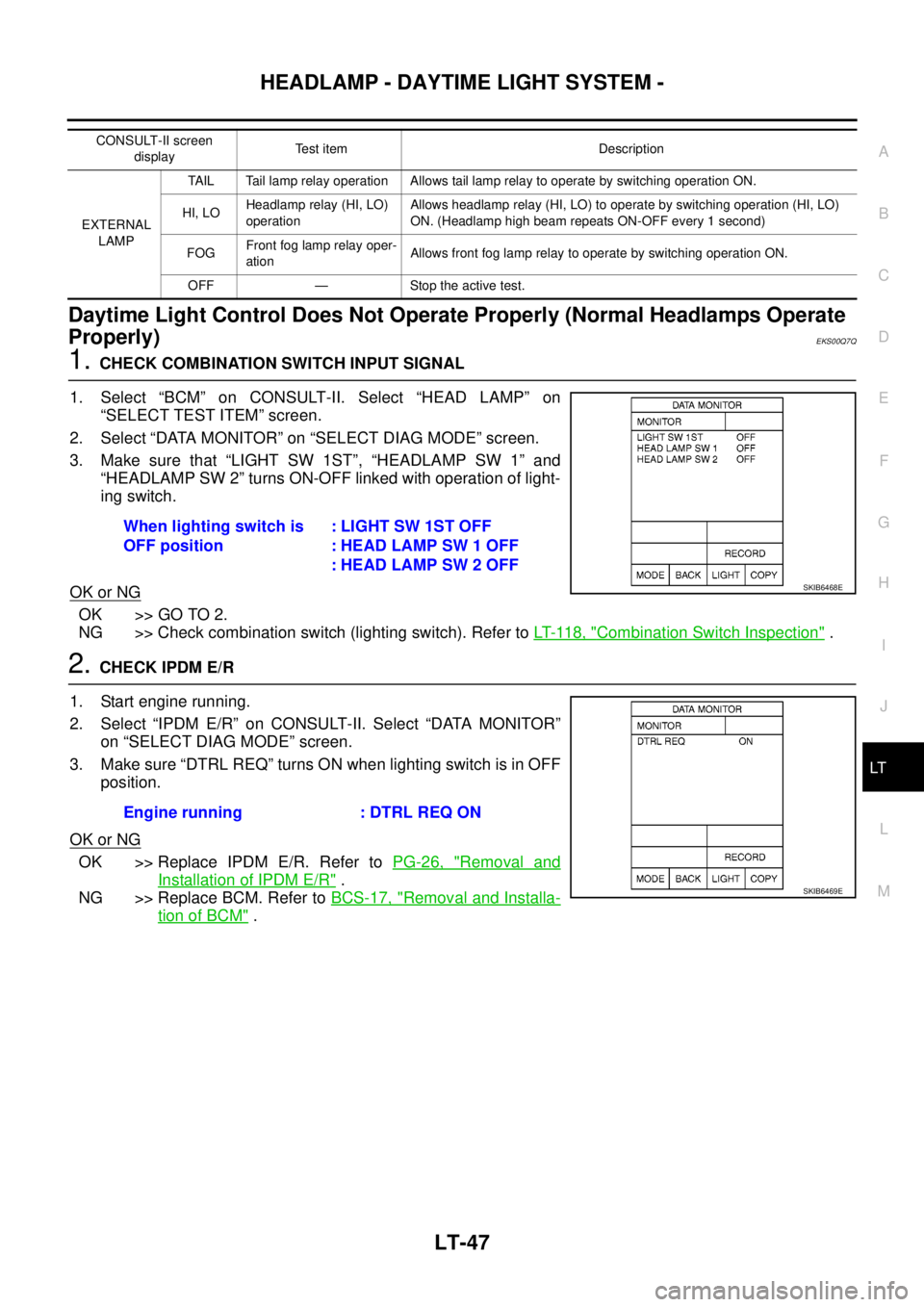

Daytime Light Control Does Not Operate Properly (Normal Headlamps Operate

Properly)

EKS00Q7Q

1.CHECK COMBINATION SWITCH INPUT SIGNAL

1. Select “BCM” on CONSULT-II. Select “HEAD LAMP” on

“SELECT TEST ITEM” screen.

2. Select “DATA MONITOR” on “SELECT DIAG MODE” screen.

3. Make sure that “LIGHT SW 1ST”, “HEADLAMP SW 1” and

“HEADLAMP SW 2” turns ON-OFF linked with operation of light-

ing switch.

OK or NG

OK >> GO TO 2.

NG >> Check combination switch (lighting switch). Refer toLT- 11 8 , "

Combination Switch Inspection".

2.CHECK IPDM E/R

1. Start engine running.

2. Select “IPDM E/R” on CONSULT-II. Select “DATA MONITOR”

on “SELECT DIAG MODE” screen.

3. Make sure “DTRL REQ” turns ON when lighting switch is in OFF

position.

OK or NG

OK >> Replace IPDM E/R. Refer toPG-26, "Removal and

Installation of IPDM E/R".

NG >> Replace BCM. Refer toBCS-17, "

Removal and Installa-

tion of BCM".

CONSULT-II screen

displayTest item Description

EXTERNAL

LAMPTAIL Tail lamp relay operation Allows tail lamp relay to operate by switching operation ON.

HI, LOHeadlamp relay (HI, LO)

operationAllows headlamp relay (HI, LO) to operate by switching operation (HI, LO)

ON. (Headlamp high beam repeats ON-OFF every 1 second)

FOGFront fog lamp relay oper-

ationAllows front fog lamp relay to operate by switching operation ON.

OFF — Stoptheactivetest.

When lighting switch is

OFF position:LIGHTSW1STOFF

: HEAD LAMP SW 1 OFF

: HEAD LAMP SW 2 OFF

SKIB6468E

Engine running : DTRL REQ ON

SKIB6469E

Page 2144 of 3171

AUTO LIGHT SYSTEM

LT-61

C

D

E

F

G

H

I

J

L

MA

B

LT

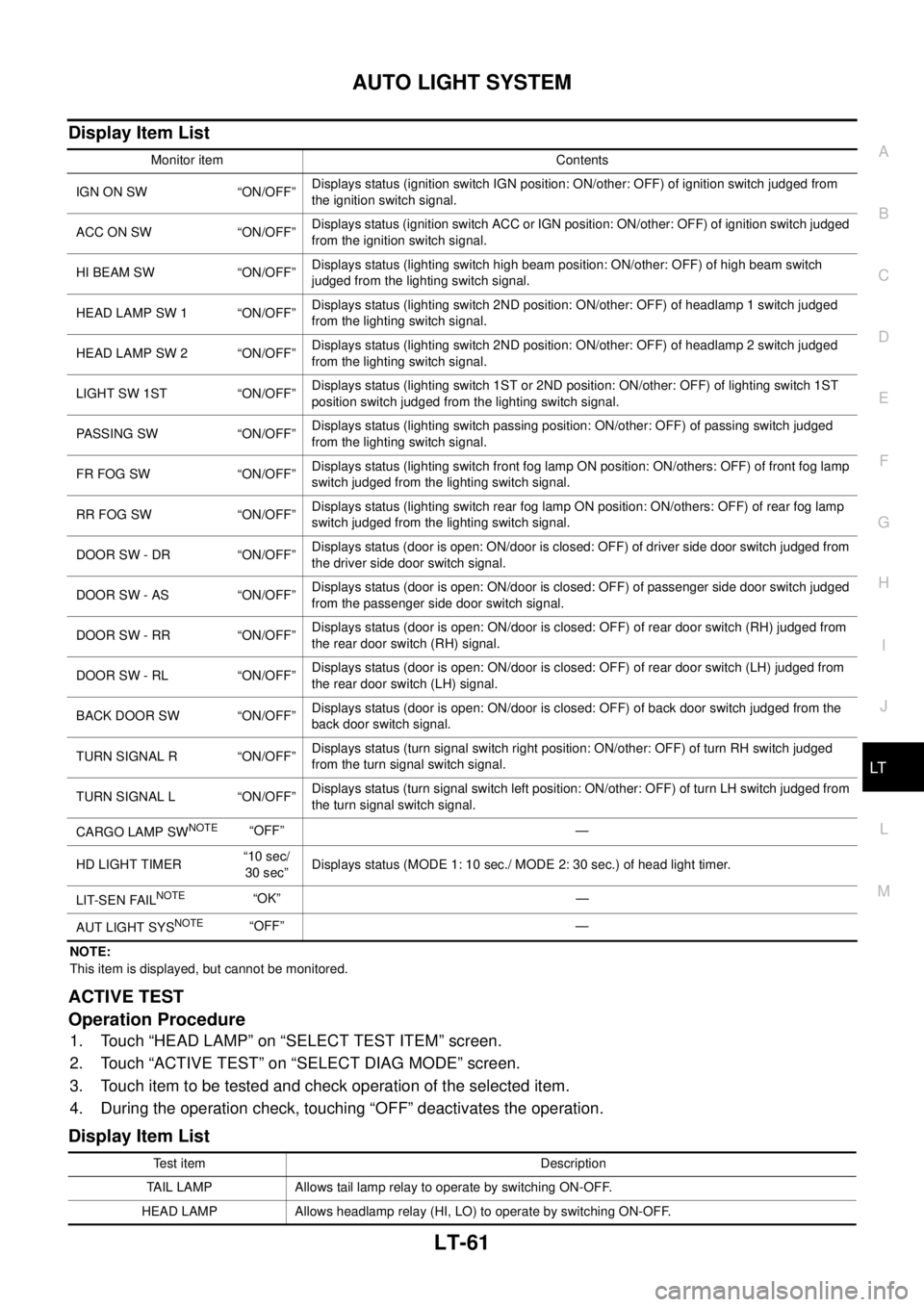

Display Item List

NOTE:

This item is displayed, but cannot be monitored.

ACTIVE TEST

Operation Procedure

1. Touch “HEAD LAMP” on “SELECT TEST ITEM” screen.

2. Touch “ACTIVE TEST” on “SELECT DIAG MODE” screen.

3. Touch item to be tested and check operation of the selected item.

4. During the operation check, touching “OFF” deactivates the operation.

Display Item List

Monitor item Contents

IGN ON SW “ON/OFF”Displays status (ignition switch IGN position: ON/other: OFF) of ignition switch judged from

the ignition switch signal.

ACC ON SW “ON/OFF”Displays status (ignition switch ACC or IGN position: ON/other: OFF) of ignition switch judged

from the ignition switch signal.

HI BEAM SW “ON/OFF”Displays status (lighting switch high beam position: ON/other: OFF) of high beam switch

judged from the lighting switch signal.

HEAD LAMP SW 1 “ON/OFF”Displays status (lighting switch 2ND position: ON/other: OFF) of headlamp 1 switch judged

from the lighting switch signal.

HEAD LAMP SW 2 “ON/OFF”Displays status (lighting switch 2ND position: ON/other: OFF) of headlamp 2 switch judged

from the lighting switch signal.

LIGHT SW 1ST “ON/OFF”Displays status (lighting switch 1ST or 2ND position: ON/other: OFF) of lighting switch 1ST

position switch judged from the lighting switch signal.

PASSING SW “ON/OFF”Displays status (lighting switch passing position: ON/other: OFF) of passing switch judged

from the lighting switch signal.

FR FOG SW “ON/OFF”Displays status (lighting switch front fog lamp ON position: ON/others: OFF) of front fog lamp

switch judged from the lighting switch signal.

RR FOG SW “ON/OFF”Displays status (lighting switch rear fog lamp ON position: ON/others: OFF) of rear fog lamp

switch judged from the lighting switch signal.

DOOR SW - DR “ON/OFF”Displays status (door is open: ON/door is closed: OFF) of driver side door switch judged from

the driver side door switch signal.

DOOR SW - AS “ON/OFF”Displays status (door is open: ON/door is closed: OFF) of passenger side door switch judged

from the passenger side door switch signal.

DOOR SW - RR “ON/OFF”Displays status (door is open: ON/door is closed: OFF) of rear door switch (RH) judged from

the rear door switch (RH) signal.

DOOR SW - RL “ON/OFF”Displays status (door is open: ON/door is closed: OFF) of rear door switch (LH) judged from

the rear door switch (LH) signal.

BACK DOOR SW “ON/OFF”Displays status (door is open: ON/door is closed: OFF) of back door switch judged from the

back door switch signal.

TURN SIGNAL R “ON/OFF”Displays status (turn signal switch right position: ON/other: OFF) of turn RH switch judged

from the turn signal switch signal.

TURN SIGNAL L “ON/OFF”Displays status (turn signal switch left position: ON/other: OFF) of turn LH switch judged from

the turn signal switch signal.

CARGO LAMP SW

NOTE“OFF” —

HD LIGHT TIMER“10 sec/

30 sec”Displays status (MODE 1: 10 sec./ MODE 2: 30 sec.) of head light timer.

LIT-SEN FAIL

NOTE“OK” —

AUT LIGHT SYS

NOTE“OFF” —

Test item Description

TAIL LAMP Allows tail lamp relay to operate by switching ON-OFF.

HEAD LAMP Allows headlamp relay (HI, LO) to operate by switching ON-OFF.

Page 2154 of 3171

FRONT FOG LAMP

LT-71

C

D

E

F

G

H

I

J

L

MA

B

LT

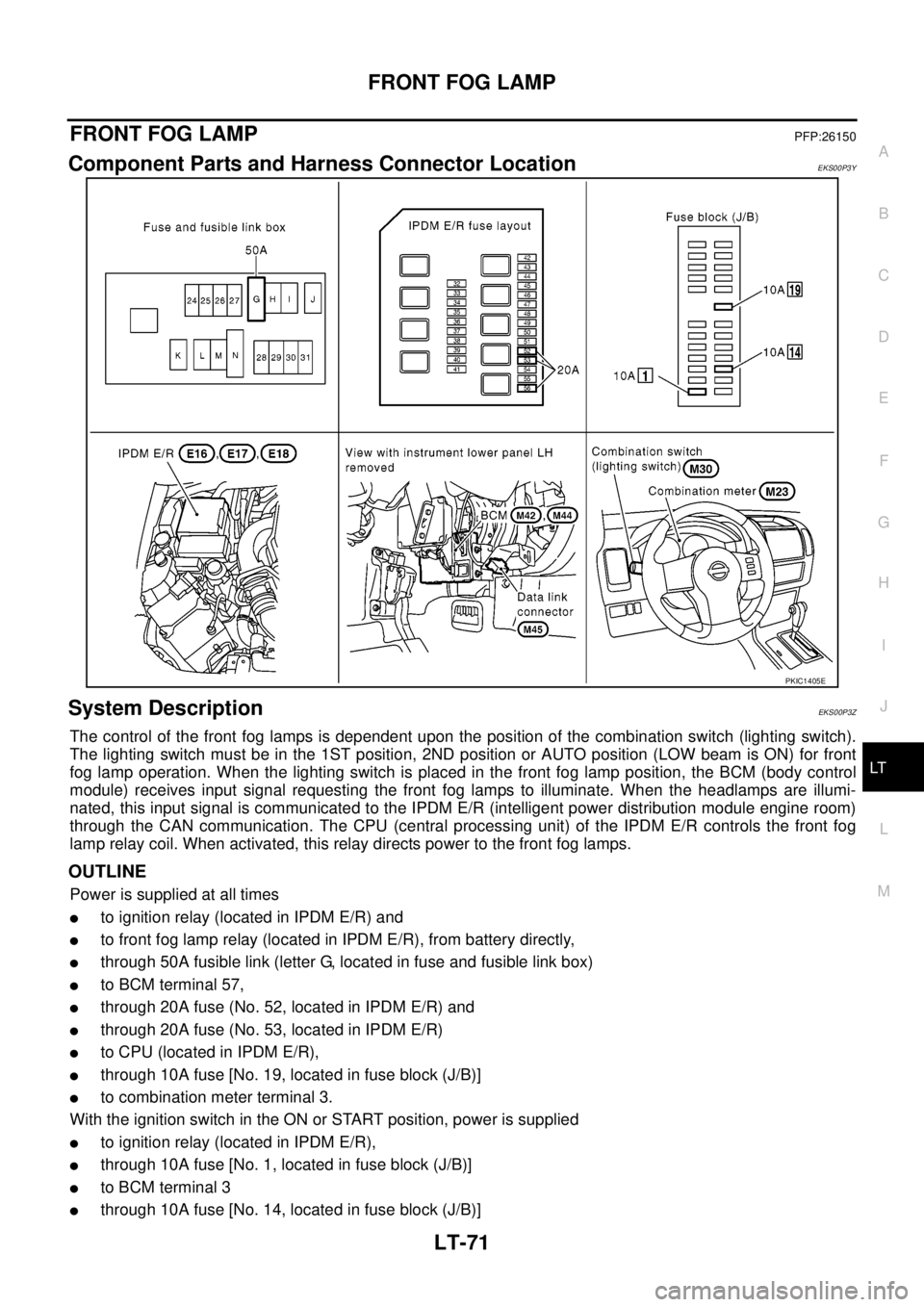

FRONT FOG LAMPPFP:26150

Component Parts and Harness Connector LocationEKS00P3Y

System DescriptionEKS00P3Z

The control of the front fog lamps is dependent upon the position of the combination switch (lighting switch).

The lighting switch must be in the 1ST position, 2ND position or AUTO position (LOW beam is ON) for front

fog lamp operation. When the lighting switch is placed in the front fog lamp position, the BCM (body control

module) receives input signal requesting the front fog lamps to illuminate. When the headlamps are illumi-

nated, this input signal is communicated to the IPDM E/R (intelligent power distribution module engine room)

through the CAN communication. The CPU (central processing unit) of the IPDM E/R controls the front fog

lamp relay coil. When activated, this relay directs power to the front fog lamps.

OUTLINE

Power is supplied at all times

lto ignition relay (located in IPDM E/R) and

lto front fog lamp relay (located in IPDM E/R), from battery directly,

lthrough 50A fusible link (letter G, located in fuse and fusible link box)

lto BCM terminal 57,

lthrough 20A fuse (No. 52, located in IPDM E/R) and

lthrough 20A fuse (No. 53, located in IPDM E/R)

lto CPU (located in IPDM E/R),

lthrough 10A fuse [No. 19, located in fuse block (J/B)]

lto combination meter terminal 3.

With the ignition switch in the ON or START position, power is supplied

lto ignition relay (located in IPDM E/R),

lthrough 10A fuse [No. 1, located in fuse block (J/B)]

lto BCM terminal 3

lthrough 10A fuse [No. 14, located in fuse block (J/B)]

PKIC1405E

Page 2155 of 3171

LT-72

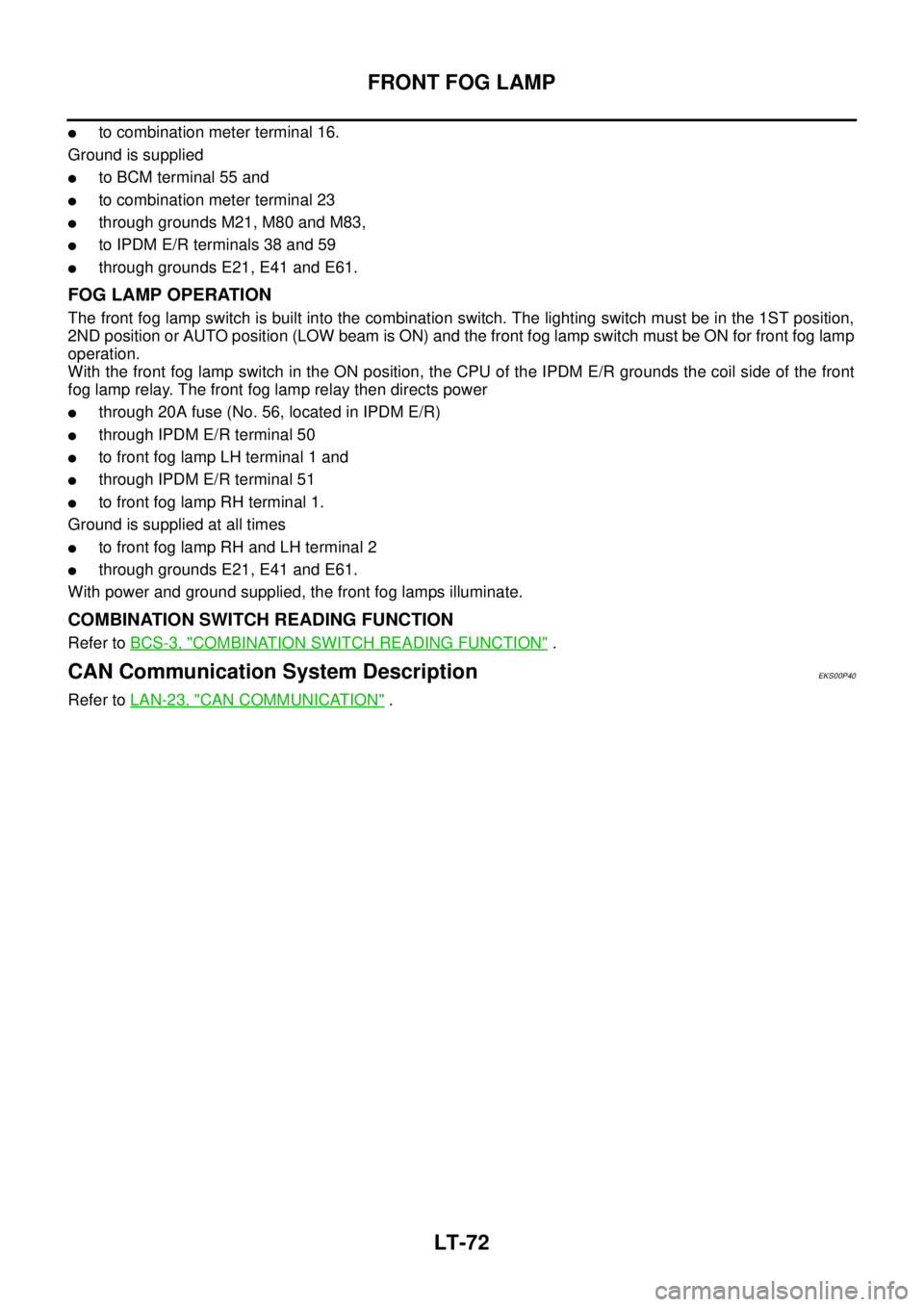

FRONT FOG LAMP

lto combination meter terminal 16.

Ground is supplied

lto BCM terminal 55 and

lto combination meter terminal 23

lthrough grounds M21, M80 and M83,

lto IPDM E/R terminals 38 and 59

lthrough grounds E21, E41 and E61.

FOG LAMP OPERATION

The front fog lamp switch is built into the combination switch. The lighting switch must be in the 1ST position,

2ND position or AUTO position (LOW beam is ON) and the front fog lamp switch must be ON for front fog lamp

operation.

With the front fog lamp switch in the ON position, the CPU of the IPDM E/R grounds the coil side of the front

fog lamp relay. The front fog lamp relay then directs power

lthrough 20A fuse (No. 56, located in IPDM E/R)

lthrough IPDM E/R terminal 50

lto front fog lamp LH terminal 1 and

lthrough IPDM E/R terminal 51

lto front fog lamp RH terminal 1.

Ground is supplied at all times

lto front fog lamp RH and LH terminal 2

lthrough grounds E21, E41 and E61.

With power and ground supplied, the front fog lamps illuminate.

COMBINATION SWITCH READING FUNCTION

Refer toBCS-3, "COMBINATION SWITCH READING FUNCTION".

CAN Communication System DescriptionEKS00P40

Refer toLAN-23, "CAN COMMUNICATION".

Page 2160 of 3171

FRONT FOG LAMP

LT-77

C

D

E

F

G

H

I

J

L

MA

B

LT

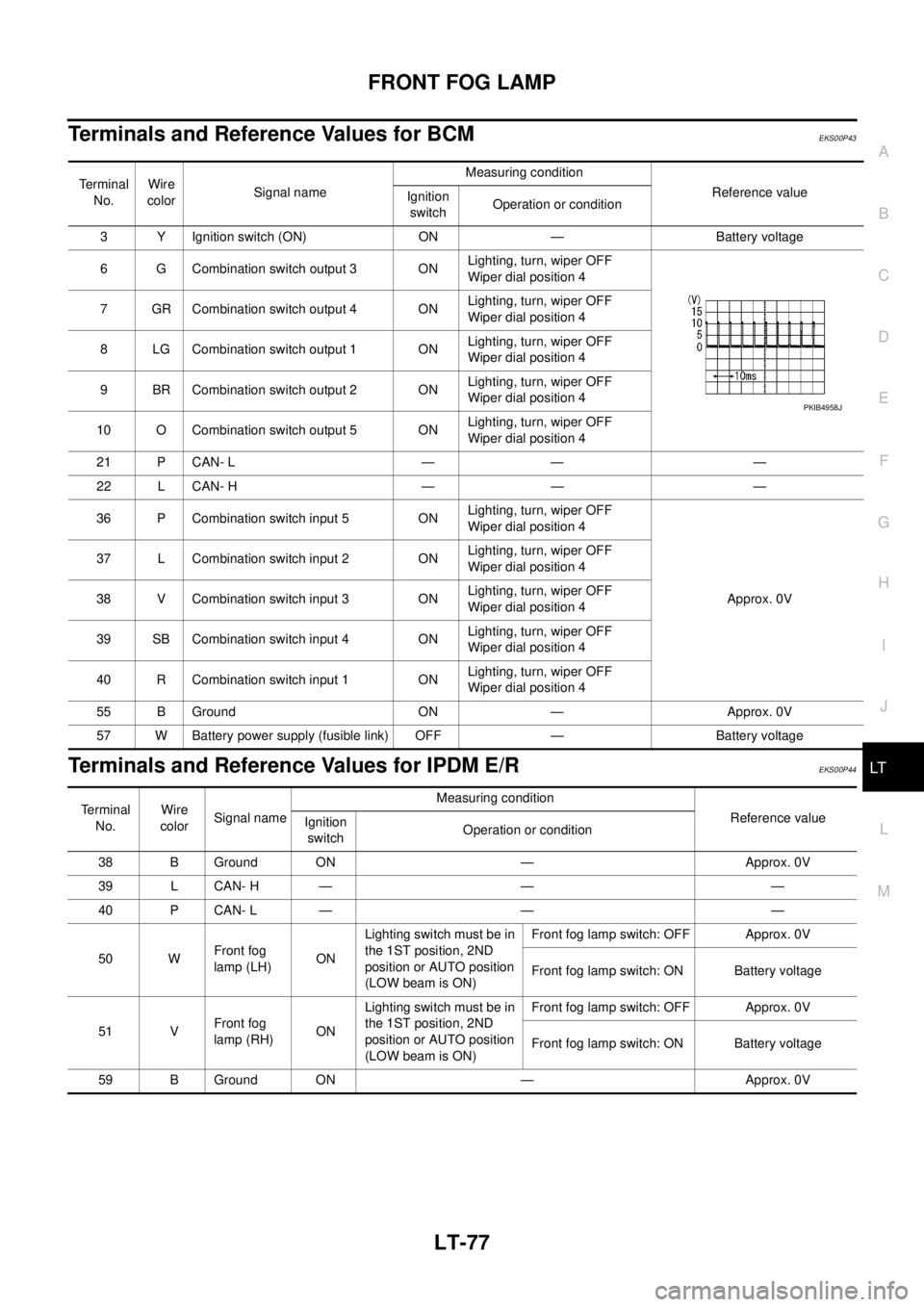

Terminals and Reference Values for BCMEKS00P43

Terminals and Reference Values for IPDM E/REKS00P44

Te r m i n a l

No.Wire

colorSignal nameMeasuring condition

Reference value

Ignition

switchOperation or condition

3 Y Ignition switch (ON) ON — Battery voltage

6 G Combination switch output 3 ONLighting, turn, wiper OFF

Wiper dial position 4

7 GR Combination switch output 4 ONLighting, turn, wiper OFF

Wiper dial position 4

8 LG Combination switch output 1 ONLighting, turn, wiper OFF

Wiper dial position 4

9 BR Combination switch output 2 ONLighting, turn, wiper OFF

Wiper dial position 4

10 O Combination switch output 5 ONLighting, turn, wiper OFF

Wiper dial position 4

21 P CAN- L — — —

22 L CAN- H — — —

36 P Combination switch input 5 ONLighting, turn, wiper OFF

Wiper dial position 4

Approx. 0V 37 L Combination switch input 2 ONLighting, turn, wiper OFF

Wiper dial position 4

38 V Combination switch input 3 ONLighting, turn, wiper OFF

Wiper dial position 4

39 SB Combination switch input 4 ONLighting, turn, wiper OFF

Wiper dial position 4

40 R Combination switch input 1 ONLighting, turn, wiper OFF

Wiper dial position 4

55 B Ground ON — Approx. 0V

57 W Battery power supply (fusible link) OFF — Battery voltage

PKIB4958J

Terminal

No.Wire

colorSignal nameMeasuring condition

Reference value

Ignition

switchOperation or condition

38 B Ground ON — Approx. 0V

39 L CAN- H — — —

40 P CAN- L — — —

50 WFront fog

lamp (LH)ONLighting switch must be in

the 1ST position, 2ND

position or AUTO position

(LOW beam is ON)Front fog lamp switch: OFF Approx. 0V

Front fog lamp switch: ON Battery voltage

51 VFront fog

lamp (RH)ONLighting switch must be in

the 1ST position, 2ND

position or AUTO position

(LOW beam is ON)Front fog lamp switch: OFF Approx. 0V

Front fog lamp switch: ON Battery voltage

59 B Ground ON — Approx. 0V