belt NISSAN NAVARA 2005 Repair Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 973 of 3171

WARNING CHIME

DI-63

C

D

E

F

G

H

I

J

L

MA

B

DI

3.CHECK FRONT DOOR SWITCH (DRIVER SIDE)

Check front door switch (driver side). Refer toDI-64, "

FRONT DOOR SWITCH (DRIVER SIDE)".

OK or NG

OK >> Replace BCM. Refer toBCS-17, "Removal and Installation of BCM".

NG >> Replace front door switch (driver side).

Seat Belt Buckle Switch Signal Inspection (Driver Side)EKS00L9P

1.CHECK OPERATION OF SEAT BELT WARNING LAMP

1. Turn ignition switch ON.

2. Check operation of seat belt warning lamp.

OK or NG

OK >> Seat belt buckle switch signal (driver side) is OK. Return toDI-61, "SYMPTOM CHART".

NG >> GO TO 2.

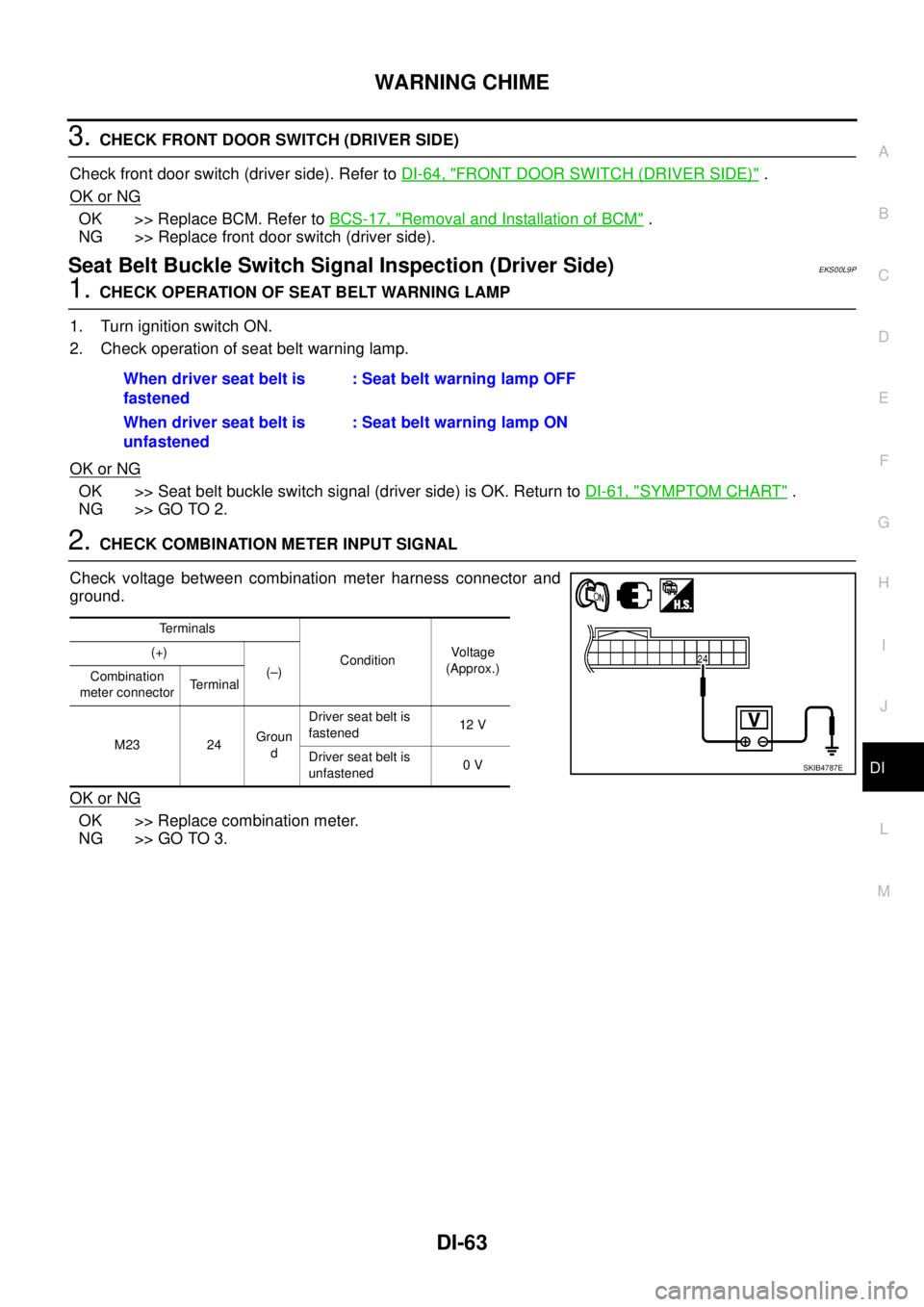

2.CHECK COMBINATION METER INPUT SIGNAL

Check voltage between combination meter harness connector and

ground.

OK or NG

OK >> Replace combination meter.

NG >> GO TO 3.When driver seat belt is

fastened: Seat belt warning lamp OFF

When driver seat belt is

unfastened: Seat belt warning lamp ON

Terminals

ConditionVoltag e

(Approx.) (+)

(–)

Combination

meter connectorTerminal

M23 24Groun

dDriver seat belt is

fastened12 V

Driver seat belt is

unfastened0V

SKIB4787E

Page 974 of 3171

DI-64

WARNING CHIME

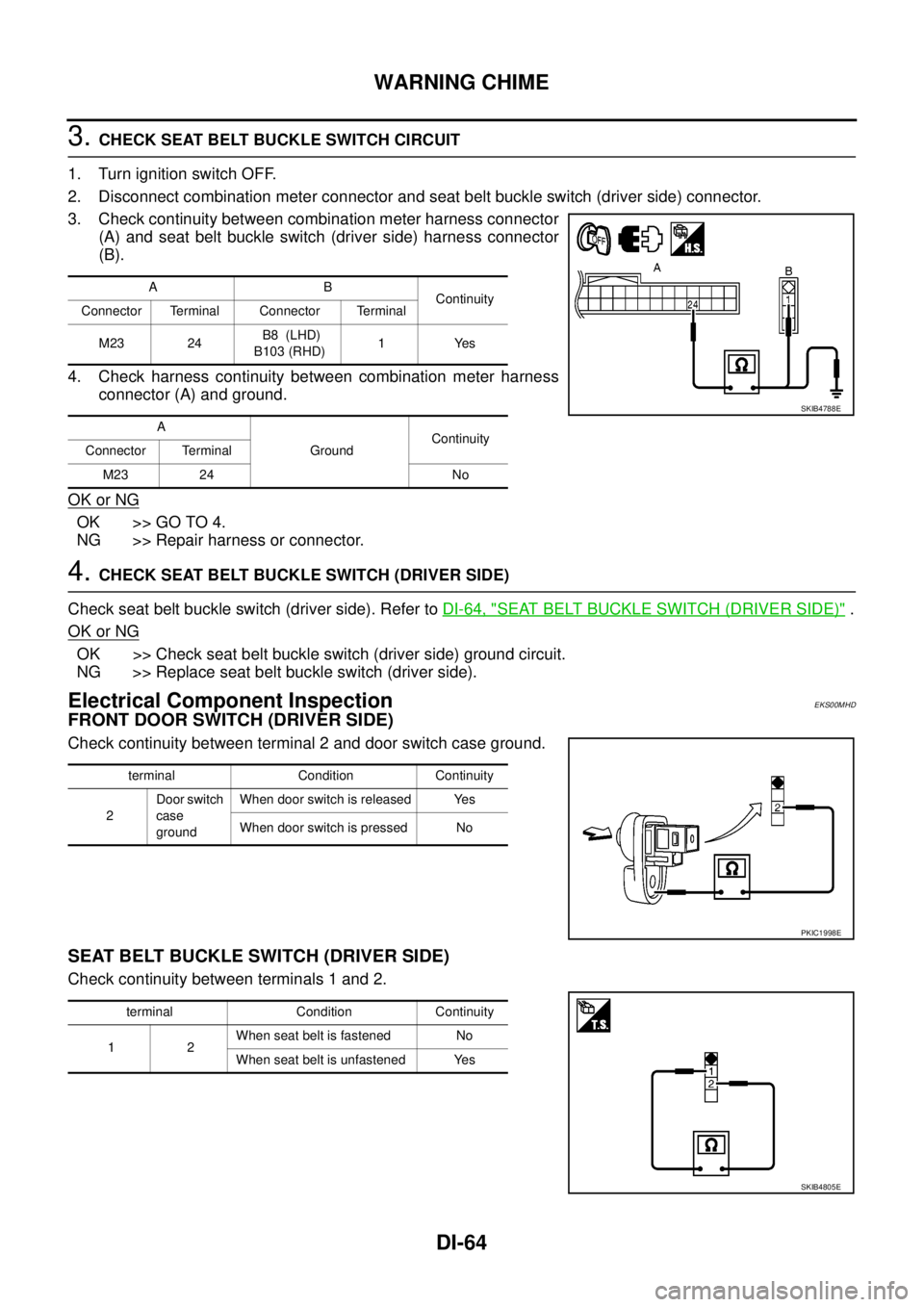

3.CHECK SEAT BELT BUCKLE SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect combination meter connector and seat belt buckle switch (driver side) connector.

3. Check continuity between combination meter harness connector

(A) and seat belt buckle switch (driver side) harness connector

(B).

4. Check harness continuity between combination meter harness

connector (A) and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair harness or connector.

4.CHECK SEAT BELT BUCKLE SWITCH (DRIVER SIDE)

Check seat belt buckle switch (driver side). Refer toDI-64, "

SEAT BELT BUCKLE SWITCH (DRIVER SIDE)".

OK or NG

OK >> Check seat belt buckle switch (driver side) ground circuit.

NG >> Replace seat belt buckle switch (driver side).

Electrical Component InspectionEKS00MHD

FRONT DOOR SWITCH (DRIVER SIDE)

Check continuity between terminal 2 and door switch case ground.

SEAT BELT BUCKLE SWITCH (DRIVER SIDE)

Check continuity between terminals 1 and 2.

AB

Continuity

Connector Terminal Connector Terminal

M23 24B8 (LHD)

B103 (RHD)1Yes

A

GroundContinuity

Connector Terminal

M23 24 No

SKIB4788E

terminal Condition Continuity

2Door switch

case

groundWhen door switch is released Yes

When door switch is pressed No

PKIC1998E

terminal Condition Continuity

12When seat belt is fastened No

When seat belt is unfastened Yes

SKIB4805E

Page 981 of 3171

EC-1

ENGINE CONTROL SYSTEM

B ENGINE

CONTENTS

C

D

E

F

G

H

I

J

K

L

M

SECTIONEC

A

EC

ENGINE CONTROL SYSTEM

INDEX FOR DTC ........................................................ 6

DTC No. Index ......................................................... 6

Alphabetical Index .................................................... 8

PRECAUTIONS ........................................................ 10

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” ................................................................ 10

On Board Diagnostic (OBD) System of Engine ...... 10

Precautions ............................................................ 10

Wiring Diagrams and Trouble Diagnosis ................ 13

PREPARATION ......................................................... 14

Special Service Tools ............................................. 14

Commercial Service Tools ...................................... 14

ENGINE CONTROL SYSTEM .................................. 15

System Diagram ..................................................... 15

Vacuum Hose Drawing ........................................... 16

System Chart ......................................................... 18

Fuel Injection Control System ................................ 18

Fuel Injection Timing Control System ..................... 20

Air Conditioning Cut Control ................................... 20

Fuel Cut Control (At No Load & High Engine Speed)... 20

Crankcase Ventilation System ............................... 21

CAN Communication .............................................. 22

BASIC SERVICE PROCEDURE .............................. 23

Fuel Filter ............................................................... 23

Fuel Pump Learning Value Clearing ...................... 24

Injector Adjustment Value Registration .................. 25

ON BOARD DIAGNOSTIC (OBD) SYSTEM ............ 27

DTC Detection Logic .............................................. 27

Diagnostic Trouble Code (DTC) ............................. 27

Freeze Frame Data ................................................ 28

NATS (Nissan Anti-theft System) ........................... 28

Malfunction Indicator (MI) ....................................... 28

Relationship Between MI, DTC, CONSULT-II and

Driving Patterns ...................................................... 31

TROUBLE DIAGNOSIS ............................................ 33

Trouble Diagnosis Introduction ............................... 33

DTC Inspection Priority Chart ................................ 37

Basic Inspection ..................................................... 38

Symptom Matrix Chart ........................................... 42Engine Control Component Parts Location ............ 46

Circuit Diagram ....................................................... 50

ECM Harness Connector Terminal Layout ............. 52

ECM Terminals And Reference Value .................... 52

CONSULT-II Function (ENGINE) ............................ 59

CONSULT-II Reference Value in Data Monitor Mode

... 66

Major Sensor Reference Graph in Data Monitor

Mode ....................................................................... 69

TROUBLE DIAGNOSIS FOR INTERMITTENT INCI-

DENT ......................................................................... 70

Description .............................................................. 70

Diagnostic Procedure ............................................. 70

POWER SUPPLY AND GROUND CIRCUIT ............. 71

ECM Terminals and Reference Value ..................... 71

Wiring Diagram ....................................................... 72

Diagnostic Procedure ............................................. 73

Ground Inspection .................................................. 78

DTC U1000 CAN COMMUNICATION LINE .............. 79

Description .............................................................. 79

On Board Diagnosis Logic ...................................... 79

DTC Confirmation Procedure ................................. 79

Wiring Diagram ....................................................... 80

Diagnostic Procedure ............................................. 81

DTC P0016 CKP - CMP CORRELATION ................. 82

On Board Diagnosis Logic ...................................... 82

DTC Confirmation Procedure ................................. 82

Diagnostic Procedure ............................................. 82

DTC P0088 FUEL SYSTEM ...................................... 84

On Board Diagnosis Logic ...................................... 84

DTC Confirmation Procedure ................................. 84

Diagnostic Procedure ............................................. 84

Removal and Installation ........................................ 85

DTC P0089 FUEL PUMP .......................................... 86

On Board Diagnosis Logic ...................................... 86

DTC Confirmation Procedure ................................. 86

Diagnostic Procedure ............................................. 87

Removal and Installation ........................................ 87

DTC P0093 FUEL SYSTEM ...................................... 88

On Board Diagnosis Logic ...................................... 88

Page 990 of 3171

EC-10

PRECAUTIONS

PRECAUTIONS

PFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EBS01KC5

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

On Board Diagnostic (OBD) System of EngineEBS01KC6

The ECM has an on board diagnostic system. It will light up the malfunction indicator (MI) to warn the driver of

a malfunction causing emission deterioration.

CAUTION:

lBe sure to turn the ignition switch OFF and disconnect the battery negative cable before any

repair or inspection work. The open/short circuit of related switches, sensors, solenoid valves,

etc. will cause the MI to light up.

lBe sure to connect and lock the connectors securely after work. A loose (unlocked) connector will

cause the MI to light up due to the open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

lCertain systems and components, especially those related to OBD, may use a new style slide-

locking type harness connector. For description and how to disconnect, refer toPG-75, "

HAR-

NESS CONNECTOR".

lBe sure to route and secure the harnesses properly after work. The interference of the harness

with a bracket, etc. may cause the MI to light up due to the short circuit.

lBe sure to connect rubber tubes properly after work. A misconnected or disconnected rubber tube

may cause the MI to light up due to the malfunction of the fuel system, etc.

lBe sure to erase the unnecessary malfunction information (repairs completed) from the ECM

before returning the vehicle to the customer.

PrecautionsEBS01KC7

lAlways use a 12 volt battery as power source.

lDo not attempt to disconnect battery cables while engine is

running.

lBefore connecting or disconnecting the ECM harness con-

nector, turn ignition switch OFF and disconnect battery

negative cable. Failure to do so may damage the ECM

because battery voltage is applied to ECM even if ignition

switch is turned off.

lBefore removing parts, turn ignition switch OFF and then

disconnect battery negative cable.

SEF289H

Page 1339 of 3171

EI-1

EXTERIOR & INTERIOR

IBODY

CONTENTS

C

D

E

F

G

H

J

K

L

M

SECTIONEI

A

B

EI

EXTERIOR & INTERIOR

PRECAUTIONS .......................................................... 3

Service Notice .......................................................... 3

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 3

Precautions for SRS “AIR BAG” and “SEAT BELT

PRE-TENSIONER” Service ..................................... 3

Precautions for Procedures without Cowl Top Cover..... 4

PREPARATION ........................................................... 5

Commercial Service Tools ........................................ 5

SQUEAK AND RATTLE TROUBLE DIAGNOSES..... 6

Work Flow ................................................................ 6

CUSTOMER INTERVIEW ..................................... 6

DUPLICATE THE NOISE AND TEST DRIVE ....... 7

CHECK RELATED SERVICE BULLETINS ........... 7

LOCATE THE NOISE AND IDENTIFY THE

ROOT CAUSE ...................................................... 7

REPAIR THE CAUSE ........................................... 7

CONFIRM THE REPAIR ....................................... 7

Generic Squeak and Rattle Troubleshooting ........... 7

INSTRUMENT PANEL .......................................... 7

CENTER CONSOLE ............................................. 8

DOORS ................................................................. 8

TRUNK .................................................................. 8

SUNROOF/HEADLINING ..................................... 8

OVERHEAD CONSOLE (FRONT AND REAR)..... 8

SEATS ................................................................... 9

UNDERHOOD ....................................................... 9

Diagnostic Worksheet ............................................ 10

CLIP AND FASTENER ............................................. 12

Clip and Fastener ................................................... 12

FRONT BUMPER ..................................................... 15

Removal and Installation ........................................ 15

FRONT BUMPER ............................................... 15

REAR BUMPER ....................................................... 17

Removal and Installation ........................................ 17

REMOVAL ........................................................... 17

INSTALLATION ................................................... 18FRONT GRILLE ........................................................ 19

Removal and Installation ........................................ 19

REMOVAL ........................................................... 19

INSTALLATION ................................................... 19

COWL TOP ............................................................... 20

Removal and Installation ........................................ 20

REMOVAL ........................................................... 20

INSTALLATION ................................................... 20

FENDER PROTECTOR ............................................ 21

Components ........................................................... 21

Removal and Installation of Front Fender Protector... 22

REMOVAL ........................................................... 22

INSTALLATION ................................................... 22

Removal and Installation of Rear Fender Protector... 22

REMOVAL ........................................................... 22

INSTALLATION ................................................... 22

MUDGUARD ............................................................. 23

Removal and Installation ........................................ 23

RUNNING BOARDS ................................................. 24

Removal and Installation ........................................ 24

REMOVAL ........................................................... 25

INSTALLATION ................................................... 25

ROOF RACK ............................................................. 26

Removal and Installation ........................................ 26

REMOVAL ........................................................... 26

INSTALLATION ................................................... 26

DOOR OUTSIDE MOLDING ..................................... 27

Removal and Installation ........................................ 27

FRONT DOOR OUTSIDE MOLDING .................. 27

SIDE GUARD MOLDING .......................................... 28

Removal and Installation ........................................ 28

REMOVAL ........................................................... 29

INSTALLATION ................................................... 29

DOOR FINISHER ...................................................... 30

Removal and Installation ........................................ 30

FRONT DOOR .................................................... 30

REAR DOOR - DOUBLE CAB ............................ 31

REAR DOOR - KING CAB .................................. 32

BODY SIDE TRIM ..................................................... 33

Components ........................................................... 33

Page 1341 of 3171

PRECAUTIONS

EI-3

C

D

E

F

G

H

J

K

L

MA

B

EI

PRECAUTIONSPFP:00001

Service NoticeEIS00DY1

lWhen removing or installing various parts, place a cloth or padding on the vehicle body to prevent

scratches.

lHandle trim, molding, instruments, grille, etc. carefully during removing or installing. Be careful not to soil

or damage them.

lApply sealing compound where necessary when installing parts.

lWhen applying sealing compound, be careful that the sealing compound does not protrude from parts.

lWhen replacing any metal parts (for example body outer panel, members, etc.), be sure to take rust pre-

vention measures.

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EIS00DZ5

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions for SRS “AIR BAG” and “SEAT BELT PRE-TENSIONER” ServiceEIS00DZ2

lDo not use electrical test equipment to check SRS circuits unless instructed to in this Service Manual.

lBefore servicing the SRS, turn ignition switch OFF, disconnect both battery cables and wait at least 3 min-

utes.

For approximately 3 minutes after the cables are removed, it is still possible for the air bag and seat belt

pre-tensioner to deploy. Therefore, do not work on any SRS connectors or wires until at least 3 minutes

have passed.

lThe air bag diagnosis sensor unit must always be installed with the arrow marks “Ü” pointing toward the

front of the vehicle for proper operation. Also check the air bag diagnosis sensor unit for cracks, deformi-

ties or rust before installation and replace as required.

lThe spiral cable must be aligned with the neutral position since its rotations are limited. Do not attempt to

turn steering wheel or column after removal of steering gear.

lHandle air bag module carefully. Always place driver and front passenger air bag modules with the pad

side facing upward and seat mounted front side air bag module standing with the stud bolt side facing

down.

lConduct self-diagnosis to check entire SRS for proper function after replacing any components.

lAfter air bag inflates, the front instrument panel assembly should be replaced if damaged.

Page 1370 of 3171

EI-32

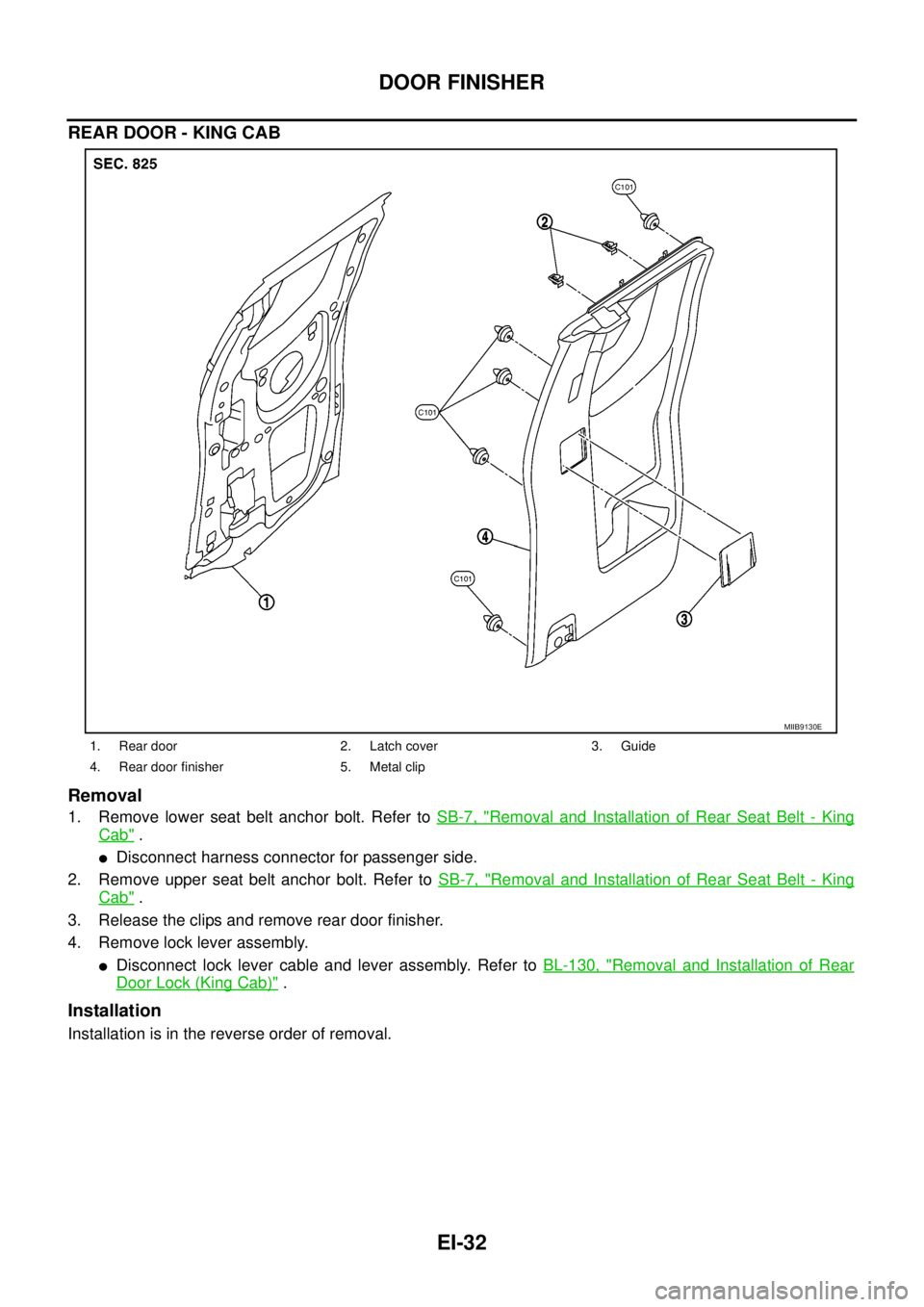

DOOR FINISHER

REAR DOOR - KING CAB

Removal

1. Remove lower seat belt anchor bolt. Refer toSB-7, "Removal and Installation of Rear Seat Belt - King

Cab".

lDisconnect harness connector for passenger side.

2. Remove upper seat belt anchor bolt. Refer toSB-7, "

Removal and Installation of Rear Seat Belt - King

Cab".

3. Release the clips and remove rear door finisher.

4. Remove lock lever assembly.

lDisconnect lock lever cable and lever assembly. Refer toBL-130, "Removal and Installation of Rear

Door Lock (King Cab)".

Installation

Installation is in the reverse order of removal.

1. Rear door 2. Latch cover 3. Guide

4. Rear door finisher 5. Metal clip

MIIB9130E

Page 1373 of 3171

BODY SIDE TRIM

EI-35

C

D

E

F

G

H

J

K

L

MA

B

EI

2. Remove front kick plate from center pillar lower finisher.

3. Remove front kick plate from dash side from lower dash side finisher.

4. Remove lower dash side finisher.

Installation

Installation is in the reverse order of removal.

CENTER PILLAR LOWER FINISHER

Removal

1. Remove front and rear door welts.

2. Remove seat belt anchor. Refer toSB-3, "

SEAT BELTS".

lOn RH side, remove the cover and disconnect seat belt tension sensor.

3. Remove front and rear kick plates. Refer toEI-35, "

KICK PLATES".

4. Remove center pillar lower finisher.

Installation

Installation is in the reverse order of removal.

CENTER PILLAR UPPER FINISHER

Removal

1. Remove front and rear door welts.

2. Remove seat belt shoulder anchor and D-ring. Refer toSB-3, "

SEAT BELTS".

3. Remove front and rear kick plates. Refer toEI-35, "

KICK PLATES".

4. Remove center pillar lower finisher.

5. Remove assist grip.

6. Remove center pillar upper finisher.

Installation

Installation is in the reverse order of removal.

FRONT PILLAR UPPER FINISHER

Removal

1. Remove front pillar lower finisher. Refer toEI-35, "FRONT PILLAR LOWER FINISHER".

2. Remove the front pillar assist grip.

3. Remove the front pillar upper finisher bolt.

4. Remove the front pillar upper finisher.

Installation

Installation is in the reverse order of removal.

FRONT PILLAR LOWER FINISHER

Removal

1. Remove front door welt and kick plate.

2. Remove the front pillar lower finisher.

Installation

Installation is in the reverse order of removal.

KICK PLATES

Removal

Release clips and remove front and/or rear kick plates.

Installation

Installation is in the reverse order of removal.

Page 1374 of 3171

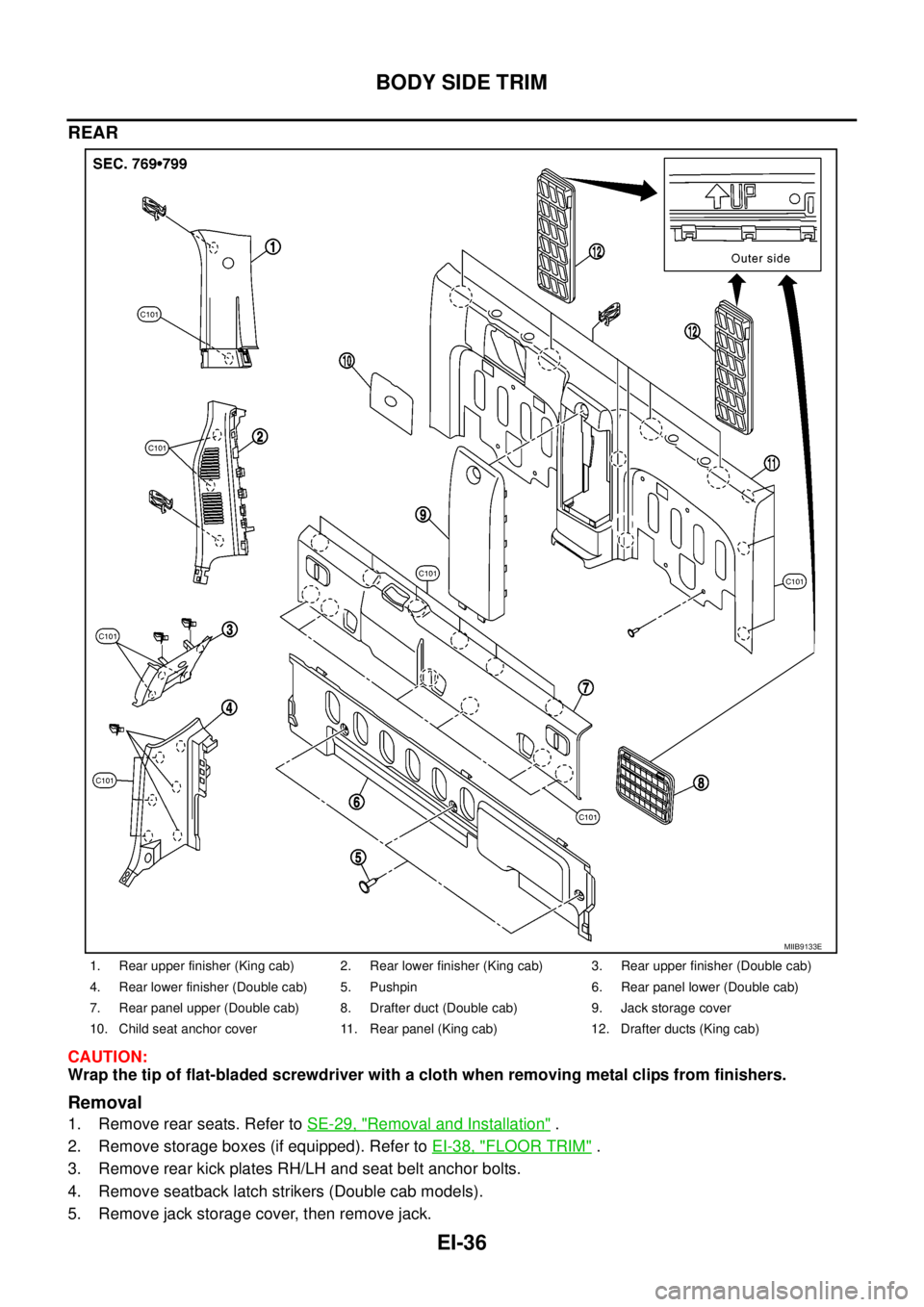

EI-36

BODY SIDE TRIM

REAR

CAUTION:

Wrap the tip of flat-bladed screwdriver with a cloth when removing metal clips from finishers.

Removal

1. Remove rear seats. Refer toSE-29, "Removal and Installation".

2. Remove storage boxes (if equipped). Refer toEI-38, "

FLOOR TRIM".

3. Remove rear kick plates RH/LH and seat belt anchor bolts.

4. Remove seatback latch strikers (Double cab models).

5. Remove jack storage cover, then remove jack.

1. Rear upper finisher (King cab) 2. Rear lower finisher (King cab) 3. Rear upper finisher (Double cab)

4. Rear lower finisher (Double cab) 5. Pushpin 6. Rear panel lower (Double cab)

7. Rear panel upper (Double cab) 8. Drafter duct (Double cab) 9. Jack storage cover

10. Child seat anchor cover 11. Rear panel (King cab) 12. Drafter ducts (King cab)

MIIB9133E

Page 1377 of 3171

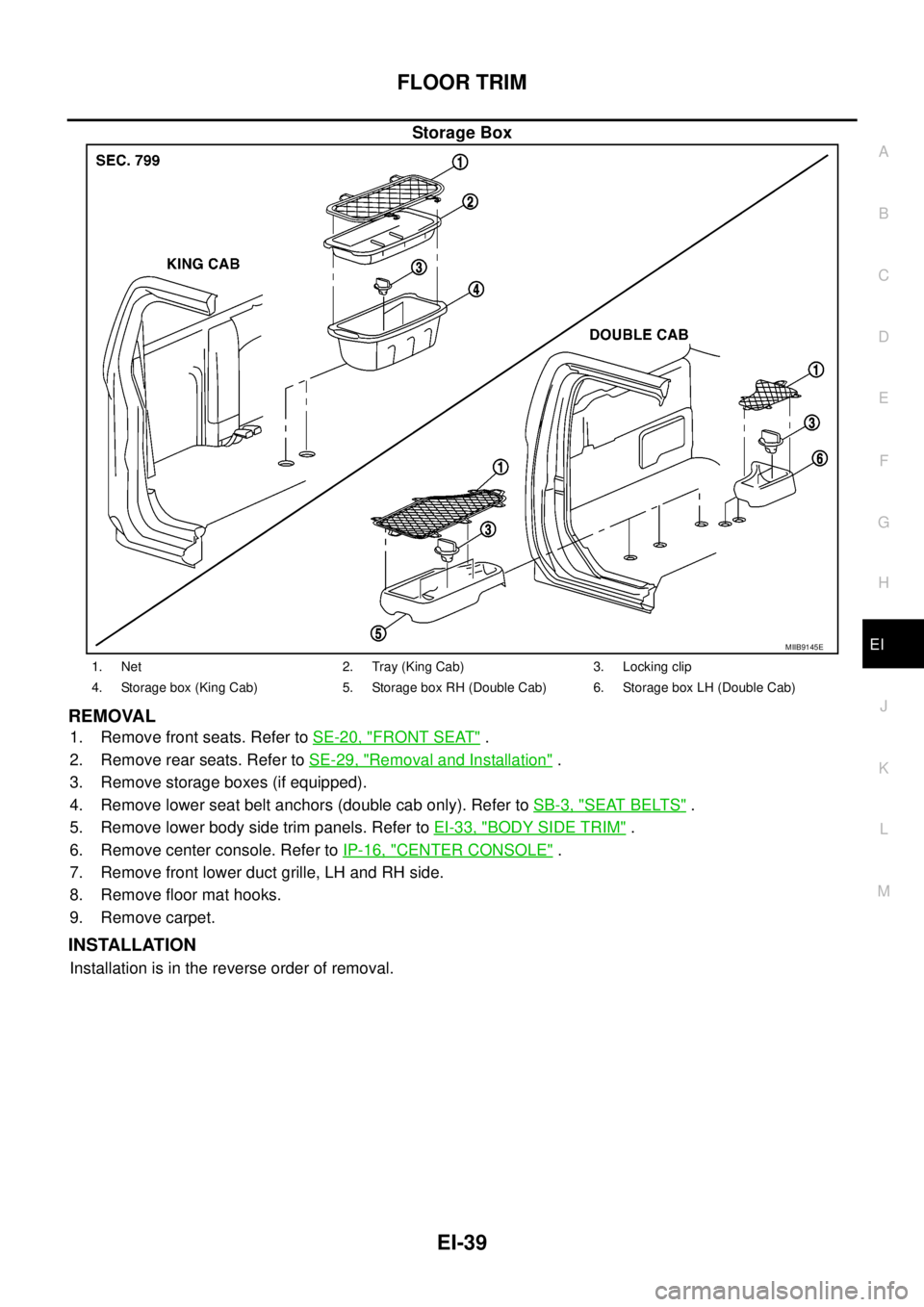

FLOOR TRIM

EI-39

C

D

E

F

G

H

J

K

L

MA

B

EI

Storage Box

REMOVAL

1. Remove front seats. Refer toSE-20, "FRONT SEAT".

2. Remove rear seats. Refer toSE-29, "

Removal and Installation".

3. Remove storage boxes (if equipped).

4. Remove lower seat belt anchors (double cab only). Refer toSB-3, "

SEAT BELTS".

5. Remove lower body side trim panels. Refer toEI-33, "

BODY SIDE TRIM".

6. Remove center console. Refer toIP-16, "

CENTER CONSOLE".

7. Remove front lower duct grille, LH and RH side.

8. Remove floor mat hooks.

9. Remove carpet.

INSTALLATION

Installation is in the reverse order of removal.

MIIB9145E

1. Net 2. Tray (King Cab) 3. Locking clip

4. Storage box (King Cab) 5. Storage box RH (Double Cab) 6. Storage box LH (Double Cab)