wheel torque NISSAN NAVARA 2005 Repair User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1555 of 3171

FRONT OIL SEAL

FFD-9

C

E

F

G

H

I

J

K

L

MA

B

FFD

FRONT OIL SEALPFP:38189

Removal and InstallationEDS00353

CAUTION:

Verify identification stamp of replacement frequency put in the lower part of gear carrier to determine

replacement for collapsible spacer when replacing front oil seal. Refer toFFD-9, "

IDENTIFICATION

STAMP OF REPLACEMENT FREQUENCY OF FRONT OIL SEAL". If necessary collapsible spacer

replacement, remove final drive assembly and disassemble it to replace front oil seal and collapsible

spacer. Refer toFFD-15, "

Removal and Installation"andFFD-17, "Disassembly and Assembly".

NOTE:

The reuse of collapsible spacer is prohibited in principle. However, it is reusable on a one-time basis

only in cases when replacing front oil seal.

IDENTIFICATION STAMP OF REPLACEMENT FREQUENCY OF FRONT OIL SEAL

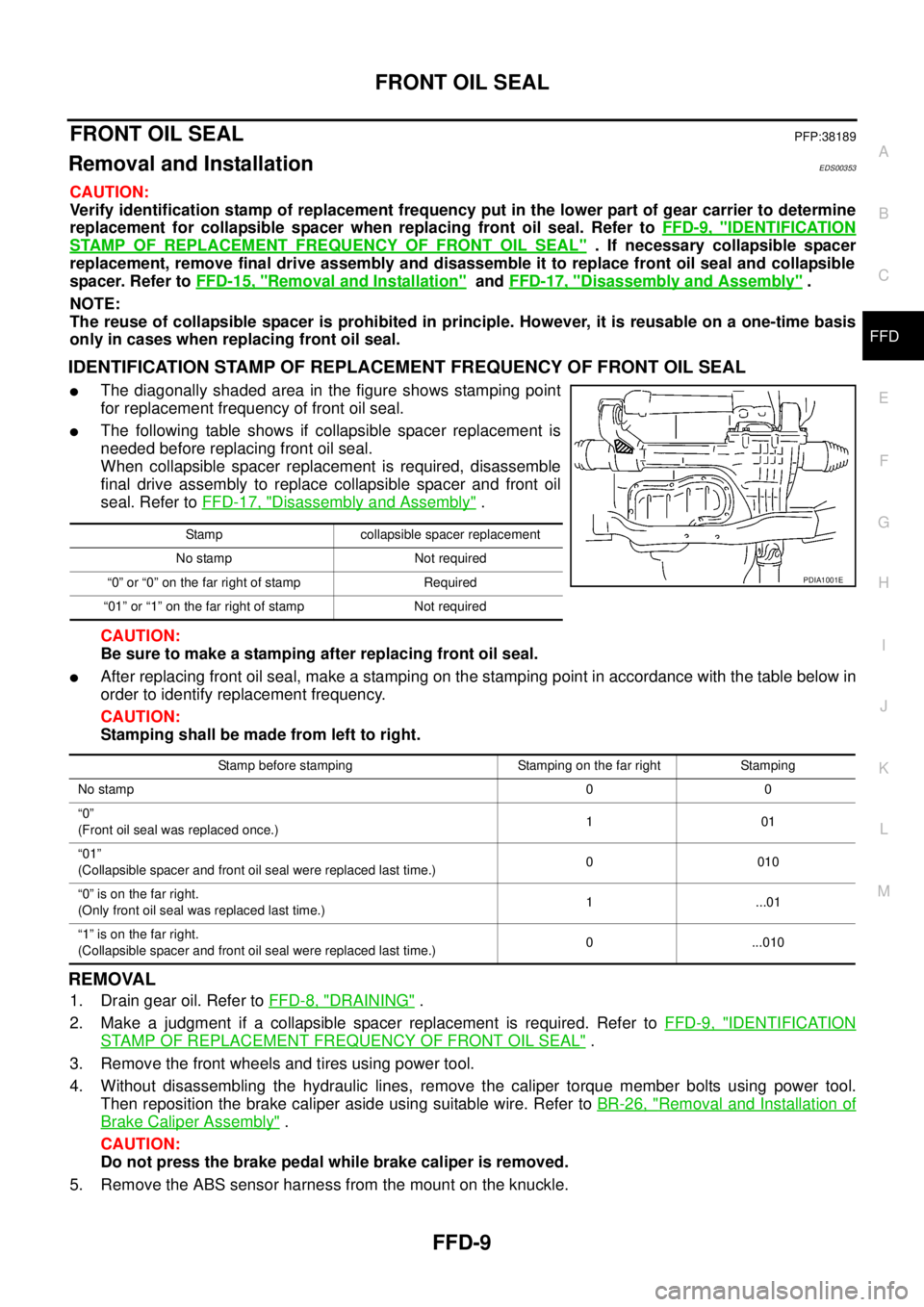

lThe diagonally shaded area in the figure shows stamping point

for replacement frequency of front oil seal.

lThe following table shows if collapsible spacer replacement is

needed before replacing front oil seal.

When collapsible spacer replacement is required, disassemble

final drive assembly to replace collapsible spacer and front oil

seal. Refer toFFD-17, "

Disassembly and Assembly".

CAUTION:

Be sure to make a stamping after replacing front oil seal.

lAfter replacing front oil seal, make a stamping on the stamping point in accordance with the table below in

order to identify replacement frequency.

CAUTION:

Stamping shall be made from left to right.

REMOVAL

1. Drain gear oil. Refer toFFD-8, "DRAINING".

2. Make a judgment if a collapsible spacer replacement is required. Refer toFFD-9, "

IDENTIFICATION

STAMP OF REPLACEMENT FREQUENCY OF FRONT OIL SEAL".

3. Remove the front wheels and tires using power tool.

4. Without disassembling the hydraulic lines, remove the caliper torque member bolts using power tool.

Then reposition the brake caliper aside using suitable wire. Refer toBR-26, "

Removal and Installation of

Brake Caliper Assembly".

CAUTION:

Do not press the brake pedal while brake caliper is removed.

5. Remove the ABS sensor harness from the mount on the knuckle.

Stamp collapsible spacer replacement

No stamp Not required

“0” or “0” on the far right of stamp Required

“01” or “1” on the far right of stamp Not required

PDIA1001E

Stamp before stamping Stamping on the far right Stamping

No stamp00

“0”

(Front oil seal was replaced once.)101

“01”

(Collapsible spacer and front oil seal were replaced last time.)0010

“0”isonthefarright.

(Only front oil seal was replaced last time.)1 ...01

“1”isonthefarright.

(Collapsible spacer and front oil seal were replaced last time.)0 ...010

Page 1558 of 3171

FFD-12

FRONT OIL SEAL

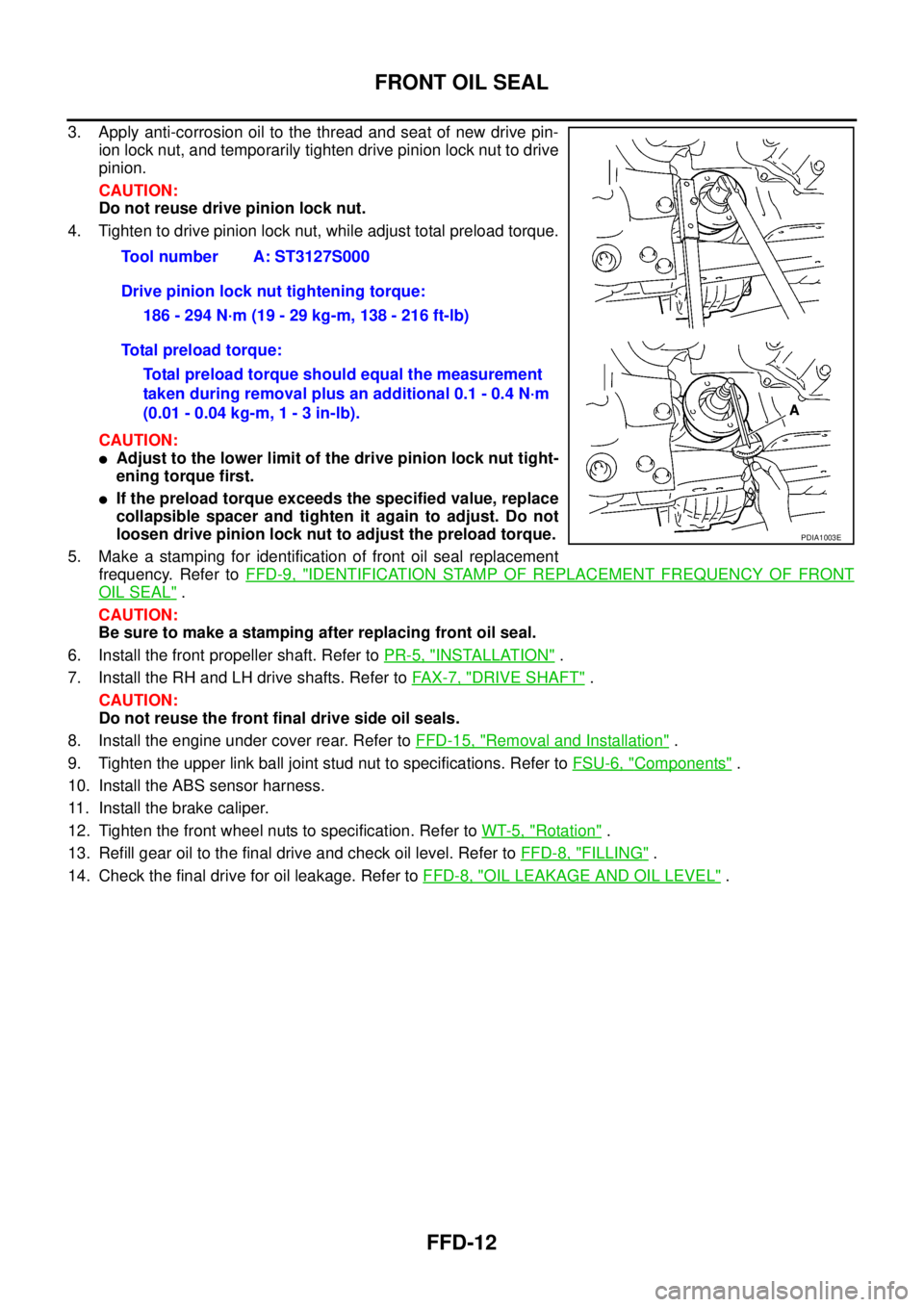

3. Apply anti-corrosion oil to the thread and seat of new drive pin-

ion lock nut, and temporarily tighten drive pinion lock nut to drive

pinion.

CAUTION:

Do not reuse drive pinion lock nut.

4. Tighten to drive pinion lock nut, while adjust total preload torque.

CAUTION:

lAdjust to the lower limit of the drive pinion lock nut tight-

ening torque first.

lIf the preload torque exceeds the specified value, replace

collapsible spacer and tighten it again to adjust. Do not

loosen drive pinion lock nut to adjust the preload torque.

5. Make a stamping for identification of front oil seal replacement

frequency. Refer toFFD-9, "

IDENTIFICATION STAMP OF REPLACEMENT FREQUENCY OF FRONT

OIL SEAL".

CAUTION:

Be sure to make a stamping after replacing front oil seal.

6. Install the front propeller shaft. Refer toPR-5, "

INSTALLATION".

7. Install the RH and LH drive shafts. Refer toFA X - 7 , "

DRIVE SHAFT".

CAUTION:

Do not reuse the front final drive side oil seals.

8. Install the engine under cover rear. Refer toFFD-15, "

Removal and Installation".

9. Tighten the upper link ball joint stud nut to specifications. Refer toFSU-6, "

Components".

10. Install the ABS sensor harness.

11. Install the brake caliper.

12. Tighten the front wheel nuts to specification. Refer toWT-5, "

Rotation".

13. Refill gear oil to the final drive and check oil level. Refer toFFD-8, "

FILLING".

14. Check the final drive for oil leakage. Refer toFFD-8, "

OIL LEAKAGE AND OIL LEVEL". Tool number A: ST3127S000

Drive pinion lock nut tightening torque:

186 - 294 N·m (19 - 29 kg-m, 138 - 216 ft-lb)

Total preload torque:

Total preload torque should equal the measurement

taken during removal plus an additional 0.1 - 0.4 N·m

(0.01 - 0.04 kg-m, 1 - 3 in-lb).

PDIA1003E

Page 1559 of 3171

SIDE OIL SEAL

FFD-13

C

E

F

G

H

I

J

K

L

MA

B

FFD

SIDE OIL SEALPFP:33142

Removal and InstallationEDS00354

REMOVAL

1. Remove the front wheels and tires using power tool.

2. Without disassembling the hydraulic lines, remove the caliper torque member bolts using power tool.

Then reposition the brake caliper aside using suitable wire. Refer toBR-26, "

Removal and Installation of

Brake Caliper Assembly".

CAUTION:

Do not press the brake pedal while brake caliper is removed.

3. Remove the ABS sensor harness from the mount on the knuckle.

CAUTION:

Do not pull on the ABS sensor harness.

4. Support the lower link using a suitable jack.

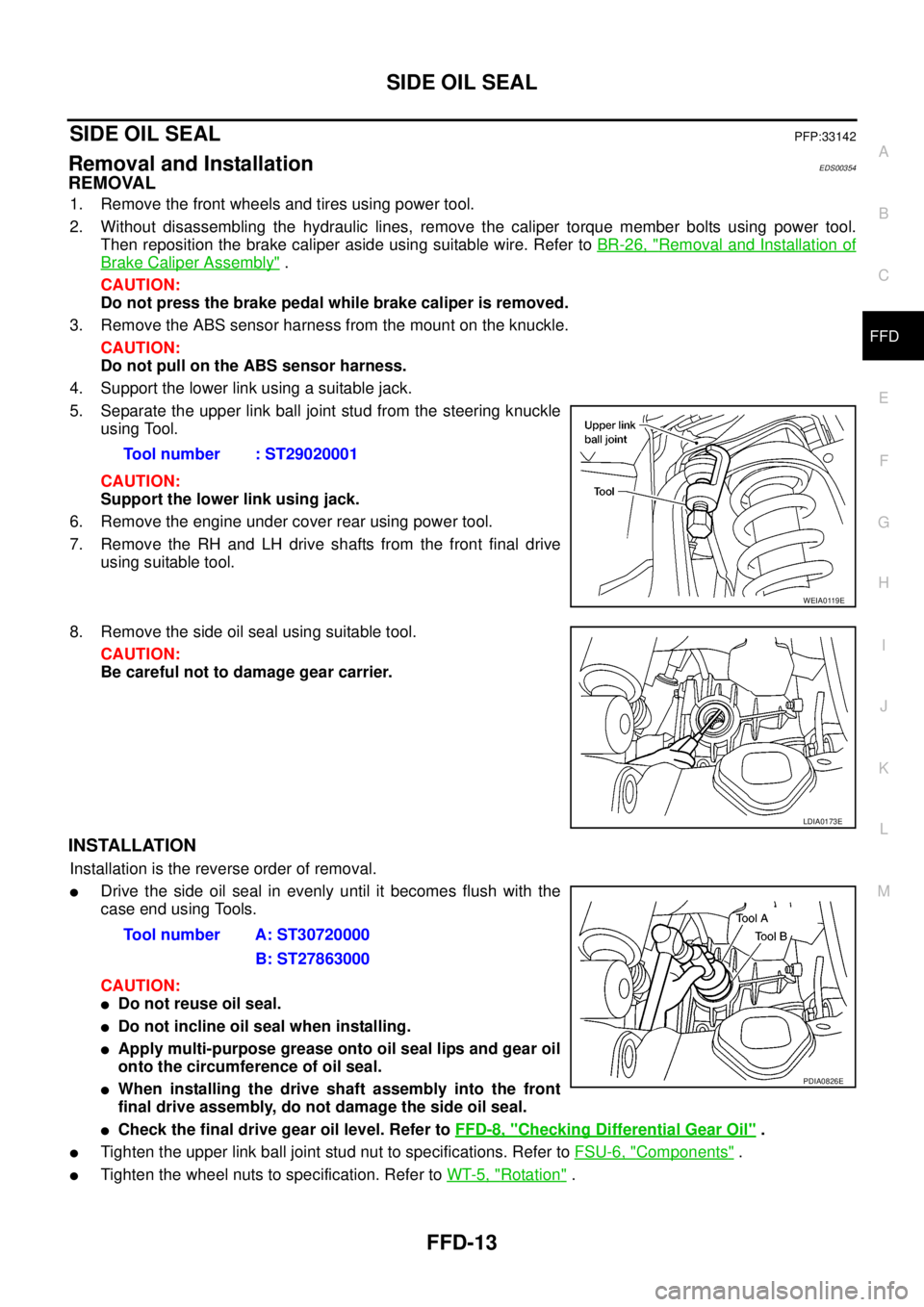

5. Separate the upper link ball joint stud from the steering knuckle

using Tool.

CAUTION:

Support the lower link using jack.

6. Remove the engine under cover rear using power tool.

7. Remove the RH and LH drive shafts from the front final drive

using suitable tool.

8. Remove the side oil seal using suitable tool.

CAUTION:

Be careful not to damage gear carrier.

INSTALLATION

Installation is the reverse order of removal.

lDrive the side oil seal in evenly until it becomes flush with the

case end using Tools.

CAUTION:

lDo not reuse oil seal.

lDo not incline oil seal when installing.

lApply multi-purpose grease onto oil seal lips and gear oil

onto the circumference of oil seal.

lWhen installing the drive shaft assembly into the front

final drive assembly, do not damage the side oil seal.

lCheck the final drive gear oil level. Refer toFFD-8, "Checking Differential Gear Oil".

lTighten the upper link ball joint stud nut to specifications. Refer toFSU-6, "Components".

lTighten the wheel nuts to specification. Refer toWT-5, "Rotation". Tool number : ST29020001

WEIA0119E

LDIA0173E

Tool number A: ST30720000

B: ST27863000

PDIA0826E

Page 1561 of 3171

FRONT FINAL DRIVE ASSEMBLY

FFD-15

C

E

F

G

H

I

J

K

L

MA

B

FFD

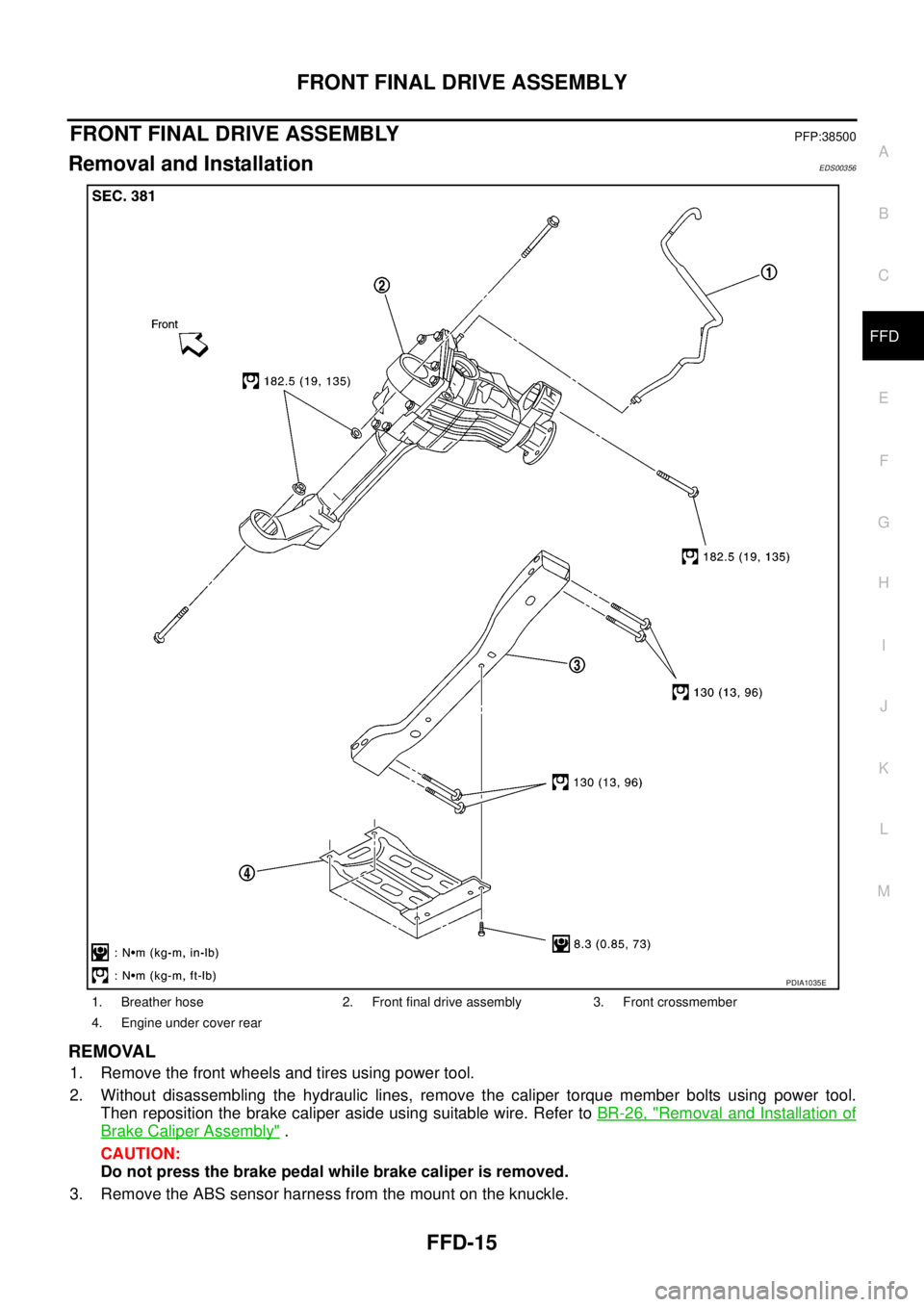

FRONT FINAL DRIVE ASSEMBLYPFP:38500

Removal and InstallationEDS00356

REMOVAL

1. Remove the front wheels and tires using power tool.

2. Without disassembling the hydraulic lines, remove the caliper torque member bolts using power tool.

Then reposition the brake caliper aside using suitable wire. Refer toBR-26, "

Removal and Installation of

Brake Caliper Assembly".

CAUTION:

Do not press the brake pedal while brake caliper is removed.

3. Remove the ABS sensor harness from the mount on the knuckle.

1. Breather hose 2. Front final drive assembly 3. Front crossmember

4. Engine under cover rear

PDIA1035E

Page 1607 of 3171

ON-VEHICLE SERVICE

FSU-7

C

D

F

G

H

I

J

K

L

MA

B

FSU

ON-VEHICLE SERVICEPFP:00000

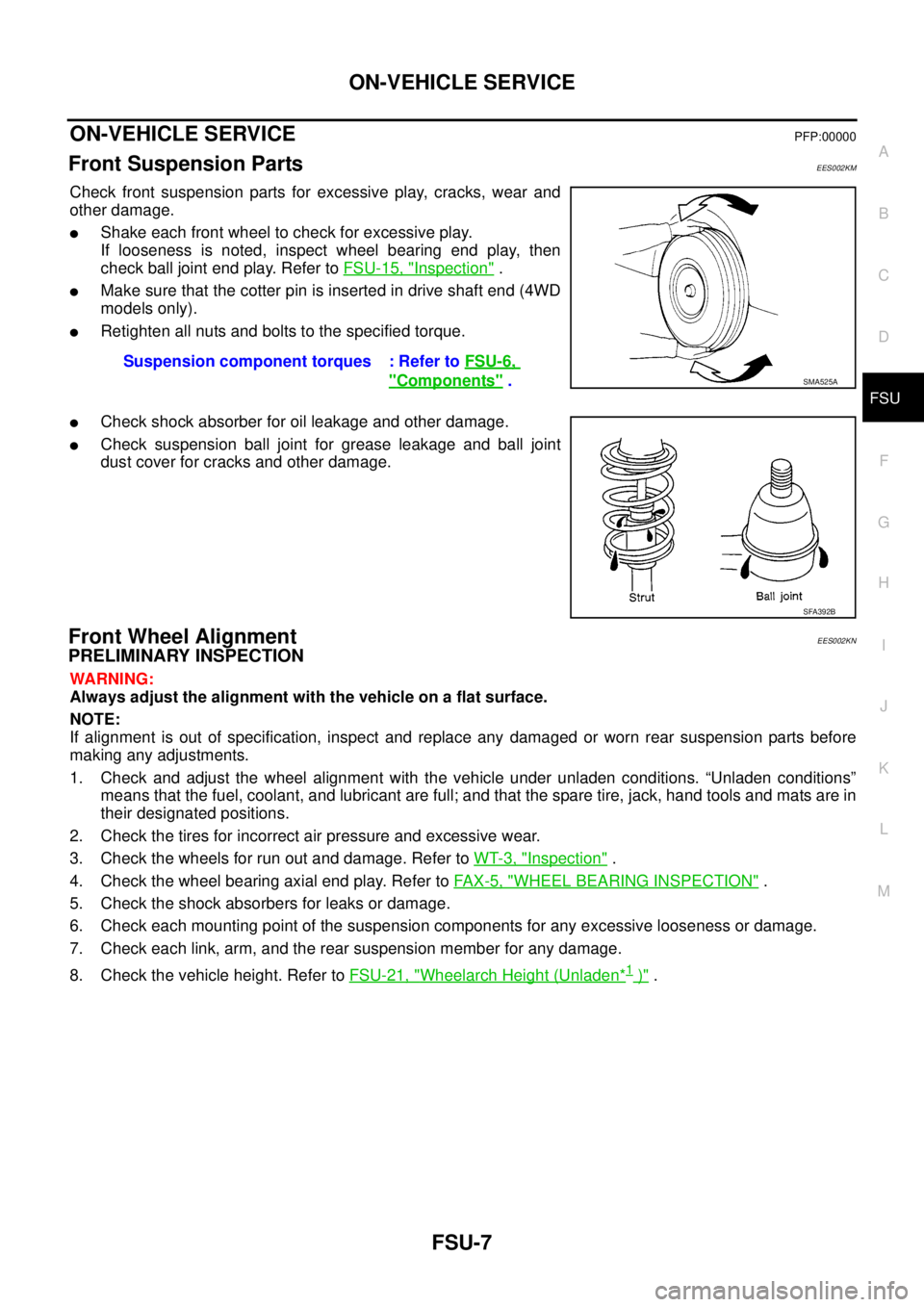

Front Suspension PartsEES002KM

Check front suspension parts for excessive play, cracks, wear and

other damage.

lShake each front wheel to check for excessive play.

If looseness is noted, inspect wheel bearing end play, then

check ball joint end play. Refer toFSU-15, "

Inspection".

lMake sure that the cotter pin is inserted in drive shaft end (4WD

models only).

lRetighten all nuts and bolts to the specified torque.

lCheck shock absorber for oil leakage and other damage.

lCheck suspension ball joint for grease leakage and ball joint

dust cover for cracks and other damage.

Front Wheel AlignmentEES002KN

PRELIMINARY INSPECTION

WARNING:

Always adjust the alignment with the vehicle on a flat surface.

NOTE:

If alignment is out of specification, inspect and replace any damaged or worn rear suspension parts before

making any adjustments.

1. Check and adjust the wheel alignment with the vehicle under unladen conditions. “Unladen conditions”

means that the fuel, coolant, and lubricant are full; and that the spare tire, jack, hand tools and mats are in

their designated positions.

2. Check the tires for incorrect air pressure and excessive wear.

3. Check the wheels for run out and damage. Refer toWT-3, "

Inspection".

4. Check the wheel bearing axial end play. Refer toFA X - 5 , "

WHEEL BEARING INSPECTION".

5. Check the shock absorbers for leaks or damage.

6. Check each mounting point of the suspension components for any excessive looseness or damage.

7. Check each link, arm, and the rear suspension member for any damage.

8. Check the vehicle height. Refer toFSU-21, "

Wheelarch Height (Unladen*1)". Suspension component torques : Refer toFSU-6,

"Components".SMA525A

SFA392B

Page 1618 of 3171

FSU-18

KNUCKLE

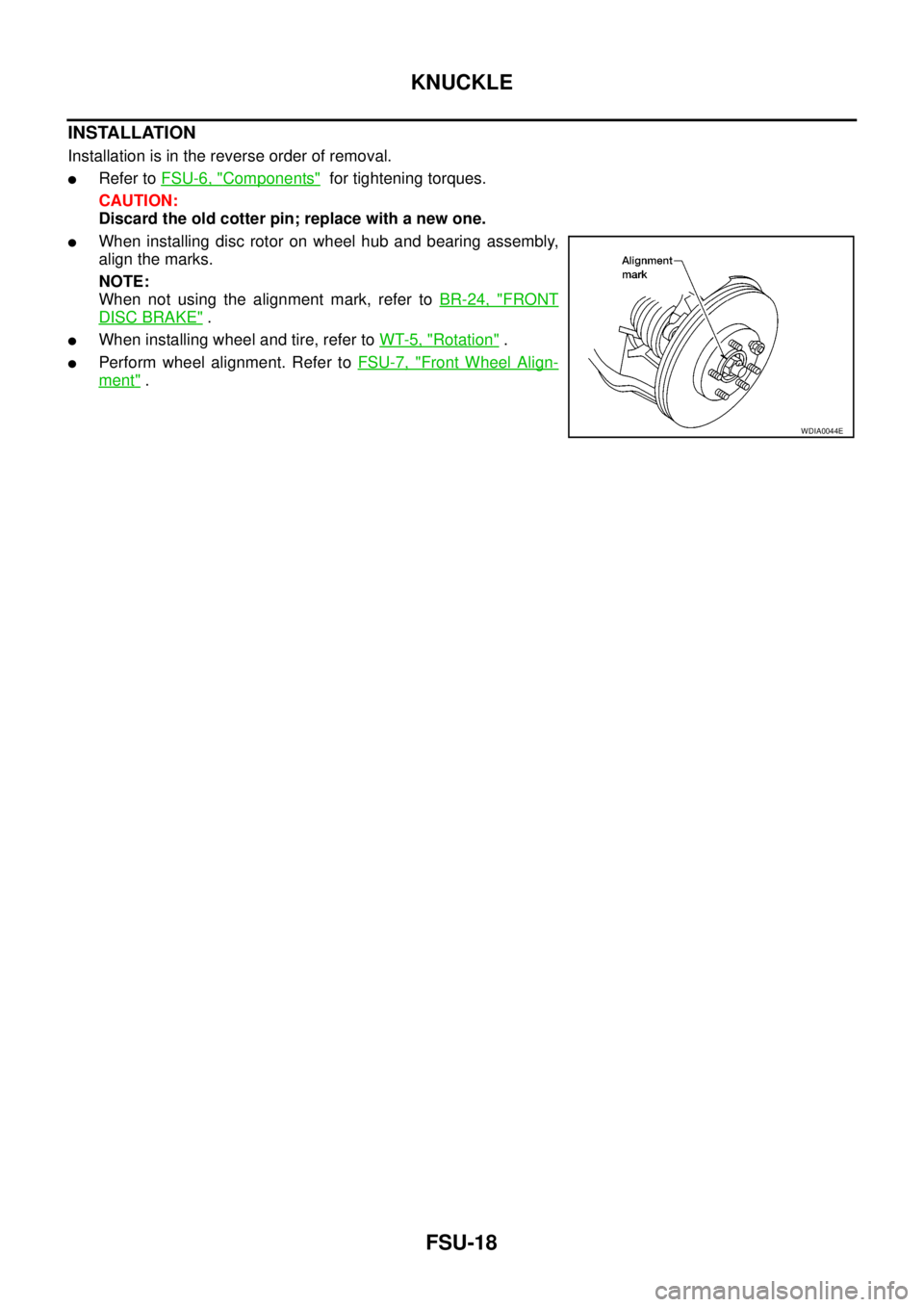

INSTALLATION

Installation is in the reverse order of removal.

lRefer toFSU-6, "Components"for tightening torques.

CAUTION:

Discard the old cotter pin; replace with a new one.

lWhen installing disc rotor on wheel hub and bearing assembly,

align the marks.

NOTE:

When not using the alignment mark, refer toBR-24, "

FRONT

DISC BRAKE".

lWhen installing wheel and tire, refer toWT-5, "Rotation".

lPerform wheel alignment. Refer toFSU-7, "Front Wheel Align-

ment".

WDIA0044E

Page 1624 of 3171

GI-2

TIGHTENING TORQUE OF STANDARD BOLTS .... 55

Tightening Torque Table ......................................... 55

IDENTIFICATION INFORMATION ............................ 56

Model Variation ....................................................... 56

Identification Number .............................................. 57

VEHICLE IDENTIFICATION NUMBER

ARRANGEMENT ................................................. 57

IDENTIFICATION PLATE .................................... 58

ENGINE SERIAL NUMBER ................................ 58TRANSFER SERIAL NUMBER ........................... 58

AUTOMATIC TRANSMISSION NUMBER ........... 58

MANUAL TRANSMISSION NUMBER ................. 59

Dimensions ............................................................. 60

KING CAB ............................................................ 60

DOUBLE CAB ...................................................... 60

Wheels & Tyres ....................................................... 60

TERMINOLOGY ........................................................ 61

ISO 15031-2 Terminology List ................................. 61

Page 1759 of 3171

IDX-7

A

C

D

E

F

G

H

I

J

K

L B

IDX

ALPHABETICAL INDEX

Starter ................................................................SC-27

Starting system ..................................................SC-27

Steering gear, linkage and transfer gear inspection .....

MA-36

,MA-37

Steering linkage .................................................PS-14

Steering wheel and column .................................PS-8

Step lamp .........................................................LT-145

Stop lamp .........................................................LT-121

Stop lamp switch .............................................EC-330

STOP/L - Wiring diagram .................................LT-121

Striking rod (M/T) ...............................................MT-23

Strut (front) ......................................................FSU-10

Sun roof, electric ................................................RF-10

Sunload sensor ..............................................ATC-112

Sunroof ..................................................RF-10,RF-21

Super lock ...........................................................BL-55

Supplemental Restraint System ........................SRS-6

Symbols and abbreviations .....................GI-10,GI-23

Symptom matrix chart ........................................EC-42

Synchronizer (M/T) ............................................MT-21

T

Tachometer ..........................................................DI-4

Tail lamp ...........................................................LT-125

TAIL/L - Wiring diagram ....................................LT-127

TC boost control solnoid valve ........................EC-309

TC boost sensor ..............................................EC-153

TCC/V - Wiring diagram ..................................EC-311

TCM circuit diagram ..........................................AT-42

TCM inspection table .........................................AT-76

Thermostat ........................................................CO-24

Three way catalyst precautions ............................GI-5

Throttle body ......................................................EM-20

Tie-rod ...............................................................PS-14

Timing chain .........................................EM-73,EM-79

Timing gear ........................................................EM-79

Tire rotation .......................................................MA-34

Tire size ..............................................................GI-60

Torque converter installation ...........................AT-250

Torque convertor clutch solenoid valveAT-110,AT-112

Tow truck towing .................................................GI-53

Towing point .......................................................GI-54

Transfer control device .............TF-74,TF-78,TF-105

Transfer control unit inspection table ..................TF-38

Transfer oil replacement ....................................MA-32

Transfer serial number .......................................GI-58

Transmission case (M/T) ...................................MT-19

Transmission serial number ....................GI-58,GI-59

Tread-FR&RR (Dimensions) ..............................GI-60

Trim .....................................................................EI-33

Trouble diagnoses ..............................................GI-11

Turbine revolution sensor ................................AT-123

Turbocharger .....................................................EM-28

Turbocharger charge air cooler .........................EM-18

Turbocharger precautions ....................................GI-6

TURN - Wiring diagram ....................................LT-100

Turn signal lamp .................................................LT-97

Two-pole lift ........................................................GI-52

V

Vacuum hose drawing (Engine control) .............EC-16

Vacuum pump ...................................................EM-42

Valve clearance ................................................EM-66

Valve guide .....................................................EM-101

Valve lifter .........................................................EM-62

Valve seat .......................................................EM-103

Valve spring ....................................................EM-104

Vanity mirror lamp .............................................LT-145

Vehicle identification number ..............................GI-57

Vehicle recovery (freeing a stuck vehicle) ..........GI-54

VEHSEC - Wiring diagram ...............................BL-143

Viscosity number (SAE) ....................................MA-15

W

Wait detection switch ..............................TF-63

,TF-66

WARN - Wiring diagram .....................................DI-30

Warning chime ....................................................DI-51

Warning lamps ....................................................DI-28

Washer, front .....................................................WW-4

Water pump ......................................................CO-21

Water temperature gauge .....................................DI-4

Wheel alignment (front) .....................................FSU-7

Wheel balance ..................................................MA-34

Wheel bearing (front) .........................................FAX-5

Wheel bearing (rear) .........................................RAX-6

Wheel sensors (ABS) .....................................BRC-37

Wheel size ..........................................................GI-60

Wheelbase (Dimensions) ....................................GI-60

Width (Dimensions) ............................................GI-60

WINDOW - Wiring diagram ...............................GW-20

Window, door ......................................GW-35,GW-38

Window, rear .....................................................GW-43

Windshield ........................................................GW-11

WIPER - Wiring diagram ..................................WW-12

Wiper, front ........................................................WW-4

Wiring Diagram (Cell code) list ..........................PG-68

Wiring diagrams ..................................................GI-15

Page 2280 of 3171

DESCRIPTION

MA-5

C

D

E

F

G

H

I

J

K

MA

B

MA

DESCRIPTIONPFP:00000

Pre-Delivery Inspection ItemsELS001K2

Shown below are Pre-delivery Inspection Items required for the new vehicle. It is recommended that

necessary items other than those listed here be added, paying due regard to the conditions in each

country.

Perform applicable items on each model. Consult text of this section for specifications.

Install vehicle protection kit

Fit all accessories ordered (if applicable) (e.g. towbar, audio, navigation, air conditioner, styling kit)

UNDER HOOD — engine off

Check coolant level and cooling system for leaks

Charge battery and check terminals for condition

Check drive belts tension

Check fuel filter for water or dust (diesel only) and fuel system for leaks

Check engine oil level and for oil leaks

Check brake and clutch fluid levels and fluid lines for leaks

Check and top up washer reservoirs

Check power steering fluid level and fluid lines for leaks (if applicable)

Check air conditioning system for gas leaks (if applicable)

ON INSIDE AND OUTSIDE

Install transit fuse if removed for vehicle storage

Check instruments, gauges, lamps, horn and accessories for operation

Check wipers and washers for operation and adjustment

Check interior and door mirrors and sun visors for operation

Set radio code and set clock

Check parking brake adjustment

Check clutch pedal adjustment

Check steering lock operation

Check seat adjusters and seat belts for operation

Check all windows for operation and alignment

Check mouldings, trim and fittings for fit and alignment

Check weatherstrips for fit and adhesion

Check hood, trunk lid, door panels and fuel lid for fit and alignment

Check latches, keys, remote key, door locks and remote trunk lid and fuel lid release for operation

Check wheel nut torques

Check tyre pressure (incl. spare tyre)

Check tool kit and jack for operation

Check automatic transmission/transaxle starter inhibitor (if applicable)

Check sunroof for operation and alignment (if applicable)

UNDER BODY

Check manual transmission/transaxle, differential and transfer box for oil level and oil leaks

Tighten bolts and nuts steering linkage and gear box, axle/suspension parts, propeller and exhaust system

Check brake and clutch lines, and oil/fluid reservoirs for leaks

Remove front suspension spacer blocks (if applicable)

Check body mounting torque (if applicable)

Page 2309 of 3171

MA-34

CHASSIS AND BODY MAINTENANCE

Changing Rear Final Drive Oil (Rear Differential Gear Oil)

ELS001IW

CAUTION:

If using the vehicle for towing, the final drive oil must be replaced as specified. Refer toMA-8, "

PERI-

ODIC MAINTENANCE".

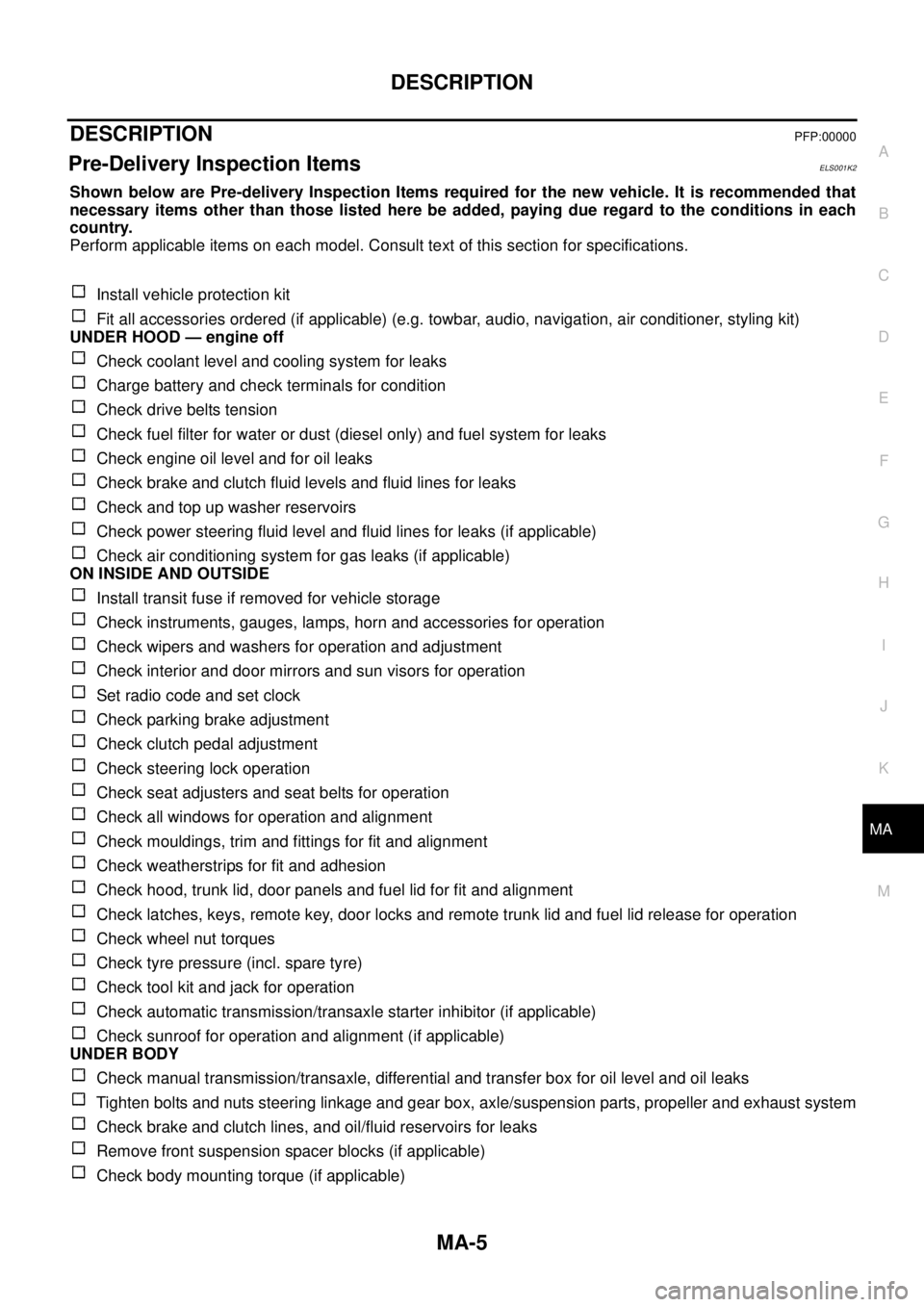

DRAINING

1. Stop the engine.

2. Remove the drain plug and gasket. Drain the gear oil.

3. Apply sealant to drain plug. Install drain plug to final drive

assembly and tighten to the specified torque. Refer toRFD-15,

"COMPONENTS"(WITH LIMITED SLIP DIFFERENTIAL) and

RFD-82, "

COMPONENTS"(WITH ELECTRONIC LOCKING

DIFFERENTIAL).

CAUTION:

Do not reuse gasket.

FILLING

1. Remove the filler plug. Fill with new gear oil until oil level

reaches the specified limit near filler plug hole.

2. After refilling oil, check oil level. Apply sealant to filler plug.

Install filler plug to final drive assembly and tighten to the speci-

fied torque. Refer toRFD-15, "

COMPONENTS"(WITH LIM-

ITED SLIP DIFFERENTIAL) andRFD-82, "

COMPONENTS"

(WITH ELECTRONIC LOCKING DIFFERENTIAL).

CAUTION:

Do not reuse gasket.

Balancing WheelsELS001IX

Adjust the wheel balance using the road wheel center. Refer toWT-6, "Road Wheel".

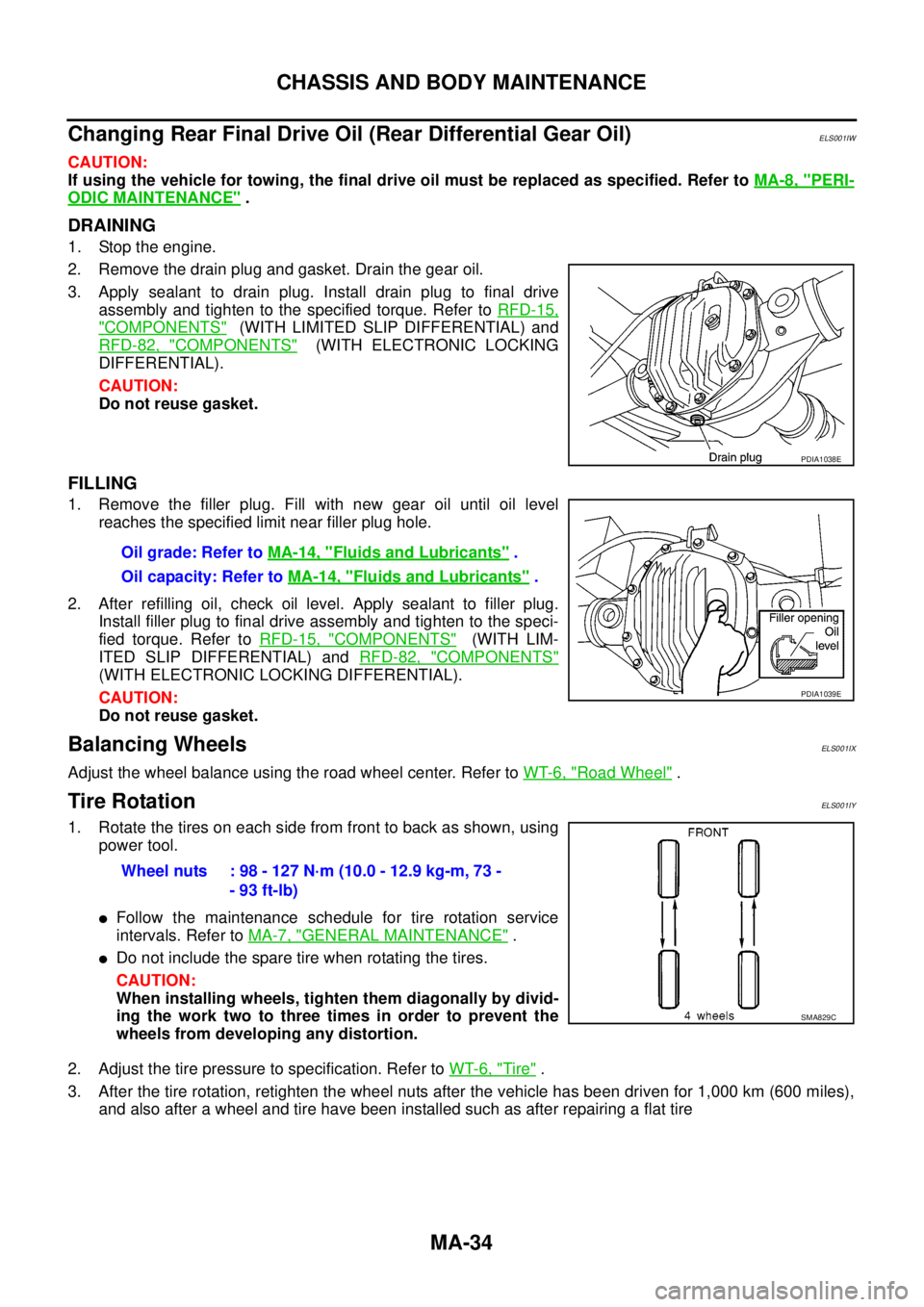

Tire RotationELS001IY

1. Rotate the tires on each side from front to back as shown, using

power tool.

lFollow the maintenance schedule for tire rotation service

intervals. Refer toMA-7, "

GENERAL MAINTENANCE".

lDo not include the spare tire when rotating the tires.

CAUTION:

When installing wheels, tighten them diagonally by divid-

ing the work two to three times in order to prevent the

wheels from developing any distortion.

2. Adjust the tire pressure to specification. Refer toWT-6, "

Tire".

3. After the tire rotation, retighten the wheel nuts after the vehicle has been driven for 1,000 km (600 miles),

and also after a wheel and tire have been installed such as after repairing a flat tire

PDIA1038E

Oil grade: Refer toMA-14, "Fluids and Lubricants".

Oil capacity: Refer toMA-14, "

Fluids and Lubricants".

PDIA1039E

Wheel nuts : 98 - 127 N·m (10.0 - 12.9 kg-m, 73 -

- 93 ft-lb)

SMA829C