roof NISSAN NAVARA 2005 Repair User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1346 of 3171

EI-8

SQUEAK AND RATTLE TROUBLE DIAGNOSES

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicone spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or rattle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation procedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid bumpers out of adjustment

2. Trunk lid striker out of adjustment

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headliner and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the console panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the console at the clip locations until the clips engage.

In addition look for:

1. Loose harness or harness connectors.

2. Front console map/reading lamp lens loose.

3. Loose screws at console attachment points.

Page 1364 of 3171

EI-26

ROOF RACK

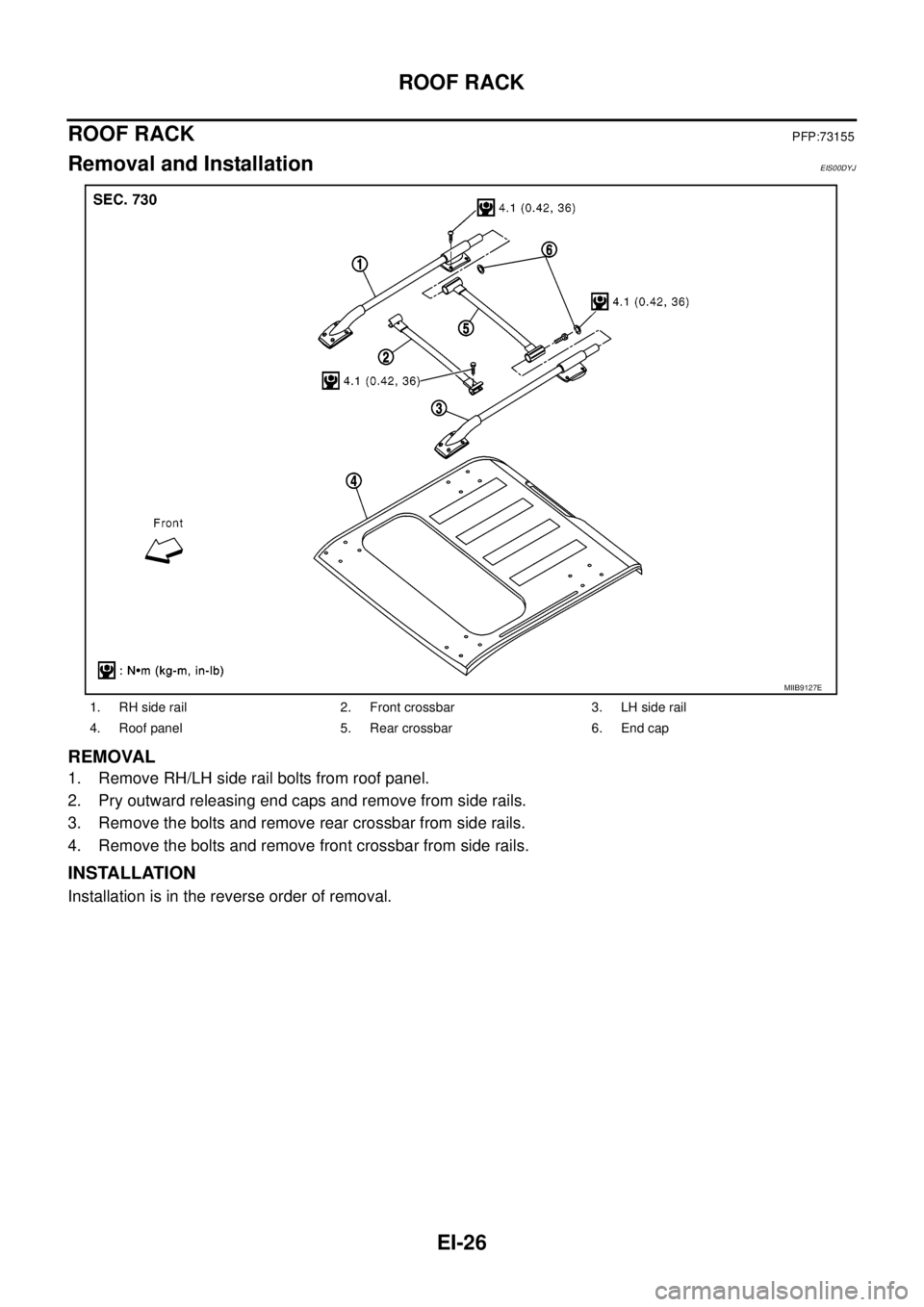

ROOF RACK

PFP:73155

Removal and InstallationEIS00DYJ

REMOVAL

1. Remove RH/LH side rail bolts from roof panel.

2. Pry outward releasing end caps and remove from side rails.

3. Remove the bolts and remove rear crossbar from side rails.

4. Remove the bolts and remove front crossbar from side rails.

INSTALLATION

Installation is in the reverse order of removal.

1. RH side rail 2. Front crossbar 3. LH side rail

4. Roof panel 5. Rear crossbar 6. End cap

MIIB9127E

Page 1379 of 3171

HEADLINING

EI-41

C

D

E

F

G

H

J

K

L

MA

B

EI

REMOVAL

CAUTION:

Disconnect both the positive and negative battery terminals in advance.

1. Remove body side trim panels. Refer toEI-33, "

BODY SIDE TRIM".

2. Remove rear trim. Refer toEI-36, "

REAR".

3. Remove sun visor assemblies, both LH and RH.

4. Remove sun visor holders LH and RH.

5. Remove roof console (if equipped).

lDisconnect harness.

6. Remove room lamp.

lDisconnect harness.

7. Remove microphone assembly (if equiped).

8. Remove inside mirror finisher, and inside mirror harness finisher (if equipped). Refer toGW-46, "

Removal

and Installation".

lDisconnect harness, then release it, from headlining.

9. Remove striker covers (King Cab only).

10. Remove assist grips.

11. Remove headlining.

NOTE:

Use an assistant to steady the headlining while lowering from roof.

lRemove clips from center of headlining (if equipped).

12. Remove assist grip brackets from roof.

INSTALLATION

CAUTION:

Use only Nissan available process to fix harness with Headlining.

Installation is in the reverse order of removal.

1. Sunroof shade cover (if equipped) 2. Sunroof welt (if equipped) 3. Assist grip

4. Sun visor assembly RH 5. Sun visor holder RH/LH 6. Sun visor assembly LH

7. Striker cover outer RH (King Cab) 8. Striker cover inner RH (King Cab) 9. Roof console with front room lamp

and sunglass bin (if equipped)

10. Striker cover outer LH (King Cab) 11. Striker cover inner LH (King Cab) 12. Coat hook

13. Headlining (King Cab) 14. Headlining (Double cab w/sunroof) 15. Room lamp

16. Microphone assembly (if equipped) 17. Inside miror harness finisher

(if equipped)18. Inside miror finisher (if equipped)

Page 1548 of 3171

FFD-2

PRECAUTIONS

PRECAUTIONS

PFP:00001

ServiceNoticeorPrecautionsEDS0034W

lBefore starting diagnosis of the vehicle, understand the symptoms well. Perform correct and systematic

operations.

lCheck for the correct installation status prior to removal or disassembly. When matching marks are

required, be certain they do not interfere with the function of the parts they are applied to.

lOverhaul should be done in a clean work area, a dust proof area is recommended.

lBefore disassembly, completely remove sand and mud from the exterior of the unit, preventing them from

entering into the unit during disassembly or assembly.

lAlways use shop paper for cleaning the inside of components.

lAvoid using cotton gloves or a shop cloth to prevent the entering of lint.

lCheck appearance of the disassembled parts for damage, deformation, and unusual wear. Replace them

with new ones if necessary.

lGaskets, seals and O-rings should be replaced any time the unit is disassembled.

lClean and flush the parts sufficiently and blow them dry.

lBe careful not to damage sliding surfaces and mating surfaces.

lWhen applying sealant, remove the old sealant from the mating surface; then remove any moisture, oil,

and foreign materials from the application and mating surfaces.

lIn principle, tighten bolts or nuts gradually in several steps working diagonally from inside to outside. If a

tightening sequence is specified, observe it.

lDuring assembly, observe the specified tightening torque.

lAdd new differential gear oil, petroleum jelly, or multi-purpose grease, as specified.

Page 1587 of 3171

FUEL SYSTEM

FL-3

C

D

E

F

G

H

I

J

K

L

MA

FL

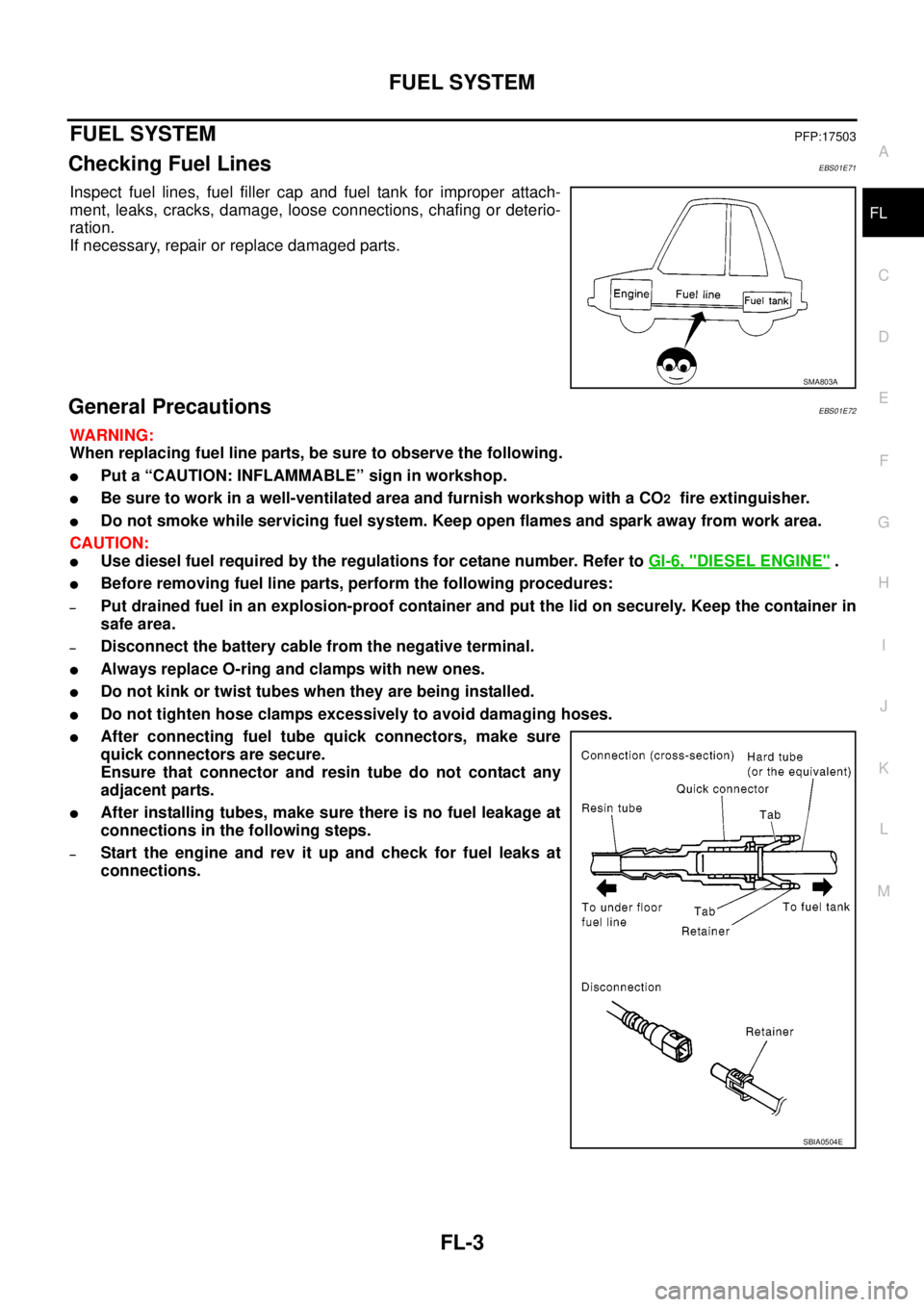

FUEL SYSTEMPFP:17503

Checking Fuel LinesEBS01E71

Inspect fuel lines, fuel filler cap and fuel tank for improper attach-

ment, leaks, cracks, damage, loose connections, chafing or deterio-

ration.

If necessary, repair or replace damaged parts.

General PrecautionsEBS01E72

WARNING:

When replacing fuel line parts, be sure to observe the following.

lPut a “CAUTION: INFLAMMABLE” sign in workshop.

lBe sure to work in a well-ventilated area and furnish workshop with a CO2fire extinguisher.

lDo not smoke while servicing fuel system. Keep open flames and spark away from work area.

CAUTION:

lUse diesel fuel required by the regulations for cetane number. Refer toGI-6, "DIESEL ENGINE".

lBefore removing fuel line parts, perform the following procedures:

–Put drained fuel in an explosion-proof container and put the lid on securely. Keep the container in

safe area.

–Disconnect the battery cable from the negative terminal.

lAlways replace O-ring and clamps with new ones.

lDo not kink or twist tubes when they are being installed.

lDo not tighten hose clamps excessively to avoid damaging hoses.

lAfter connecting fuel tube quick connectors, make sure

quick connectors are secure.

Ensure that connector and resin tube do not contact any

adjacent parts.

lAfter installing tubes, make sure there is no fuel leakage at

connections in the following steps.

–Start the engine and rev it up and check for fuel leaks at

connections.

SMA803A

SBIA0504E

Page 1682 of 3171

GI-60

IDENTIFICATION INFORMATION

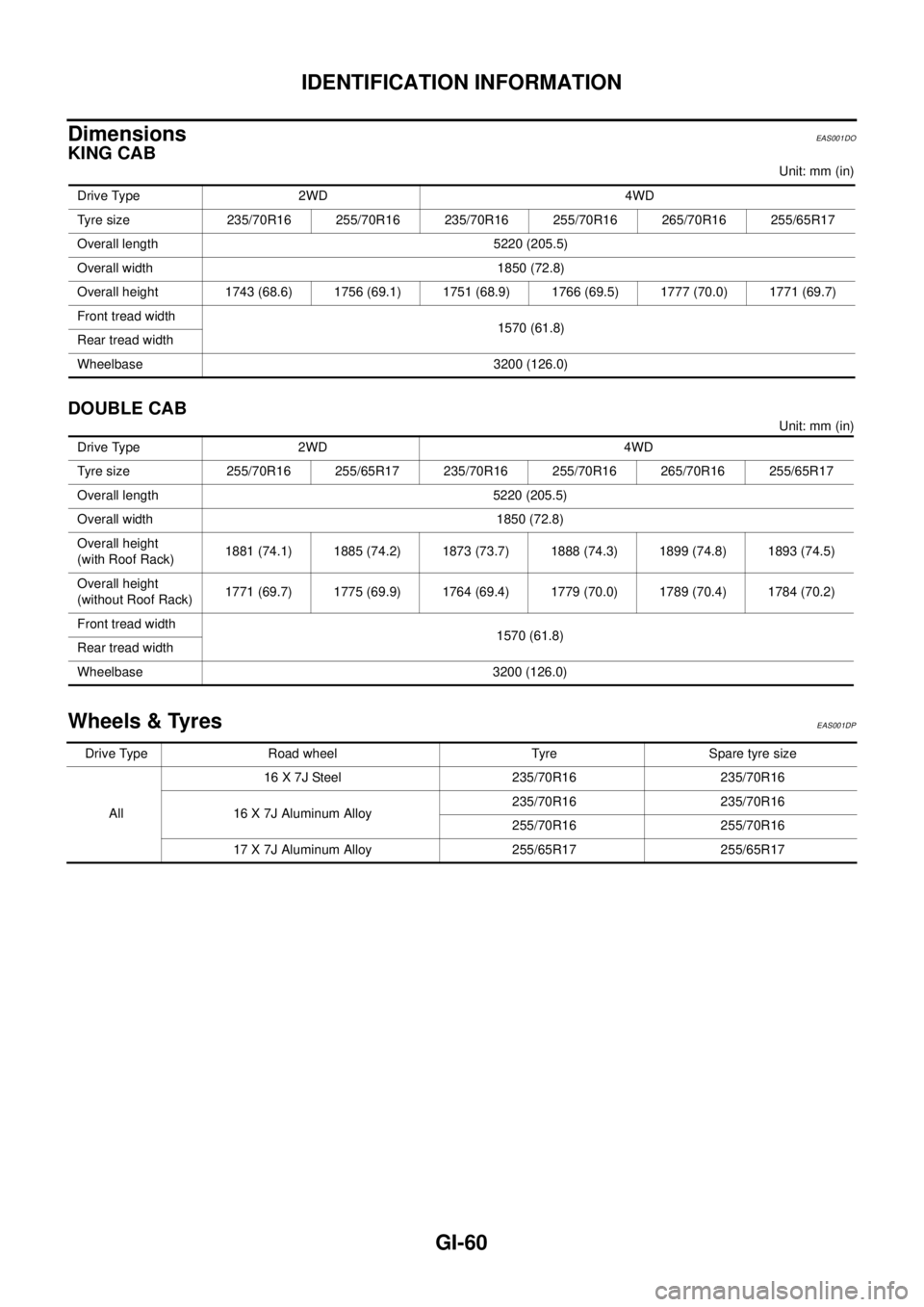

Dimensions

EAS001DO

KING CAB

Unit: mm (in)

DOUBLE CAB

Unit: mm (in)

Wheels & TyresEAS001DP

Drive Type 2WD 4WD

Tyre size 235/70R16 255/70R16 235/70R16 255/70R16 265/70R16 255/65R17

Overall length 5220 (205.5)

Overall width 1850 (72.8)

Overall height 1743 (68.6) 1756 (69.1) 1751 (68.9) 1766 (69.5) 1777 (70.0) 1771 (69.7)

Front tread width

1570 (61.8)

Rear tread width

Wheelbase 3200 (126.0)

Drive Type 2WD 4WD

Tyre size 255/70R16 255/65R17 235/70R16 255/70R16 265/70R16 255/65R17

Overall length 5220 (205.5)

Overall width 1850 (72.8)

Overall height

(with Roof Rack)1881 (74.1) 1885 (74.2) 1873 (73.7) 1888 (74.3) 1899 (74.8) 1893 (74.5)

Overall height

(without Roof Rack)1771 (69.7) 1775 (69.9) 1764 (69.4) 1779 (70.0) 1789 (70.4) 1784 (70.2)

Front tread width

1570 (61.8)

Rear tread width

Wheelbase 3200 (126.0)

Drive Type Road wheel Tyre Spare tyre size

All16 X 7J Steel 235/70R16 235/70R16

16 X 7J Aluminum Alloy235/70R16 235/70R16

255/70R16 255/70R16

17 X 7J Aluminum Alloy 255/65R17 255/65R17

Page 1687 of 3171

GW-1

GLASSES, WINDOW SYSTEM & MIRRORS

IBODY

CONTENTS

C

D

E

F

G

H

J

K

L

M

SECTIONGW

A

B

GW

GLASSES, WINDOW SYSTEM & MIRRORS

PRECAUTIONS .......................................................... 3

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 3

Precautions for Procedures without Cowl Top Cover..... 3

Handling for Adhesive and Primer ........................... 3

Trouble Diagnosis Precaution .................................. 3

PREPARATION ........................................................... 4

Commercial Service Tool ......................................... 4

SQUEAK AND RATTLE TROUBLE DIAGNOSES..... 5

Work Flow ................................................................ 5

CUSTOMER INTERVIEW ..................................... 5

DUPLICATE THE NOISE AND TEST DRIVE ....... 6

CHECK RELATED SERVICE BULLETINS ........... 6

LOCATE THE NOISE AND IDENTIFY THE

ROOT CAUSE ...................................................... 6

REPAIR THE CAUSE ........................................... 6

CONFIRM THE REPAIR ....................................... 7

Generic Squeak and Rattle Troubleshooting ........... 7

INSTRUMENT PANEL .......................................... 7

CENTER CONSOLE ............................................. 7

DOORS ................................................................. 7

TRUNK .................................................................. 8

SUNROOF/HEADLINING ..................................... 8

SEATS ................................................................... 8

UNDERHOOD ....................................................... 8

Diagnostic Worksheet .............................................. 9

WINDSHIELD GLASS ...............................................11

Removal and Installation ......................................... 11

REMOVAL ............................................................ 11

INSTALLATION .................................................... 11

POWER WINDOW SYSTEM .................................... 15

Component Parts and Harness Connector Location... 15

System Description ................................................ 15

MANUAL OPERATION ....................................... 16

AUTO OPERATION ............................................ 18

POWER WINDOW LOCK ................................... 18

DRIVER WINDOW ANTI-PINCH FUNCTION ..... 18

Schematic .............................................................. 19Wiring Diagram – WINDOW – ................................ 20

Terminal and Reference Value for Power Window

Main Switch ............................................................ 24

Terminal and Reference Value for Each Door's

Power Window Switch ............................................ 24

Terminal and Reference Value for BCM ................. 25

Work Flow ............................................................... 25

Trouble Diagnosis Symptom Chart ......................... 25

BCM Power Supply and Ground Circuit Check ...... 26

Power Window Main Switch Power Supply and

Ground Circuit Check ............................................. 27

Driver Side Power Window Motor Check ............... 28

Passenger Side Power Window Motor Circuit

Check ..................................................................... 29

Rear LH Power Window Motor Circuit Check ......... 30

Rear RH Power Window Motor Circuit Check ........ 31

Passenger Side Power Window Circuit Check ....... 31

Rear LH Power Window Circuit Check ................... 32

Rear RH Power Window Circuit Check .................. 33

Power Window Switch Check 1 .............................. 33

Power Window Switch Check 2 .............................. 34

FRONT DOOR GLASS AND REGULATOR ............. 35

Removal and Installation ........................................ 35

DOOR GLASS ..................................................... 35

REGULATOR ASSEMBLY .................................. 36

Disassembly and Assembly .................................... 37

REGULATOR ASSEMBLY .................................. 37

Inspection after Installation ..................................... 37

FITTING INSPECTION ....................................... 37

RESET OPERATION ........................................... 37

REAR DOOR GLASS AND REGULATOR ............... 38

Removal and Installation ........................................ 38

DOOR GLASS ..................................................... 38

REGULATOR ASSEMBLY .................................. 39

Disassembly and Assembly .................................... 40

REGULATOR ASSEMBLY .................................. 40

Inspection after Installation ..................................... 40

FITTING INSPECTION ....................................... 40

Page 1694 of 3171

GW-8

SQUEAK AND RATTLE TROUBLE DIAGNOSES

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid dumpers out of adjustment

2. Trunk lid striker out of adjustment

3. Trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sunvisor shaft shaking in the holder

3. Front or rear windshield touching headlining and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

SEATS

When isolating seat noise it's important to note the position the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. Rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of these incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Page 1699 of 3171

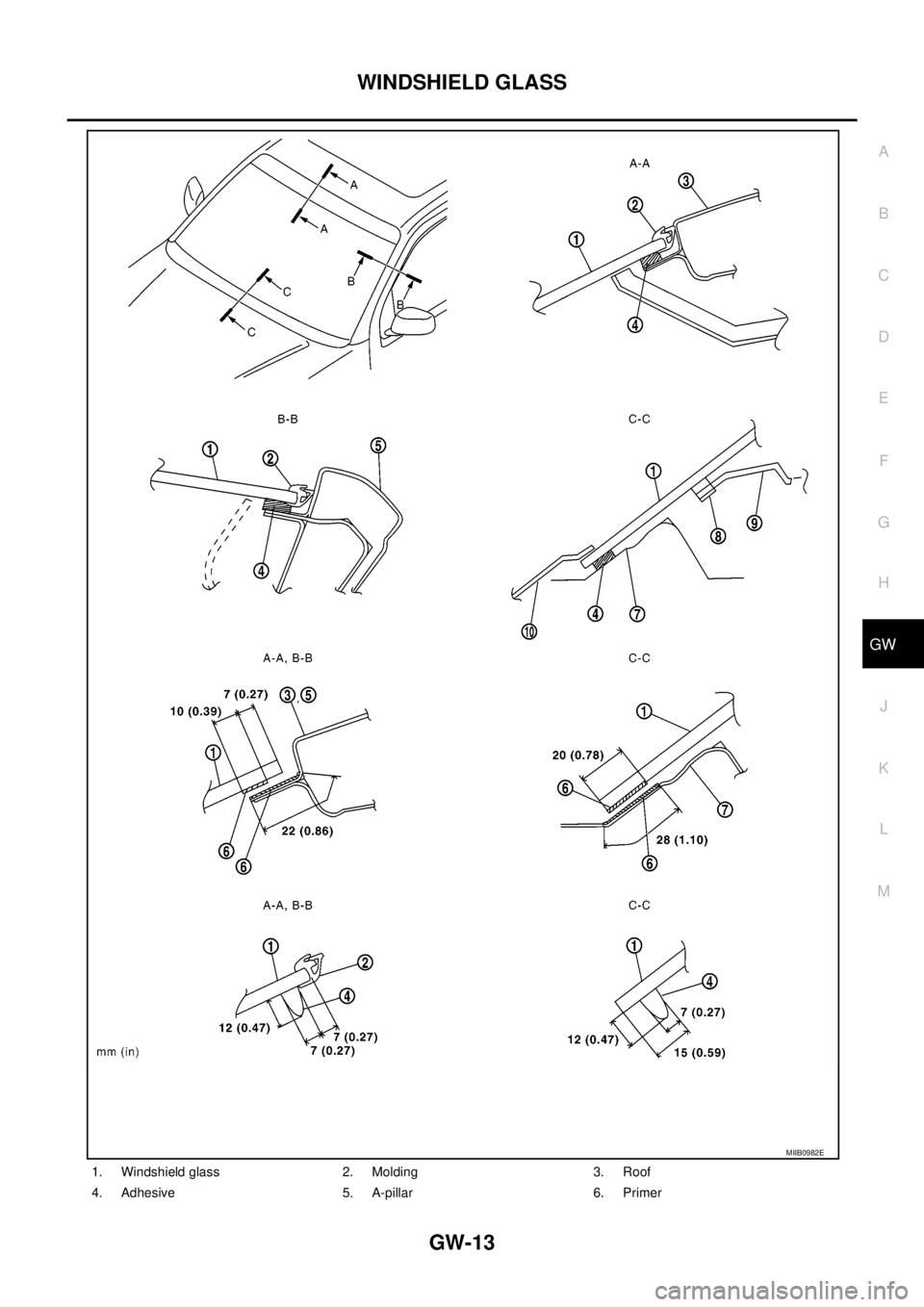

WINDSHIELD GLASS

GW-13

C

D

E

F

G

H

J

K

L

MA

B

GW

1. Windshield glass 2. Molding 3. Roof

4. Adhesive 5. A-pillar 6. Primer

MIIB0982E

Page 1729 of 3171

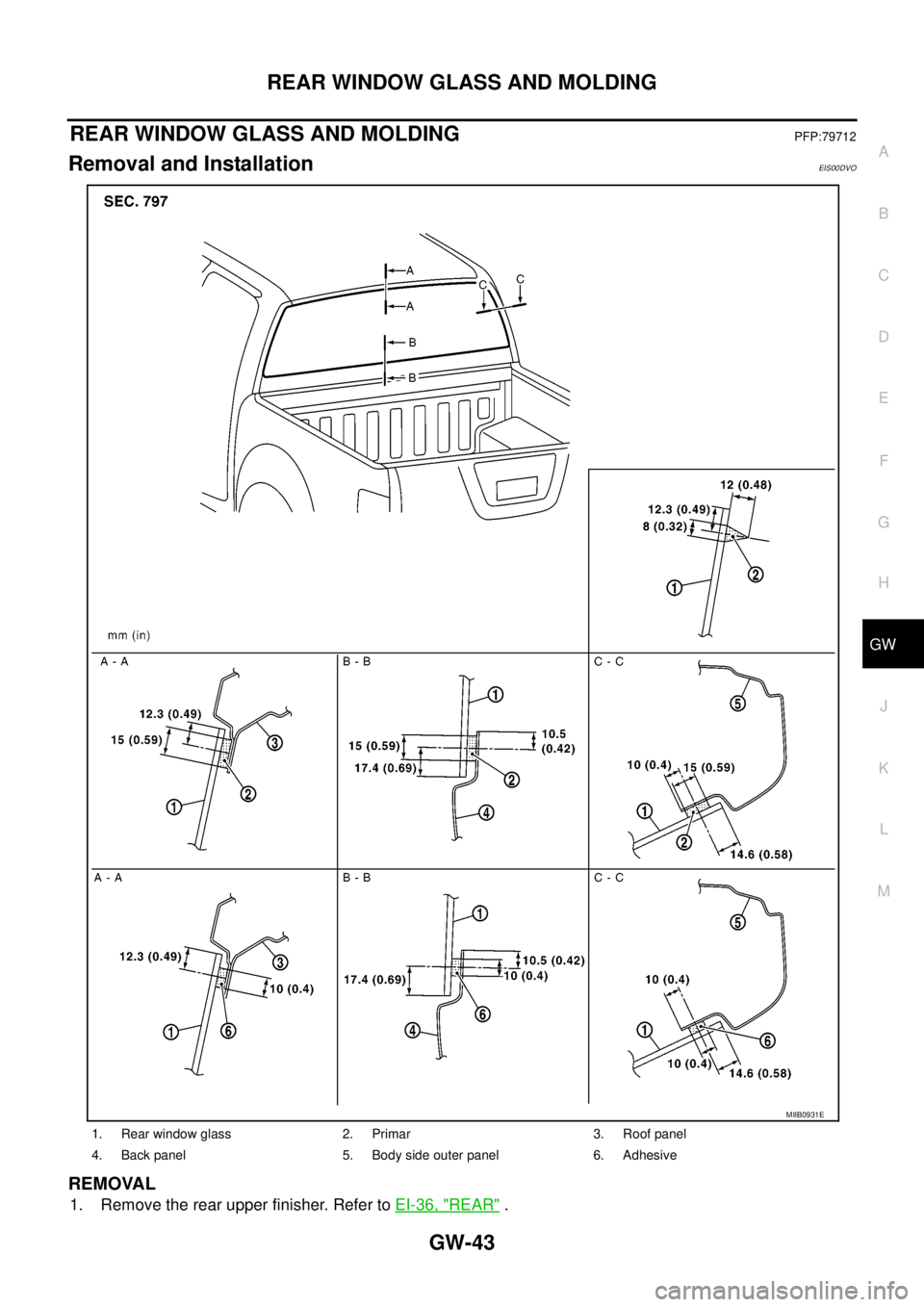

REAR WINDOW GLASS AND MOLDING

GW-43

C

D

E

F

G

H

J

K

L

MA

B

GW

REAR WINDOW GLASS AND MOLDINGPFP:79712

Removal and InstallationEIS00DVO

REMOVAL

1. Remove the rear upper finisher. Refer toEI-36, "REAR".

1. Rear window glass 2. Primar 3. Roof panel

4. Back panel 5. Body side outer panel 6. Adhesive

MIIB0931E