check engine NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2308 of 3171

CHASSIS AND BODY MAINTENANCE

MA-33

C

D

E

F

G

H

I

J

K

MA

B

MA

Changing Front Final Drive Oil (Front Differential Gear Oil)ELS001IU

CAUTION:

If using the vehicle for towing, the final drive oil must be replaced as specified. Refer toMA-8, "

PERI-

ODIC MAINTENANCE".

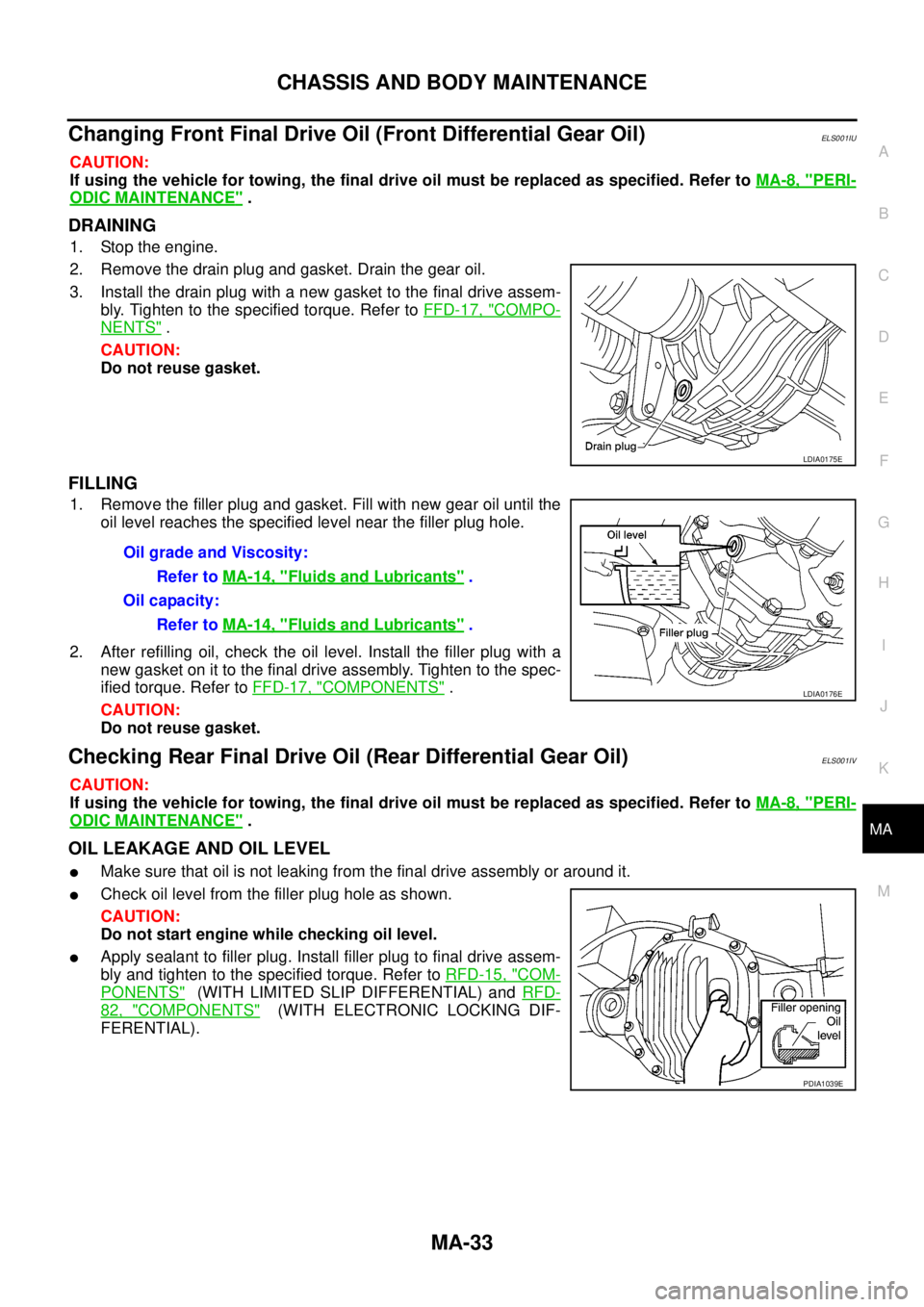

DRAINING

1. Stop the engine.

2. Remove the drain plug and gasket. Drain the gear oil.

3. Install the drain plug with a new gasket to the final drive assem-

bly. Tighten to the specified torque. Refer toFFD-17, "

COMPO-

NENTS".

CAUTION:

Do not reuse gasket.

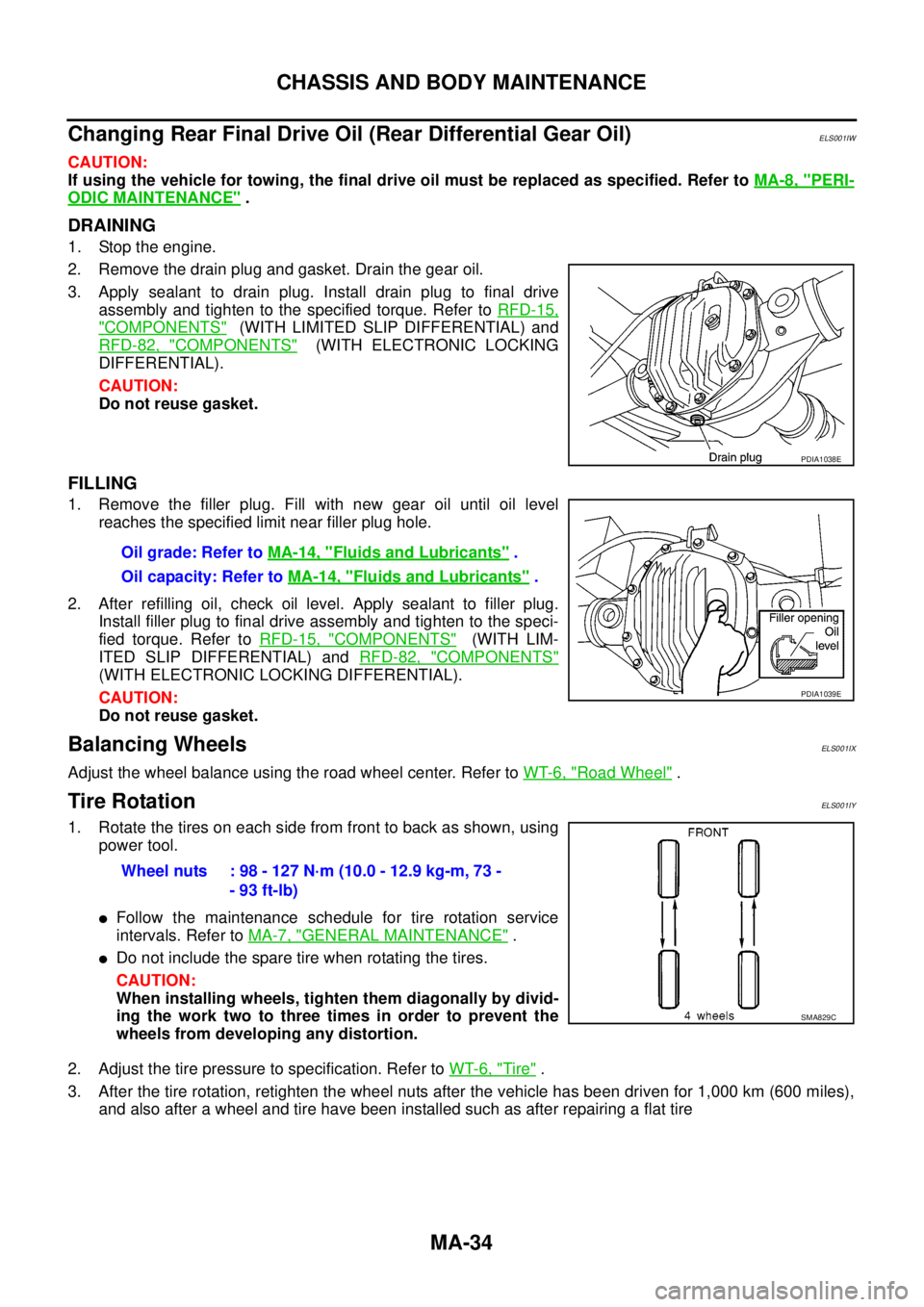

FILLING

1. Remove the filler plug and gasket. Fill with new gear oil until the

oil level reaches the specified level near the filler plug hole.

2. After refilling oil, check the oil level. Install the filler plug with a

new gasket on it to the final drive assembly. Tighten to the spec-

ified torque. Refer toFFD-17, "

COMPONENTS".

CAUTION:

Do not reuse gasket.

Checking Rear Final Drive Oil (Rear Differential Gear Oil)ELS001IV

CAUTION:

If using the vehicle for towing, the final drive oil must be replaced as specified. Refer toMA-8, "

PERI-

ODIC MAINTENANCE".

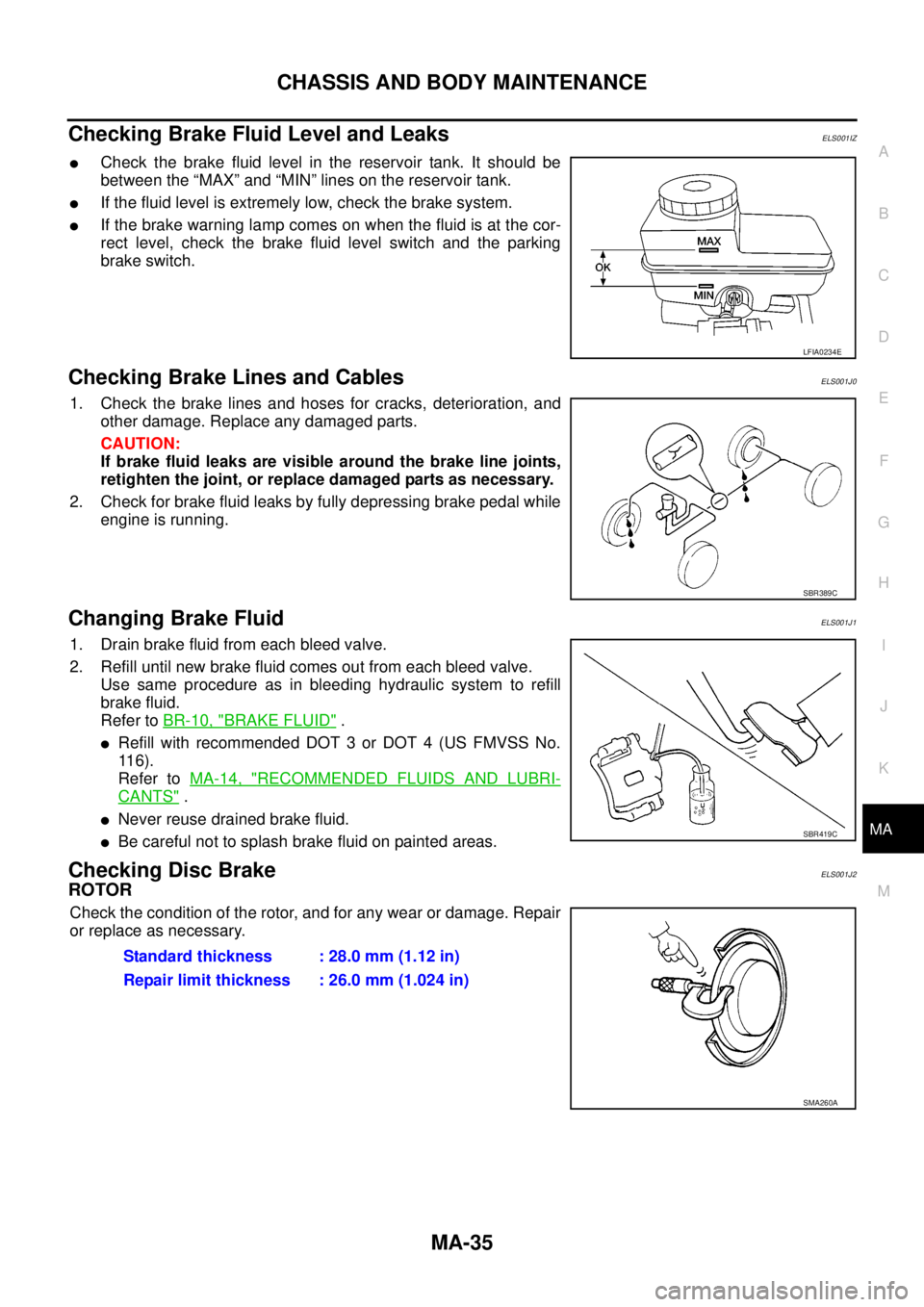

OIL LEAKAGE AND OIL LEVEL

lMake sure that oil is not leaking from the final drive assembly or around it.

lCheck oil level from the filler plug hole as shown.

CAUTION:

Do not start engine while checking oil level.

lApply sealant to filler plug. Install filler plug to final drive assem-

bly and tighten to the specified torque. Refer toRFD-15, "

COM-

PONENTS"(WITH LIMITED SLIP DIFFERENTIAL) andRFD-

82, "COMPONENTS"(WITH ELECTRONIC LOCKING DIF-

FERENTIAL).

LDIA0175E

OilgradeandViscosity:

Refer toMA-14, "

Fluids and Lubricants".

Oil capacity:

Refer toMA-14, "

Fluids and Lubricants".

LDIA0176E

PDIA1039E

Page 2309 of 3171

MA-34

CHASSIS AND BODY MAINTENANCE

Changing Rear Final Drive Oil (Rear Differential Gear Oil)

ELS001IW

CAUTION:

If using the vehicle for towing, the final drive oil must be replaced as specified. Refer toMA-8, "

PERI-

ODIC MAINTENANCE".

DRAINING

1. Stop the engine.

2. Remove the drain plug and gasket. Drain the gear oil.

3. Apply sealant to drain plug. Install drain plug to final drive

assembly and tighten to the specified torque. Refer toRFD-15,

"COMPONENTS"(WITH LIMITED SLIP DIFFERENTIAL) and

RFD-82, "

COMPONENTS"(WITH ELECTRONIC LOCKING

DIFFERENTIAL).

CAUTION:

Do not reuse gasket.

FILLING

1. Remove the filler plug. Fill with new gear oil until oil level

reaches the specified limit near filler plug hole.

2. After refilling oil, check oil level. Apply sealant to filler plug.

Install filler plug to final drive assembly and tighten to the speci-

fied torque. Refer toRFD-15, "

COMPONENTS"(WITH LIM-

ITED SLIP DIFFERENTIAL) andRFD-82, "

COMPONENTS"

(WITH ELECTRONIC LOCKING DIFFERENTIAL).

CAUTION:

Do not reuse gasket.

Balancing WheelsELS001IX

Adjust the wheel balance using the road wheel center. Refer toWT-6, "Road Wheel".

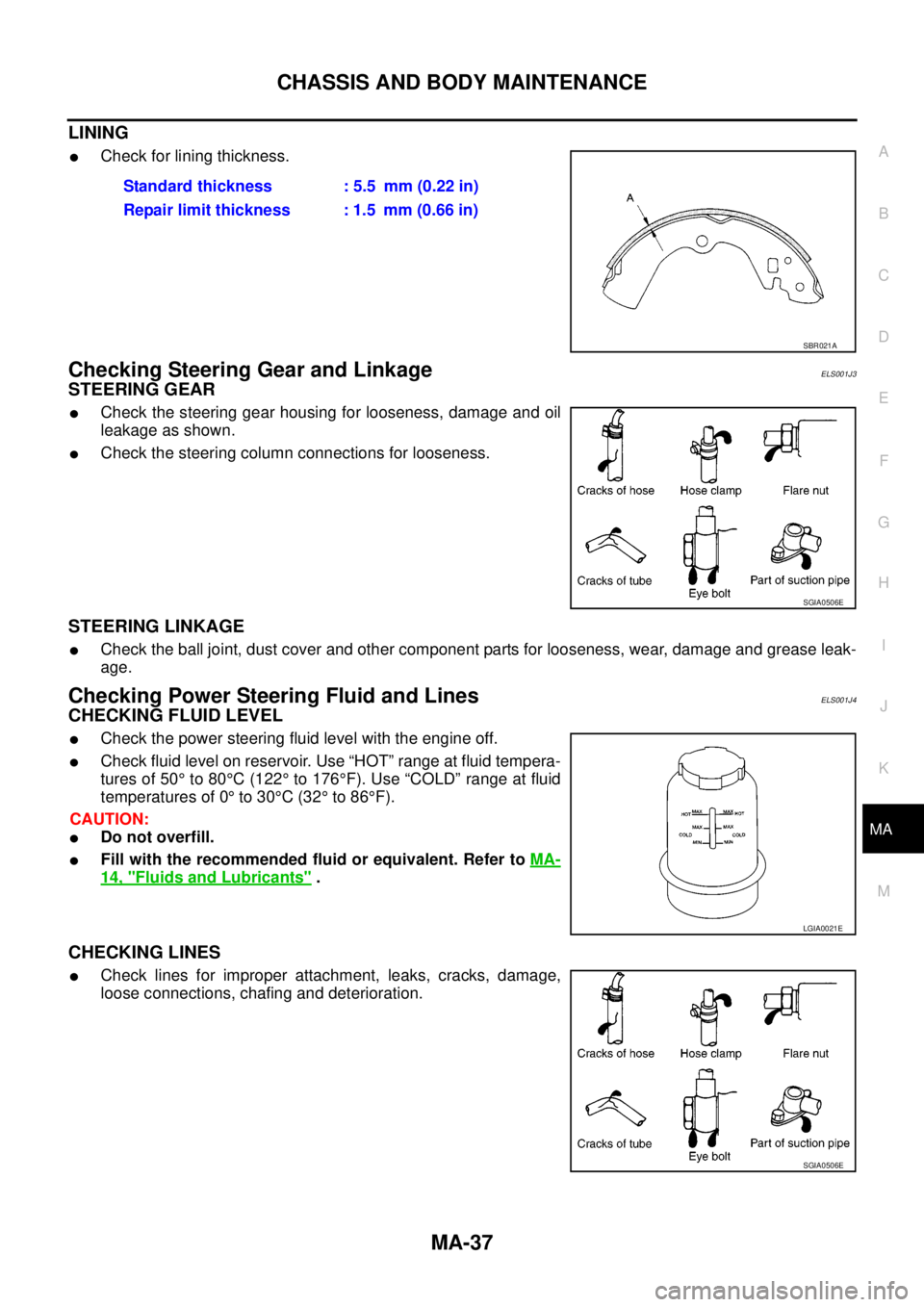

Tire RotationELS001IY

1. Rotate the tires on each side from front to back as shown, using

power tool.

lFollow the maintenance schedule for tire rotation service

intervals. Refer toMA-7, "

GENERAL MAINTENANCE".

lDo not include the spare tire when rotating the tires.

CAUTION:

When installing wheels, tighten them diagonally by divid-

ing the work two to three times in order to prevent the

wheels from developing any distortion.

2. Adjust the tire pressure to specification. Refer toWT-6, "

Tire".

3. After the tire rotation, retighten the wheel nuts after the vehicle has been driven for 1,000 km (600 miles),

and also after a wheel and tire have been installed such as after repairing a flat tire

PDIA1038E

Oil grade: Refer toMA-14, "Fluids and Lubricants".

Oil capacity: Refer toMA-14, "

Fluids and Lubricants".

PDIA1039E

Wheel nuts : 98 - 127 N·m (10.0 - 12.9 kg-m, 73 -

- 93 ft-lb)

SMA829C

Page 2310 of 3171

CHASSIS AND BODY MAINTENANCE

MA-35

C

D

E

F

G

H

I

J

K

MA

B

MA

Checking Brake Fluid Level and LeaksELS001IZ

lCheck the brake fluid level in the reservoir tank. It should be

between the “MAX” and “MIN” lines on the reservoir tank.

lIf the fluid level is extremely low, check the brake system.

lIf the brake warning lamp comes on when the fluid is at the cor-

rect level, check the brake fluid level switch and the parking

brake switch.

Checking Brake Lines and CablesELS001J0

1. Check the brake lines and hoses for cracks, deterioration, and

other damage. Replace any damaged parts.

CAUTION:

If brake fluid leaks are visible around the brake line joints,

retighten the joint, or replace damaged parts as necessary.

2. Check for brake fluid leaks by fully depressing brake pedal while

engine is running.

Changing Brake FluidELS001J1

1. Drain brake fluid from each bleed valve.

2. Refill until new brake fluid comes out from each bleed valve.

Use same procedure as in bleeding hydraulic system to refill

brake fluid.

Refer toBR-10, "

BRAKE FLUID".

lRefill with recommended DOT 3 or DOT 4 (US FMVSS No.

11 6 ) .

Refer toMA-14, "

RECOMMENDED FLUIDS AND LUBRI-

CANTS".

lNever reuse drained brake fluid.

lBe careful not to splash brake fluid on painted areas.

Checking Disc BrakeELS001J2

ROTOR

Check the condition of the rotor, and for any wear or damage. Repair

or replace as necessary.

LFIA0234E

SBR389C

SBR419C

Standard thickness : 28.0 mm (1.12 in)

Repair limit thickness : 26.0 mm (1.024 in)

SMA260A

Page 2312 of 3171

CHASSIS AND BODY MAINTENANCE

MA-37

C

D

E

F

G

H

I

J

K

MA

B

MA

LINING

lCheck for lining thickness.

Checking Steering Gear and LinkageELS001J3

STEERING GEAR

lCheck the steering gear housing for looseness, damage and oil

leakage as shown.

lCheck the steering column connections for looseness.

STEERING LINKAGE

lCheck the ball joint, dust cover and other component parts for looseness, wear, damage and grease leak-

age.

Checking Power Steering Fluid and LinesELS001J4

CHECKING FLUID LEVEL

lCheck the power steering fluid level with the engine off.

lCheck fluid level on reservoir. Use “HOT” range at fluid tempera-

tures of 50°to 80°C(122°to 176°F). Use “COLD” range at fluid

temperatures of 0°to 30°C(32°to 86°F).

CAUTION:

lDo not overfill.

lFill with the recommended fluid or equivalent. Refer toMA-

14, "Fluids and Lubricants".

CHECKING LINES

lCheck lines for improper attachment, leaks, cracks, damage,

loose connections, chafing and deterioration.Standard thickness : 5.5 mm (0.22 in)

Repair limit thickness : 1.5 mm (0.66 in)

SBR021A

SGIA0506E

LGIA0021E

SGIA0506E

Page 2315 of 3171

MA-40

CHASSIS AND BODY MAINTENANCE

Checking Seat Belts, Buckles, Retractors, Anchors and Adjusters

ELS001J7

Check the seat belt buckles, webbing, retractors, anchors and adjusters. Replace any seat belt assembly as

necessary. Refer toSB-11, "

Seat Belt Inspection".

lCheck the seat belt anchors for loose mounting bolts, damage, or excessive wear.

lCheck the seat belt webbing for any damage, cuts, fraying, or excessive wear.

lCheck the retractor for smooth operation.

lCheck the function of the buckles by inserting the seat belt tongue and checking for proper engagement of

the buckle and press the button on the buckle to check for proper release of the seat belt tongue.

CAUTION:

lAfter any collision, inspect all seat belt assemblies, including retractors and other attached com-

ponents, such as the guide rail set. NISSAN recommends replacing all seat belt assemblies in use

during a collision, unless they are not damaged and are inspected to confirm they are operating

properly after a minor collision.

Also inspect all seat belt assemblies that are not in use during a collision, and replace any compo-

nents if damaged or not operating properly. The seat belt pre-tensioner should be replaced even if

the seat belts are not in use during a frontal collision where the driver and passenger air bags

have been deployed.

lIf any component of the seat belt assembly is suspected of being damaged or not operating prop-

erly, do not repair the component. Replace the components as an assembly.

lIf the seat belt webbing is cut, frayed, or damaged then replace the seat belt assembly.

lNever lubricate the seat belt buckle or tongue.

lWhen replacing any seat belt assembly always use a Genuine NISSAN seat belt assembly.

Checking Body CorrosionELS001K3

Visually check body panels for collision damage (scratches, chipping, rubbing, etc.) or damage to the anti-cor-

rosion materials. In particular, check the following locations.

HEMMED PANELS

Hood front end, door lower end, trunk lid rear end, etc.

PANEL JOINT

Side sill of rear fender and center pillar, rear wheel housing of rear fender, around strut tower in engine com-

partment, etc.

PANEL EDGE

Trunk lid opening, sunroof opening, fender wheel-arch flange, fuel filler lid flange, around holes in panel, etc.

PARTS CONTACT

Waist moulding, windshield moulding, bumper, etc.

PROTECTORS

Damage or condition of mudguard, fender protector, chipping protector, etc.

ANTI-CORROSION MATERIALS

Damage or separation of anti-corrosion materials under the body.

DRAIN HOLES

Condition of drain holes at door and side sill. When repairing corroded areas, refer to the Corrosion Repair

Manual.

Page 2326 of 3171

M/T OIL

MT-9

D

E

F

G

H

I

J

K

L

MA

B

MT

M/T OILPFP:KLD20

Changing M/T OilECS00ID3

DRAINING

1. Start engine and let it run to warm up transmission.

2. Stop engine. Remove drain plug and gasket and then drain oil.

3. Set a gasket on drain plug and install it to transmission case. Tighten drain plug to the specified torque.

Refer toMT-19, "

Case Components".

CAUTION:

Do no reuse gasket.

FILLING

1. Remove filler plug and gasket. Fill with new oil until oil level reaches the specified limit near filler plug

mounting hole.

2. After refilling oil, check oil level. Set a gasket to filler plug, then install it to transmission case. Tighten filler

plug to the specified torque. Refer toMT-19, "

Case Components".

CAUTION:

Do no reuse gasket.

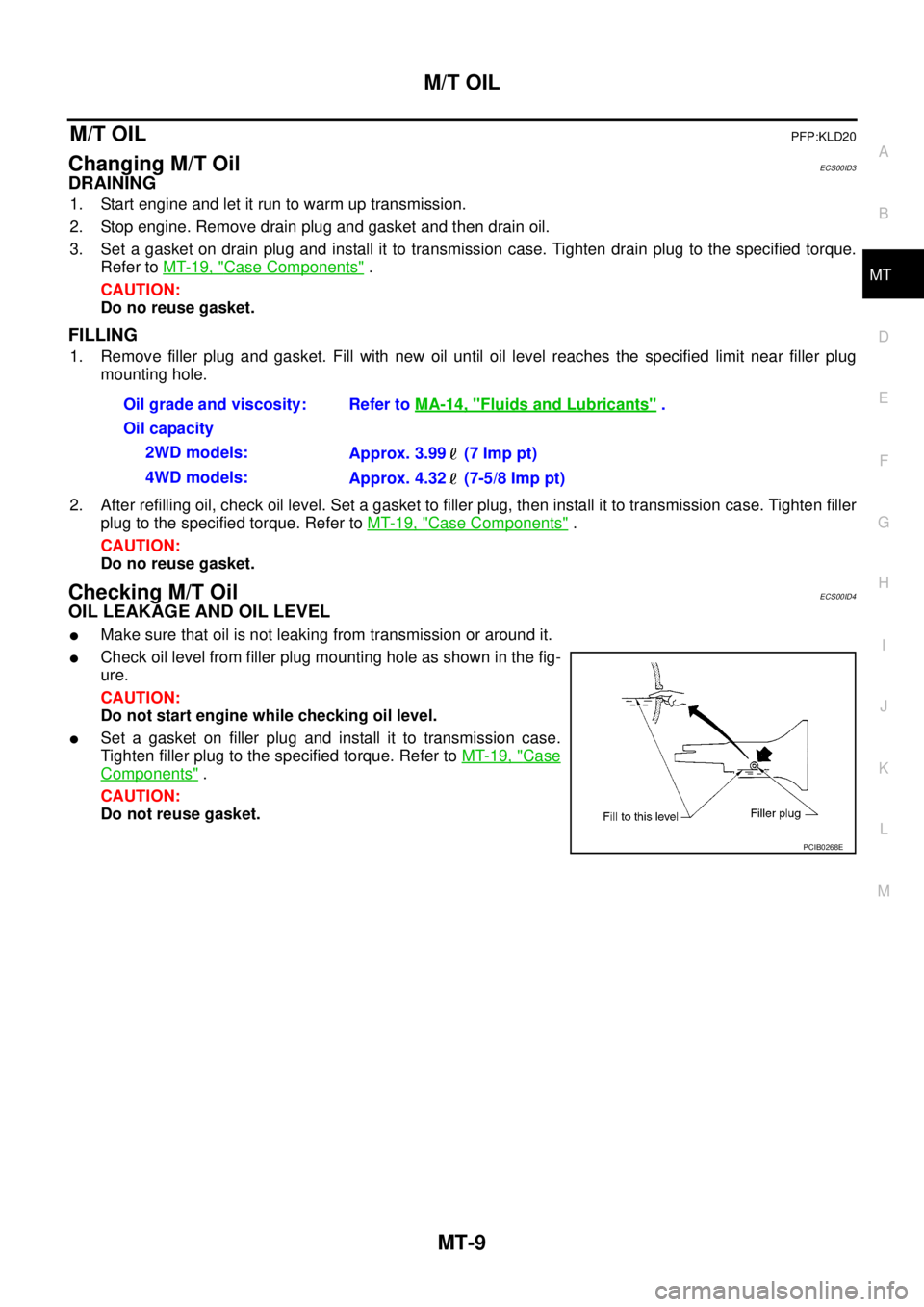

Checking M/T OilECS00ID4

OIL LEAKAGE AND OIL LEVEL

lMake sure that oil is not leaking from transmission or around it.

lCheck oil level from filler plug mounting hole as shown in the fig-

ure.

CAUTION:

Do not start engine while checking oil level.

lSet a gasket on filler plug and install it to transmission case.

Tighten filler plug to the specified torque. Refer toMT-19, "

Case

Components".

CAUTION:

Do not reuse gasket.Oil grade and viscosity: Refer toMA-14, "

Fluids and Lubricants".

Oil capacity

2WD models:

Approx. 3.99 (7 Imp pt)

4WD models:

Approx. 4.32 (7-5/8 Imp pt)

PCIB0268E

Page 2388 of 3171

MTC-1

MANUAL AIR CONDITIONER

J AIR CONDITIONER

CONTENTS

C

D

E

F

G

H

I

K

L

M

SECTIONMTC

A

B

MTC

MANUAL AIR CONDITIONER

PRECAUTIONS .......................................................... 4

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 4

Precautions for Working with HFC-134a (R-134a)..... 4

Contaminated Refrigerant ........................................ 4

General Refrigerant Precautions .............................. 5

Precautions for Refrigerant Connection ................... 5

ABOUT ONE-TOUCH JOINT ................................ 5

FEATURES OF NEW TYPE REFRIGERANT

CONNECTION ...................................................... 7

O-RING AND REFRIGERANT CONNECTION..... 9

Precautions for Servicing Compressor ................... 12

Precautions for Service Equipment ........................ 12

RECOVERY/RECYCLING EQUIPMENT ............ 12

ELECTRONIC LEAK DETECTOR ...................... 12

VACUUM PUMP ................................................. 13

MANIFOLD GAUGE SET .................................... 13

SERVICE HOSES ............................................... 13

SERVICE COUPLERS ........................................ 14

REFRIGERANT WEIGHT SCALE ...................... 14

CALIBRATING ACR4 WEIGHT SCALE .............. 14

CHARGING CYLINDER ...................................... 14

Precautions for Leak Detection Dye ....................... 14

IDENTIFICATION ................................................ 15

IDENTIFICATION LABEL FOR VEHICLE ........... 15

Wiring Diagrams and Trouble Diagnosis ................ 15

PREPARATION ......................................................... 16

Special Service Tools ............................................. 16

HFC-134a (R-134a) Service Tools and Equipment... 16

Commercial Service Tools ...................................... 19

REFRIGERATION SYSTEM ..................................... 20

Refrigerant Cycle ................................................... 20

REFRIGERANT FLOW ....................................... 20

FREEZE PROTECTION ..................................... 20

Refrigerant System Protection ............................... 20

REFRIGERANT PRESSURE SENSOR ............. 20

PRESSURE RELIEF VALVE ............................... 21

Component Layout ................................................. 22

REFRIGERATION SYSTEM ............................... 22LUBRICANT .............................................................. 24

Maintenance of Lubricant Quantity in Compressor... 24

LUBRICANT ........................................................ 24

CHECKING AND ADJUSTING ............................ 24

AIR CONDITIONER CONTROL ............................... 26

Description .............................................................. 26

Operation ................................................................ 26

AIR MIX DOOR CONTROL ................................. 26

BLOWER SPEED CONTROL ............................. 26

INTAKE DOORS CONTROL ............................... 26

MODE DOOR CONTROL ................................... 26

DEFROSTER DOOR CONTROL ........................ 26

MAGNET CLUTCH CONTROL ........................... 27

SELF-DIAGNOSTIC SYSTEM ............................ 27

Description of Control System ................................ 28

Control Operation ................................................... 28

DISPLAY SCREEN .............................................. 29

TEMPERATURE SWITCH (TEMPERATURE

CONTROL) (FRONT) .......................................... 29

RECIRCULATION () SWITCH ............................. 29

REAR WINDOW DEFOGGER SWITCH ............. 29

OFF SWITCH (BLOWER SPEED SET TO 0) ..... 29

A/C SWITCH ....................................................... 29

MODE SWITCH .................................................. 29

Discharge Air Flow ................................................. 30

FRONT ................................................................ 30

System Description ................................................. 31

SWITCHES AND THEIR CONTROL FUNCTION... 31

CAN Communication System Description .............. 32

TROUBLE DIAGNOSIS ............................................ 33

CONSULT-II ............................................................ 33

CONSULT-II BASIC OPERATION ....................... 33

DATA MONITOR ................................................. 34

How to Perform Trouble Diagnosis for Quick and

Accurate Repair ...................................................... 35

WORK FLOW ...................................................... 35

SYMPTOM TABLE .............................................. 35

Component Parts and Harness Connector Location... 36

ENGINE COMPARTMENT .................................. 36

FRONT PASSENGER COMPARTMENT ............ 37

Page 2390 of 3171

MTC-3

C

D

E

F

G

H

I

K

L

MA

B

MTC BLOWER MOTOR RESISTOR ................................112

Components .......................................................... 112

Removal and Installation ....................................... 112

REMOVAL .......................................................... 112

INSTALLATION .................................................. 112

DUCTS AND GRILLES ...........................................113

Components .......................................................... 113

Removal and Installation ....................................... 116

CENTER CONSOLE HEAT DUCT AND REAR

FINISHER ASSEMBLY GRILLE ........................ 116

DEFROSTER NOZZLE ...................................... 116

RH AND LH SIDE DEMISTER DUCT ................ 116

RH AND LH VENTILATOR DUCT ...................... 116

CENTER VENTILATOR DUCT .......................... 116

FLOOR DUCT .................................................... 116

GRILLES ............................................................ 116

REFRIGERANT LINES ............................................118

HFC-134a (R-134a) Service Procedure ................ 118

SETTING OF SERVICE TOOLS AND EQUIP-

MENT ................................................................. 118

Components ......................................................... 120

Removal and Installation for Compressor ............ 122

REMOVAL ......................................................... 122

INSTALLATION ................................................. 122

Removal and Installation for Compressor Clutch . 123

REMOVAL ......................................................... 123

INSPECTION .................................................... 124

INSTALLATION ................................................. 124

BREAK-IN OPERATION ................................... 126

Removal and Installation for Low-pressure Flexible

Hose ..................................................................... 126

REMOVAL ......................................................... 126

INSTALLATION ................................................. 126

Removal and Installation for High-pressure Flexible

Hose ..................................................................... 126

REMOVAL ......................................................... 126INSTALLATION .................................................126

Removal and Installation for High-pressure Pipe . 126

REMOVAL .........................................................126

INSTALLATION .................................................126

Removal and Installation for Low-pressure Pipe ..127

REMOVAL .........................................................127

INSTALLATION .................................................127

Removal and Installation for Refrigerant Pressure

Sensor ..................................................................127

REMOVAL .........................................................127

INSTALLATION .................................................127

Removal and Installation for Condenser ..............127

REMOVAL .........................................................127

INSTALLATION .................................................128

Removal and Installation for Evaporator ..............129

REMOVAL .........................................................130

INSTALLATION .................................................130

Removal and Installation for Expansion Valve ......130

REMOVAL .........................................................130

INSTALLATION .................................................130

Checking for Refrigerant Leaks ............................131

Checking System for Leaks Using the Fluorescent

Leak Detector .......................................................131

Dye Injection .........................................................131

Electronic Refrigerant Leak Detector ....................132

PRECAUTIONS FOR HANDLING LEAK

DETECTOR .......................................................132

CHECKING PROCEDURE ...............................133

SERVICE DATA AND SPECIFICATIONS (SDS) ....135

Service Data and Specifications (SDS) ................135

COMPRESSOR ................................................135

LUBRICANT ......................................................135

REFRIGERANT .................................................135

ENGINE IDLING SPEED ..................................135

BELT TENSION .................................................135

Page 2399 of 3171

MTC-12

PRECAUTIONS

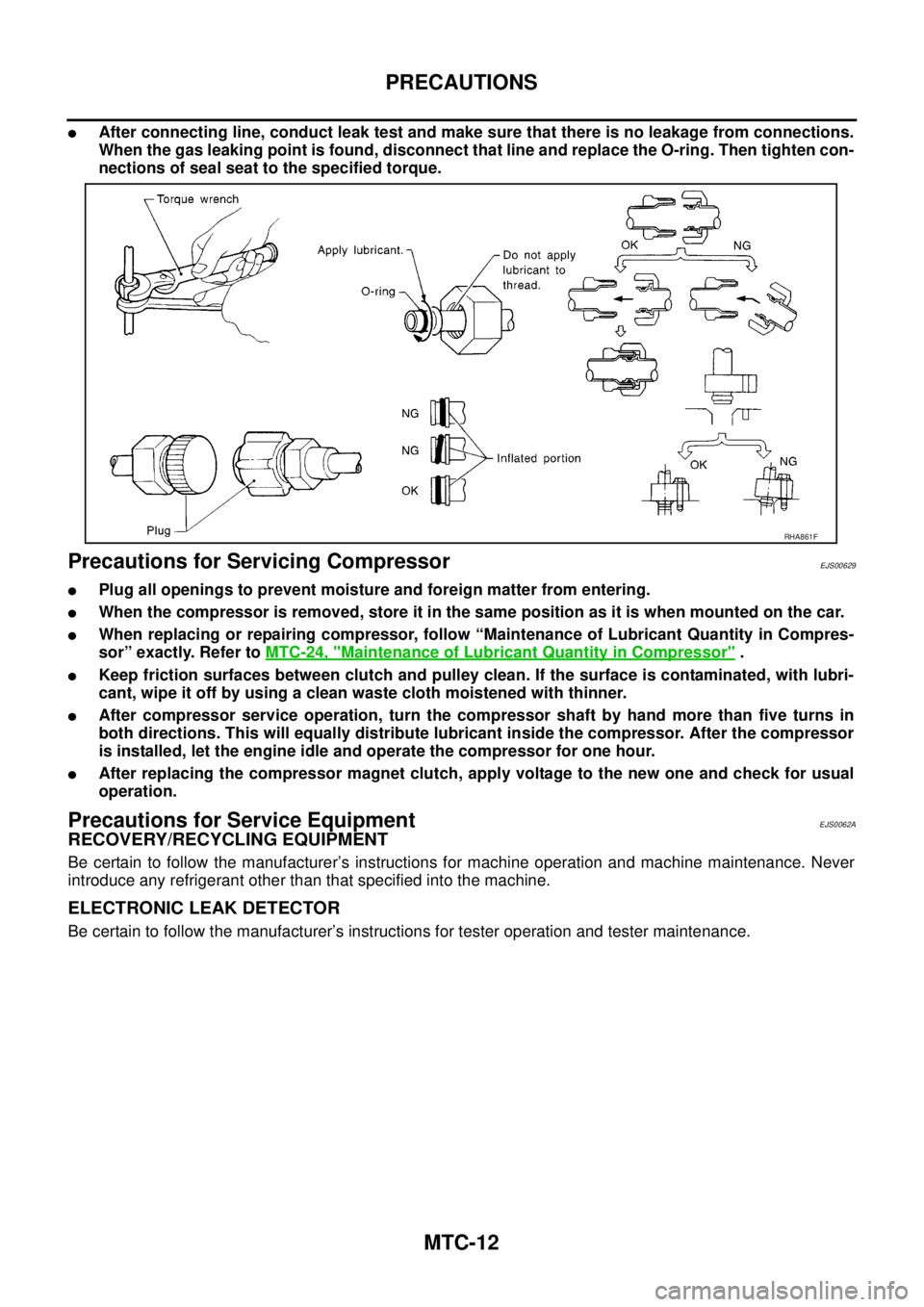

lAfter connecting line, conduct leak test and make sure that there is no leakage from connections.

When the gas leaking point is found, disconnect that line and replace the O-ring. Then tighten con-

nections of seal seat to the specified torque.

Precautions for Servicing CompressorEJS00629

lPlug all openings to prevent moisture and foreign matter from entering.

lWhen the compressor is removed, store it in the same position as it is when mounted on the car.

lWhen replacing or repairing compressor, follow “Maintenance of Lubricant Quantity in Compres-

sor” exactly. Refer toMTC-24, "

Maintenance of Lubricant Quantity in Compressor".

lKeep friction surfaces between clutch and pulley clean. If the surface is contaminated, with lubri-

cant, wipe it off by using a clean waste cloth moistened with thinner.

lAfter compressor service operation, turn the compressor shaft by hand more than five turns in

both directions. This will equally distribute lubricant inside the compressor. After the compressor

is installed, let the engine idle and operate the compressor for one hour.

lAfter replacing the compressor magnet clutch, apply voltage to the new one and check for usual

operation.

Precautions for Service EquipmentEJS0062A

RECOVERY/RECYCLING EQUIPMENT

Be certain to follow the manufacturer’s instructions for machine operation and machine maintenance. Never

introduce any refrigerant other than that specified into the machine.

ELECTRONIC LEAK DETECTOR

Be certain to follow the manufacturer’s instructions for tester operation and tester maintenance.

RHA861F

Page 2411 of 3171

MTC-24

LUBRICANT

LUBRICANT

PFP:KLG00

Maintenance of Lubricant Quantity in CompressorEJS005FV

The lubricant in the compressor circulates through the system with the refrigerant. Add lubricant to compres-

sor when replacing any component or after a large refrigerant leakage has occurred. It is important to maintain

the specified amount.

If lubricant quantity is not maintained properly, the following malfunctions may result:

lLack of lubricant: May lead to a seized compressor

lExcessive lubricant: Inadequate cooling (thermal exchange interference)

LUBRICANT

Name: NISSAN A/C System Lubricant Type S (DH-PS)

Part number: KLH00-PAGS0

CHECKING AND ADJUSTING

CAUTION:

If excessive lubricant leakage is noted, do not perform the lubricant return operation.

Start the engine and set the following conditions:

test condition

lEngine speed: Idling to 1,200 rpm

lA/C switch: On

lBlower speed: Max. position

lTemp. control: Optional [Set so that intake air temperature is 25°to 30°C(77°to 86°F).]

lIntake position: Recirculation ( )

lPerform lubricant return operation for about ten minutes

Adjust the lubricant quantity according to the following table.

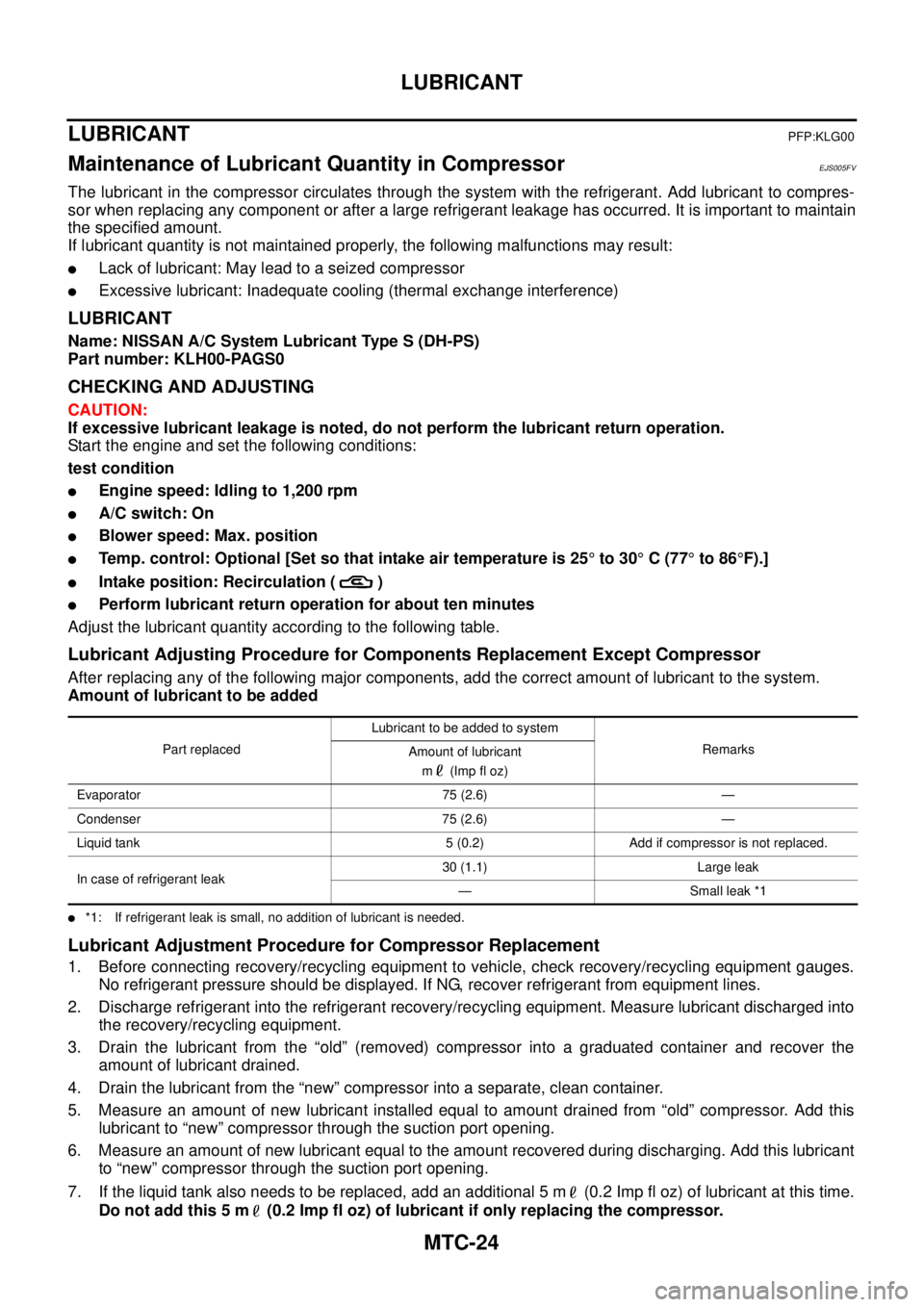

Lubricant Adjusting Procedure for Components Replacement Except Compressor

After replacing any of the following major components, add the correct amount of lubricant to the system.

Amount of lubricant to be added

l*1: If refrigerant leak is small, no addition of lubricant is needed.

Lubricant Adjustment Procedure for Compressor Replacement

1. Before connecting recovery/recycling equipment to vehicle, check recovery/recycling equipment gauges.

No refrigerant pressure should be displayed. If NG, recover refrigerant from equipment lines.

2. Discharge refrigerant into the refrigerant recovery/recycling equipment. Measure lubricant discharged into

the recovery/recycling equipment.

3. Drain the lubricant from the “old” (removed) compressor into a graduated container and recover the

amount of lubricant drained.

4. Drain the lubricant from the “new” compressor into a separate, clean container.

5. Measure an amount of new lubricant installed equal to amount drained from “old” compressor. Add this

lubricant to “new” compressor through the suction port opening.

6. Measure an amount of new lubricant equal to the amount recovered during discharging. Add this lubricant

to “new” compressor through the suction port opening.

7. If the liquid tank also needs to be replaced, add an additional 5 m (0.2 Imp fl oz) of lubricant at this time.

Do not add this 5 m (0.2 Imp fl oz) of lubricant if only replacing the compressor.

Part replacedLubricant to be added to system

Remarks

Amount of lubricant

m(Impfloz)

Evaporator 75 (2.6) —

Condenser 75 (2.6) —

Liquid tank 5 (0.2) Add if compressor is not replaced.

In case of refrigerant leak30 (1.1) Large leak

— Small leak *1