light NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2948 of 3171

SPIRAL CABLE

SRS-39

C

D

E

F

G

I

J

K

L

MA

B

SRS

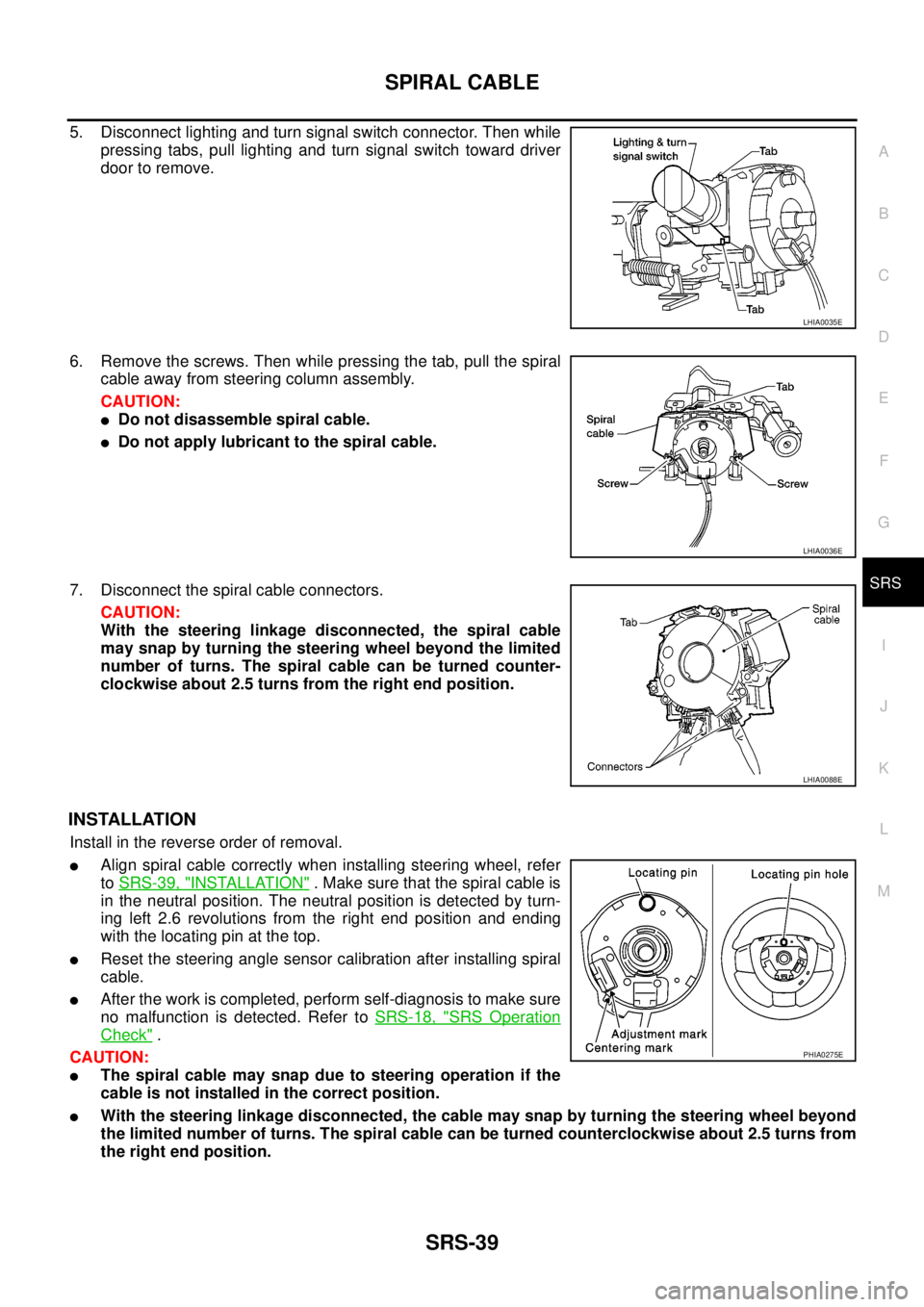

5. Disconnect lighting and turn signal switch connector. Then while

pressing tabs, pull lighting and turn signal switch toward driver

door to remove.

6. Remove the screws. Then while pressing the tab, pull the spiral

cable away from steering column assembly.

CAUTION:

lDo not disassemble spiral cable.

lDo not apply lubricant to the spiral cable.

7. Disconnect the spiral cable connectors.

CAUTION:

With the steering linkage disconnected, the spiral cable

may snap by turning the steering wheel beyond the limited

number of turns. The spiral cable can be turned counter-

clockwise about 2.5 turns from the right end position.

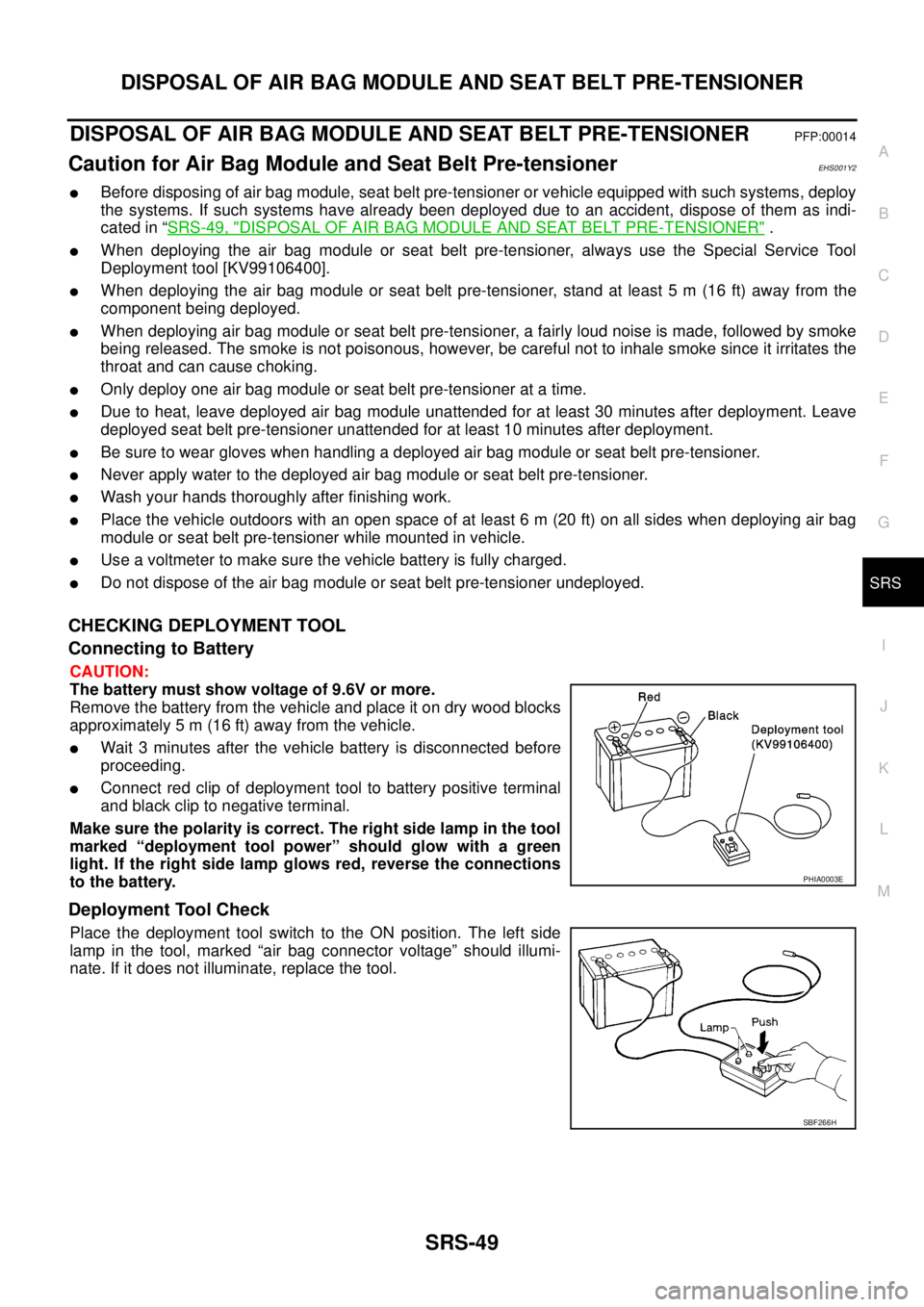

INSTALLATION

Install in the reverse order of removal.

lAlign spiral cable correctly when installing steering wheel, refer

toSRS-39, "

INSTALLATION". Make sure that the spiral cable is

in the neutral position. The neutral position is detected by turn-

ing left 2.6 revolutions from the right end position and ending

with the locating pin at the top.

lReset the steering angle sensor calibration after installing spiral

cable.

lAfter the work is completed, perform self-diagnosis to make sure

no malfunction is detected. Refer toSRS-18, "

SRS Operation

Check".

CAUTION:

lThe spiral cable may snap due to steering operation if the

cable is not installed in the correct position.

lWith the steering linkage disconnected, the cable may snap by turning the steering wheel beyond

the limited number of turns. The spiral cable can be turned counterclockwise about 2.5 turns from

the right end position.

LHIA0035E

LHIA0036E

LHIA0088E

PHIA0275E

Page 2958 of 3171

DISPOSAL OF AIR BAG MODULE AND SEAT BELT PRE-TENSIONER

SRS-49

C

D

E

F

G

I

J

K

L

MA

B

SRS

DISPOSAL OF AIR BAG MODULE AND SEAT BELT PRE-TENSIONERPFP:00014

Caution for Air Bag Module and Seat Belt Pre-tensionerEHS001Y2

lBefore disposing of air bag module, seat belt pre-tensioner or vehicle equipped with such systems, deploy

the systems. If such systems have already been deployed due to an accident, dispose of them as indi-

cated in “SRS-49, "

DISPOSAL OF AIR BAG MODULE AND SEAT BELT PRE-TENSIONER".

lWhen deploying the air bag module or seat belt pre-tensioner, always use the Special Service Tool

Deployment tool [KV99106400].

lWhen deploying the air bag module or seat belt pre-tensioner, stand at least 5 m (16 ft) away from the

component being deployed.

lWhen deploying air bag module or seat belt pre-tensioner, a fairly loud noise is made, followed by smoke

being released. The smoke is not poisonous, however, be careful not to inhale smoke since it irritates the

throat and can cause choking.

lOnly deploy one air bag module or seat belt pre-tensioner at a time.

lDue to heat, leave deployed air bag module unattended for at least 30 minutes after deployment. Leave

deployed seat belt pre-tensioner unattended for at least 10 minutes after deployment.

lBe sure to wear gloves when handling a deployed air bag module or seat belt pre-tensioner.

lNever apply water to the deployed air bag module or seat belt pre-tensioner.

lWash your hands thoroughly after finishing work.

lPlace the vehicle outdoors with an open space of at least 6 m (20 ft) on all sides when deploying air bag

module or seat belt pre-tensioner while mounted in vehicle.

lUse a voltmeter to make sure the vehicle battery is fully charged.

lDo not dispose of the air bag module or seat belt pre-tensioner undeployed.

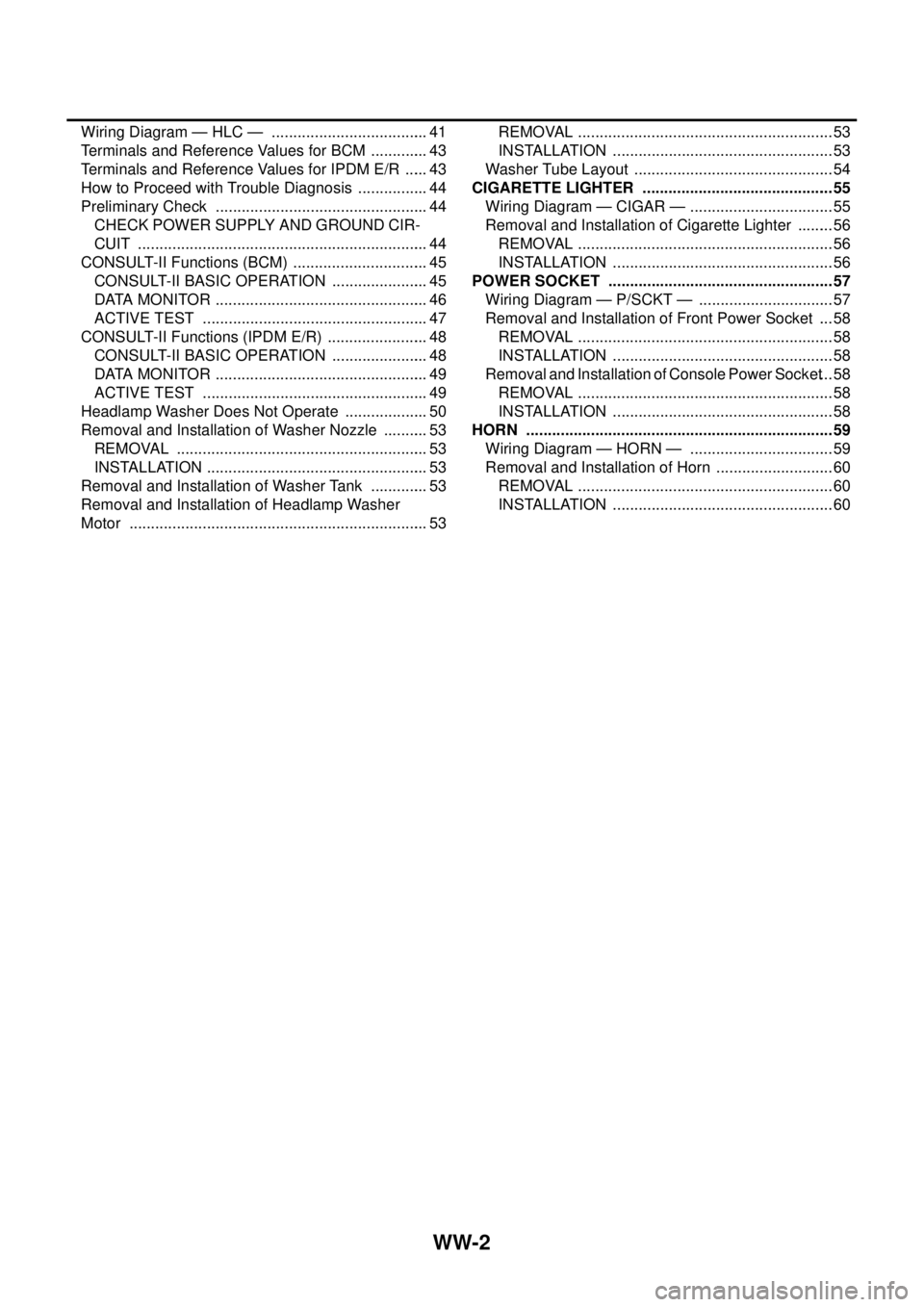

CHECKING DEPLOYMENT TOOL

Connecting to Battery

CAUTION:

The battery must show voltage of 9.6V or more.

Remove the battery from the vehicle and place it on dry wood blocks

approximately 5 m (16 ft) away from the vehicle.

lWait 3 minutes after the vehicle battery is disconnected before

proceeding.

lConnect red clip of deployment tool to battery positive terminal

and black clip to negative terminal.

Makesurethepolarityiscorrect.Therightsidelampinthetool

marked “deployment tool power” should glow with a green

light. If the right side lamp glows red, reverse the connections

to the battery.

Deployment Tool Check

Place the deployment tool switch to the ON position. The left side

lamp in the tool, marked “air bag connector voltage” should illumi-

nate. If it does not illuminate, replace the tool.

PHIA0003E

SBF266H

Page 3113 of 3171

WW-2

Wiring Diagram — HLC — ..................................... 41

Terminals and Reference Values for BCM .............. 43

Terminals and Reference Values for IPDM E/R ...... 43

How to Proceed with Trouble Diagnosis ................. 44

Preliminary Check .................................................. 44

CHECK POWER SUPPLY AND GROUND CIR-

CUIT .................................................................... 44

CONSULT-II Functions (BCM) ................................ 45

CONSULT-II BASIC OPERATION ....................... 45

DATA MONITOR .................................................. 46

ACTIVE TEST ..................................................... 47

CONSULT-II Functions (IPDM E/R) ........................ 48

CONSULT-II BASIC OPERATION ....................... 48

DATA MONITOR .................................................. 49

ACTIVE TEST ..................................................... 49

Headlamp Washer Does Not Operate .................... 50

Removal and Installation of Washer Nozzle ........... 53

REMOVAL ........................................................... 53

INSTALLATION .................................................... 53

Removal and Installation of Washer Tank .............. 53

Removal and Installation of Headlamp Washer

Motor ...................................................................... 53REMOVAL ............................................................ 53

INSTALLATION .................................................... 53

Washer Tube Layout ............................................... 54

CIGARETTE LIGHTER ............................................. 55

Wiring Diagram — CIGAR — .................................. 55

Removal and Installation of Cigarette Lighter ......... 56

REMOVAL ............................................................ 56

INSTALLATION .................................................... 56

POWER SOCKET ..................................................... 57

Wiring Diagram — P/SCKT — ................................ 57

Removal and Installation of Front Power Socket .... 58

REMOVAL ............................................................ 58

INSTALLATION .................................................... 58

Removal and Installation of Console Power Socket...58

REMOVAL ............................................................ 58

INSTALLATION .................................................... 58

HORN ........................................................................ 59

Wiring Diagram — HORN — .................................. 59

Removal and Installation of Horn ............................ 60

REMOVAL ............................................................ 60

INSTALLATION .................................................... 60

Page 3117 of 3171

WW-6

FRONT WIPER AND WASHER SYSTEM

INTERMITTENT OPERATION

When front wiper switch is turned to INT position, wiper performs intermittent operation, low-speed operation,

and high-speed operation according to water drop increase rate on windshield detected by light and rain sen-

sor. If light and rain sensor malfunctions, it operates as vehicle speed sensing wiper during driving and oper-

ates intermittent operation according to INT-volume switch with vehicle stopped. During this time, BCM

controls each operation.

The BCM then sends a front wiper (HI or LOW) request signal with CAN communication.

lfrom BCM terminals 21 and 22

lto IPDM E/R terminals 39 and 40.

When the BCM determines that combination switch status is front wiper intermittent ON, it performs the follow-

ing operations.

lBCM detects intermittent wiper dial position.

lBCM sends front wiper request signal (HI or LOW) to IPDM E/R at calculated operation interval.

When IPDM E/R receives front wiper request signal (HI or LOW), it supplies ground to energize the front wiper

main relay and front wiper LOW/HIGH relay. It then sends an auto-stop signal to the BCM, and conducts inter-

mittent front wiper motor operation.

AUTO STOP OPERATION

When the wiper arms are not located at the base of the windshield, and the wiper switch is turned OFF, the

wiper motor will continue to operate until the wiper arms reach the windshield base. When the wiper arms

reach the base of windshield, front wiper motor terminals 2 and 5 are connected.

Ground is supplied

lto IPDM E/R terminal 43

lthrough front wiper motor terminal 5

lthrough front wiper motor terminal 2

lthrough grounds E21, E41 and E61.

The IPDM E/R sends an auto stop operation signal to the BCM with CAN communication.

When the BCM receives an auto stop operation signal, the BCM sends wiper stop signal to the IPDM E/R over

CAN communication lines. The IPDM E/R then de-energizes the front wiper main relay.

The wiper motor will then stop the wiper arms at the STOP position.

FRONT WASHER OPERATION

When the ignition switch is in the ON or START position, and the front washer switches are OFF, the front

washer motor is supplied power

lthrough 10A fuse [No. 15, located in fuse block (J/B)]

lthrough combination switch (wiper switch) terminal 2

lthrough combination switch (wiper switch) terminal 4

lto front washer motor terminal 1.

When the front wiper switch is in the front washer position, the BCM detects a front washer signal request

through the combination switch (wiper switch) reading function.

Combination switch ground is supplied

lto front washer motor terminal 2

lthrough combination switch (wiper switch) terminal 3

lthrough combination switch (wiper switch) terminal 9

lthrough grounds M21, M80 and M83.

With ground supplied, the front washer motor is operated in the front direction.

When the BCM detects that front washer motor has operated for 0.4 seconds or longer, the BCM uses CAN

communication and sends a wiper request signal to the IPDM E/R for low speed operation of wipers.

When the BCM detects that the washer switch is OFF, low speed operation cycles approximately 3 times and

then stops.

Page 3121 of 3171

WW-10

FRONT WIPER AND WASHER SYSTEM

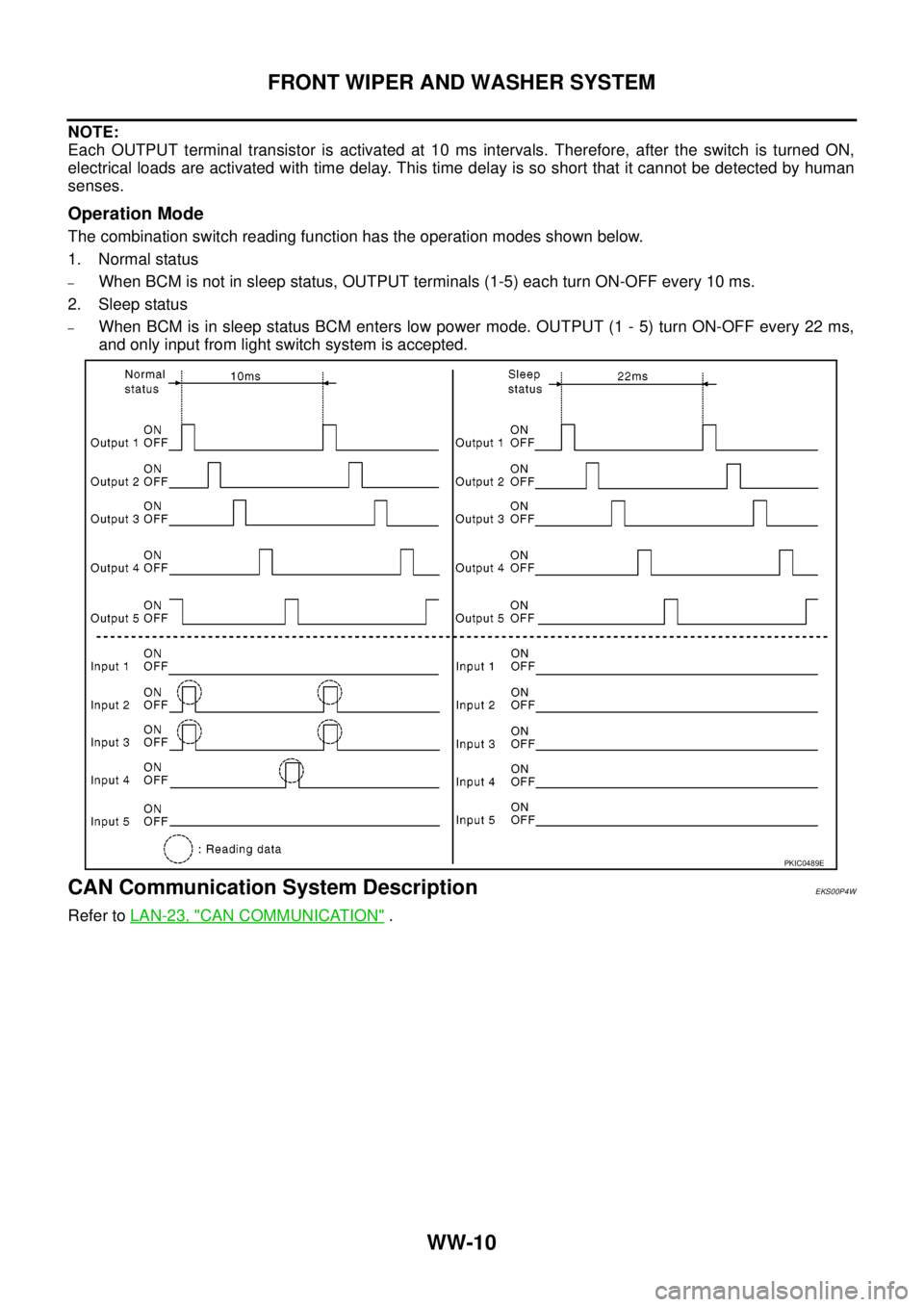

NOTE:

Each OUTPUT terminal transistor is activated at 10 ms intervals. Therefore, after the switch is turned ON,

electrical loads are activated with time delay. This time delay is so short that it cannot be detected by human

senses.

Operation Mode

The combination switch reading function has the operation modes shown below.

1. Normal status

–When BCM is not in sleep status, OUTPUT terminals (1-5) each turn ON-OFF every 10 ms.

2. Sleep status

–When BCM is in sleep status BCM enters low power mode. OUTPUT (1 - 5) turn ON-OFF every 22 ms,

and only input from light switch system is accepted.

CAN Communication System DescriptionEKS00P4W

Refer toLAN-23, "CAN COMMUNICATION".

PKIC0489E

Page 3126 of 3171

FRONT WIPER AND WASHER SYSTEM

WW-15

C

D

E

F

G

H

I

J

L

MA

B

WW

Terminals and Reference Values for BCMEKS00P4Z

Te r m i n a l

No.Wire

colorSignal nameMeasuring condition

Reference value

Ignition

switchOperation or condition

3 Y Ignition switch (ON) ON — Battery voltage

6 G Combination switch output 3 ONLighting, turn, wiper OFF

Wiper dial position 4

7 GR Combination switch output 4 ONLighting, turn, wiper OFF

Wiper dial position 4

8 LG Combination switch output 1 ONLighting, turn, wiper OFF

Wiper dial position 4

9 BR Combination switch output 2 ONLighting, turn, wiper OFF

Wiper dial position 4

10 O Combination switch output 5 ONLighting, turn, wiper OFF

Wiper dial position 4

21 P CAN-L—— —

22 L CAN-H—— —

24 R Light and rain sensor signal — Ignition switchON

OFF Battery voltage

36 P Combination switch input 5 ONLighting, turn, wiper OFF

Wiper dial position 4

Approx. 0V 37 L Combination switch input 2 ONLighting, turn, wiper OFF

Wiper dial position 4

38 V Combination switch input 3 ONLighting, turn, wiper OFF

Wiper dial position 4

39 SB Combination switch input 4 ONLighting, turn, wiper OFF

Wiper dial position 4

40 R Combination switch input 1 ONLighting, turn, wiper OFF

Wiper dial position 4

42 V Room lamp power supply OFF — Battery voltage

55 B Ground ON — Approx. 0V

57 W Battery power supply (fusible link) OFF — Battery voltage

PKIB4958J

PKIC1618E

Page 3134 of 3171

FRONT WIPER AND WASHER SYSTEM

WW-23

C

D

E

F

G

H

I

J

L

MA

B

WW

Front Wiper Does Not Operate in Rain (Front Wiper Switch Turned to INT Posi-

tion)

EKS00Q9V

1.CHECK CONDITIONS OF WINDSHIELD ( LIGHT AND RAIN SENSOR DETECTION AREA)

Check light and rain sensor detection area of windshield for dirt such as greases.

OK or NG

OK >> GO TO 2.

NG >> Clean light and rain sensor detection area of windshield fully.

2.CHECK LIGHT AND RAIN SENSOR INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Turn ignition switch ON.

4. Check waveform between BCM harness connector and ground.

OK or NG

OK >> Replace light and rain sensor. Refer toLT-65, "Removal and Installation of Light and Rain Sensor"

. If front wiper does not operate, replace BCM. Refer toBCS-17, "Removal and Installation of

BCM".

NG >> GO TO 3.

3.CHECK LIGHT AND RAIN SENSOR SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector and light and rain sensor connector.

3. Check continuity between BCM harness connector (A) and light

and rain sensor harness connector (B).

4. Check continuity between BCM harness connector (A) and

ground.

OK or NG

OK >> GO TO 4.

NG >> Repair harness or connector.

Terminal

Condition Voltage (+)

(-)

BCM

connectorTerminal

M42 24 GroundIgnition

switchON

OFF Batterly voltage

SKIB6405E

PKIC1618E

AB

Continuity

Connector Terminal Connector Terminal

M42 24 R3 2 Yes

A

GroundContinuity

Connector Terminal

M42 24 No

PKIC1377E

Page 3135 of 3171

WW-24

FRONT WIPER AND WASHER SYSTEM

4.CHECK LIGHT AND RAIN SENSOR GROUND CIRCUIT

Check continuity between light and rain sensor harness connector

and ground.

OK or NG

OK >> GO TO 5.

NG >> Repair harness or connector.

5.CHECK LIGHT AND RAIN SENSOR POWER SUPPLY CIRCUIT

1. Check continuity between BCM harness connector (A) and light

and rain sensor harness connector (B).

2. Check continuity between BCM harness connector (A) and

ground.

OK or NG

OK >> GO TO 6.

NG >> Repair harness or connector.

6.CHECK LIGHT AND RAIN SENSOR POWER SUPPLY

1. Connect BCM connector.

2. Turn ignition switch ON.

3. Check voltage between light and rain sensor harness connector

and ground.

OK or NG

OK >> Replace light and rain sensor. Refer toLT-65, "Removal

and Installation of Light and Rain Sensor".

NG >> Replace BCM. Refer toBCS-17, "

Removal and Installation of BCM".

Light and rain

sensor connectorTerminal

GroundContinuity

R3 3 Yes

PKIC1375E

AB

Continuity

Connector Terminal Connector Terminal

M43 42 R3 1 Yes

A

GroundContinuity

Connector Terminal

M43 42 No

PKIC1376E

Terminal

Voltage (+)

(-)

Light and rain sensor

connectorTe r m i n a l

R3 1 Ground Battery voltage

SKIB6406E

Page 3150 of 3171

HEADLAMP WASHER

WW-39

C

D

E

F

G

H

I

J

L

MA

B

WW

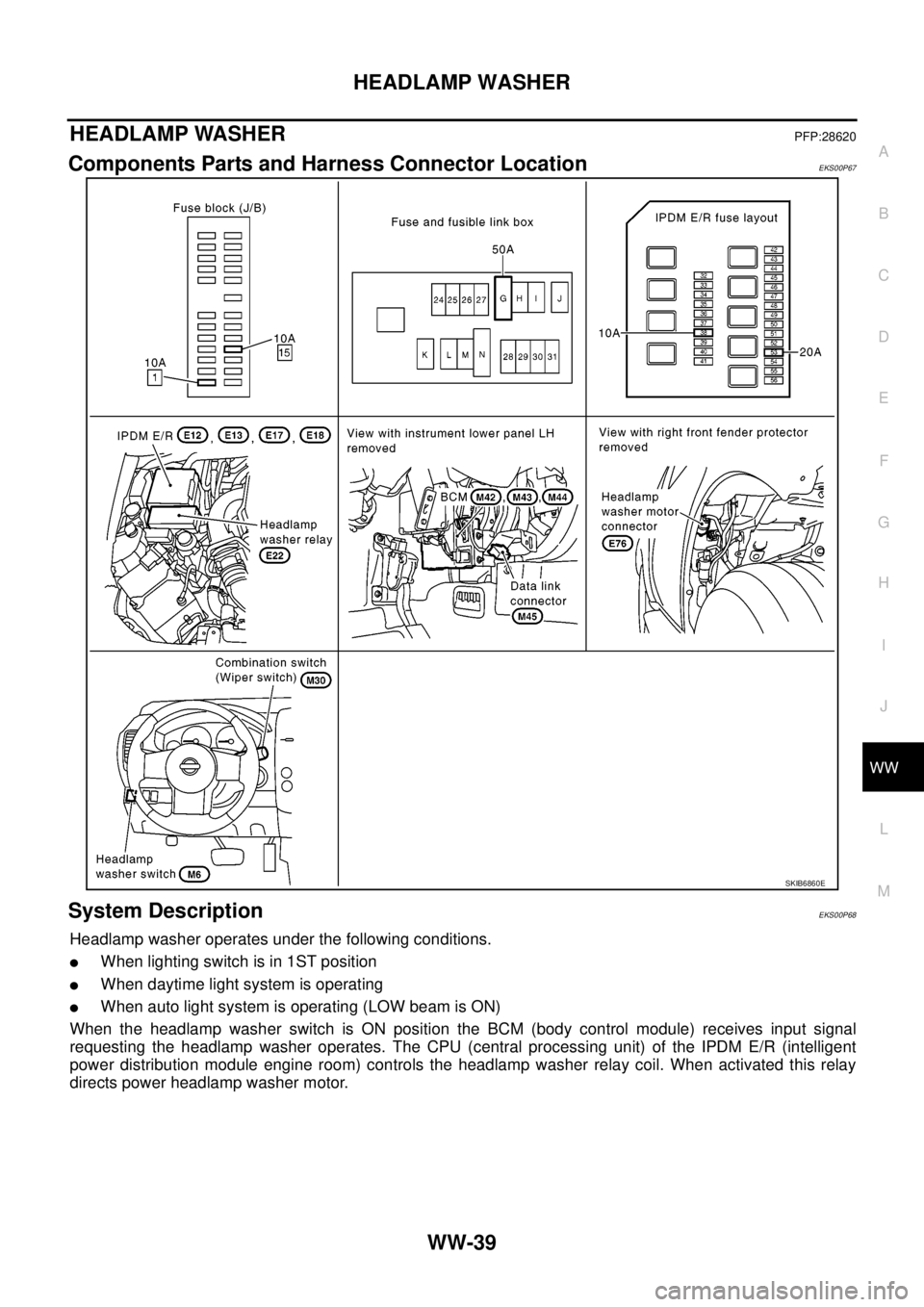

HEADLAMP WASHERPFP:28620

Components Parts and Harness Connector LocationEKS00P67

System DescriptionEKS00P68

Headlamp washer operates under the following conditions.

lWhen lighting switch is in 1ST position

lWhen daytime light system is operating

lWhen auto light system is operating (LOW beam is ON)

When the headlamp washer switch is ON position the BCM (body control module) receives input signal

requesting the headlamp washer operates. The CPU (central processing unit) of the IPDM E/R (intelligent

power distribution module engine room) controls the headlamp washer relay coil. When activated this relay

directs power headlamp washer motor.

SKIB6860E

Page 3154 of 3171

HEADLAMP WASHER

WW-43

C

D

E

F

G

H

I

J

L

MA

B

WW

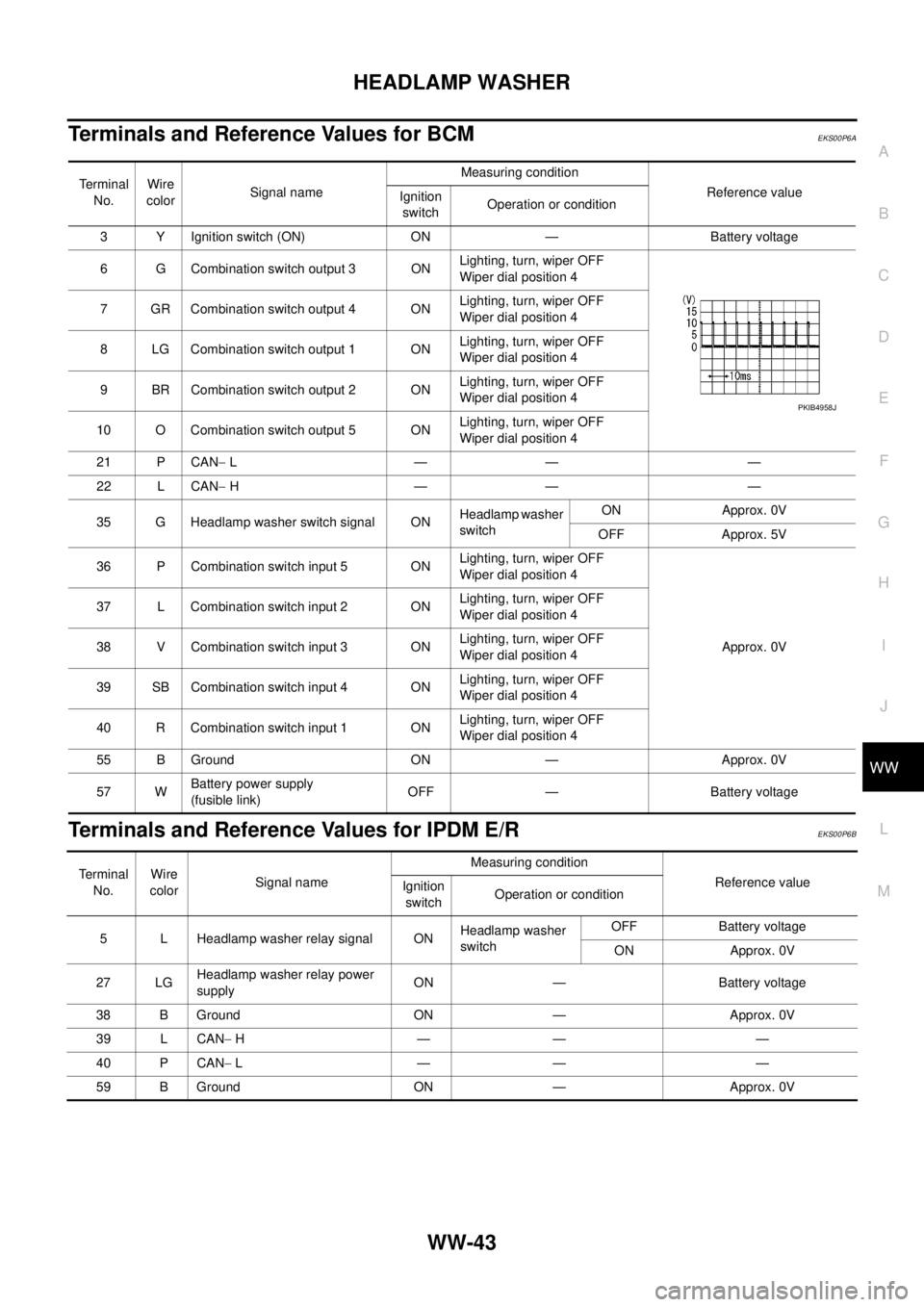

Terminals and Reference Values for BCMEKS00P6A

Terminals and Reference Values for IPDM E/REKS00P6B

Te r m i n a l

No.Wire

colorSignal nameMeasuring condition

Reference value

Ignition

switchOperation or condition

3 Y Ignition switch (ON) ON — Battery voltage

6 G Combination switch output 3 ONLighting, turn, wiper OFF

Wiper dial position 4

7 GR Combination switch output 4 ONLighting, turn, wiper OFF

Wiper dial position 4

8 LG Combination switch output 1 ONLighting, turn, wiper OFF

Wiper dial position 4

9 BR Combination switch output 2 ONLighting, turn, wiper OFF

Wiper dial position 4

10 O Combination switch output 5 ONLighting, turn, wiper OFF

Wiper dial position 4

21 P CAN-L—— —

22 L CAN-H—— —

35 G Headlamp washer switch signal ONHeadlamp washer

switchON Approx. 0V

OFF Approx. 5V

36 P Combination switch input 5 ONLighting, turn, wiper OFF

Wiper dial position 4

Approx. 0V 37 L Combination switch input 2 ONLighting, turn, wiper OFF

Wiper dial position 4

38 V Combination switch input 3 ONLighting, turn, wiper OFF

Wiper dial position 4

39 SB Combination switch input 4 ONLighting, turn, wiper OFF

Wiper dial position 4

40 R Combination switch input 1 ONLighting, turn, wiper OFF

Wiper dial position 4

55 B Ground ON — Approx. 0V

57 WBattery power supply

(fusible link)OFF — Battery voltage

PKIB4958J

Te r m i n a l

No.Wire

colorSignal nameMeasuring condition

Reference value

Ignition

switchOperation or condition

5 L Headlamp washer relay signal ONHeadlamp washer

switchOFF Battery voltage

ON Approx. 0V

27 LGHeadlamp washer relay power

supplyON — Battery voltage

38 B Ground ON — Approx. 0V

39 L CAN-H—— —

40 P CAN-L—— —

59 B Ground ON — Approx. 0V