check engine NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2264 of 3171

ENGINE OIL

LU-7

C

D

E

F

G

H

I

J

K

L

MA

LU

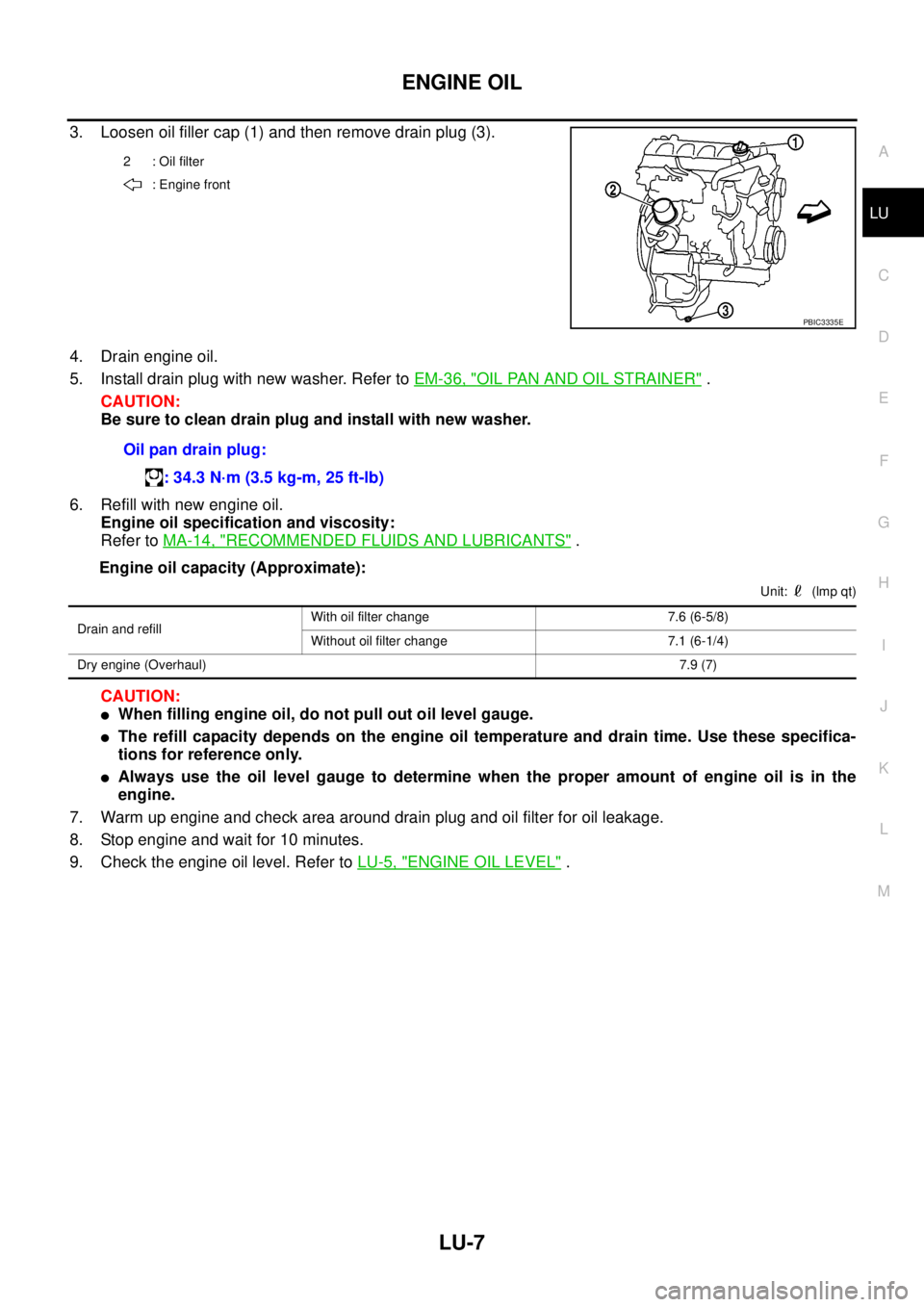

3. Loosen oil filler cap (1) and then remove drain plug (3).

4. Drain engine oil.

5. Install drain plug with new washer. Refer toEM-36, "

OIL PAN AND OIL STRAINER".

CAUTION:

Be sure to clean drain plug and install with new washer.

6. Refill with new engine oil.

Engine oil specification and viscosity:

Refer toMA-14, "

RECOMMENDED FLUIDS AND LUBRICANTS".

Engine oil capacity (Approximate):

Unit: (lmp qt)

CAUTION:

lWhen filling engine oil, do not pull out oil level gauge.

lThe refill capacity depends on the engine oil temperature and drain time. Use these specifica-

tions for reference only.

lAlways use the oil level gauge to determine when the proper amount of engine oil is in the

engine.

7. Warm up engine and check area around drain plug and oil filter for oil leakage.

8. Stop engine and wait for 10 minutes.

9. Check the engine oil level. Refer toLU-5, "

ENGINE OIL LEVEL".

2 : Oil filter

: Engine front

PBIC3335E

Oil pan drain plug:

: 34.3 N·m (3.5 kg-m, 25 ft-lb)

Drain and refillWith oil filter change 7.6 (6-5/8)

Without oil filter change 7.1 (6-1/4)

Dry engine (Overhaul)7.9 (7)

Page 2265 of 3171

LU-8

OIL FILTER

OIL FILTER

PFP:15208

Removal and InstallationEBS01E58

REMOVAL

1. Remove engine undercover middle.

2. Place a pan to catch the engine oil under the lower part of drain hose outlet before removing oil filter.

3. Using the oil filter wrench, remove oil filter.

CAUTION:

lBe careful not to get burned when engine and engine oil are hot.

lWhen removing, prepare a shop cloth to absorb any engine oil leakage or spillage.

lDo not allow engine oil to adhere to drive belts.

lCompletely wipe off any engine oil that adhere to engine and vehicle.

lOil filter is provided with a relief valve. Use Genuine Nissan Oil Filter or equivalent.

INSTALLATION

1. Remove foreign materials adhering to the oil filter installation surface.

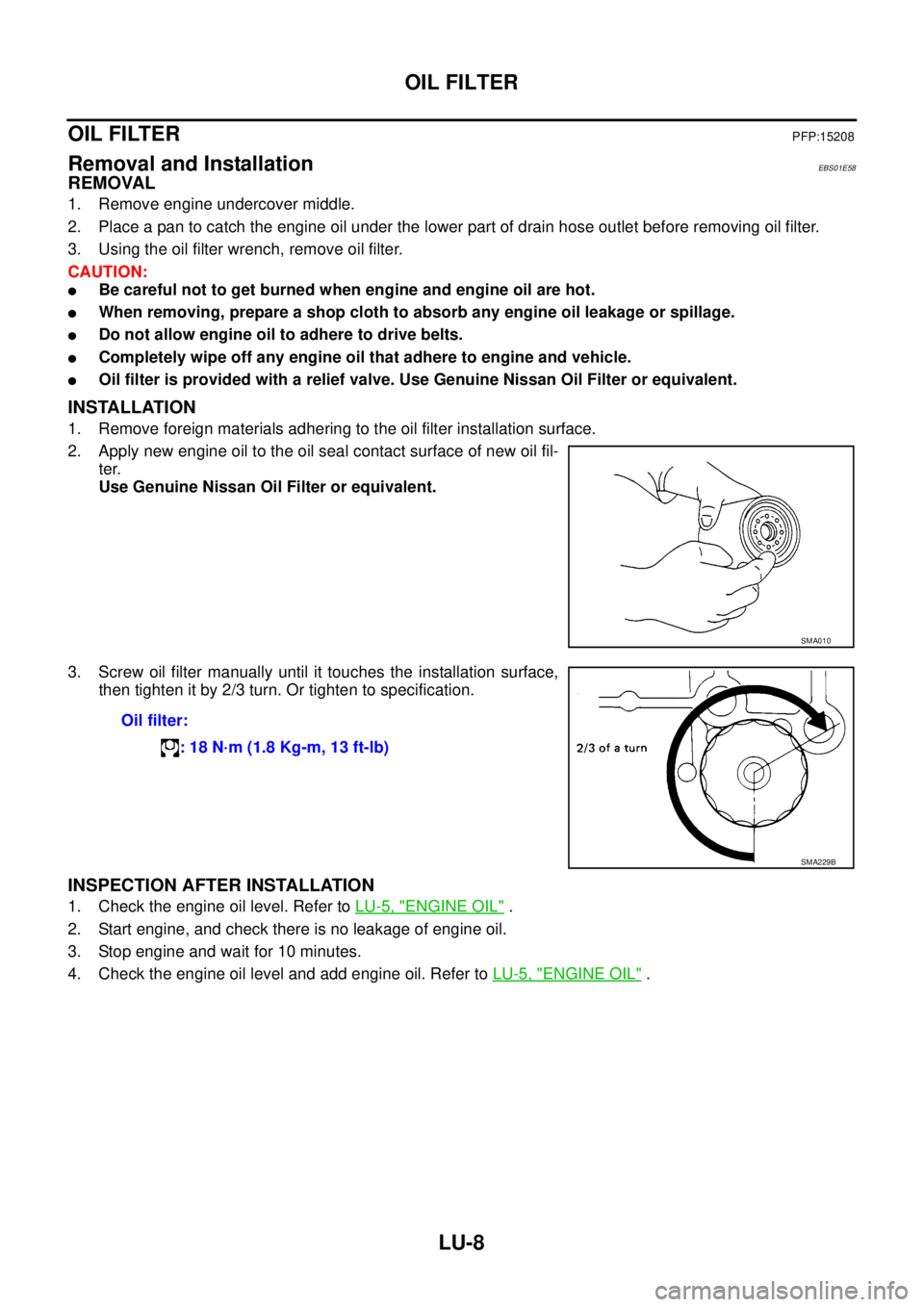

2. Apply new engine oil to the oil seal contact surface of new oil fil-

ter.

Use Genuine Nissan Oil Filter or equivalent.

3. Screw oil filter manually until it touches the installation surface,

then tighten it by 2/3 turn. Or tighten to specification.

INSPECTION AFTER INSTALLATION

1. Check the engine oil level. Refer toLU-5, "ENGINE OIL".

2. Start engine, and check there is no leakage of engine oil.

3. Stop engine and wait for 10 minutes.

4. Check the engine oil level and add engine oil. Refer toLU-5, "

ENGINE OIL".

SMA010

Oil filter:

: 18 N·m (1.8 Kg-m, 13 ft-lb)

SMA229B

Page 2267 of 3171

LU-10

OIL FILTER BRACKET

INSTALLATION

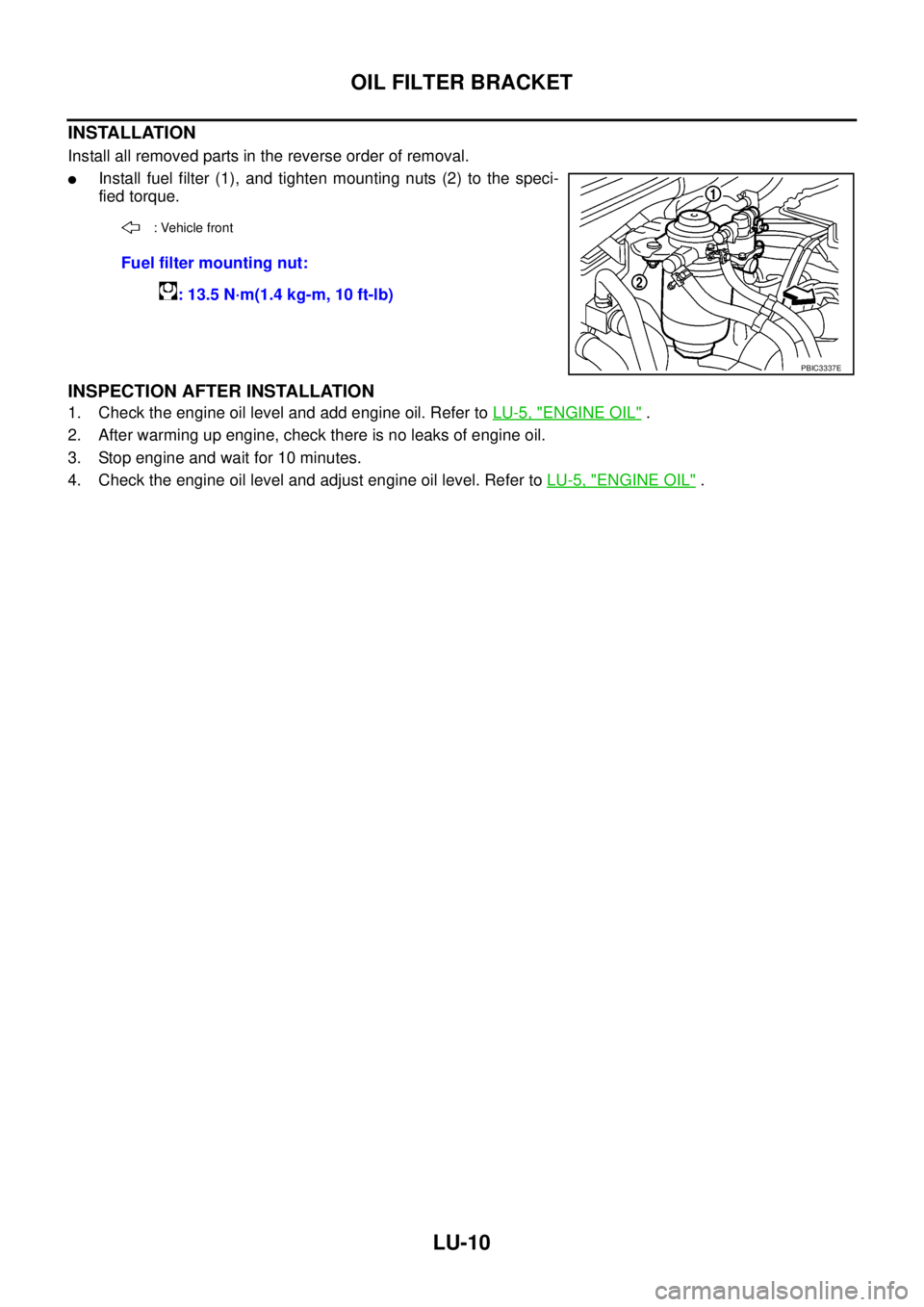

Install all removed parts in the reverse order of removal.

lInstall fuel filter (1), and tighten mounting nuts (2) to the speci-

fied torque.

INSPECTION AFTER INSTALLATION

1. Check the engine oil level and add engine oil. Refer toLU-5, "ENGINE OIL".

2. After warming up engine, check there is no leaks of engine oil.

3. Stop engine and wait for 10 minutes.

4. Check the engine oil level and adjust engine oil level. Refer toLU-5, "

ENGINE OIL".

: Vehicle front

Fuel filter mounting nut:

: 13.5 N·m(1.4 kg-m, 10 ft-lb)

PBIC3337E

Page 2269 of 3171

LU-12

OIL COOLER

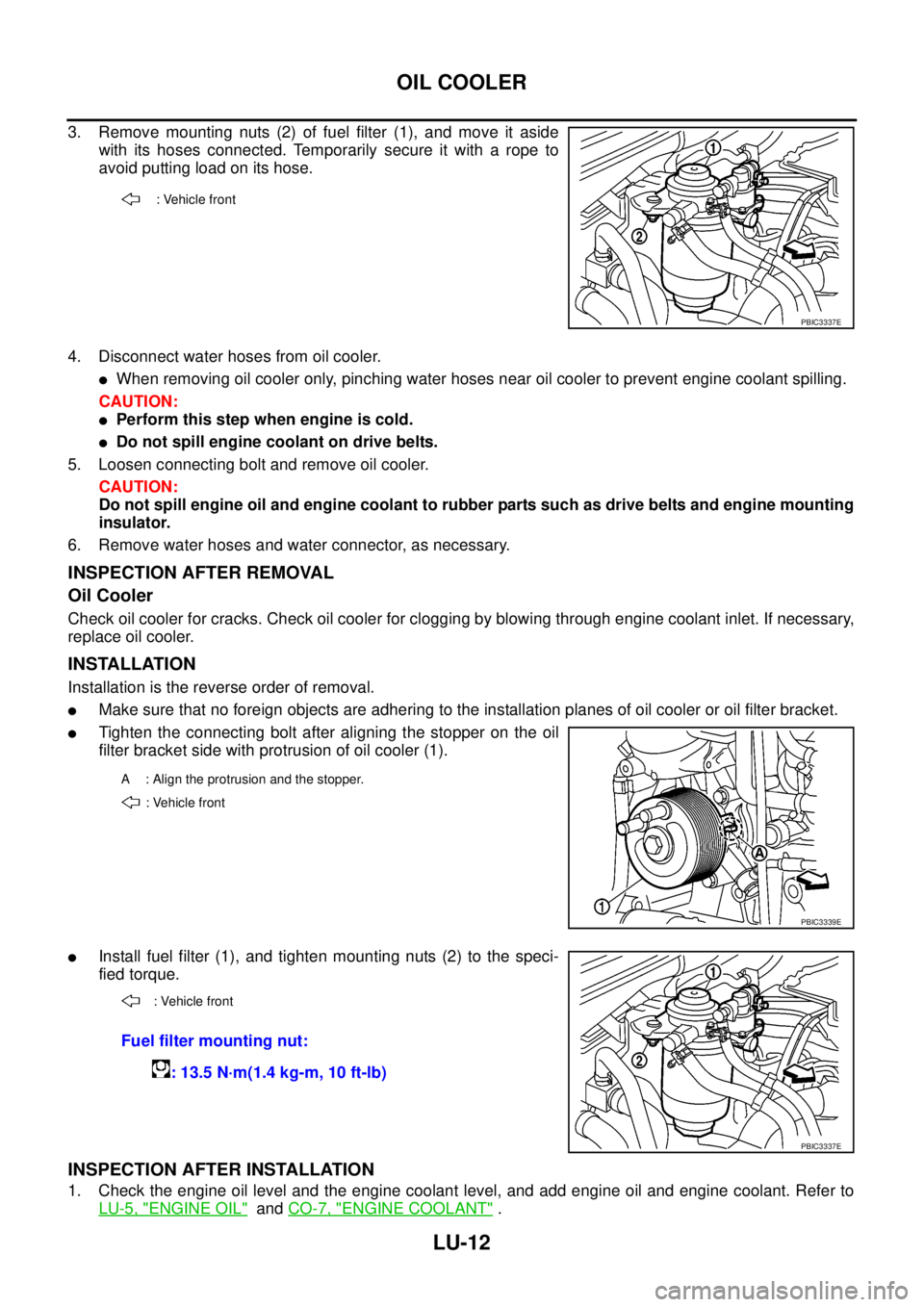

3. Remove mounting nuts (2) of fuel filter (1), and move it aside

with its hoses connected. Temporarily secure it with a rope to

avoid putting load on its hose.

4. Disconnect water hoses from oil cooler.

lWhen removing oil cooler only, pinching water hoses near oil cooler to prevent engine coolant spilling.

CAUTION:

lPerform this step when engine is cold.

lDo not spill engine coolant on drive belts.

5. Loosen connecting bolt and remove oil cooler.

CAUTION:

Do not spill engine oil and engine coolant to rubber parts such as drive belts and engine mounting

insulator.

6. Remove water hoses and water connector, as necessary.

INSPECTION AFTER REMOVAL

Oil Cooler

Check oil cooler for cracks. Check oil cooler for clogging by blowing through engine coolant inlet. If necessary,

replace oil cooler.

INSTALLATION

Installation is the reverse order of removal.

lMake sure that no foreign objects are adhering to the installation planes of oil cooler or oil filter bracket.

lTighten the connecting bolt after aligning the stopper on the oil

filter bracket side with protrusion of oil cooler (1).

lInstall fuel filter (1), and tighten mounting nuts (2) to the speci-

fied torque.

INSPECTION AFTER INSTALLATION

1. Check the engine oil level and the engine coolant level, and add engine oil and engine coolant. Refer to

LU-5, "

ENGINE OIL"andCO-7, "ENGINE COOLANT".

: Vehicle front

PBIC3337E

A : Align the protrusion and the stopper.

: Vehicle front

PBIC3339E

: Vehicle front

Fuel filter mounting nut:

: 13.5 N·m(1.4 kg-m, 10 ft-lb)

PBIC3337E

Page 2270 of 3171

OIL COOLER

LU-13

C

D

E

F

G

H

I

J

K

L

MA

LU

2. Start engine, and make sure that there is no leaks of engine oil or engine coolant.

3. Stop engine and wait for 10 minutes.

4. Check the engine oil level and the engine coolant level again. Refer toLU-5, "

ENGINE OIL"andCO-7,

"ENGINE COOLANT".

Page 2271 of 3171

LU-14

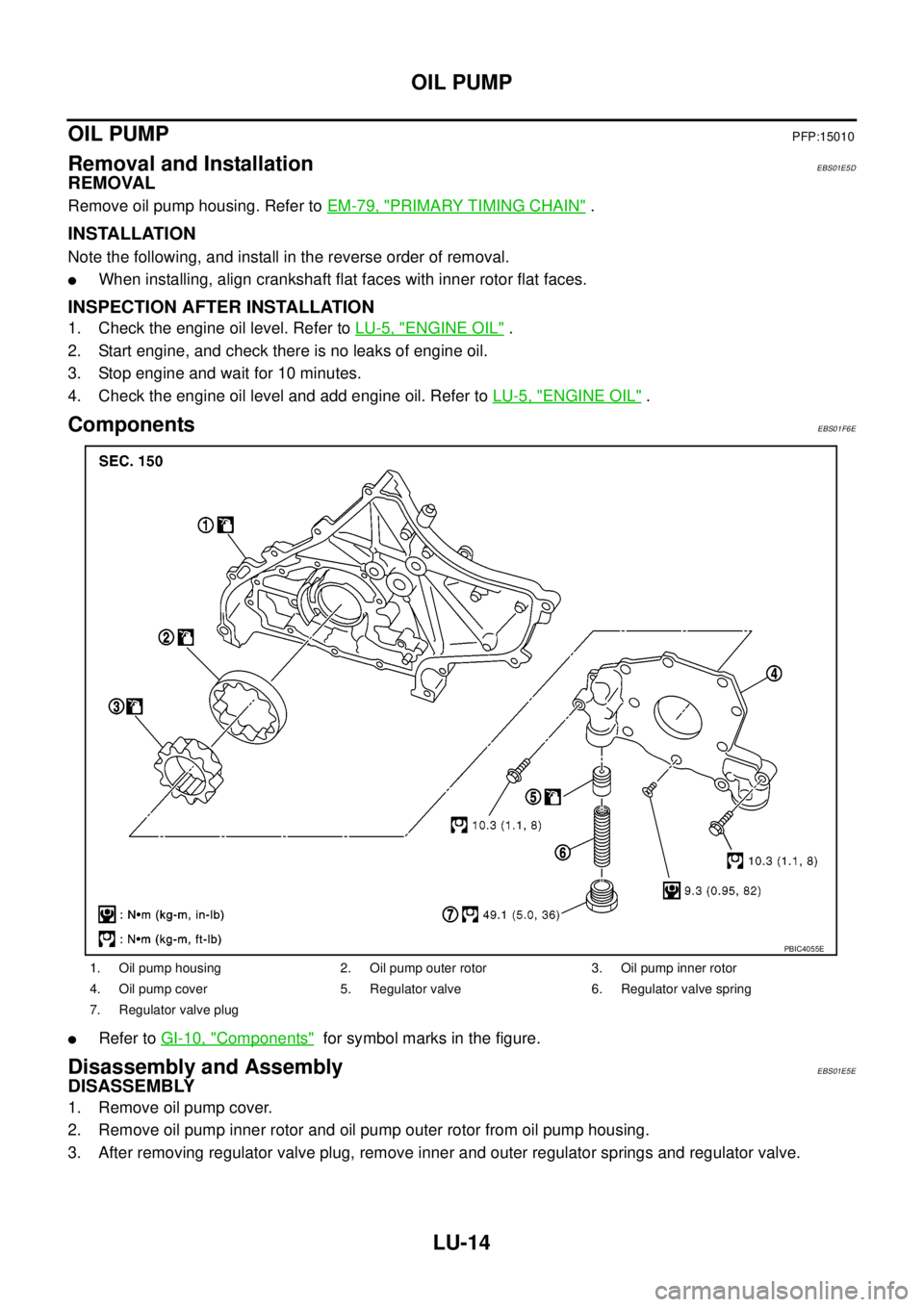

OIL PUMP

OIL PUMP

PFP:15010

Removal and InstallationEBS01E5D

REMOVAL

Remove oil pump housing. Refer toEM-79, "PRIMARY TIMING CHAIN".

INSTALLATION

Note the following, and install in the reverse order of removal.

lWhen installing, align crankshaft flat faces with inner rotor flat faces.

INSPECTION AFTER INSTALLATION

1. Check the engine oil level. Refer toLU-5, "ENGINE OIL".

2. Start engine, and check there is no leaks of engine oil.

3. Stop engine and wait for 10 minutes.

4. Check the engine oil level and add engine oil. Refer toLU-5, "

ENGINE OIL".

ComponentsEBS01F6E

lRefer toGI-10, "Components"for symbol marks in the figure.

Disassembly and AssemblyEBS01E5E

DISASSEMBLY

1. Remove oil pump cover.

2. Remove oil pump inner rotor and oil pump outer rotor from oil pump housing.

3. After removing regulator valve plug, remove inner and outer regulator springs and regulator valve.

1. Oil pump housing 2. Oil pump outer rotor 3. Oil pump inner rotor

4. Oil pump cover 5. Regulator valve 6. Regulator valve spring

7. Regulator valve plug

PBIC4055E

Page 2276 of 3171

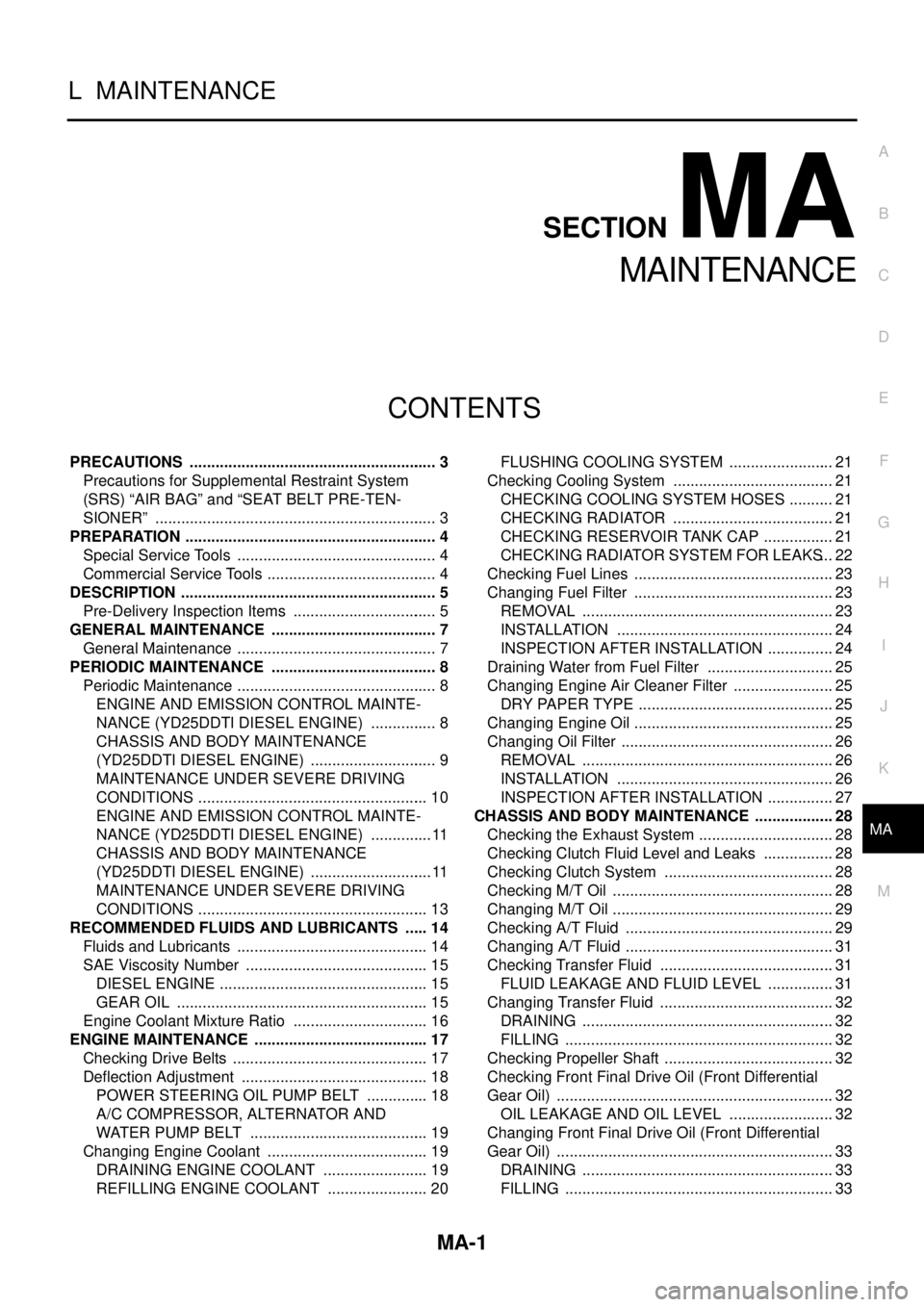

MA-1

MAINTENANCE

L MAINTENANCE

CONTENTS

C

D

E

F

G

H

I

J

K

M

SECTIONMA

A

B

MA

MAINTENANCE

PRECAUTIONS .......................................................... 3

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 3

PREPARATION ........................................................... 4

Special Service Tools ............................................... 4

Commercial Service Tools ........................................ 4

DESCRIPTION ............................................................ 5

Pre-Delivery Inspection Items .................................. 5

GENERAL MAINTENANCE ....................................... 7

General Maintenance ............................................... 7

PERIODIC MAINTENANCE ....................................... 8

Periodic Maintenance ............................................... 8

ENGINE AND EMISSION CONTROL MAINTE-

NANCE (YD25DDTI DIESEL ENGINE) ................ 8

CHASSIS AND BODY MAINTENANCE

(YD25DDTI DIESEL ENGINE) .............................. 9

MAINTENANCE UNDER SEVERE DRIVING

CONDITIONS ...................................................... 10

ENGINE AND EMISSION CONTROL MAINTE-

NANCE (YD25DDTI DIESEL ENGINE) ............... 11

CHASSIS AND BODY MAINTENANCE

(YD25DDTI DIESEL ENGINE) ............................. 11

MAINTENANCE UNDER SEVERE DRIVING

CONDITIONS ...................................................... 13

RECOMMENDED FLUIDS AND LUBRICANTS ...... 14

Fluids and Lubricants ............................................. 14

SAE Viscosity Number ........................................... 15

DIESEL ENGINE ................................................. 15

GEAR OIL ........................................................... 15

Engine Coolant Mixture Ratio ................................ 16

ENGINE MAINTENANCE ......................................... 17

Checking Drive Belts .............................................. 17

Deflection Adjustment ............................................ 18

POWER STEERING OIL PUMP BELT ............... 18

A/C COMPRESSOR, ALTERNATOR AND

WATER PUMP BELT .......................................... 19

Changing Engine Coolant ...................................... 19

DRAINING ENGINE COOLANT ......................... 19

REFILLING ENGINE COOLANT ........................ 20FLUSHING COOLING SYSTEM ......................... 21

Checking Cooling System ...................................... 21

CHECKING COOLING SYSTEM HOSES ........... 21

CHECKING RADIATOR ...................................... 21

CHECKING RESERVOIR TANK CAP ................. 21

CHECKING RADIATOR SYSTEM FOR LEAKS... 22

Checking Fuel Lines ............................................... 23

Changing Fuel Filter ............................................... 23

REMOVAL ........................................................... 23

INSTALLATION ................................................... 24

INSPECTION AFTER INSTALLATION ................ 24

Draining Water from Fuel Filter .............................. 25

Changing Engine Air Cleaner Filter ........................ 25

DRY PAPER TYPE .............................................. 25

Changing Engine Oil ............................................... 25

Changing Oil Filter .................................................. 26

REMOVAL ........................................................... 26

INSTALLATION ................................................... 26

INSPECTION AFTER INSTALLATION ................ 27

CHASSIS AND BODY MAINTENANCE ................... 28

Checking the Exhaust System ................................ 28

Checking Clutch Fluid Level and Leaks ................. 28

Checking Clutch System ........................................ 28

Checking M/T Oil .................................................... 28

Changing M/T Oil .................................................... 29

Checking A/T Fluid ................................................. 29

Changing A/T Fluid ................................................. 31

Checking Transfer Fluid ......................................... 31

FLUID LEAKAGE AND FLUID LEVEL ................ 31

Changing Transfer Fluid ......................................... 32

DRAINING ........................................................... 32

FILLING ............................................................... 32

Checking Propeller Shaft ........................................ 32

Checking Front Final Drive Oil (Front Differential

Gear Oil) ................................................................. 32

OIL LEAKAGE AND OIL LEVEL ......................... 32

Changing Front Final Drive Oil (Front Differential

Gear Oil) ................................................................. 33

DRAINING ........................................................... 33

FILLING ............................................................... 33

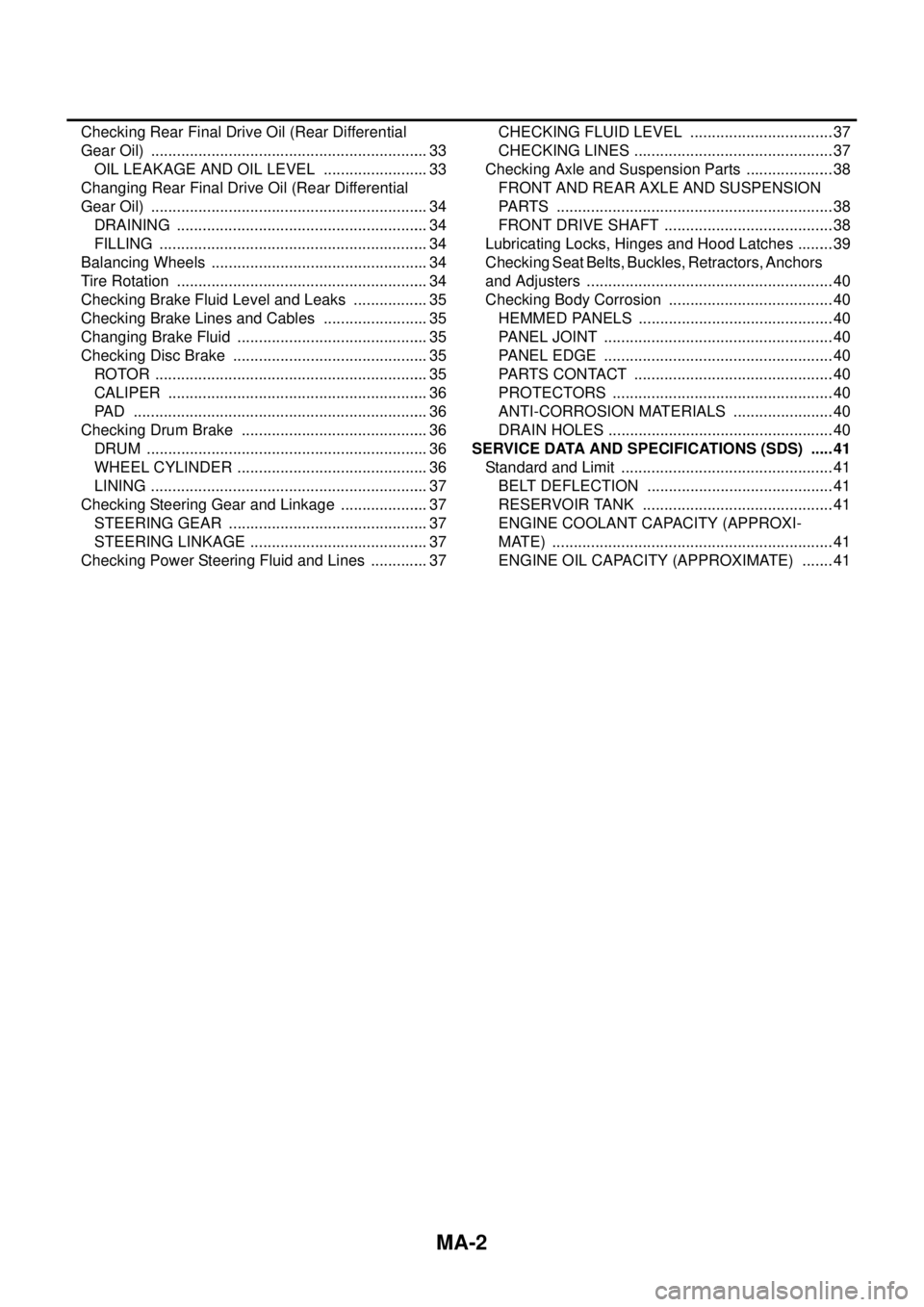

Page 2277 of 3171

MA-2

Checking Rear Final Drive Oil (Rear Differential

Gear Oil) ................................................................. 33

OIL LEAKAGE AND OIL LEVEL ......................... 33

Changing Rear Final Drive Oil (Rear Differential

Gear Oil) ................................................................. 34

DRAINING ........................................................... 34

FILLING ............................................................... 34

Balancing Wheels ................................................... 34

Tire Rotation ........................................................... 34

Checking Brake Fluid Level and Leaks .................. 35

Checking Brake Lines and Cables ......................... 35

Changing Brake Fluid ............................................. 35

Checking Disc Brake .............................................. 35

ROTOR ................................................................ 35

CALIPER ............................................................. 36

PAD ..................................................................... 36

Checking Drum Brake ............................................ 36

DRUM .................................................................. 36

WHEEL CYLINDER ............................................. 36

LINING ................................................................. 37

Checking Steering Gear and Linkage ..................... 37

STEERING GEAR ............................................... 37

STEERING LINKAGE .......................................... 37

Checking Power Steering Fluid and Lines .............. 37CHECKING FLUID LEVEL .................................. 37

CHECKING LINES ............................................... 37

Checking Axle and Suspension Parts ..................... 38

FRONT AND REAR AXLE AND SUSPENSION

PARTS ................................................................. 38

FRONT DRIVE SHAFT ........................................ 38

Lubricating Locks, Hinges and Hood Latches ......... 39

Checking Seat Belts, Buckles, Retractors, Anchors

and Adjusters .......................................................... 40

Checking Body Corrosion ....................................... 40

HEMMED PANELS .............................................. 40

PANEL JOINT ...................................................... 40

PANEL EDGE ...................................................... 40

PARTS CONTACT ............................................... 40

PROTECTORS .................................................... 40

ANTI-CORROSION MATERIALS ........................ 40

DRAIN HOLES ..................................................... 40

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 41

Standard and Limit .................................................. 41

BELT DEFLECTION ............................................ 41

RESERVOIR TANK ............................................. 41

ENGINE COOLANT CAPACITY (APPROXI-

MATE) .................................................................. 41

ENGINE OIL CAPACITY (APPROXIMATE) ........ 41

Page 2280 of 3171

DESCRIPTION

MA-5

C

D

E

F

G

H

I

J

K

MA

B

MA

DESCRIPTIONPFP:00000

Pre-Delivery Inspection ItemsELS001K2

Shown below are Pre-delivery Inspection Items required for the new vehicle. It is recommended that

necessary items other than those listed here be added, paying due regard to the conditions in each

country.

Perform applicable items on each model. Consult text of this section for specifications.

Install vehicle protection kit

Fit all accessories ordered (if applicable) (e.g. towbar, audio, navigation, air conditioner, styling kit)

UNDER HOOD — engine off

Check coolant level and cooling system for leaks

Charge battery and check terminals for condition

Check drive belts tension

Check fuel filter for water or dust (diesel only) and fuel system for leaks

Check engine oil level and for oil leaks

Check brake and clutch fluid levels and fluid lines for leaks

Check and top up washer reservoirs

Check power steering fluid level and fluid lines for leaks (if applicable)

Check air conditioning system for gas leaks (if applicable)

ON INSIDE AND OUTSIDE

Install transit fuse if removed for vehicle storage

Check instruments, gauges, lamps, horn and accessories for operation

Check wipers and washers for operation and adjustment

Check interior and door mirrors and sun visors for operation

Set radio code and set clock

Check parking brake adjustment

Check clutch pedal adjustment

Check steering lock operation

Check seat adjusters and seat belts for operation

Check all windows for operation and alignment

Check mouldings, trim and fittings for fit and alignment

Check weatherstrips for fit and adhesion

Check hood, trunk lid, door panels and fuel lid for fit and alignment

Check latches, keys, remote key, door locks and remote trunk lid and fuel lid release for operation

Check wheel nut torques

Check tyre pressure (incl. spare tyre)

Check tool kit and jack for operation

Check automatic transmission/transaxle starter inhibitor (if applicable)

Check sunroof for operation and alignment (if applicable)

UNDER BODY

Check manual transmission/transaxle, differential and transfer box for oil level and oil leaks

Tighten bolts and nuts steering linkage and gear box, axle/suspension parts, propeller and exhaust system

Check brake and clutch lines, and oil/fluid reservoirs for leaks

Remove front suspension spacer blocks (if applicable)

Check body mounting torque (if applicable)

Page 2281 of 3171

MA-6

DESCRIPTION

ROAD TEST

Check clutch operation

Check foot brake operation

Check parking brake operation

Check steering operation, self-centering and steering wheel alignment

Check engine performance

Check for squeaks, rattles and noise from interior, suspension and brakes

Check heating, ventilation and air conditioning operation

Check radio, cassette and CD player operation

Check odometer and trip meter operation and cancelling

Check instruments for operation

Check automatic transmission/transaxle shift pattern and kickdown operation (if applicable)

Check cruise control and navigation system operation (if applicable)

ENGINE OPERATING AND HOT

Check idle speed

Check automatic transmission/transaxle oil level (if applicable)

FINAL INSPECTION

Remove vehicle protection kit

Fit interior mats and wheel covers

Check for interior and exterior metal and paint damage

Wash, clean interior and exterior

: Not applicable to this model