light NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2214 of 3171

PARKING, LICENSE PLATE AND TAIL LAMPS

LT-131

C

D

E

F

G

H

I

J

L

MA

B

LT

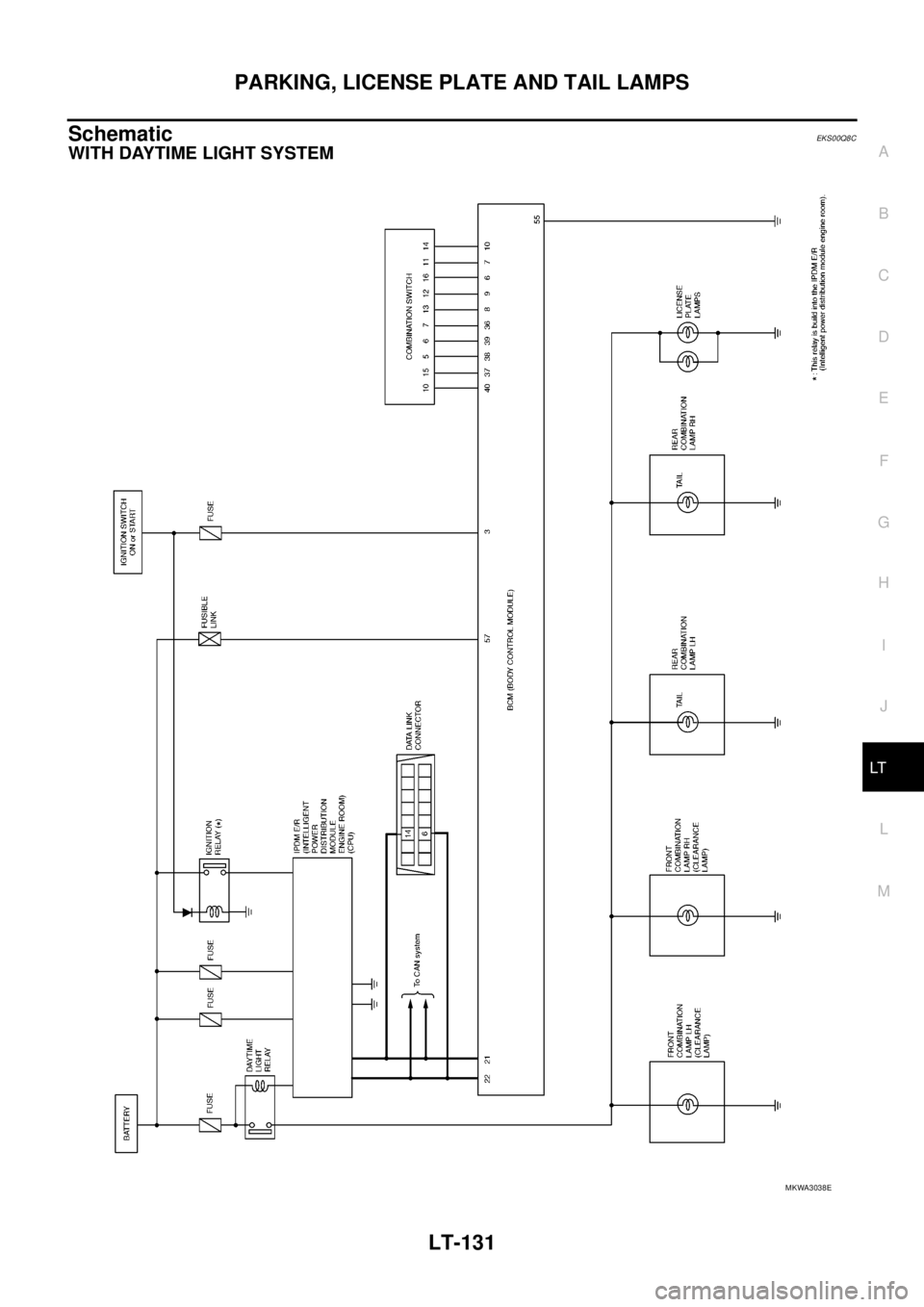

SchematicEKS00Q8C

WITH DAYTIME LIGHT SYSTEM

MKWA3038E

Page 2215 of 3171

LT-132

PARKING, LICENSE PLATE AND TAIL LAMPS

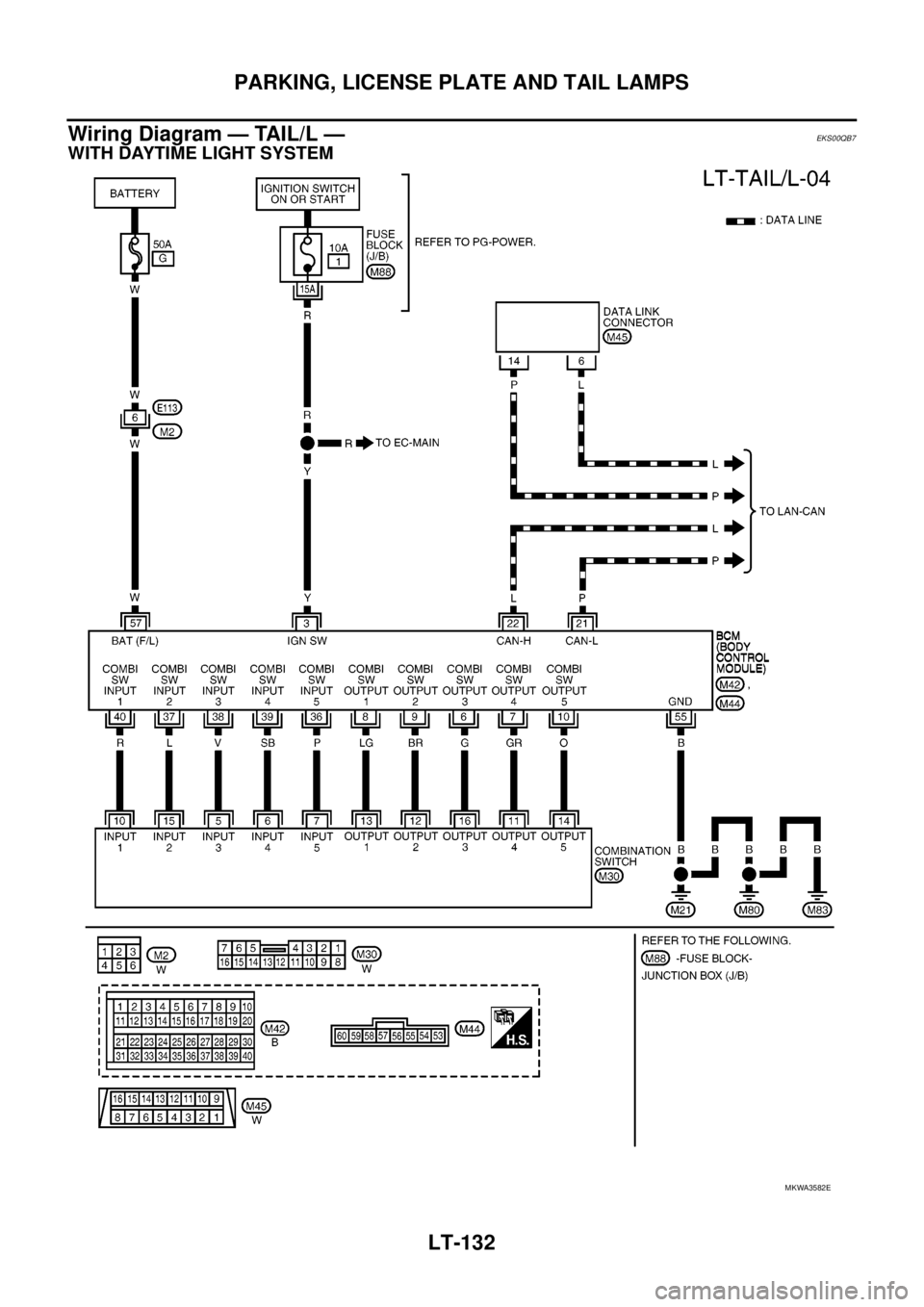

Wiring Diagram — TAIL/L —

EKS00QB7

WITH DAYTIME LIGHT SYSTEM

MKWA3582E

Page 2218 of 3171

PARKING, LICENSE PLATE AND TAIL LAMPS

LT-135

C

D

E

F

G

H

I

J

L

MA

B

LT

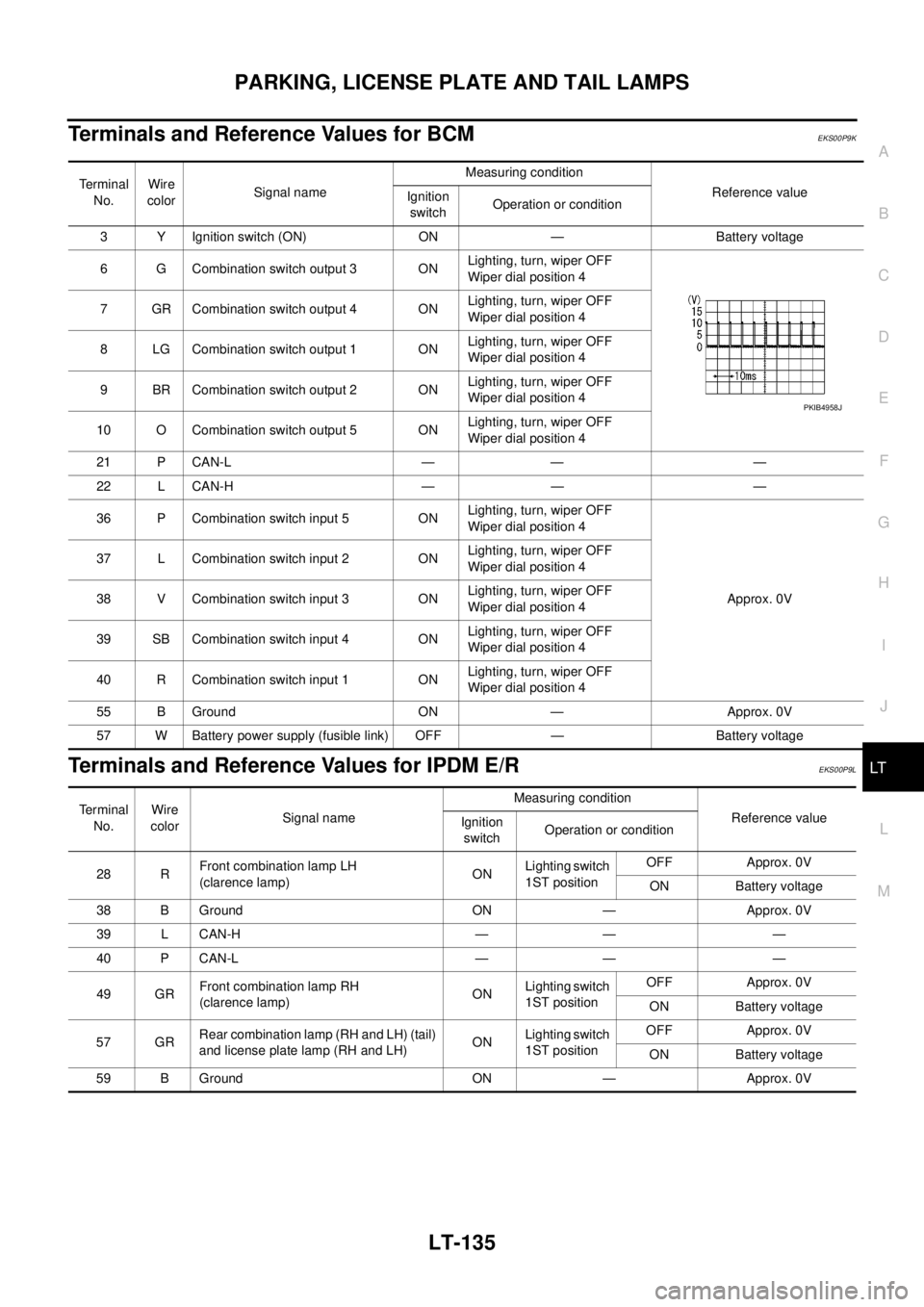

Terminals and Reference Values for BCMEKS00P9K

Terminals and Reference Values for IPDM E/REKS00P9L

Te r m i n a l

No.Wire

colorSignal nameMeasuring condition

Reference value

Ignition

switchOperation or condition

3 Y Ignition switch (ON) ON — Battery voltage

6 G Combination switch output 3 ONLighting, turn, wiper OFF

Wiper dial position 4

7 GR Combination switch output 4 ONLighting, turn, wiper OFF

Wiper dial position 4

8 LG Combination switch output 1 ONLighting, turn, wiper OFF

Wiper dial position 4

9 BR Combination switch output 2 ONLighting, turn, wiper OFF

Wiper dial position 4

10 O Combination switch output 5 ONLighting, turn, wiper OFF

Wiper dial position 4

21 P CAN-L — — —

22 L CAN-H — — —

36 P Combination switch input 5 ONLighting, turn, wiper OFF

Wiper dial position 4

Approx. 0V 37 L Combination switch input 2 ONLighting, turn, wiper OFF

Wiper dial position 4

38 V Combination switch input 3 ONLighting, turn, wiper OFF

Wiper dial position 4

39 SB Combination switch input 4 ONLighting, turn, wiper OFF

Wiper dial position 4

40 R Combination switch input 1 ONLighting, turn, wiper OFF

Wiper dial position 4

55 B Ground ON — Approx. 0V

57 W Battery power supply (fusible link) OFF — Battery voltage

PKIB4958J

Terminal

No.Wire

colorSignal nameMeasuring condition

Reference value

Ignition

switchOperation or condition

28 RFront combination lamp LH

(clarence lamp)ONLighting switch

1ST positionOFF Approx. 0V

ON Battery voltage

38 B Ground ON — Approx. 0V

39 L CAN-H — — —

40 P CAN-L — — —

49 GRFront combination lamp RH

(clarence lamp)ONLighting switch

1ST positionOFF Approx. 0V

ON Battery voltage

57 GRRear combination lamp (RH and LH) (tail)

and license plate lamp (RH and LH)ONLighting switch

1ST positionOFF Approx. 0V

ON Battery voltage

59 B Ground ON — Approx. 0V

Page 2221 of 3171

LT-138

PARKING, LICENSE PLATE AND TAIL LAMPS

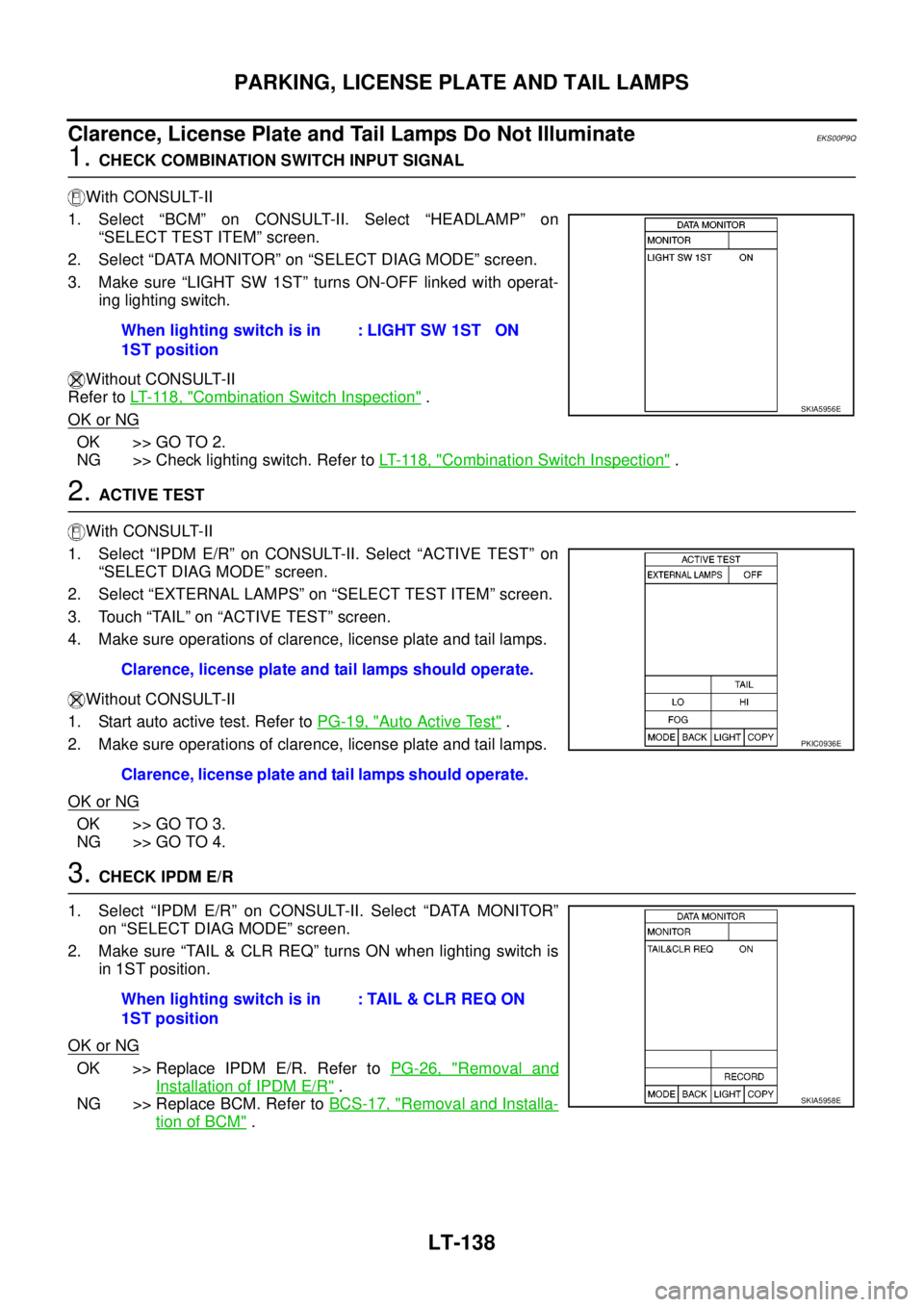

Clarence, License Plate and Tail Lamps Do Not Illuminate

EKS00P9Q

1.CHECK COMBINATION SWITCH INPUT SIGNAL

With CONSULT-II

1. Select “BCM” on CONSULT-II. Select “HEADLAMP” on

“SELECT TEST ITEM” screen.

2. Select “DATA MONITOR” on “SELECT DIAG MODE” screen.

3. Make sure “LIGHT SW 1ST” turns ON-OFF linked with operat-

ing lighting switch.

Without CONSULT-II

Refer toLT- 11 8 , "

Combination Switch Inspection".

OK or NG

OK >> GO TO 2.

NG >> Check lighting switch. Refer toLT- 11 8 , "

Combination Switch Inspection".

2.ACTIVE TEST

With CONSULT-II

1. Select “IPDM E/R” on CONSULT-II. Select “ACTIVE TEST” on

“SELECT DIAG MODE” screen.

2. Select “EXTERNAL LAMPS” on “SELECT TEST ITEM” screen.

3. Touch “TAIL” on “ACTIVE TEST” screen.

4. Make sure operations of clarence, license plate and tail lamps.

Without CONSULT-II

1. Start auto active test. Refer toPG-19, "

Auto Active Test".

2. Make sure operations of clarence, license plate and tail lamps.

OK or NG

OK >> GO TO 3.

NG >> GO TO 4.

3.CHECK IPDM E/R

1. Select “IPDM E/R” on CONSULT-II. Select “DATA MONITOR”

on “SELECT DIAG MODE” screen.

2. Make sure “TAIL & CLR REQ” turns ON when lighting switch is

in 1ST position.

OK or NG

OK >> Replace IPDM E/R. Refer toPG-26, "Removal and

Installation of IPDM E/R".

NG >> Replace BCM. Refer toBCS-17, "

Removal and Installa-

tion of BCM". When lighting switch is in

1ST position: LIGHT SW 1ST ON

SKIA5956E

Clarence, license plate and tail lamps should operate.

Clarence, license plate and tail lamps should operate.

PKIC0936E

When lighting switch is in

1ST position: TAIL & CLR REQ ON

SKIA5958E

Page 2224 of 3171

PARKING, LICENSE PLATE AND TAIL LAMPS

LT-141

C

D

E

F

G

H

I

J

L

MA

B

LT

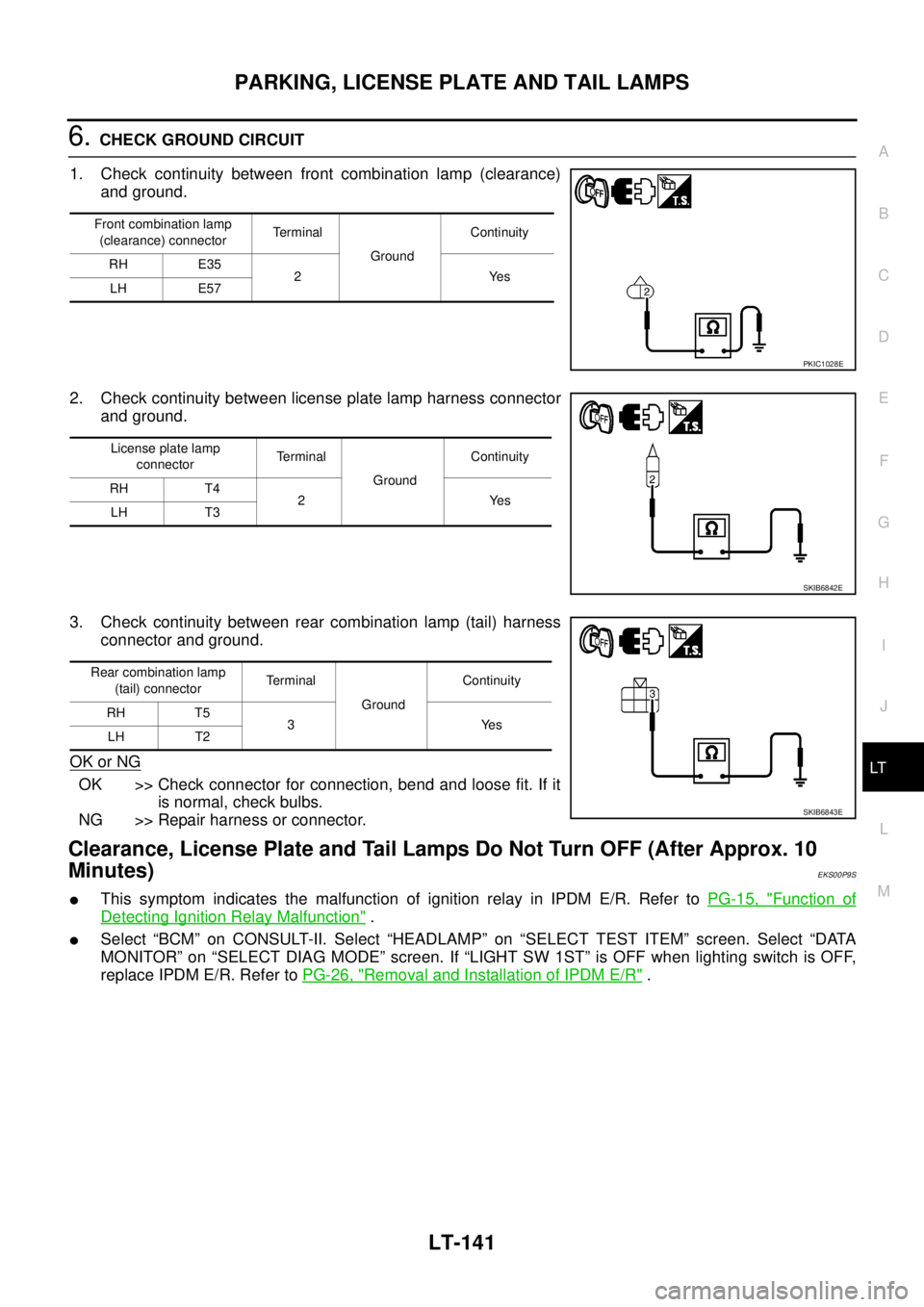

6.CHECK GROUND CIRCUIT

1. Check continuity between front combination lamp (clearance)

and ground.

2. Check continuity between license plate lamp harness connector

and ground.

3. Check continuity between rear combination lamp (tail) harness

connector and ground.

OK or NG

OK >> Check connector for connection, bend and loose fit. If it

is normal, check bulbs.

NG >> Repair harness or connector.

Clearance, License Plate and Tail Lamps Do Not Turn OFF (After Approx. 10

Minutes)

EKS00P9S

lThis symptom indicates the malfunction of ignition relay in IPDM E/R. Refer toPG-15, "Function of

Detecting Ignition Relay Malfunction".

lSelect “BCM” on CONSULT-II. Select “HEADLAMP” on “SELECT TEST ITEM” screen. Select “DATA

MONITOR” on “SELECT DIAG MODE” screen. If “LIGHT SW 1ST” is OFF when lighting switch is OFF,

replace IPDM E/R. Refer toPG-26, "

Removal and Installation of IPDM E/R".

Front combination lamp

(clearance) connectorTerminal

GroundContinuity

RH E35

2Yes

LH E57

PKIC1028E

License plate lamp

connectorTerminal

GroundContinuity

RH T4

2Yes

LH T3

SKIB6842E

Rear combination lamp

(tail) connectorTerminal

GroundContinuity

RH T5

3Yes

LH T2

SKIB6843E

Page 2245 of 3171

LT-162

ILLUMINATION

ILLUMINATION

PFP:27545

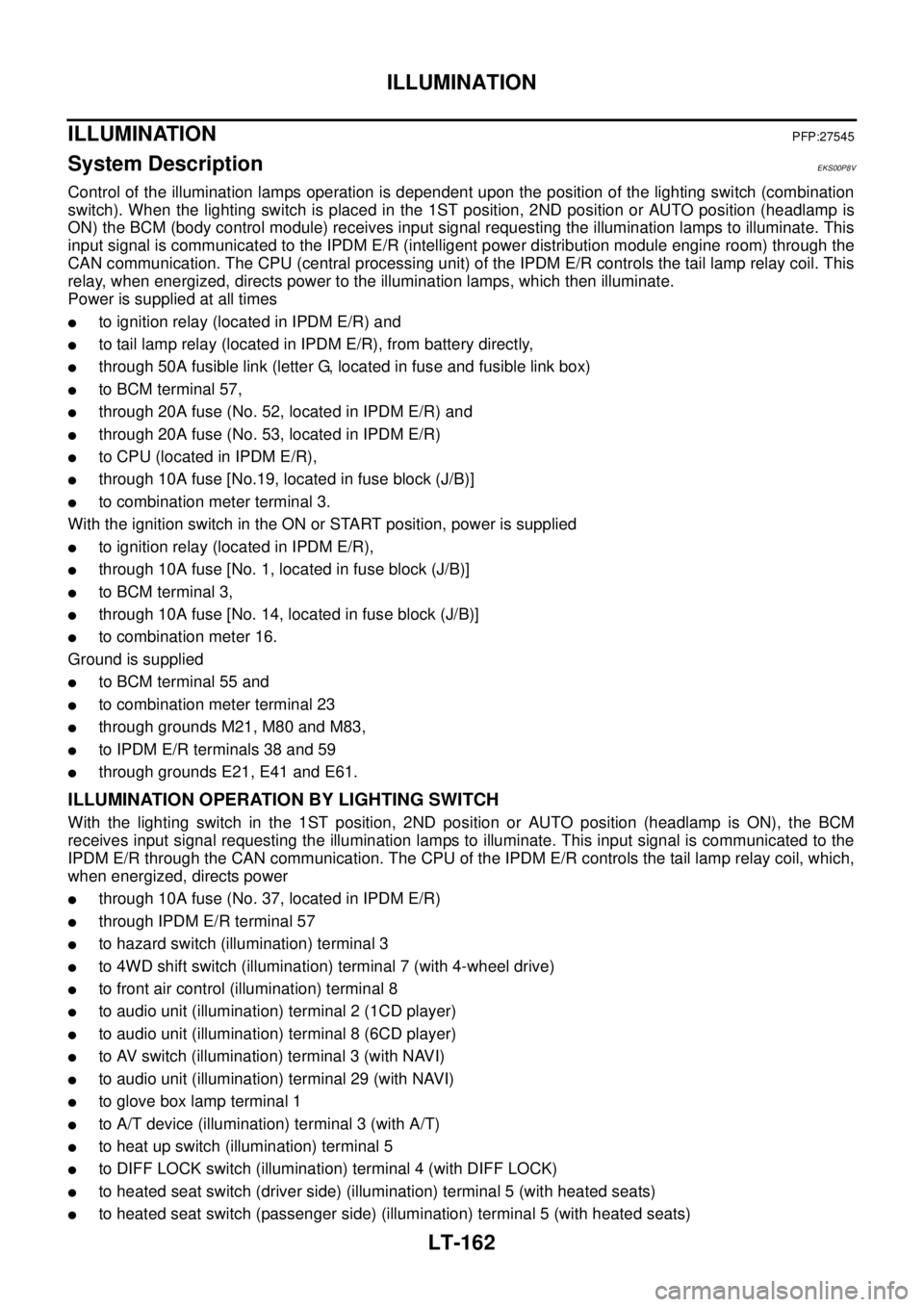

System DescriptionEKS00P8V

Control of the illumination lamps operation is dependent upon the position of the lighting switch (combination

switch). When the lighting switch is placed in the 1ST position, 2ND position or AUTO position (headlamp is

ON) the BCM (body control module) receives input signal requesting the illumination lamps to illuminate. This

input signal is communicated to the IPDM E/R (intelligent power distribution module engine room) through the

CAN communication. The CPU (central processing unit) of the IPDM E/R controls the tail lamp relay coil. This

relay, when energized, directs power to the illumination lamps, which then illuminate.

Power is supplied at all times

lto ignition relay (located in IPDM E/R) and

lto tail lamp relay (located in IPDM E/R), from battery directly,

lthrough 50A fusible link (letter G, located in fuse and fusible link box)

lto BCM terminal 57,

lthrough 20A fuse (No. 52, located in IPDM E/R) and

lthrough 20A fuse (No. 53, located in IPDM E/R)

lto CPU (located in IPDM E/R),

lthrough 10A fuse [No.19, located in fuse block (J/B)]

lto combination meter terminal 3.

With the ignition switch in the ON or START position, power is supplied

lto ignition relay (located in IPDM E/R),

lthrough 10A fuse [No. 1, located in fuse block (J/B)]

lto BCM terminal 3,

lthrough 10A fuse [No. 14, located in fuse block (J/B)]

lto combination meter 16.

Ground is supplied

lto BCM terminal 55 and

lto combination meter terminal 23

lthrough grounds M21, M80 and M83,

lto IPDM E/R terminals 38 and 59

lthrough grounds E21, E41 and E61.

ILLUMINATION OPERATION BY LIGHTING SWITCH

With the lighting switch in the 1ST position, 2ND position or AUTO position (headlamp is ON), the BCM

receives input signal requesting the illumination lamps to illuminate. This input signal is communicated to the

IPDM E/R through the CAN communication. The CPU of the IPDM E/R controls the tail lamp relay coil, which,

when energized, directs power

lthrough 10A fuse (No. 37, located in IPDM E/R)

lthrough IPDM E/R terminal 57

lto hazard switch (illumination) terminal 3

lto 4WD shift switch (illumination) terminal 7 (with 4-wheel drive)

lto front air control (illumination) terminal 8

lto audio unit (illumination) terminal 2 (1CD player)

lto audio unit (illumination) terminal 8 (6CD player)

lto AV switch (illumination) terminal 3 (with NAVI)

lto audio unit (illumination) terminal 29 (with NAVI)

lto glove box lamp terminal 1

lto A/T device (illumination) terminal 3 (with A/T)

lto heat up switch (illumination) terminal 5

lto DIFF LOCK switch (illumination) terminal 4 (with DIFF LOCK)

lto heated seat switch (driver side) (illumination) terminal 5 (with heated seats)

lto heated seat switch (passenger side) (illumination) terminal 5 (with heated seats)

Page 2246 of 3171

ILLUMINATION

LT-163

C

D

E

F

G

H

I

J

L

MA

B

LT

lto cigarette lighter (illumination) terminal 1

lto ashtray (illumination) terminal 1

lto headlamp washer switch (illumination) terminal 3

lto headlamp aiming switch (illumination) terminal 3 and

lto NAVI control unit (illumination) terminal 61 (with NAVI).

Ground is supplied

lto hazard switch (illumination) terminal 4

lto 4WD shift switch (illumination) terminal 8 (with 4-wheel drive)

lto front air control (illumination) terminal 9

lto AV switch (illumination) terminal 4 (with NAVI)

lto audio unit (illumination) terminal 28 (with NAVI)

lto DIFF LOCK switch (illumination) terminal 5 (with DIFF LOCK)

lto heated seat switch (driver side) (illumination) terminal 6 (with heated seats) and

lto heated seat switch (passenger side) (illumination) terminal 6 (with heated seats)

lthrough combination meter terminal 22

lthrough combination meter terminal 23

lthrough ground M21, M80 and M83,

lto glove box lamp terminal 2

lto A/T device (illumination) terminal 5 (with A/T)

lto heat up switch (illumination) terminal 6

lto ashtray (illumination) terminal 2

lto headlamp washer switch (illumination) terminal 4 and

lto headlamp aiming switch (illumination) terminal 4

ltrough ground M21, M80 and M83,

lto audio unit (illumination) (1CD and 6CD player)

lthrough case ground of audio unit,

lto cigarette lighter (illumination)

lthrough case ground of cigarette lighter,

lto NAVI control unit (illumination) terminal 1 (with NAVI)

lthrough ground B106 and B121.

With power and ground supplied, illumination lamps illuminate.

CAN Communication System DescriptionEKS00P8W

Refer toLAN-23, "CAN COMMUNICATION".

CAN Communication UnitEKS00P8X

Refer toLAN-30, "CAN Communication Unit".

Page 2259 of 3171

LU-2

PRECAUTIONS

PRECAUTIONS

PFP:00001

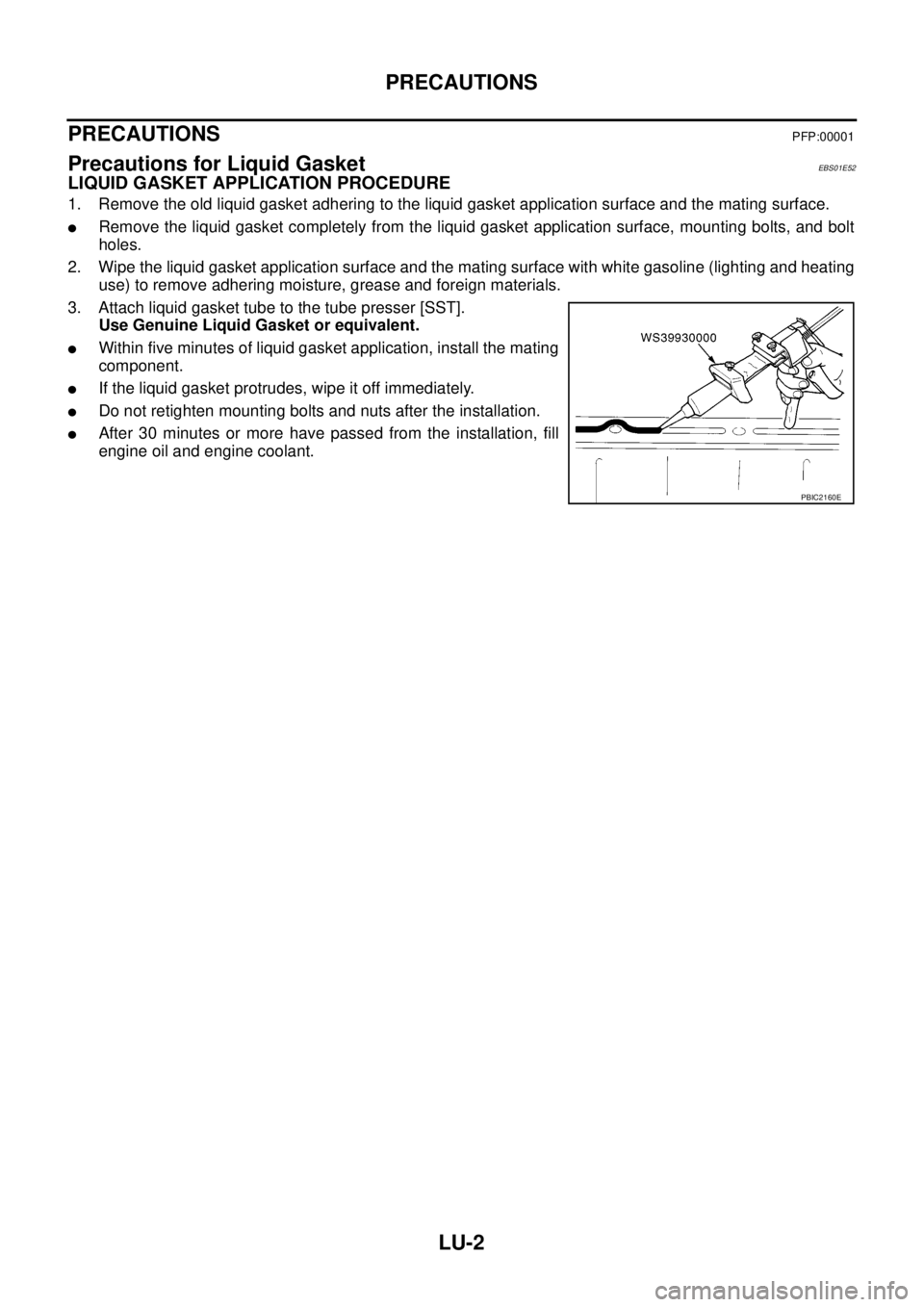

Precautions for Liquid GasketEBS01E52

LIQUID GASKET APPLICATION PROCEDURE

1. Remove the old liquid gasket adhering to the liquid gasket application surface and the mating surface.

lRemove the liquid gasket completely from the liquid gasket application surface, mounting bolts, and bolt

holes.

2. Wipe the liquid gasket application surface and the mating surface with white gasoline (lighting and heating

use) to remove adhering moisture, grease and foreign materials.

3. Attach liquid gasket tube to the tube presser [SST].

Use Genuine Liquid Gasket or equivalent.

lWithin five minutes of liquid gasket application, install the mating

component.

lIf the liquid gasket protrudes, wipe it off immediately.

lDo not retighten mounting bolts and nuts after the installation.

lAfter 30 minutes or more have passed from the installation, fill

engine oil and engine coolant.

PBIC2160E

Page 2403 of 3171

MTC-16

PREPARATION

PREPARATION

PFP:00002

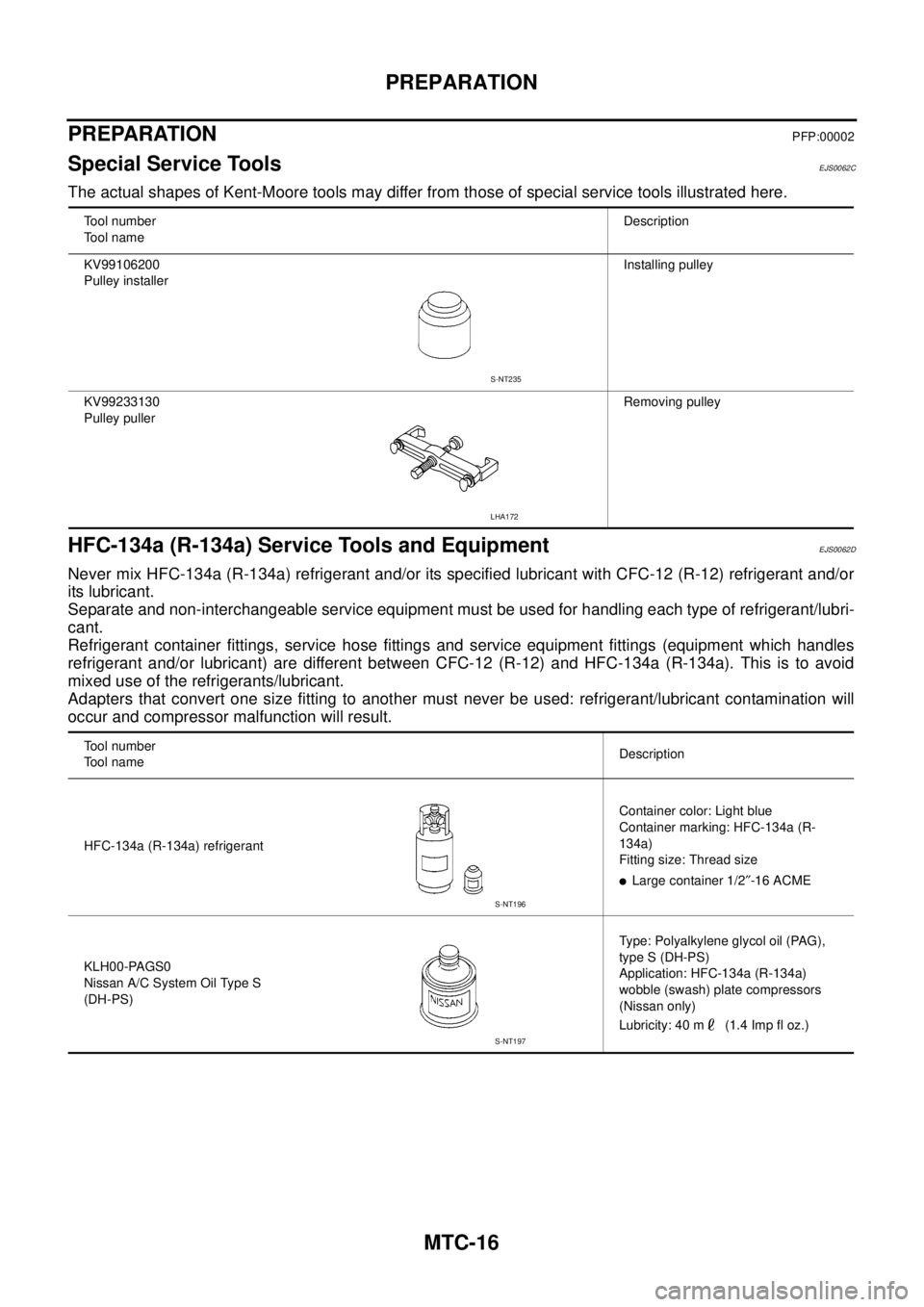

Special Service ToolsEJS0062C

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

HFC-134a (R-134a) Service Tools and EquipmentEJS0062D

Never mix HFC-134a (R-134a) refrigerant and/or its specified lubricant with CFC-12 (R-12) refrigerant and/or

its lubricant.

Separate and non-interchangeable service equipment must be used for handling each type of refrigerant/lubri-

cant.

Refrigerant container fittings, service hose fittings and service equipment fittings (equipment which handles

refrigerant and/or lubricant) are different between CFC-12 (R-12) and HFC-134a (R-134a). This is to avoid

mixed use of the refrigerants/lubricant.

Adapters that convert one size fitting to another must never be used: refrigerant/lubricant contamination will

occur and compressor malfunction will result.

Tool number

Tool nameDescription

KV99106200

Pulley installerInstalling pulley

KV99233130

Pulley pullerRemoving pulley

S-NT235

LHA172

Tool number

Tool nameDescription

HFC-134a (R-134a) refrigerantContainer color: Light blue

Container marking: HFC-134a (R-

134a)

Fitting size: Thread size

lLarge container 1/2²-16 ACME

KLH00-PAGS0

Nissan A/C System Oil Type S

(DH-PS)Type: Polyalkylene glycol oil (PAG),

type S (DH-PS)

Application: HFC-134a (R-134a)

wobble (swash) plate compressors

(Nissan only)

Lubricity: 40 m (1.4 Imp fl oz.)

S-NT196

S-NT197

Page 2404 of 3171

PREPARATION

MTC-17

C

D

E

F

G

H

I

K

L

MA

B

MTC

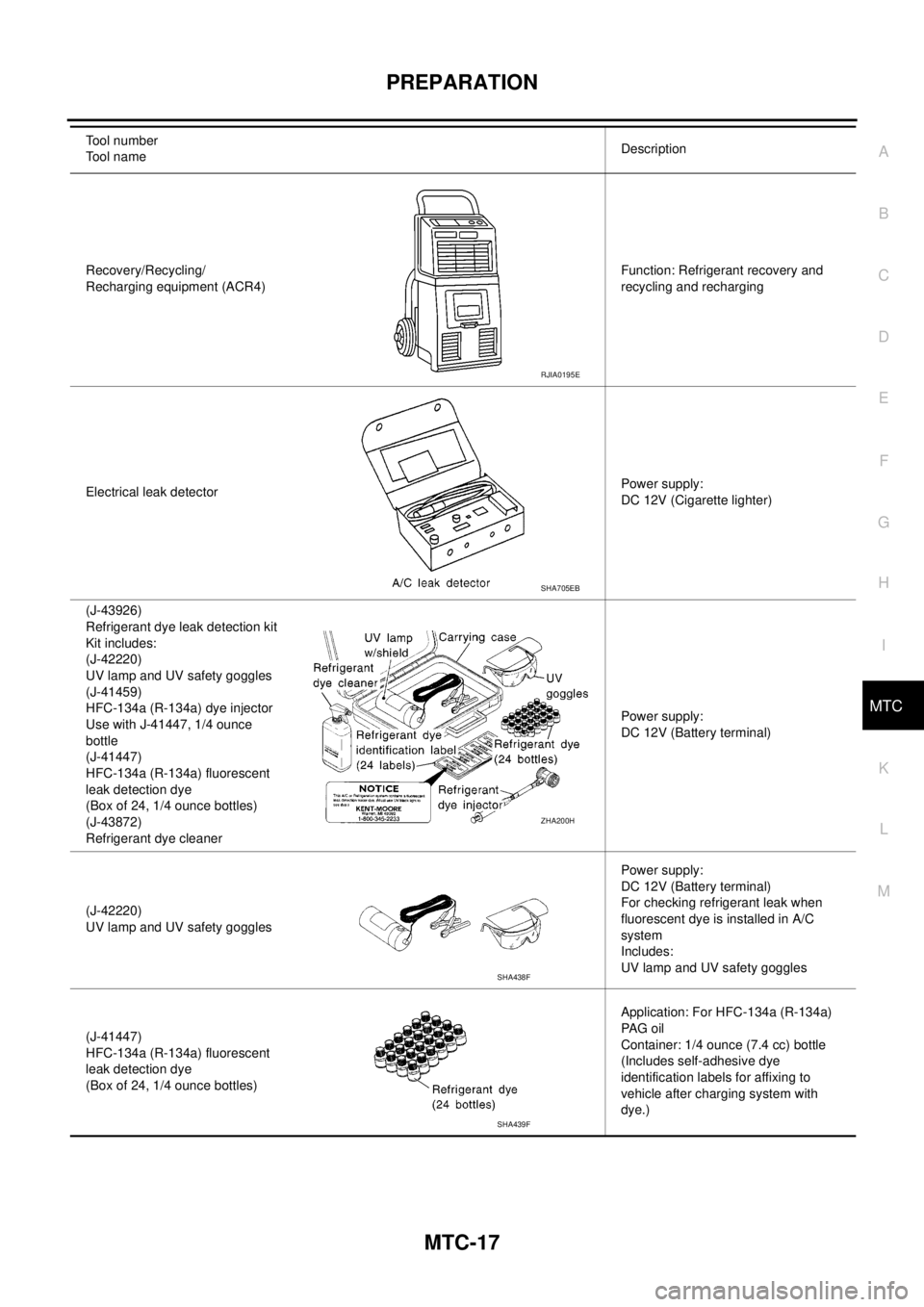

Recovery/Recycling/

Recharging equipment (ACR4)Function: Refrigerant recovery and

recycling and recharging

Electrical leak detectorPower supply:

DC 12V (Cigarette lighter)

(J-43926)

Refrigerant dye leak detection kit

Kit includes:

(J-42220)

UV lamp and UV safety goggles

(J-41459)

HFC-134a (R-134a) dye injector

Use with J-41447, 1/4 ounce

bottle

(J-41447)

HFC-134a (R-134a) fluorescent

leak detection dye

(Box of 24, 1/4 ounce bottles)

(J-43872)

Refrigerant dye cleanerPower supply:

DC 12V (Battery terminal)

(J-42220)

UV lamp and UV safety gogglesPower supply:

DC 12V (Battery terminal)

For checking refrigerant leak when

fluorescent dye is installed in A/C

system

Includes:

UV lamp and UV safety goggles

(J-41447)

HFC-134a (R-134a) fluorescent

leak detection dye

(Box of 24, 1/4 ounce bottles)Application: For HFC-134a (R-134a)

PA G o i l

Container: 1/4 ounce (7.4 cc) bottle

(Includes self-adhesive dye

identification labels for affixing to

vehicle after charging system with

dye.) Tool number

Tool nameDescription

RJIA0195E

SHA705EB

ZHA200H

SHA438F

SHA439F