suspension NISSAN NAVARA 2005 Repair Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2313 of 3171

MA-38

CHASSIS AND BODY MAINTENANCE

Checking Axle and Suspension Parts

ELS001J5

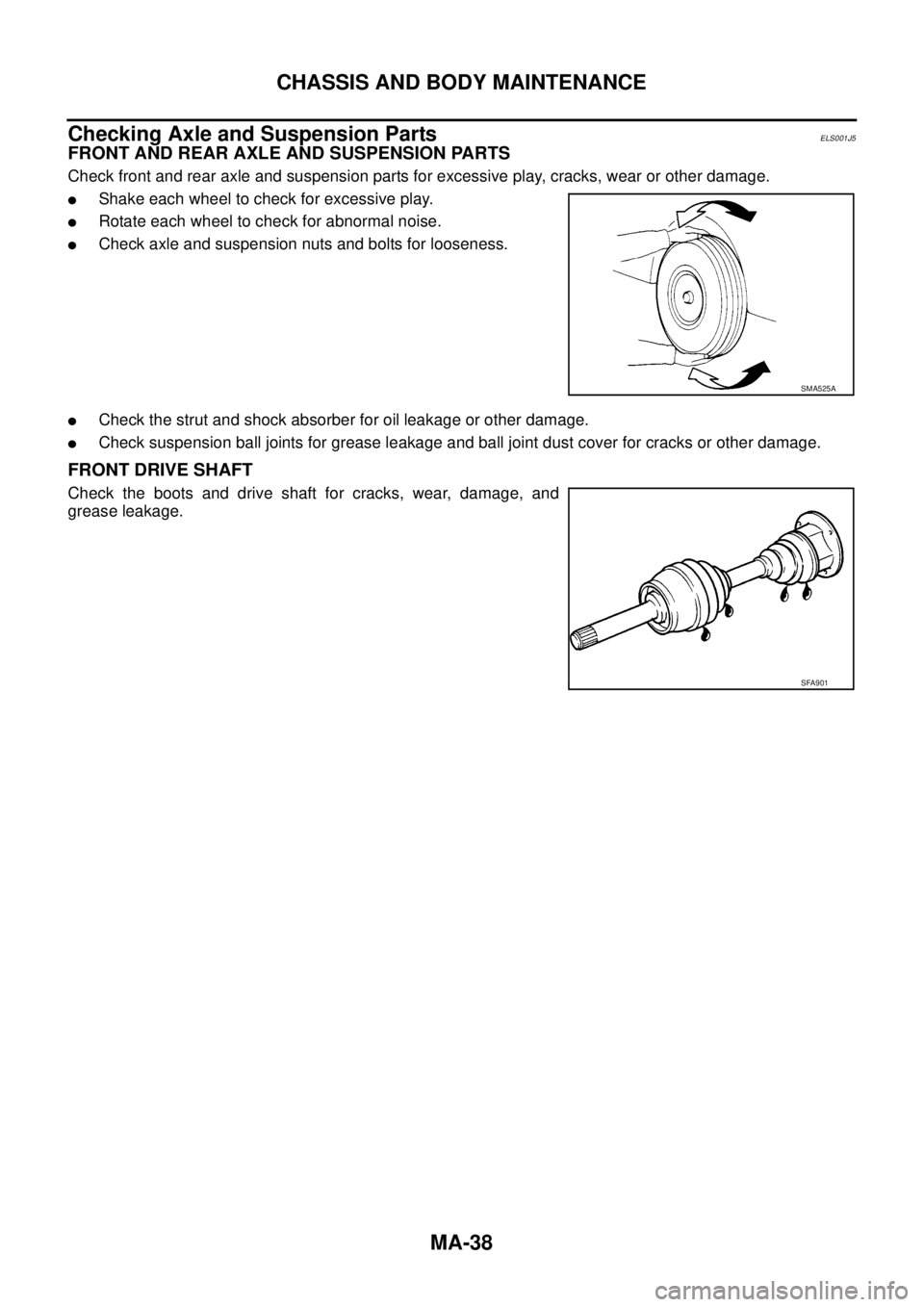

FRONT AND REAR AXLE AND SUSPENSION PARTS

Check front and rear axle and suspension parts for excessive play, cracks, wear or other damage.

lShake each wheel to check for excessive play.

lRotate each wheel to check for abnormal noise.

lCheck axle and suspension nuts and bolts for looseness.

lCheck the strut and shock absorber for oil leakage or other damage.

lCheck suspension ball joints for grease leakage and ball joint dust cover for cracks or other damage.

FRONT DRIVE SHAFT

Check the boots and drive shaft for cracks, wear, damage, and

grease leakage.

SMA525A

SFA901

Page 2544 of 3171

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PG-15

C

D

E

F

G

H

I

J

L

MA

B

PG

IPDM E/R STATUS CONTROL

In order to save power, IPDM E/R switches status by itself based on each operating condition.

1. CAN communication status

lCAN communication is normally performed with other control units.

lIndividual unit control by IPDM E/R is normally performed.

lA status is changed into sleep transient status when receiving a sleep request signal from BCM while

all the systems controlled by IPDM E/R under suspension.

2. Sleep transient status

lProcess to stop CAN communication is activated.

lAll systems controlled by IPDM E/R are stopped. When 3 second has elapsed after CAN communica-

tion with other control units is stopped, status switches to sleep status.

3. Sleep status

lIPDM E/R operates in low power mode.

lCAN communication is stopped.

lWhen a change in CAN communication signal is detected, status switches to CAN communication sta-

tus.

lWhen a change in ignition switch signal is detected, status switches to CAN communication status.

CAN Communication System DescriptionEKS00PA9

Refer toLAN-23, "CAN COMMUNICATION".

Function of Detecting Ignition Relay MalfunctionEKS00PAA

lWhen the integrated ignition relay is stuck in a “closed contact” position and cannot be turned OFF, IPDM

E/R turns ON tail and parking lamps for 10 minutes to indicate IPDM E/R malfunction.

lWhen the state of the integrated ignition relay does not agree with the state of the ignition switch signal

received with CAN communication, the IPDM E/R activates the tail lamp relay.

NOTE:

When the ignition switch is turned ON, the tail lamps are OFF.

Ignition switch signal Ignition relay status Tail lamp relay

ON ON —

OFF OFF —

ON OFF —

OFF ON ON (10 minutes)

Page 2617 of 3171

PR-2

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

PFP:00003

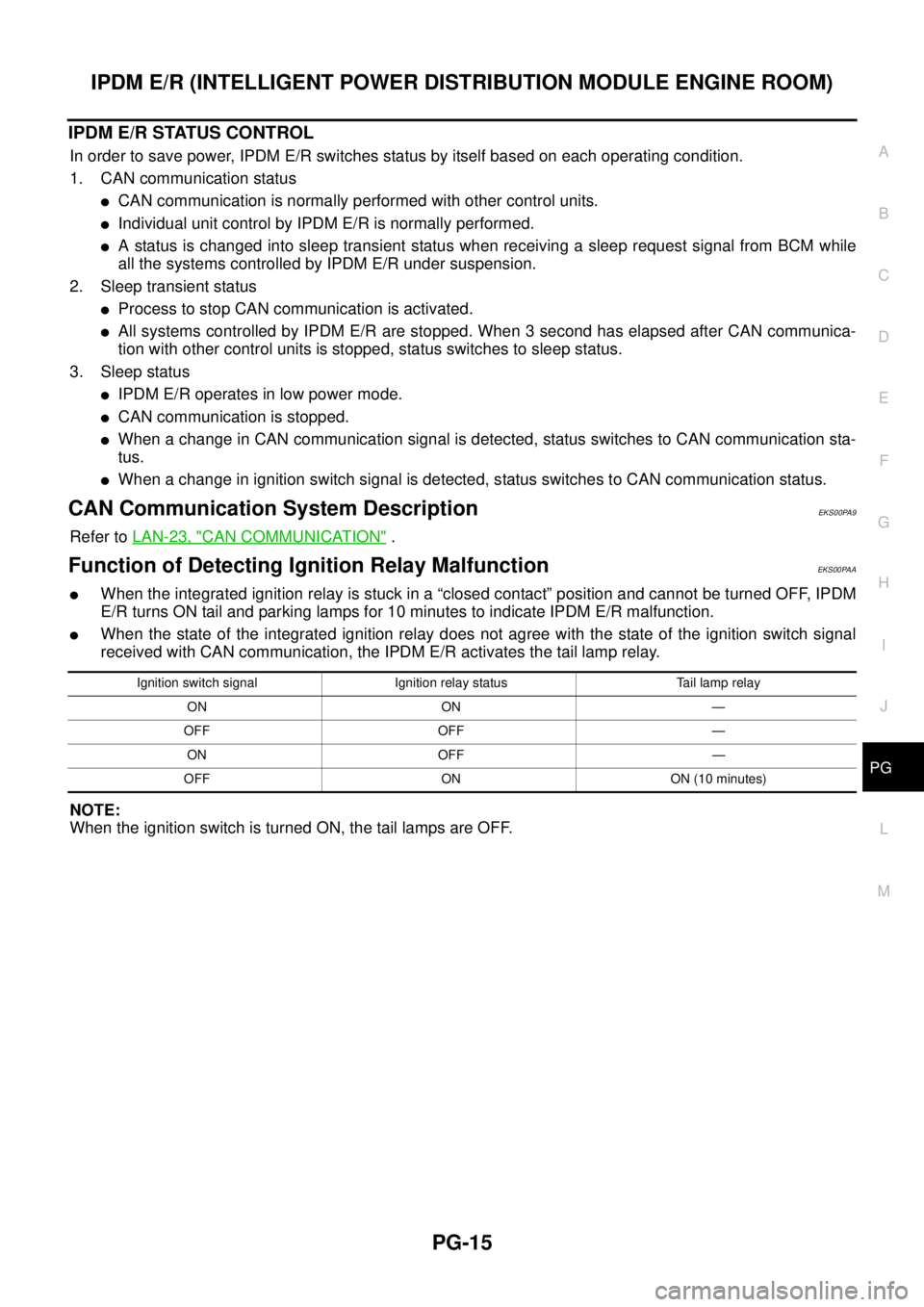

NVH Troubleshooting ChartEDS002WN

Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

´: ApplicableReference page

PR-3

(front)

PR-7(rear)

PR-3(front)

PR-7(rear)

PR-3(front)

PR-7(rear)

RFD-7, "

NVH Troubleshooting Chart

"

RFD-39, "

NVH Troubleshooting Chart

"

FA X -4 , "

NVH Troubleshooting Chart

"

RAX-5, "

NVH Troubleshooting Chart

"

FSU-5, "

NVH Troubleshooting Chart

"

RSU-3, "

NVH Troubleshooting Chart

"

WT-2, "

NVH Troubleshooting Chart

"

WT-2, "

NVH Troubleshooting Chart

"

FA X -4 , "

NVH Troubleshooting Chart

"

RAX-5, "

NVH Troubleshooting Chart

"

BR-5, "

NVH Troubleshooting Chart

"

PS-5, "

NVH Troubleshooting Chart

"

Possible cause and suspected parts

Uneven rotation torque

Rotation imbalance

Excessive runout

Differential

Axle

Suspension

Tires

Road wheel

Drive shaft

Axle shaft

Brakes

Steering

SymptomNoise´´´´´´´´´´´´

Shake´´´´´´´´

Vibration´´´ ´´´ ´´ ´

Page 2632 of 3171

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

PS-5

C

D

E

F

H

I

J

K

L

MA

B

PS

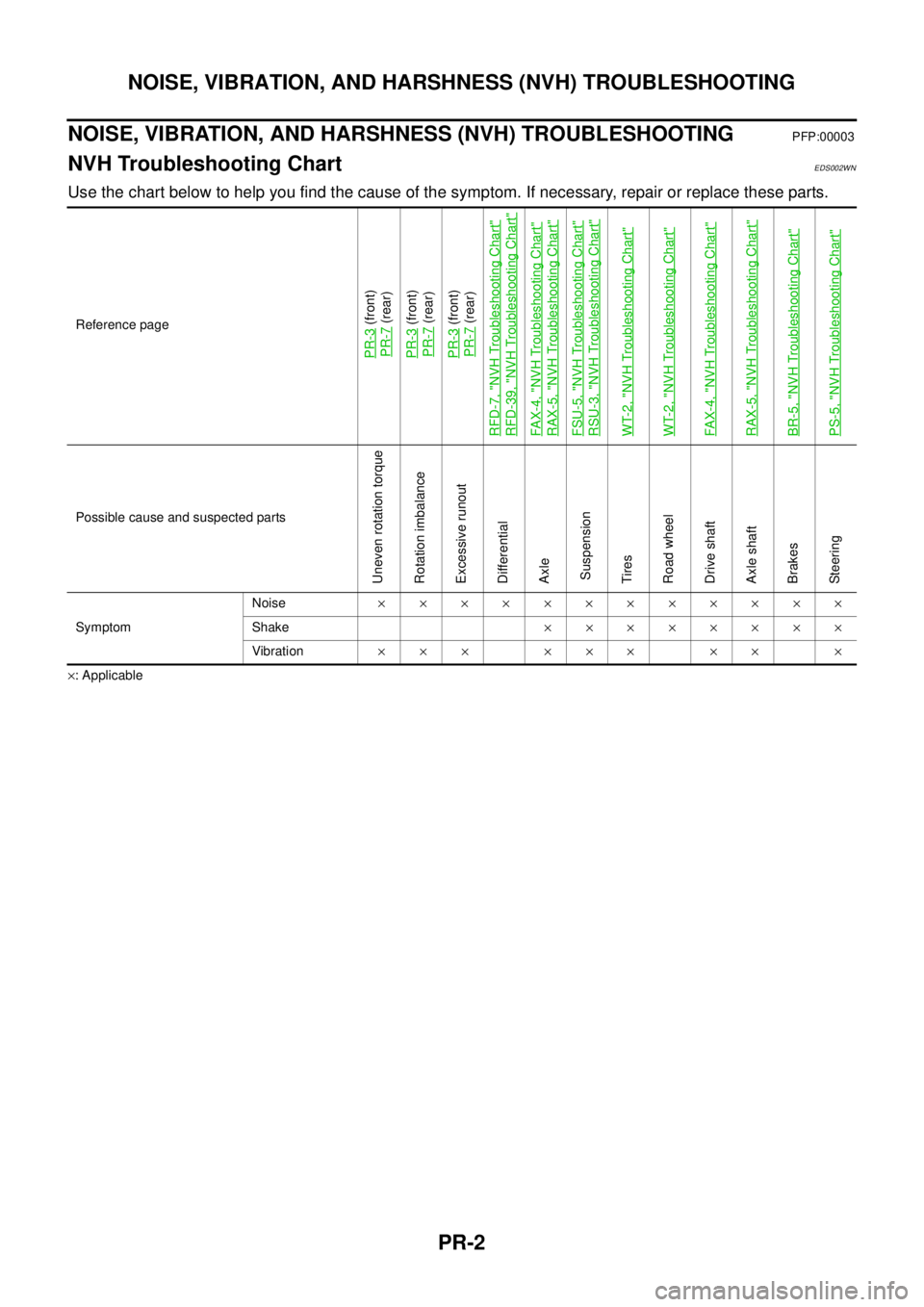

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTINGPFP:00003

NVH Troubleshooting ChartEGS001LC

Use chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

´: ApplicableReference page

PS-6PS-6PS-18PS-18PS-18PS-6PS-8PS-8EM-12PS-8—

PS-18PS-12PS-11PS-16

NVHinPRsection

NVH in RFD section

NVH in FAX, RAX, FSU, RSU section

NVH in WT section

NVH in WT section

NVHinBRsection

NVHinBRsection

Possible cause and SUSPECTED PARTS

Fluid level

Air in hydraulic system

Outer socket ball joint swinging force

Outer socket ball joint rotating torque

Outer socket ball joint end play

Steering fluid leakage

Steering wheel play

Steering gear rack sliding force

Drive belt looseness

Improper steering wheel

Improper installation or looseness of tilt lock lever

Mounting rubber deterioration

Steering column deformation or damage

Improper installation or looseness of steering column

Steering linkage looseness

PROPELLER SHAFT

DIFFERENTIAL

AXLE and SUSPENSION

TYRES

ROAD WHEEL

DRIVE SHAFT

BRAKES

Symptom SteeringNoise´ ´ ´´´´´ ´ ´ ´´´´´´ ´

Shake´´´ ´ ´´´´ ´

Vibration´´´´´ ´ ´´ ´

Shimmy´´´ ´ ´´´ ´

Shudder´ ´ ´´´ ´

Page 2635 of 3171

PS-8

STEERING WHEEL

STEERING WHEEL

PFP:48430

On-Vehicle Inspection and ServiceEGS001LG

CHECKING CONDITION OF INSTALLATION

lCheck installation conditions of steering gear assembly, front suspension assembly, axle and steering col-

umn assembly.

lCheck if movement exists when steering wheel is moved up and down, to the left and right and to the axial

direction.

lCheck steering gear assembly mounting bolts and nuts for looseness. Refer toPS-14, "COMPONENT".

CHECKING STEERING WHEEL PLAY

lTurn steering wheel so that front wheels come to the straight-ahead position. Start engine and lightly turn

steering wheel to the left and right until front wheels start to move. Measure steering wheel movement on

the outer circumference.

lWhen the measurement value is outside the standard value, check backlash for each joint of steering col-

umn assembly and installation condition of steering gear assembly.

CHECKING NEUTRAL POSITION STEERING WHEEL

lMake sure that steering gear assembly, steering column assembly and steering wheel are installed in the

correct position.

lPerform neutral position inspection after wheel alignment. Refer toFSU-7, "Front Wheel Alignment".

lSet vehicle to the straight-ahead position and confirm steering wheel is in the neutral position.

lLoosen outer socket lock nut and turn inner socket to left and right equally to make fine adjustment if

steering wheel is not in the neutral position.

CHECKING STEERING WHEEL TURNING FORCE

1. Park vehicle on a level and dry surface, set parking brake.

2. Start engine.

3. Bring power steering fluid up to adequate operating temperature. [Make sure temperature of fluid is

approximately 50 to 80°C(122to176°F).]

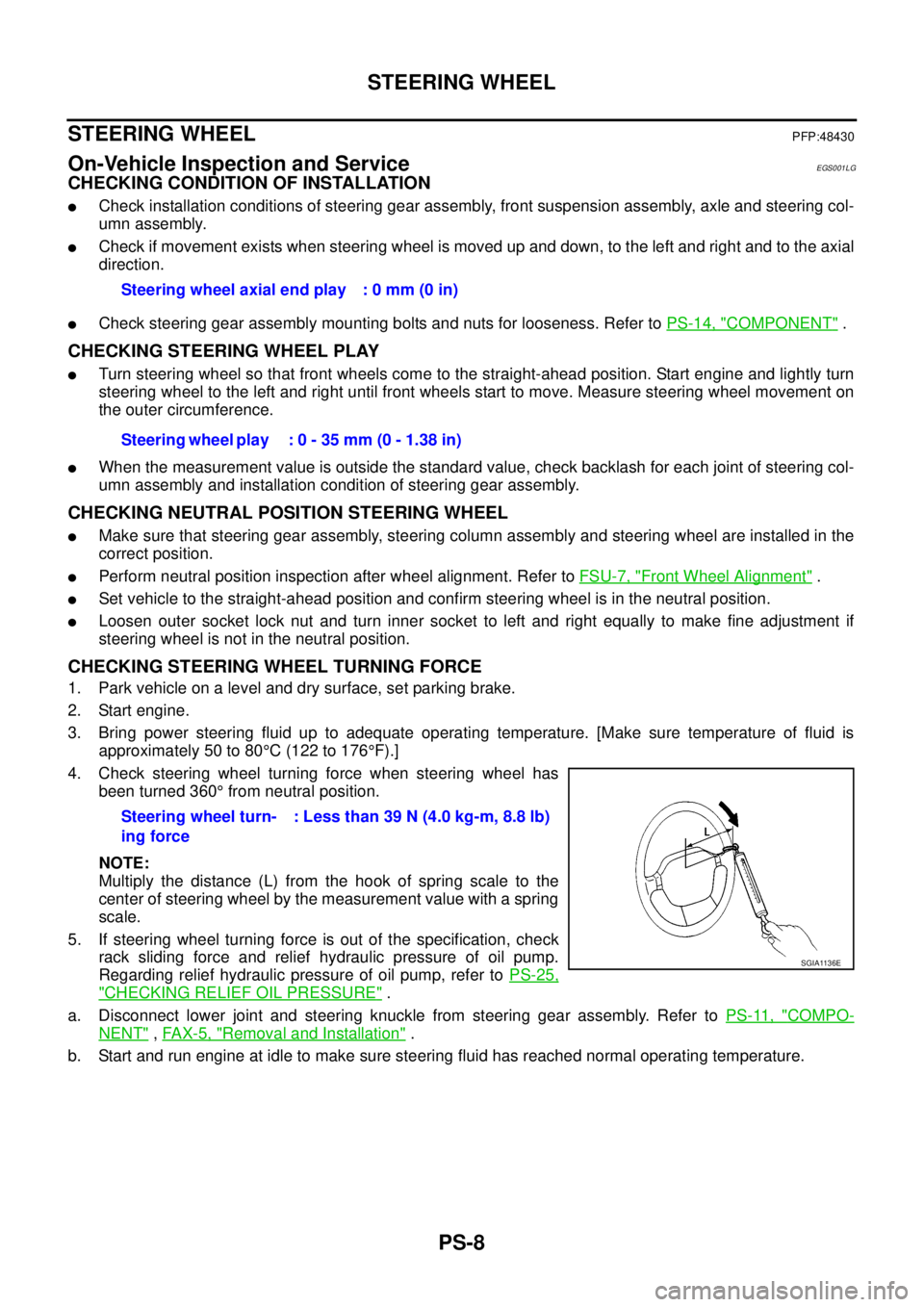

4. Check steering wheel turning force when steering wheel has

been turned 360°from neutral position.

NOTE:

Multiply the distance (L) from the hook of spring scale to the

center of steering wheel by the measurement value with a spring

scale.

5. If steering wheel turning force is out of the specification, check

rack sliding force and relief hydraulic pressure of oil pump.

Regarding relief hydraulic pressure of oil pump, refer toPS-25,

"CHECKING RELIEF OIL PRESSURE".

a. Disconnect lower joint and steering knuckle from steering gear assembly. Refer toPS-11, "

COMPO-

NENT",FAX-5, "Removal and Installation".

b. Start and run engine at idle to make sure steering fluid has reached normal operating temperature.Steering wheel axial end play : 0 mm (0 in)

Steering wheel play : 0 - 35 mm (0 - 1.38 in)

Steering wheel turn-

ing force: Less than 39 N (4.0 kg-m, 8.8 lb)

SGIA1136E

Page 2636 of 3171

STEERING WHEEL

PS-9

C

D

E

F

H

I

J

K

L

MA

B

PS

c. While pulling outer socket slowly in±11 . 5 m m (±0.453 in) range

from neutral position, make sure rack sliding force is within

specification.

d. If rack sliding force is not within specification, overhaul steering

gear assembly.

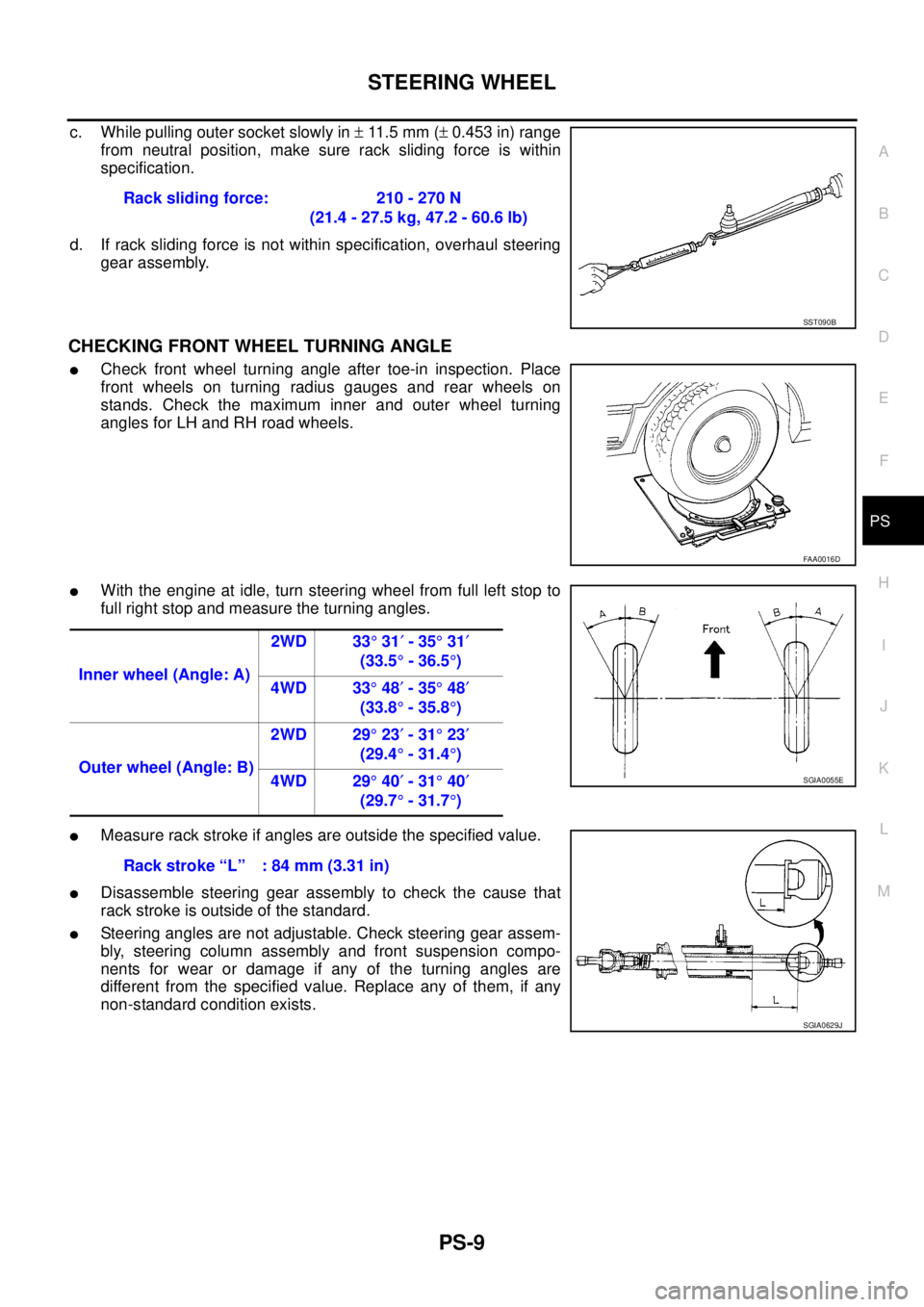

CHECKING FRONT WHEEL TURNING ANGLE

lCheck front wheel turning angle after toe-in inspection. Place

front wheels on turning radius gauges and rear wheels on

stands. Check the maximum inner and outer wheel turning

angles for LH and RH road wheels.

lWith the engine at idle, turn steering wheel from full left stop to

full right stop and measure the turning angles.

lMeasure rack stroke if angles are outside the specified value.

lDisassemble steering gear assembly to check the cause that

rack stroke is outside of the standard.

lSteering angles are not adjustable. Check steering gear assem-

bly, steering column assembly and front suspension compo-

nents for wear or damage if any of the turning angles are

different from the specified value. Replace any of them, if any

non-standard condition exists.Rack sliding force: 210 - 270 N

(21.4 - 27.5 kg, 47.2 - 60.6 lb)

SST090B

FAA0016D

Inner wheel (Angle: A)2WD 33°31¢-35°31¢

(33.5°-36.5°)

4WD 33°48¢-35°48¢

(33.8°-35.8°)

Outer wheel (Angle: B)2WD 29°23¢-31°23¢

(29.4°-31.4°)

4WD 29°40¢-31°40¢

(29.7°-31.7°)

SGIA0055E

Rack stroke “L” : 84 mm (3.31 in)

SGIA0629J

Page 2642 of 3171

POWER STEERING GEAR AND LINKAGE

PS-15

C

D

E

F

H

I

J

K

L

MA

B

PS

7. Remove high and low pressure piping of hydraulic piping, and

then drain power steering fluid. Refer toPS-6, "

POWER

STEERING FLUID".

8. Remove steering hydraulic piping bracket from front suspension

member. Refer toPS-30, "

HYDRAULIC LINE".

9. Remove mounting bolts and nuts of steering gear assembly, and

then remove steering gear assembly, rack mounting bracket,

rack mounting insulator and washer from vehicle.

INSTALLATION

lInstallation is the reverse order of removal. For tightening torque, refer toPS-14, "COMPONENT".

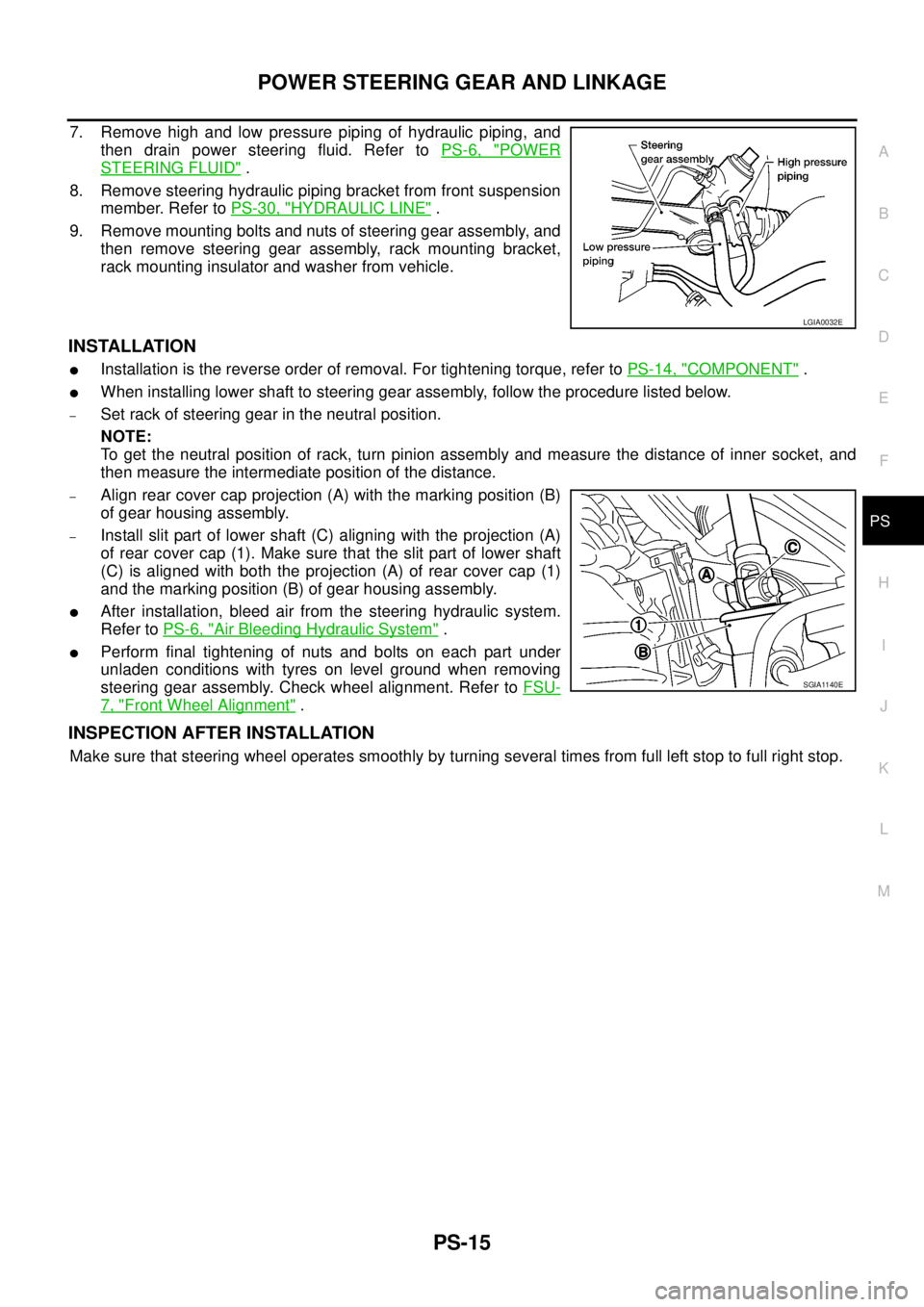

lWhen installing lower shaft to steering gear assembly, follow the procedure listed below.

–Set rack of steering gear in the neutral position.

NOTE:

To get the neutral position of rack, turn pinion assembly and measure the distance of inner socket, and

then measure the intermediate position of the distance.

–Align rear cover cap projection (A) with the marking position (B)

of gear housing assembly.

–Install slit part of lower shaft (C) aligning with the projection (A)

of rear cover cap (1). Make sure that the slit part of lower shaft

(C) is aligned with both the projection (A) of rear cover cap (1)

and the marking position (B) of gear housing assembly.

lAfter installation, bleed air from the steering hydraulic system.

Refer toPS-6, "

Air Bleeding Hydraulic System".

lPerform final tightening of nuts and bolts on each part under

unladen conditions with tyres on level ground when removing

steering gear assembly. Check wheel alignment. Refer toFSU-

7, "Front Wheel Alignment".

INSPECTION AFTER INSTALLATION

Make sure that steering wheel operates smoothly by turning several times from full left stop to full right stop.

LGIA0032E

SGIA1140E

Page 2668 of 3171

![NISSAN NAVARA 2005 Repair Owners Manual NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

RAX-5

[M226]

C

E

F

G

H

I

J

K

L

MA

B

RAX

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTINGPFP:00003

NVH Troubleshooting ChartEDS003HW

Use the c NISSAN NAVARA 2005 Repair Owners Manual NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

RAX-5

[M226]

C

E

F

G

H

I

J

K

L

MA

B

RAX

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTINGPFP:00003

NVH Troubleshooting ChartEDS003HW

Use the c](/img/5/57362/w960_57362-2667.png)

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

RAX-5

[M226]

C

E

F

G

H

I

J

K

L

MA

B

RAX

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTINGPFP:00003

NVH Troubleshooting ChartEDS003HW

Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

´: Applicable Reference page

RAX-7

(M226 all)

RAX-7(M226 all)

RAX-7(M226 all)

PR-2, "

NVH Troubleshooting Chart

"

RFD-7

(with LSD),RFD-39

(with LD)

RSU-3, "

NVH Troubleshooting Chart

"

WT-2, "

NVH Troubleshooting Chart

"

WT-2, "

NVH Troubleshooting Chart

"

BR-5, "

NVH Troubleshooting Chart

"

Possible cause and SUSPECTED PARTS

Improper installation, looseness

Parts interference

Wheel bearing damage

PROPELLER SHAFT

REAR FINAL DRIVE

SUSPENSION

TIRES

ROAD WHEEL

BRAKES

SymptomNoise´´ ´´´´´´

Shake´´ ´ ´´´´

Vibration´´ ´ ´´

Shimmy´´ ´´´´

Shudder´ ´´´´

Poor quality ride or handling´´´ ´´´

Page 2710 of 3171

![NISSAN NAVARA 2005 Repair Owners Manual NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

RFD-7

[WITH LIMITED SLIP DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTINGPFP:00003

NVH Troubleshooti NISSAN NAVARA 2005 Repair Owners Manual NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

RFD-7

[WITH LIMITED SLIP DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTINGPFP:00003

NVH Troubleshooti](/img/5/57362/w960_57362-2709.png)

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

RFD-7

[WITH LIMITED SLIP DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTINGPFP:00003

NVH Troubleshooting ChartEDS00392

Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

´: ApplicableReference page

RFD-22, "

INSPECTION AFTER DISASSEMBLY

"

RFD-16, "

Tooth Contact

"

RFD-22, "

INSPECTION AFTER DISASSEMBLY

"

RFD-17, "

Backlash

"

RFD-18, "

Companion Flange Runout

"

RFD-9, "

Checking Differential Gear Oil

"

PR-2, "

NVH Troubleshooting Chart

"

RAX-5, "

NVH Troubleshooting Chart

",RSU-3, "

NVH Troubleshooting Chart

"

WT-2, "

NVH Troubleshooting Chart

"

RAX-5, "

NVH Troubleshooting Chart

"

BR-5, "

NVH Troubleshooting Chart

"

PS-5, "

NVH Troubleshooting Chart

"

Possible cause and SUSPECTED PARTS

Gear tooth rough

Gear contact improper

Tooth surfaces worn

Backlash incorrect

Companion flange excessive runout

Gear oil improper

PROPELLER SHAFT

AXLE AND SUSPENSION

TIRES

ROAD WHEEL

AXLE SHAFT

BRAKES

STEERING

Symptom Noise´´´´´´´´´´´´´

Page 2742 of 3171

![NISSAN NAVARA 2005 Repair Owners Manual NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

RFD-39

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGPFP:00003

NVH Troubles NISSAN NAVARA 2005 Repair Owners Manual NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

RFD-39

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGPFP:00003

NVH Troubles](/img/5/57362/w960_57362-2741.png)

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

RFD-39

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGPFP:00003

NVH Troubleshooting ChartEDS003AM

Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

´: ApplicableReference page

RFD-90, "

INSPECTION AFTER DISASSEMBLY

"

RFD-83, "

Tooth Contact

"

RFD-90, "

INSPECTION AFTER DISASSEMBLY

"

RFD-84, "

Backlash

"

RFD-85, "

Companion Flange Runout

"

RFD-40, "

Checking Differential Gear Oil

"

PR-2, "

NVH Troubleshooting Chart

"

RAX-5, "

NVH Troubleshooting Chart

",RSU-3, "

NVH Troubleshooting Chart

"

WT-2, "

NVH Troubleshooting Chart

"

RAX-5, "

NVH Troubleshooting Chart

"

BR-5, "

NVH Troubleshooting Chart

"

PS-5, "

NVH Troubleshooting Chart

"

Possible cause and SUSPECTED PARTS

Gear tooth rough

Gear contact improper

Tooth surfaces worn

Backlash incorrect

Companion flange excessive runout

Gear oil improper

PROPELLER SHAFT

AXLE AND SUSPENSION

TIRES

ROAD WHEEL

AXLE SHAFT

BRAKES

STEERING

Symptom Noise´´´´´´´´´´´´´