light NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2185 of 3171

LT-102

TURN SIGNAL AND HAZARD WARNING LAMPS

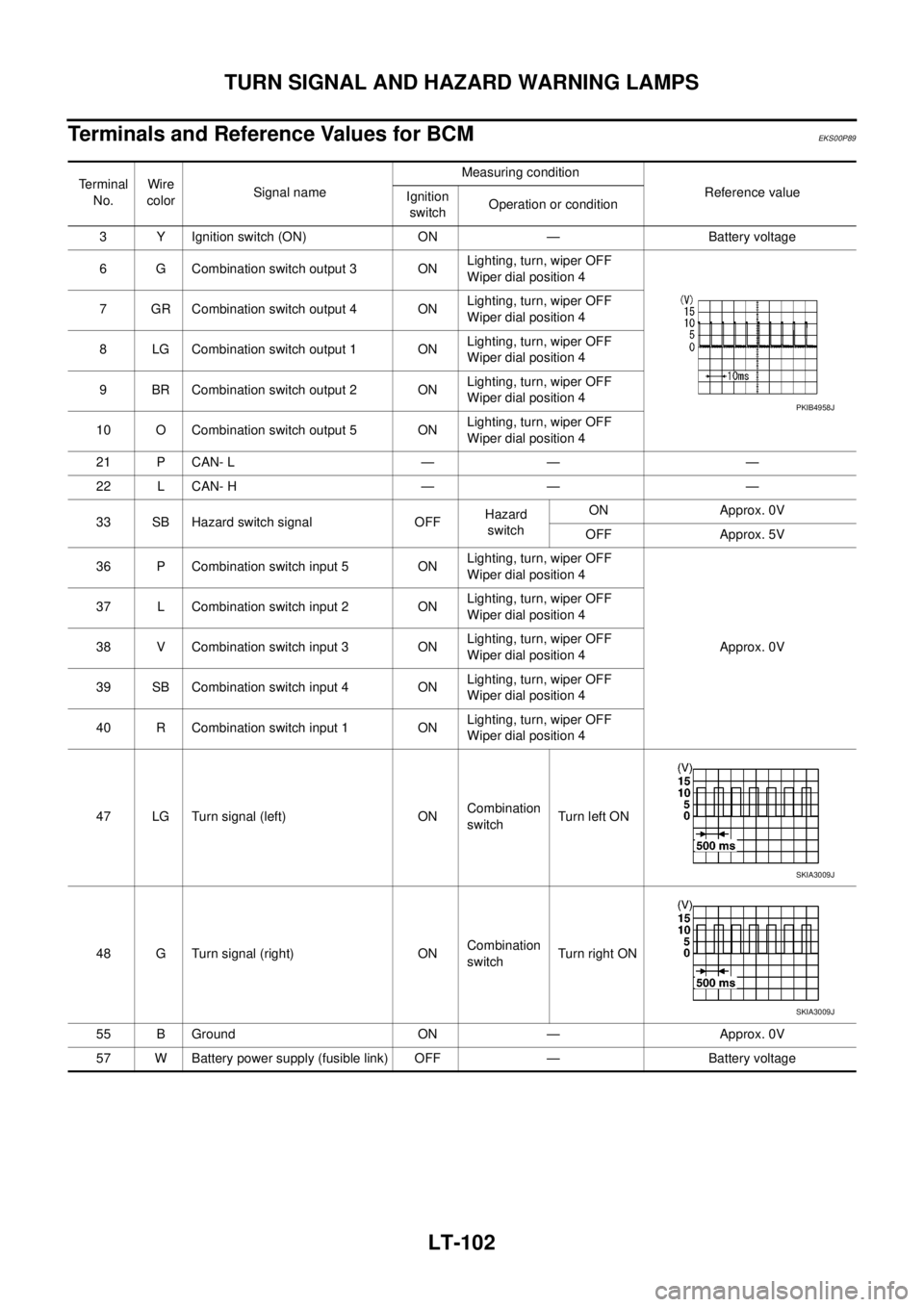

Terminals and Reference Values for BCM

EKS00P89

Terminal

No.Wire

colorSignal nameMeasuring condition

Reference value

Ignition

switchOperation or condition

3 Y Ignition switch (ON) ON — Battery voltage

6 G Combination switch output 3 ONLighting, turn, wiper OFF

Wiper dial position 4

7 GR Combination switch output 4 ONLighting, turn, wiper OFF

Wiper dial position 4

8 LG Combination switch output 1 ONLighting, turn, wiper OFF

Wiper dial position 4

9 BR Combination switch output 2 ONLighting, turn, wiper OFF

Wiper dial position 4

10 O Combination switch output 5 ONLighting, turn, wiper OFF

Wiper dial position 4

21 P CAN- L — — —

22 L CAN- H — — —

33 SB Hazard switch signal OFFHazard

switchON Approx. 0V

OFF Approx. 5V

36 P Combination switch input 5 ONLighting, turn, wiper OFF

Wiper dial position 4

Approx. 0V 37 L Combination switch input 2 ONLighting, turn, wiper OFF

Wiper dial position 4

38 V Combination switch input 3 ONLighting, turn, wiper OFF

Wiper dial position 4

39 SB Combination switch input 4 ONLighting, turn, wiper OFF

Wiper dial position 4

40 R Combination switch input 1 ONLighting, turn, wiper OFF

Wiper dial position 4

47 LG Turn signal (left) ONCombination

switchTurn left ON

48 G Turn signal (right) ONCombination

switchTu rn righ t ON

55 B Ground ON — Approx. 0V

57 W Battery power supply (fusible link) OFF — Battery voltage

PKIB4958J

SKIA3009J

SKIA3009J

Page 2190 of 3171

TURN SIGNAL AND HAZARD WARNING LAMPS

LT-107

C

D

E

F

G

H

I

J

L

MA

B

LT

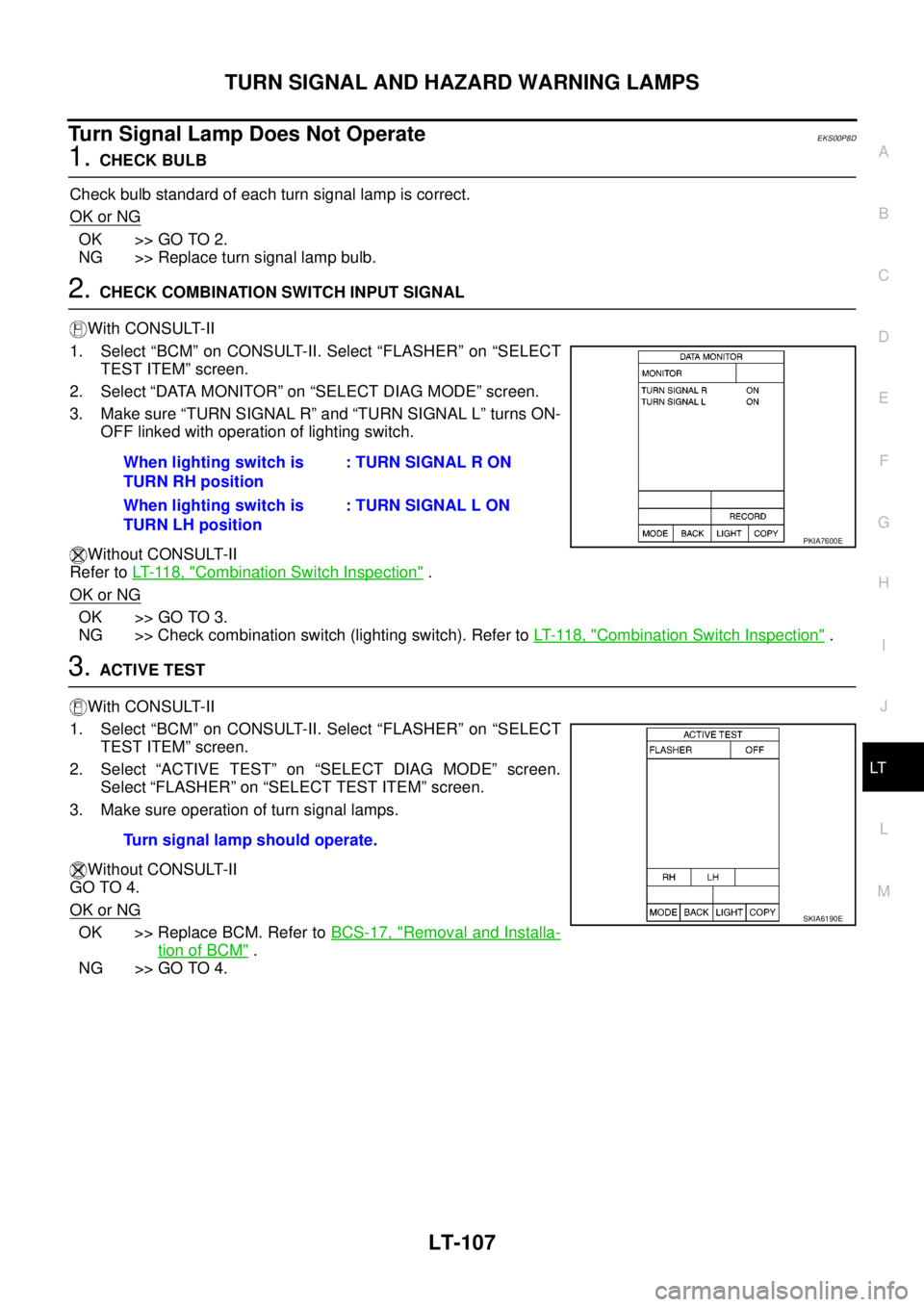

Turn Signal Lamp Does Not OperateEKS00P8D

1.CHECK BULB

Check bulb standard of each turn signal lamp is correct.

OK or NG

OK >> GO TO 2.

NG >> Replace turn signal lamp bulb.

2.CHECK COMBINATION SWITCH INPUT SIGNAL

With CONSULT-II

1. Select “BCM” on CONSULT-II. Select “FLASHER” on “SELECT

TEST ITEM” screen.

2. Select “DATA MONITOR” on “SELECT DIAG MODE” screen.

3. Make sure “TURN SIGNAL R” and “TURN SIGNAL L” turns ON-

OFF linked with operation of lighting switch.

Without CONSULT-II

Refer toLT- 11 8 , "

Combination Switch Inspection".

OK or NG

OK >> GO TO 3.

NG >> Check combination switch (lighting switch). Refer toLT- 11 8 , "

Combination Switch Inspection".

3.ACTIVE TEST

With CONSULT-II

1. Select “BCM” on CONSULT-II. Select “FLASHER” on “SELECT

TEST ITEM” screen.

2. Select “ACTIVE TEST” on “SELECT DIAG MODE” screen.

Select “FLASHER” on “SELECT TEST ITEM” screen.

3. Make sure operation of turn signal lamps.

Without CONSULT-II

GO TO 4.

OK or NG

OK >> Replace BCM. Refer toBCS-17, "Removal and Installa-

tion of BCM".

NG >> GO TO 4.When lighting switch is

TURN RH position: TURN SIGNAL R ON

When lighting switch is

TURN LH position: TURN SIGNAL L ON

PKIA7600E

Turn signal lamp should operate.

SKIA6190E

Page 2195 of 3171

LT-112

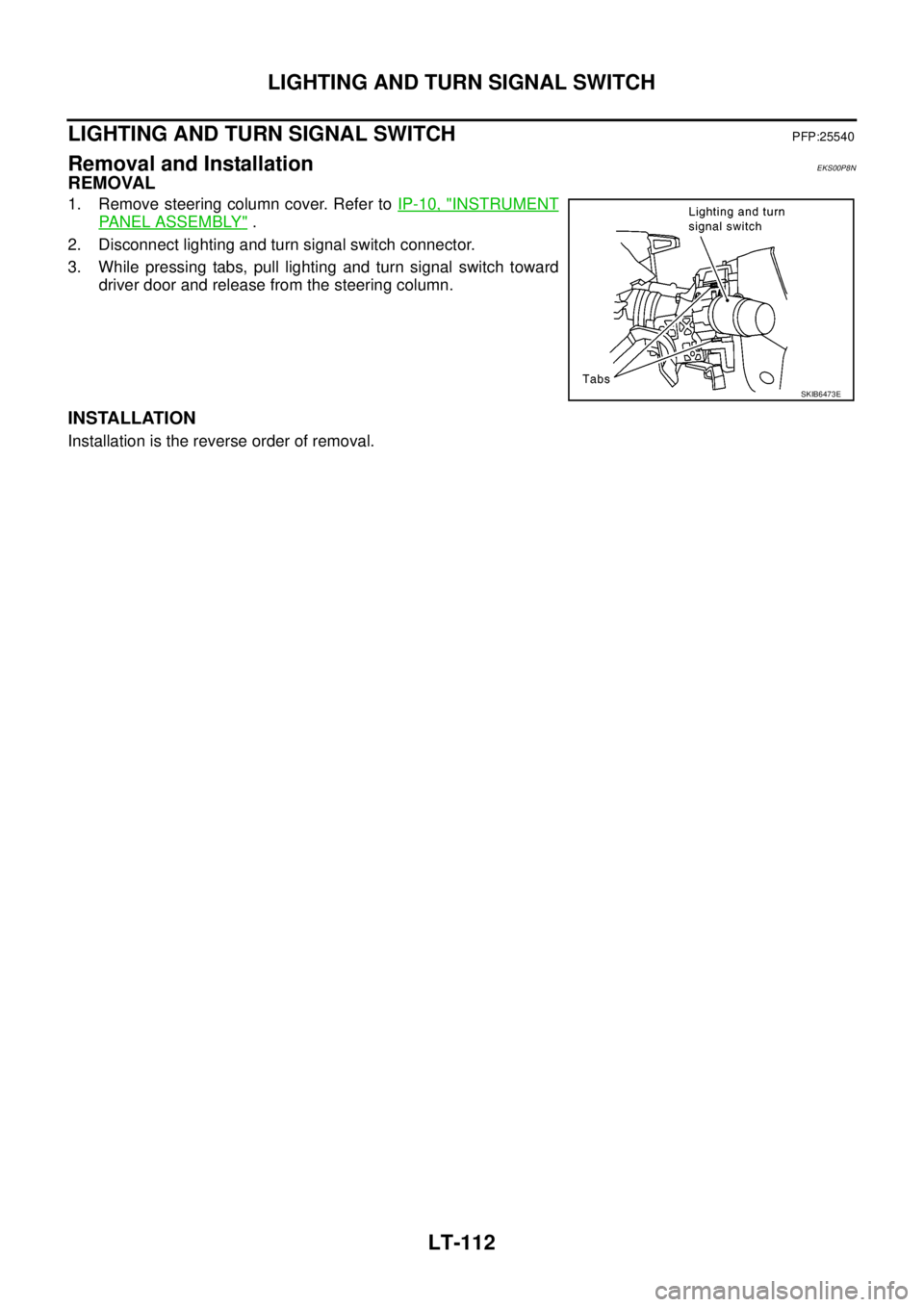

LIGHTING AND TURN SIGNAL SWITCH

LIGHTING AND TURN SIGNAL SWITCH

PFP:25540

Removal and InstallationEKS00P8N

REMOVAL

1. Remove steering column cover. Refer toIP-10, "INSTRUMENT

PANEL ASSEMBLY".

2. Disconnect lighting and turn signal switch connector.

3. While pressing tabs, pull lighting and turn signal switch toward

driver door and release from the steering column.

INSTALLATION

Installation is the reverse order of removal.

SKIB6473E

Page 2199 of 3171

LT-116

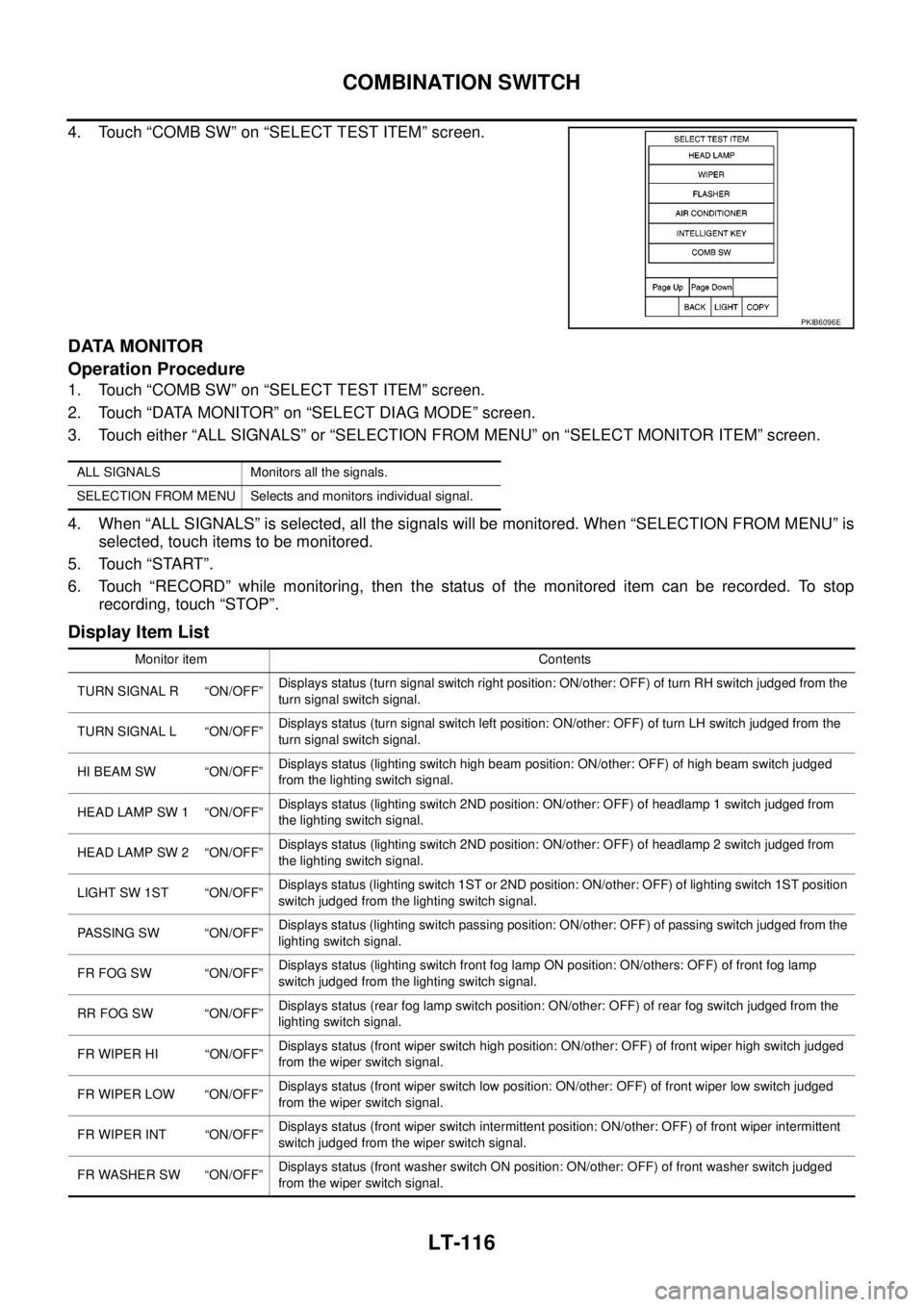

COMBINATION SWITCH

4. Touch “COMB SW” on “SELECT TEST ITEM” screen.

DATA MONITOR

Operation Procedure

1. Touch “COMB SW” on “SELECT TEST ITEM” screen.

2. Touch “DATA MONITOR” on “SELECT DIAG MODE” screen.

3. Touch either “ALL SIGNALS” or “SELECTION FROM MENU” on “SELECT MONITOR ITEM” screen.

4. When “ALL SIGNALS” is selected, all the signals will be monitored. When “SELECTION FROM MENU” is

selected, touch items to be monitored.

5. Touch “START”.

6. Touch “RECORD” while monitoring, then the status of the monitored item can be recorded. To stop

recording, touch “STOP”.

Display Item List

PKIB6096E

ALL SIGNALS Monitors all the signals.

SELECTION FROM MENU Selects and monitors individual signal.

Monitor item Contents

TURN SIGNAL R “ON/OFF”Displays status (turn signal switch right position: ON/other: OFF) of turn RH switch judged from the

turn signal switch signal.

TURN SIGNAL L “ON/OFF”Displays status (turn signal switch left position: ON/other: OFF) of turn LH switch judged from the

turn signal switch signal.

HI BEAM SW “ON/OFF”Displays status (lighting switch high beam position: ON/other: OFF) of high beam switch judged

from the lighting switch signal.

HEAD LAMP SW 1 “ON/OFF”Displays status (lighting switch 2ND position: ON/other: OFF) of headlamp 1 switch judged from

the lighting switch signal.

HEAD LAMP SW 2 “ON/OFF”Displays status (lighting switch 2ND position: ON/other: OFF) of headlamp 2 switch judged from

the lighting switch signal.

LIGHT SW 1ST “ON/OFF”Displays status (lighting switch 1ST or 2ND position: ON/other: OFF) of lighting switch 1ST position

switch judged from the lighting switch signal.

PASSING SW “ON/OFF”Displays status (lighting switch passing position: ON/other: OFF) of passing switch judged from the

lighting switch signal.

FR FOG SW “ON/OFF”Displays status (lighting switch front fog lamp ON position: ON/others: OFF) of front fog lamp

switch judged from the lighting switch signal.

RR FOG SW “ON/OFF”Displays status (rear fog lamp switch position: ON/other: OFF) of rear fog switch judged from the

lighting switch signal.

FR WIPER HI “ON/OFF”Displays status (front wiper switch high position: ON/other: OFF) of front wiper high switch judged

from the wiper switch signal.

FR WIPER LOW “ON/OFF”Displays status (front wiper switch low position: ON/other: OFF) of front wiper low switch judged

from the wiper switch signal.

FR WIPER INT “ON/OFF”Displays status (front wiper switch intermittent position: ON/other: OFF) of front wiper intermittent

switch judged from the wiper switch signal.

FR WASHER SW “ON/OFF”Displays status (front washer switch ON position: ON/other: OFF) of front washer switch judged

from the wiper switch signal.

Page 2201 of 3171

LT-118

COMBINATION SWITCH

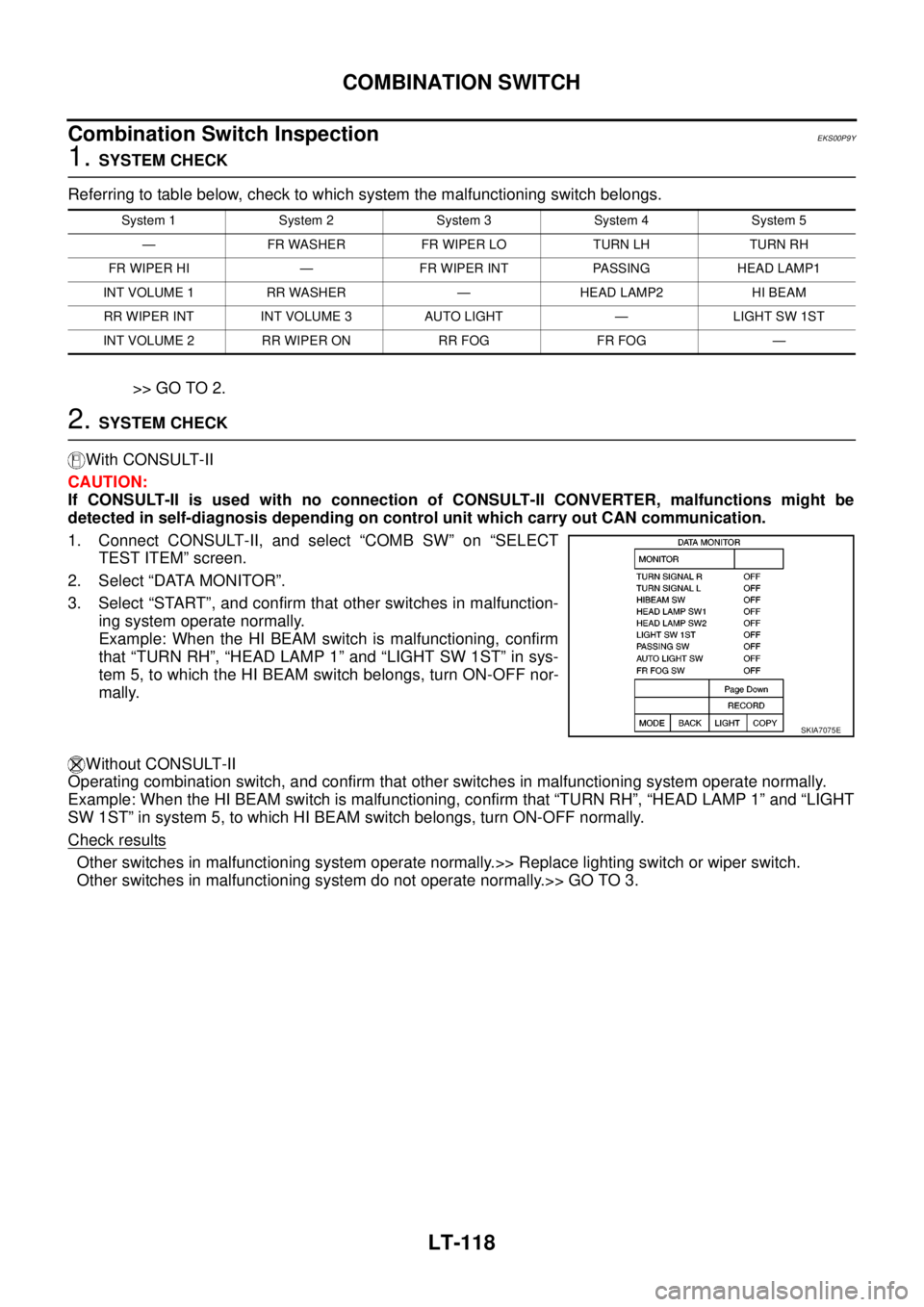

Combination Switch Inspection

EKS00P9Y

1.SYSTEM CHECK

Referring to table below, check to which system the malfunctioning switch belongs.

>> GO TO 2.

2.SYSTEM CHECK

With CONSULT-II

CAUTION:

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunctions might be

detected in self-diagnosis depending on control unit which carry out CAN communication.

1. Connect CONSULT-II, and select “COMB SW” on “SELECT

TEST ITEM” screen.

2. Select “DATA MONITOR”.

3. Select “START”, and confirm that other switches in malfunction-

ing system operate normally.

Example: When the HI BEAM switch is malfunctioning, confirm

that “TURN RH”, “HEAD LAMP 1” and “LIGHT SW 1ST” in sys-

tem 5, to which the HI BEAM switch belongs, turn ON-OFF nor-

mally.

Without CONSULT-II

Operating combination switch, and confirm that other switches in malfunctioning system operate normally.

Example: When the HI BEAM switch is malfunctioning, confirm that “TURN RH”, “HEAD LAMP 1” and “LIGHT

SW 1ST” in system 5, to which HI BEAM switch belongs, turn ON-OFF normally.

Check results

Other switches in malfunctioning system operate normally.>> Replace lighting switch or wiper switch.

Other switches in malfunctioning system do not operate normally.>> GO TO 3.

System 1 System 2 System 3 System 4 System 5

— FR WASHER FR WIPER LO TURN LH TURN RH

FR WIPER HI — FR WIPER INT PASSING HEAD LAMP1

INT VOLUME 1 RR WASHER — HEAD LAMP2 HI BEAM

RR WIPER INT INT VOLUME 3 AUTO LIGHT — LIGHT SW 1ST

INT VOLUME 2 RR WIPER ON RR FOG FR FOG —

SKIA7075E

Page 2203 of 3171

LT-120

COMBINATION SWITCH

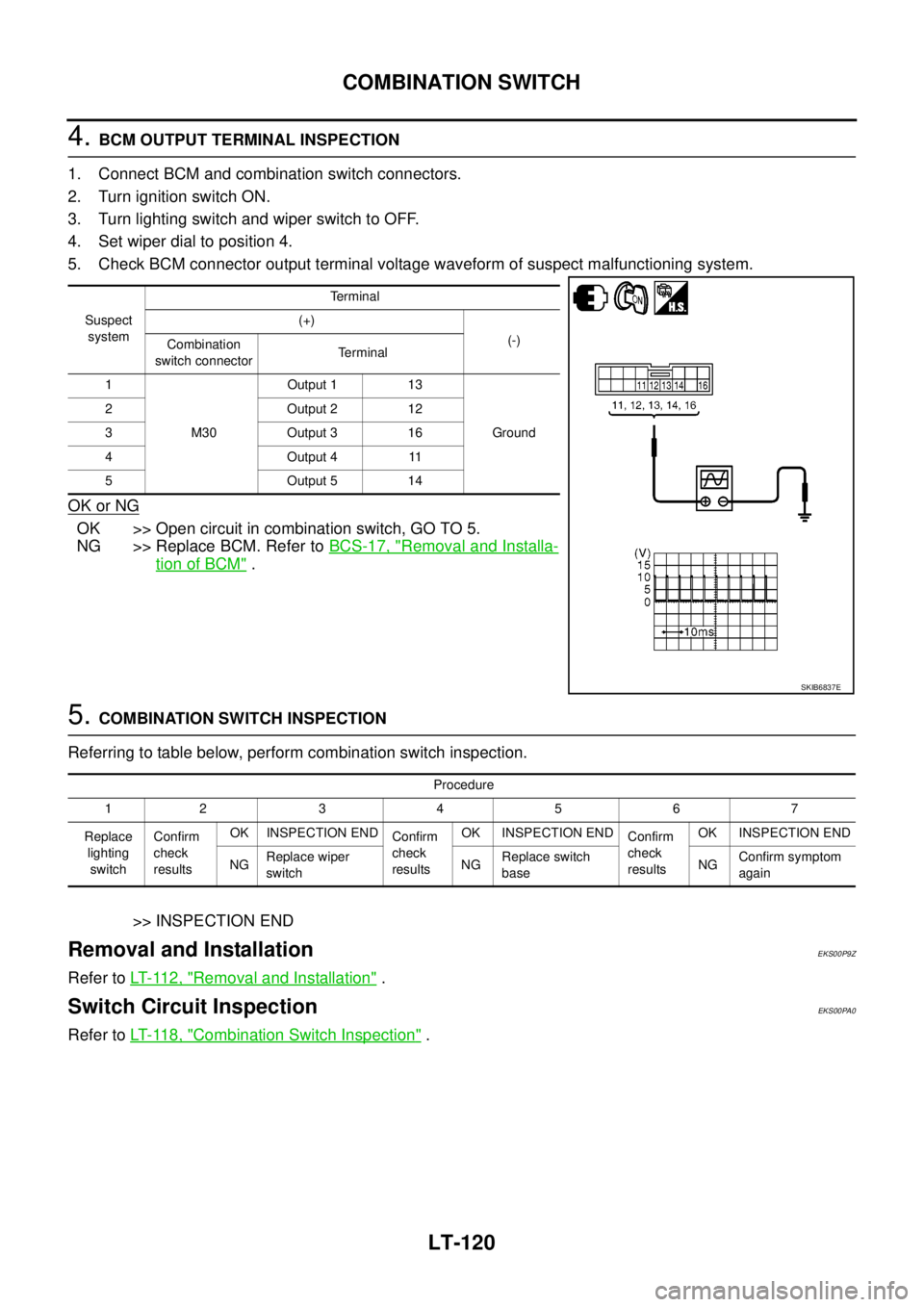

4.BCM OUTPUT TERMINAL INSPECTION

1. Connect BCM and combination switch connectors.

2. Turn ignition switch ON.

3. Turn lighting switch and wiper switch to OFF.

4. Set wiper dial to position 4.

5. Check BCM connector output terminal voltage waveform of suspect malfunctioning system.

OK or NG

OK >> Open circuit in combination switch, GO TO 5.

NG >> Replace BCM. Refer toBCS-17, "

Removal and Installa-

tion of BCM".

5.COMBINATION SWITCH INSPECTION

Referring to table below, perform combination switch inspection.

>> INSPECTION END

Removal and InstallationEKS00P9Z

Refer toLT- 11 2 , "Removal and Installation".

Switch Circuit InspectionEKS00PA0

Refer toLT- 11 8 , "Combination Switch Inspection".

Suspect

systemTerminal

(+)

(-)

Combination

switch connectorTerminal

1

M30Output 1 13

Ground 2 Output 2 12

3 Output 3 16

4Output411

5 Output 5 14

SKIB6837E

Procedure

12 34567

Replace

lighting

switchConfirm

check

resultsOK INSPECTION END

Confirm

check

resultsOK INSPECTION END

Confirm

check

resultsOK INSPECTION END

NGReplace wiper

switchNGReplace switch

baseNGConfirm symptom

again

Page 2208 of 3171

PARKING, LICENSE PLATE AND TAIL LAMPS

LT-125

C

D

E

F

G

H

I

J

L

MA

B

LT

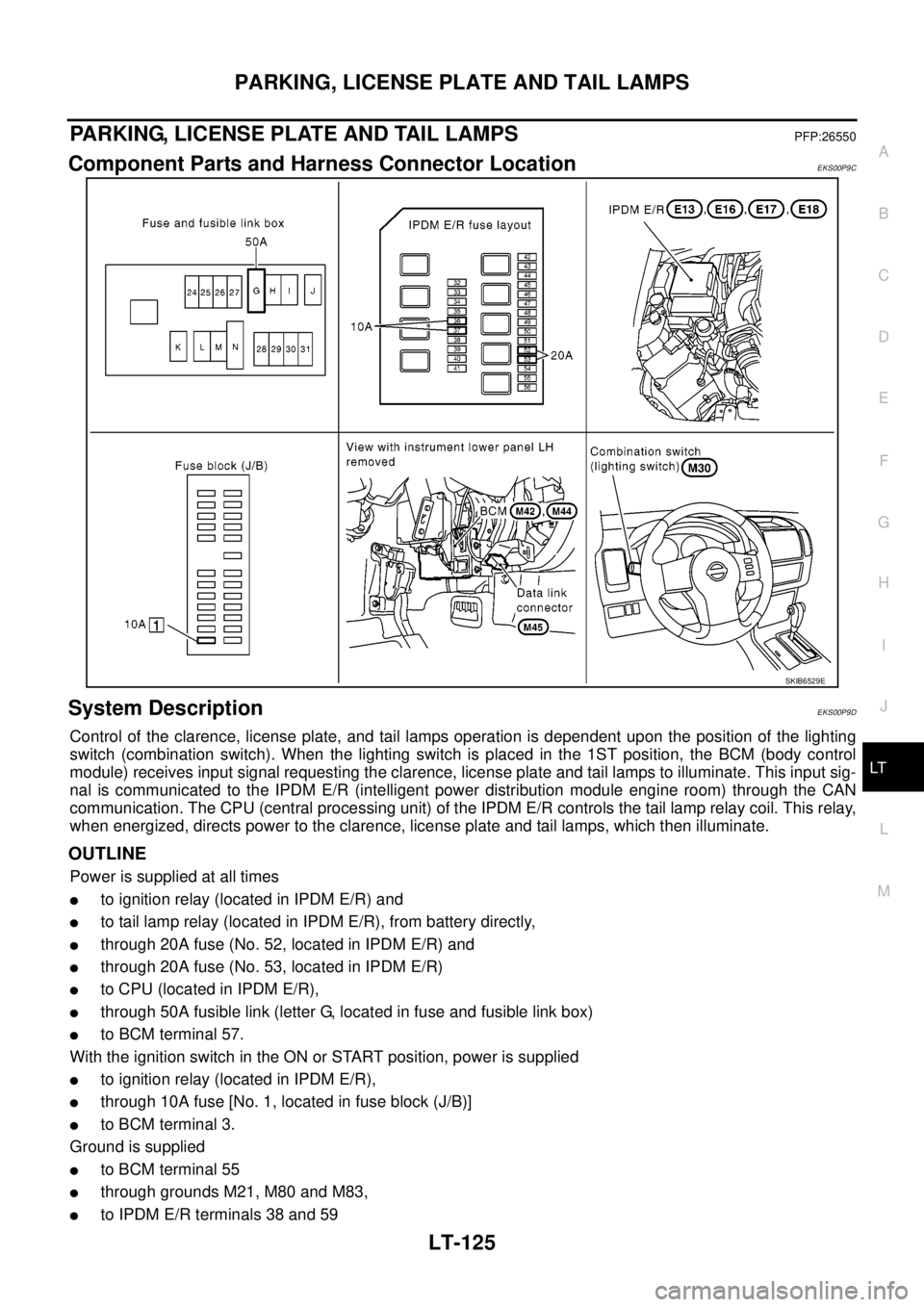

PARKING, LICENSE PLATE AND TAIL LAMPSPFP:26550

Component Parts and Harness Connector LocationEKS00P9C

System DescriptionEKS00P9D

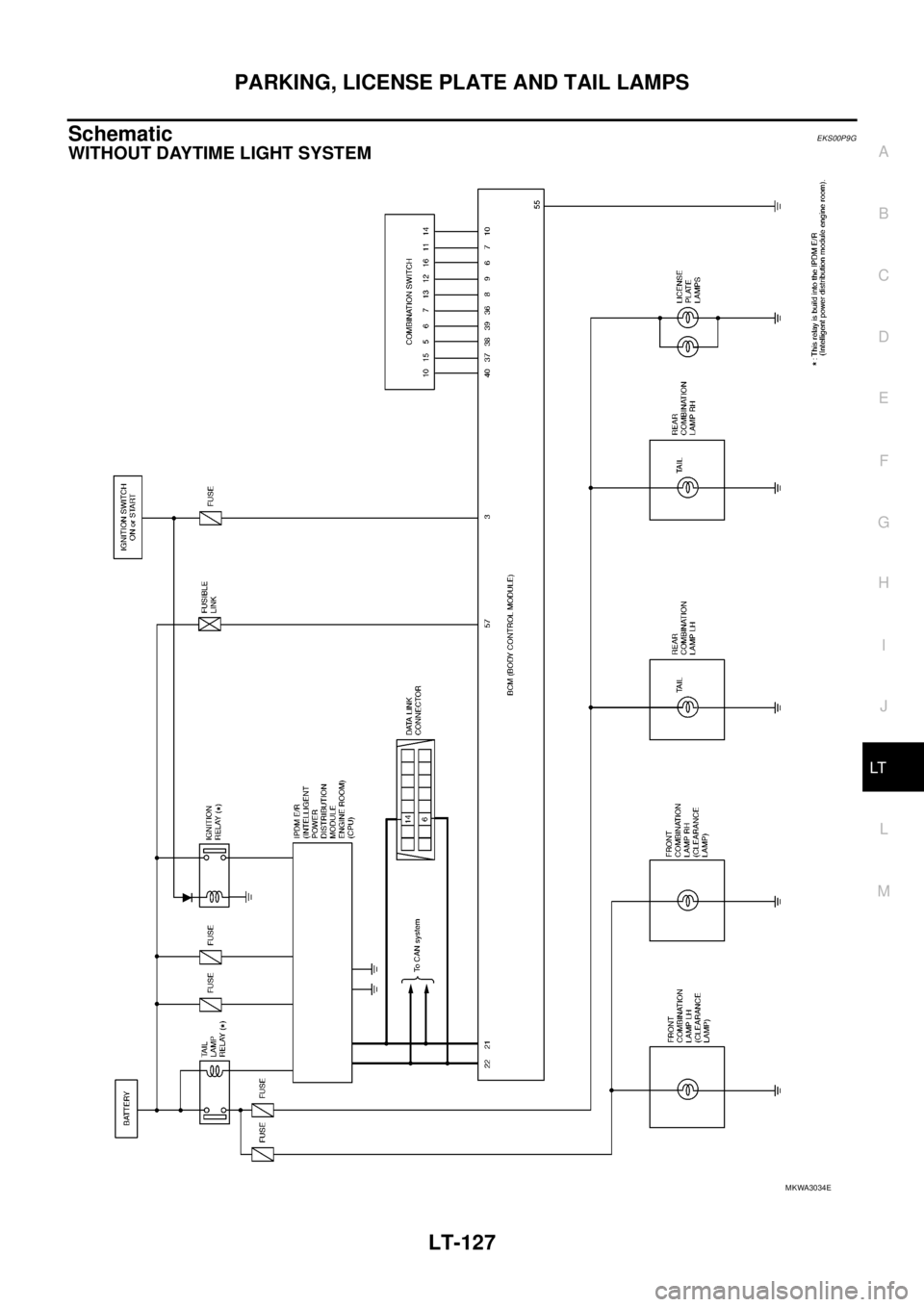

Control of the clarence, license plate, and tail lamps operation is dependent upon the position of the lighting

switch (combination switch). When the lighting switch is placed in the 1ST position, the BCM (body control

module) receives input signal requesting the clarence, license plate and tail lamps to illuminate. This input sig-

nal is communicated to the IPDM E/R (intelligent power distribution module engine room) through the CAN

communication. The CPU (central processing unit) of the IPDM E/R controls the tail lamp relay coil. This relay,

when energized, directs power to the clarence, license plate and tail lamps, which then illuminate.

OUTLINE

Power is supplied at all times

lto ignition relay (located in IPDM E/R) and

lto tail lamp relay (located in IPDM E/R), from battery directly,

lthrough 20A fuse (No. 52, located in IPDM E/R) and

lthrough 20A fuse (No. 53, located in IPDM E/R)

lto CPU (located in IPDM E/R),

lthrough 50A fusible link (letter G, located in fuse and fusible link box)

lto BCM terminal 57.

With the ignition switch in the ON or START position, power is supplied

lto ignition relay (located in IPDM E/R),

lthrough 10A fuse [No. 1, located in fuse block (J/B)]

lto BCM terminal 3.

Ground is supplied

lto BCM terminal 55

lthrough grounds M21, M80 and M83,

lto IPDM E/R terminals 38 and 59

SKIB6529E

Page 2209 of 3171

LT-126

PARKING, LICENSE PLATE AND TAIL LAMPS

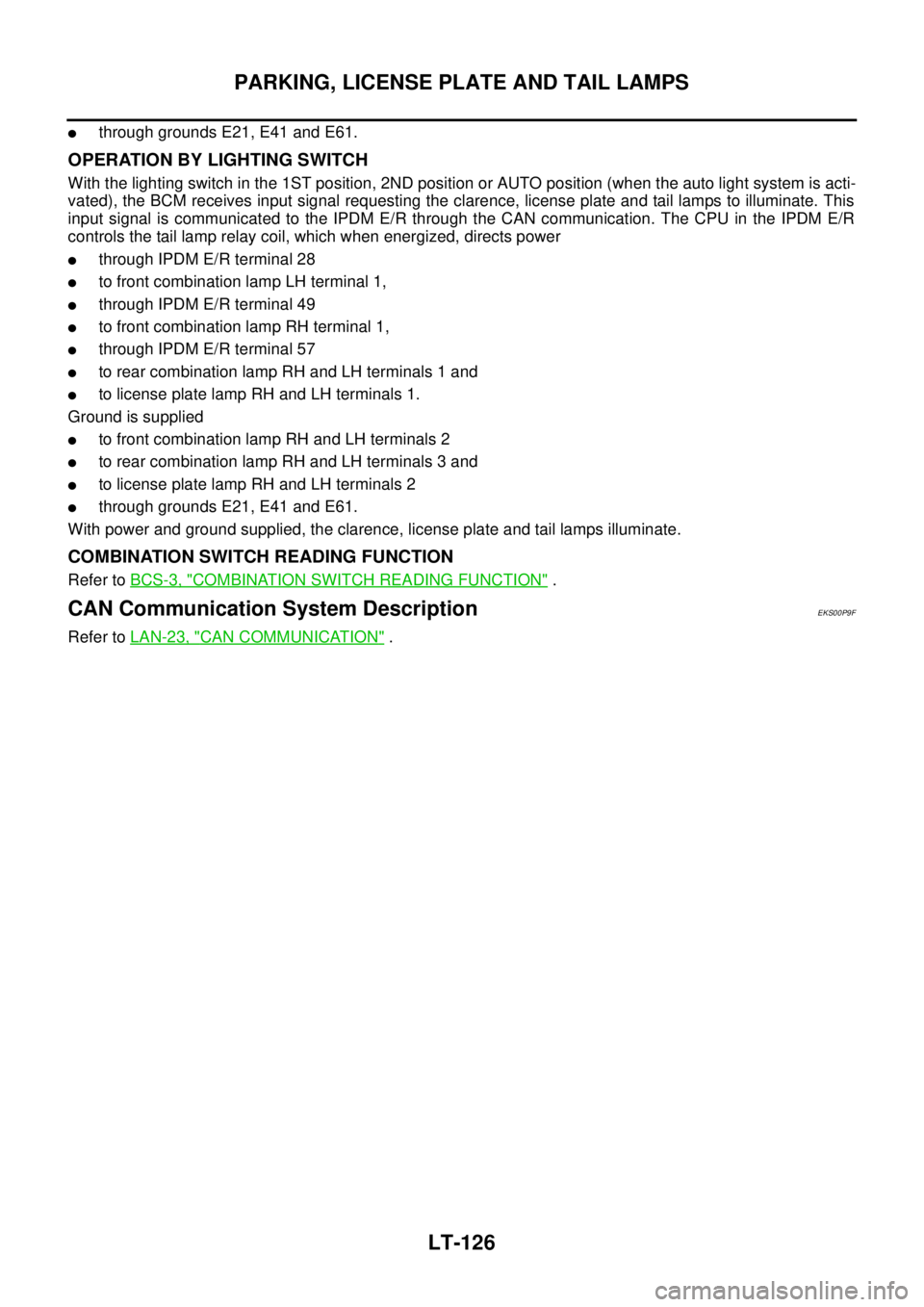

lthrough grounds E21, E41 and E61.

OPERATION BY LIGHTING SWITCH

With the lighting switch in the 1ST position, 2ND position or AUTO position (when the auto light system is acti-

vated), the BCM receives input signal requesting the clarence, license plate and tail lamps to illuminate. This

input signal is communicated to the IPDM E/R through the CAN communication. The CPU in the IPDM E/R

controls the tail lamp relay coil, which when energized, directs power

lthrough IPDM E/R terminal 28

lto front combination lamp LH terminal 1,

lthrough IPDM E/R terminal 49

lto front combination lamp RH terminal 1,

lthrough IPDM E/R terminal 57

lto rear combination lamp RH and LH terminals 1 and

lto license plate lamp RH and LH terminals 1.

Ground is supplied

lto front combination lamp RH and LH terminals 2

lto rear combination lamp RH and LH terminals 3 and

lto license plate lamp RH and LH terminals 2

lthrough grounds E21, E41 and E61.

With power and ground supplied, the clarence, license plate and tail lamps illuminate.

COMBINATION SWITCH READING FUNCTION

Refer toBCS-3, "COMBINATION SWITCH READING FUNCTION".

CAN Communication System DescriptionEKS00P9F

Refer toLAN-23, "CAN COMMUNICATION".

Page 2210 of 3171

PARKING, LICENSE PLATE AND TAIL LAMPS

LT-127

C

D

E

F

G

H

I

J

L

MA

B

LT

SchematicEKS00P9G

WITHOUT DAYTIME LIGHT SYSTEM

MKWA3034E

Page 2211 of 3171

LT-128

PARKING, LICENSE PLATE AND TAIL LAMPS

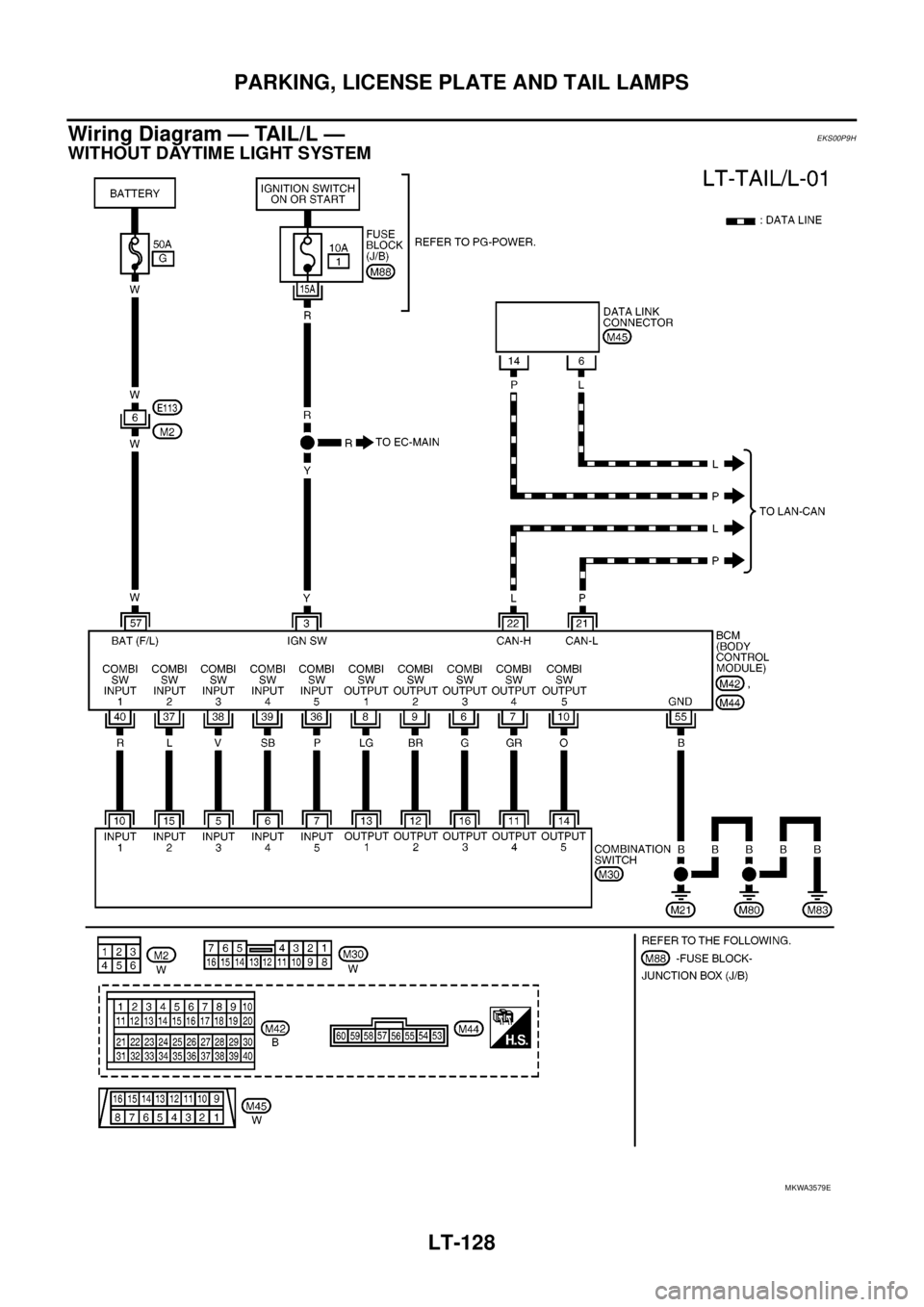

Wiring Diagram — TAIL/L —

EKS00P9H

WITHOUT DAYTIME LIGHT SYSTEM

MKWA3579E