belt NISSAN NAVARA 2005 Repair Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 789 of 3171

PRECAUTIONS

BR-3

C

D

E

G

H

I

J

K

L

MA

B

BR

PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EFS006DL

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions for Brake SystemEFS005SD

lClean dust on front brake and rear brake with a vacuum dust collector. Do not blow with compressed air.

lRecommended fluid is brake fluid “DOT 3” or “DOT 4”.

lNever reuse drained brake fluid.

lBe careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is splashed

on painted areas, wash it away with water immediately.

lTo clean or wash all parts of master cylinder, disc brake caliper, wheel cylinder, use new brake fluid.

lNever use mineral oils such as gasoline or kerosene. They will ruin rubber parts of the hydraulic system.

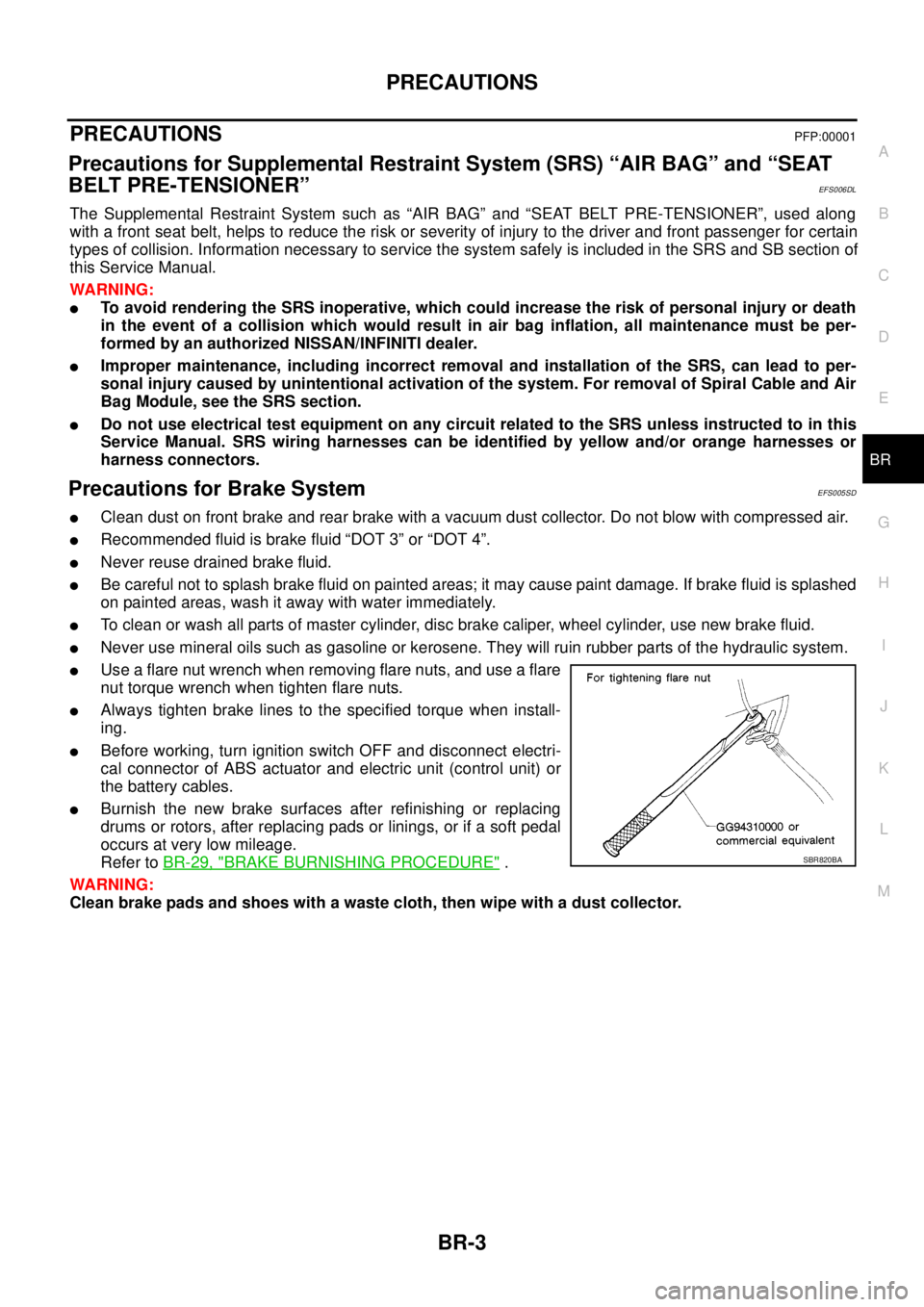

lUse a flare nut wrench when removing flare nuts, and use a flare

nut torque wrench when tighten flare nuts.

lAlways tighten brake lines to the specified torque when install-

ing.

lBefore working, turn ignition switch OFF and disconnect electri-

cal connector of ABS actuator and electric unit (control unit) or

the battery cables.

lBurnish the new brake surfaces after refinishing or replacing

drums or rotors, after replacing pads or linings, or if a soft pedal

occurs at very low mileage.

Refer toBR-29, "

BRAKE BURNISHING PROCEDURE".

WARNING:

Clean brake pads and shoes with a waste cloth, then wipe with a dust collector.SBR820BA

Page 823 of 3171

BRC-1

BRAKE CONTROL SYSTEM

F BRAKES

CONTENTS

C

D

E

G

H

I

J

K

L

M

SECTIONBRC

A

B

BRC

BRAKE CONTROL SYSTEM

ABS

PRECAUTIONS .......................................................... 3

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 3

Precautions for Brake System .................................. 3

Precautions for Brake Control .................................. 3

PREPARATION ........................................................... 4

Special Service Tools (SST) ..................................... 4

SYSTEM DESCRIPTION ............................................ 5

System Diagram ....................................................... 5

Functions .................................................................. 5

Operation That Is Not “System Error” ...................... 5

Fail-Safe Function .................................................... 5

ABS, EBD SYSTEM .............................................. 5

Hydraulic Circuit Diagram ........................................ 6

CAN COMMUNICATION ............................................ 7

System Description .................................................. 7

TROUBLE DIAGNOSIS .............................................. 8

How to Perform Trouble Diagnosis for Quick and

Accurate Repair ....................................................... 8

INTRODUCTION ................................................... 8

DIAGNOSIS FLOWCHART .................................. 9

ASKING COMPLAINTS ...................................... 10

EXAMPLE OF DIAGNOSIS SHEET ................... 10

Component Parts Location ...................................... 11

Schematic — ABS — ............................................. 12

Wiring Diagram — ABS — ..................................... 13

CONSULT- II Functions .......................................... 17

CONSULT-II MAIN FUNCTION ........................... 17

CONSULT-II BASIC OPERATION PROCEDURE

... 17

Self-Diagnosis ........................................................ 18

OPERATION PROCEDURE ............................... 18

ERASE MEMORY ............................................... 18

DISPLAY ITEM LIST ........................................... 18

Data Monitor ........................................................... 20

OPERATION PROCEDURE ............................... 20

DISPLAY ITEM LIST ........................................... 20Active Test .............................................................. 21

OPERATION PROCEDURE ................................ 21

SOLENOID VALVE .............................................. 22

ABS MOTOR ....................................................... 22

For Fast and Accurate Diagnosis ........................... 23

PRECAUTIONS FOR DIAGNOSIS ..................... 23

Basic Inspection ..................................................... 23

BASIC INSPECTION 1 BRAKE FLUID LEVEL,

LEAKS, AND BRAKE PADS ................................ 23

BASIC INSPECTION 2 POWER SYSTEM TER-

MINAL LOOSENESS AND BATTERY INSPEC-

TION .................................................................... 23

BASIC INSPECTION 3 ABS WARNING LAMP

AND BRAKE WARNING LAMP INSPECTION .... 24

Inspection 1 Wheel Sensor System ........................ 24

Inspection 2 ABS Actuator and Electric Unit (Control

Unit) ........................................................................ 26

Inspection 3 ABS Actuator Relay or ABS Motor

Relay Circuit ........................................................... 26

Inspection 4 CAN Communication Circuit .............. 28

Inspection 5 ABS Actuator and Electric Unit (Control

Unit) Power Supply and Ground Circuit .................. 28

Inspection 6 Brake Fluid Level Switch Circuit ......... 30

Inspection 7 Parking Brake Switch Circuit .............. 32

Inspection 8 Warning lamp system ......................... 33

Symptom 1: Excessive ABS Function Operation

Frequency ............................................................... 33

Symptom 2: Unexpected Pedal Reaction ............... 34

Symptom 3: The Stopping Distance Is Long .......... 34

Symptom 4: ABS Function Does Not Operate ....... 35

Symptom 5: Pedal Vibration or ABS Operation

Sound Occurs ......................................................... 35

Symptom 6: ABS Warning Lamp Indication Is Not

Normal .................................................................... 35

WHEEL SENSORS ................................................... 37

Removal and Installation ........................................ 37

REMOVAL ........................................................... 38

INSTALLATION ................................................... 38

Page 825 of 3171

![NISSAN NAVARA 2005 Repair Owners Manual PRECAUTIONS

BRC-3

[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

[ABS]PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EFS006DM

The Supplement NISSAN NAVARA 2005 Repair Owners Manual PRECAUTIONS

BRC-3

[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

[ABS]PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EFS006DM

The Supplement](/img/5/57362/w960_57362-824.png)

PRECAUTIONS

BRC-3

[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

[ABS]PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EFS006DM

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions for Brake SystemEFS005TG

lRecommended fluid is brake fluid “DOT 3” or “DOT 4”.

lNever reuse drained brake fluid.

lBe careful not to splash brake fluid on painted areas.If brake fluid is splashed, wipe it off and flush area

with water immediately.

lNever use mineral oils such as gasoline or kerosene. They will ruin rubber parts of the hydraulic system.

lUse flare nut wrench when removing flare nuts, and use a flare

nut torque wrench when tighten flare nuts.

lBrake system is an important safety part.If a brake fluid leak is

detected, always disassemble the affected part.If a malfunction

is detected, replace part with new one.

lBefore working, turn ignition switch OFF and disconnect con-

nector of ABS actuator and electric unit (control unit) or the bat-

tery cables.

lWhen installing brake tube and hose, be sure to torque.

WARNING:

Clean brake pads and shoes with a waster cloth, then wipe with

a dust collector.

Precautions for Brake ControlEFS005TH

lJust after starting vehicle after ignition switch ON, brake pedal may vibrate or motor operating noise may

be heard from engine room. This is a normal status of operation check.

lStopping distance may be longer than that of vehicles without ABS when vehicle drives on rough, gravel,

or snow-covered (fresh, deep snow) roads.

lWhen an error is indicated by ABS or another warning lamp, collect all necessary information from cus-

tomer (what symptoms are present under what conditions) and check for simple causes before starting

diagnostic servicing. Besides electrical system inspection, check brake booster operation, brake fluid

level, and fluid leaks.

lIf tyre size and type are used in an improper combination, or brake pads are not Genuine NISSAN parts,

stopping distance or steering stability may deteriorate.

lIf there is a radio, antenna, or antenna lead-in wire (including wiring) near control module, ABS function

may have a malfunction or error.

lIf aftermarket parts (car stereo, CD player, etc.) have been installed, check for incidents such as harness

pinches, open circuits, and improper wiring.

SBR820BA

Page 888 of 3171

CO-4

OVERHEATING CAUSE ANALYSIS

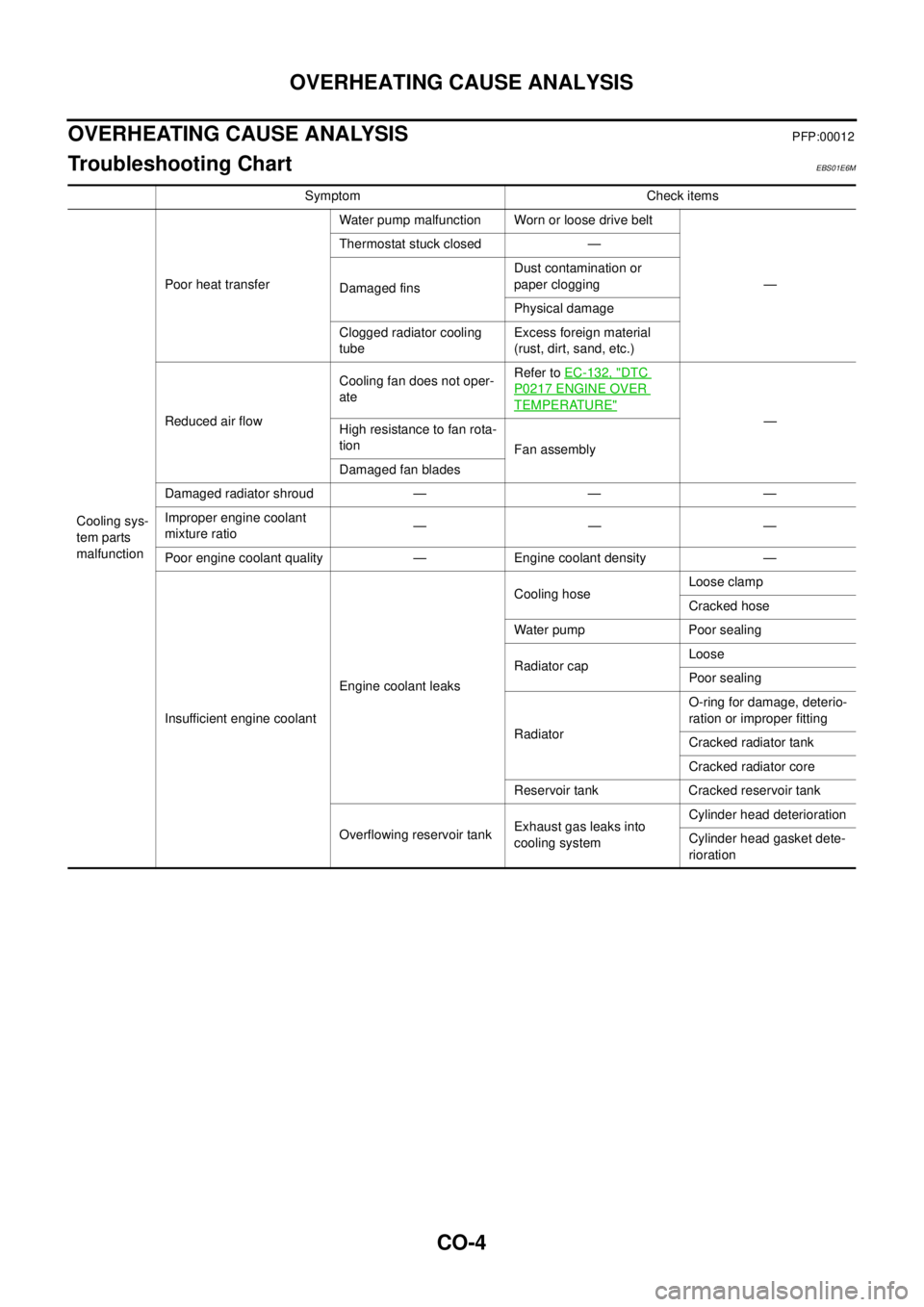

OVERHEATING CAUSE ANALYSIS

PFP:00012

Troubleshooting ChartEBS01E6M

Symptom Check items

Cooling sys-

tem parts

malfunctionPoor heat transferWater pump malfunction Worn or loose drive belt

— Thermostat stuck closed —

Damaged finsDust contamination or

paper clogging

Physical damage

Clogged radiator cooling

tubeExcess foreign material

(rust, dirt, sand, etc.)

Reduced air flowCooling fan does not oper-

ateRefer toEC-132, "

DTC

P0217 ENGINE OVER

TEMPERATURE"

—

Highresistancetofanrota-

tion

Fan assembly

Damaged fan blades

Damaged radiator shroud — — —

Improper engine coolant

mixture ratio—— —

Poor engine coolant quality — Engine coolant density —

Insufficient engine coolantEngine coolant leaksCooling hoseLoose clamp

Cracked hose

Water pump Poor sealing

Radiator capLoose

Poor sealing

RadiatorO-ring for damage, deterio-

ration or improper fitting

Cracked radiator tank

Cracked radiator core

Reservoir tank Cracked reservoir tank

Overflowing reservoir tankExhaust gas leaks into

cooling systemCylinder head deterioration

Cylinder head gasket dete-

rioration

Page 891 of 3171

ENGINE COOLANT

CO-7

C

D

E

F

G

H

I

J

K

L

MA

CO

ENGINE COOLANTPFP:KQ100

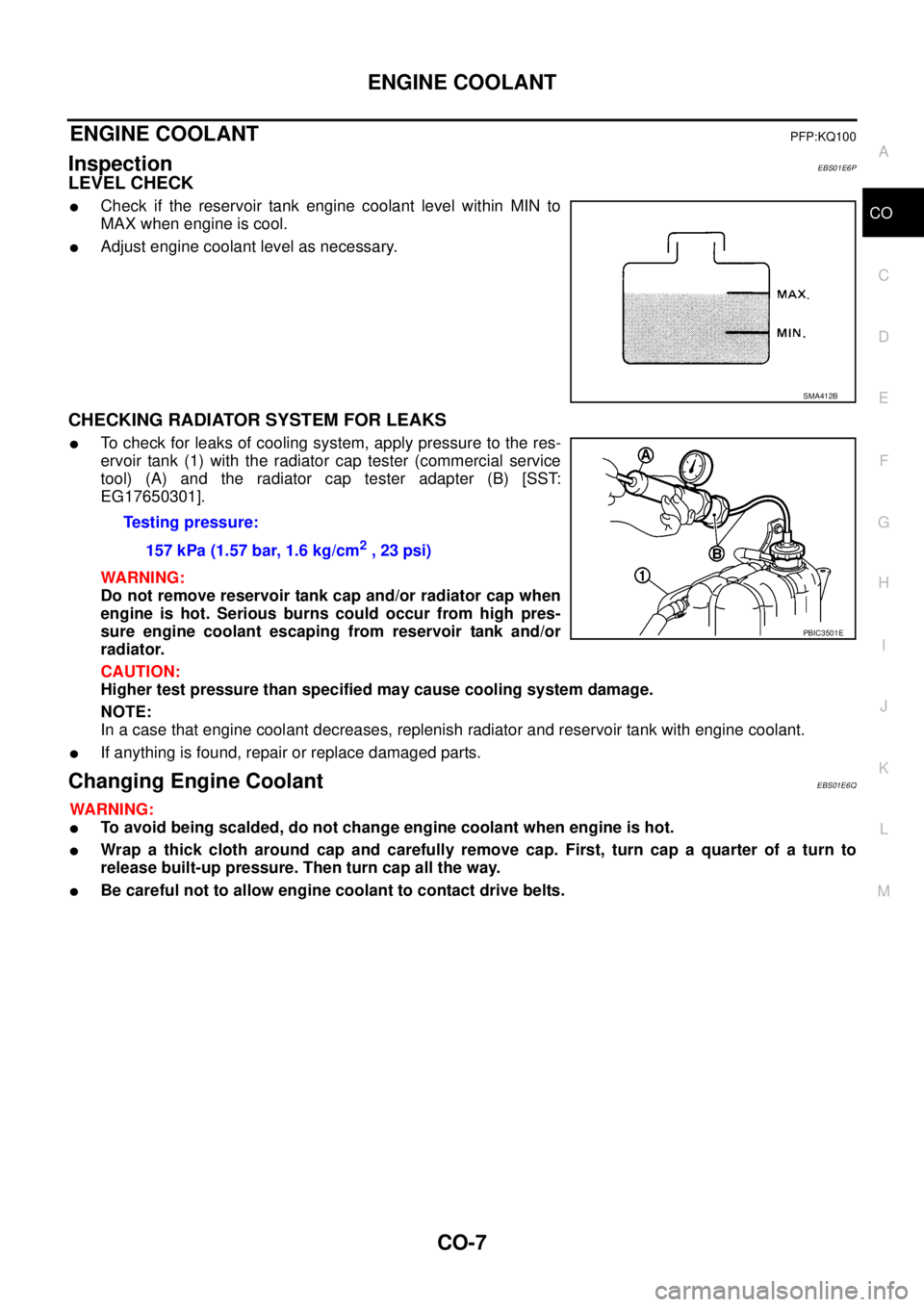

InspectionEBS01E6P

LEVEL CHECK

lCheck if the reservoir tank engine coolant level within MIN to

MAX when engine is cool.

lAdjust engine coolant level as necessary.

CHECKING RADIATOR SYSTEM FOR LEAKS

lTo check for leaks of cooling system, apply pressure to the res-

ervoir tank (1) with the radiator cap tester (commercial service

tool) (A) and the radiator cap tester adapter (B) [SST:

EG17650301].

WARNING:

Do not remove reservoir tank cap and/or radiator cap when

engine is hot. Serious burns could occur from high pres-

sure engine coolant escaping from reservoir tank and/or

radiator.

CAUTION:

Higher test pressure than specified may cause cooling system damage.

NOTE:

In a case that engine coolant decreases, replenish radiator and reservoir tank with engine coolant.

lIf anything is found, repair or replace damaged parts.

Changing Engine CoolantEBS01E6Q

WARNING:

lTo avoid being scalded, do not change engine coolant when engine is hot.

lWrap a thick cloth around cap and carefully remove cap. First, turn cap a quarter of a turn to

release built-up pressure. Then turn cap all the way.

lBe careful not to allow engine coolant to contact drive belts.

SMA412B

Testing pressure:

157 kPa (1.57 bar, 1.6 kg/cm

2,23psi)

PBIC3501E

Page 892 of 3171

CO-8

ENGINE COOLANT

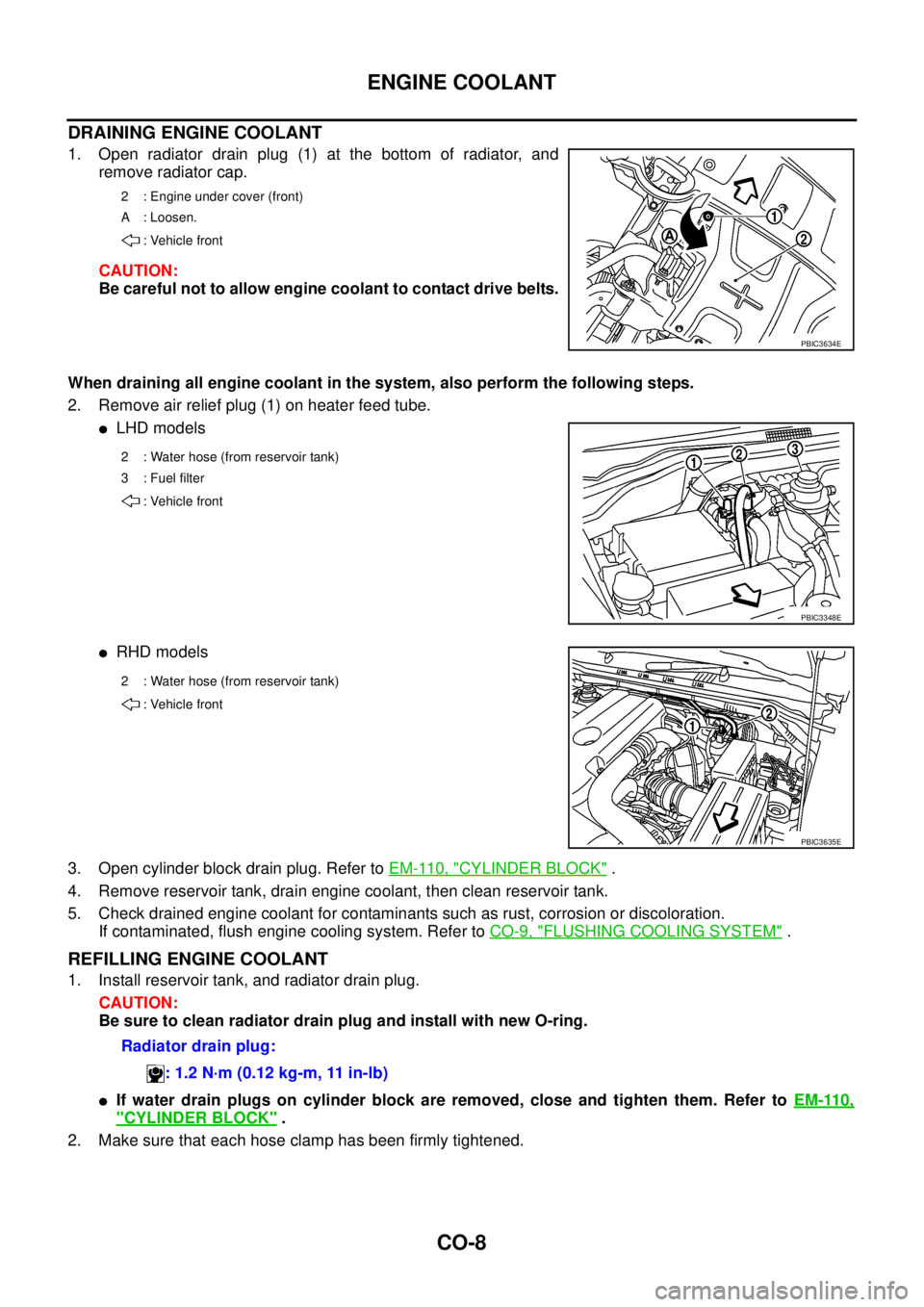

DRAINING ENGINE COOLANT

1. Open radiator drain plug (1) at the bottom of radiator, and

remove radiator cap.

CAUTION:

Be careful not to allow engine coolant to contact drive belts.

When draining all engine coolant in the system, also perform the following steps.

2. Remove air relief plug (1) on heater feed tube.

lLHD models

lRHD models

3. Open cylinder block drain plug. Refer toEM-110, "

CYLINDER BLOCK".

4. Remove reservoir tank, drain engine coolant, then clean reservoir tank.

5. Check drained engine coolant for contaminants such as rust, corrosion or discoloration.

If contaminated, flush engine cooling system. Refer toCO-9, "

FLUSHING COOLING SYSTEM".

REFILLING ENGINE COOLANT

1. Install reservoir tank, and radiator drain plug.

CAUTION:

Be sure to clean radiator drain plug and install with new O-ring.

lIf water drain plugs on cylinder block are removed, close and tighten them. Refer toEM-110,

"CYLINDER BLOCK".

2. Make sure that each hose clamp has been firmly tightened.

2 : Engine under cover (front)

A : Loosen.

: Vehicle front

PBIC3634E

2 : Water hose (from reservoir tank)

3 : Fuel filter

: Vehicle front

PBIC3348E

2 : Water hose (from reservoir tank)

: Vehicle front

PBIC3635E

Radiator drain plug:

: 1.2 N·m (0.12 kg-m, 11 in-lb)

Page 895 of 3171

RADIATOR

CO-11

C

D

E

F

G

H

I

J

K

L

MA

CO

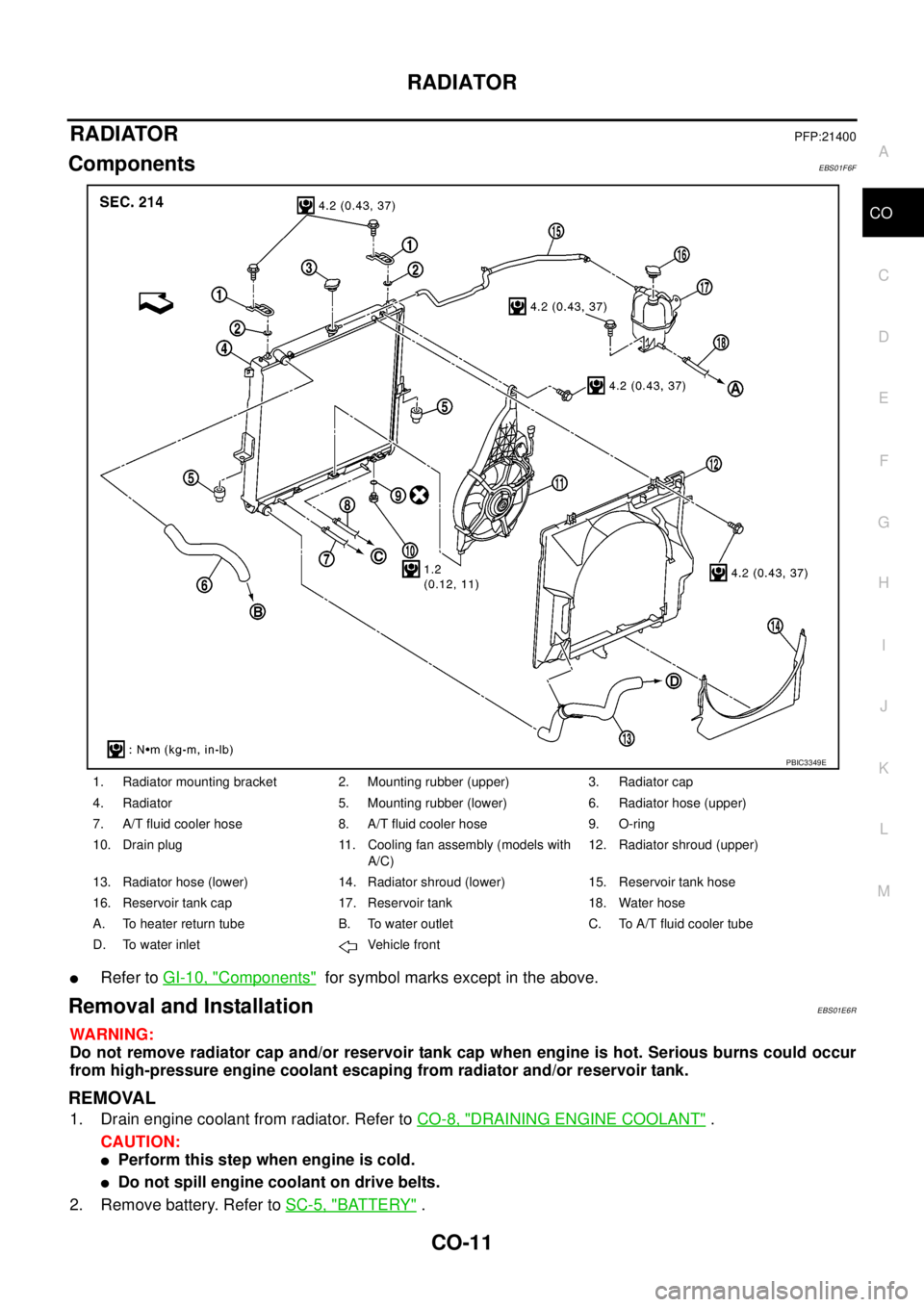

RADIATORPFP:21400

ComponentsEBS01F6F

lRefer toGI-10, "Components"for symbol marks except in the above.

Removal and InstallationEBS01E6R

WARNING:

Do not remove radiator cap and/or reservoir tank cap when engine is hot. Serious burns could occur

from high-pressure engine coolant escaping from radiator and/or reservoir tank.

REMOVAL

1. Drain engine coolant from radiator. Refer toCO-8, "DRAINING ENGINE COOLANT".

CAUTION:

lPerform this step when engine is cold.

lDo not spill engine coolant on drive belts.

2. Remove battery. Refer toSC-5, "

BATTERY".

1. Radiator mounting bracket 2. Mounting rubber (upper) 3. Radiator cap

4. Radiator 5. Mounting rubber (lower) 6. Radiator hose (upper)

7. A/T fluid cooler hose 8. A/T fluid cooler hose 9. O-ring

10. Drain plug 11. Cooling fan assembly (models with

A/C)12. Radiator shroud (upper)

13. Radiator hose (lower) 14. Radiator shroud (lower) 15. Reservoir tank hose

16. Reservoir tank cap 17. Reservoir tank 18. Water hose

A. To heater return tube B. To water outlet C. To A/T fluid cooler tube

D. To water inlet Vehicle front

PBIC3349E

Page 896 of 3171

CO-12

RADIATOR

3. Remove engine cover. Refer toEM-20, "INTAKE MANIFOLD".

4. Remove air inlet hoses between engine to charge air cooler. Refer toEM-18, "

CHARGE AIR COOLER".

5. Disconnect radiator hose (upper and lower) and reservoir tank hose.

CAUTION:

Be careful not to allow engine coolant to contact drive belts.

6. Remove reservoir tank.

7. Remove cooling fans (crankshaft driven type and motor driven type) and radiator shrouds (upper and

lower). Refer toCO-19, "

COOLING FAN".

8. Disconnect A/T fluid cooler hoses. (A/T models)

lInstall blind plug to avoid leakage of A/T fluid.

9. Remove radiator mounting brackets.

10. Remove the two A/C condenser bolts. (models with A/C)

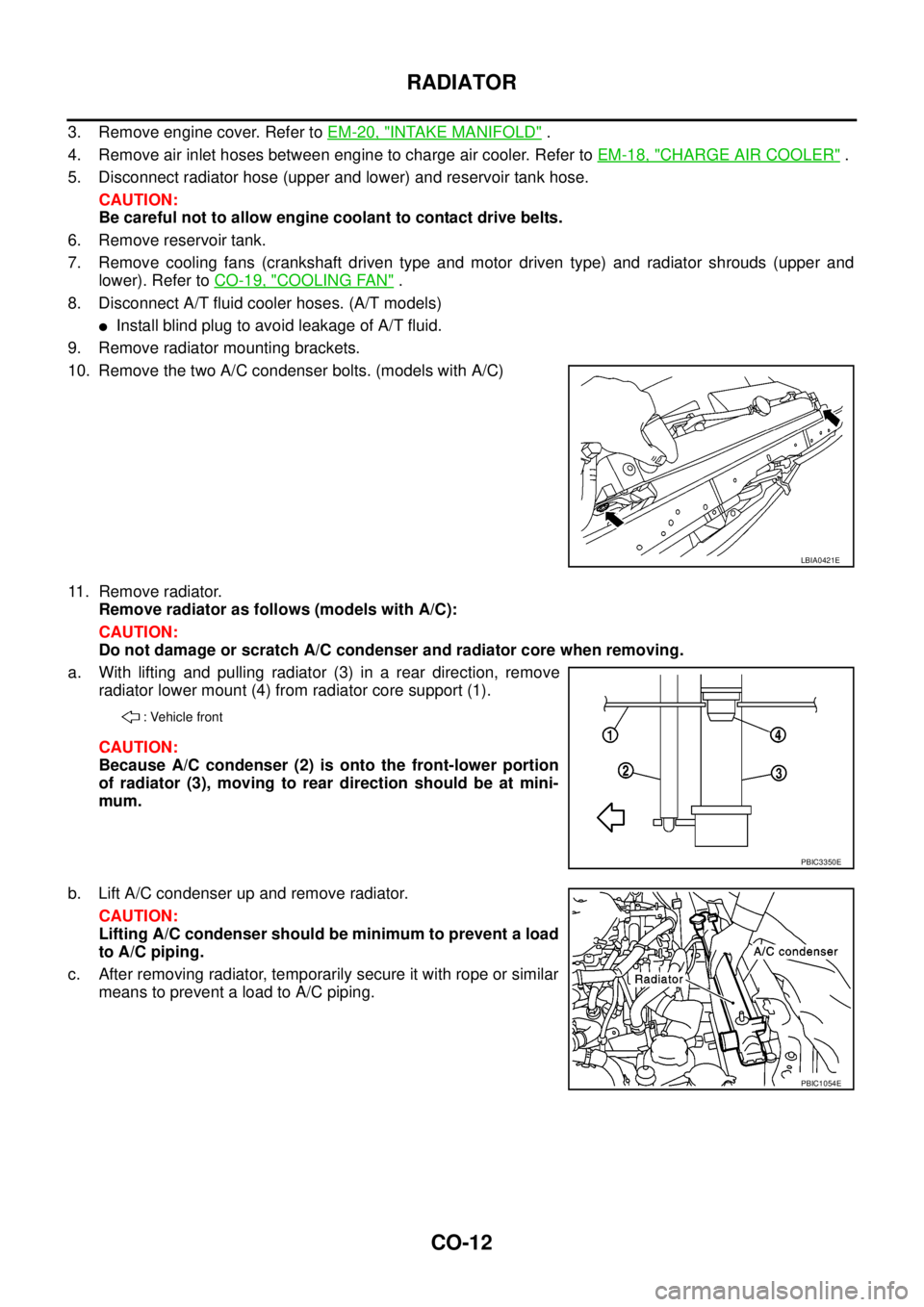

11. Remove radiator.

Remove radiator as follows (models with A/C):

CAUTION:

Do not damage or scratch A/C condenser and radiator core when removing.

a. With lifting and pulling radiator (3) in a rear direction, remove

radiator lower mount (4) from radiator core support (1).

CAUTION:

Because A/C condenser (2) is onto the front-lower portion

of radiator (3), moving to rear direction should be at mini-

mum.

b. Lift A/C condenser up and remove radiator.

CAUTION:

Lifting A/C condenser should be minimum to prevent a load

to A/C piping.

c. After removing radiator, temporarily secure it with rope or similar

means to prevent a load to A/C piping.

LBIA0421E

: Vehicle front

PBIC3350E

PBIC1054E

Page 903 of 3171

COOLING FAN

CO-19

C

D

E

F

G

H

I

J

K

L

MA

CO

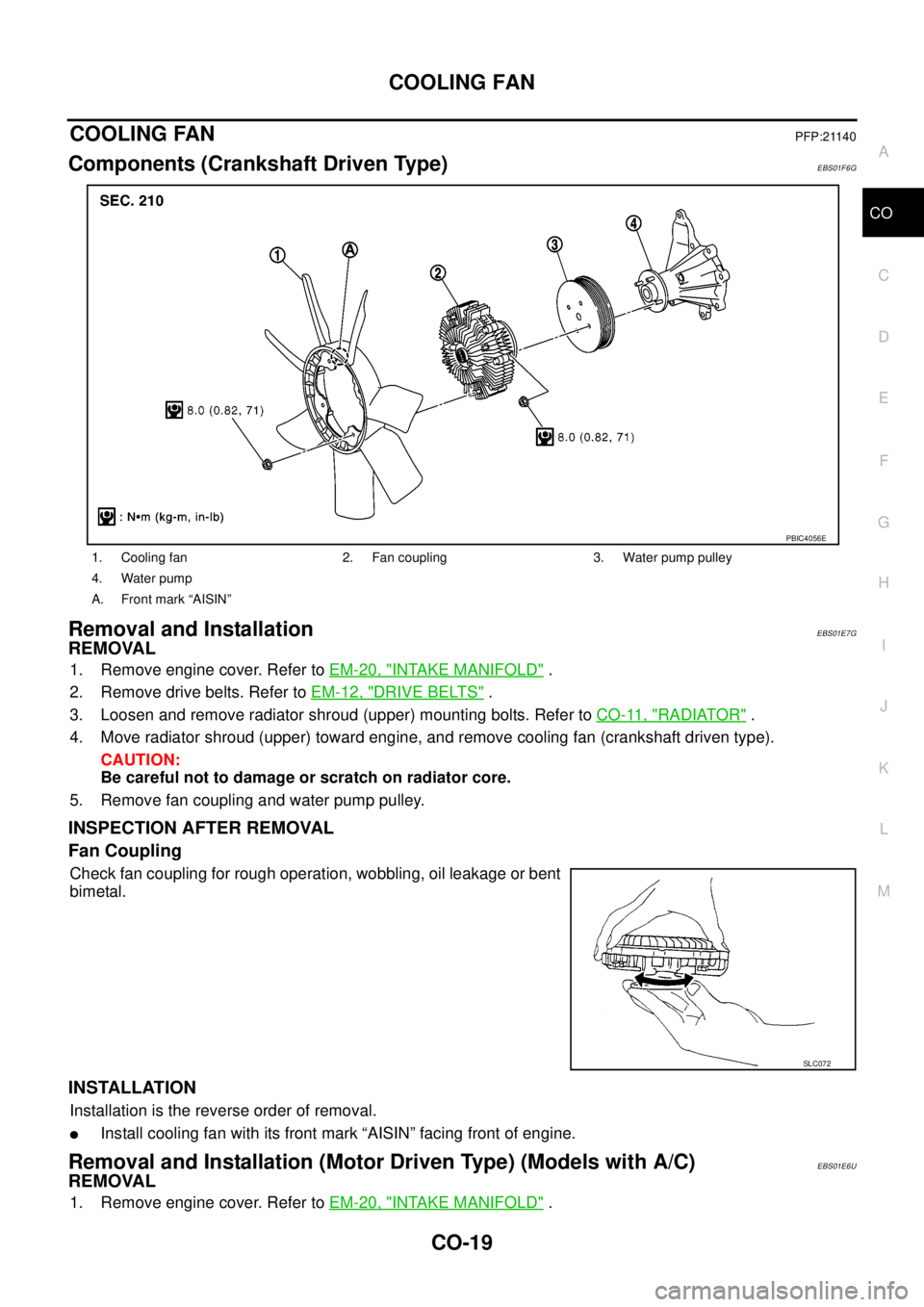

COOLING FANPFP:21140

Components (Crankshaft Driven Type)EBS01F6G

Removal and InstallationEBS01E7G

REMOVAL

1. Remove engine cover. Refer toEM-20, "INTAKE MANIFOLD".

2. Remove drive belts. Refer toEM-12, "

DRIVE BELTS".

3. Loosen and remove radiator shroud (upper) mounting bolts. Refer toCO-11, "

RADIATOR".

4. Move radiator shroud (upper) toward engine, and remove cooling fan (crankshaft driven type).

CAUTION:

Be careful not to damage or scratch on radiator core.

5. Remove fan coupling and water pump pulley.

INSPECTION AFTER REMOVAL

Fan Coupling

Check fan coupling for rough operation, wobbling, oil leakage or bent

bimetal.

INSTALLATION

Installation is the reverse order of removal.

lInstall cooling fan with its front mark “AISIN” facing front of engine.

Removal and Installation (Motor Driven Type) (Models with A/C)EBS01E6U

REMOVAL

1. Remove engine cover. Refer toEM-20, "INTAKE MANIFOLD".

1. Cooling fan 2. Fan coupling 3. Water pump pulley

4. Water pump

A. Front mark “AISIN”

PBIC4056E

SLC072

Page 905 of 3171

WATER PUMP

CO-21

C

D

E

F

G

H

I

J

K

L

MA

CO

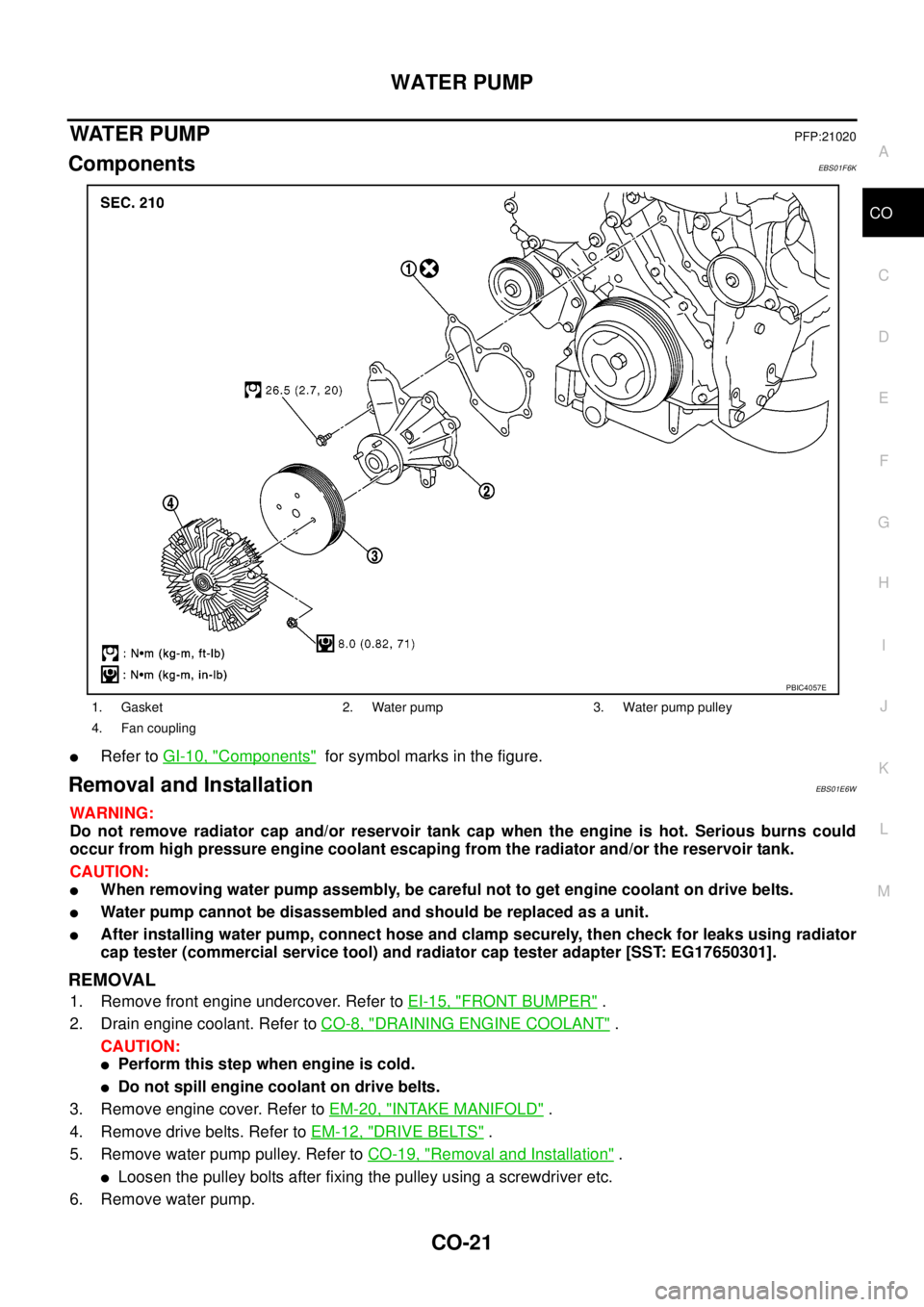

WAT E R P U MPPFP:21020

ComponentsEBS01F6K

lRefer toGI-10, "Components"for symbol marks in the figure.

Removal and InstallationEBS01E6W

WARNING:

Do not remove radiator cap and/or reservoir tank cap when the engine is hot. Serious burns could

occur from high pressure engine coolant escaping from the radiator and/or the reservoir tank.

CAUTION:

lWhen removing water pump assembly, be careful not to get engine coolant on drive belts.

lWater pump cannot be disassembled and should be replaced as a unit.

lAfter installing water pump, connect hose and clamp securely, then check for leaks using radiator

cap tester (commercial service tool) and radiator cap tester adapter [SST: EG17650301].

REMOVAL

1. Remove front engine undercover. Refer toEI-15, "FRONT BUMPER".

2. Drain engine coolant. Refer toCO-8, "

DRAINING ENGINE COOLANT".

CAUTION:

lPerform this step when engine is cold.

lDo not spill engine coolant on drive belts.

3. Remove engine cover. Refer toEM-20, "

INTAKE MANIFOLD".

4. Remove drive belts. Refer toEM-12, "

DRIVE BELTS".

5. Remove water pump pulley. Refer toCO-19, "

Removal and Installation".

lLoosen the pulley bolts after fixing the pulley using a screwdriver etc.

6. Remove water pump.

1. Gasket 2. Water pump 3. Water pump pulley

4. Fan coupling

PBIC4057E