display NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 988 of 3171

EC-8

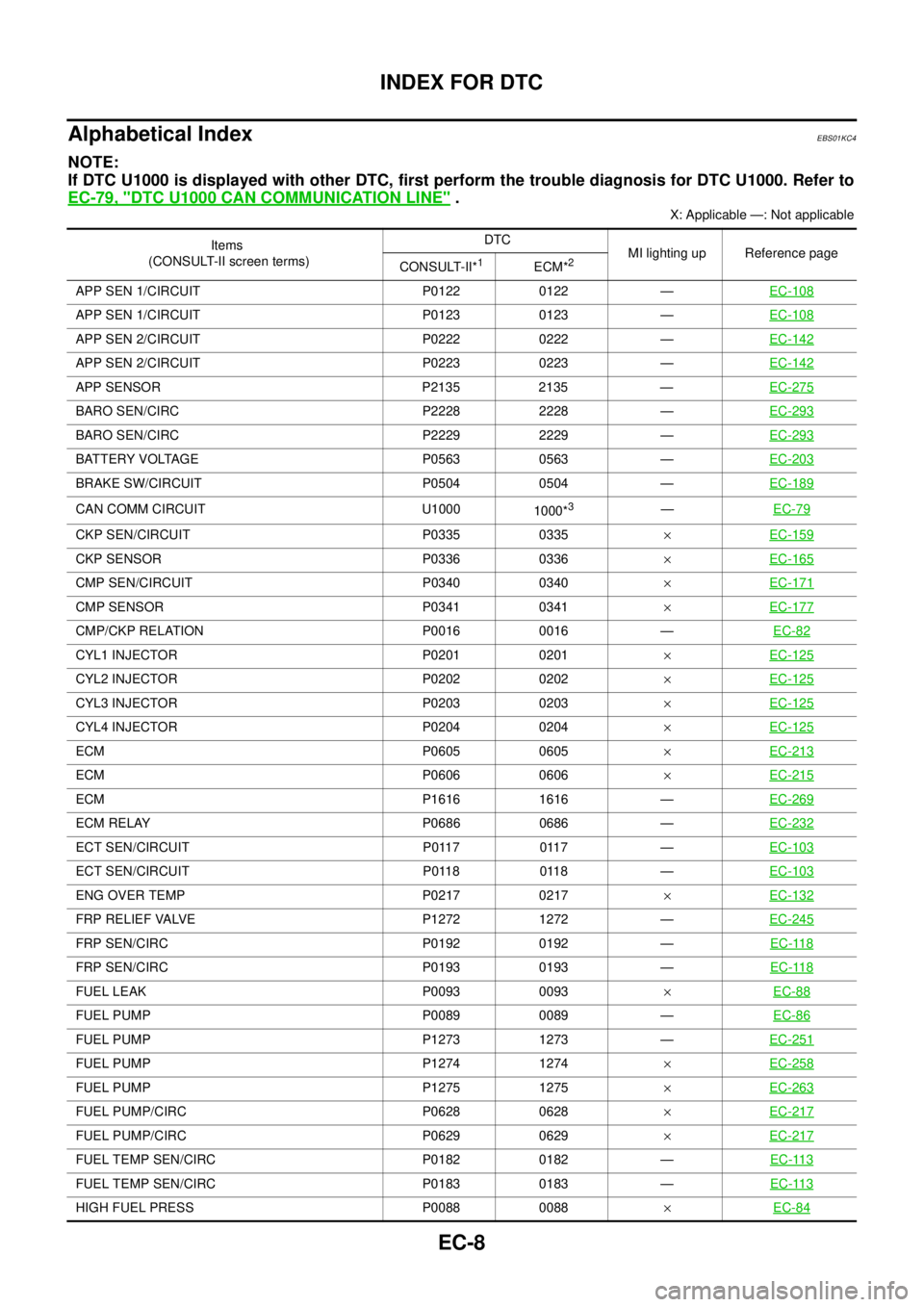

INDEX FOR DTC

Alphabetical Index

EBS01KC4

NOTE:

If DTC U1000 is displayed with other DTC, first perform the trouble diagnosis for DTC U1000. Refer to

EC-79, "

DTC U1000 CAN COMMUNICATION LINE".

X: Applicable —: Not applicable

Items

(CONSULT-II screen terms)DTC

MI lighting up Reference page

CONSULT-II*

1ECM*2

APP SEN 1/CIRCUIT P0122 0122 —EC-108

APP SEN 1/CIRCUIT P0123 0123 —EC-108

APP SEN 2/CIRCUIT P0222 0222 —EC-142

APP SEN 2/CIRCUIT P0223 0223 —EC-142

APP SENSOR P2135 2135 —EC-275

BARO SEN/CIRC P2228 2228 —EC-293

BARO SEN/CIRC P2229 2229 —EC-293

BATTERY VOLTAGE P0563 0563 —EC-203

BRAKE SW/CIRCUIT P0504 0504 —EC-189

CAN COMM CIRCUIT U1000

1000*3—EC-79

CKP SEN/CIRCUIT P0335 0335´EC-159

CKP SENSOR P0336 0336´EC-165

CMP SEN/CIRCUIT P0340 0340´EC-171

CMP SENSOR P0341 0341´EC-177

CMP/CKP RELATION P0016 0016 —EC-82

CYL1 INJECTOR P0201 0201´EC-125

CYL2 INJECTOR P0202 0202´EC-125

CYL3 INJECTOR P0203 0203´EC-125

CYL4 INJECTOR P0204 0204´EC-125

ECM P0605 0605´EC-213

ECM P0606 0606´EC-215

ECM P1616 1616 —EC-269

ECM RELAY P0686 0686 —EC-232

ECT SEN/CIRCUIT P0117 0117 —EC-103

ECT SEN/CIRCUIT P0118 0118 —EC-103

ENG OVER TEMP P0217 0217´EC-132

FRP RELIEF VALVE P1272 1272 —EC-245

FRP SEN/CIRC P0192 0192 —EC-118

FRP SEN/CIRC P0193 0193 —EC-118

FUEL LEAK P0093 0093´EC-88

FUEL PUMP P0089 0089 —EC-86

FUEL PUMP P1273 1273 —EC-251

FUEL PUMP P1274 1274´EC-258

FUEL PUMP P1275 1275´EC-263

FUEL PUMP/CIRC P0628 0628´EC-217

FUEL PUMP/CIRC P0629 0629´EC-217

FUEL TEMP SEN/CIRC P0182 0182 —EC-113

FUEL TEMP SEN/CIRC P0183 0183 —EC-113

HIGH FUEL PRESS P0088 0088´EC-84

Page 992 of 3171

EC-12

PRECAUTIONS

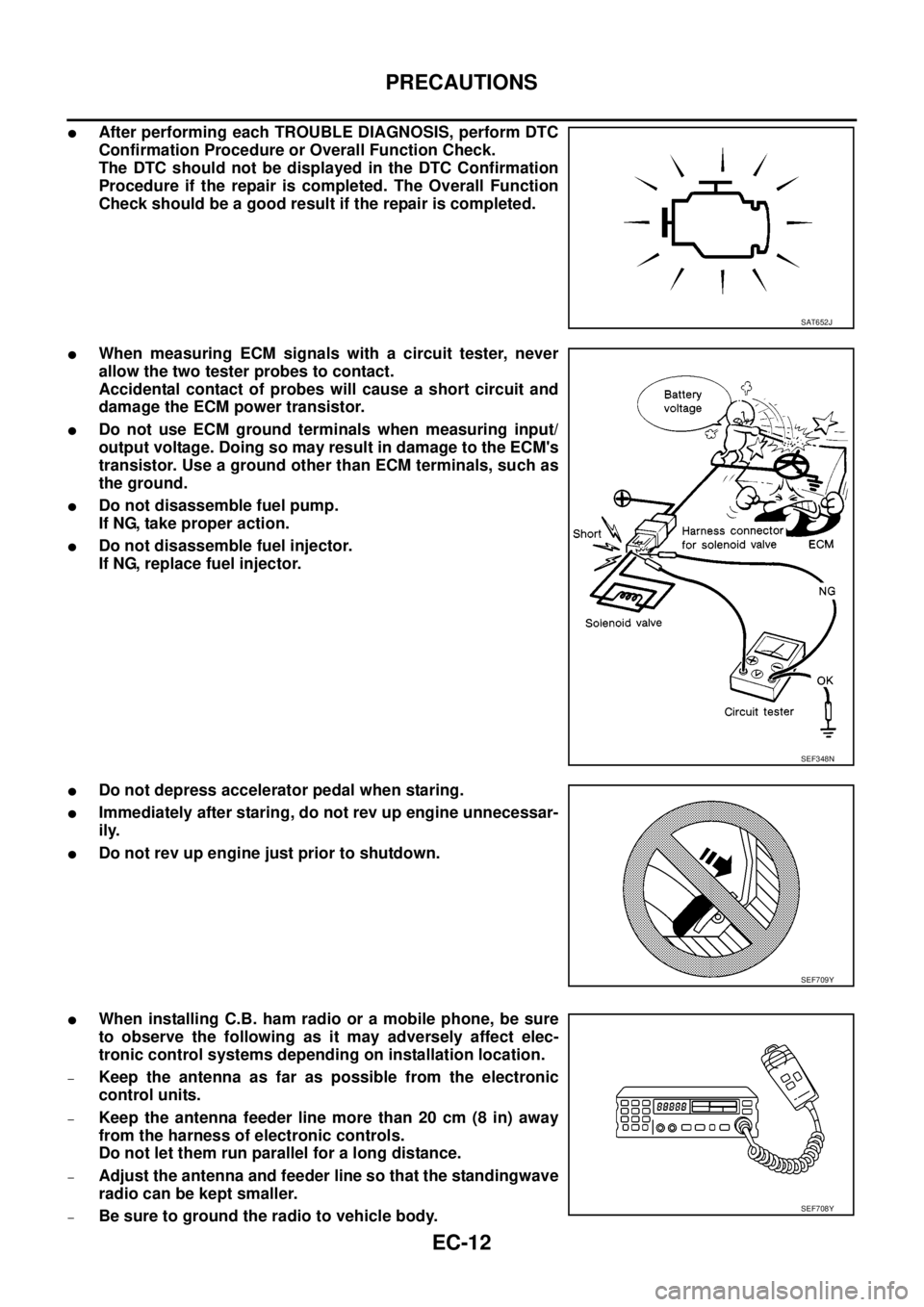

lAfter performing each TROUBLE DIAGNOSIS, perform DTC

Confirmation Procedure or Overall Function Check.

The DTC should not be displayed in the DTC Confirmation

Procedure if the repair is completed. The Overall Function

Check should be a good result if the repair is completed.

lWhen measuring ECM signals with a circuit tester, never

allow the two tester probes to contact.

Accidental contact of probes will cause a short circuit and

damage the ECM power transistor.

lDo not use ECM ground terminals when measuring input/

output voltage. Doing so may result in damage to the ECM's

transistor. Use a ground other than ECM terminals, such as

the ground.

lDo not disassemble fuel pump.

If NG, take proper action.

lDo not disassemble fuel injector.

If NG, replace fuel injector.

lDo not depress accelerator pedal when staring.

lImmediately after staring, do not rev up engine unnecessar-

ily.

lDo not rev up engine just prior to shutdown.

lWhen installing C.B. ham radio or a mobile phone, be sure

to observe the following as it may adversely affect elec-

tronic control systems depending on installation location.

–Keep the antenna as far as possible from the electronic

control units.

–Keep the antenna feeder line more than 20 cm (8 in) away

from the harness of electronic controls.

Do not let them run parallel for a long distance.

–Adjust the antenna and feeder line so that the standingwave

radio can be kept smaller.

–Be sure to ground the radio to vehicle body.

SAT652J

SEF348N

SEF709Y

SEF708Y

Page 1004 of 3171

EC-24

BASIC SERVICE PROCEDURE

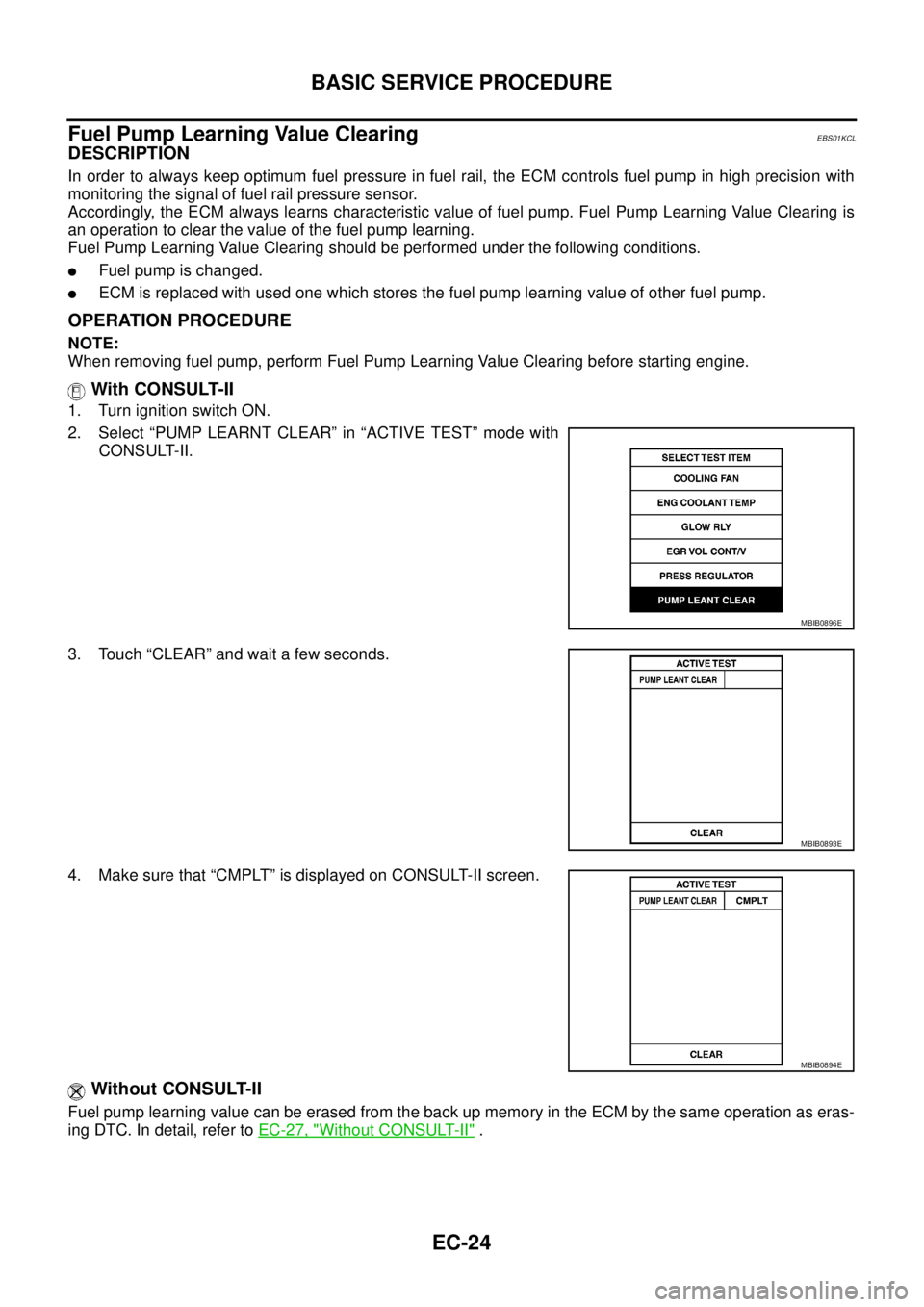

Fuel Pump Learning Value Clearing

EBS01KCL

DESCRIPTION

In order to always keep optimum fuel pressure in fuel rail, the ECM controls fuel pump in high precision with

monitoring the signal of fuel rail pressure sensor.

Accordingly, the ECM always learns characteristic value of fuel pump. Fuel Pump Learning Value Clearing is

an operation to clear the value of the fuel pump learning.

Fuel Pump Learning Value Clearing should be performed under the following conditions.

lFuel pump is changed.

lECM is replaced with used one which stores the fuel pump learning value of other fuel pump.

OPERATION PROCEDURE

NOTE:

When removing fuel pump, perform Fuel Pump Learning Value Clearing before starting engine.

With CONSULT-II

1. Turn ignition switch ON.

2. Select “PUMP LEARNT CLEAR” in “ACTIVE TEST” mode with

CONSULT-II.

3. Touch “CLEAR” and wait a few seconds.

4. Make sure that “CMPLT” is displayed on CONSULT-II screen.

Without CONSULT-II

Fuel pump learning value can be erased from the back up memory in the ECM by the same operation as eras-

ingDTC.Indetail,refertoEC-27, "

Without CONSULT-II".

MBIB0896E

MBIB0893E

MBIB0894E

Page 1005 of 3171

BASIC SERVICE PROCEDURE

EC-25

C

D

E

F

G

H

I

J

K

L

MA

EC

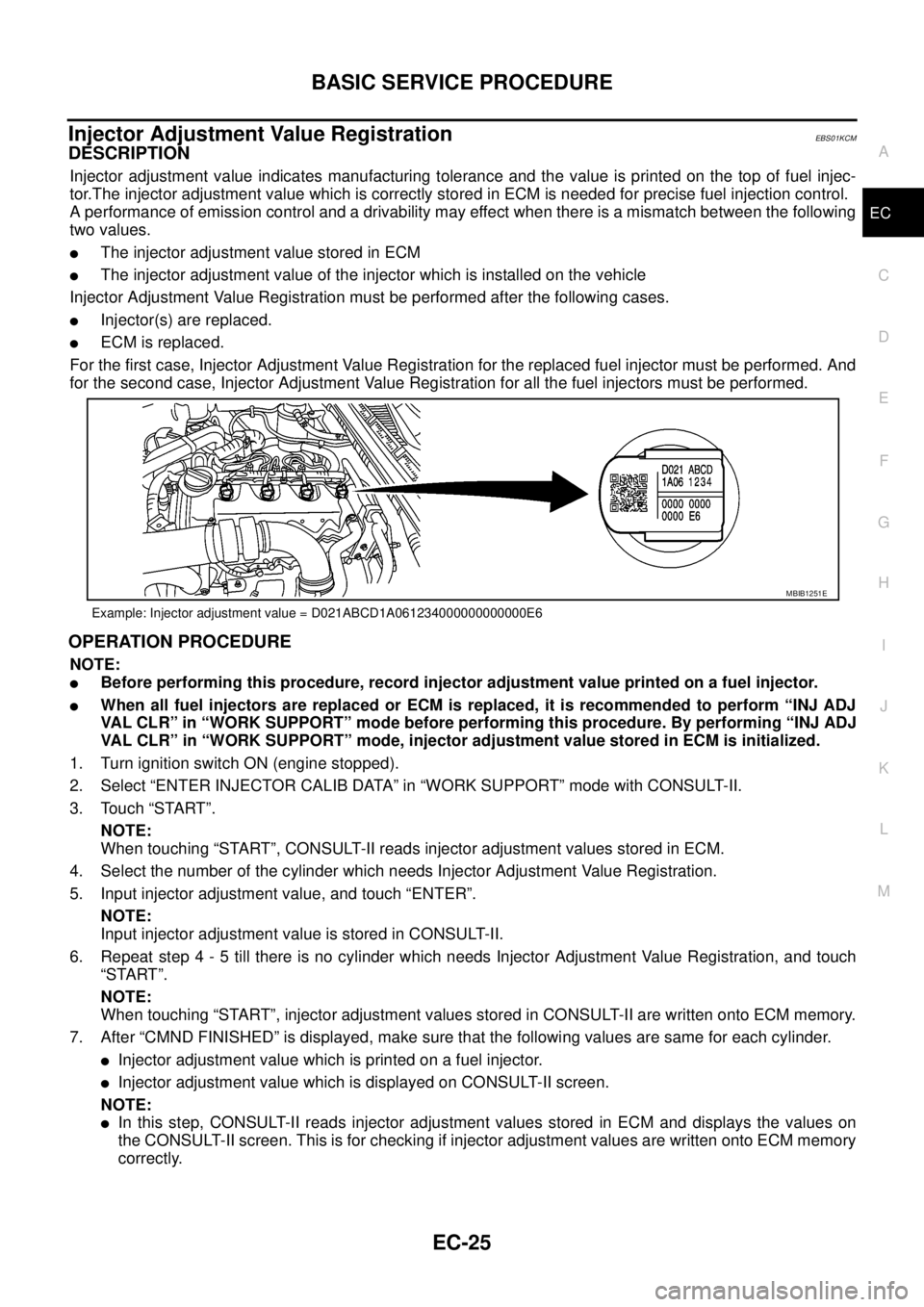

Injector Adjustment Value RegistrationEBS01KCM

DESCRIPTION

Injector adjustment value indicates manufacturing tolerance and the value is printed on the top of fuel injec-

tor.The injector adjustment value which is correctly stored in ECM is needed for precise fuel injection control.

A performance of emission control and a drivability may effect when there is a mismatch between the following

two values.

lThe injector adjustment value stored in ECM

lThe injector adjustment value of the injector which is installed on the vehicle

Injector Adjustment Value Registration must be performed after the following cases.

lInjector(s) are replaced.

lECM is replaced.

For the first case, Injector Adjustment Value Registration for the replaced fuel injector must be performed. And

for the second case, Injector Adjustment Value Registration for all the fuel injectors must be performed.

OPERATION PROCEDURE

NOTE:

lBefore performing this procedure, record injector adjustment value printed on a fuel injector.

lWhen all fuel injectors are replaced or ECM is replaced, it is recommended to perform “INJ ADJ

VAL CLR” in “WORK SUPPORT” mode before performing this procedure. By performing “INJ ADJ

VAL CLR” in “WORK SUPPORT” mode, injector adjustment value stored in ECM is initialized.

1. Turn ignition switch ON (engine stopped).

2. Select “ENTER INJECTOR CALIB DATA” in “WORK SUPPORT” mode with CONSULT-II.

3. Touch “START”.

NOTE:

When touching “START”, CONSULT-II reads injector adjustment values stored in ECM.

4. Select the number of the cylinder which needs Injector Adjustment Value Registration.

5. Input injector adjustment value, and touch “ENTER”.

NOTE:

Input injector adjustment value is stored in CONSULT-II.

6. Repeat step 4 - 5 till there is no cylinder which needs Injector Adjustment Value Registration, and touch

“START”.

NOTE:

When touching “START”, injector adjustment values stored in CONSULT-II are written onto ECM memory.

7. After “CMND FINISHED” is displayed, make sure that the following values are same for each cylinder.

lInjector adjustment value which is printed on a fuel injector.

lInjector adjustment value which is displayed on CONSULT-II screen.

NOTE:

lIn this step, CONSULT-II reads injector adjustment values stored in ECM and displays the values on

the CONSULT-II screen. This is for checking if injector adjustment values are written onto ECM memory

correctly.

Example: Injector adjustment value = D021ABCD1A061234000000000000E6

MBIB1251E

Page 1007 of 3171

ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-27

C

D

E

F

G

H

I

J

K

L

MA

EC

ON BOARD DIAGNOSTIC (OBD) SYSTEMPFP:00028

DTC Detection LogicEBS01KCN

When a malfunction is detected, the malfunction (DTC) and freeze frame data are stored in the ECM memory.

The MI will light up each time the ECM detects malfunction. For diagnostic items causing the MI to light up,

refer toEC-6, "

INDEX FOR DTC".

Diagnostic Trouble Code (DTC)EBS01KCO

HOW TO READ DTC

The DTC can be read by the following methods.

With CONSULT-II

CONSULT-IIdisplaystheDTCin"SELF-DIAGRESULTS"mode.Example:P0117,P0335,P1268,etc.These

DTCs are prescribed by ISO15031-5.

(CONSULT-II also displays the malfunctioning component or system.)

Without CONSULT-II

The number of blinks of the MI in the Diagnostic Test Mode II (Self-Diagnostic Results) indicates the DTC.

Example: 0117, 0335, 1260, etc.

lOutput of a DTC indicates a malfunction. However, the Diagnostic Test Mode II does not indicate

whether the malfunction is still occurring or has occurred in the past and has returned to normal.

CONSULT-II can identify malfunction status as shown below. Therefore, using CONSULT-II (if avail-

able) is recommended.

HOW TO ERASE DTC

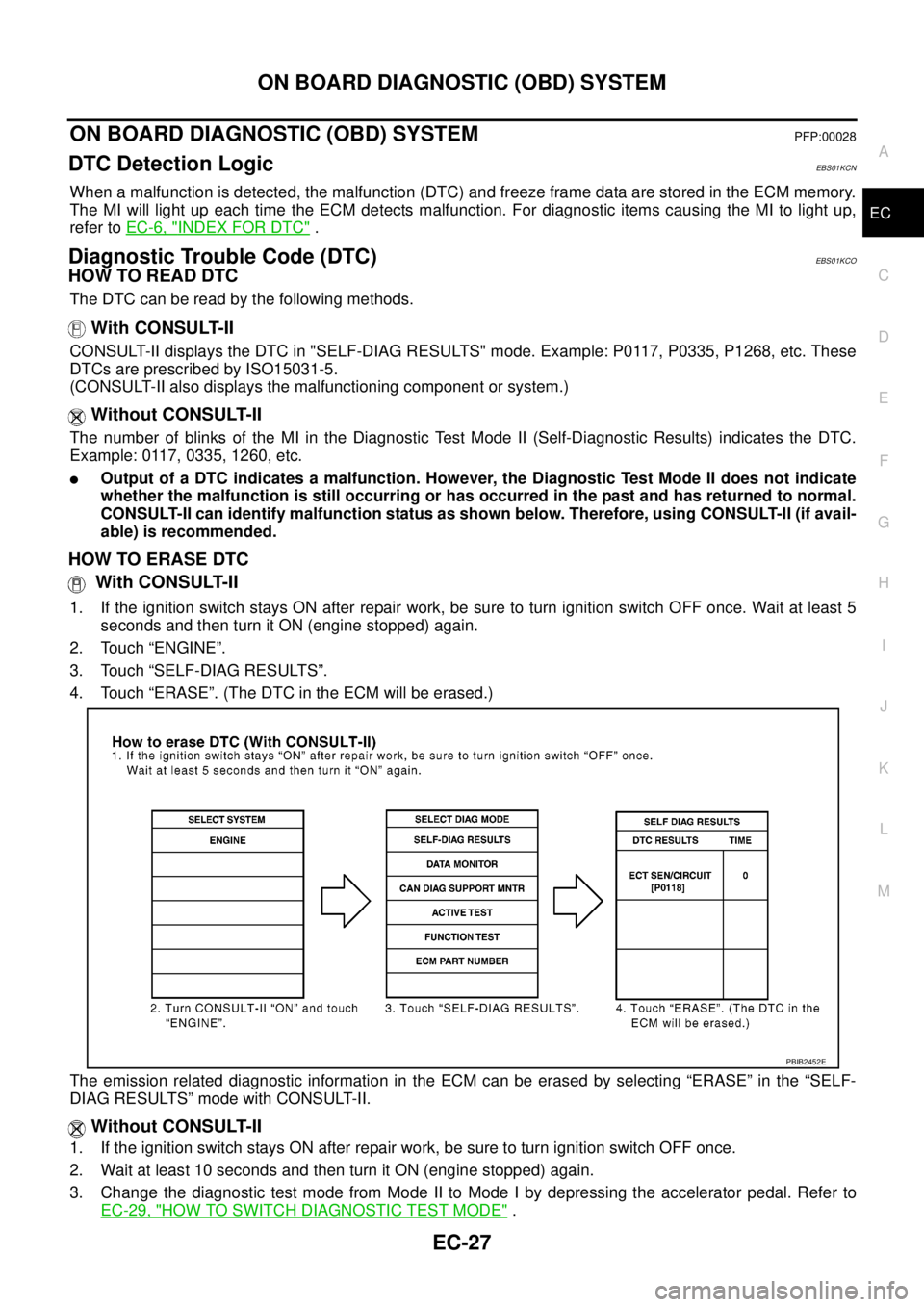

With CONSULT-II

1. If the ignition switch stays ON after repair work, be sure to turn ignition switch OFF once. Wait at least 5

seconds and then turn it ON (engine stopped) again.

2. Touch “ENGINE”.

3. Touch “SELF-DIAG RESULTS”.

4. Touch “ERASE”. (The DTC in the ECM will be erased.)

The emission related diagnostic information in the ECM can be erased by selecting “ERASE” in the “SELF-

DIAG RESULTS” mode with CONSULT-II.

Without CONSULT-II

1. If the ignition switch stays ON after repair work, be sure to turn ignition switch OFF once.

2. Wait at least 10 seconds and then turn it ON (engine stopped) again.

3. Change the diagnostic test mode from Mode II to Mode I by depressing the accelerator pedal. Refer to

EC-29, "

HOW TO SWITCH DIAGNOSTIC TEST MODE".

PBIB2452E

Page 1008 of 3171

EC-28

ON BOARD DIAGNOSTIC (OBD) SYSTEM

lIf the battery is disconnected, the emission-related diagnostic information will be lost within 24

hours.

lThe following data are cleared when the ECM memory is erased.

–Diagnostic trouble codes

–Freeze frame data

–Fuel pump learning value

Actual work procedures are explained using a DTC as an example. Be careful so that not only the DTC, but all

of the data listed above, are cleared from the ECM memory during work procedures.

Freeze Frame DataEBS01KCP

The ECM records the driving conditions such as calculated load value, engine coolant temperature, engine

speed, vehicle speed and intake manifold pressure at the moment a malfunction is detected.

The data, stored together with the DTC data, are called freeze frame data and displayed on CONSULT-II. For

details, seeEC-28, "

Freeze Frame Data".

Only one set of freeze frame data can be stored in the ECM. If freeze frame data is stored in the ECM memory

and another freeze frame data occurs later, the first (original) freeze frame data remains unchanged in the

ECM memory.

Freeze frame data (along with the DTCs) are cleared when the ECM memory is erased. Procedures for clear-

ing the ECM memory are described inEC-27, "

HOW TO ERASE DTC".

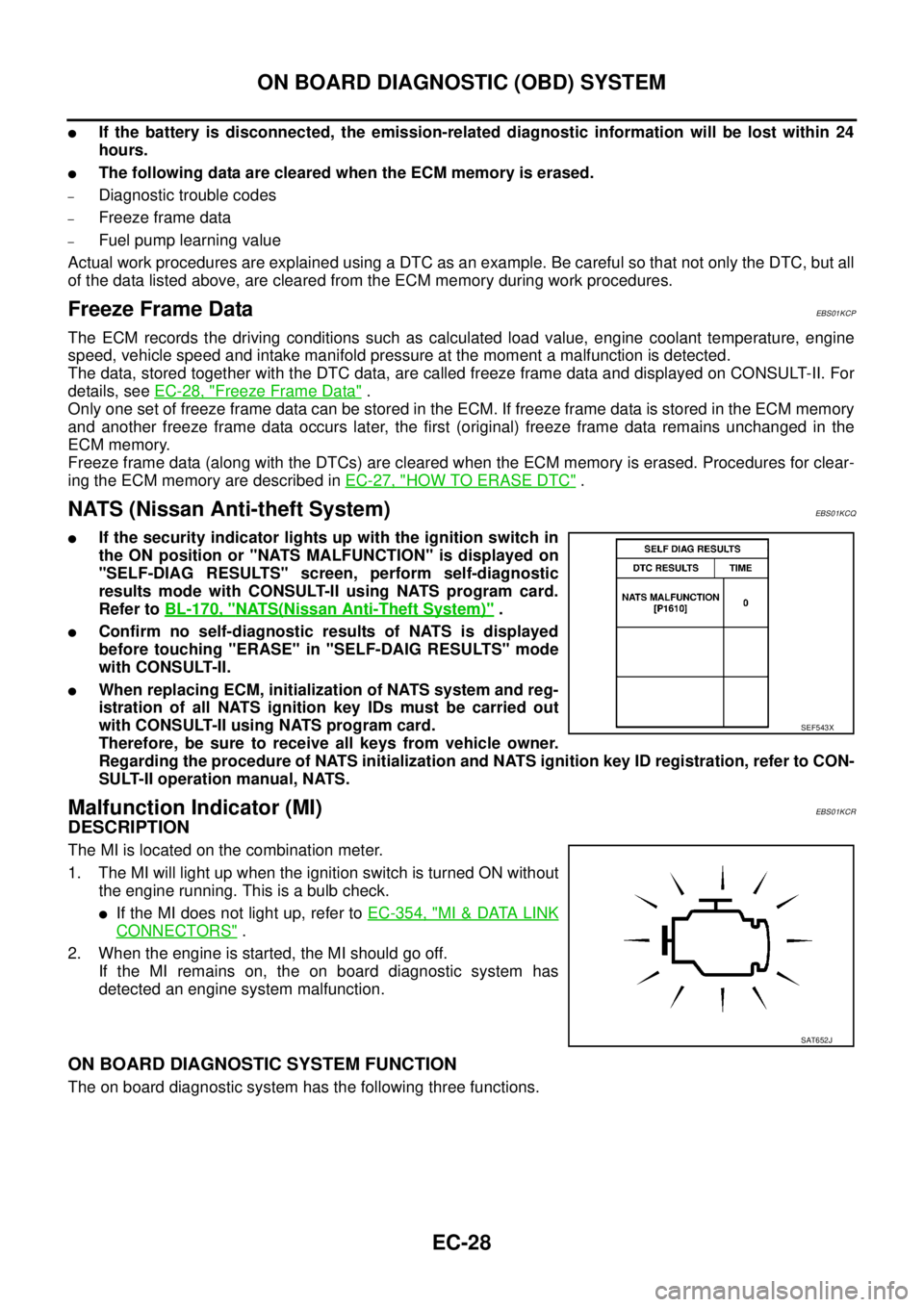

NATS (Nissan Anti-theft System)EBS01KCQ

lIf the security indicator lights up with the ignition switch in

the ON position or "NATS MALFUNCTION" is displayed on

"SELF-DIAG RESULTS" screen, perform self-diagnostic

results mode with CONSULT-II using NATS program card.

Refer toBL-170, "

NATS(Nissan Anti-Theft System)".

lConfirm no self-diagnostic results of NATS is displayed

before touching "ERASE" in "SELF-DAIG RESULTS" mode

with CONSULT-II.

lWhen replacing ECM, initialization of NATS system and reg-

istration of all NATS ignition key IDs must be carried out

with CONSULT-II using NATS program card.

Therefore, be sure to receive all keys from vehicle owner.

Regarding the procedure of NATS initialization and NATS ignition key ID registration, refer to CON-

SULT-II operation manual, NATS.

Malfunction Indicator (MI)EBS01KCR

DESCRIPTION

The MI is located on the combination meter.

1. The MI will light up when the ignition switch is turned ON without

the engine running. This is a bulb check.

lIf the MI does not light up, refer toEC-354, "MI&DATA LINK

CONNECTORS".

2. When the engine is started, the MI should go off.

If the MI remains on, the on board diagnostic system has

detected an engine system malfunction.

ON BOARD DIAGNOSTIC SYSTEM FUNCTION

The on board diagnostic system has the following three functions.

SEF543X

SAT652J

Page 1010 of 3171

EC-30

ON BOARD DIAGNOSTIC (OBD) SYSTEM

How to Erase Diagnostic Test Mode II (Self-diagnostic Results)

1. Set ECM in Diagnostic Test Mode II (Self-diagnostic results). Refer toEC-29, "How to Set Diagnostic Test

Mode II (Self-diagnostic Results)".

2. Fully depress the accelerator pedal and keep it for more than 10 seconds.

The emission-related diagnostic information has been erased from the backup memory in the ECM.

3. Fully release the accelerator pedal, and confirm the DTC 0000 is displayed.

DIAGNOSTIC TEST MODE I — BULB CHECK

In this mode, the MI on the combination meter should stay ON. If it remains OFF, check the bulb. Refer toEC-

354, "MI&DATA LINK CONNECTORS".

DIAGNOSTIC TEST MODE I — MALFUNCTION WARNING

These DTC numbers are clarified in Diagnostic Test Mode II (SELF-DIAGNOSTIC RESULTS)

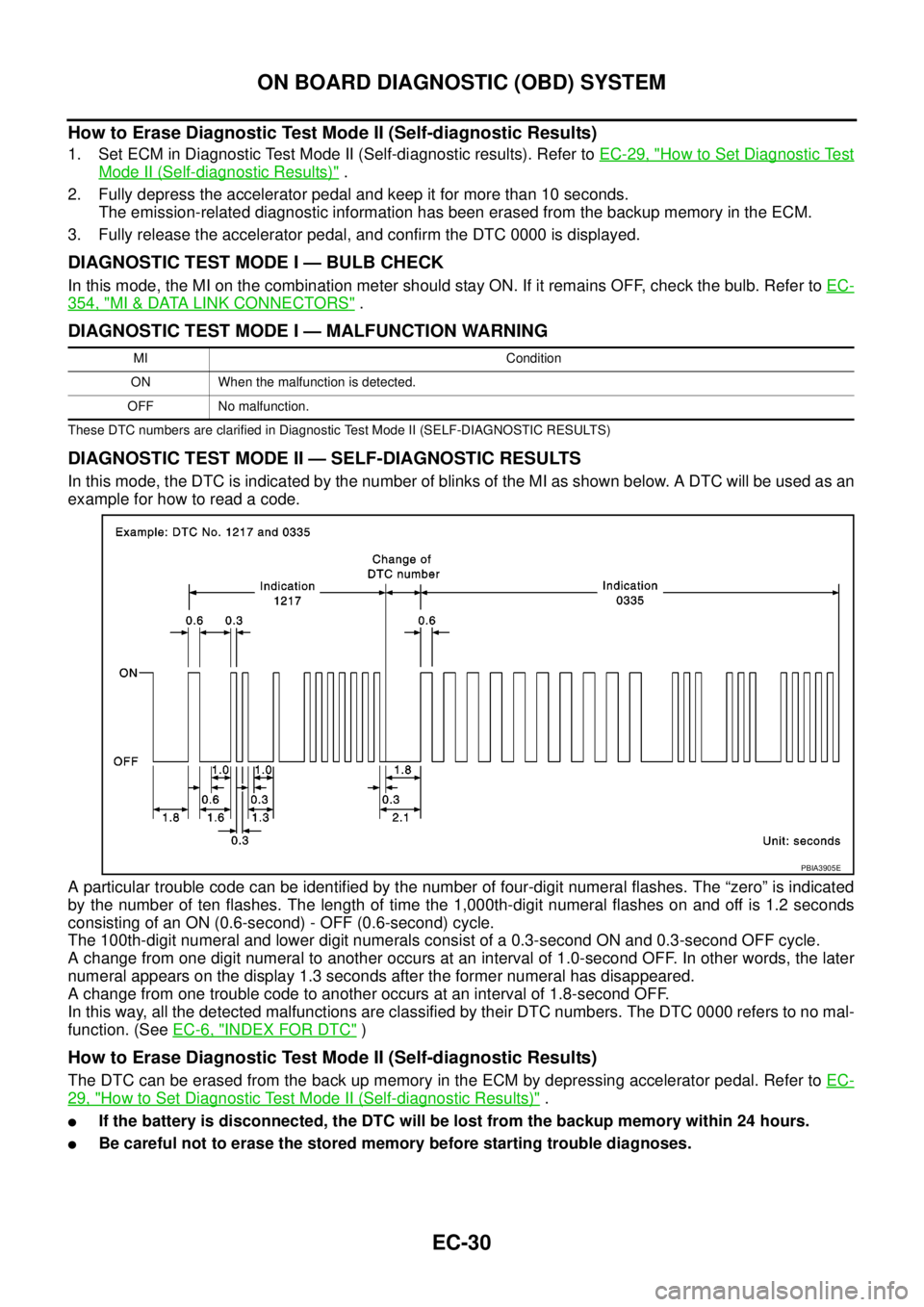

DIAGNOSTIC TEST MODE II — SELF-DIAGNOSTIC RESULTS

In this mode, the DTC is indicated by the number of blinks of the MI as shown below. A DTC will be used as an

example for how to read a code.

A particular trouble code can be identified by the number of four-digit numeral flashes. The “zero” is indicated

by the number of ten flashes. The length of time the 1,000th-digit numeral flashes on and off is 1.2 seconds

consisting of an ON (0.6-second) - OFF (0.6-second) cycle.

The 100th-digit numeral and lower digit numerals consist of a 0.3-second ON and 0.3-second OFF cycle.

A change from one digit numeral to another occurs at an interval of 1.0-second OFF. In other words, the later

numeral appears on the display 1.3 seconds after the former numeral has disappeared.

A change from one trouble code to another occurs at an interval of 1.8-second OFF.

In this way, all the detected malfunctions are classified by their DTC numbers. The DTC 0000 refers to no mal-

function. (SeeEC-6, "

INDEX FOR DTC")

How to Erase Diagnostic Test Mode II (Self-diagnostic Results)

The DTC can be erased from the back up memory in the ECM by depressing accelerator pedal. Refer toEC-

29, "How to Set Diagnostic Test Mode II (Self-diagnostic Results)".

lIf the battery is disconnected, the DTC will be lost from the backup memory within 24 hours.

lBe careful not to erase the stored memory before starting trouble diagnoses.

MI Condition

ON When the malfunction is detected.

OFF No malfunction.

PBIA3905E

Page 1011 of 3171

ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-31

C

D

E

F

G

H

I

J

K

L

MA

EC

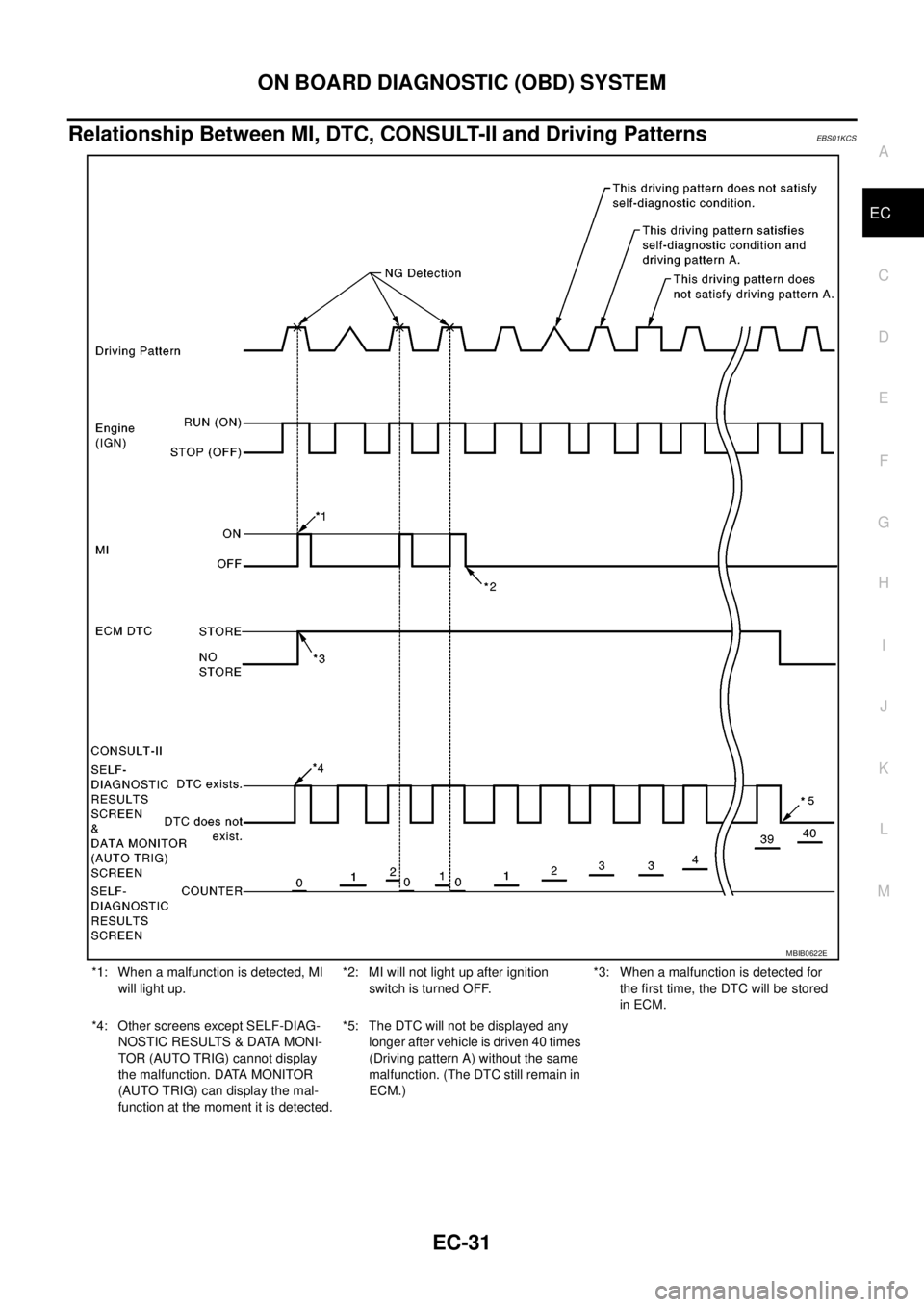

Relationship Between MI, DTC, CONSULT-II and Driving PatternsEBS01KCS

*1: When a malfunction is detected, MI

will light up.*2: MI will not light up after ignition

switch is turned OFF.*3: When a malfunction is detected for

the first time, the DTC will be stored

in ECM.

*4: Other screens except SELF-DIAG-

NOSTIC RESULTS & DATA MONI-

TOR (AUTO TRIG) cannot display

the malfunction. DATA MONITOR

(AUTO TRIG) can display the mal-

function at the moment it is detected.*5: The DTC will not be displayed any

longer after vehicle is driven 40 times

(Driving pattern A) without the same

malfunction. (The DTC still remain in

ECM.)

MBIB0622E

Page 1012 of 3171

EC-32

ON BOARD DIAGNOSTIC (OBD) SYSTEM

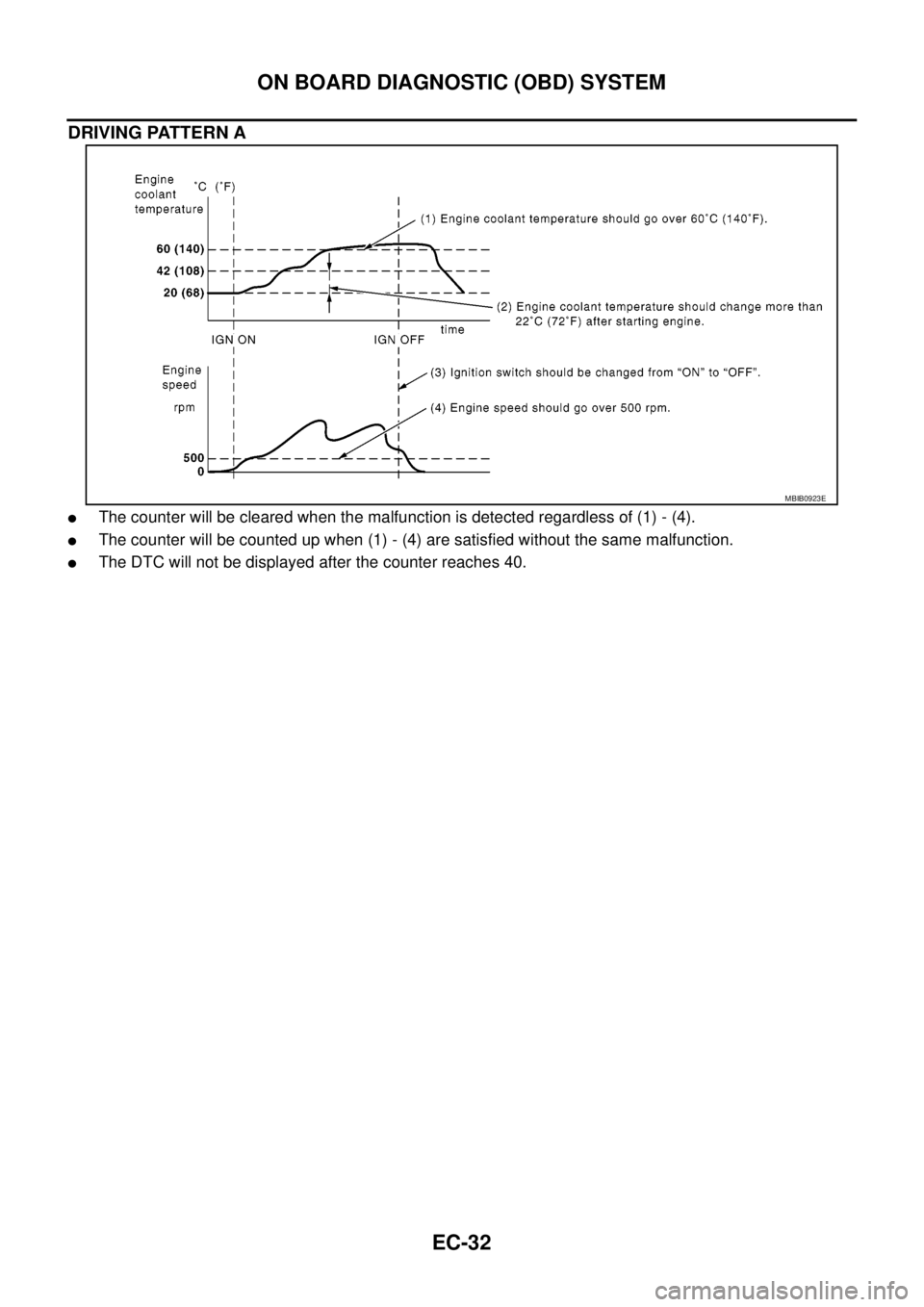

DRIVING PATTERN A

lThe counter will be cleared when the malfunction is detected regardless of (1) - (4).

lThe counter will be counted up when (1) - (4) are satisfied without the same malfunction.

lThe DTC will not be displayed after the counter reaches 40.

MBIB0923E

Page 1015 of 3171

TROUBLE DIAGNOSIS

EC-35

C

D

E

F

G

H

I

J

K

L

MA

EC

Description for Work Flow

DIAGNOSTIC WORK SHEET

There are many operating conditions that lead to the malfunction of

engine components. A good grasp of such conditions can make trou-

bleshooting faster and more accurate.

In general, each customer feels differently about an incident. It is

important to fully understand the symptoms or conditions for a cus-

tomer complaint.

Utilize a diagnostic worksheet like the one shown below in order to

organize all the information for troubleshooting.

STEP DESCRIPTION

STEP IGet detailed information about the conditions and the environment when the incident/symptom occurred using the

EC-35, "

DIAGNOSTIC WORK SHEET".

STEP IIBefore confirming the concern, check and write down (print out using CONSULT-II) the DTC and the freeze frame

data, then erase the DTC. The DTC and the freeze frame data can be used when duplicating the incident at STEP III

&IV.RefertoEC-27

.

If the incident cannot be verified, performEC-70, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT".

Study the relationship between the cause, specified by DTC, and the symptom described by the customer. (The

“Symptom Matrix Chart” will be useful. Refer toEC-42

.) Also check related service bulletins for information.

STEP IIITry to confirm the symptom and under what conditions the incident occurs.

The “DIAGNOSTIC WORK SHEET” and the freeze frame data are useful to verify the incident. Connect CONSULT-II

to the vehicle in DATA MONITOR (AUTO TRIG) mode and check real time diagnosis results.

If the incident cannot be verified, performEC-70, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT".

If the malfunction code is detected, skip STEP IV and perform STEP V.

STEP IVTry to detect the DTC by driving in (or performing) the DTC Confirmation Procedure. Check and read the DTC and the

freeze frame data by using CONSULT-II.

During the DTC verification, be sure to connect CONSULT-II to the vehicle in DATA MONITOR (AUTO TRIG) mode

and check real time diagnosis results.

If the incident cannot be verified, performEC-70, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT".

In case the DTC Confirmation Procedure is not available, perform the Overall Function Check instead. The DTC can-

not be displayed by this check, however, this simplified “check” is an effective alternative.

The “NG” result of the Overall Function Check is the same as the DTC detection.

STEP VTake the appropriate action based on the results of STEP I through IV.

If the malfunction code is indicated, proceed to Trouble Diagnosis for DTC PXXXX.

If the normal code is indicated, proceed to the Basic Inspection,EC-38

. Then perform inspections according to the

Symptom Matrix Chart. Refer toEC-42

.

STEP VIIdentify where to begin diagnosis based on the relationship study between symptom and possible causes. Inspect the

system for mechanical binding, loose connectors or wiring damage using (tracing) Harness Layouts.

Gently shake the related connectors, components or wiring harness with CONSULT-II set in “DATA MONITOR (AUTO

TRIG)” mode.

Check the voltage of the related ECM terminals or monitor the output data from the related sensors with CONSULT-II.

Refer toEC-52

orEC-66.

The Diagnostic Procedure in EC section contains a description based on open circuit inspection. A short circuit

inspection is also required for the circuit check in the Diagnostic Procedure. For details, refer toGI-24, "

How to Per-

form Efficient Diagnosis for an Electrical Incident", “Circuit Inspection”.

Repair or replace the malfunction parts.

If the malfunctioning part cannot be detected, performEC-70, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCI-

DENT".

STEP VIIOnce you have repaired the circuit or replaced a component, you need to run the engine in the same conditions and

circumstances which resulted in the customer's initial complaint.

Perform the DTC Confirmation Procedure and confirm the normal code (DTC P0000) is detected. If the incident is still

detected in the final check, perform STEP VI by using a different method from the previous one.

Before returning the vehicle to the customer, be sure to erase the unnecessary (already fixed) DTC in ECM. (Refer to

EC-27

.)

SEF907L