belt NISSAN NAVARA 2005 Repair Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 911 of 3171

DI-1

DRIVER INFORMATION SYSTEM

K ELECTRICAL

CONTENTS

C

D

E

F

G

H

I

J

L

M

SECTIONDI

A

B

DI

DRIVER INFORMATION SYSTEM

PRECAUTION ............................................................ 3

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 3

Wiring Diagrams and Trouble Diagnosis .................. 3

COMBINATION METERS ........................................... 4

System Description .................................................. 4

UNIFIED METER CONTROL UNIT ...................... 4

POWER SUPPLY AND GROUND CIRCUIT ........ 4

SPEEDOMETER ................................................... 4

TACHOMETER ..................................................... 4

WATER TEMPERATURE GAUGE ........................ 4

FUEL GAUGE ....................................................... 5

ODO/TRIP METER ............................................... 5

TRIP COMPUTER ................................................ 5

ENGINE OIL MAINTENANCE INFORMATION..... 6

METER ILLUMINATION CONTROL ..................... 6

CLOCK .................................................................. 6

AMBIENT AIR TEMPERATURE INDICATION ...... 6

Component Parts and Harness Connector Location..... 7

Arrangement of Combination Meter ......................... 8

Internal Circuit .......................................................... 9

Wiring Diagram — METER — ................................ 10

Terminals and Reference Value for Combination

Meter ...................................................................... 12

Self-Diagnosis Mode of Combination Meter ........... 13

FUNCTION .......................................................... 13

OPERATION PROCEDURE ............................... 13

TEST ITEM ......................................................... 13

CONSULT-II Function (METER) ............................. 15

CONSULT-II BASIC OPERATION ....................... 15

SELF-DIAG RESULTS ........................................ 16

DATA MONITOR ................................................. 17

Trouble Diagnosis .................................................. 18

HOW TO PERFORM TROUBLE DIAGNOSIS ... 18

PRELIMINARY CHECK ...................................... 19

Symptom Chart ...................................................... 19

Power Supply and Ground Circuit Inspection ........ 19

Vehicle Speed Signal Inspection ............................ 20

Engine Speed Signal Inspection ............................ 21Engine Coolant Temperature Signal Inspection ..... 21

Fuel Level Sensor Signal Inspection ...................... 22

Ambient Sensor Signal Inspection .......................... 24

Fuel Gauge Fluctuates, Indicates Wrong Value, or

Varies ...................................................................... 25

Fuel Gauge Does Not Move to Full position ........... 25

DTC [U1000] CAN Communication Circuit ............. 26

DTC [B2205] Vehicle Speed Circuit ........................ 26

Electrical Components Inspection .......................... 27

FUEL LEVEL SENSOR UNIT CHECK ................ 27

AMBIENT SENSOR CHECK ............................... 27

Removal and Installation of Combination Meter ..... 27

WARNING LAMPS .................................................... 28

System Description ................................................. 28

OIL PRESSURE WARNING LAMP ..................... 28

Component Parts and Harness Connector Location... 28

Schematic ............................................................... 29

Wiring Diagram — WARN — .................................. 30

A/T MODELS ....................................................... 30

M/T MODELS ...................................................... 37

Oil Pressure Warning Lamp Stays Off (Ignition

Switch ON) ............................................................. 44

Oil Pressure Warning Lamp Does Not Turn Off (Oil

Pressure Is Normal) ................................................ 45

Oil Pressure Warning Lamp Keeps Blinking (Oil

Level Is Normal) ..................................................... 46

Component Inspection ............................................ 47

OIL PRESSURE SWITCH ................................... 47

OIL LEVEL SENSOR .......................................... 47

A/T INDICATOR ........................................................ 48

System Description ................................................. 48

Wiring Diagram — AT/IND — ................................. 49

A/T Indicator Does Not Illuminate ........................... 50

WARNING CHIME ..................................................... 51

System Description ................................................. 51

POWER SUPPLY AND GROUND CIRCUIT ....... 51

LIGHT WARNING CHIME ................................... 51

KEY REMINDER WARNING CHIME .................. 51

LOW-FUEL WARNING CHIME ........................... 51

SEAT BELT WARNING CHIME ........................... 52

Page 912 of 3171

DI-2

Component Parts and Harness Connector Location... 52

Wiring Diagram — CHIME — ................................. 53

LHD MODELS ..................................................... 53

RHD MODELS ..................................................... 55

Terminals and Reference Value for BCM ................ 57

Terminals and Reference Value for Combination

Meter ...................................................................... 57

CONSULT-II Function (BCM) .................................. 58

DIAGNOSTIC ITEMS DESCRIPTION ................. 58

CONSULT-II BASIC OPERATION PROCEDURE

... 58

DATA MONITOR .................................................. 59

ACTIVE TEST ..................................................... 59

SELF-DIAG RESULTS ........................................ 60

Trouble Diagnosis ................................................... 60

HOW TO PERFORM TROUBLE DIAGNOSIS .... 60

PRELIMINARY INSPECTION ............................. 60

SYMPTOM CHART ............................................. 61

Meter Buzzer Circuit Inspection .............................. 61Lighting Switch Signal Inspection ........................... 62

Front Door Switch (Driver Side) Signal Inspection... 62

Seat Belt Buckle Switch Signal Inspection (Driver

Side) ........................................................................ 63

Electrical Component Inspection ............................ 64

FRONT DOOR SWITCH (DRIVER SIDE) ........... 64

SEAT BELT BUCKLE SWITCH (DRIVER SIDE)... 64

CAN COMMUNICATION ........................................... 65

System Description ................................................. 65

CAN Communication Unit ....................................... 65

COMPASS ................................................................. 66

System Description ................................................. 66

DIRECTION DISPLAY ......................................... 66

Zone Variation Change Procedure .......................... 66

Correction Functions of the Compass Display ........ 67

AUTOMATIC CORRECTION ............................... 67

MANUAL CORRECTION PROCEDURE ............. 67

Wiring Diagram — COMPAS — .............................. 68

Removal and Installation of Compass ..................... 69

Page 913 of 3171

PRECAUTION

DI-3

C

D

E

F

G

H

I

J

L

MA

B

DI

PRECAUTIONPFP:00011

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EKS00N1V

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Wiring Diagrams and Trouble DiagnosisEKS00L8C

When reading wiring diagrams, refer to the following:

lGI-15, "How to Read Wiring Diagrams"

lPG-4, "POWER SUPPLY ROUTING CIRCUIT"for power distribution circuit

When performing trouble diagnosis, refer to the following:

lGI-11, "HOW TO FOLLOW TEST GROUPS IN TROUBLE DIAGNOSES"

lGI-24, "How to Perform Efficient Diagnosis for an Electrical Incident"

Page 914 of 3171

DI-4

COMBINATION METERS

COMBINATION METERS

PFP:24814

System DescriptionEKS00L8E

UNIFIED METER CONTROL UNIT

lSpeedometer, odo/trip meter, tachometer, fuel gauge and water temperature gauge are controlled by the

unified meter control unit, which is built into the combination meter.

lWarning lamp and indicator lamp are controlled by signals drawn from each unit with CAN communication

and components connected directly to the combination meter.

lOdo/trip meter display is included in the combination meter, which displays odometer, trip-meter, vehicle

information (trip computer, engine oil maintenance information)

*and A/T position*.

*: Vehicles with each system only.

lClock display is included in the combination meter, which displays current time, ambient air temperature*

and 4WD indicator*.

*: Vehicles with each system only.

lUnified meter control unit corresponds a CONSULT-II function (self-diagnosis results and data monitor).

lThe following items can be checked during self-diagnosis mode.

–Sweep of gauges pointer

–Present gauge values

–Odo/trip meter display and clock display segments

–Condition of warning lamps/indicator lamps controlled by unified meter control unit

–Battery voltage

–Driver's seat belt buckle switch status

–CPU status of unified meter control unit

POWER SUPPLY AND GROUND CIRCUIT

Power is supplied at all times

lthrough 10A fuse [No.19, located in the fuse block (J/B)]

lto combination meter terminal 3.

With the ignition switch in the ON or START position, power is supplied

lthrough 10A fuse [No.14, located in the fuse block (J/B)]

lto combination meter terminal 16.

Ground is supplied

lto combination meter terminals 13 and 23

lthrough grounds M21, M80 and M83.

SPEEDOMETER

The speedometer indicates the vehicle speed.

lABS actuator and electric unit (control unit) converses a pulse signal from wheel sensor to vehicle speed

signal, and transmits vehicle speed signal to combination meter with CAN communication.

lCombination meter converses the vehicle speed signal to angle signal, and commands to speedometer.

TACHOMETER

The tachometer indicates engine speed in revolutions per minute (rpm).

lECM converses a signal from crank position sensor to engine speed signal, and transmits to combination

meter with CAN communication.

lCombination meter converses the engine speed signal to angle signal, and commands to tachometer.

WATER TEMPERATURE GAUGE

The water temperature gauge indicates the engine coolant temperature.

lECM converses a signal from water temperature sensor to engine coolant temperature signal, and trans-

mits to combination meter with CAN communication.

lCombination meter converses the engine coolant temperature signal to angle signal, and commands to

water temperature gauge.

Page 923 of 3171

COMBINATION METERS

DI-13

C

D

E

F

G

H

I

J

L

MA

B

DI

Self-Diagnosis Mode of Combination MeterEKS00L8K

FUNCTION

The following items can be checked during self-diagnosis mode.

lSweep of gauges pointer

lPresent gauge data values

lOdo/trip meter display and clock display segments

lCondition of warning lamps/indicator lamps controlled by unified meter control unit

lBattery voltage

lDriver's seat belt buckle switch status

lCPU of unified meter control unit status

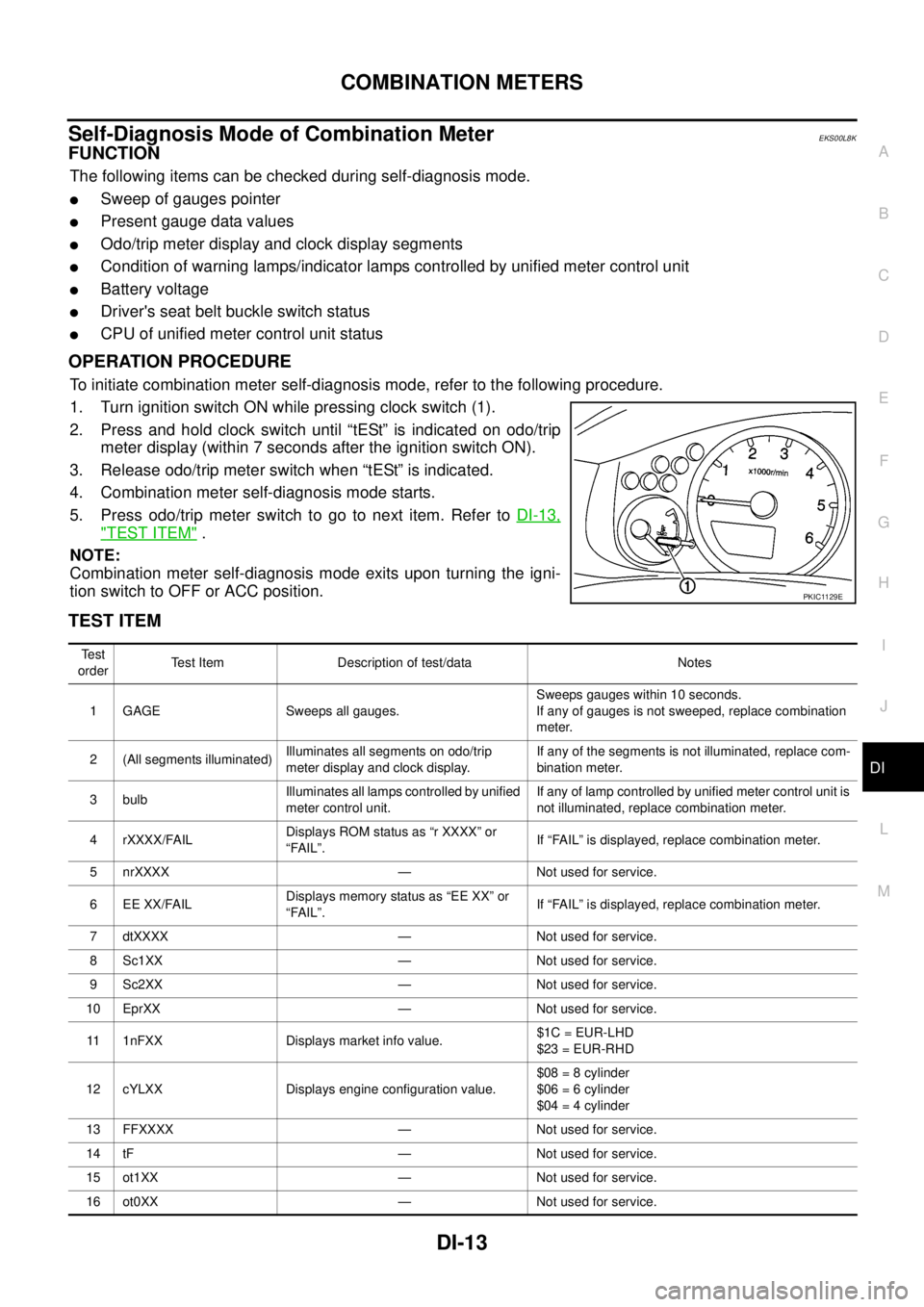

OPERATION PROCEDURE

To initiate combination meter self-diagnosis mode, refer to the following procedure.

1. Turn ignition switch ON while pressing clock switch (1).

2. Press and hold clock switch until “tESt” is indicated on odo/trip

meter display (within 7 seconds after the ignition switch ON).

3. Release odo/trip meter switch when “tESt” is indicated.

4. Combination meter self-diagnosis mode starts.

5. Pressodo/tripmeterswitchtogotonextitem.RefertoDI-13,

"TEST ITEM".

NOTE:

Combination meter self-diagnosis mode exits upon turning the igni-

tion switch to OFF or ACC position.

TEST ITEM

PKIC1129E

Te s t

orderTest Item Description of test/data Notes

1 GAGE Sweeps all gauges.Sweeps gauges within 10 seconds.

If any of gauges is not sweeped, replace combination

meter.

2 (All segments illuminated)Illuminates all segments on odo/trip

meter display and clock display.If any of the segments is not illuminated, replace com-

bination meter.

3 bulbIlluminates all lamps controlled by unified

meter control unit.If any of lamp controlled by unified meter control unit is

not illuminated, replace combination meter.

4 rXXXX/FAILDisplays ROM status as “r XXXX” or

“FAIL”.If “FAIL” is displayed, replace combination meter.

5 nrXXXX — Not used for service.

6 EE XX/FAILDisplays memory status as “EE XX” or

“FAIL”.If “FAIL” is displayed, replace combination meter.

7 dtXXXX — Not used for service.

8 Sc1XX — Not used for service.

9 Sc2XX — Not used for service.

10 EprXX — Not used for service.

11 1nFXX Displays market info value.$1C = EUR-LHD

$23 = EUR-RHD

12 cYLXX Displays engine configuration value.$08 = 8 cylinder

$06 = 6 cylinder

$04 = 4 cylinder

13 FFXXXX — Not used for service.

14 tF — Not used for service.

15 ot1XX — Not used for service.

16 ot0XX — Not used for service.

Page 924 of 3171

DI-14

COMBINATION METERS

17 XXXXXDisplays vehicle speed signal value

(MPH).Displays “-----” if message is not received.

Displays “99999” if data received is invalid.

If “-----” or “99999” is displayed, performDI-20, "Ve h i-

cle Speed Signal Inspection".

18 XXXXXDisplays vehicle speed signal value

(km/h).Displays “-----” if message is not received.

Displays “99999” if data received is invalid.

If “-----” or “99999” is displayed, performDI-20, "

Ve h i-

cle Speed Signal Inspection".

19 tXXXXDisplays engine speed signal value

(RPM).Displays “-----” if message is not received.

If “-----” is displayed, performDI-21, "

Engine Speed

Signal Inspection".

20 F1 XXXXDisplays ratioed fuel level sensor signal

value.000-009 = Short circuit

010-254 = Normal range

255 = Open circuit

--- = Missing 5 seconds

If “000-009” or “255” is displayed, performDI-22, "

Fuel

Level Sensor Signal Inspection".

21 XXXCDisplays engine coolant temperature sig-

nal value (°C).Displays “---” C if message is not received.

Displays “999” C if data received is invalid.

If “---” or “999” is displayed, performDI-21, "

Engine

Coolant Temperature Signal Inspection".

22 BAt XXX Displays battery voltage.

23 rES -X Driver's seat belt buckle switch status.1= Buckled

0 = Unbuckled

24 PA -XX — Not used for service.

25 Pb -XX — Not used for service.

26 PE -XX — Not used for service.

27 PL -XX — Not used for service.

28 P6 -XX — Not used for service.

29 Pn -XX — Not used for service.

30 PP -XX — Not used for service.

31 PS -XX — Not used for service.

32 Pt -XX — Not used for service.

33 Pu -XX — Not used for service.

34 P4 -XX — Not used for service.

35 Puu -XX — Not used for service.

36 A00XXX — Not used for service.

37 A01XXX — Not used for service.

38 A02XXX — Not used for service.

39 A03XXX — Not used for service.

40 A04XXX — Not used for service.

41 A05XXX — Not used for service.

42 A06XXX — Not used for service.

43 A07XXX — Not used for service.

44 A08XXX — Not used for service.

45 A09XXX — Not used for service.

46 A10XXX — Not used for service.

47 A11XXX — Not used for service.

48 A12XXX — Not used for service. Te s t

orderTest Item Description of test/data Notes

Page 927 of 3171

COMBINATION METERS

DI-17

C

D

E

F

G

H

I

J

L

MA

B

DI

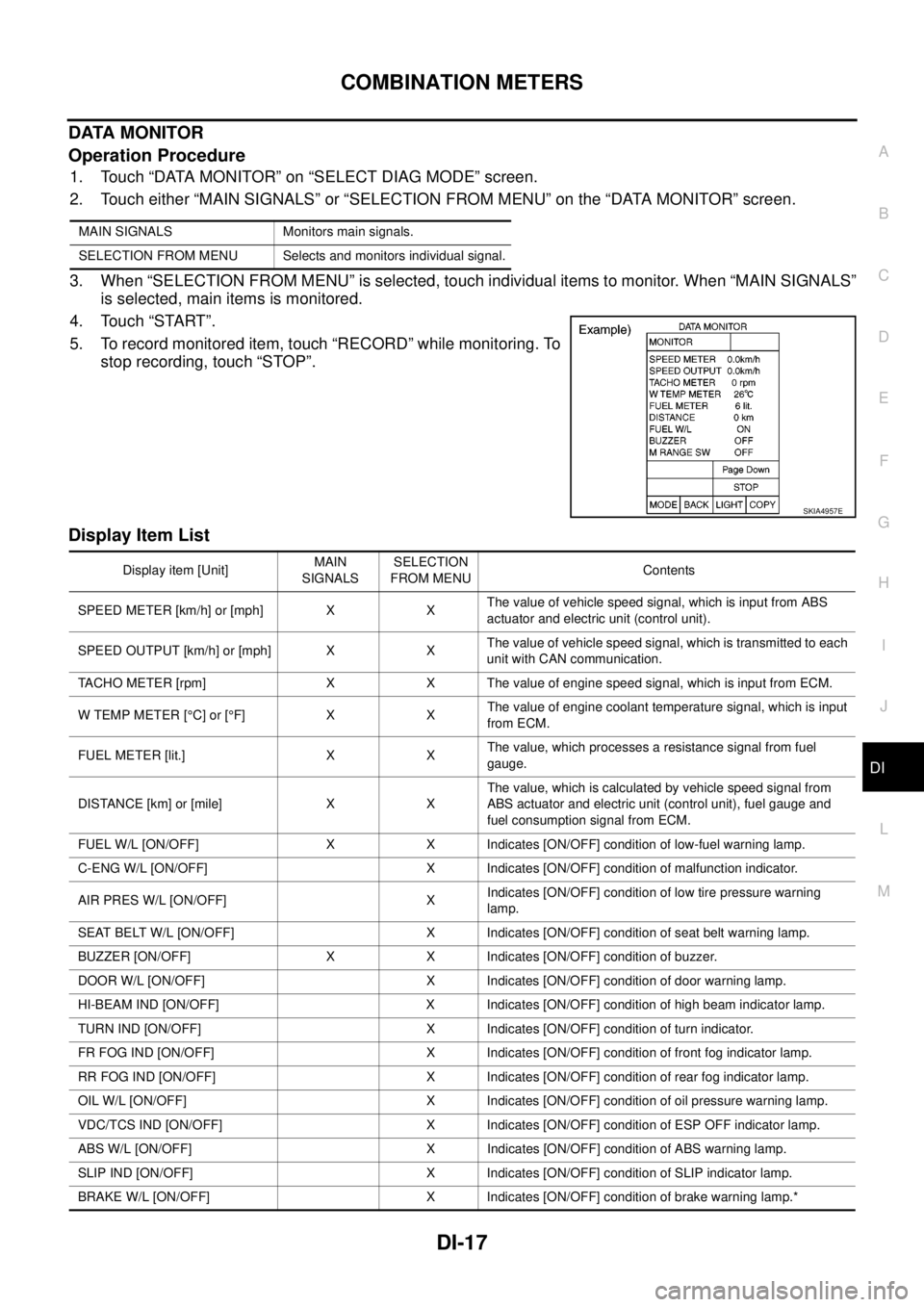

DATA MONITOR

Operation Procedure

1. Touch “DATA MONITOR” on “SELECT DIAG MODE” screen.

2. Touch either “MAIN SIGNALS” or “SELECTION FROM MENU” on the “DATA MONITOR” screen.

3. When “SELECTION FROM MENU” is selected, touch individual items to monitor. When “MAIN SIGNALS”

is selected, main items is monitored.

4. Touch “START”.

5. To record monitored item, touch “RECORD” while monitoring. To

stop recording, touch “STOP”.

Display Item List

MAIN SIGNALS Monitors main signals.

SELECTION FROM MENU Selects and monitors individual signal.

SKIA4957E

Display item [Unit]MAIN

SIGNALSSELECTION

FROM MENUContents

SPEED METER [km/h] or [mph] X XThe value of vehicle speed signal, which is input from ABS

actuator and electric unit (control unit).

SPEED OUTPUT [km/h] or [mph] X XThe value of vehicle speed signal, which is transmitted to each

unit with CAN communication.

TACHO METER [rpm] X X The value of engine speed signal, which is input from ECM.

W TEMP METER [°C] or [°F] X XThe value of engine coolant temperature signal, which is input

from ECM.

FUEL METER [lit.] X XThe value, which processes a resistance signal from fuel

gauge.

DISTANCE [km] or [mile] X XThe value, which is calculated by vehicle speed signal from

ABS actuator and electric unit (control unit), fuel gauge and

fuel consumption signal from ECM.

FUEL W/L [ON/OFF] X X Indicates [ON/OFF] condition of low-fuel warning lamp.

C-ENG W/L [ON/OFF] X Indicates [ON/OFF] condition of malfunction indicator.

AIR PRES W/L [ON/OFF] XIndicates [ON/OFF] condition of low tire pressure warning

lamp.

SEAT BELT W/L [ON/OFF] X Indicates [ON/OFF] condition of seat belt warning lamp.

BUZZER [ON/OFF] X X Indicates [ON/OFF] condition of buzzer.

DOOR W/L [ON/OFF] X Indicates [ON/OFF] condition of door warning lamp.

HI-BEAM IND [ON/OFF] X Indicates [ON/OFF] condition of high beam indicator lamp.

TURN IND [ON/OFF] X Indicates [ON/OFF] condition of turn indicator.

FR FOG IND [ON/OFF] X Indicates [ON/OFF] condition of front fog indicator lamp.

RR FOG IND [ON/OFF] X Indicates [ON/OFF] condition of rear fog indicator lamp.

OIL W/L [ON/OFF] X Indicates [ON/OFF] condition of oil pressure warning lamp.

VDC/TCS IND [ON/OFF] X Indicates [ON/OFF] condition of ESP OFF indicator lamp.

ABS W/L [ON/OFF] X Indicates [ON/OFF] condition of ABS warning lamp.

SLIP IND [ON/OFF] X Indicates [ON/OFF] condition of SLIP indicator lamp.

BRAKE W/L [ON/OFF] X Indicates [ON/OFF] condition of brake warning lamp.*

Page 962 of 3171

DI-52

WARNING CHIME

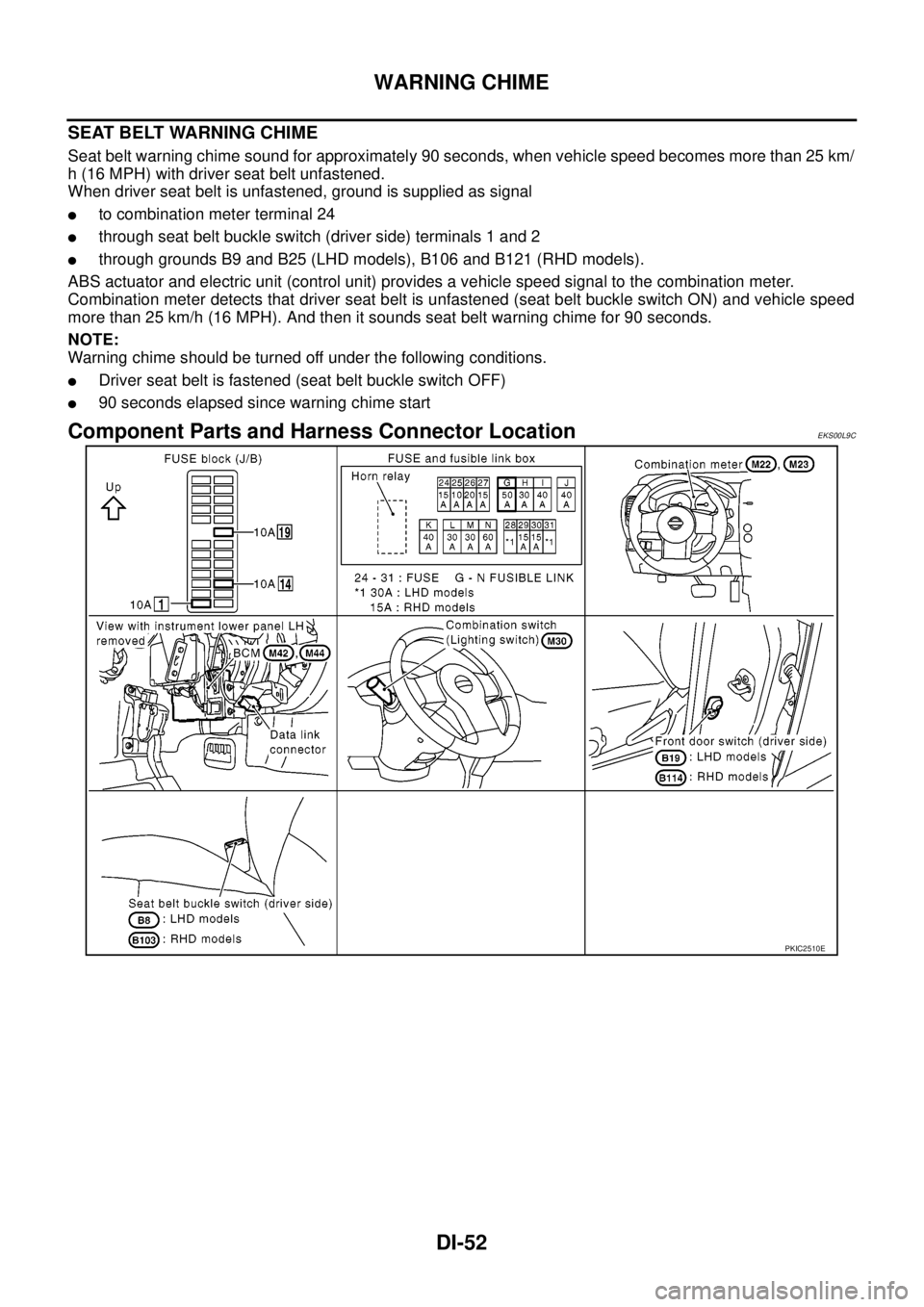

SEAT BELT WARNING CHIME

Seat belt warning chime sound for approximately 90 seconds, when vehicle speed becomes more than 25 km/

h (16 MPH) with driver seat belt unfastened.

When driver seat belt is unfastened, ground is supplied as signal

lto combination meter terminal 24

lthrough seat belt buckle switch (driver side) terminals 1 and 2

lthrough grounds B9 and B25 (LHD models), B106 and B121 (RHD models).

ABS actuator and electric unit (control unit) provides a vehicle speed signal to the combination meter.

Combination meter detects that driver seat belt is unfastened (seat belt buckle switch ON) and vehicle speed

more than 25 km/h (16 MPH). And then it sounds seat belt warning chime for 90 seconds.

NOTE:

Warning chime should be turned off under the following conditions.

lDriver seat belt is fastened (seat belt buckle switch OFF)

l90 seconds elapsed since warning chime start

Component Parts and Harness Connector LocationEKS00L9C

PKIC2510E

Page 967 of 3171

WARNING CHIME

DI-57

C

D

E

F

G

H

I

J

L

MA

B

DI

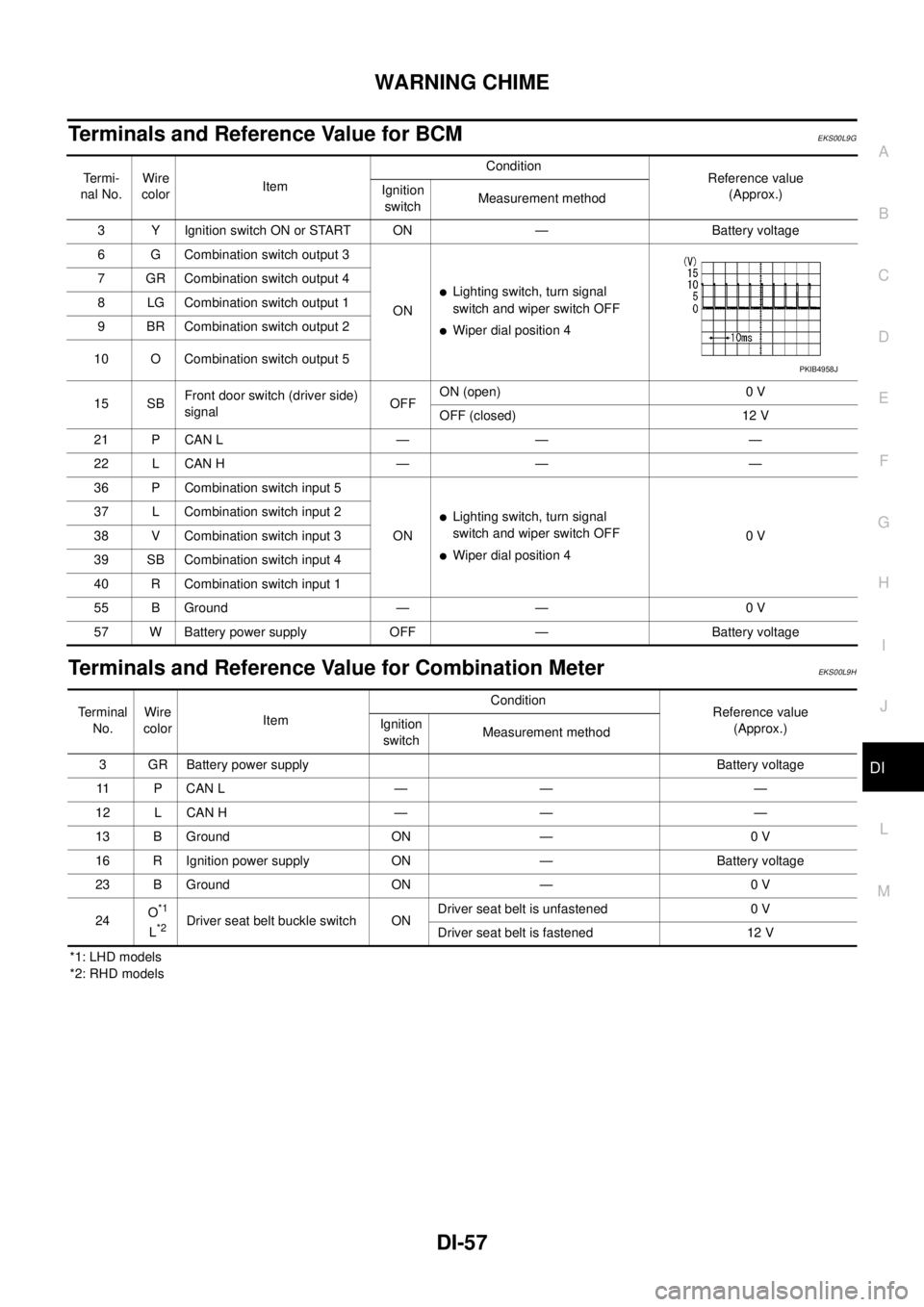

Terminals and Reference Value for BCMEKS00L9G

Terminals and Reference Value for Combination MeterEKS00L9H

*1: LHD models

*2: RHD modelsTe r m i -

nal No.Wire

colorItemCondition

Reference value

(Approx.) Ignition

switchMeasurement method

3 Y Ignition switch ON or START ON — Battery voltage

6 G Combination switch output 3

ON

lLighting switch, turn signal

switch and wiper switch OFF

lWiper dial position 4 7 GR Combination switch output 4

8 LG Combination switch output 1

9 BR Combination switch output 2

10 O Combination switch output 5

15 SBFront door switch (driver side)

signalOFFON (open) 0 V

OFF (closed) 12 V

21 P CAN L — — —

22 L CAN H — — —

36 P Combination switch input 5

ON

lLighting switch, turn signal

switch and wiper switch OFF

lWiper dial position 40V 37 L Combination switch input 2

38 V Combination switch input 3

39 SB Combination switch input 4

40 R Combination switch input 1

55 B Ground — — 0 V

57 W Battery power supply OFF — Battery voltage

PKIB4958J

Terminal

No.Wire

colorItemCondition

Reference value

(Approx.) Ignition

switchMeasurement method

3 GR Battery power supply Battery voltage

11 P C A N L — — —

12 L CAN H — — —

13 B Ground ON — 0 V

16 R Ignition power supply ON — Battery voltage

23 B Ground ON — 0 V

24O

*1

L*2Driver seat belt buckle switch ONDriver seat belt is unfastened 0 V

Driver seat belt is fastened 12 V

Page 971 of 3171

WARNING CHIME

DI-61

C

D

E

F

G

H

I

J

L

MA

B

DI

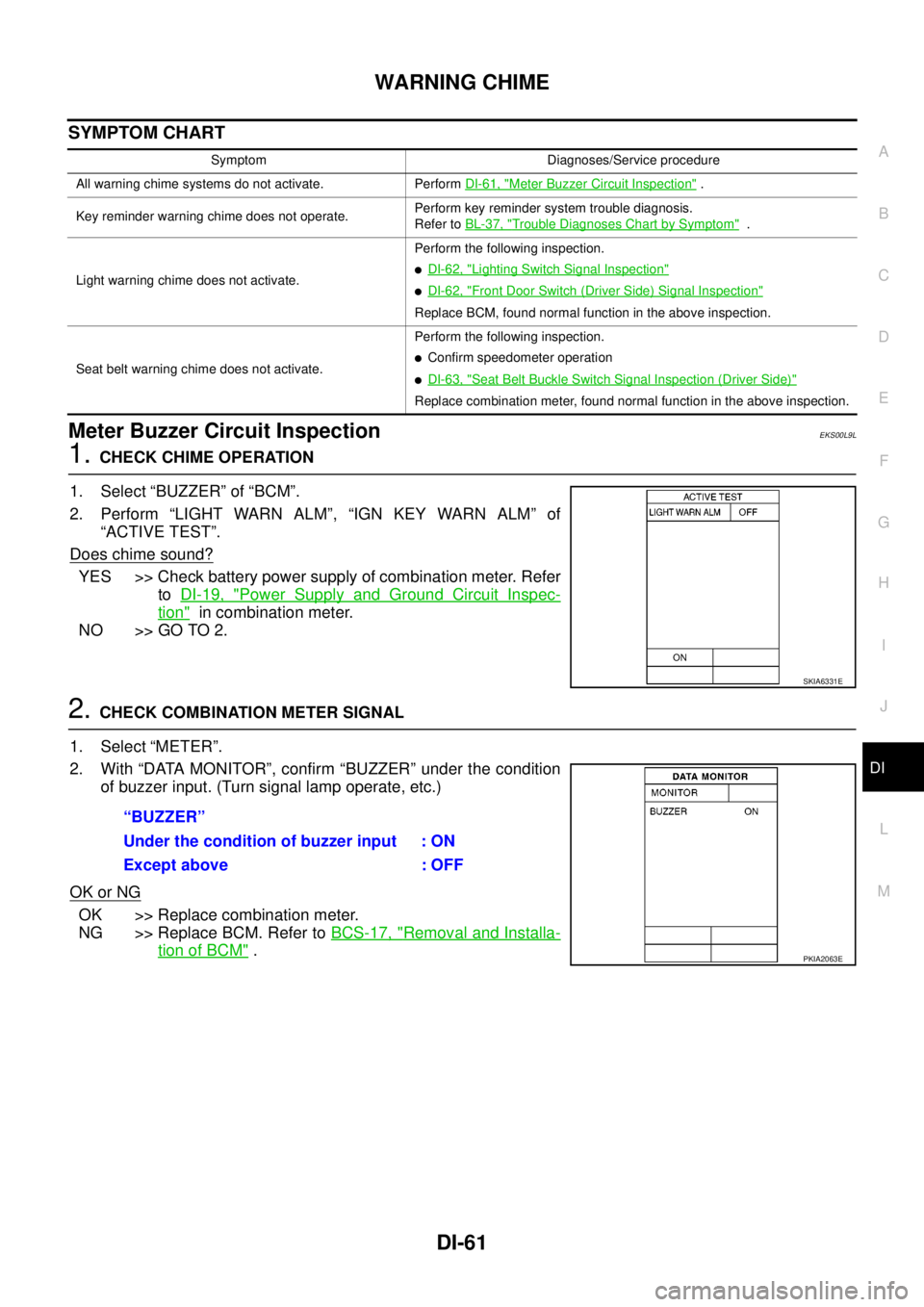

SYMPTOM CHART

Meter Buzzer Circuit InspectionEKS00L9L

1.CHECK CHIME OPERATION

1. Select “BUZZER” of “BCM”.

2. Perform “LIGHT WARN ALM”, “IGN KEY WARN ALM” of

“ACTIVE TEST”.

Does chime sound?

YES >> Check battery power supply of combination meter. Refer

toDI-19, "

Power Supply and Ground Circuit Inspec-

tion"in combination meter.

NO >> GO TO 2.

2.CHECK COMBINATION METER SIGNAL

1. Select “METER”.

2. With “DATA MONITOR”, confirm “BUZZER” under the condition

of buzzer input. (Turn signal lamp operate, etc.)

OK or NG

OK >> Replace combination meter.

NG >> Replace BCM. Refer toBCS-17, "

Removal and Installa-

tion of BCM".

Symptom Diagnoses/Service procedure

All warning chime systems do not activate. PerformDI-61, "

Meter Buzzer Circuit Inspection".

Key reminder warning chime does not operate.Perform key reminder system trouble diagnosis.

Refer toBL-37, "

Trouble Diagnoses Chart by Symptom".

Light warning chime does not activate.Perform the following inspection.

lDI-62, "Lighting Switch Signal Inspection"

lDI-62, "Front Door Switch (Driver Side) Signal Inspection"

Replace BCM, found normal function in the above inspection.

Seat belt warning chime does not activate.Perform the following inspection.

lConfirm speedometer operation

lDI-63, "Seat Belt Buckle Switch Signal Inspection (Driver Side)"

Replace combination meter, found normal function in the above inspection.

SKIA6331E

“BUZZER”

Under the condition of buzzer input : ON

Except above : OFF

PKIA2063E