NISSAN NAVARA 2005 Repair Workshop Manual

Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2801 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual RFD-98

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

REAR FINAL DRIVE ASSEMBLY

11. Apply gear oil to side bearings. Install differential case assembly

with side bearing outer races into axle housing.

12. App NISSAN NAVARA 2005 Repair Workshop Manual RFD-98

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

REAR FINAL DRIVE ASSEMBLY

11. Apply gear oil to side bearings. Install differential case assembly

with side bearing outer races into axle housing.

12. App](/img/5/57362/w960_57362-2800.png)

RFD-98

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

REAR FINAL DRIVE ASSEMBLY

11. Apply gear oil to side bearings. Install differential case assembly

with side bearing outer races into axle housing.

12. Apply multi-purpose grease to sensor connector.

CAUTION:

Do not reuse sensor connector.

13. Connect differential lock solenoid harness and sensor connec-

tor. Then install it to axle housing, tighten to the specified torque.

Refer toRFD-82, "

COMPONENTS".

14. Align paint matching mark on side bearing cap with that on axle

housing and install side bearing caps on axle housing.

CAUTION:

Do not tighten at this point. This allows further tightening of

side bearing adjusters.

15. Tighten each side bearing adjusters using Tool.

16. Adjust backlash of drive gear and drive pinion. Refer toRFD-84,

"Backlash".

17. Check tooth contact. Refer toRFD-83, "

To o t h C o n t a c t".

18. Check total preload. Refer toRFD-83, "

Total Preload Torque".

19. Apply sealant to mating surface of carrier cover. Refer toRFD-

82, "COMPONENTS".

CAUTION:

Remove old sealant adhering to mating surfaces. Also

remove any moisture, oil, or foreign material adhering to

application and mating surfaces.

SDIA2588E

SDIA3456E

SDIA2632E

Tool number : KV38108800

PDIA1044E

PDIA1061E

Page 2802 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual REAR FINAL DRIVE ASSEMBLY

RFD-99

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

20. Install carrier cover and bracket on axle housing. Then tighten

carrier cover bolts to the specif NISSAN NAVARA 2005 Repair Workshop Manual REAR FINAL DRIVE ASSEMBLY

RFD-99

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

20. Install carrier cover and bracket on axle housing. Then tighten

carrier cover bolts to the specif](/img/5/57362/w960_57362-2801.png)

REAR FINAL DRIVE ASSEMBLY

RFD-99

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

20. Install carrier cover and bracket on axle housing. Then tighten

carrier cover bolts to the specified torque. Refer toRFD-82,

"COMPONENTS".

PDIA1066E

Page 2803 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual RFD-100

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

PFP:00030

General SpecificationsEDS003BH

Inspection and AdjustmentEDS003BI

PR NISSAN NAVARA 2005 Repair Workshop Manual RFD-100

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

PFP:00030

General SpecificationsEDS003BH

Inspection and AdjustmentEDS003BI

PR](/img/5/57362/w960_57362-2802.png)

RFD-100

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

PFP:00030

General SpecificationsEDS003BH

Inspection and AdjustmentEDS003BI

PRELOAD TORQUE

Unit: N·m (kg-m, in-lb)

BACKLASH

Unit: mm (in)

COMPANION FLANGE RUNOUT

Unit: mm (in) Applied modelYD25DDTi

4WD

5A/T 6M/T

Final drive modelM226

Gear ratio 3.538 3.692

Number of pinion gears 2

Number of teeth (Drive gear / drive pinion) 46/13 48/13

Oil capacity (Approx.)

(lmp pt)2.01 (3-1/2)

Drive pinion adjustment spacer type Collapsible

ItemStandard

Gear ratio: 3.538 type Gear ratio: 3.692 type

Total preload 2.34 - 4.34 (0.24 - 0.44, 21 - 38) 2.32 - 4.34 (0.24 - 0.44, 21 - 38)

Pinion bearing preload 1.7 - 3.1 (0.18 - 0.31, 15 - 27)

Item Standard

Drive gear to drive pinion gear 0.08 - 0.13 (0.0031 - 0.0051)

Item Runout limit

Companion flange face 0.10 (0.0039) or less

Inner side of companion flange 0.13 (0.0051) or less

Page 2804 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual SERVICE DATA AND SPECIFICATIONS (SDS)

RFD-101

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

SELECTIVE PARTS

Drive Pinion Height Adjusting Washer

Unit: mm (in)

*Always check with th NISSAN NAVARA 2005 Repair Workshop Manual SERVICE DATA AND SPECIFICATIONS (SDS)

RFD-101

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

SELECTIVE PARTS

Drive Pinion Height Adjusting Washer

Unit: mm (in)

*Always check with th](/img/5/57362/w960_57362-2803.png)

SERVICE DATA AND SPECIFICATIONS (SDS)

RFD-101

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

SELECTIVE PARTS

Drive Pinion Height Adjusting Washer

Unit: mm (in)

*Always check with the Parts Department for the latest parts information.Thickness Package part number*

0.076 (0.030)

0.079 (0.031)

0.081 (0.032)

0.084 (0.033)

0.086 (0.034)38151 8S101

0.089 (0.035)

0.091 (0.036)

0.094 (0.037)

0.097 (0.038)

0.099 (0.039)38151 8S102

0.102 (0.040)

0.104 (0.041)

0.107 (0.042)

0.109 (0.043)

0.112 (0.044)38151 8S103

0.114 (0.045)

0.117 (0.046)

0.119 (0.047)

0.122 (0.048)

0.124 (0.049)38151 8S104

0.127 (0.050)

0.130 (0.051)

0.132 (0.052)

0.135 (0.053)

0.137 (0.054)38151 8S105

Page 2805 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual RFD-102

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

SERVICE DATA AND SPECIFICATIONS (SDS) NISSAN NAVARA 2005 Repair Workshop Manual RFD-102

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

SERVICE DATA AND SPECIFICATIONS (SDS)](/img/5/57362/w960_57362-2804.png)

RFD-102

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

SERVICE DATA AND SPECIFICATIONS (SDS)

Page 2806 of 3171

RSU-1

REAR SUSPENSION

E SUSPENSION

CONTENTS

C

D

F

G

H

I

J

K

L

M

SECTIONRSU

A

B

RSU

REAR SUSPENSION

PRECAUTIONS .......................................................... 2

Precautions .............................................................. 2

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 3

NVH Troubleshooting Chart ..................................... 3

REAR SUSPENSION ASSEMBLY ............................. 4

Components ............................................................. 4

On-Vehicle Inspection and Service .......................... 5

SHOCK ABSORBER .................................................. 6

Removal and Installation .......................................... 6

REMOVAL ............................................................. 6

INSPECTION AFTER REMOVAL ......................... 6

INSTALLATION ..................................................... 6LEAF SPRING ............................................................ 7

Removal and Installation .......................................... 7

REMOVAL ............................................................. 8

INSPECTION AFTER REMOVAL ......................... 9

INSTALLATION ..................................................... 9

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 11

General Specifications (Rear) ................................ 11

Wheelarch Height (Unladen*

1) .............................. 11

Page 2807 of 3171

RSU-2

PRECAUTIONS

PRECAUTIONS

PFP:00001

PrecautionsEES002JD

lWhen installing rubber parts, final tightening must be carried out under unladen condition* with

tires on ground.

*Fuel, radiator coolant, and engine oil are full. Spare tire, jack, hand tools, and mats are in their

designated positions. Oil will shorten the life of rubber bushings, so wipe off any spilled oil imme-

diately.

lLock nuts are not reusable. Always use new lock nuts for installation. New lock nuts are pre-oiled,

do not apply any additional lubrication.

Page 2808 of 3171

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

RSU-3

C

D

F

G

H

I

J

K

L

MA

B

RSU

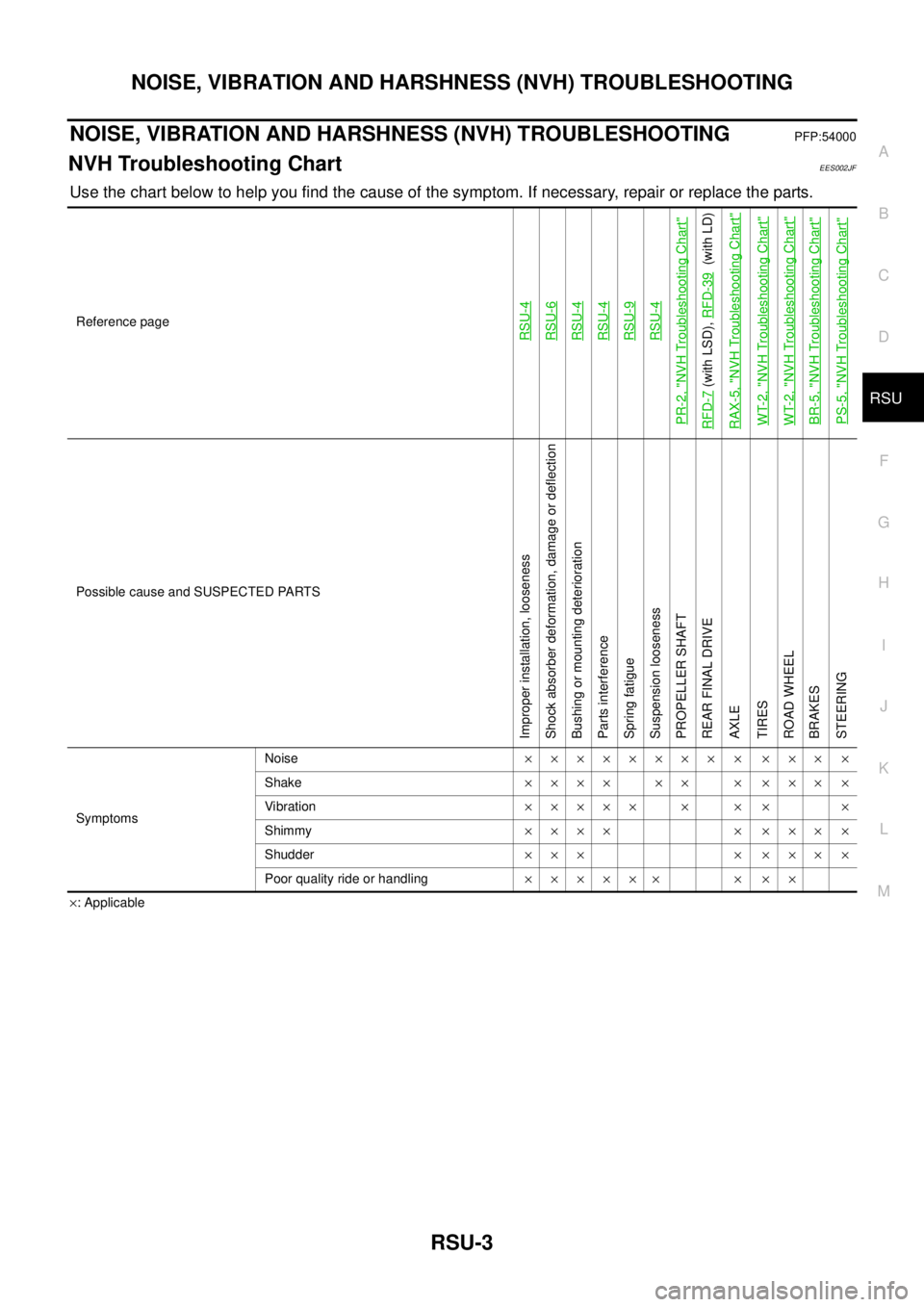

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGPFP:54000

NVH Troubleshooting ChartEES002JF

Use the chart below to help you find the cause of the symptom. If necessary, repair or replace the parts.

´: Applicable Reference page

RSU-4RSU-6RSU-4RSU-4RSU-9RSU-4

PR-2, "

NVH Troubleshooting Chart

"

RFD-7

(with LSD),RFD-39

(with LD)

RAX-5, "

NVH Troubleshooting Chart

"

WT-2, "

NVH Troubleshooting Chart

"

WT-2, "

NVH Troubleshooting Chart

"

BR-5, "

NVH Troubleshooting Chart

"

PS-5, "

NVH Troubleshooting Chart

"

Possible cause and SUSPECTED PARTS

Improper installation, looseness

Shock absorber deformation, damage or deflection

Bushing or mounting deterioration

Parts interference

Spring fatigue

Suspension looseness

PROPELLER SHAFT

REAR FINAL DRIVE

AXLE

TIRES

ROAD WHEEL

BRAKES

STEERING

SymptomsNoise´´´´´´´´ ´ ´´´ ´

Shake´´´´ ´´ ´ ´´´ ´

Vibration´´´´´ ´ ´ ´ ´

Shimmy´´´´ ´ ´´´ ´

Shudder´´´ ´ ´´´ ´

Poor quality ride or handling´´´´´´ ´ ´´

Page 2809 of 3171

RSU-4

REAR SUSPENSION ASSEMBLY

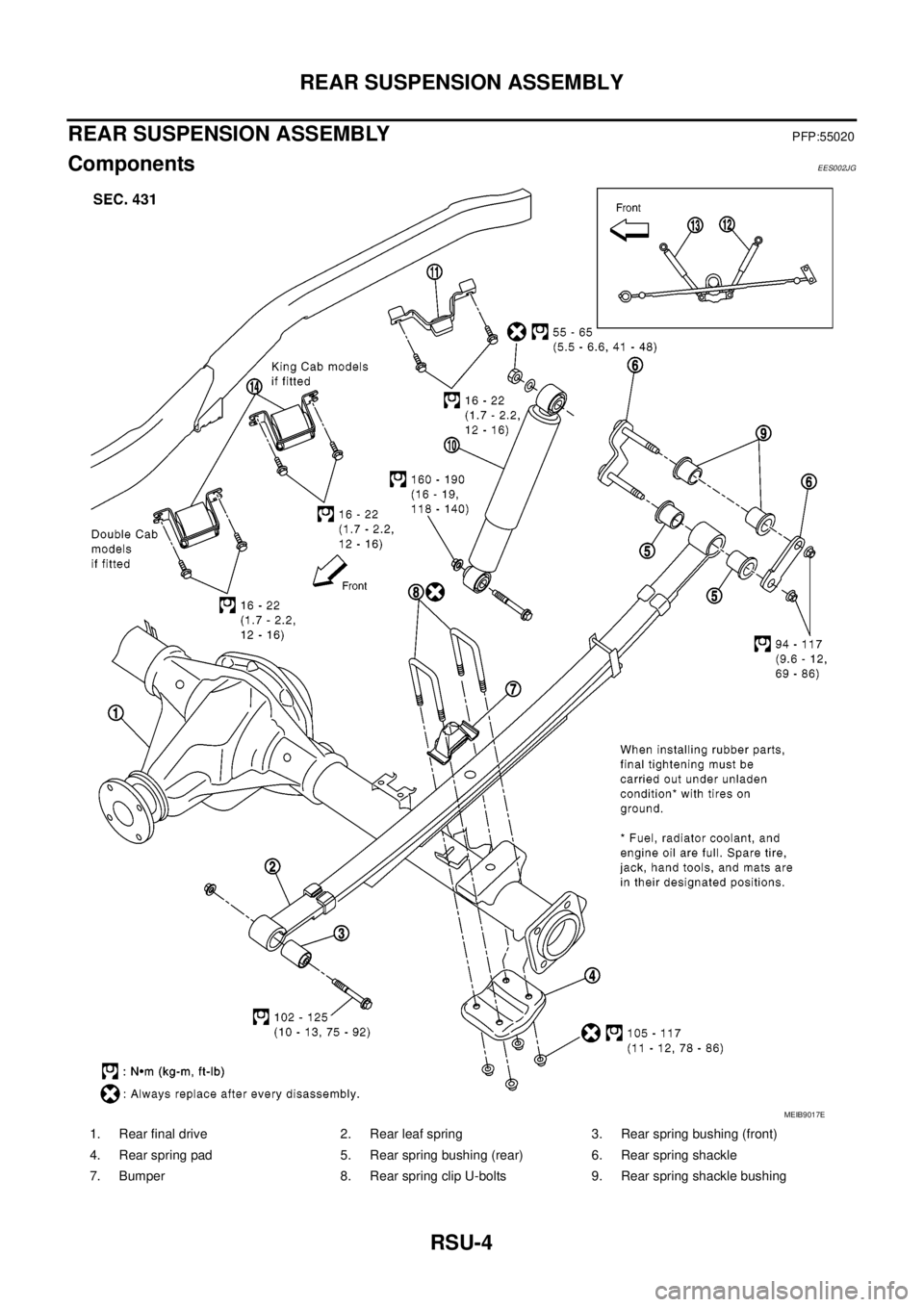

REAR SUSPENSION ASSEMBLY

PFP:55020

ComponentsEES002JG

1. Rear final drive 2. Rear leaf spring 3. Rear spring bushing (front)

4. Rear spring pad 5. Rear spring bushing (rear) 6. Rear spring shackle

7. Bumper 8. Rear spring clip U-bolts 9. Rear spring shackle bushing

MEIB9017E

Page 2810 of 3171

REAR SUSPENSION ASSEMBLY

RSU-5

C

D

F

G

H

I

J

K

L

MA

B

RSU

CAUTION:

When installing the components with rubber bushings, the final tightening of the nuts and bolts must

be done with the vehicle in an unladen condition (the fuel, engine coolant, and engine oil full; the

spare tire, jack, hand tools and mats in their designated positions) with the tires on the ground.

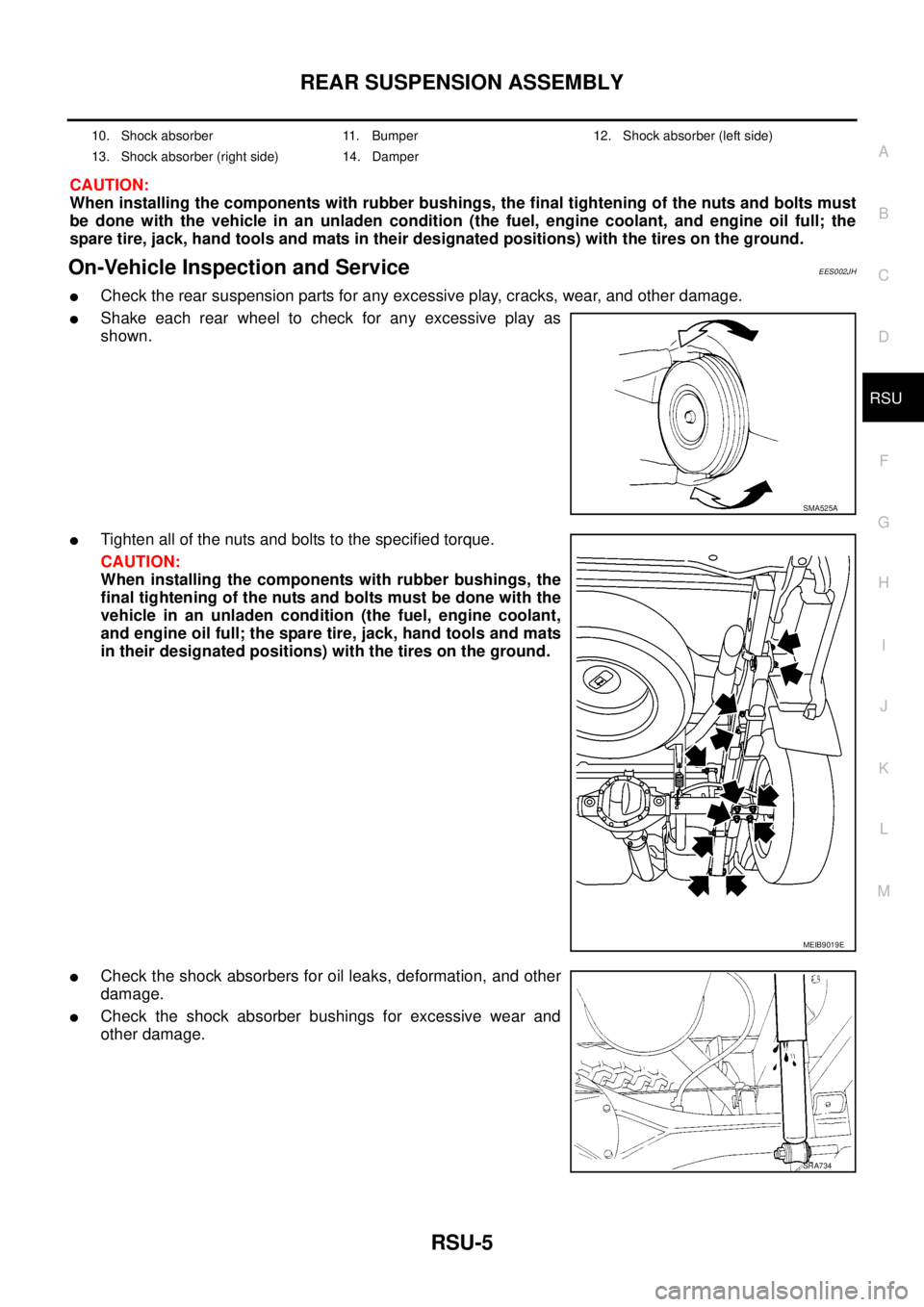

On-Vehicle Inspection and ServiceEES002JH

lCheck the rear suspension parts for any excessive play, cracks, wear, and other damage.

lShake each rear wheel to check for any excessive play as

shown.

lTighten all of the nuts and bolts to the specified torque.

CAUTION:

When installing the components with rubber bushings, the

final tightening of the nuts and bolts must be done with the

vehicle in an unladen condition (the fuel, engine coolant,

and engine oil full; the spare tire, jack, hand tools and mats

in their designated positions) with the tires on the ground.

lCheck the shock absorbers for oil leaks, deformation, and other

damage.

lCheck the shock absorber bushings for excessive wear and

other damage.

10. Shock absorber 11. Bumper 12. Shock absorber (left side)

13. Shock absorber (right side) 14. Damper

SMA525A

MEIB9019E

SRA734