tire pressure NISSAN NAVARA 2005 Repair User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2282 of 3171

GENERAL MAINTENANCE

MA-7

C

D

E

F

G

H

I

J

K

MA

B

MA

GENERAL MAINTENANCEPFP:00000

General MaintenanceELS001HT

General maintenance includes those items which should be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owners can perform the

checks and inspections themselves or they can have their NISSAN dealers do them for a nominal charge.

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed from time to time, unless otherwise specified.

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the

vehicle, etc.

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically e.g. each time you check the engine oil or refuel.Item Reference page

TiresCheck the pressure with a gauge periodically when at a service station, includ-

ing the spare, and adjust to the specified pressure if necessary. Check carefully

for damage, cuts or excessive wear.—

Windshield wiper

bladesCheck for cracks or wear if not functioning correctly. —

Doors and engine

hoodCheck that all doors, the engine hood, the trunk lid and back door operate prop-

erly. Also ensure that all latches lock securely. Lubricate if necessary. Make sure

that the secondary latch keeps the hood from opening when the primary latch is

released.

When driving in areas using road salt or other corrosive materials, check for

lubrication frequently.MA-39

,BL-12

Tire rotationTires should be rotated every 10,000 km (6,000 miles) for 2WD models and

every 5,000 km (3,000 miles) for 4WD models.MA-34

Item Reference page

LampsMake sure that the headlamps, stop lamps, tail lamps, turn signal lamps, and

other lamps are all operating properly and installed securely. Also check

headlamp aim.—

Warning lamps and

chimesMake sure that all warning lamps and buzzers/chimes are operating properly. —

Steering wheelCheck that it has the specified play.

Check for changes in the steering conditions, such as excessive free play, hard

steering or strange noises.

Free play: Less than 35 mm (1.38 in)—

Seat beltsCheck that all parts of the seat belt system (e.g. buckles, anchors, adjusters and

retractors) operate properly and smoothly, and are installed securely. Check the

belt webbing for cuts, fraying, wear or damage.MA-40

Item Reference page

Windshield washer

fluidCheck that there is adequate fluid in the tank. —

Engine coolant levelCheck the coolant level when the engine is cold.MA-19

(YD25DDTi)

Engine oil levelCheck the level after parking the vehicle (on level ground) and turning off the

engine.MA-25

(YD25DDTi)

Brake and clutch fluid

levelsMake sure that the brake and clutch fluid levels are between the “MAX” and

“MIN” lines on the reservoir.MA-28

,MA-35

BatteryCheck the fluid level in each cell. It should be between the “MAX” and “MIN”

lines.—

Page 2309 of 3171

MA-34

CHASSIS AND BODY MAINTENANCE

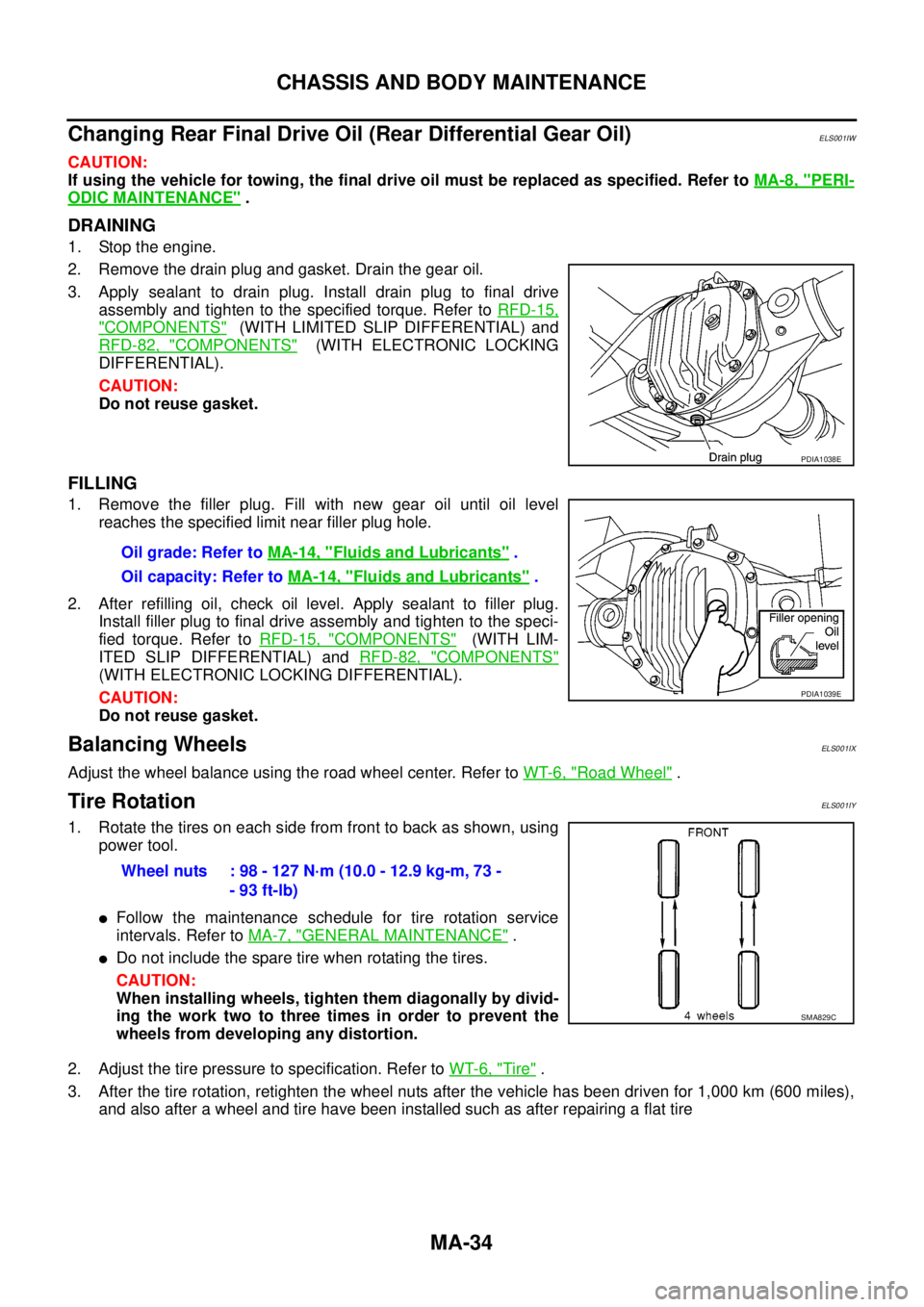

Changing Rear Final Drive Oil (Rear Differential Gear Oil)

ELS001IW

CAUTION:

If using the vehicle for towing, the final drive oil must be replaced as specified. Refer toMA-8, "

PERI-

ODIC MAINTENANCE".

DRAINING

1. Stop the engine.

2. Remove the drain plug and gasket. Drain the gear oil.

3. Apply sealant to drain plug. Install drain plug to final drive

assembly and tighten to the specified torque. Refer toRFD-15,

"COMPONENTS"(WITH LIMITED SLIP DIFFERENTIAL) and

RFD-82, "

COMPONENTS"(WITH ELECTRONIC LOCKING

DIFFERENTIAL).

CAUTION:

Do not reuse gasket.

FILLING

1. Remove the filler plug. Fill with new gear oil until oil level

reaches the specified limit near filler plug hole.

2. After refilling oil, check oil level. Apply sealant to filler plug.

Install filler plug to final drive assembly and tighten to the speci-

fied torque. Refer toRFD-15, "

COMPONENTS"(WITH LIM-

ITED SLIP DIFFERENTIAL) andRFD-82, "

COMPONENTS"

(WITH ELECTRONIC LOCKING DIFFERENTIAL).

CAUTION:

Do not reuse gasket.

Balancing WheelsELS001IX

Adjust the wheel balance using the road wheel center. Refer toWT-6, "Road Wheel".

Tire RotationELS001IY

1. Rotate the tires on each side from front to back as shown, using

power tool.

lFollow the maintenance schedule for tire rotation service

intervals. Refer toMA-7, "

GENERAL MAINTENANCE".

lDo not include the spare tire when rotating the tires.

CAUTION:

When installing wheels, tighten them diagonally by divid-

ing the work two to three times in order to prevent the

wheels from developing any distortion.

2. Adjust the tire pressure to specification. Refer toWT-6, "

Tire".

3. After the tire rotation, retighten the wheel nuts after the vehicle has been driven for 1,000 km (600 miles),

and also after a wheel and tire have been installed such as after repairing a flat tire

PDIA1038E

Oil grade: Refer toMA-14, "Fluids and Lubricants".

Oil capacity: Refer toMA-14, "

Fluids and Lubricants".

PDIA1039E

Wheel nuts : 98 - 127 N·m (10.0 - 12.9 kg-m, 73 -

- 93 ft-lb)

SMA829C

Page 2509 of 3171

MTC-122

REFRIGERANT LINES

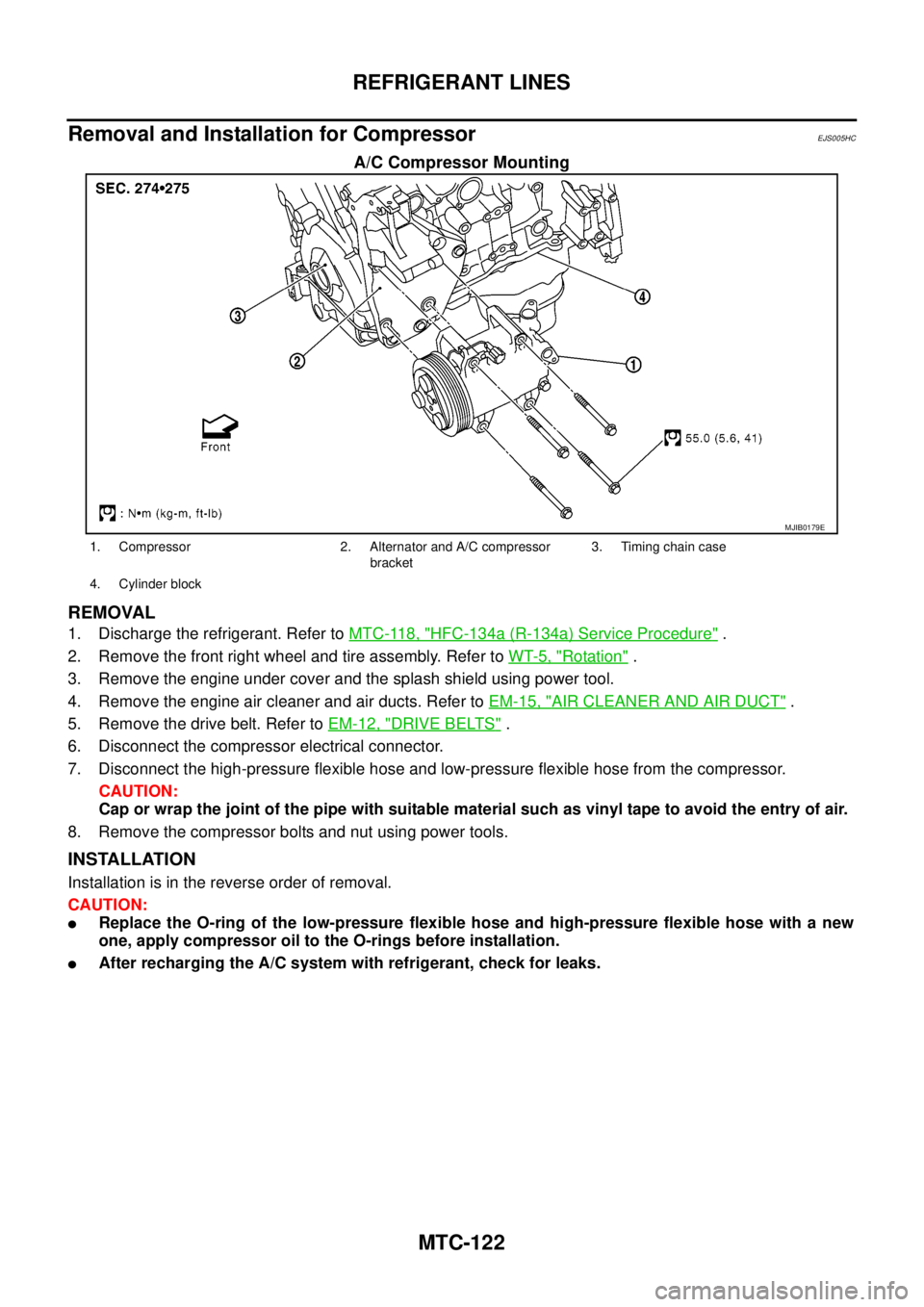

Removal and Installation for Compressor

EJS005HC

A/C Compressor Mounting

REMOVAL

1. Discharge the refrigerant. Refer toMTC-118, "HFC-134a (R-134a) Service Procedure".

2. Remove the front right wheel and tire assembly. Refer toWT-5, "

Rotation".

3. Remove the engine under cover and the splash shield using power tool.

4. Remove the engine air cleaner and air ducts. Refer toEM-15, "

AIR CLEANER AND AIR DUCT".

5. Remove the drive belt. Refer toEM-12, "

DRIVE BELTS".

6. Disconnect the compressor electrical connector.

7. Disconnect the high-pressure flexible hose and low-pressure flexible hose from the compressor.

CAUTION:

Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

8. Remove the compressor bolts and nut using power tools.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

lReplace the O-ring of the low-pressure flexible hose and high-pressure flexible hose with a new

one, apply compressor oil to the O-rings before installation.

lAfter recharging the A/C system with refrigerant, check for leaks.

MJIB0179E

1. Compressor 2. Alternator and A/C compressor

bracket3. Timing chain case

4. Cylinder block

Page 2513 of 3171

MTC-126

REFRIGERANT LINES

BREAK-IN OPERATION

When replacing compressor clutch assembly, always conduct the break-in operation. This is done by engag-

ing and disengaging the clutch about 30 times. Break-in operation raises the level of transmitted torque.

Removal and Installation for Low-pressure Flexible HoseEJS005HE

REMOVAL

1. Remove the engine room cover using power tools.

2. Remove the engine air cleaner and air ducts. Refer toEM-15, "

AIR CLEANER AND AIR DUCT".

3. Remove the cowl top extension. Refer toEI-20, "

COWL TOP".

4. Discharge the refrigerant. Refer toMTC-118, "

HFC-134a (R-134a) Service Procedure".

CAUTION:

Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

5. Remove the low-pressure flexible hose. Refer toMTC-120, "

Components".

INSTALLATION

Installation is in the reverse order of removal.

Refer toMTC-120, "

Components".

CAUTION:

lReplace the O-ring of the low-pressure flexible hose with a new one, then apply compressor oil to

it when installing it.

lAfter charging refrigerant, check for leaks.

Removal and Installation for High-pressure Flexible HoseEJS005HF

REMOVAL

1. Remove the engine under cover.

2. Remove the engine air cleaner and air ducts. Refer toEM-15, "

AIR CLEANER AND AIR DUCT"

3. Discharge the refrigerant. Refer toMTC-118, "HFC-134a (R-134a) Service Procedure".

4. Remove the high-pressure flexible hose. Refer toMTC-120, "

Components".

CAUTION:

Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

Refer toMTC-120, "

Components".

CAUTION:

lReplace the O-ring of the high-pressure flexible hose with a new one, then apply compressor oil to

it when installing it.

lAfter charging refrigerant, check for leaks.

Removal and Installation for High-pressure PipeEJS005HG

REMOVAL

1. Remove the cowl top extension. Refer toEI-20, "COWL TOP".

2. Disconnect the battery negative cable.

3. Reposition the IPDM E/R aside.

4. Remove the front right wheel and tire assembly. Refer toWT-5, "

Rotation".

5. Position aside the front floor insulator.

6. Discharge the refrigerant. Refer toMTC-118, "

HFC-134a (R-134a) Service Procedure".

7. Remove the low pressure pipe. Refer toMTC-127, "

Removal and Installation for Low-pressure Pipe".

8. Remove the high-pressure pipe. Refer toMTC-120, "

Components".

CAUTION:

Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

Refer toMTC-120, "

Components".

Page 2751 of 3171

![NISSAN NAVARA 2005 Repair User Guide RFD-48

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

TROUBLE DIAGNOSIS

Trouble Diagnosis Chart for Symptoms

EDS003AY

If DIFF LOCK indicator lamp does not turn ON after engine start, perform self-diagnosis. R NISSAN NAVARA 2005 Repair User Guide RFD-48

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

TROUBLE DIAGNOSIS

Trouble Diagnosis Chart for Symptoms

EDS003AY

If DIFF LOCK indicator lamp does not turn ON after engine start, perform self-diagnosis. R](/img/5/57362/w960_57362-2750.png)

RFD-48

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

TROUBLE DIAGNOSIS

Trouble Diagnosis Chart for Symptoms

EDS003AY

If DIFF LOCK indicator lamp does not turn ON after engine start, perform self-diagnosis. Refer toRFD-51, "SELF-DIAG RESULTSMODE".

Differential Lock Control Unit Input/Output Signal Reference ValuesEDS003AZ

DIFFERENTIAL LOCK CONTROL UNIT INSPECTION TABLE

Specifications with CONSULT-II

Symptom Condition Check itemReference

page

DIFF LOCK indicator lamp does not turn ON.

(DIFF LOCK indicator lamp check)Ignition switch: ONCAN communication line

RFD-70

Power supply and ground for differential

lock control unit

Combination meter

DIFF LOCK indicator lamp does not change.

lEngine running

lDifferential lock mode

switch: ONCombination meter

RFD-73Differential lock mode switch

CAN communication line

DIFF LOCK indicator lamp sometimes flashes.

lEngine running

lDifferential lock mode

switch: ONCombination meter

RFD-74Differential lock mode switch

Differential lock position switch

Differential inner parts

Monitor item [Unit] Content Condition Display value

BATTERY VOLT [V]Power supply voltage for

differential lock control unitIgnition switch: ON Battery voltage

4WD MODE [2H/4H/

4Lo]Condition of 4WD shift

switch4WD shift switch

(Engine running)2WD 2H

4H 4H

4LO 4Lo

VHCL S/SEN-R [km/h]

or [mph]Wheel speed

(Rear wheel right)Vehicle stopped 0 km/h (0 mph)

Vehicle running

CAUTION:

Check air pressure of tire under standard condition.Approximately

equal to the indi-

cation on speed-

ometer (Inside of

±10%)

VHCL S/SEN-L [km/h] or

[mph]Wheel speed

(Rear wheel left)Vehicle stopped 0 km/h (0 mph)

Vehicle running

CAUTION:

Check air pressure of tire under standard condition.Approximately

equal to the indi-

cation on speed-

ometer (Inside of

±10%)

VHCL S/SEN-RL [km/h]

or [mph]Wheel speed

(Average value of rear

wheel right and left)Vehicle stopped 0 km/h (0 mph)

Vehicle running

CAUTION:

Check air pressure of tire under standard condition.Approximately

equal to the indi-

cation on speed-

ometer (Inside of

±10%)

D-LOCK SW SIG [ON/

OFF]Condition of differential

lock mode switchDifferential lock mode switch: ON ON

Differential lock mode switch: OFF OFF

D-LOCK SIG [ON/OFF]Control status of differen-

tial lock

lVehicle stopped

lEngine running

l4WD shift switch: 4LODifferential lock mode

switch: ONON

Differential lock mode

switch: OFFOFF

Page 3005 of 3171

TF-38

TROUBLE DIAGNOSIS

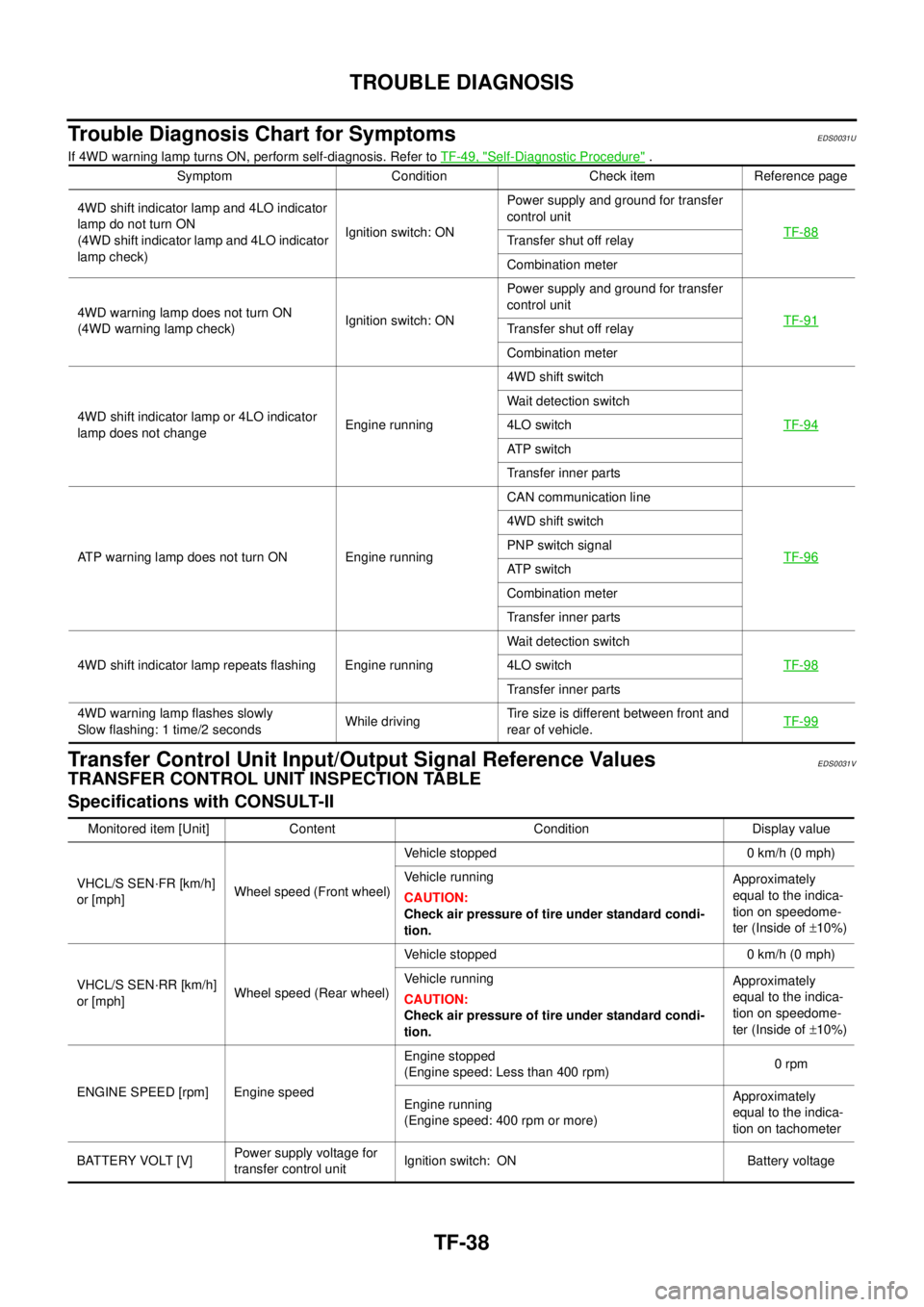

Trouble Diagnosis Chart for Symptoms

EDS0031U

If 4WD warning lamp turns ON, perform self-diagnosis. Refer toTF-49, "Self-Diagnostic Procedure".

Transfer Control Unit Input/Output Signal Reference ValuesEDS0031V

TRANSFER CONTROL UNIT INSPECTION TABLE

Specifications with CONSULT-II

Symptom Condition Check item Reference page

4WD shift indicator lamp and 4LO indicator

lamp do not turn ON

(4WD shift indicator lamp and 4LO indicator

lamp check)Ignition switch: ONPower supply and ground for transfer

control unit

TF-88

Transfer shut off relay

Combination meter

4WD warning lamp does not turn ON

(4WD warning lamp check)Ignition switch: ONPower supply and ground for transfer

control unit

TF-91

Transfer shut off relay

Combination meter

4WD shift indicator lamp or 4LO indicator

lamp does not changeEngine running4WD shift switch

TF-94

Wait detection switch

4LO switch

AT P s w i t c h

Transfer inner parts

ATP warning lamp does not turn ON Engine runningCAN communication line

TF-96

4WD shift switch

PNP switch signal

AT P s w i t c h

Combination meter

Transfer inner parts

4WD shift indicator lamp repeats flashing Engine runningWait detection switch

TF-98

4LO switch

Transfer inner parts

4WD warning lamp flashes slowly

Slow flashing: 1 time/2 secondsWhile drivingTire size is different between front and

rear of vehicle.TF-99

Monitored item [Unit] Content Condition Display value

VHCL/S SEN·FR [km/h]

or [mph]Wheel speed (Front wheel)Vehicle stopped 0 km/h (0 mph)

Vehicle running

CAUTION:

Check air pressure of tire under standard condi-

tion.Approximately

equal to the indica-

tion on speedome-

ter (Inside of±10%)

VHCL/S SEN·RR [km/h]

or [mph]Wheel speed (Rear wheel)Vehicle stopped 0 km/h (0 mph)

Vehicle running

CAUTION:

Check air pressure of tire under standard condi-

tion.Approximately

equal to the indica-

tion on speedome-

ter (Inside of±10%)

ENGINE SPEED [rpm] Engine speedEngine stopped

(Engine speed: Less than 400 rpm)0rpm

Engine running

(Engine speed: 400 rpm or more)Approximately

equal to the indica-

tion on tachometer

BATTERY VOLT [V]Power supply voltage for

transfer control unitIgnition switch: ON Battery voltage

Page 3006 of 3171

![NISSAN NAVARA 2005 Repair User Guide TROUBLE DIAGNOSIS

TF-39

C

E

F

G

H

I

J

K

L

MA

B

TF

2WDSWITCH[ON/

OFF]Input condition from 4WD

shift switch4WD shift switch: 2WD ON

4WD shift switch: 4H and 4LO OFF

4H SWITCH [ON/OFF]Input condition fro NISSAN NAVARA 2005 Repair User Guide TROUBLE DIAGNOSIS

TF-39

C

E

F

G

H

I

J

K

L

MA

B

TF

2WDSWITCH[ON/

OFF]Input condition from 4WD

shift switch4WD shift switch: 2WD ON

4WD shift switch: 4H and 4LO OFF

4H SWITCH [ON/OFF]Input condition fro](/img/5/57362/w960_57362-3005.png)

TROUBLE DIAGNOSIS

TF-39

C

E

F

G

H

I

J

K

L

MA

B

TF

2WDSWITCH[ON/

OFF]Input condition from 4WD

shift switch4WD shift switch: 2WD ON

4WD shift switch: 4H and 4LO OFF

4H SWITCH [ON/OFF]Input condition from 4WD

shift switch4WD shift switch: 4H ON

4WD shift switch: 2WD and 4LO OFF

4L SWITCH [ON/OFF]Input condition from 4WD

shift switch4WD shift switch: 4LO ON

4WD shift switch: 2WD and 4H OFF

4L POSI SW [ON/OFF] Condition of 4LO switch

lVehicle stopped

lEngine running

lFor A/T models, A/T

selector lever “N” posi-

tion with brake pedal

depressed.

lFor M/T models, M/T

shift lever neutral posi-

tion with clutch and

brake pedal depressed.4WD shift switch: 4LO ON

Except the above OFF

ATP SWITCH [ON/OFF] Condition of ATP switch

lVehicle stopped

lEngine running

lA/T selector lever “N”

position with brake

pedal depressed.4WD shift switch:

4H to 4LO or 4LO to 4H

(While actuator motor is

operating.)ON

Except the above OFF

WAIT DETCT SW [ON/

OFF]Condition of wait detection

switch

lVehicle stopped

lEngine running

lFor A/T models, A/T

selector lever “N” posi-

tion with brake pedal

depressed.

lFor M/T models, M/T

shift lever neutral posi-

tion with clutch and

brake pedal depressed.4WD shift switch:

4H and 4LOON

4WD shift switch: 2WD OFF

4WD MODE [2H/4H/4L]Control status of 4WD

(Output condition of 4WD

shift indicator lamp and

4LO indicator lamp)4WD shift switch

(Engine running)2WD 2H

4H 4H

4LO 4L

VHCL/S COMP [km/h]

or [mph]Vehicle speedVehicle stopped 0 km/h (0 mph)

Vehicle running

CAUTION:

Check air pressure of tires under standard condi-

tion.Approximately

equal to the indica-

tion on speedome-

ter (Inside of±10%)

SHIFT ACT 1 [ON/OFF]Output condition to actua-

tor motor (clockwise)

lVehicle stopped

lEngine running

lFor A/T models, A/T

selector lever “N” posi-

tion with brake pedal

depressed.

lFor M/T models, M/T

shift lever neutral posi-

tion with clutch and

brake pedal depressed.4WD shift switch:

2WDto4Hor4Hto4LO

or 2WD to 4LOON

Except the above OFF Monitored item [Unit] Content Condition Display value

Page 3066 of 3171

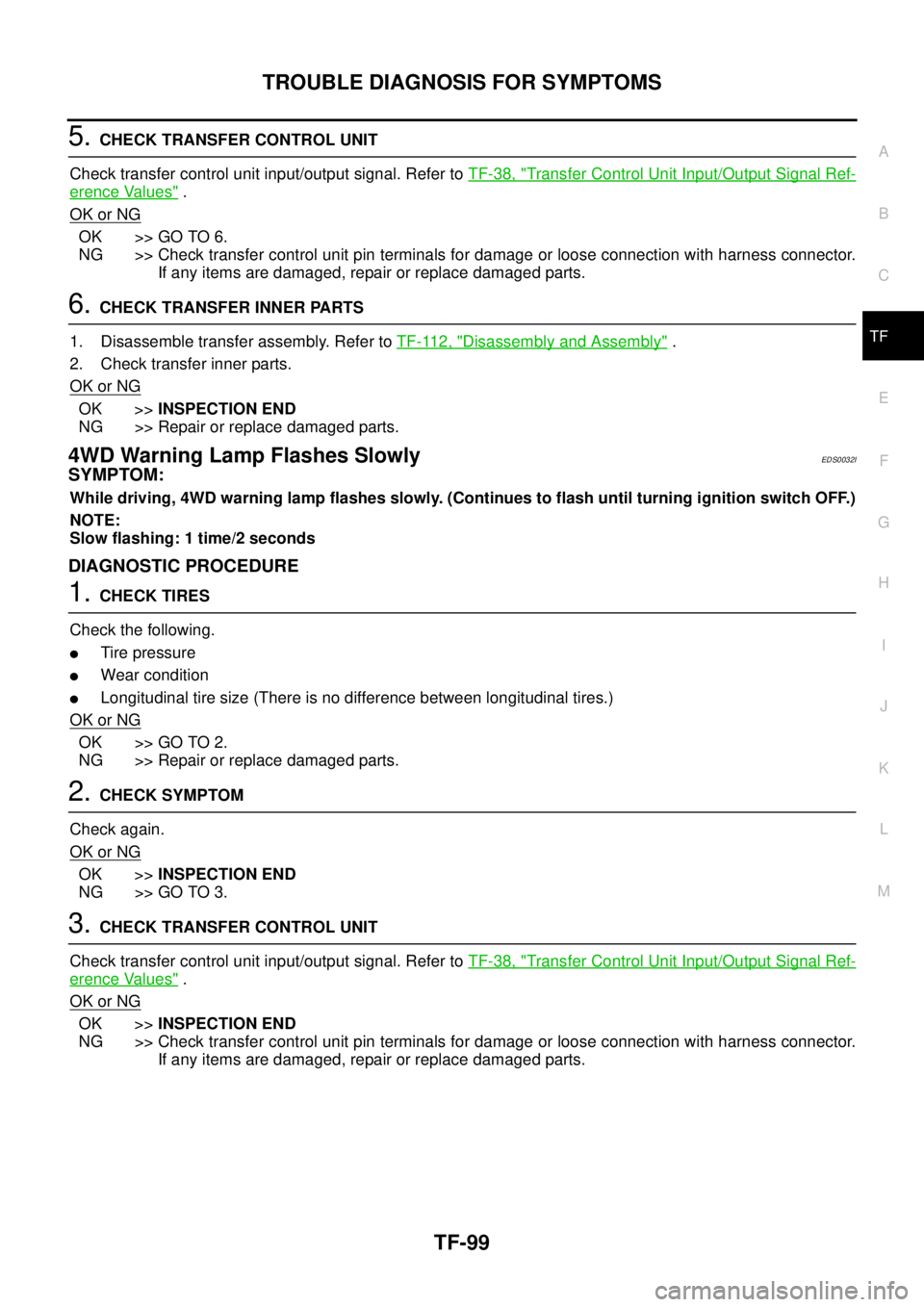

TROUBLE DIAGNOSIS FOR SYMPTOMS

TF-99

C

E

F

G

H

I

J

K

L

MA

B

TF

5.CHECK TRANSFER CONTROL UNIT

Check transfer control unit input/output signal. Refer toTF-38, "

Transfer Control Unit Input/Output Signal Ref-

erence Values".

OK or NG

OK >> GO TO 6.

NG >> Check transfer control unit pin terminals for damage or loose connection with harness connector.

If any items are damaged, repair or replace damaged parts.

6.CHECK TRANSFER INNER PARTS

1. Disassemble transfer assembly. Refer toTF-112, "

Disassembly and Assembly".

2. Check transfer inner parts.

OK or NG

OK >>INSPECTION END

NG >> Repair or replace damaged parts.

4WD Warning Lamp Flashes SlowlyEDS0032I

SYMPTOM:

While driving, 4WD warning lamp flashes slowly. (Continues to flash until turning ignition switch OFF.)

NOTE:

Slow flashing: 1 time/2 seconds

DIAGNOSTIC PROCEDURE

1.CHECK TIRES

Check the following.

lTire pressure

lWear condition

lLongitudinal tire size (There is no difference between longitudinal tires.)

OK or NG

OK >> GO TO 2.

NG >> Repair or replace damaged parts.

2.CHECK SYMPTOM

Check again.

OK or NG

OK >>INSPECTION END

NG >> GO TO 3.

3.CHECK TRANSFER CONTROL UNIT

Check transfer control unit input/output signal. Refer toTF-38, "

Transfer Control Unit Input/Output Signal Ref-

erence Values".

OK or NG

OK >>INSPECTION END

NG >> Check transfer control unit pin terminals for damage or loose connection with harness connector.

If any items are damaged, repair or replace damaged parts.

Page 3107 of 3171

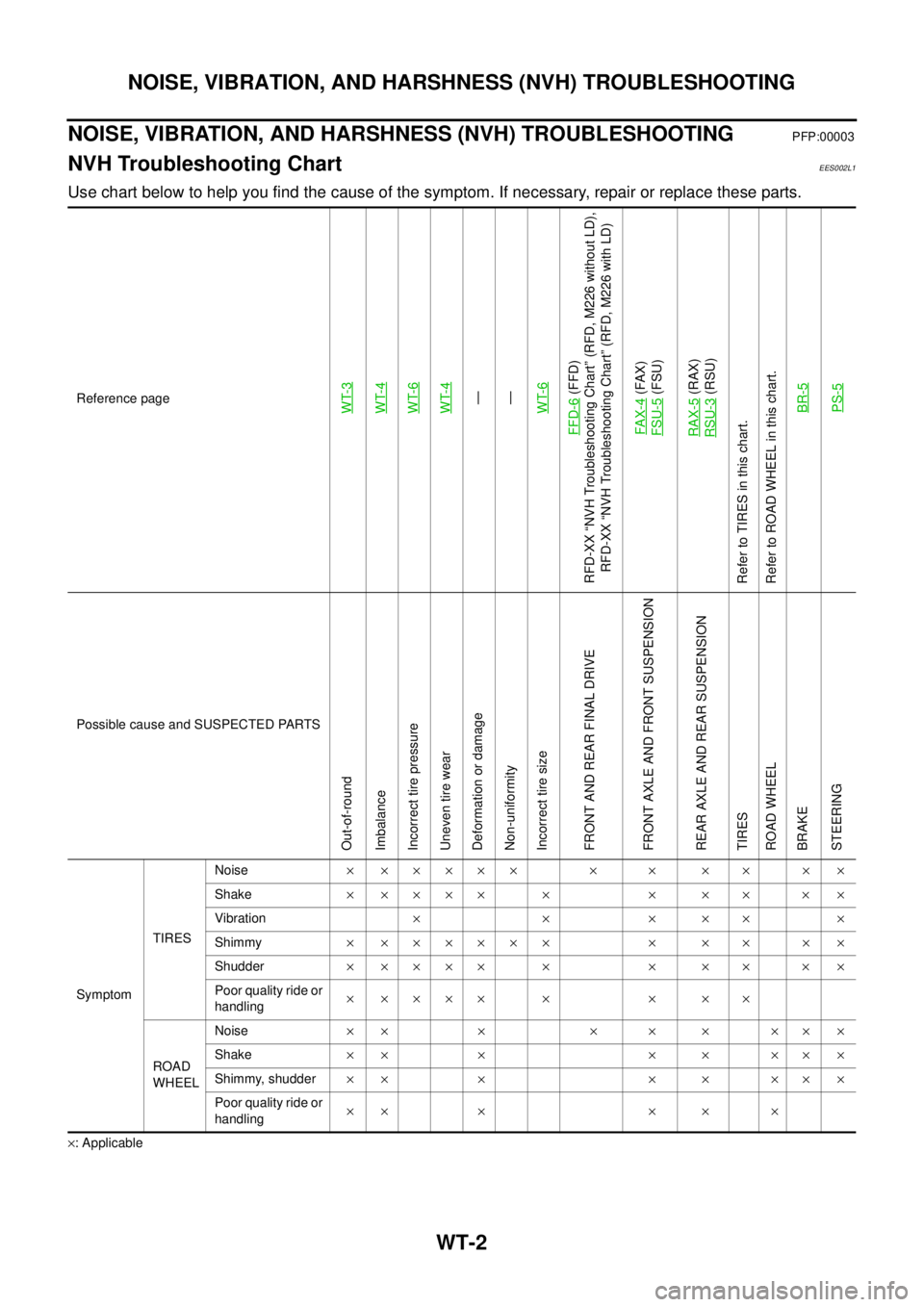

WT-2

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

PFP:00003

NVH Troubleshooting ChartEES002L1

Use chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

´: ApplicableReference page

WT-3WT-4WT-6WT-4—

—

WT-6

FFD-6

(FFD)

RFD-XX “NVH Troubleshooting Chart” (RFD, M226 without LD),

RFD-XX “NVH Troubleshooting Chart” (RFD, M226 with LD)

FAX-4(FAX)

FSU-5(FSU)

RAX-5(RAX)

RSU-3(RSU)

Refer to TIRES in this chart.

Refer to ROAD WHEEL in this chart.

BR-5

PS-5

Possible cause and SUSPECTED PARTS

Out-of-round

Imbalance

Incorrect tire pressure

Uneven tire wear

Deformation or damage

Non-uniformity

Incorrect tire size

FRONT AND REAR FINAL DRIVE

FRONT AXLE AND FRONT SUSPENSION

REAR AXLE AND REAR SUSPENSION

TIRES

ROAD WHEEL

BRAKE

STEERING

SymptomTIRESNoise´ ´´´´´ ´ ´ ´ ´ ´ ´

Shake´´´´´ ´ ´ ´ ´ ´´

Vibration´´´´´´

Shimmy´ ´´´´´´ ´ ´ ´ ´ ´

Shudder´´´´´ ´ ´ ´ ´ ´´

Poor quality ride or

handling´´´´´ ´ ´ ´ ´

ROAD

WHEELNoise´´ ´ ´ ´ ´ ´´´

Shake´´ ´ ´ ´ ´´´

Shimmy, shudder´´ ´ ´ ´ ´´´

Poor quality ride or

handling´´ ´ ´ ´ ´

Page 3111 of 3171

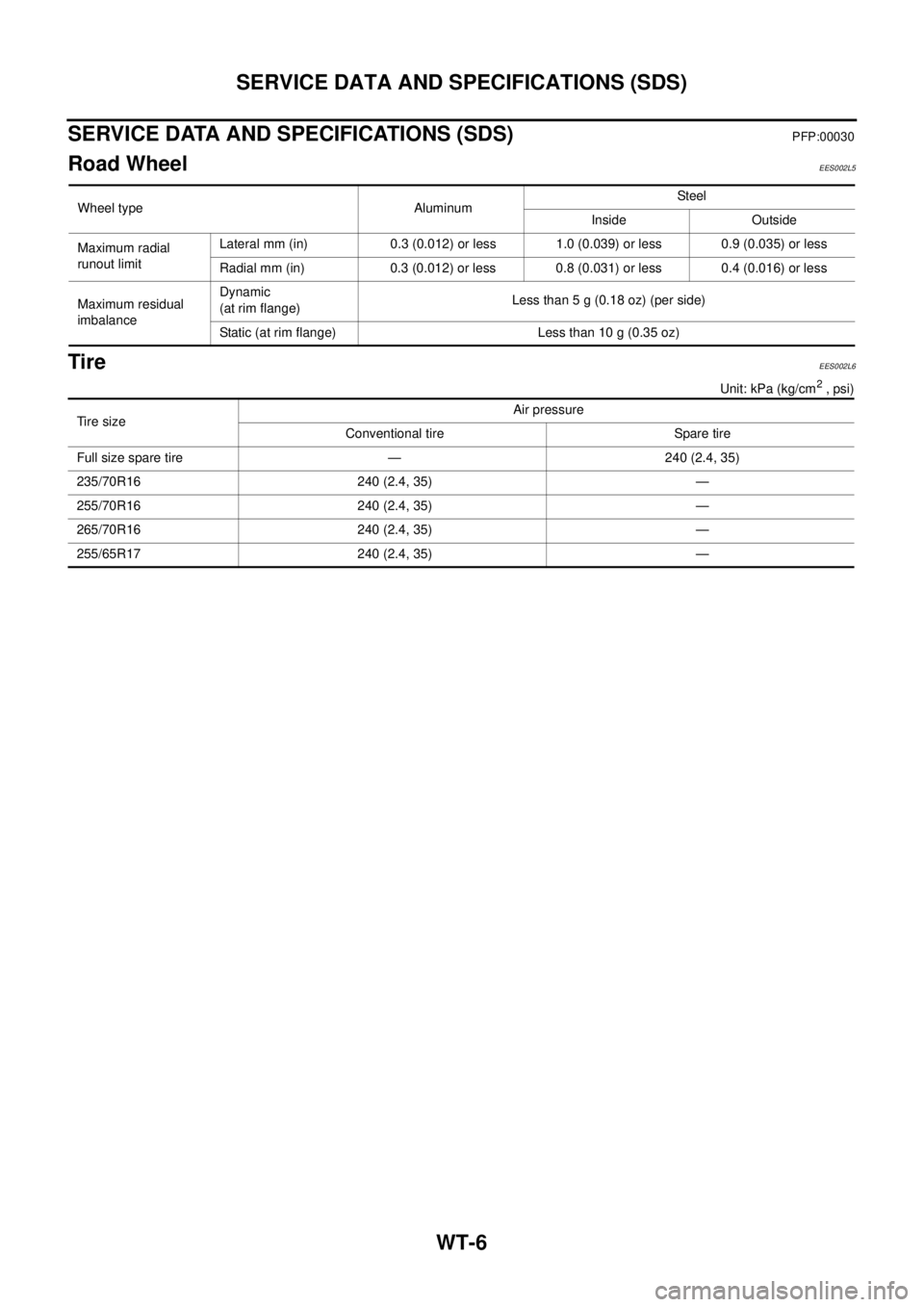

WT-6

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

PFP:00030

Road WheelEES002L5

TireEES002L6

Unit: kPa (kg/cm2, psi) Wheel type AluminumSteel

Inside Outside

Maximum radial

runout limitLateral mm (in) 0.3 (0.012) or less 1.0 (0.039) or less 0.9 (0.035) or less

Radial mm (in) 0.3 (0.012) or less 0.8 (0.031) or less 0.4 (0.016) or less

Maximum residual

imbalanceDynamic

(at rim flange)Less than 5 g (0.18 oz) (per side)

Static (at rim flange) Less than 10 g (0.35 oz)

Tire sizeAir pressure

Conventional tire Spare tire

Full size spare tire — 240 (2.4, 35)

235/70R16 240 (2.4, 35) —

255/70R16 240 (2.4, 35) —

265/70R16 240 (2.4, 35) —

255/65R17 240 (2.4, 35) —