seats NISSAN NAVARA 2005 Repair User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1486 of 3171

EM-104

CYLINDER HEAD

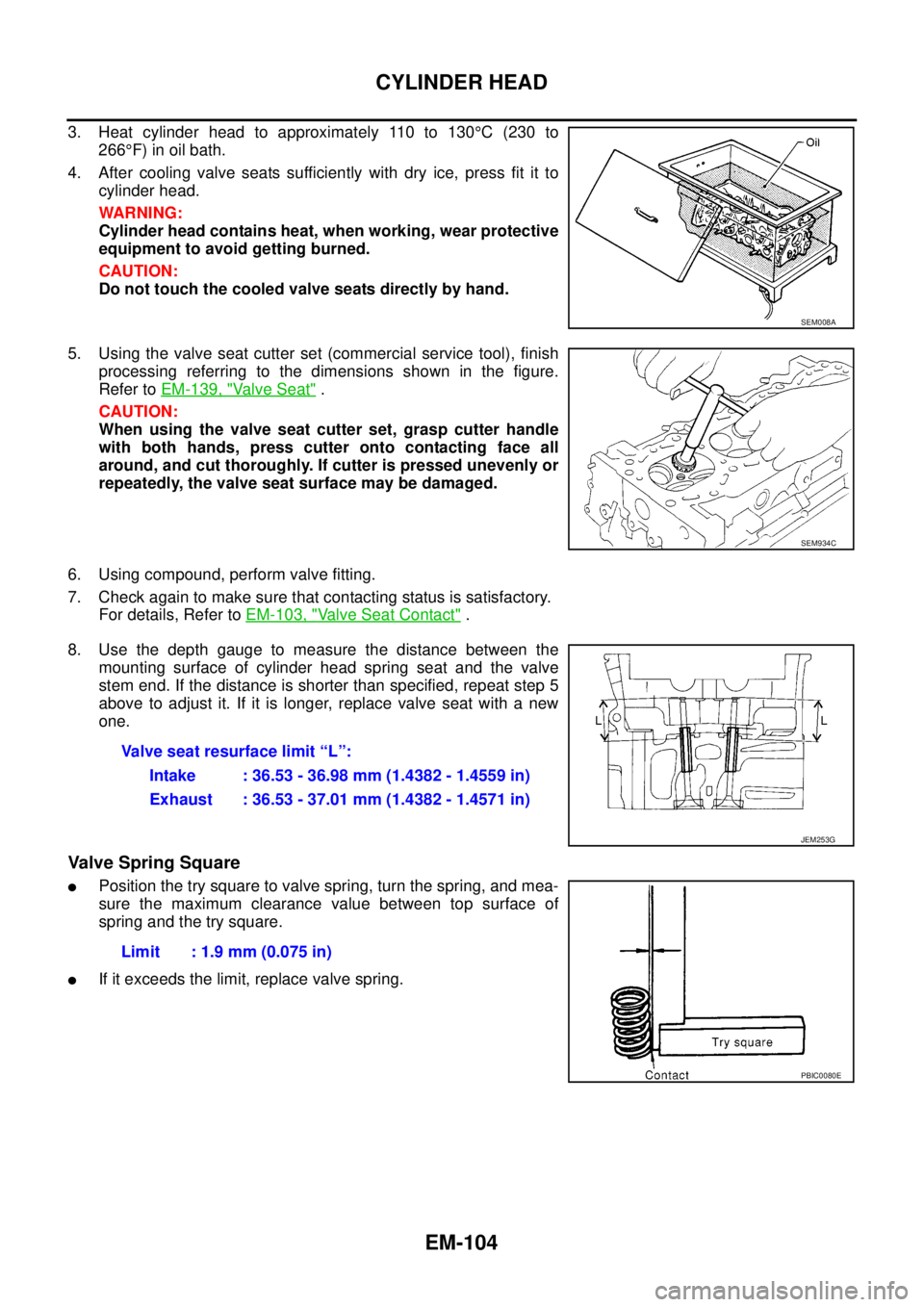

3. Heat cylinder head to approximately 110 to 130°C(230to

266°F) in oil bath.

4. After cooling valve seats sufficiently with dry ice, press fit it to

cylinder head.

WARNING:

Cylinder head contains heat, when working, wear protective

equipment to avoid getting burned.

CAUTION:

Do not touch the cooled valve seats directly by hand.

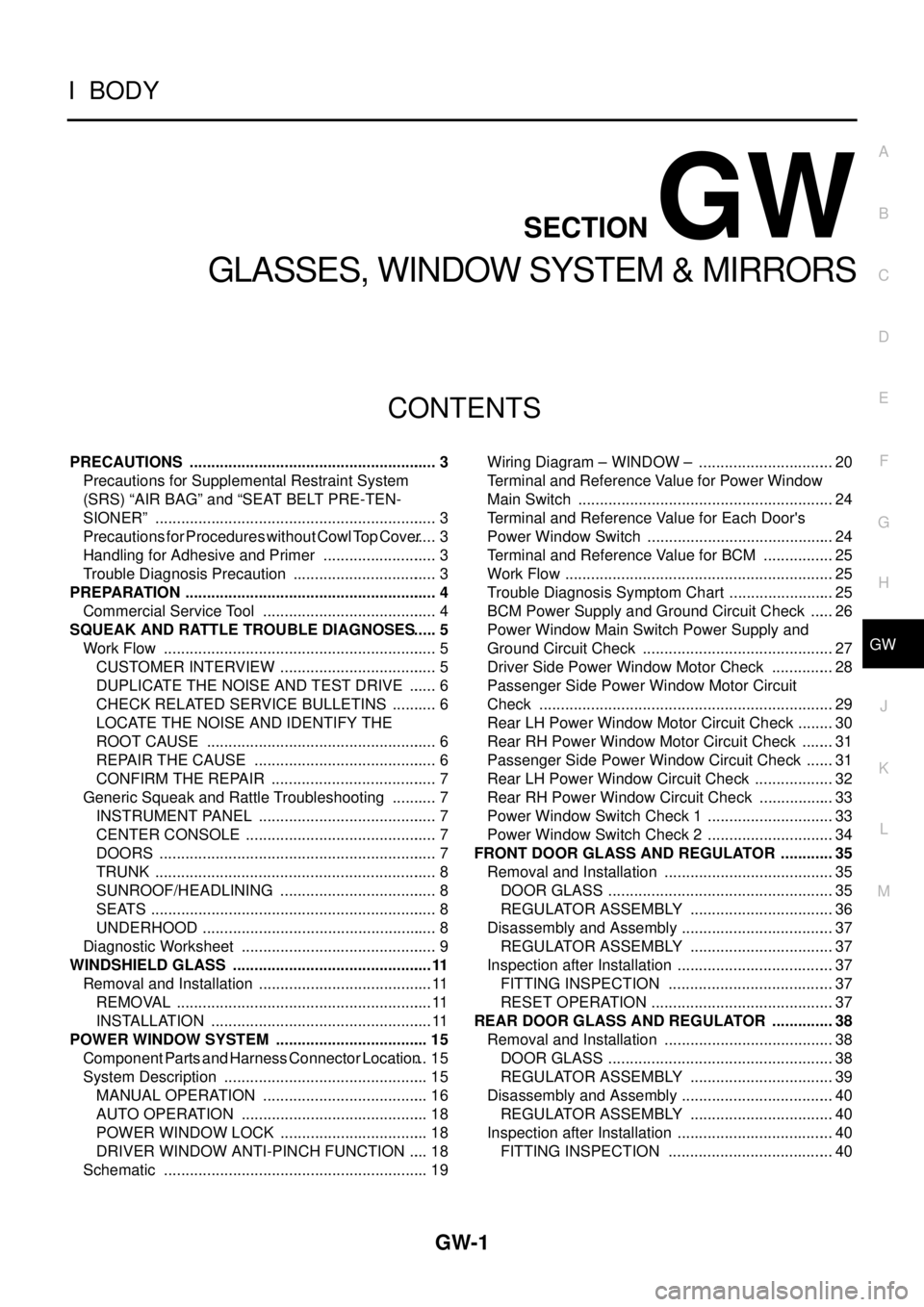

5. Using the valve seat cutter set (commercial service tool), finish

processing referring to the dimensions shown in the figure.

Refer toEM-139, "

Va l v e S e a t".

CAUTION:

When using the valve seat cutter set, grasp cutter handle

with both hands, press cutter onto contacting face all

around, and cut thoroughly. If cutter is pressed unevenly or

repeatedly, the valve seat surface may be damaged.

6. Using compound, perform valve fitting.

7. Check again to make sure that contacting status is satisfactory.

For details, Refer toEM-103, "

Valve Seat Contact".

8. Use the depth gauge to measure the distance between the

mounting surface of cylinder head spring seat and the valve

stem end. If the distance is shorter than specified, repeat step 5

above to adjust it. If it is longer, replace valve seat with a new

one.

Valve Spring Square

lPosition the try square to valve spring, turn the spring, and mea-

sure the maximum clearance value between top surface of

spring and the try square.

lIf it exceeds the limit, replace valve spring.

SEM008A

SEM934C

Valve seat resurface limit “L”:

Intake : 36.53 - 36.98 mm (1.4382 - 1.4559 in)

Exhaust : 36.53 - 37.01 mm (1.4382 - 1.4571 in)

JEM253G

Limit : 1.9 mm (0.075 in)

PBIC0080E

Page 1687 of 3171

GW-1

GLASSES, WINDOW SYSTEM & MIRRORS

IBODY

CONTENTS

C

D

E

F

G

H

J

K

L

M

SECTIONGW

A

B

GW

GLASSES, WINDOW SYSTEM & MIRRORS

PRECAUTIONS .......................................................... 3

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 3

Precautions for Procedures without Cowl Top Cover..... 3

Handling for Adhesive and Primer ........................... 3

Trouble Diagnosis Precaution .................................. 3

PREPARATION ........................................................... 4

Commercial Service Tool ......................................... 4

SQUEAK AND RATTLE TROUBLE DIAGNOSES..... 5

Work Flow ................................................................ 5

CUSTOMER INTERVIEW ..................................... 5

DUPLICATE THE NOISE AND TEST DRIVE ....... 6

CHECK RELATED SERVICE BULLETINS ........... 6

LOCATE THE NOISE AND IDENTIFY THE

ROOT CAUSE ...................................................... 6

REPAIR THE CAUSE ........................................... 6

CONFIRM THE REPAIR ....................................... 7

Generic Squeak and Rattle Troubleshooting ........... 7

INSTRUMENT PANEL .......................................... 7

CENTER CONSOLE ............................................. 7

DOORS ................................................................. 7

TRUNK .................................................................. 8

SUNROOF/HEADLINING ..................................... 8

SEATS ................................................................... 8

UNDERHOOD ....................................................... 8

Diagnostic Worksheet .............................................. 9

WINDSHIELD GLASS ...............................................11

Removal and Installation ......................................... 11

REMOVAL ............................................................ 11

INSTALLATION .................................................... 11

POWER WINDOW SYSTEM .................................... 15

Component Parts and Harness Connector Location... 15

System Description ................................................ 15

MANUAL OPERATION ....................................... 16

AUTO OPERATION ............................................ 18

POWER WINDOW LOCK ................................... 18

DRIVER WINDOW ANTI-PINCH FUNCTION ..... 18

Schematic .............................................................. 19Wiring Diagram – WINDOW – ................................ 20

Terminal and Reference Value for Power Window

Main Switch ............................................................ 24

Terminal and Reference Value for Each Door's

Power Window Switch ............................................ 24

Terminal and Reference Value for BCM ................. 25

Work Flow ............................................................... 25

Trouble Diagnosis Symptom Chart ......................... 25

BCM Power Supply and Ground Circuit Check ...... 26

Power Window Main Switch Power Supply and

Ground Circuit Check ............................................. 27

Driver Side Power Window Motor Check ............... 28

Passenger Side Power Window Motor Circuit

Check ..................................................................... 29

Rear LH Power Window Motor Circuit Check ......... 30

Rear RH Power Window Motor Circuit Check ........ 31

Passenger Side Power Window Circuit Check ....... 31

Rear LH Power Window Circuit Check ................... 32

Rear RH Power Window Circuit Check .................. 33

Power Window Switch Check 1 .............................. 33

Power Window Switch Check 2 .............................. 34

FRONT DOOR GLASS AND REGULATOR ............. 35

Removal and Installation ........................................ 35

DOOR GLASS ..................................................... 35

REGULATOR ASSEMBLY .................................. 36

Disassembly and Assembly .................................... 37

REGULATOR ASSEMBLY .................................. 37

Inspection after Installation ..................................... 37

FITTING INSPECTION ....................................... 37

RESET OPERATION ........................................... 37

REAR DOOR GLASS AND REGULATOR ............... 38

Removal and Installation ........................................ 38

DOOR GLASS ..................................................... 38

REGULATOR ASSEMBLY .................................. 39

Disassembly and Assembly .................................... 40

REGULATOR ASSEMBLY .................................. 40

Inspection after Installation ..................................... 40

FITTING INSPECTION ....................................... 40

Page 1694 of 3171

GW-8

SQUEAK AND RATTLE TROUBLE DIAGNOSES

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid dumpers out of adjustment

2. Trunk lid striker out of adjustment

3. Trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sunvisor shaft shaking in the holder

3. Front or rear windshield touching headlining and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

SEATS

When isolating seat noise it's important to note the position the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. Rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of these incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Page 1760 of 3171

IP-1

INSTRUMENT PANEL

IBODY

CONTENTS

C

D

E

F

G

H

J

K

L

M

SECTIONIP

A

B

IP

INSTRUMENT PANEL

PRECAUTIONS .......................................................... 2

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 2

Precautions for SRS “AIR BAG” and “SEAT BELT

PRE-TENSIONER” Service ..................................... 2

PREPARATION ........................................................... 3

Commercial Service Tools ........................................ 3

SQUEAK AND RATTLE TROUBLE DIAGNOSES..... 4

Work Flow ................................................................ 4

CUSTOMER INTERVIEW ..................................... 4

DUPLICATE THE NOISE AND TEST DRIVE ....... 5

CHECK RELATED SERVICE BULLETINS ........... 5

LOCATE THE NOISE AND IDENTIFY THE

ROOT CAUSE ...................................................... 5

REPAIR THE CAUSE ........................................... 5

CONFIRM THE REPAIR ....................................... 5

Generic Squeak and Rattle Troubleshooting ........... 6

INSTRUMENT PANEL .......................................... 6

CENTER CONSOLE ............................................. 6

DOORS ................................................................. 6TRUNK .................................................................. 6

SUNROOF/HEADLINING ..................................... 7

OVERHEAD CONSOLE (FRONT AND REAR)..... 7

SEATS ................................................................... 7

UNDERHOOD ....................................................... 7

Diagnostic Worksheet ............................................... 8

INSTRUMENT PANEL ASSEMBLY ......................... 10

Removal and Installation ........................................ 10

INSTRUMENT PANEL ........................................ 10

CLUSTER LID C ................................................. 11

CLUSTER LID D ................................................. 12

LOWER INSTRUMENT PANEL LH ..................... 13

COMBINATION METER ...................................... 13

A/T CONTROL FINISHER (A/T) .......................... 14

CONSOLE BOOT M/T ........................................ 14

LOWER INSTRUMENT PANEL RH AND GLOVE

BOX ..................................................................... 15

CENTER CONSOLE ........................................... 16

Disassembly and Assembly .................................... 17

CENTER CONSOLE ........................................... 17

Page 1766 of 3171

SQUEAK AND RATTLE TROUBLE DIAGNOSES

IP-7

C

D

E

F

G

H

J

K

L

MA

B

IP

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headliner and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the console panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the console at the clip locations until the clips engage.

In addition look for:

1. Loose harness or harness connectors.

2. Front console map/reading lamp lens loose.

3. Loose screws at console attachment points.

SEATS

When isolating seat noise it's important to note the position the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of these incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Page 2245 of 3171

LT-162

ILLUMINATION

ILLUMINATION

PFP:27545

System DescriptionEKS00P8V

Control of the illumination lamps operation is dependent upon the position of the lighting switch (combination

switch). When the lighting switch is placed in the 1ST position, 2ND position or AUTO position (headlamp is

ON) the BCM (body control module) receives input signal requesting the illumination lamps to illuminate. This

input signal is communicated to the IPDM E/R (intelligent power distribution module engine room) through the

CAN communication. The CPU (central processing unit) of the IPDM E/R controls the tail lamp relay coil. This

relay, when energized, directs power to the illumination lamps, which then illuminate.

Power is supplied at all times

lto ignition relay (located in IPDM E/R) and

lto tail lamp relay (located in IPDM E/R), from battery directly,

lthrough 50A fusible link (letter G, located in fuse and fusible link box)

lto BCM terminal 57,

lthrough 20A fuse (No. 52, located in IPDM E/R) and

lthrough 20A fuse (No. 53, located in IPDM E/R)

lto CPU (located in IPDM E/R),

lthrough 10A fuse [No.19, located in fuse block (J/B)]

lto combination meter terminal 3.

With the ignition switch in the ON or START position, power is supplied

lto ignition relay (located in IPDM E/R),

lthrough 10A fuse [No. 1, located in fuse block (J/B)]

lto BCM terminal 3,

lthrough 10A fuse [No. 14, located in fuse block (J/B)]

lto combination meter 16.

Ground is supplied

lto BCM terminal 55 and

lto combination meter terminal 23

lthrough grounds M21, M80 and M83,

lto IPDM E/R terminals 38 and 59

lthrough grounds E21, E41 and E61.

ILLUMINATION OPERATION BY LIGHTING SWITCH

With the lighting switch in the 1ST position, 2ND position or AUTO position (headlamp is ON), the BCM

receives input signal requesting the illumination lamps to illuminate. This input signal is communicated to the

IPDM E/R through the CAN communication. The CPU of the IPDM E/R controls the tail lamp relay coil, which,

when energized, directs power

lthrough 10A fuse (No. 37, located in IPDM E/R)

lthrough IPDM E/R terminal 57

lto hazard switch (illumination) terminal 3

lto 4WD shift switch (illumination) terminal 7 (with 4-wheel drive)

lto front air control (illumination) terminal 8

lto audio unit (illumination) terminal 2 (1CD player)

lto audio unit (illumination) terminal 8 (6CD player)

lto AV switch (illumination) terminal 3 (with NAVI)

lto audio unit (illumination) terminal 29 (with NAVI)

lto glove box lamp terminal 1

lto A/T device (illumination) terminal 3 (with A/T)

lto heat up switch (illumination) terminal 5

lto DIFF LOCK switch (illumination) terminal 4 (with DIFF LOCK)

lto heated seat switch (driver side) (illumination) terminal 5 (with heated seats)

lto heated seat switch (passenger side) (illumination) terminal 5 (with heated seats)

Page 2246 of 3171

ILLUMINATION

LT-163

C

D

E

F

G

H

I

J

L

MA

B

LT

lto cigarette lighter (illumination) terminal 1

lto ashtray (illumination) terminal 1

lto headlamp washer switch (illumination) terminal 3

lto headlamp aiming switch (illumination) terminal 3 and

lto NAVI control unit (illumination) terminal 61 (with NAVI).

Ground is supplied

lto hazard switch (illumination) terminal 4

lto 4WD shift switch (illumination) terminal 8 (with 4-wheel drive)

lto front air control (illumination) terminal 9

lto AV switch (illumination) terminal 4 (with NAVI)

lto audio unit (illumination) terminal 28 (with NAVI)

lto DIFF LOCK switch (illumination) terminal 5 (with DIFF LOCK)

lto heated seat switch (driver side) (illumination) terminal 6 (with heated seats) and

lto heated seat switch (passenger side) (illumination) terminal 6 (with heated seats)

lthrough combination meter terminal 22

lthrough combination meter terminal 23

lthrough ground M21, M80 and M83,

lto glove box lamp terminal 2

lto A/T device (illumination) terminal 5 (with A/T)

lto heat up switch (illumination) terminal 6

lto ashtray (illumination) terminal 2

lto headlamp washer switch (illumination) terminal 4 and

lto headlamp aiming switch (illumination) terminal 4

ltrough ground M21, M80 and M83,

lto audio unit (illumination) (1CD and 6CD player)

lthrough case ground of audio unit,

lto cigarette lighter (illumination)

lthrough case ground of cigarette lighter,

lto NAVI control unit (illumination) terminal 1 (with NAVI)

lthrough ground B106 and B121.

With power and ground supplied, illumination lamps illuminate.

CAN Communication System DescriptionEKS00P8W

Refer toLAN-23, "CAN COMMUNICATION".

CAN Communication UnitEKS00P8X

Refer toLAN-30, "CAN Communication Unit".

Page 2394 of 3171

PRECAUTIONS

MTC-7

C

D

E

F

G

H

I

K

L

MA

B

MTC

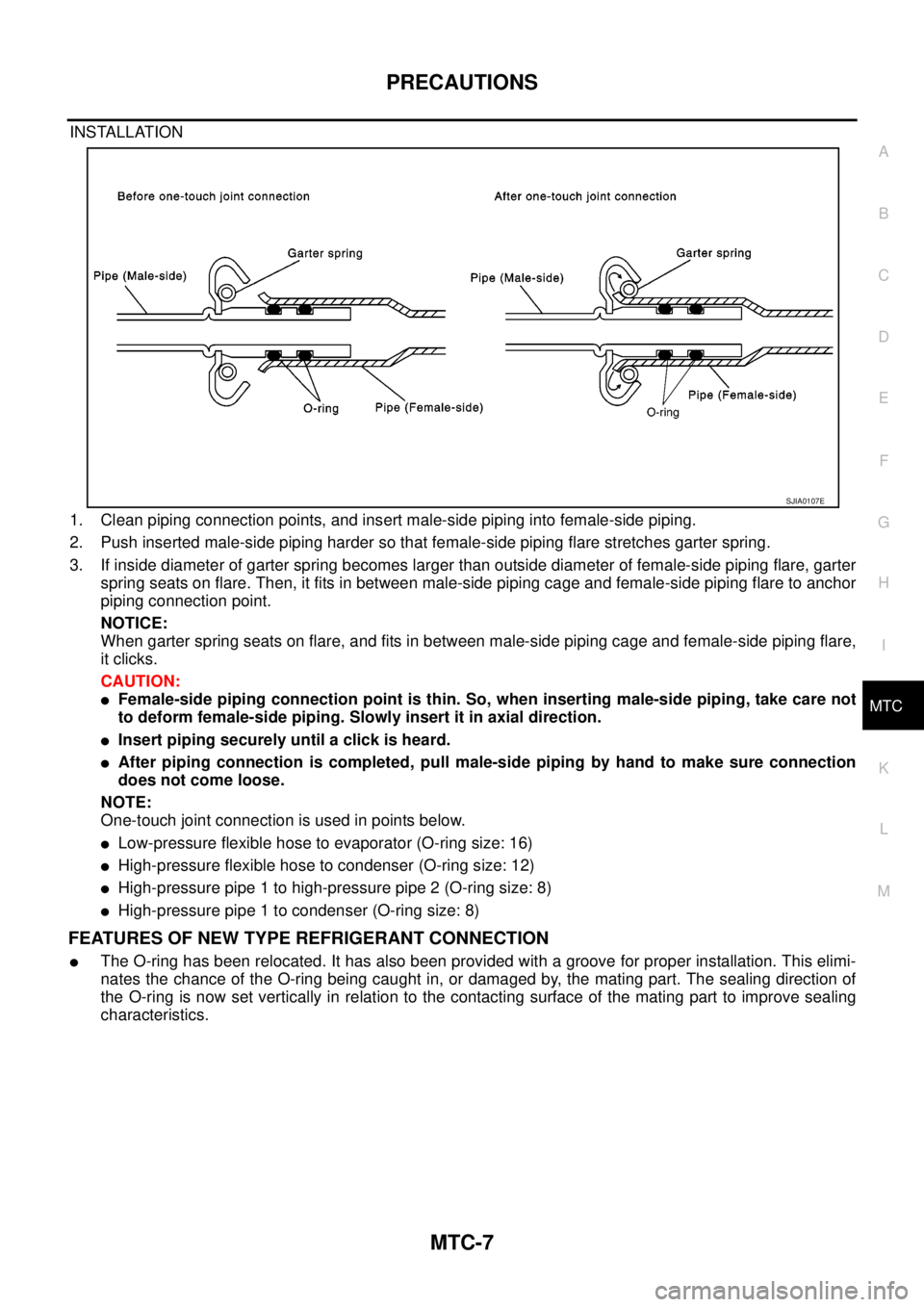

INSTALLATION

1. Clean piping connection points, and insert male-side piping into female-side piping.

2. Push inserted male-side piping harder so that female-side piping flare stretches garter spring.

3. If inside diameter of garter spring becomes larger than outside diameter of female-side piping flare, garter

spring seats on flare. Then, it fits in between male-side piping cage and female-side piping flare to anchor

piping connection point.

NOTICE:

When garter spring seats on flare, and fits in between male-side piping cage and female-side piping flare,

it clicks.

CAUTION:

lFemale-side piping connection point is thin. So, when inserting male-side piping, take care not

to deform female-side piping. Slowly insert it in axial direction.

lInsert piping securely until a click is heard.

lAfter piping connection is completed, pull male-side piping by hand to make sure connection

does not come loose.

NOTE:

One-touch joint connection is used in points below.

lLow-pressure flexible hose to evaporator (O-ring size: 16)

lHigh-pressure flexible hose to condenser (O-ring size: 12)

lHigh-pressure pipe 1 to high-pressure pipe 2 (O-ring size: 8)

lHigh-pressure pipe 1 to condenser (O-ring size: 8)

FEATURES OF NEW TYPE REFRIGERANT CONNECTION

lThe O-ring has been relocated. It has also been provided with a groove for proper installation. This elimi-

nates the chance of the O-ring being caught in, or damaged by, the mating part. The sealing direction of

the O-ring is now set vertically in relation to the contacting surface of the mating part to improve sealing

characteristics.

SJIA0107E

Page 2492 of 3171

HEATER & COOLING UNIT ASSEMBLY

MTC-105

C

D

E

F

G

H

I

K

L

MA

B

MTC

Removal and InstallationEJS005GY

REMOVAL

1. Discharge the refrigerant from the A/C system. Refer toMTC-118, "Discharging Refrigerant".

2. Drain the coolant from the engine cooling system. Refer toCO-8, "

DRAINING ENGINE COOLANT".

3. Remove the cowl top extension. Refer toEI-20, "

Removal and Installation".

4. Remove the exhaust system. Refer toEX-3, "

Removal and Installation".

5. Disconnect the heater hoses from the heater core.

6. Disconnect the high/low pressure pipes from the expansion valve.

7. Move the two front seats to the rearmost position on the seat track.

8. Remove the instrument panel and console panel. Refer toIP-10, "

Removal and Installation".

9. Remove the steering column. Refer toPS-11, "

Removal and Installation".

10. Disconnect the instrument panel wire harness at the RH and LH in-line connector brackets, and the fuse

block (J/B) electrical connectors. Refer toPG-38, "

Harness Layout".

11. Disconnect the steering member from each side of the vehicle body.

12. Remove the heater and cooling unit assembly with it attached to the steering member, from the vehicle.

CAUTION:

Use care not to damage the seats and interior trim panels when removing the heater and cooling

unit assembly with it attached to the steering member.

13. Remove the heater and cooling unit assembly from the steering member.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

lReplace the O-ring of the low-pressure pipe and high-pressure pipe with a new one, and apply

compressor oil to it when installing it.

lAfter charging the refrigerant, check for leaks.

NOTE:

lFill the engine cooling system with the specified coolant mixture. Refer toCO-8, "REFILLING ENGINE

COOLANT".

lRecharge the A/C system. Refer toMTC-118, "Evacuating System and Charging Refrigerant".

Page 2678 of 3171

RF-1

ROOF

IBODY

CONTENTS

C

D

E

F

G

H

J

K

L

M

SECTIONRF

A

B

RF

ROOF

PRECAUTIONS .......................................................... 2

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 2

Precautions .............................................................. 2

PREPARATION ........................................................... 3

Commercial Service Tool ......................................... 3

SQUEAK AND RATTLE TROUBLE DIAGNOSES..... 4

Work Flow ................................................................ 4

CUSTOMER INTERVIEW ..................................... 4

DUPLICATE THE NOISE AND TEST DRIVE ....... 5

CHECK RELATED SERVICE BULLETINS ........... 5

LOCATE THE NOISE AND IDENTIFY THE

ROOT CAUSE ...................................................... 5

REPAIR THE CAUSE ........................................... 5

CONFIRM THE REPAIR ....................................... 6

Generic Squeak and Rattle Troubleshooting ........... 6

INSTRUMENT PANEL .......................................... 6

CENTER CONSOLE ............................................. 6

DOORS ................................................................. 6

TRUNK .................................................................. 7

SUNROOF/HEADLINING ..................................... 7

SEATS ................................................................... 7

UNDERHOOD ....................................................... 7

Diagnostic Worksheet .............................................. 8

SUNROOF ................................................................ 10

Component Parts and Harness Connector Location... 10

System Description ................................................. 11

TILT UP / SLIDE CLOSE OPERATION ................ 11

TILT DOWN / SLIDE OPEN OPERATION ........... 11AUTO OPERATION ............................................. 11

ANTI-PINCH FUNCTION .................................... 11

MEMORY RESET PROCEDURE ....................... 12

INITIALIZATION PROCEDURE .......................... 12

CAN Communication System Description .............. 13

CAN Communication Unit ....................................... 13

Wiring Diagram — SROOF — ................................ 14

Terminals and Reference Value for BCM ............... 15

Terminals and Reference Value for Sunroof Motor

Assembly ................................................................ 15

Work Flow ............................................................... 16

Trouble Diagnosis Symptom Chart ......................... 16

BCM Power Supply and Ground Circuit Check ...... 16

Sunroof Motor Assembly Power Supply and Ground

Circuit Check .......................................................... 17

Sunroof Switch System Check ............................... 18

Fitting Adjustment ................................................... 20

GAP ADJUSTMENT ............................................ 20

HEIGHT DIFFERENCE ADJUSTMENT .............. 20

Removal and Installation ........................................ 21

SUNROOF UNIT ................................................. 22

GLASS LID .......................................................... 22

WIND DEFLECTOR ............................................ 23

SUNSHADE ........................................................ 23

SUNROOF MOTOR ............................................ 23

DRAIN HOSES .................................................... 25

WEATHERSTRIP ................................................ 25

REAR DRAIN ASSEMBLY .................................. 25

LINK AND WIRE ASSEMBLY ............................. 26