service NISSAN NAVARA 2005 Repair User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 85 of 3171

TROUBLE DIAGNOSIS

AT-77

D

E

F

G

H

I

J

K

L

MA

B

AT

CONSULT-II Function (A/T)ECS00FXA

CONSULT-II can display each diagnostic item using the diagnostic test modes shown following.

FUNCTION

CONSULT-II REFERENCE VALUE

NOTICE:

1. The CONSULT-II electrically displays shift timing and lock-up timing (that is, operation timing of each sole-

noid).

Check for time difference between actual shift timing and the CONSULT-II display. If the difference is

noticeable, mechanical parts (except solenoids, sensors, etc.) may be malfunctioning. Check mechanical

parts using applicable diagnostic procedures.

2. Shift schedule (which implies gear position) displayed on CONSULT-II and that indicated in Service Man-

ual may differ slightly. This occurs because of the following reasons:

–Actual shift schedule has more or less tolerance or allowance,

–Shift schedule indicated in Service Manual refers to the point where shifts start, and

–Gear position displayed on CONSULT-II indicates the point where shifts are completed.

3. Display of solenoid valves on CONSULT-II changes at the start of shifting, while gear position is displayed

upon completion of shifting (which is computed by TCM).

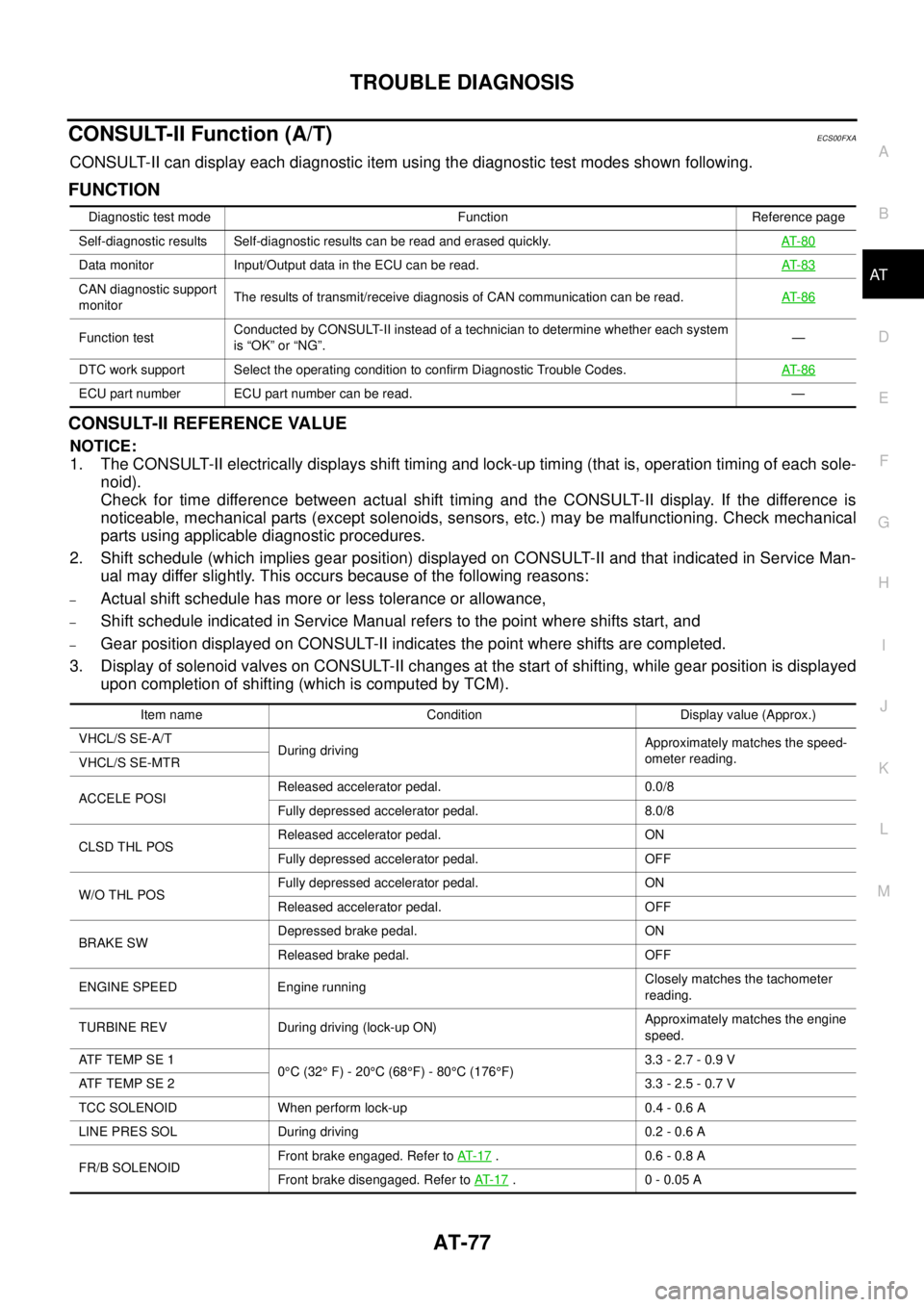

Diagnostic test mode Function Reference page

Self-diagnostic results Self-diagnostic results can be read and erased quickly.AT- 8 0

Data monitor Input/Output data in the ECU can be read.AT- 8 3

CAN diagnostic support

monitorThe results of transmit/receive diagnosis of CAN communication can be read.AT- 8 6

Function testConducted by CONSULT-II instead of a technician to determine whether each system

is “OK” or “NG”.—

DTC work support Select the operating condition to confirm Diagnostic Trouble Codes.AT- 8 6

ECU part number ECU part number can be read. —

Item name Condition Display value (Approx.)

VHCL/S SE-A/T

During drivingApproximately matches the speed-

ometer reading.

VHCL/S SE-MTR

ACCELE POSIReleased accelerator pedal. 0.0/8

Fully depressed accelerator pedal. 8.0/8

CLSD THL POSReleased accelerator pedal. ON

Fully depressed accelerator pedal. OFF

W/O THL POSFully depressed accelerator pedal. ON

Released accelerator pedal. OFF

BRAKE SWDepressed brake pedal. ON

Released brake pedal. OFF

ENGINE SPEED Engine runningClosely matches the tachometer

reading.

TURBINE REV During driving (lock-up ON)Approximately matches the engine

speed.

ATFTEMPSE1

0°C(32°F)-20°C(68°F)-80°C (176°F)3.3 - 2.7 - 0.9 V

ATFTEMPSE23.3 - 2.5 - 0.7 V

TCC SOLENOID When perform lock-up 0.4 - 0.6 A

LINE PRES SOL During driving 0.2 - 0.6 A

FR/B SOLENOIDFront brake engaged. Refer toAT- 1 7

. 0.6 - 0.8 A

Front brake disengaged. Refer toAT- 1 7

.0-0.05A

Page 87 of 3171

TROUBLE DIAGNOSIS

AT-79

D

E

F

G

H

I

J

K

L

MA

B

AT

CONSULT-II SETTING PROCEDURE

CAUTION:

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunctions might be

detected in self-diagnosis depending on control unit which carry out CAN communication.

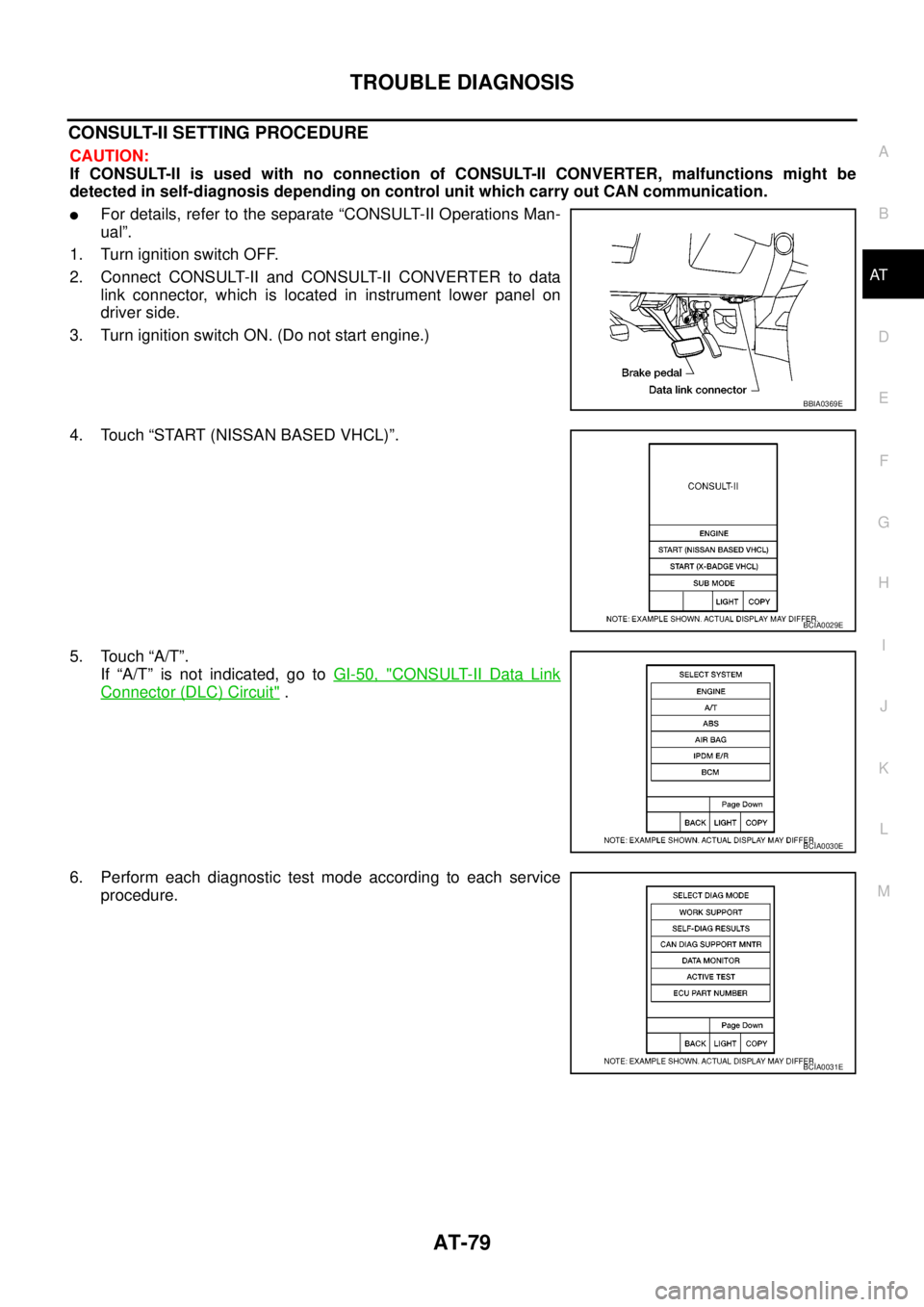

lFor details, refer to the separate “CONSULT-II Operations Man-

ual”.

1. Turn ignition switch OFF.

2. Connect CONSULT-II and CONSULT-II CONVERTER to data

link connector, which is located in instrument lower panel on

driver side.

3. Turn ignition switch ON. (Do not start engine.)

4. Touch “START (NISSAN BASED VHCL)”.

5. Touch “A/T”.

If “A/T” is not indicated, go toGI-50, "

CONSULT-II Data Link

Connector (DLC) Circuit".

6. Perform each diagnostic test mode according to each service

procedure.

BBIA0369E

BCIA0029E

BCIA0030E

BCIA0031E

Page 226 of 3171

AT-218

ON-VEHICLE SERVICE

ON-VEHICLE SERVICE

PFP:00000

Control Valve With TCM and A/T Fluid Temperature Sensor 2ECS00G36

COMPONENTS

1. A/T 2. Snap ring 3. Sub-harness

4. Control valve with TCM 5. Bracket 6. A/T fluid temperature sensor 2

7. Oil pan gasket 8. Oil pan 9. Magnet

10. Drain plug 11. Drain plug gasket 12. Oil pan mounting bolt

13. Terminal cord assembly 14. O-ring

SCIA5478E

Page 227 of 3171

ON-VEHICLE SERVICE

AT-219

D

E

F

G

H

I

J

K

L

MA

B

AT

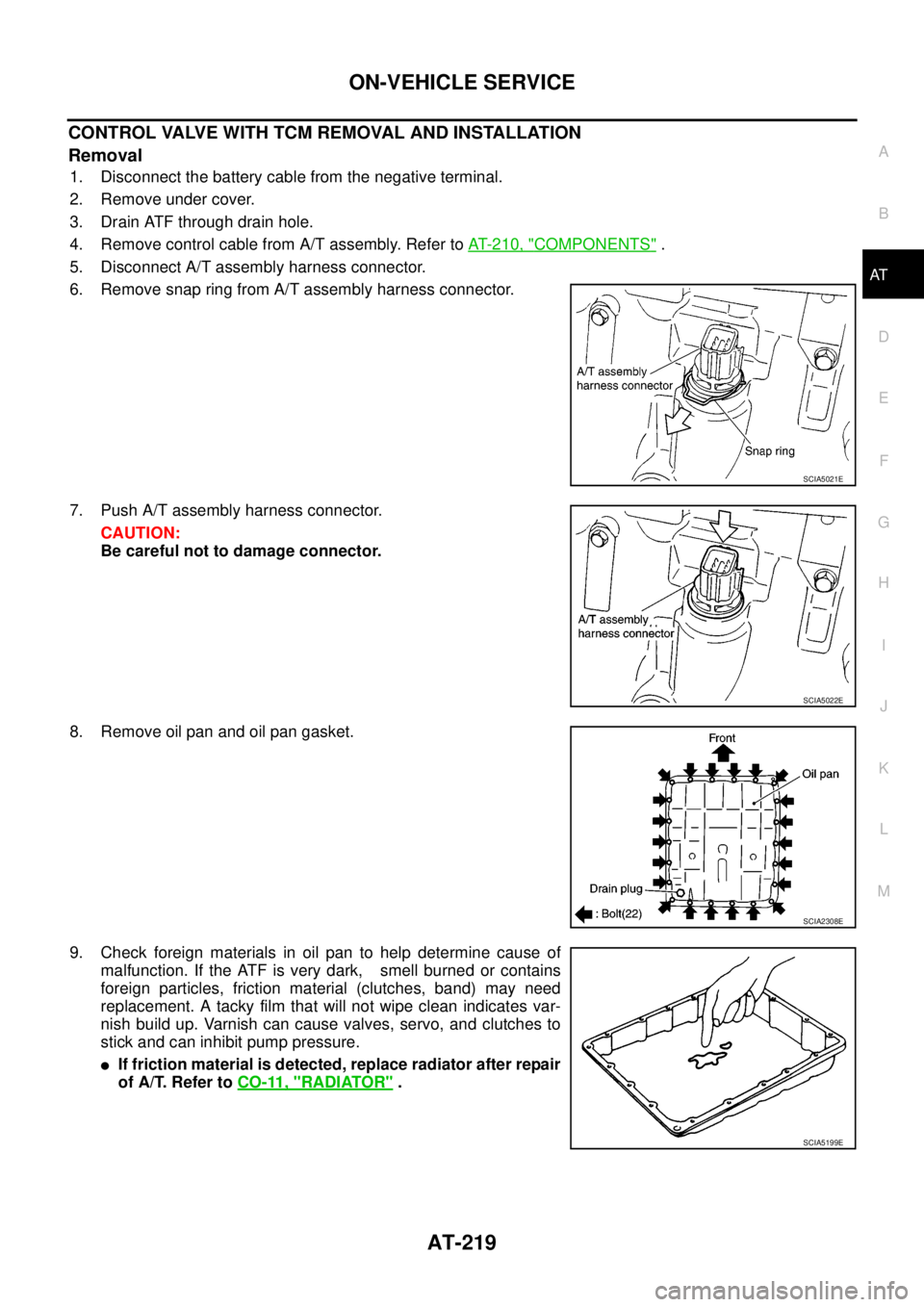

CONTROL VALVE WITH TCM REMOVAL AND INSTALLATION

Removal

1. Disconnect the battery cable from the negative terminal.

2. Remove under cover.

3. Drain ATF through drain hole.

4. Remove control cable from A/T assembly. Refer toAT- 2 1 0 , "

COMPONENTS".

5. Disconnect A/T assembly harness connector.

6. Remove snap ring from A/T assembly harness connector.

7. Push A/T assembly harness connector.

CAUTION:

Be careful not to damage connector.

8. Remove oil pan and oil pan gasket.

9. Check foreign materials in oil pan to help determine cause of

malfunction. If the ATF is very dark, smell burned or contains

foreign particles, friction material (clutches, band) may need

replacement. A tacky film that will not wipe clean indicates var-

nish build up. Varnish can cause valves, servo, and clutches to

stick and can inhibit pump pressure.

lIf friction material is detected, replace radiator after repair

of A/T. Refer toCO-11, "

RADIATOR".

SCIA5021E

SCIA5022E

SCIA2308E

SCIA5199E

Page 228 of 3171

AT-220

ON-VEHICLE SERVICE

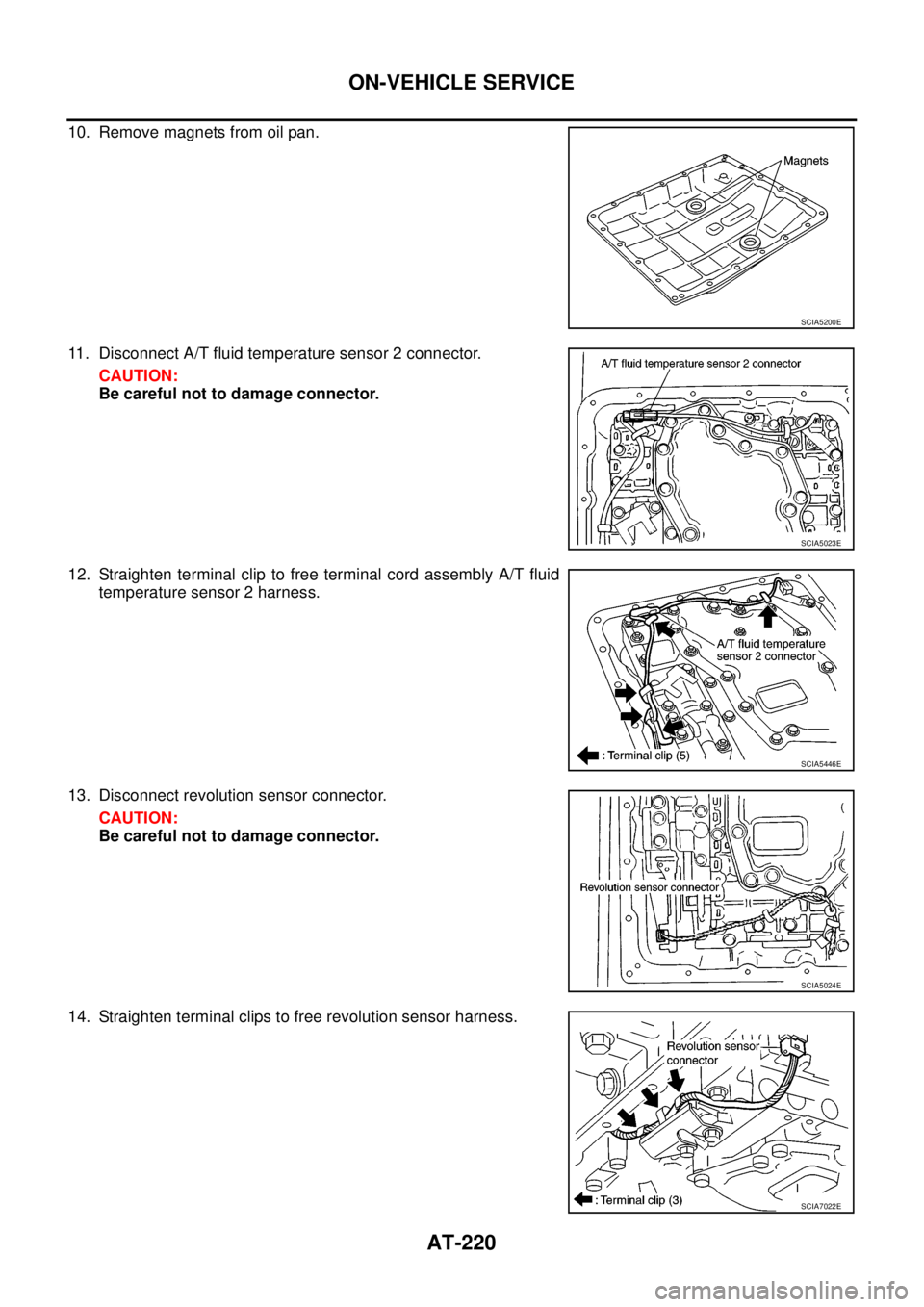

10. Remove magnets from oil pan.

11. Disconnect A/T fluid temperature sensor 2 connector.

CAUTION:

Be careful not to damage connector.

12. Straighten terminal clip to free terminal cord assembly A/T fluid

temperature sensor 2 harness.

13. Disconnect revolution sensor connector.

CAUTION:

Be careful not to damage connector.

14. Straighten terminal clips to free revolution sensor harness.

SCIA5200E

SCIA5023E

SCIA5446E

SCIA5024E

SCIA7022E

Page 229 of 3171

ON-VEHICLE SERVICE

AT-221

D

E

F

G

H

I

J

K

L

MA

B

AT

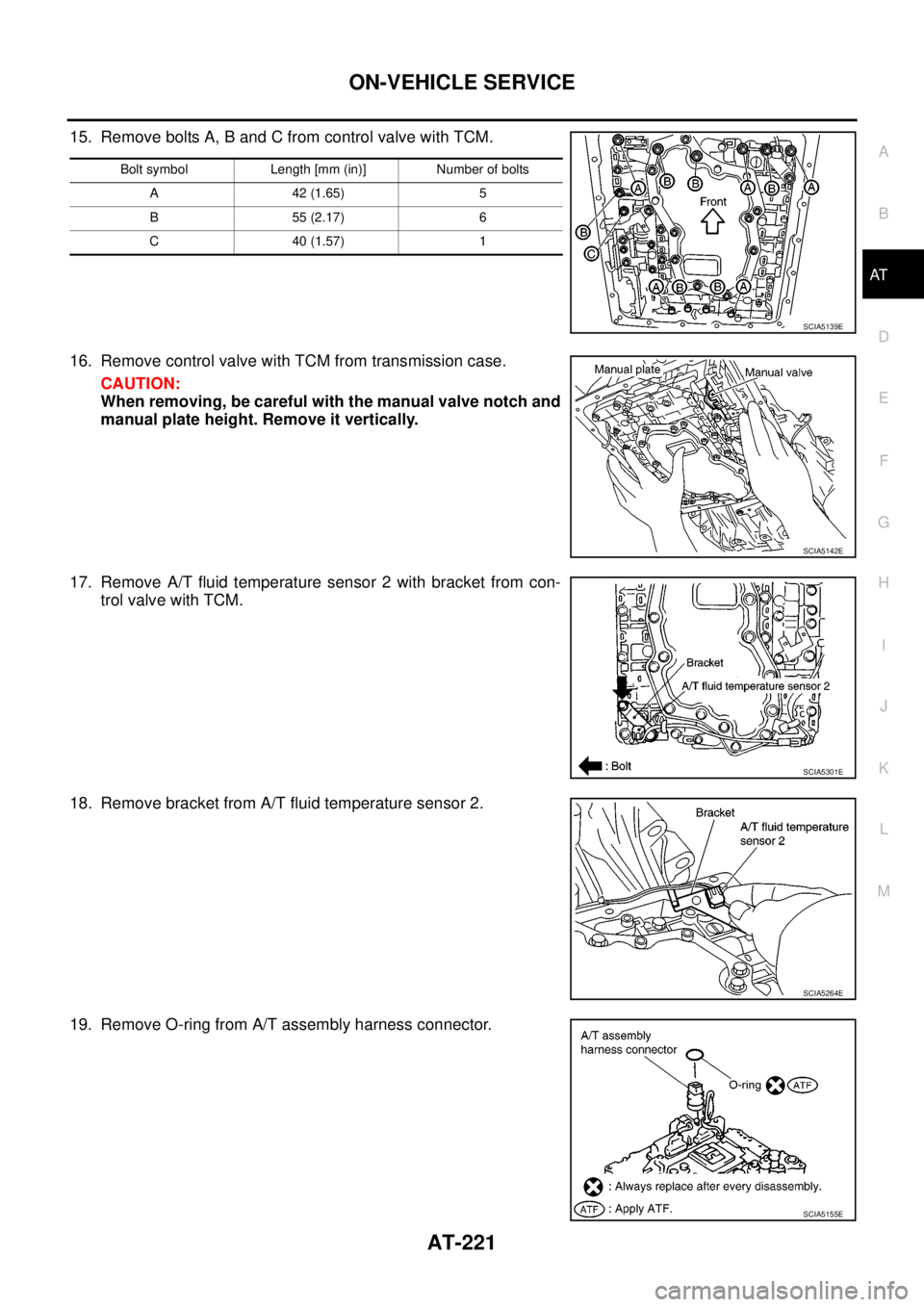

15. Remove bolts A, B and C from control valve with TCM.

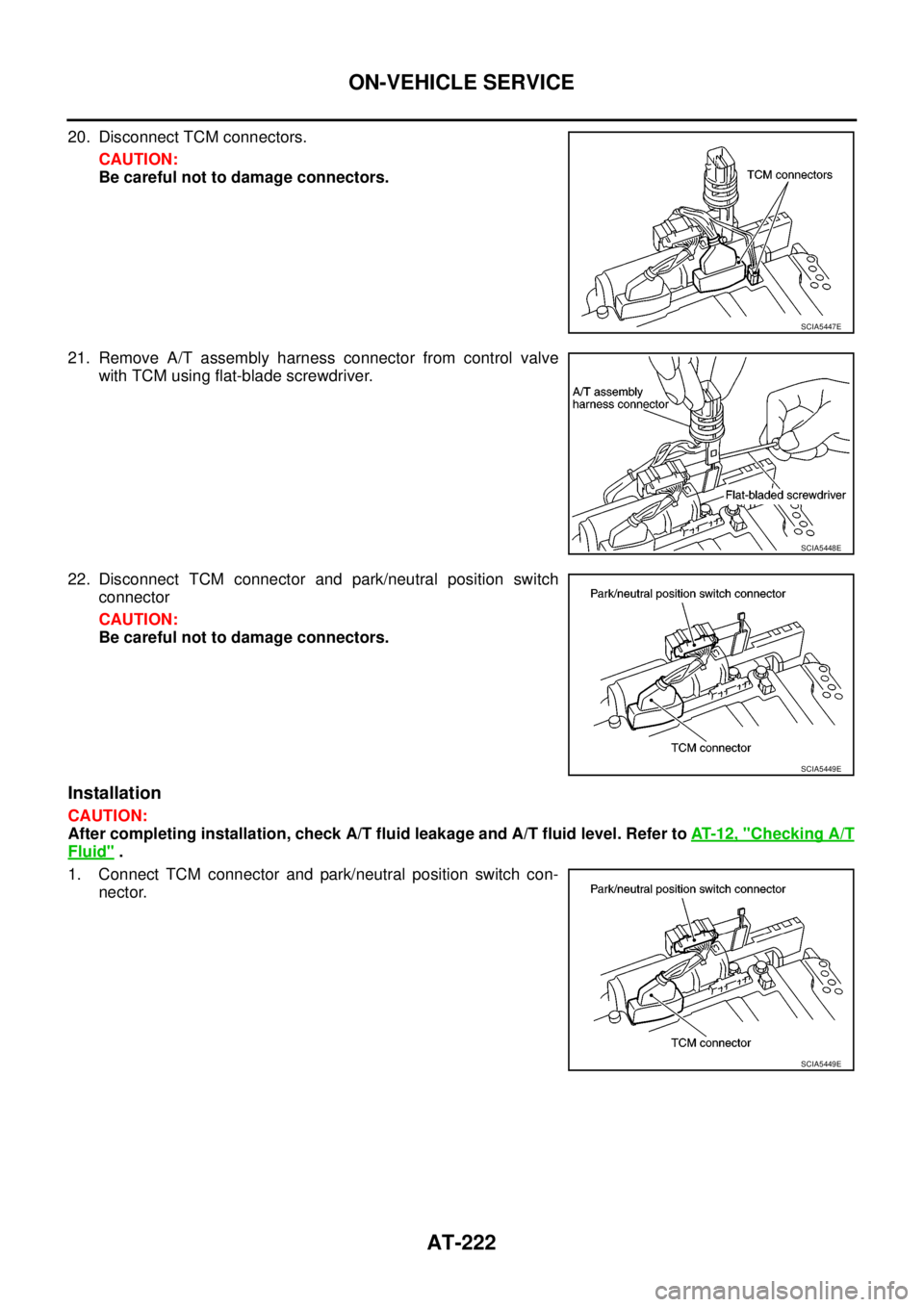

16. Remove control valve with TCM from transmission case.

CAUTION:

When removing, be careful with the manual valve notch and

manual plate height. Remove it vertically.

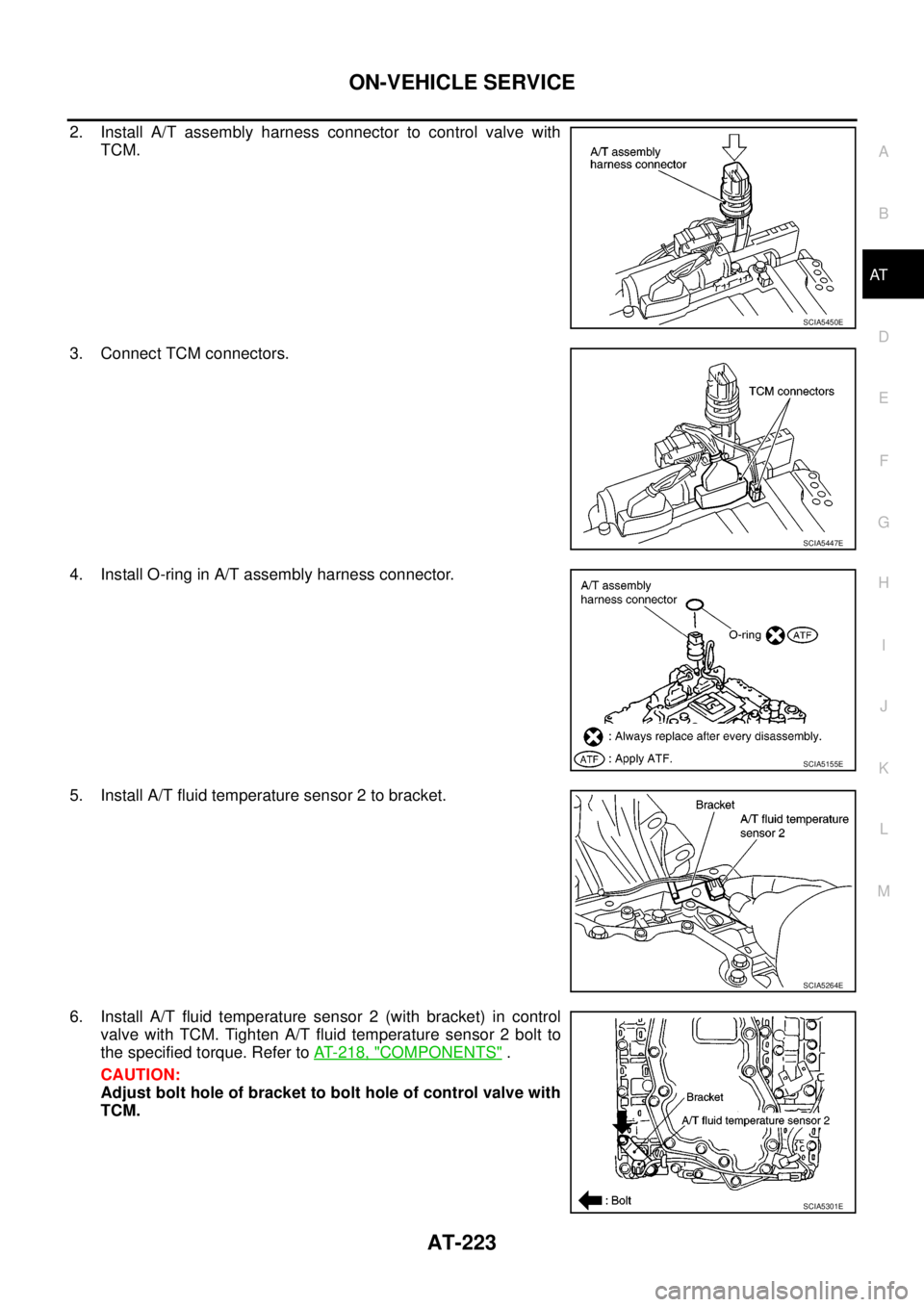

17. Remove A/T fluid temperature sensor 2 with bracket from con-

trol valve with TCM.

18. Remove bracket from A/T fluid temperature sensor 2.

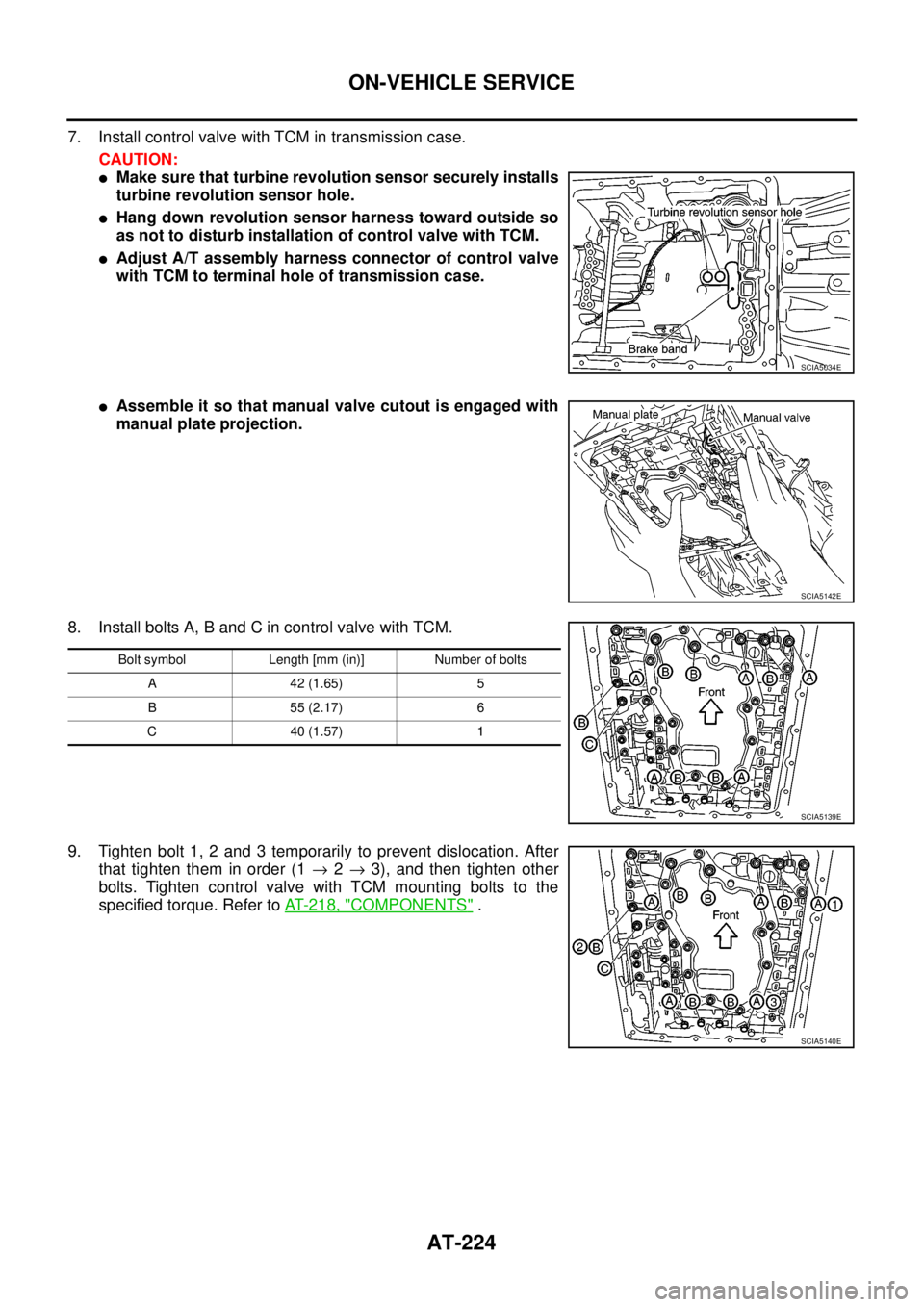

19. Remove O-ring from A/T assembly harness connector.

Bolt symbol Length [mm (in)] Number of bolts

A42(1.65) 5

B55(2.17) 6

C40(1.57) 1

SCIA5139E

SCIA5142E

SCIA5301E

SCIA5264E

SCIA5155E

Page 230 of 3171

AT-222

ON-VEHICLE SERVICE

20. Disconnect TCM connectors.

CAUTION:

Be careful not to damage connectors.

21. Remove A/T assembly harness connector from control valve

with TCM using flat-blade screwdriver.

22. Disconnect TCM connector and park/neutral position switch

connector

CAUTION:

Be careful not to damage connectors.

Installation

CAUTION:

After completing installation, check A/T fluid leakage and A/T fluid level. Refer toAT-12, "

Checking A/T

Fluid".

1. Connect TCM connector and park/neutral position switch con-

nector.

SCIA5447E

SCIA5448E

SCIA5449E

SCIA5449E

Page 231 of 3171

ON-VEHICLE SERVICE

AT-223

D

E

F

G

H

I

J

K

L

MA

B

AT

2. Install A/T assembly harness connector to control valve with

TCM.

3. Connect TCM connectors.

4. Install O-ring in A/T assembly harness connector.

5. Install A/T fluid temperature sensor 2 to bracket.

6. Install A/T fluid temperature sensor 2 (with bracket) in control

valve with TCM. Tighten A/T fluid temperature sensor 2 bolt to

the specified torque. Refer toAT- 2 1 8 , "

COMPONENTS".

CAUTION:

Adjust bolt hole of bracket to bolt hole of control valve with

TCM.

SCIA5450E

SCIA5447E

SCIA5155E

SCIA5264E

SCIA5301E

Page 232 of 3171

AT-224

ON-VEHICLE SERVICE

7. Install control valve with TCM in transmission case.

CAUTION:

lMake sure that turbine revolution sensor securely installs

turbine revolution sensor hole.

lHang down revolution sensor harness toward outside so

as not to disturb installation of control valve with TCM.

lAdjust A/T assembly harness connector of control valve

with TCM to terminal hole of transmission case.

lAssemble it so that manual valve cutout is engaged with

manual plate projection.

8. Install bolts A, B and C in control valve with TCM.

9. Tighten bolt 1, 2 and 3 temporarily to prevent dislocation. After

that tighten them in order (1®2®3), and then tighten other

bolts. Tighten control valve with TCM mounting bolts to the

specified torque. Refer toAT- 2 1 8 , "

COMPONENTS".

SCIA5034E

SCIA5142E

Bolt symbol Length [mm (in)] Number of bolts

A 42 (1.65) 5

B 55 (2.17) 6

C 40 (1.57) 1

SCIA5139E

SCIA5140E

Page 233 of 3171

ON-VEHICLE SERVICE

AT-225

D

E

F

G

H

I

J

K

L

MA

B

AT

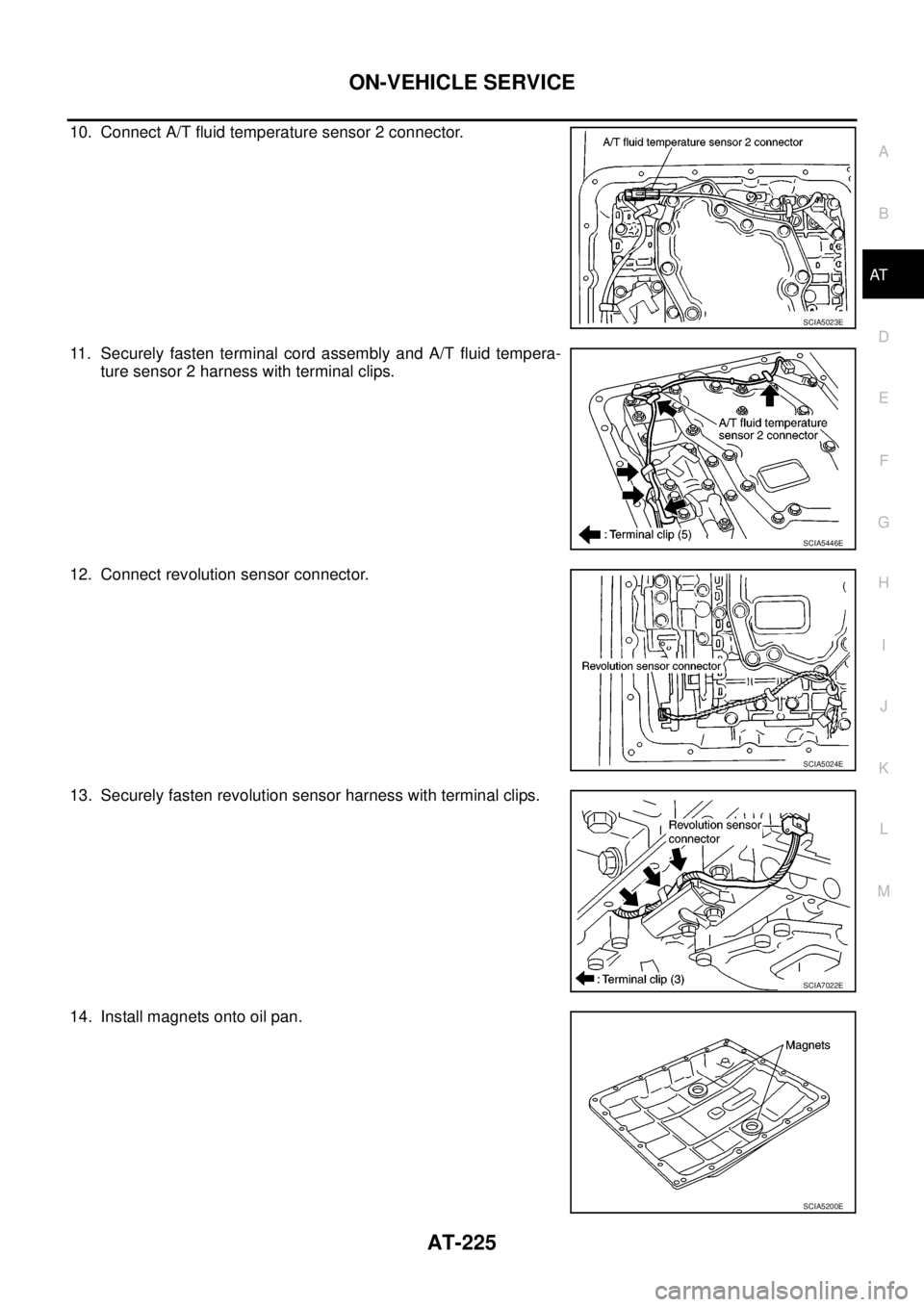

10. Connect A/T fluid temperature sensor 2 connector.

11. Securely fasten terminal cord assembly and A/T fluid tempera-

ture sensor 2 harness with terminal clips.

12. Connect revolution sensor connector.

13. Securely fasten revolution sensor harness with terminal clips.

14. Install magnets onto oil pan.

SCIA5023E

SCIA5446E

SCIA5024E

SCIA7022E

SCIA5200E