low beam NISSAN NAVARA 2005 Repair Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2168 of 3171

FRONT FOG LAMP

LT-85

C

D

E

F

G

H

I

J

L

MA

B

LT

Aiming AdjustmentEKS00P4D

The fog lamp is a semi-sealed beam type which uses a replaceable halogen bulb. Before performing aiming

adjustment, make sure of the following.

lKeep all tires inflated to correct pressure.

lPlace vehicle on level surface.

lSee that vehicle is unloaded (except for full levels of coolant, engine oil and fuel, and spare tire, jack, and

tools). Have the driver or equivalent weight placed in driver's seat.

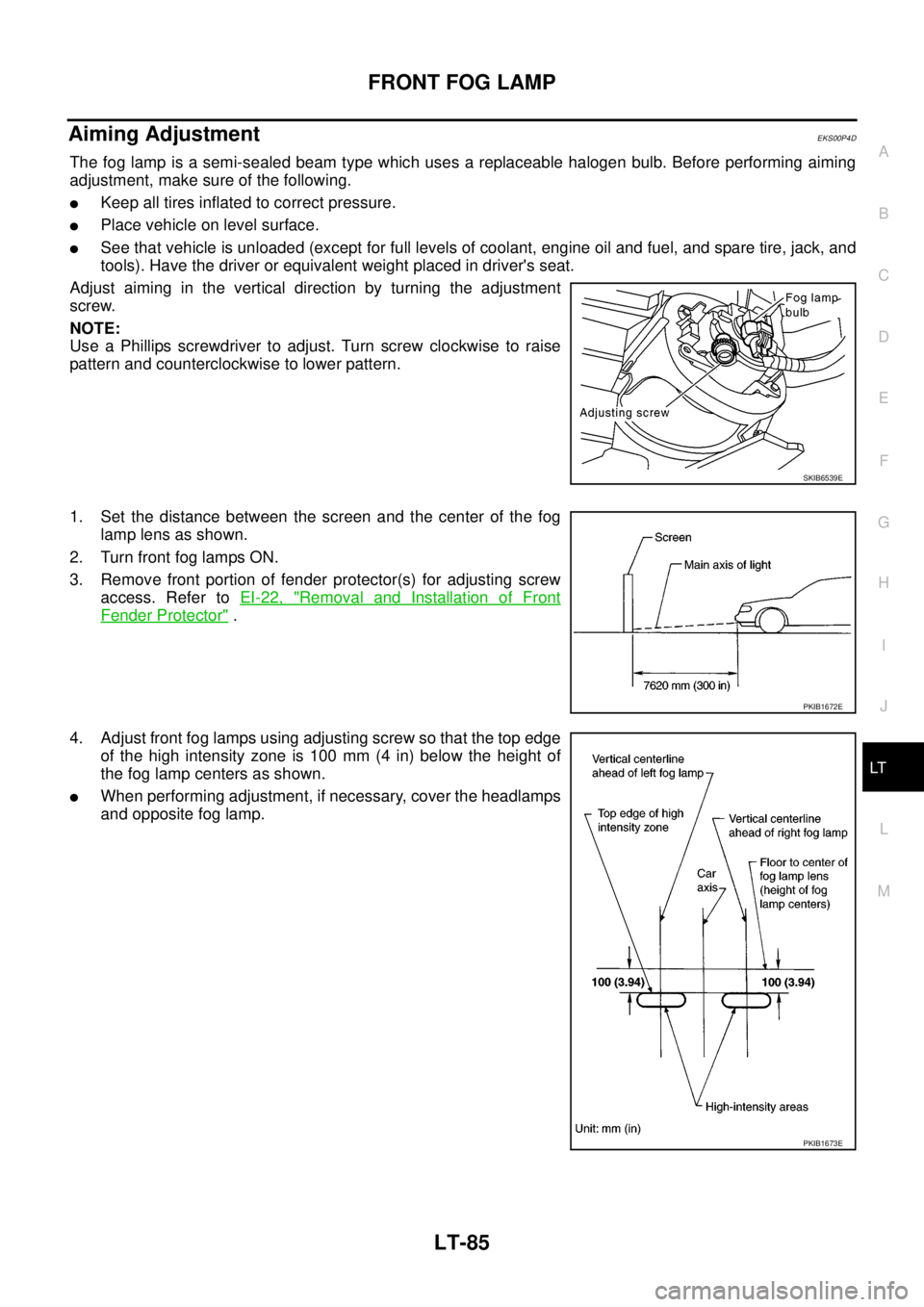

Adjust aiming in the vertical direction by turning the adjustment

screw.

NOTE:

Use a Phillips screwdriver to adjust. Turn screw clockwise to raise

pattern and counterclockwise to lower pattern.

1. Set the distance between the screen and the center of the fog

lamp lens as shown.

2. Turn front fog lamps ON.

3. Remove front portion of fender protector(s) for adjusting screw

access. Refer toEI-22, "

Removal and Installation of Front

Fender Protector".

4. Adjust front fog lamps using adjusting screw so that the top edge

of the high intensity zone is 100 mm (4 in) below the height of

the fog lamp centers as shown.

lWhen performing adjustment, if necessary, cover the headlamps

and opposite fog lamp.

SKIB6539E

PKIB1672E

PKIB1673E

Page 2170 of 3171

REAR FOG LAMP

LT-87

C

D

E

F

G

H

I

J

L

MA

B

LT

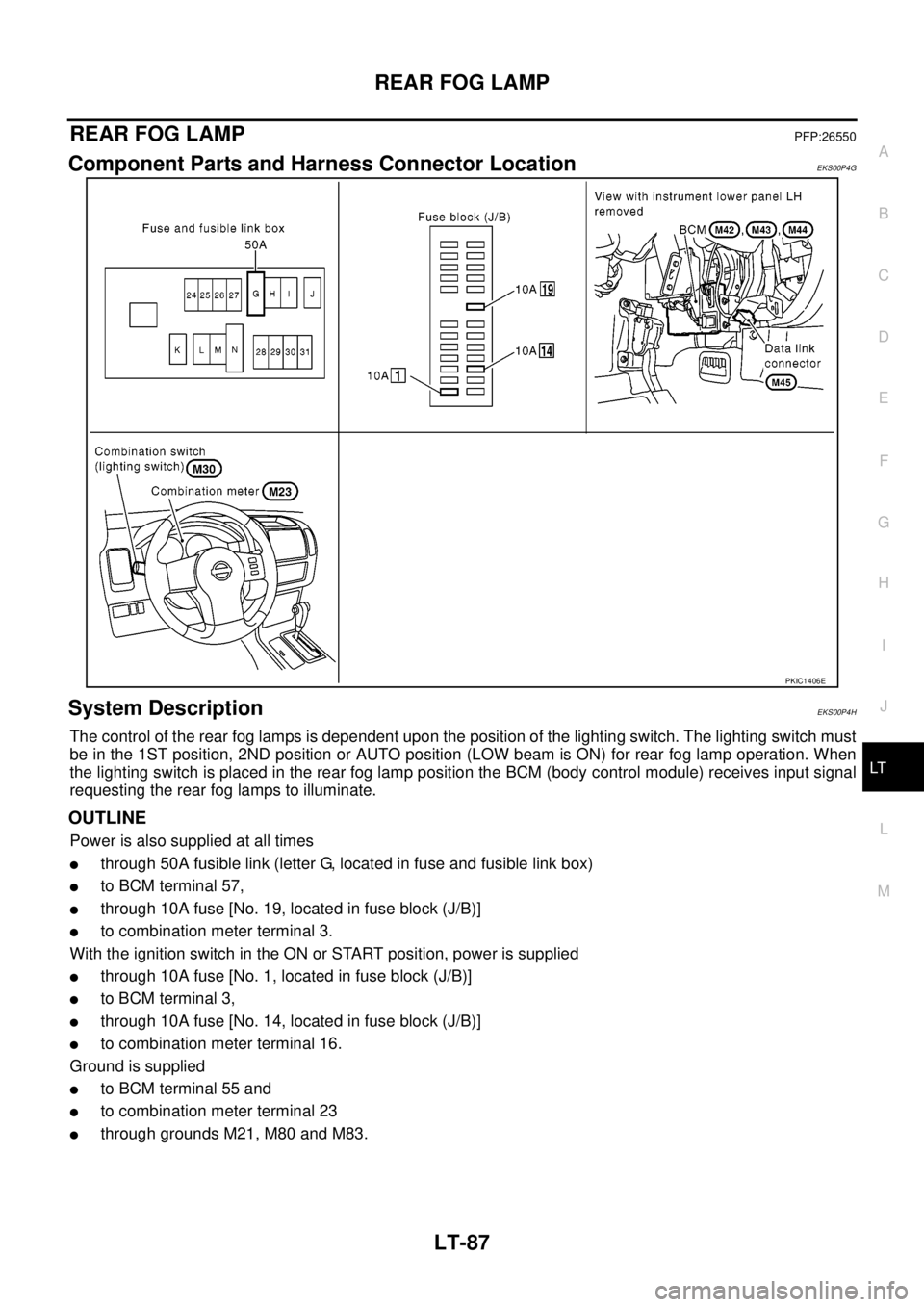

REAR FOG LAMPPFP:26550

Component Parts and Harness Connector LocationEKS00P4G

System DescriptionEKS00P4H

The control of the rear fog lamps is dependent upon the position of the lighting switch. The lighting switch must

be in the 1ST position, 2ND position or AUTO position (LOW beam is ON) for rear fog lamp operation. When

the lighting switch is placed in the rear fog lamp position the BCM (body control module) receives input signal

requesting the rear fog lamps to illuminate.

OUTLINE

Power is also supplied at all times

lthrough 50A fusible link (letter G, located in fuse and fusible link box)

lto BCM terminal 57,

lthrough 10A fuse [No. 19, located in fuse block (J/B)]

lto combination meter terminal 3.

With the ignition switch in the ON or START position, power is supplied

lthrough 10A fuse [No. 1, located in fuse block (J/B)]

lto BCM terminal 3,

lthrough 10A fuse [No. 14, located in fuse block (J/B)]

lto combination meter terminal 16.

Ground is supplied

lto BCM terminal 55 and

lto combination meter terminal 23

lthrough grounds M21, M80 and M83.

PKIC1406E

Page 2171 of 3171

LT-88

REAR FOG LAMP

REAR FOG LAMP OPERATION

The lighting switch must be in the 1ST position, 2ND position or AUTO position (LOW beam is ON) for rear fog

lamp operation.

With the rear fog lamp switch in the ON position, the BCM directs power

lthrough BCM terminal 49

lto rear combination lamp LH terminal 6 (LHD models)

lto rear combination lamp RH terminal 6 (RHD models).

Ground is supplied

lto rear combination lamp RH and LH terminals 3

lthrough grounds E21, E41 and E61.

With power and ground supplied, the rear fog lamps illuminate.

COMBINATION SWITCH READING FUNCTION

Refer toBCS-3, "COMBINATION SWITCH READING FUNCTION".

CAN Communication System DescriptionEKS00P4I

Refer toLAN-23, "CAN COMMUNICATION".

CAN Communication UnitEKS00P4J

Refer toLAN-30, "CAN Communication Unit".

Page 2199 of 3171

LT-116

COMBINATION SWITCH

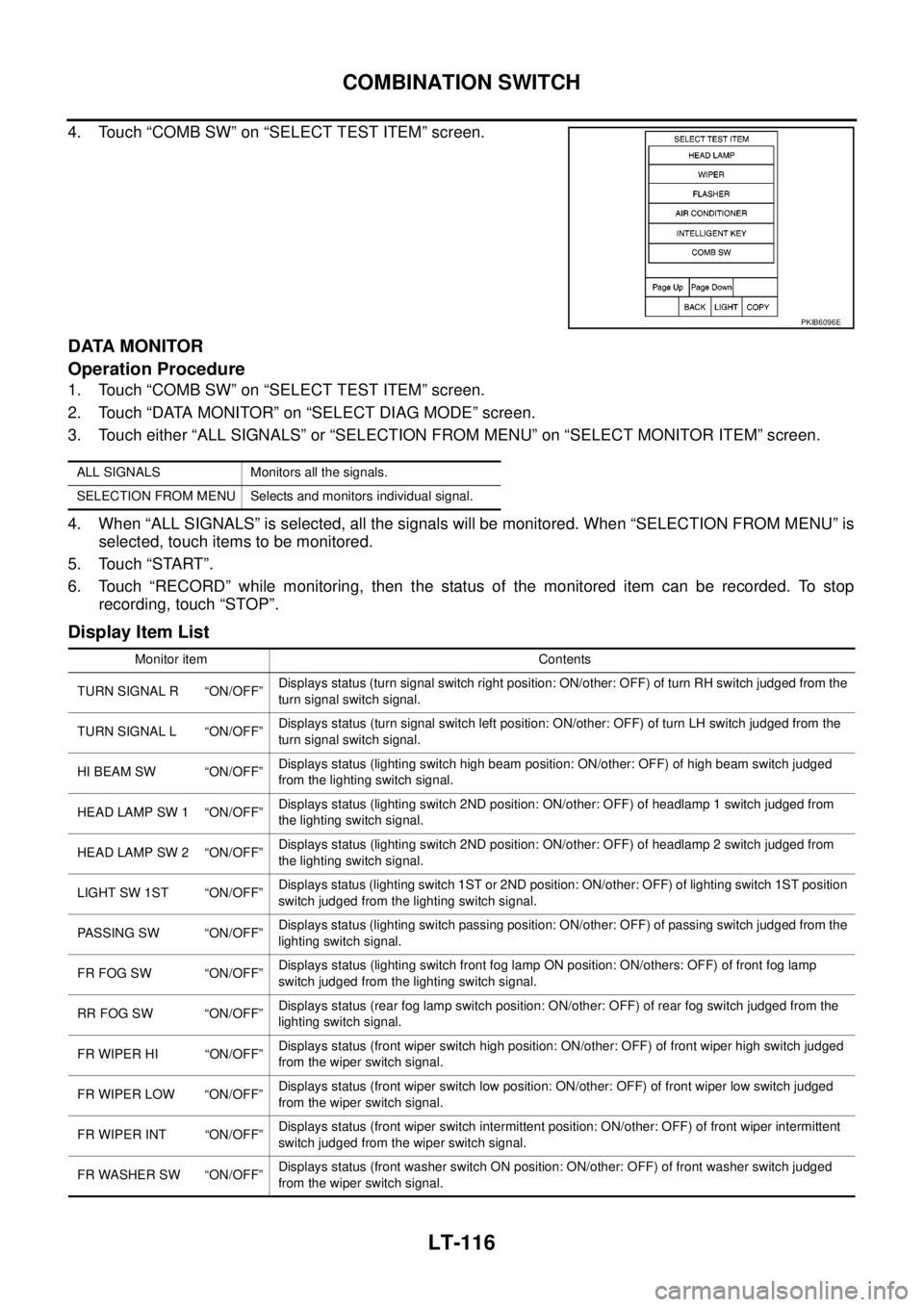

4. Touch “COMB SW” on “SELECT TEST ITEM” screen.

DATA MONITOR

Operation Procedure

1. Touch “COMB SW” on “SELECT TEST ITEM” screen.

2. Touch “DATA MONITOR” on “SELECT DIAG MODE” screen.

3. Touch either “ALL SIGNALS” or “SELECTION FROM MENU” on “SELECT MONITOR ITEM” screen.

4. When “ALL SIGNALS” is selected, all the signals will be monitored. When “SELECTION FROM MENU” is

selected, touch items to be monitored.

5. Touch “START”.

6. Touch “RECORD” while monitoring, then the status of the monitored item can be recorded. To stop

recording, touch “STOP”.

Display Item List

PKIB6096E

ALL SIGNALS Monitors all the signals.

SELECTION FROM MENU Selects and monitors individual signal.

Monitor item Contents

TURN SIGNAL R “ON/OFF”Displays status (turn signal switch right position: ON/other: OFF) of turn RH switch judged from the

turn signal switch signal.

TURN SIGNAL L “ON/OFF”Displays status (turn signal switch left position: ON/other: OFF) of turn LH switch judged from the

turn signal switch signal.

HI BEAM SW “ON/OFF”Displays status (lighting switch high beam position: ON/other: OFF) of high beam switch judged

from the lighting switch signal.

HEAD LAMP SW 1 “ON/OFF”Displays status (lighting switch 2ND position: ON/other: OFF) of headlamp 1 switch judged from

the lighting switch signal.

HEAD LAMP SW 2 “ON/OFF”Displays status (lighting switch 2ND position: ON/other: OFF) of headlamp 2 switch judged from

the lighting switch signal.

LIGHT SW 1ST “ON/OFF”Displays status (lighting switch 1ST or 2ND position: ON/other: OFF) of lighting switch 1ST position

switch judged from the lighting switch signal.

PASSING SW “ON/OFF”Displays status (lighting switch passing position: ON/other: OFF) of passing switch judged from the

lighting switch signal.

FR FOG SW “ON/OFF”Displays status (lighting switch front fog lamp ON position: ON/others: OFF) of front fog lamp

switch judged from the lighting switch signal.

RR FOG SW “ON/OFF”Displays status (rear fog lamp switch position: ON/other: OFF) of rear fog switch judged from the

lighting switch signal.

FR WIPER HI “ON/OFF”Displays status (front wiper switch high position: ON/other: OFF) of front wiper high switch judged

from the wiper switch signal.

FR WIPER LOW “ON/OFF”Displays status (front wiper switch low position: ON/other: OFF) of front wiper low switch judged

from the wiper switch signal.

FR WIPER INT “ON/OFF”Displays status (front wiper switch intermittent position: ON/other: OFF) of front wiper intermittent

switch judged from the wiper switch signal.

FR WASHER SW “ON/OFF”Displays status (front washer switch ON position: ON/other: OFF) of front washer switch judged

from the wiper switch signal.

Page 2201 of 3171

LT-118

COMBINATION SWITCH

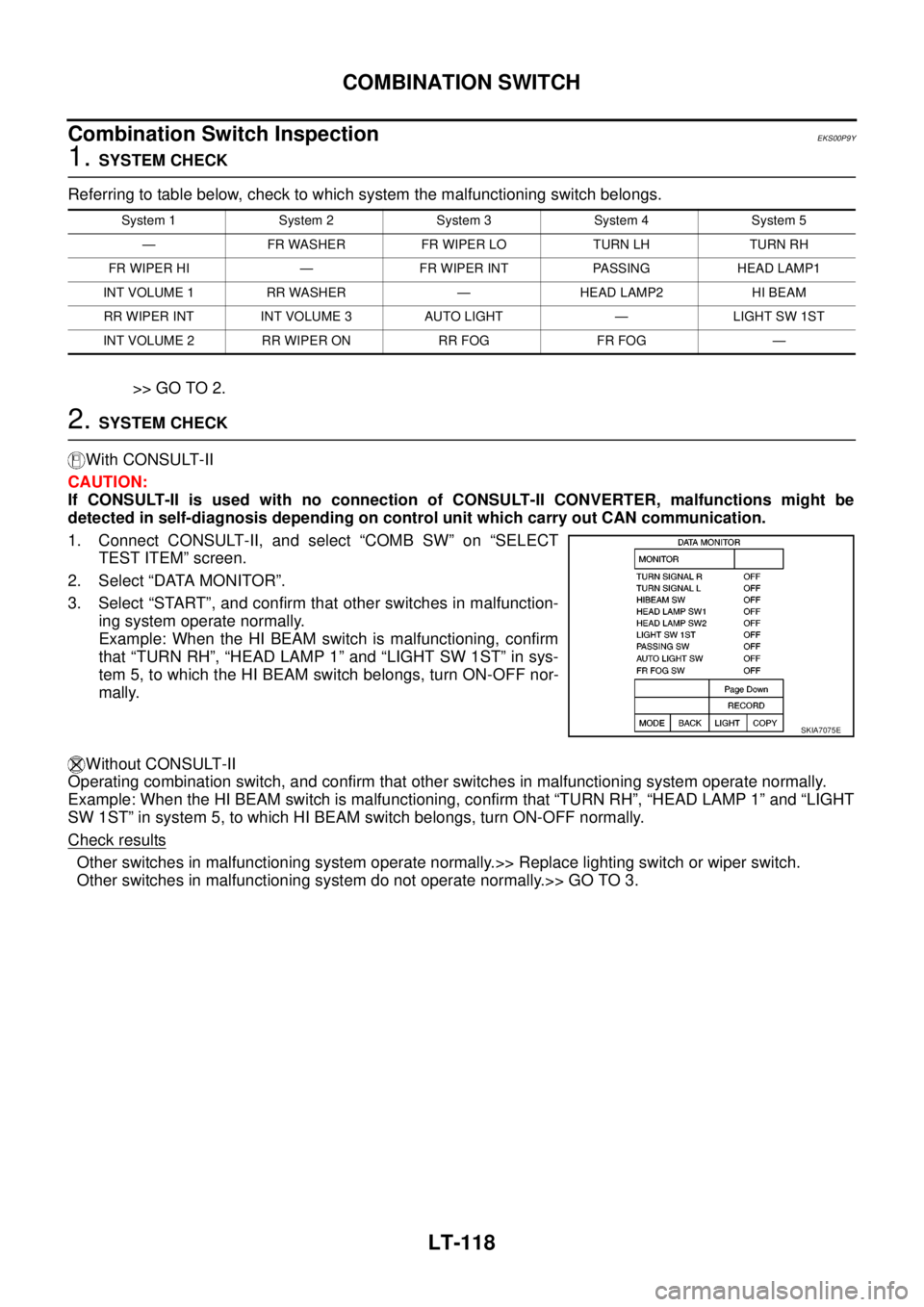

Combination Switch Inspection

EKS00P9Y

1.SYSTEM CHECK

Referring to table below, check to which system the malfunctioning switch belongs.

>> GO TO 2.

2.SYSTEM CHECK

With CONSULT-II

CAUTION:

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunctions might be

detected in self-diagnosis depending on control unit which carry out CAN communication.

1. Connect CONSULT-II, and select “COMB SW” on “SELECT

TEST ITEM” screen.

2. Select “DATA MONITOR”.

3. Select “START”, and confirm that other switches in malfunction-

ing system operate normally.

Example: When the HI BEAM switch is malfunctioning, confirm

that “TURN RH”, “HEAD LAMP 1” and “LIGHT SW 1ST” in sys-

tem 5, to which the HI BEAM switch belongs, turn ON-OFF nor-

mally.

Without CONSULT-II

Operating combination switch, and confirm that other switches in malfunctioning system operate normally.

Example: When the HI BEAM switch is malfunctioning, confirm that “TURN RH”, “HEAD LAMP 1” and “LIGHT

SW 1ST” in system 5, to which HI BEAM switch belongs, turn ON-OFF normally.

Check results

Other switches in malfunctioning system operate normally.>> Replace lighting switch or wiper switch.

Other switches in malfunctioning system do not operate normally.>> GO TO 3.

System 1 System 2 System 3 System 4 System 5

— FR WASHER FR WIPER LO TURN LH TURN RH

FR WIPER HI — FR WIPER INT PASSING HEAD LAMP1

INT VOLUME 1 RR WASHER — HEAD LAMP2 HI BEAM

RR WIPER INT INT VOLUME 3 AUTO LIGHT — LIGHT SW 1ST

INT VOLUME 2 RR WIPER ON RR FOG FR FOG —

SKIA7075E

Page 3150 of 3171

HEADLAMP WASHER

WW-39

C

D

E

F

G

H

I

J

L

MA

B

WW

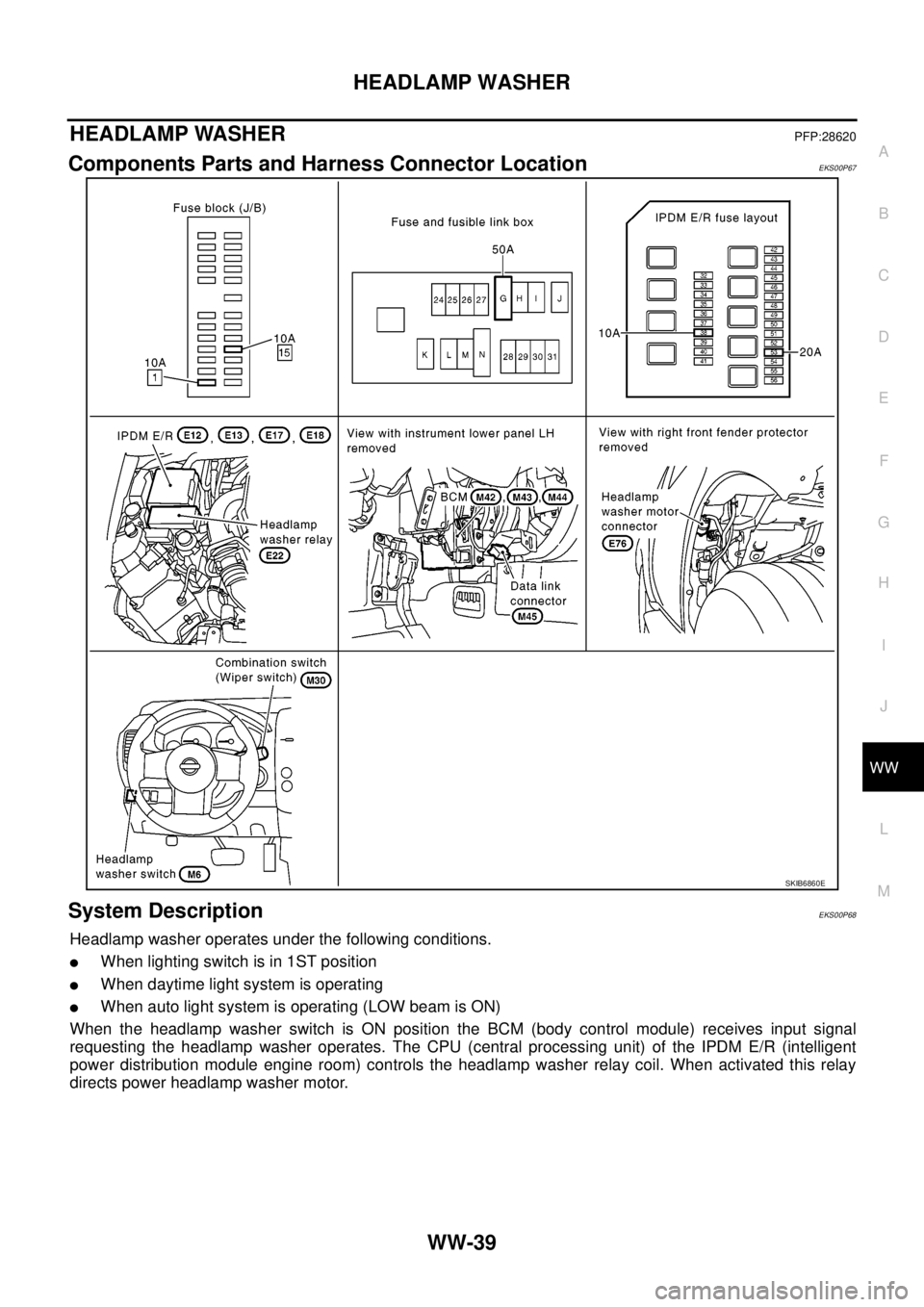

HEADLAMP WASHERPFP:28620

Components Parts and Harness Connector LocationEKS00P67

System DescriptionEKS00P68

Headlamp washer operates under the following conditions.

lWhen lighting switch is in 1ST position

lWhen daytime light system is operating

lWhen auto light system is operating (LOW beam is ON)

When the headlamp washer switch is ON position the BCM (body control module) receives input signal

requesting the headlamp washer operates. The CPU (central processing unit) of the IPDM E/R (intelligent

power distribution module engine room) controls the headlamp washer relay coil. When activated this relay

directs power headlamp washer motor.

SKIB6860E

Page 3160 of 3171

HEADLAMP WASHER

WW-49

C

D

E

F

G

H

I

J

L

MA

B

WW

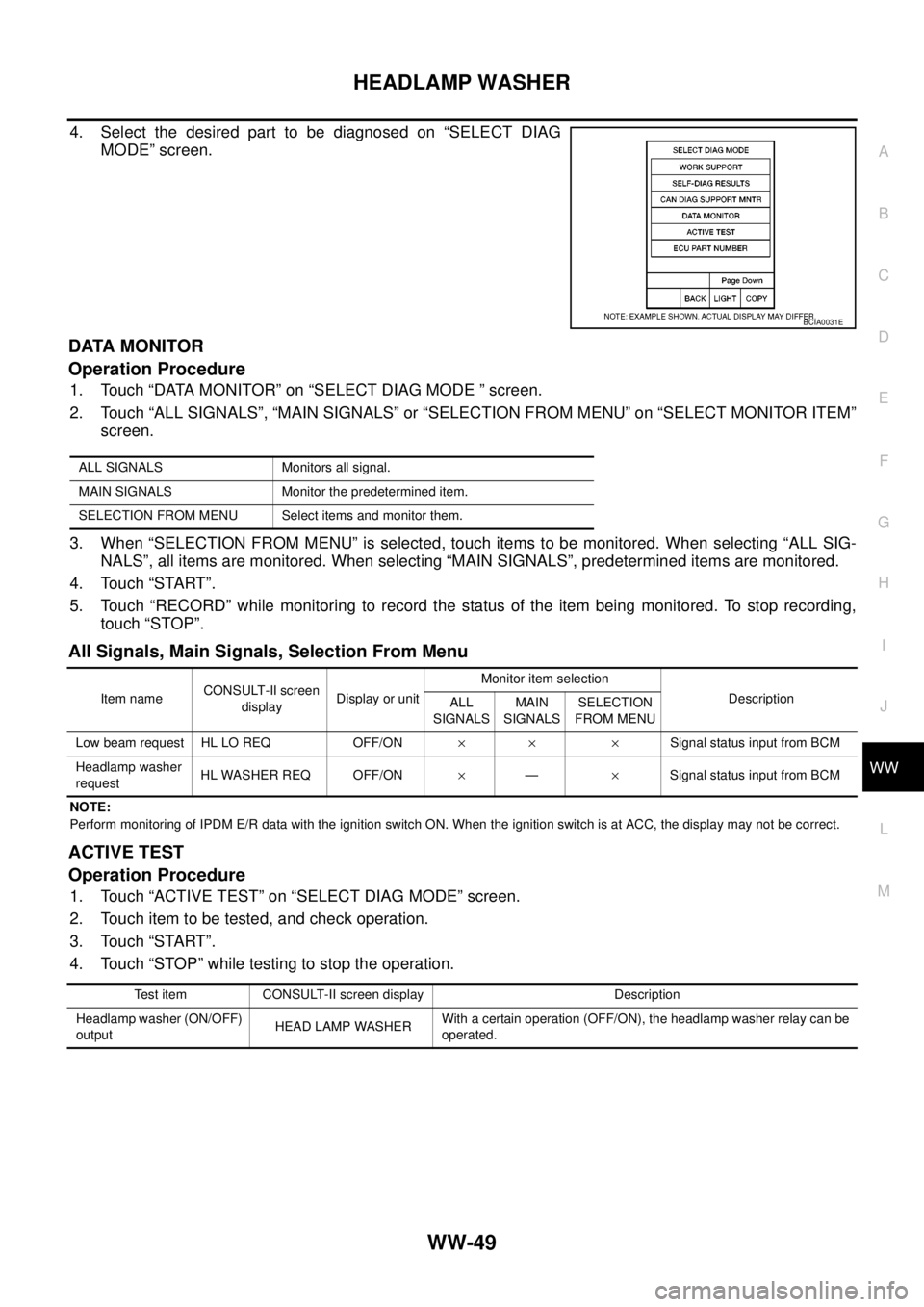

4. Select the desired part to be diagnosed on “SELECT DIAG

MODE” screen.

DATA MONITOR

Operation Procedure

1. Touch “DATA MONITOR” on “SELECT DIAG MODE ” screen.

2. Touch “ALL SIGNALS”, “MAIN SIGNALS” or “SELECTION FROM MENU” on “SELECT MONITOR ITEM”

screen.

3. When “SELECTION FROM MENU” is selected, touch items to be monitored. When selecting “ALL SIG-

NALS”, all items are monitored. When selecting “MAIN SIGNALS”, predetermined items are monitored.

4. Touch “START”.

5. Touch “RECORD” while monitoring to record the status of the item being monitored. To stop recording,

touch “STOP”.

All Signals, Main Signals, Selection From Menu

NOTE:

Perform monitoring of IPDM E/R data with the ignition switch ON. When the ignition switch is at ACC, the display may not be correct.

ACTIVE TEST

Operation Procedure

1. Touch “ACTIVE TEST” on “SELECT DIAG MODE” screen.

2. Touch item to be tested, and check operation.

3. Touch “START”.

4. Touch “STOP” while testing to stop the operation.

BCIA0031E

ALL SIGNALS Monitors all signal.

MAIN SIGNALS Monitor the predetermined item.

SELECTION FROM MENU Select items and monitor them.

Item nameCONSULT-II screen

displayDisplay or unitMonitor item selection

Description

ALL

SIGNALSMAIN

SIGNALSSELECTION

FROM MENU

Low beam request HL LO REQ OFF/ON´´ ´Signal status input from BCM

Headlamp washer

requestHL WASHER REQ OFF/ON´—´Signal status input from BCM

Test item CONSULT-II screen display Description

Headlamp washer (ON/OFF)

outputHEAD LAMP WASHERWith a certain operation (OFF/ON), the headlamp washer relay can be

operated.