roof NISSAN NAVARA 2005 Repair Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2678 of 3171

RF-1

ROOF

IBODY

CONTENTS

C

D

E

F

G

H

J

K

L

M

SECTIONRF

A

B

RF

ROOF

PRECAUTIONS .......................................................... 2

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 2

Precautions .............................................................. 2

PREPARATION ........................................................... 3

Commercial Service Tool ......................................... 3

SQUEAK AND RATTLE TROUBLE DIAGNOSES..... 4

Work Flow ................................................................ 4

CUSTOMER INTERVIEW ..................................... 4

DUPLICATE THE NOISE AND TEST DRIVE ....... 5

CHECK RELATED SERVICE BULLETINS ........... 5

LOCATE THE NOISE AND IDENTIFY THE

ROOT CAUSE ...................................................... 5

REPAIR THE CAUSE ........................................... 5

CONFIRM THE REPAIR ....................................... 6

Generic Squeak and Rattle Troubleshooting ........... 6

INSTRUMENT PANEL .......................................... 6

CENTER CONSOLE ............................................. 6

DOORS ................................................................. 6

TRUNK .................................................................. 7

SUNROOF/HEADLINING ..................................... 7

SEATS ................................................................... 7

UNDERHOOD ....................................................... 7

Diagnostic Worksheet .............................................. 8

SUNROOF ................................................................ 10

Component Parts and Harness Connector Location... 10

System Description ................................................. 11

TILT UP / SLIDE CLOSE OPERATION ................ 11

TILT DOWN / SLIDE OPEN OPERATION ........... 11AUTO OPERATION ............................................. 11

ANTI-PINCH FUNCTION .................................... 11

MEMORY RESET PROCEDURE ....................... 12

INITIALIZATION PROCEDURE .......................... 12

CAN Communication System Description .............. 13

CAN Communication Unit ....................................... 13

Wiring Diagram — SROOF — ................................ 14

Terminals and Reference Value for BCM ............... 15

Terminals and Reference Value for Sunroof Motor

Assembly ................................................................ 15

Work Flow ............................................................... 16

Trouble Diagnosis Symptom Chart ......................... 16

BCM Power Supply and Ground Circuit Check ...... 16

Sunroof Motor Assembly Power Supply and Ground

Circuit Check .......................................................... 17

Sunroof Switch System Check ............................... 18

Fitting Adjustment ................................................... 20

GAP ADJUSTMENT ............................................ 20

HEIGHT DIFFERENCE ADJUSTMENT .............. 20

Removal and Installation ........................................ 21

SUNROOF UNIT ................................................. 22

GLASS LID .......................................................... 22

WIND DEFLECTOR ............................................ 23

SUNSHADE ........................................................ 23

SUNROOF MOTOR ............................................ 23

DRAIN HOSES .................................................... 25

WEATHERSTRIP ................................................ 25

REAR DRAIN ASSEMBLY .................................. 25

LINK AND WIRE ASSEMBLY ............................. 26

Page 2684 of 3171

SQUEAK AND RATTLE TROUBLE DIAGNOSES

RF-7

C

D

E

F

G

H

J

K

L

MA

B

RF

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid dumpers out of adjustment

2. Trunk lid striker out of adjustment

3. Trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sunvisor shaft shaking in the holder

3. Front or rear windshield touching headlining and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

SEATS

When isolating seat noise it's important to note the position the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. Rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of these incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Page 2687 of 3171

RF-10

SUNROOF

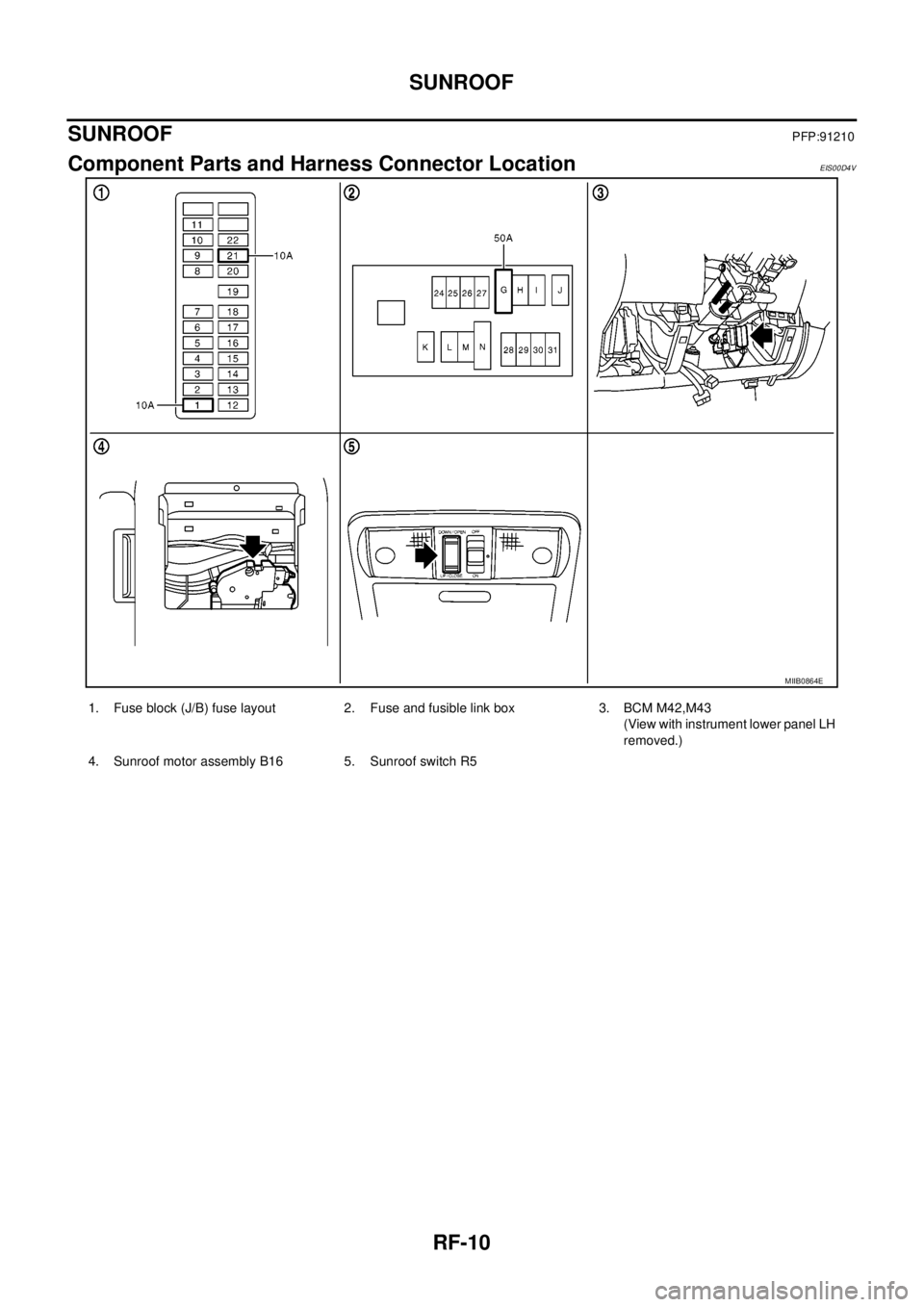

SUNROOF

PFP:91210

Component Parts and Harness Connector LocationEIS00D4V

MIIB0864E

1. Fuse block (J/B) fuse layout 2. Fuse and fusible link box 3. BCM M42,M43

(View with instrument lower panel LH

removed.)

4. Sunroof motor assembly B16 5. Sunroof switch R5

Page 2688 of 3171

SUNROOF

RF-11

C

D

E

F

G

H

J

K

L

MA

B

RF

System DescriptionEIS00D4W

Power supplied at all time

lthrough 50A fusible link (letterG, located in the fuse and fusible link box)

lto BCM terminal 57.

lthrough 10A fuse [No.21, located in the fuse block (J/B)]

lto BCM terminal 41.

lthrough BCM terminal 58

lto sunroof motor assembly terminal 7.

Ground is supplied

lto BCM terminal 55

lthrough body grounds M21, M80 and M83.

lto sunroof motor assembly terminal 10

lthrough body grounds B9 and B25.

When ignition switch ON or START position,

Power is supplied

lthrough 10A fuse [No.1, located in the fuse block (J/B)]

lto BCM terminal 3.

lthrough BCM terminal 53

lto sunroof motor assembly terminal 9.

TILT UP / SLIDE CLOSE OPERATION

When tilt up / slide close switch is pressed,

Ground is supplied

lto sunroof motor assembly terminal 1

lthrough sunroof switch terminal 3

lthrough sunroof switch terminal 2

lthrough body grounds M21, M80 and M83.

Then, the sunroof tilt up / slide close.

TILT DOWN / SLIDE OPEN OPERATION

When tilt down / slide open switch is pressed,

Ground is supplied

lto sunroof motor assembly terminal 5

lthrough sunroof switch terminal 1

lthrough sunroof switch terminal 2

lthrough body grounds M21, M80 and M83.

Then, the sunroof tilt down / slide open.

AUTO OPERATION

The power sunroof AUTO feature makes it possible to slide open and slide close or tilt up and tilt down the

sunroof without holding the sunroof switch in the TILT UP/SLIDE CLOSE, TILT DOWN/SLIDE OPEN position.

ANTI-PINCH FUNCTION

The CPU of sunroof motor assembly monitors the sunroof motor operation and the sunroof position (fully-

closed or other) by the signals from sunroof motor.

When sunroof motor detects an interruption during the following slide close and tilt down operation, sunroof

switch controls the motor for open and the sunroof will operate until it reaches full up position (when tilt down

operate) or 125 mm (4.92 in) or more in an open direction (during slide close operate).

lclose operation and tilt down when ignition switch is in the ON position.

Page 2689 of 3171

RF-12

SUNROOF

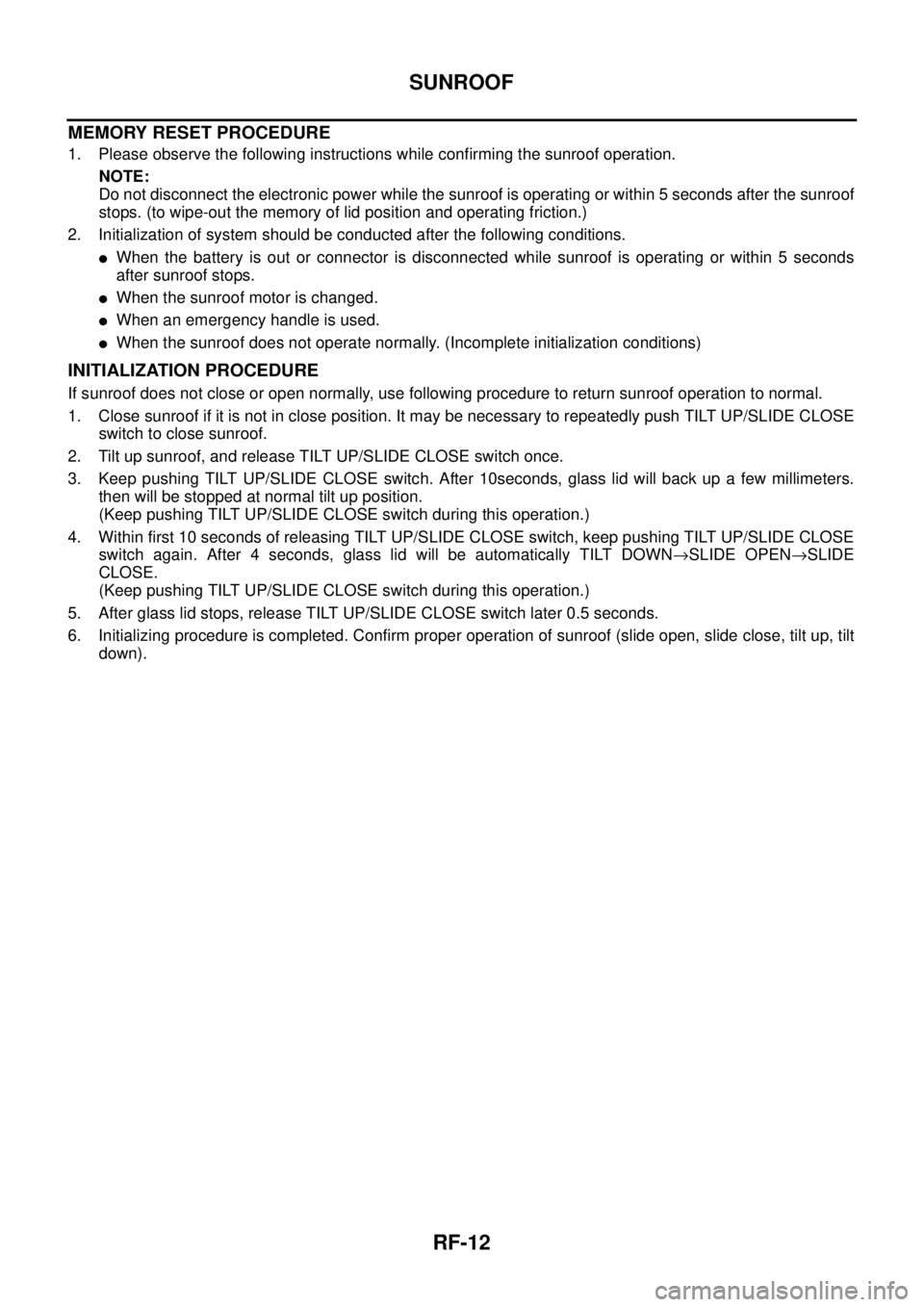

MEMORY RESET PROCEDURE

1. Please observe the following instructions while confirming the sunroof operation.

NOTE:

Do not disconnect the electronic power while the sunroof is operating or within 5 seconds after the sunroof

stops. (to wipe-out the memory of lid position and operating friction.)

2. Initialization of system should be conducted after the following conditions.

lWhen the battery is out or connector is disconnected while sunroof is operating or within 5 seconds

after sunroof stops.

lWhen the sunroof motor is changed.

lWhen an emergency handle is used.

lWhen the sunroof does not operate normally. (Incomplete initialization conditions)

INITIALIZATION PROCEDURE

If sunroof does not close or open normally, use following procedure to return sunroof operation to normal.

1. Close sunroof if it is not in close position. It may be necessary to repeatedly push TILT UP/SLIDE CLOSE

switch to close sunroof.

2. Tilt up sunroof, and release TILT UP/SLIDE CLOSE switch once.

3. Keep pushing TILT UP/SLIDE CLOSE switch. After 10seconds, glass lid will back up a few millimeters.

then will be stopped at normal tilt up position.

(Keep pushing TILT UP/SLIDE CLOSE switch during this operation.)

4. Within first 10 seconds of releasing TILT UP/SLIDE CLOSE switch, keep pushing TILT UP/SLIDE CLOSE

switch again. After 4 seconds, glass lid will be automatically TILT DOWN®SLIDE OPEN®SLIDE

CLOSE.

(Keep pushing TILT UP/SLIDE CLOSE switch during this operation.)

5. After glass lid stops, release TILT UP/SLIDE CLOSE switch later 0.5 seconds.

6. Initializing procedure is completed. Confirm proper operation of sunroof (slide open, slide close, tilt up, tilt

down).

Page 2690 of 3171

SUNROOF

RF-13

C

D

E

F

G

H

J

K

L

MA

B

RF

CAN Communication System DescriptionEIS00D4X

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

CAN Communication UnitEIS00D4Y

Refer toLAN-30, "CAN Communication Unit".

Page 2691 of 3171

RF-14

SUNROOF

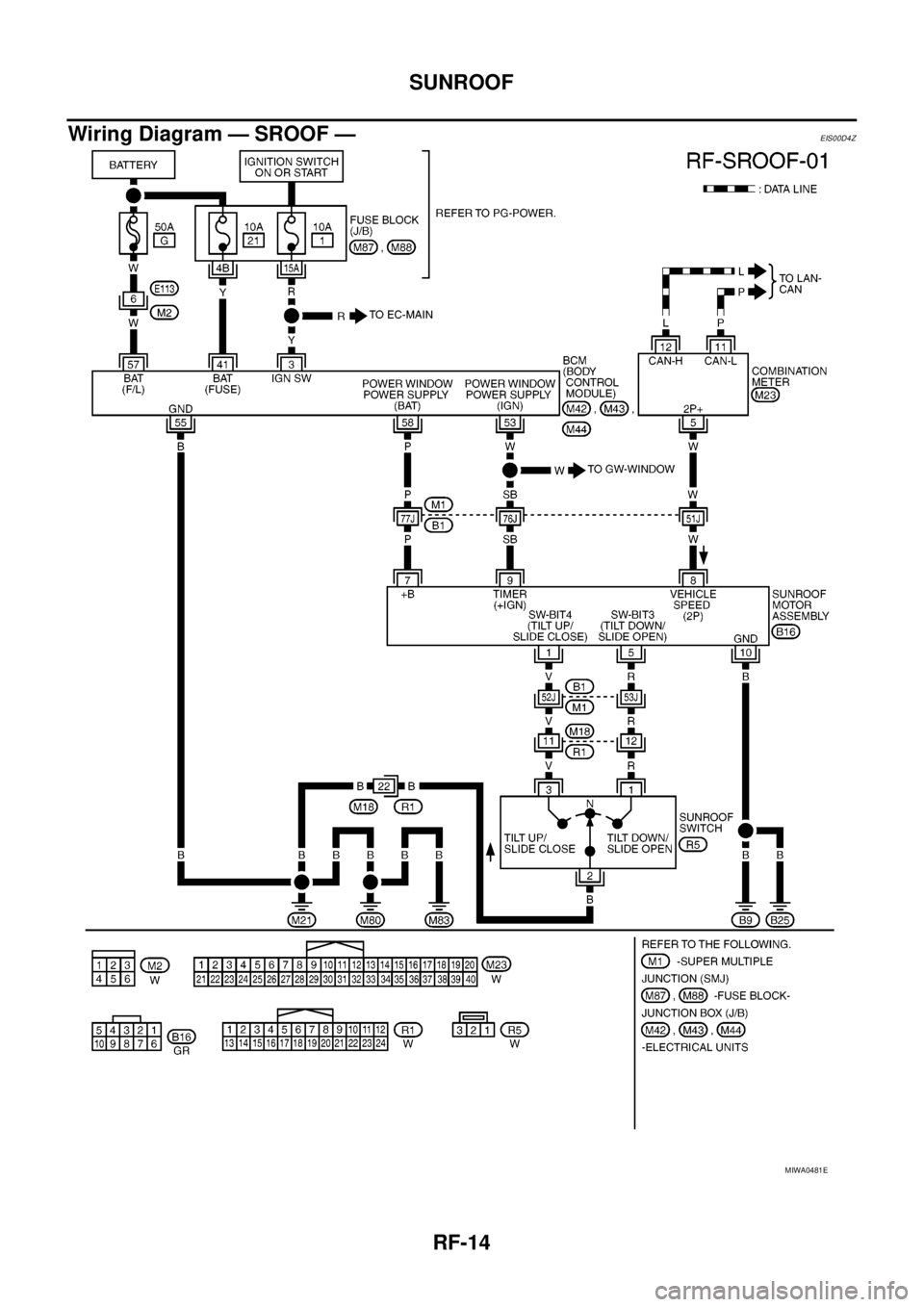

Wiring Diagram — SROOF —

EIS00D4Z

MIWA0481E

Page 2692 of 3171

SUNROOF

RF-15

C

D

E

F

G

H

J

K

L

MA

B

RF

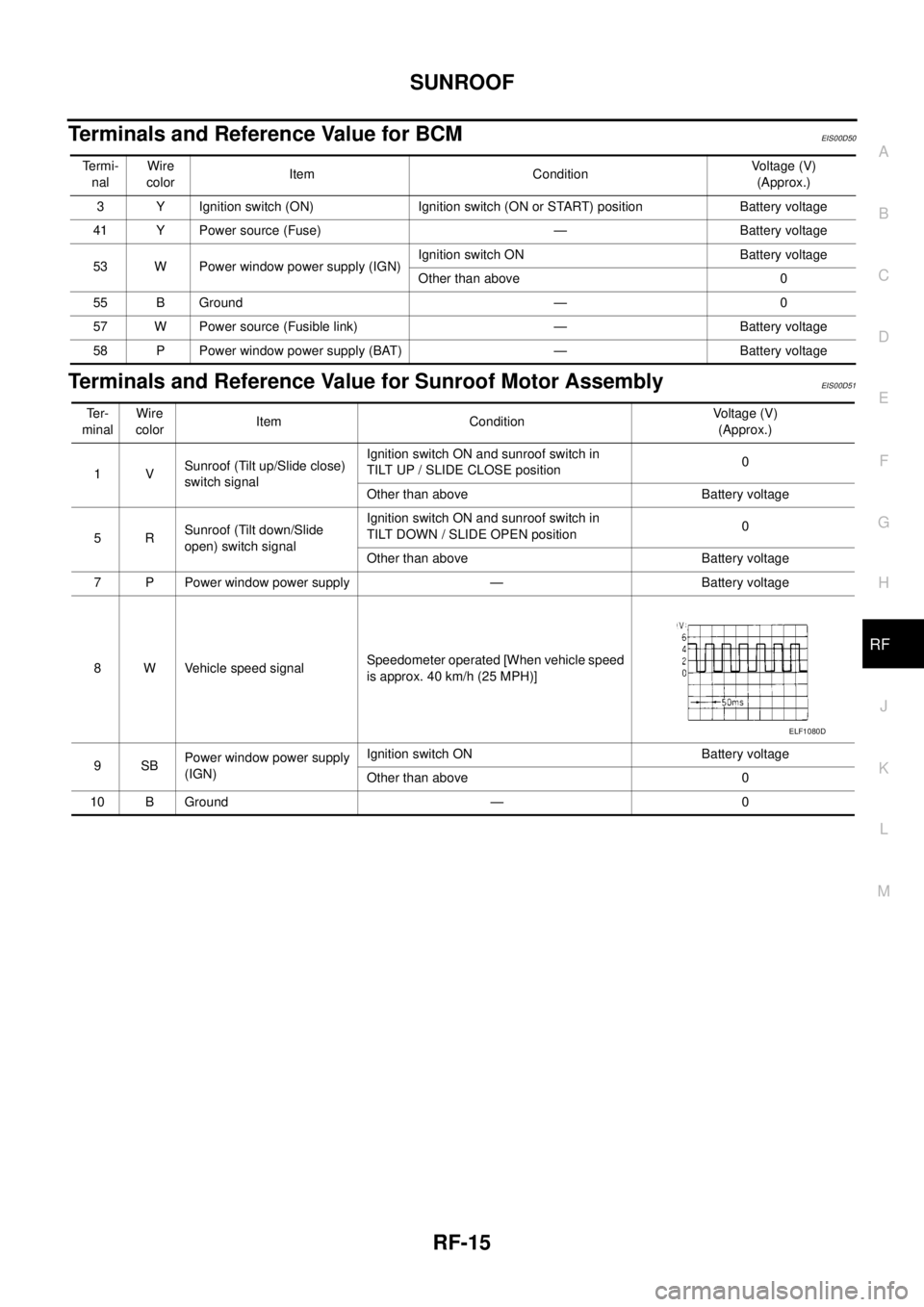

Terminals and Reference Value for BCMEIS00D50

Terminals and Reference Value for Sunroof Motor AssemblyEIS00D51

Te r m i -

nalWire

colorItem ConditionVo l ta g e (V )

(Approx.)

3 Y Ignition switch (ON) Ignition switch (ON or START) position Battery voltage

41 Y Power source (Fuse) — Battery voltage

53 W Power window power supply (IGN)Ignition switch ON Battery voltage

Other than above 0

55 B Ground — 0

57 W Power source (Fusible link) — Battery voltage

58 P Power window power supply (BAT) — Battery voltage

Te r -

minalWire

colorItem ConditionVoltage (V)

(Approx.)

1VSunroof (Tilt up/Slide close)

switch signalIgnition switch ON and sunroof switch in

TILT UP / SLIDE CLOSE position0

Other than above Battery voltage

5RSunroof (Tilt down/Slide

open) switch signalIgnition switch ON and sunroof switch in

TILT DOWN / SLIDE OPEN position0

Other than above Battery voltage

7 P Power window power supply — Battery voltage

8 W Vehicle speed signalSpeedometer operated [When vehicle speed

is approx. 40 km/h (25 MPH)]

9SBPower window power supply

(IGN)Ignition switch ON Battery voltage

Other than above 0

10 B Ground — 0

ELF1080D

Page 2693 of 3171

RF-16

SUNROOF

Work Flow

EIS00D52

1. Check the symptom and customer's requests.

2. Understand the outline of system. Refer toRF-11, "

System Description".

3. According to the trouble diagnosis chart, repair or replace the cause of the malfunction. Refer toRF-16,

"Trouble Diagnosis Symptom Chart".

4. Does sunroof system operate normally? If Yes, GO TO 5. If No, GO TO 3.

5. INSPECTION END.

Trouble Diagnosis Symptom ChartEIS00D53

BCM Power Supply and Ground Circuit CheckEIS00D54

1.FUSE INSPECTION

Check the following.

l50A fusible link (letterG, located in the fuse and fusible link box)

l10A fuse [No. 1, located in the fuse block (J/B)]

l10A fuse [No.21 located in the fuse block (J/B)]

NOTE:

Refer toRF-10, "

Component Parts and Harness Connector Location".

OK or NG

OK >> GO TO 2.

NG >> If fuse is blown, be sure to eliminate cause of malfunction before installing new fuse, refer toPG-

4, "POWER SUPPLY ROUTING CIRCUIT".

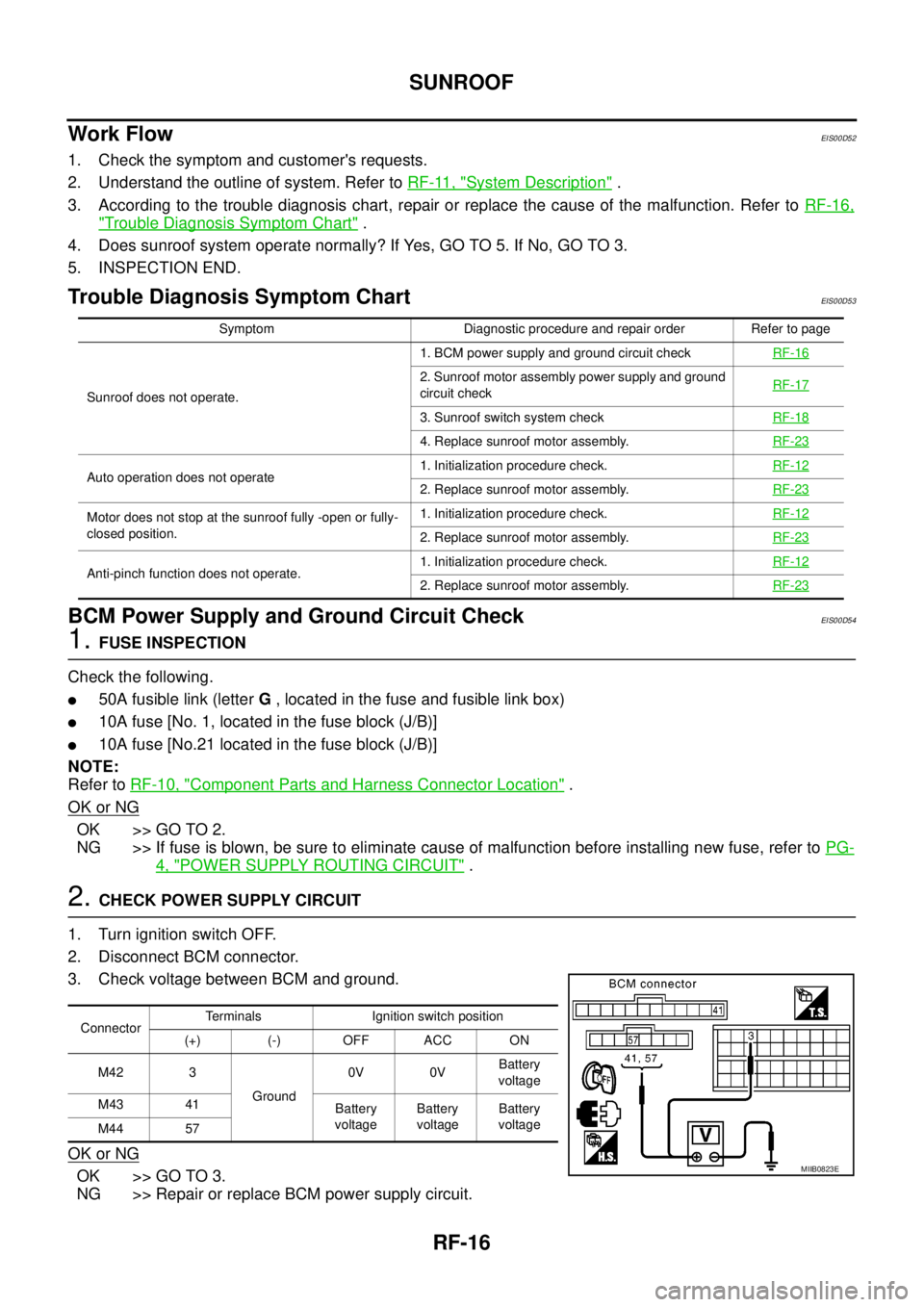

2.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Check voltage between BCM and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace BCM power supply circuit.

Symptom Diagnostic procedure and repair order Refer to page

Sunroof does not operate.1. BCM power supply and ground circuit checkRF-16

2. Sunroof motor assembly power supply and ground

circuit checkRF-17

3. Sunroof switch system checkRF-18

4. Replace sunroof motor assembly.RF-23

Auto operation does not operate1. Initialization procedure check.RF-122. Replace sunroof motor assembly.RF-23

Motor does not stop at the sunroof fully -open or fully-

closed position.1. Initialization procedure check.RF-12

2. Replace sunroof motor assembly.RF-23

Anti-pinch function does not operate.1. Initialization procedure check.RF-122. Replace sunroof motor assembly.RF-23

ConnectorTerminals Ignition switch position

(+) (-) OFF ACC ON

M42 3

Ground0V 0VBattery

voltage

M43 41

Battery

voltageBattery

voltageBattery

voltage

M44 57

MIIB0823E

Page 2694 of 3171

SUNROOF

RF-17

C

D

E

F

G

H

J

K

L

MA

B

RF

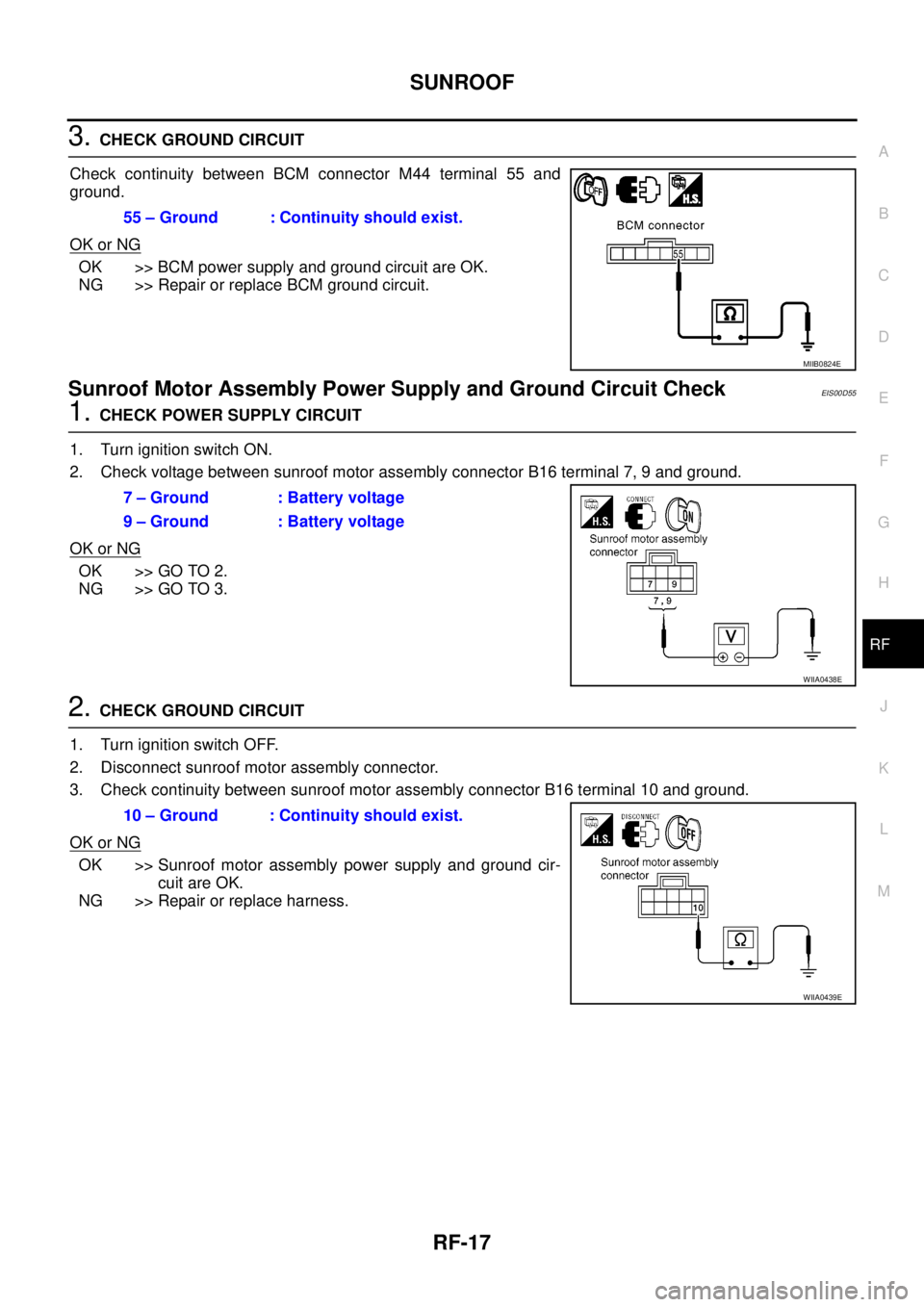

3.CHECK GROUND CIRCUIT

Check continuity between BCM connector M44 terminal 55 and

ground.

OK or NG

OK >> BCM power supply and ground circuit are OK.

NG >> Repair or replace BCM ground circuit.

Sunroof Motor Assembly Power Supply and Ground Circuit CheckEIS00D55

1.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch ON.

2. Check voltage between sunroof motor assembly connector B16 terminal 7, 9 and ground.

OK or NG

OK >> GO TO 2.

NG >> GO TO 3.

2.CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect sunroof motor assembly connector.

3. Check continuity between sunroof motor assembly connector B16 terminal 10 and ground.

OK or NG

OK >> Sunroof motor assembly power supply and ground cir-

cuit are OK.

NG >> Repair or replace harness.55 – Ground : Continuity should exist.

MIIB0824E

7 – Ground : Battery voltage

9 – Ground : Battery voltage

WIIA0438E

10 – Ground : Continuity should exist.

WIIA0439E