roof NISSAN NAVARA 2005 Repair Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1755 of 3171

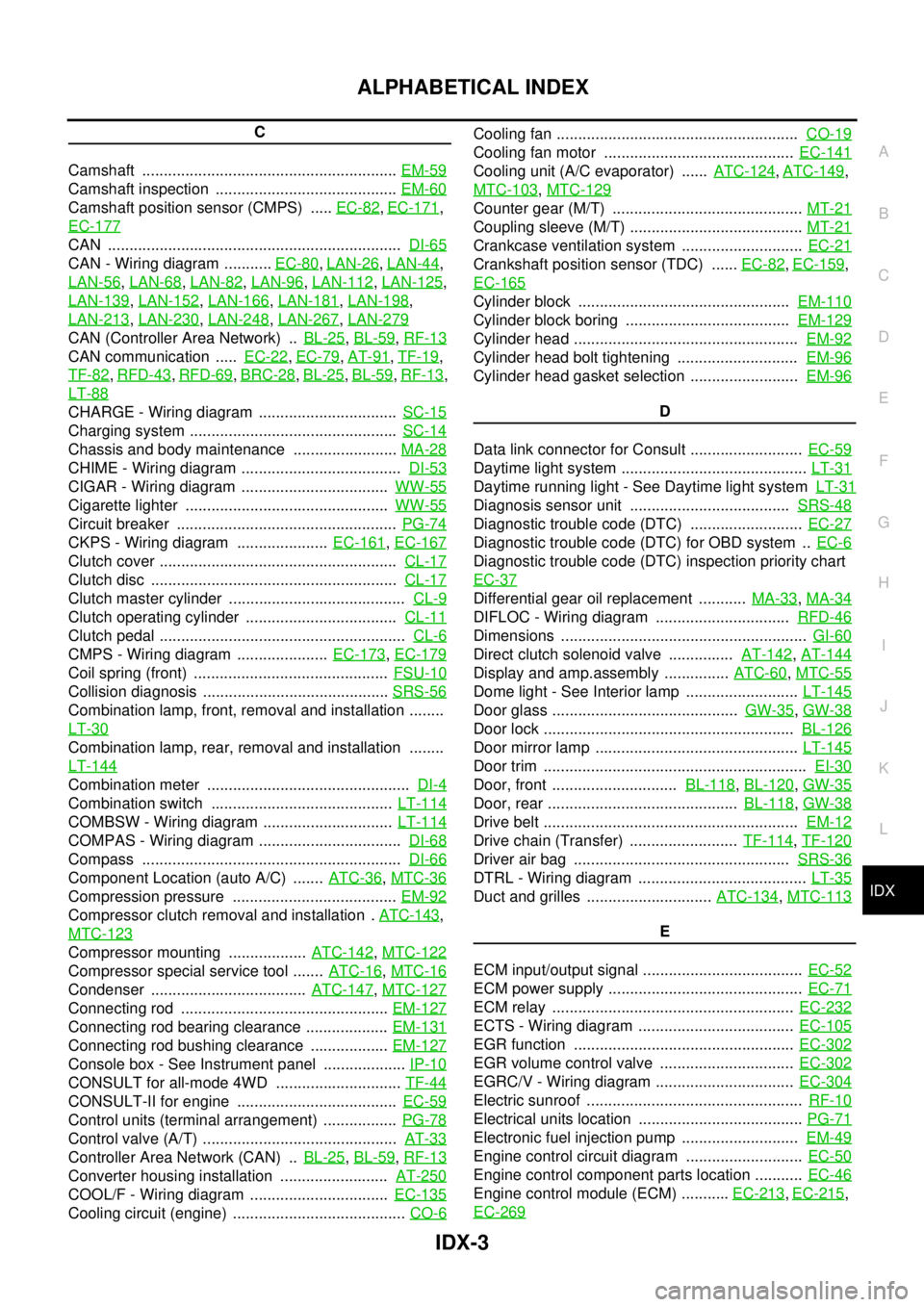

IDX-3

A

C

D

E

F

G

H

I

J

K

L B

IDX

ALPHABETICAL INDEX

C

Camshaft ...........................................................EM-59

Camshaft inspection ..........................................EM-60

Camshaft position sensor (CMPS) .....EC-82,EC-171,

EC-177

CAN ....................................................................DI-65

CAN - Wiring diagram ...........EC-80,LAN-26,LAN-44,

LAN-56

,LAN-68,LAN-82,LAN-96,LAN-112,LAN-125,

LAN-139

,LAN-152,LAN-166,LAN-181,LAN-198,

LAN-213

,LAN-230,LAN-248,LAN-267,LAN-279

CAN (Controller Area Network) ..BL-25,BL-59,RF-13

CAN communication .....EC-22,EC-79,AT-91,TF-19,

TF-82

,RFD-43,RFD-69,BRC-28,BL-25,BL-59,RF-13,

LT-88

CHARGE - Wiring diagram ................................SC-15

Charging system ................................................SC-14

Chassis and body maintenance ........................MA-28

CHIME - Wiring diagram .....................................DI-53

CIGAR - Wiring diagram ..................................WW-55

Cigarette lighter ...............................................WW-55

Circuit breaker ...................................................PG-74

CKPS - Wiring diagram .....................EC-161,EC-167

Clutch cover .......................................................CL-17

Clutch disc .........................................................CL-17

Clutch master cylinder .........................................CL-9

Clutch operating cylinder ...................................CL-11

Clutch pedal .........................................................CL-6

CMPS - Wiring diagram .....................EC-173,EC-179

Coil spring (front) .............................................FSU-10

Collision diagnosis ...........................................SRS-56

Combination lamp, front, removal and installation ........

LT-30

Combination lamp, rear, removal and installation ........

LT-144

Combination meter ...............................................DI-4

Combination switch ..........................................LT-114

COMBSW - Wiring diagram ..............................LT-114

COMPAS - Wiring diagram .................................DI-68

Compass ............................................................DI-66

Component Location (auto A/C) .......ATC-36,MTC-36

Compression pressure ......................................EM-92

Compressor clutch removal and installation .ATC-143,

MTC-123

Compressor mounting ..................ATC-142,MTC-122

Compressor special service tool .......ATC-16,MTC-16

Condenser ....................................ATC-147,MTC-127

Connecting rod ................................................EM-127

Connecting rod bearing clearance ...................EM-131

Connecting rod bushing clearance ..................EM-127

Console box - See Instrument panel ...................IP-10

CONSULT for all-mode 4WD .............................TF-44

CONSULT-II for engine .....................................EC-59

Control units (terminal arrangement) .................PG-78

Control valve (A/T) .............................................AT-33

Controller Area Network (CAN) ..BL-25,BL-59,RF-13

Converter housing installation .........................AT-250

COOL/F - Wiring diagram ................................EC-135

Cooling circuit (engine) ........................................CO-6

Cooling fan ........................................................CO-19

Cooling fan motor ............................................EC-141

Cooling unit (A/C evaporator) ......ATC-124,ATC-149,

MTC-103

,MTC-129

Counter gear (M/T) ............................................MT-21

Coupling sleeve (M/T) ........................................MT-21

Crankcase ventilation system ............................EC-21

Crankshaft position sensor (TDC) ......EC-82,EC-159,

EC-165

Cylinder block .................................................EM-110

Cylinder block boring ......................................EM-129

Cylinder head ....................................................EM-92

Cylinder head bolt tightening ............................EM-96

Cylinder head gasket selection .........................EM-96

D

Data link connector for Consult ..........................EC-59

Daytime light system ...........................................LT-31

Daytime running light - See Daytime light systemLT-31

Diagnosis sensor unit .....................................SRS-48

Diagnostic trouble code (DTC) ..........................EC-27

Diagnostic trouble code (DTC) for OBD system ..EC-6

Diagnostic trouble code (DTC) inspection priority chart

EC-37

Differential gear oil replacement ...........MA-33,MA-34

DIFLOC - Wiring diagram ...............................RFD-46

Dimensions .........................................................GI-60

Direct clutch solenoid valve ...............AT-142,AT-144

Display and amp.assembly ...............ATC-60,MTC-55

Dome light - See Interior lamp ..........................LT-145

Door glass ...........................................GW-35,GW-38

Door lock ..........................................................BL-126

Door mirror lamp ...............................................LT-145

Door trim .............................................................EI-30

Door, front .............................BL-118,BL-120,GW-35

Door, rear ............................................BL-118,GW-38

Drive belt ...........................................................EM-12

Drive chain (Transfer) .........................TF-114,TF-120

Driver air bag ..................................................SRS-36

DTRL - Wiring diagram .......................................LT-35

Duct and grilles .............................ATC-134,MTC-113

E

ECM input/output signal .....................................EC-52

ECM power supply .............................................EC-71

ECM relay ........................................................EC-232

ECTS - Wiring diagram ....................................EC-105

EGR function ...................................................EC-302

EGR volume control valve ...............................EC-302

EGRC/V - Wiring diagram ................................EC-304

Electric sunroof ..................................................RF-10

Electrical units location ......................................PG-71

Electronic fuel injection pump ...........................EM-49

Engine control circuit diagram ...........................EC-50

Engine control component parts location ...........EC-46

Engine control module (ECM) ...........EC-213,EC-215,

EC-269

Page 1758 of 3171

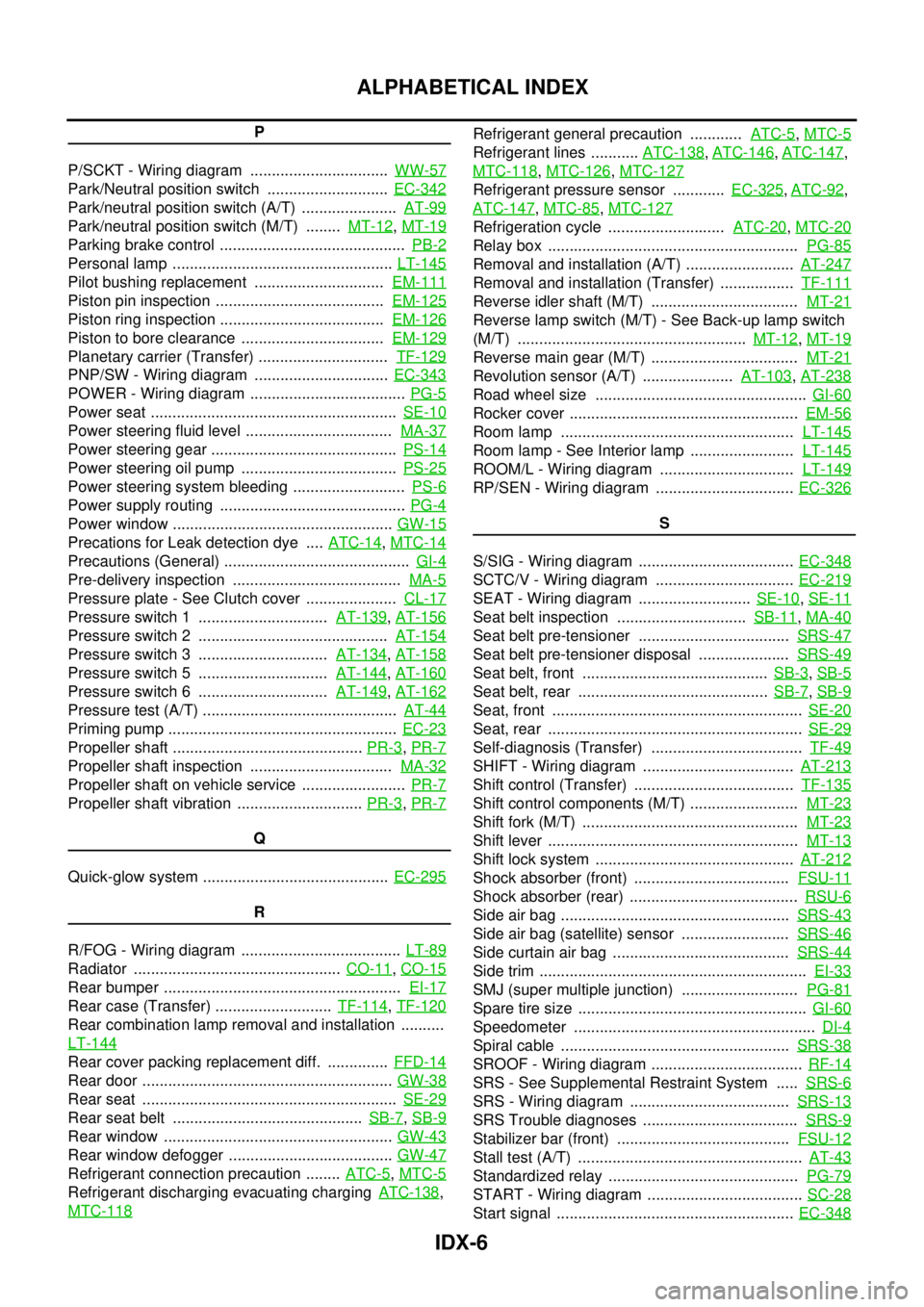

IDX-6

ALPHABETICAL INDEX

P

P/SCKT - Wiring diagram ................................WW-57

Park/Neutral position switch ............................EC-342

Park/neutral position switch (A/T) ......................AT-99

Park/neutral position switch (M/T) ........MT-12,MT-19

Parking brake control ...........................................PB-2

Personal lamp ...................................................LT-145

Pilot bushing replacement ..............................EM-111

Piston pin inspection .......................................EM-125

Piston ring inspection ......................................EM-126

Piston to bore clearance .................................EM-129

Planetary carrier (Transfer) ..............................TF-129

PNP/SW - Wiring diagram ...............................EC-343

POWER - Wiring diagram ....................................PG-5

Power seat .........................................................SE-10

Power steering fluid level ..................................MA-37

Power steering gear ...........................................PS-14

Power steering oil pump ....................................PS-25

Power steering system bleeding ..........................PS-6

Power supply routing ...........................................PG-4

Power window ...................................................GW-15

Precations for Leak detection dye ....ATC-14,MTC-14

Precautions (General) ...........................................GI-4

Pre-delivery inspection .......................................MA-5

Pressure plate - See Clutch cover .....................CL-17

Pressure switch 1 ..............................AT-139,AT-156

Pressure switch 2 ............................................AT-154

Pressure switch 3 ..............................AT-134,AT-158

Pressure switch 5 ..............................AT-144,AT-160

Pressure switch 6 ..............................AT-149,AT-162

Pressure test (A/T) .............................................AT-44

Priming pump .....................................................EC-23

Propeller shaft ............................................PR-3,PR-7

Propeller shaft inspection .................................MA-32

Propeller shaft on vehicle service ........................PR-7

Propeller shaft vibration .............................PR-3,PR-7

Q

Quick-glow system ...........................................EC-295

R

R/FOG - Wiring diagram .....................................LT-89

Radiator ................................................CO-11,CO-15

Rear bumper .......................................................EI-17

Rear case (Transfer) ...........................TF-114,TF-120

Rear combination lamp removal and installation ..........

LT-144

Rear cover packing replacement diff. ..............FFD-14

Rear door ..........................................................GW-38

Rear seat ...........................................................SE-29

Rear seat belt ............................................SB-7,SB-9

Rear window .....................................................GW-43

Rear window defogger ......................................GW-47

Refrigerant connection precaution ........ATC-5,MTC-5

Refrigerant discharging evacuating chargingATC-138,

MTC-118

Refrigerant general precaution ............ATC-5,MTC-5

Refrigerant lines ...........ATC-138,ATC-146,ATC-147,

MTC-118

,MTC-126,MTC-127

Refrigerant pressure sensor ............EC-325,ATC-92,

ATC-147

,MTC-85,MTC-127

Refrigeration cycle ...........................ATC-20,MTC-20

Relay box ..........................................................PG-85

Removal and installation (A/T) .........................AT-247

Removal and installation (Transfer) .................TF-111

Reverse idler shaft (M/T) ..................................MT-21

Reverse lamp switch (M/T) - See Back-up lamp switch

(M/T) .....................................................MT-12

,MT-19

Reverse main gear (M/T) ..................................MT-21

Revolution sensor (A/T) .....................AT-103,AT-238

Road wheel size .................................................GI-60

Rocker cover .....................................................EM-56

Room lamp ......................................................LT-145

Room lamp - See Interior lamp ........................LT-145

ROOM/L - Wiring diagram ...............................LT-149

RP/SEN - Wiring diagram ................................EC-326

S

S/SIG - Wiring diagram ....................................EC-348

SCTC/V - Wiring diagram ................................EC-219

SEAT - Wiring diagram ..........................SE-10,SE-11

Seat belt inspection ..............................SB-11,MA-40

Seat belt pre-tensioner ...................................SRS-47

Seat belt pre-tensioner disposal .....................SRS-49

Seat belt, front ...........................................SB-3,SB-5

Seat belt, rear ............................................SB-7,SB-9

Seat, front ..........................................................SE-20

Seat, rear ...........................................................SE-29

Self-diagnosis (Transfer) ...................................TF-49

SHIFT - Wiring diagram ...................................AT-213

Shift control (Transfer) .....................................TF-135

Shift control components (M/T) .........................MT-23

Shift fork (M/T) ..................................................MT-23

Shift lever ..........................................................MT-13

Shift lock system ..............................................AT-212

Shock absorber (front) ....................................FSU-11

Shock absorber (rear) .......................................RSU-6

Side air bag .....................................................SRS-43

Side air bag (satellite) sensor .........................SRS-46

Side curtain air bag .........................................SRS-44

Side trim ..............................................................EI-33

SMJ (super multiple junction) ...........................PG-81

Spare tire size .....................................................GI-60

Speedometer ........................................................DI-4

Spiral cable .....................................................SRS-38

SROOF - Wiring diagram ...................................RF-14

SRS - See Supplemental Restraint System .....SRS-6

SRS - Wiring diagram .....................................SRS-13

SRS Trouble diagnoses ....................................SRS-9

Stabilizer bar (front) ........................................FSU-12

Stall test (A/T) ....................................................AT-43

Standardized relay ............................................PG-79

START - Wiring diagram ....................................SC-28

Start signal .......................................................EC-348

Page 1759 of 3171

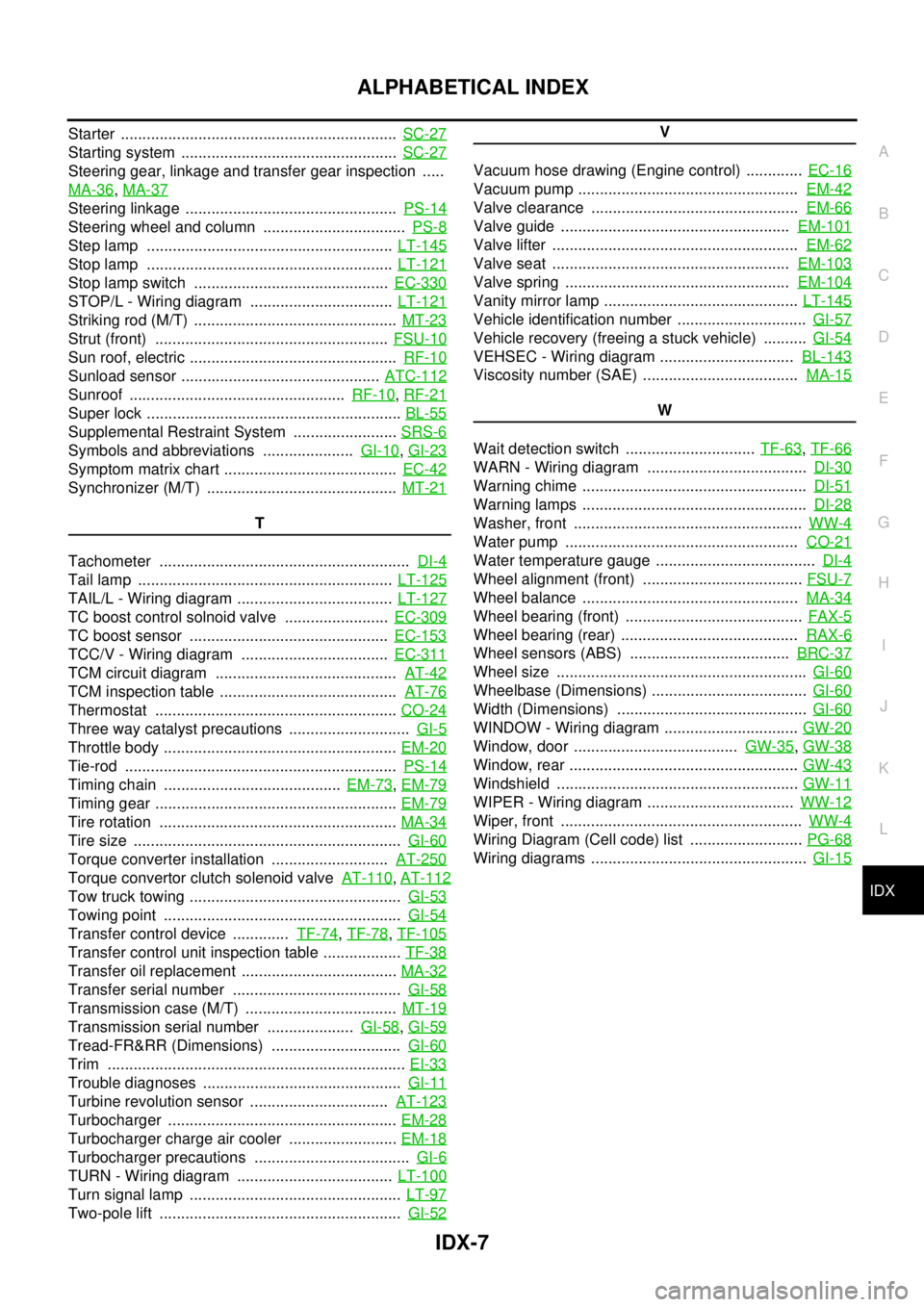

IDX-7

A

C

D

E

F

G

H

I

J

K

L B

IDX

ALPHABETICAL INDEX

Starter ................................................................SC-27

Starting system ..................................................SC-27

Steering gear, linkage and transfer gear inspection .....

MA-36

,MA-37

Steering linkage .................................................PS-14

Steering wheel and column .................................PS-8

Step lamp .........................................................LT-145

Stop lamp .........................................................LT-121

Stop lamp switch .............................................EC-330

STOP/L - Wiring diagram .................................LT-121

Striking rod (M/T) ...............................................MT-23

Strut (front) ......................................................FSU-10

Sun roof, electric ................................................RF-10

Sunload sensor ..............................................ATC-112

Sunroof ..................................................RF-10,RF-21

Super lock ...........................................................BL-55

Supplemental Restraint System ........................SRS-6

Symbols and abbreviations .....................GI-10,GI-23

Symptom matrix chart ........................................EC-42

Synchronizer (M/T) ............................................MT-21

T

Tachometer ..........................................................DI-4

Tail lamp ...........................................................LT-125

TAIL/L - Wiring diagram ....................................LT-127

TC boost control solnoid valve ........................EC-309

TC boost sensor ..............................................EC-153

TCC/V - Wiring diagram ..................................EC-311

TCM circuit diagram ..........................................AT-42

TCM inspection table .........................................AT-76

Thermostat ........................................................CO-24

Three way catalyst precautions ............................GI-5

Throttle body ......................................................EM-20

Tie-rod ...............................................................PS-14

Timing chain .........................................EM-73,EM-79

Timing gear ........................................................EM-79

Tire rotation .......................................................MA-34

Tire size ..............................................................GI-60

Torque converter installation ...........................AT-250

Torque convertor clutch solenoid valveAT-110,AT-112

Tow truck towing .................................................GI-53

Towing point .......................................................GI-54

Transfer control device .............TF-74,TF-78,TF-105

Transfer control unit inspection table ..................TF-38

Transfer oil replacement ....................................MA-32

Transfer serial number .......................................GI-58

Transmission case (M/T) ...................................MT-19

Transmission serial number ....................GI-58,GI-59

Tread-FR&RR (Dimensions) ..............................GI-60

Trim .....................................................................EI-33

Trouble diagnoses ..............................................GI-11

Turbine revolution sensor ................................AT-123

Turbocharger .....................................................EM-28

Turbocharger charge air cooler .........................EM-18

Turbocharger precautions ....................................GI-6

TURN - Wiring diagram ....................................LT-100

Turn signal lamp .................................................LT-97

Two-pole lift ........................................................GI-52

V

Vacuum hose drawing (Engine control) .............EC-16

Vacuum pump ...................................................EM-42

Valve clearance ................................................EM-66

Valve guide .....................................................EM-101

Valve lifter .........................................................EM-62

Valve seat .......................................................EM-103

Valve spring ....................................................EM-104

Vanity mirror lamp .............................................LT-145

Vehicle identification number ..............................GI-57

Vehicle recovery (freeing a stuck vehicle) ..........GI-54

VEHSEC - Wiring diagram ...............................BL-143

Viscosity number (SAE) ....................................MA-15

W

Wait detection switch ..............................TF-63

,TF-66

WARN - Wiring diagram .....................................DI-30

Warning chime ....................................................DI-51

Warning lamps ....................................................DI-28

Washer, front .....................................................WW-4

Water pump ......................................................CO-21

Water temperature gauge .....................................DI-4

Wheel alignment (front) .....................................FSU-7

Wheel balance ..................................................MA-34

Wheel bearing (front) .........................................FAX-5

Wheel bearing (rear) .........................................RAX-6

Wheel sensors (ABS) .....................................BRC-37

Wheel size ..........................................................GI-60

Wheelbase (Dimensions) ....................................GI-60

Width (Dimensions) ............................................GI-60

WINDOW - Wiring diagram ...............................GW-20

Window, door ......................................GW-35,GW-38

Window, rear .....................................................GW-43

Windshield ........................................................GW-11

WIPER - Wiring diagram ..................................WW-12

Wiper, front ........................................................WW-4

Wiring Diagram (Cell code) list ..........................PG-68

Wiring diagrams ..................................................GI-15

Page 1760 of 3171

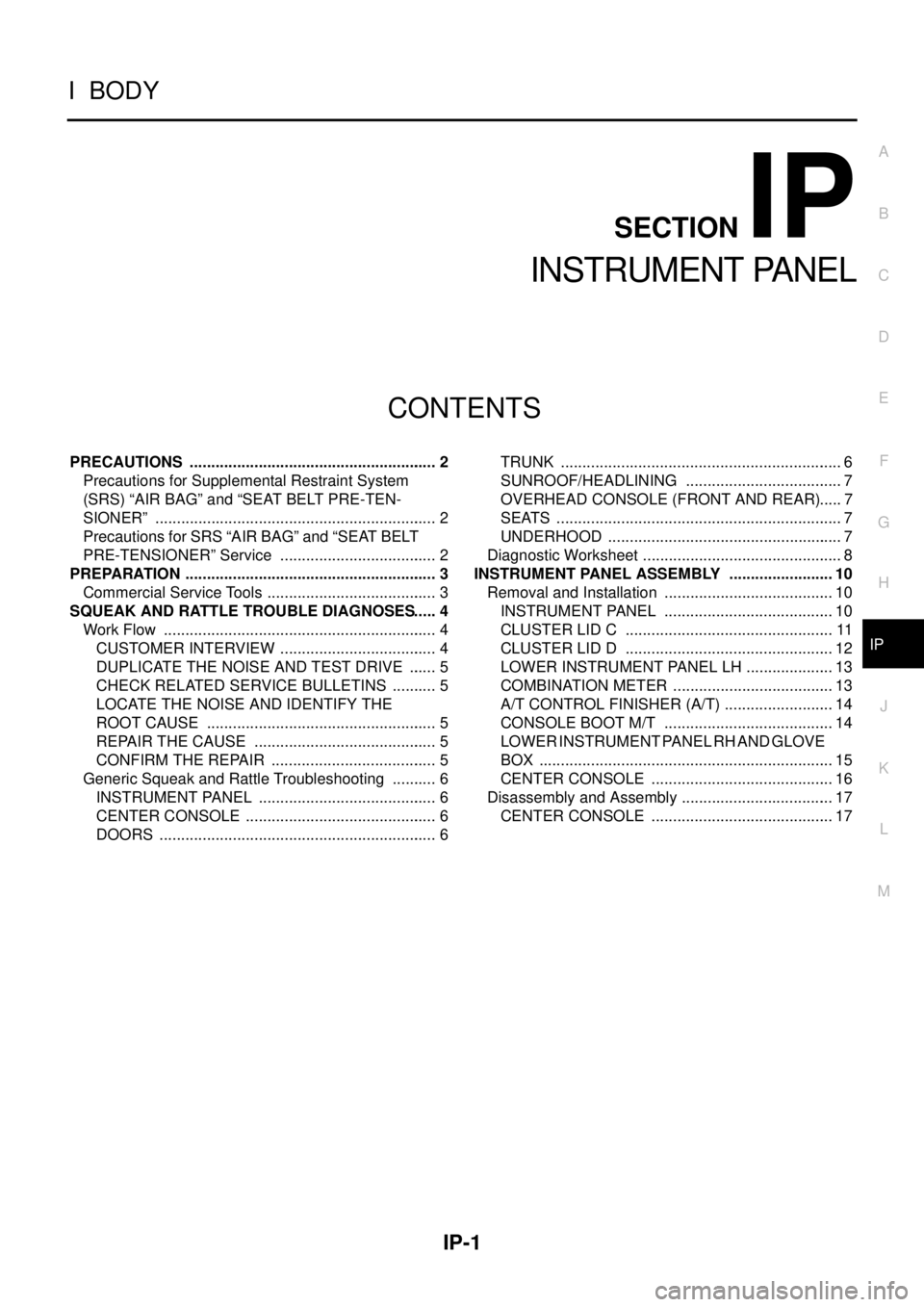

IP-1

INSTRUMENT PANEL

IBODY

CONTENTS

C

D

E

F

G

H

J

K

L

M

SECTIONIP

A

B

IP

INSTRUMENT PANEL

PRECAUTIONS .......................................................... 2

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 2

Precautions for SRS “AIR BAG” and “SEAT BELT

PRE-TENSIONER” Service ..................................... 2

PREPARATION ........................................................... 3

Commercial Service Tools ........................................ 3

SQUEAK AND RATTLE TROUBLE DIAGNOSES..... 4

Work Flow ................................................................ 4

CUSTOMER INTERVIEW ..................................... 4

DUPLICATE THE NOISE AND TEST DRIVE ....... 5

CHECK RELATED SERVICE BULLETINS ........... 5

LOCATE THE NOISE AND IDENTIFY THE

ROOT CAUSE ...................................................... 5

REPAIR THE CAUSE ........................................... 5

CONFIRM THE REPAIR ....................................... 5

Generic Squeak and Rattle Troubleshooting ........... 6

INSTRUMENT PANEL .......................................... 6

CENTER CONSOLE ............................................. 6

DOORS ................................................................. 6TRUNK .................................................................. 6

SUNROOF/HEADLINING ..................................... 7

OVERHEAD CONSOLE (FRONT AND REAR)..... 7

SEATS ................................................................... 7

UNDERHOOD ....................................................... 7

Diagnostic Worksheet ............................................... 8

INSTRUMENT PANEL ASSEMBLY ......................... 10

Removal and Installation ........................................ 10

INSTRUMENT PANEL ........................................ 10

CLUSTER LID C ................................................. 11

CLUSTER LID D ................................................. 12

LOWER INSTRUMENT PANEL LH ..................... 13

COMBINATION METER ...................................... 13

A/T CONTROL FINISHER (A/T) .......................... 14

CONSOLE BOOT M/T ........................................ 14

LOWER INSTRUMENT PANEL RH AND GLOVE

BOX ..................................................................... 15

CENTER CONSOLE ........................................... 16

Disassembly and Assembly .................................... 17

CENTER CONSOLE ........................................... 17

Page 1766 of 3171

SQUEAK AND RATTLE TROUBLE DIAGNOSES

IP-7

C

D

E

F

G

H

J

K

L

MA

B

IP

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headliner and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the console panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the console at the clip locations until the clips engage.

In addition look for:

1. Loose harness or harness connectors.

2. Front console map/reading lamp lens loose.

3. Loose screws at console attachment points.

SEATS

When isolating seat noise it's important to note the position the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of these incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Page 2280 of 3171

DESCRIPTION

MA-5

C

D

E

F

G

H

I

J

K

MA

B

MA

DESCRIPTIONPFP:00000

Pre-Delivery Inspection ItemsELS001K2

Shown below are Pre-delivery Inspection Items required for the new vehicle. It is recommended that

necessary items other than those listed here be added, paying due regard to the conditions in each

country.

Perform applicable items on each model. Consult text of this section for specifications.

Install vehicle protection kit

Fit all accessories ordered (if applicable) (e.g. towbar, audio, navigation, air conditioner, styling kit)

UNDER HOOD — engine off

Check coolant level and cooling system for leaks

Charge battery and check terminals for condition

Check drive belts tension

Check fuel filter for water or dust (diesel only) and fuel system for leaks

Check engine oil level and for oil leaks

Check brake and clutch fluid levels and fluid lines for leaks

Check and top up washer reservoirs

Check power steering fluid level and fluid lines for leaks (if applicable)

Check air conditioning system for gas leaks (if applicable)

ON INSIDE AND OUTSIDE

Install transit fuse if removed for vehicle storage

Check instruments, gauges, lamps, horn and accessories for operation

Check wipers and washers for operation and adjustment

Check interior and door mirrors and sun visors for operation

Set radio code and set clock

Check parking brake adjustment

Check clutch pedal adjustment

Check steering lock operation

Check seat adjusters and seat belts for operation

Check all windows for operation and alignment

Check mouldings, trim and fittings for fit and alignment

Check weatherstrips for fit and adhesion

Check hood, trunk lid, door panels and fuel lid for fit and alignment

Check latches, keys, remote key, door locks and remote trunk lid and fuel lid release for operation

Check wheel nut torques

Check tyre pressure (incl. spare tyre)

Check tool kit and jack for operation

Check automatic transmission/transaxle starter inhibitor (if applicable)

Check sunroof for operation and alignment (if applicable)

UNDER BODY

Check manual transmission/transaxle, differential and transfer box for oil level and oil leaks

Tighten bolts and nuts steering linkage and gear box, axle/suspension parts, propeller and exhaust system

Check brake and clutch lines, and oil/fluid reservoirs for leaks

Remove front suspension spacer blocks (if applicable)

Check body mounting torque (if applicable)

Page 2315 of 3171

MA-40

CHASSIS AND BODY MAINTENANCE

Checking Seat Belts, Buckles, Retractors, Anchors and Adjusters

ELS001J7

Check the seat belt buckles, webbing, retractors, anchors and adjusters. Replace any seat belt assembly as

necessary. Refer toSB-11, "

Seat Belt Inspection".

lCheck the seat belt anchors for loose mounting bolts, damage, or excessive wear.

lCheck the seat belt webbing for any damage, cuts, fraying, or excessive wear.

lCheck the retractor for smooth operation.

lCheck the function of the buckles by inserting the seat belt tongue and checking for proper engagement of

the buckle and press the button on the buckle to check for proper release of the seat belt tongue.

CAUTION:

lAfter any collision, inspect all seat belt assemblies, including retractors and other attached com-

ponents, such as the guide rail set. NISSAN recommends replacing all seat belt assemblies in use

during a collision, unless they are not damaged and are inspected to confirm they are operating

properly after a minor collision.

Also inspect all seat belt assemblies that are not in use during a collision, and replace any compo-

nents if damaged or not operating properly. The seat belt pre-tensioner should be replaced even if

the seat belts are not in use during a frontal collision where the driver and passenger air bags

have been deployed.

lIf any component of the seat belt assembly is suspected of being damaged or not operating prop-

erly, do not repair the component. Replace the components as an assembly.

lIf the seat belt webbing is cut, frayed, or damaged then replace the seat belt assembly.

lNever lubricate the seat belt buckle or tongue.

lWhen replacing any seat belt assembly always use a Genuine NISSAN seat belt assembly.

Checking Body CorrosionELS001K3

Visually check body panels for collision damage (scratches, chipping, rubbing, etc.) or damage to the anti-cor-

rosion materials. In particular, check the following locations.

HEMMED PANELS

Hood front end, door lower end, trunk lid rear end, etc.

PANEL JOINT

Side sill of rear fender and center pillar, rear wheel housing of rear fender, around strut tower in engine com-

partment, etc.

PANEL EDGE

Trunk lid opening, sunroof opening, fender wheel-arch flange, fuel filler lid flange, around holes in panel, etc.

PARTS CONTACT

Waist moulding, windshield moulding, bumper, etc.

PROTECTORS

Damage or condition of mudguard, fender protector, chipping protector, etc.

ANTI-CORROSION MATERIALS

Damage or separation of anti-corrosion materials under the body.

DRAIN HOLES

Condition of drain holes at door and side sill. When repairing corroded areas, refer to the Corrosion Repair

Manual.

Page 2567 of 3171

PG-38

HARNESS

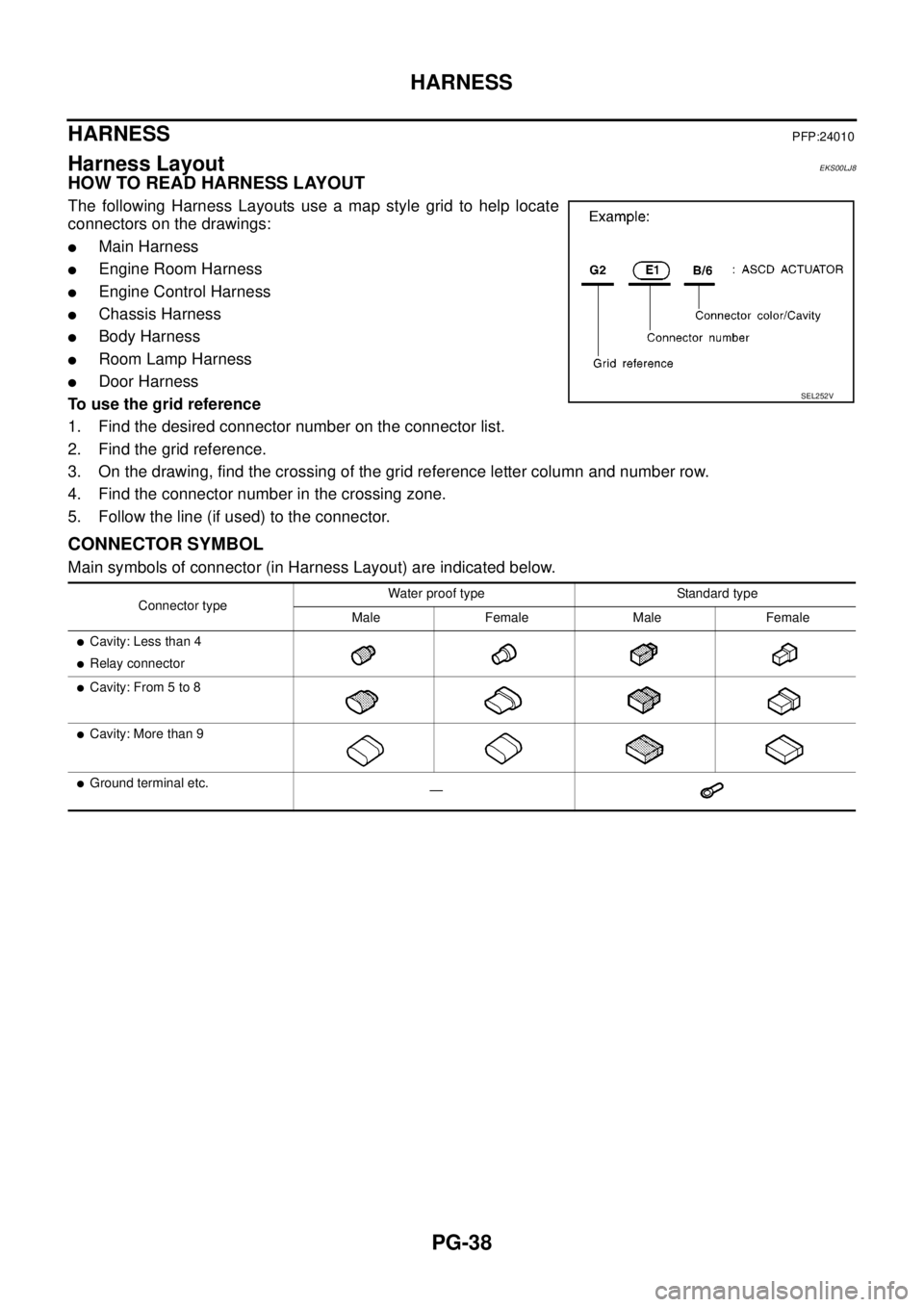

HARNESS

PFP:24010

Harness LayoutEKS00LJ8

HOW TO READ HARNESS LAYOUT

The following Harness Layouts use a map style grid to help locate

connectors on the drawings:

lMain Harness

lEngine Room Harness

lEngine Control Harness

lChassis Harness

lBody Harness

lRoom Lamp Harness

lDoor Harness

To use the grid reference

1. Find the desired connector number on the connector list.

2. Find the grid reference.

3. On the drawing, find the crossing of the grid reference letter column and number row.

4. Find the connector number in the crossing zone.

5. Follow the line (if used) to the connector.

CONNECTOR SYMBOL

Main symbols of connector (in Harness Layout) are indicated below.

SEL252V

Connector typeWater proof type Standard type

Male Female Male Female

lCavity: Less than 4

lRelay connector

lCavity: From 5 to 8

lCavity: More than 9

lGround terminal etc.

—

Page 2598 of 3171

HARNESS

PG-69

C

D

E

F

G

H

I

J

L

MA

B

PG

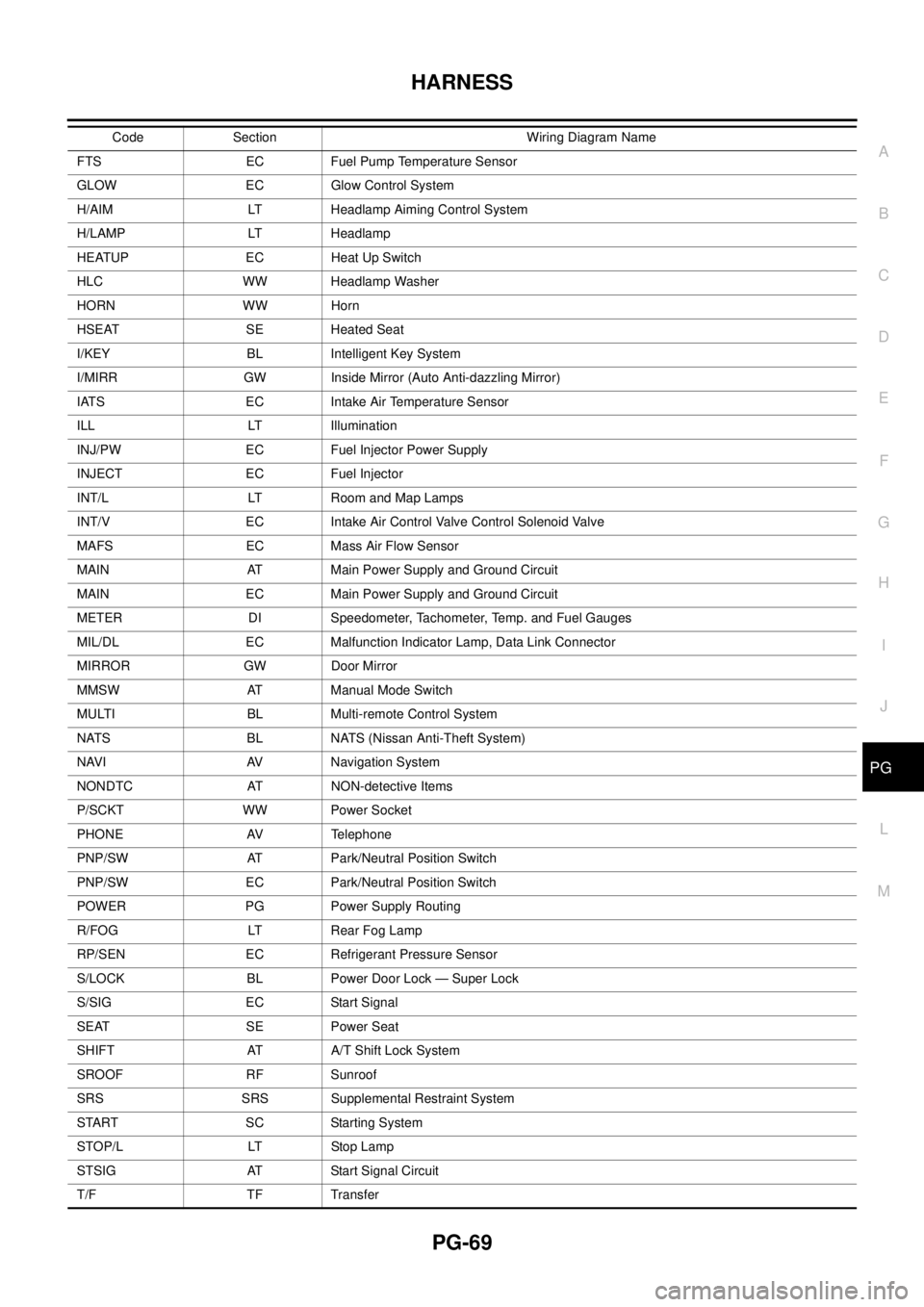

FTS EC Fuel Pump Temperature Sensor

GLOW EC Glow Control System

H/AIM LT Headlamp Aiming Control System

H/LAMP LT Headlamp

HEATUP EC Heat Up Switch

HLC WW Headlamp Washer

HORN WW Horn

HSEAT SE Heated Seat

I/KEY BL Intelligent Key System

I/MIRR GW Inside Mirror (Auto Anti-dazzling Mirror)

IATS EC Intake Air Temperature Sensor

ILL LT Illumination

INJ/PW EC Fuel Injector Power Supply

INJECT EC Fuel Injector

INT/L LT Room and Map Lamps

INT/V EC Intake Air Control Valve Control Solenoid Valve

MAFS EC Mass Air Flow Sensor

MAIN AT Main Power Supply and Ground Circuit

MAIN EC Main Power Supply and Ground Circuit

METER DI Speedometer, Tachometer, Temp. and Fuel Gauges

MIL/DL EC Malfunction Indicator Lamp, Data Link Connector

MIRROR GW Door Mirror

MMSW AT Manual Mode Switch

MULTI BL Multi-remote Control System

NATS BL NATS (Nissan Anti-Theft System)

NAVI AV Navigation System

NONDTC AT NON-detective Items

P/SCKT WW Power Socket

PHONE AV Telephone

PNP/SW AT Park/Neutral Position Switch

PNP/SW EC Park/Neutral Position Switch

POWER PG Power Supply Routing

R/FOG LT Rear Fog Lamp

RP/SEN EC Refrigerant Pressure Sensor

S/LOCK BL Power Door Lock — Super Lock

S/SIG EC Start Signal

SEAT SE Power Seat

SHIFT AT A/T Shift Lock System

SROOF RF Sunroof

SRS SRS Supplemental Restraint System

START SC Starting System

STOP/L LT Stop Lamp

STSIG AT Start Signal Circuit

T/F TF TransferCode Section Wiring Diagram Name

Page 2603 of 3171

PG-74

ELECTRICAL UNITS LOCATION

Fuse

EKS00LJB

lIf fuse is blown, be sure to eliminate cause of incident before

installing new fuse.

lUse fuse of specified rating. Never use fuse of more than speci-

fied rating.

lDo not partially install fuse; always insert it into fuse holder prop-

erly.

lRemove fuse for “ELECTRICAL PARTS (BAT)” if vehicle is not

used for a long period of time.

Fusible LinkEKS00LJC

A melted fusible link can be detected either by visual inspection or by feeling with finger tip. If its condition is

questionable, use circuit tester or test lamp.

CAUTION:

lIf fusible link should melt, it is possible that critical circuit (power supply or large current carrying

circuit) is shorted. In such a case, carefully check and eliminate cause of incident.

lNever wrap outside of fusible link with vinyl tape.

lNever let fusible link touch any other wiring harness, vinyl or rubber parts.

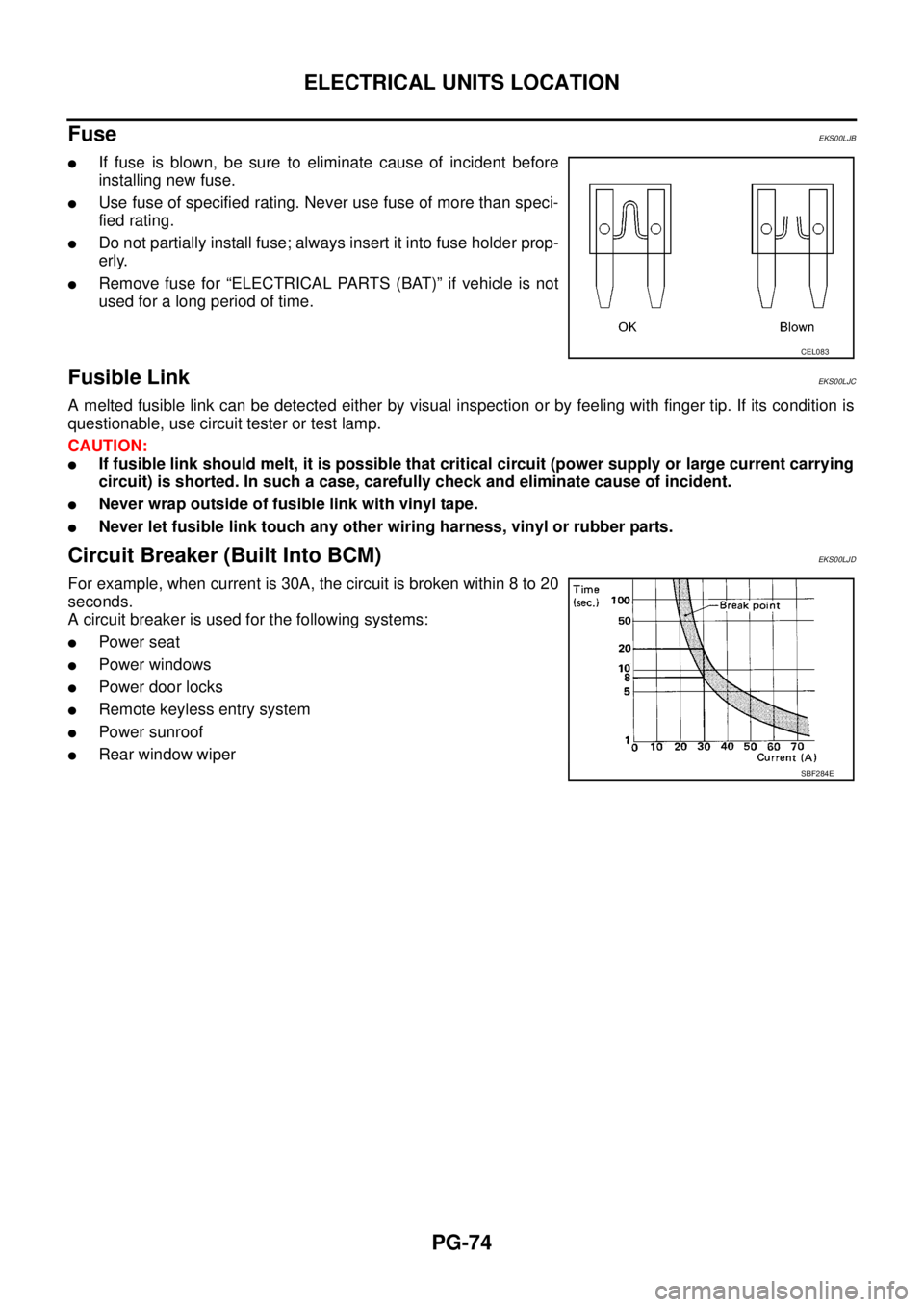

Circuit Breaker (Built Into BCM)EKS00LJD

For example, when current is 30A, the circuit is broken within 8 to 20

seconds.

A circuit breaker is used for the following systems:

lPower seat

lPower windows

lPowerdoorlocks

lRemote keyless entry system

lPower sunroof

lRear window wiper

CEL083

SBF284E