check engine NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1764 of 3171

SQUEAK AND RATTLE TROUBLE DIAGNOSES

IP-5

C

D

E

F

G

H

J

K

L

MA

B

IP

DUPLICATE THE NOISE AND TEST DRIVE

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or location of the noise. This information can be used to

duplicate the same conditions when you confirm the repair.

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following:

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle “twist”.

5) At idle, apply engine load (electrical load, half-clutch on M/T model, drive position on A/T model).

6) Raisethevehicleonahoistandhitatirewitharubberhammer.

lDrive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

lIf it is difficult to duplicate the noise, drive the vehicle slowly on an undulating or rough road to stress the

vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, check ASIST for Technical Service Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, follow the procedure to repair the noise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area.To help pinpoint the source of the noise, use a listening tool

(Engine Ear and mechanic's stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by:

lremoving the components in the area that you suspect the noise is coming from.

Do not use too much force when removing clips and fasteners, otherwise clips and fasteners can be bro-

ken or lost during the repair, resulting in the creation of new noise.

ltapping or pushing/pulling the component that you suspect is causing the noise.

Do not tap or push/pull the component with excessive force, otherwise the noise will be eliminated only

temporarily.

lfeeling for a vibration with your hand by touching the component(s) that you suspect is (are) causing the

noise.

lplacing a piece of paper between components that you suspect are causing the noise.

llooking for loose components and contact marks.

Refer toIP-6, "

Generic Squeak and Rattle Troubleshooting".

REPAIR THE CAUSE

lIf the cause is a loose component, tighten the component securely.

lIf the cause is insufficient clearance between components:

–separate components by repositioning or loosening and retightening the component, if possible.

–insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or ure-

thane tape. A NISSAN Squeak and Rattle Kit (J-43980) is available through your authorized NISSAN

Parts Department.

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

Always check with the Parts Department for the latest parts information.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Page 1787 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual LAN-10

[CAN]

TROUBLE DIAGNOSES WORK FLOW

Example of Filling in Check Sheet When Initial Conditions Are Reproduced

1. Put a check mark to “No indication” if some of unit names listed on the column NISSAN NAVARA 2005 Repair Workshop Manual LAN-10

[CAN]

TROUBLE DIAGNOSES WORK FLOW

Example of Filling in Check Sheet When Initial Conditions Are Reproduced

1. Put a check mark to “No indication” if some of unit names listed on the column](/img/5/57362/w960_57362-1786.png)

LAN-10

[CAN]

TROUBLE DIAGNOSES WORK FLOW

Example of Filling in Check Sheet When Initial Conditions Are Reproduced

1. Put a check mark to “No indication” if some of unit names listed on the column of diagnosis system selec-

tion screen of a check sheet table are not displayed on “SELECT SYSTEM” screen attached to the check

sheet.

NOTE:

Put a check mark to “No indication” of METER because METER is not displayed on “SELECT SYSTEM”

screen.

2. Confirm the unit name that “UNKWN” is displayed from the copy of “CAN DIAG SUPPORT MNTR” screen

of “ENGINE” attached to the check sheet, and then put a check mark to the check sheet table.

NOTE:

In “CAN DIAG SUPPORT MNTR” screen, “UNKWN” is displayed on “METER/M&A”. Put a check mark to

it.

PKIC2526E

Page 1788 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSES WORK FLOW

LAN-11

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

3. Confirm the unit name that “UNKWN” is displayed on the copy of “CAN DIAG SUPPORT MNTR” screen

of “A/T”, “HVAC”, � NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSES WORK FLOW

LAN-11

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

3. Confirm the unit name that “UNKWN” is displayed on the copy of “CAN DIAG SUPPORT MNTR” screen

of “A/T”, “HVAC”, �](/img/5/57362/w960_57362-1787.png)

TROUBLE DIAGNOSES WORK FLOW

LAN-11

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

3. Confirm the unit name that “UNKWN” is displayed on the copy of “CAN DIAG SUPPORT MNTR” screen

of “A/T”, “HVAC”, “BCM”, “ABS” and “IPDM E/R” as well as “ENGINE”. And then, put a check mark to the

check sheet table.

NOTE:

lFor “A/T”, “UNKWN” is displayed on “METER/M&A”, “ICC/e4WD” and “AWD/4WD”. But put a check

mark to “METER/M&A” because “UNKWN” is listed on the column of reception diagnosis of the check

sheet table.

lFor “HVAC”, “UNKWN” is not displayed. Do not put a check mark to it.

lFor “BCM”, “UNKWN” is displayed on “METER/M&A” and “I-KEY”. But put a check mark to “METER/

M&A” because “UNKWN” is listed on the column of reception diagnosis of the check sheet table.

lFor “ABS”, “UNKWN” is not displayed. Do not put a check mark to it.

lFor “IPDM E/R”, “UNKWN” is not displayed. Do not put a check mark to it.

PKIC2527E

Page 1790 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSES WORK FLOW

LAN-13

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Example of Filling in Check Sheet When Initial Conditions Are Not Reproduced

1. See “SELF-DIAG RESULTS” of all units attached to NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSES WORK FLOW

LAN-13

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Example of Filling in Check Sheet When Initial Conditions Are Not Reproduced

1. See “SELF-DIAG RESULTS” of all units attached to](/img/5/57362/w960_57362-1789.png)

TROUBLE DIAGNOSES WORK FLOW

LAN-13

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Example of Filling in Check Sheet When Initial Conditions Are Not Reproduced

1. See “SELF-DIAG RESULTS” of all units attached to the check sheet. If “CAN COMM CIRCUIT” or “CAN

COMM CIRCUIT [U1000]” is displayed, put a check mark to the applicable column of self-diagnostic

results of the check sheet table.

NOTE:

lFor “ENGINE”, “CAN COMM CIRCUIT [U1000]” is displayed. Put a check mark to it.

lFor “A/T”, “CAN COMM CIRCUIT [U1000]” is displayed. Put a check mark to it.

lFor “HVAC”, “NO DTC IS DETECTED” is displayed. Do not put a check mark to it.

lFor “BCM”, “NO DTC IS DETECTED” is displayed. Do not put a check mark to it.

lFor “METER”, “CAN COMM CIRCUIT [U1000]” is displayed. Put a check mark to it.

lFor “ABS”, “NO DTC IS DETECTED” is displayed. Do not put a check mark to it.

lFor “IPDM E/R”, “NO DTC IS DETECTED” is displayed. Do not put a check mark to it.

PKIC2529E

Page 2111 of 3171

LT-28

HEADLAMP -CONVENTIONAL TYPE-

Aiming Adjustment

EKS00P7Y

For details, refer to the regulations in your state.

Before performing aiming adjustment, check the following.

1. Ensure all tires are inflated to correct pressure.

2. Place vehicle and screen on level surface.

3. Ensure there is no load in vehicle other than the driver (or equivalent weight placed in driver's position).

Coolant and engine oil filled to correct level, and fuel tank full.

4. Confirm spare tire, jack and tools are properly stowed.

LOW BEAM AND HIGH BEAM

NOTE:

Aim each headlamp individually and ensure other headlamp beam pattern is blocked from screen.

1. Turn headlamp low beam ON.

2. Use adjusting screws to perform aiming adjustment.

lFirst tighten the adjusting screw all the way and then make adjustment by loosening the screw.

If the vehicle front body has been repaired and/or the headlamp assembly has been replaced, check

aiming. Use the aiming chart shown in the figure.

PKIC1216E

Page 2130 of 3171

HEADLAMP - DAYTIME LIGHT SYSTEM -

LT-47

C

D

E

F

G

H

I

J

L

MA

B

LT

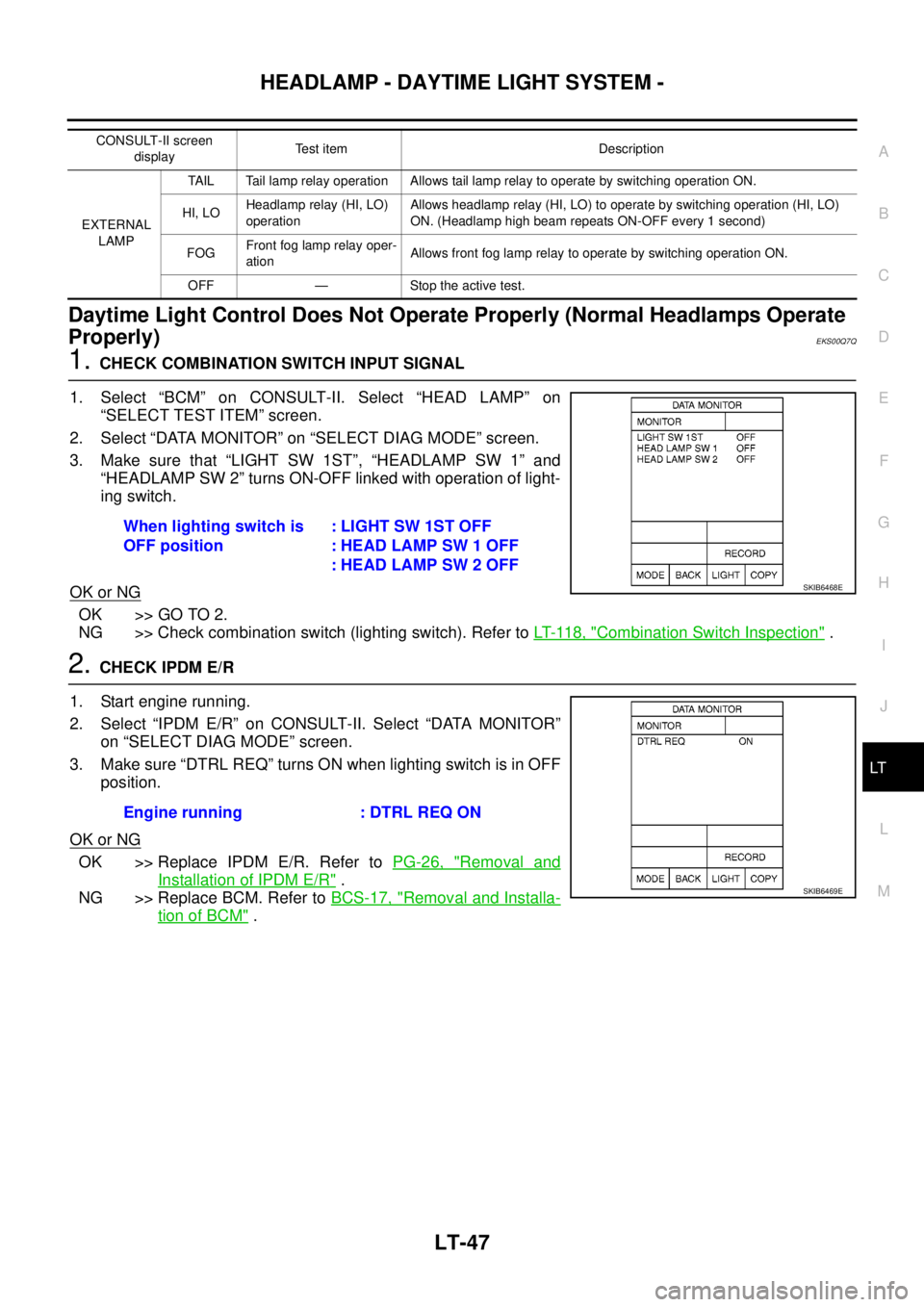

Daytime Light Control Does Not Operate Properly (Normal Headlamps Operate

Properly)

EKS00Q7Q

1.CHECK COMBINATION SWITCH INPUT SIGNAL

1. Select “BCM” on CONSULT-II. Select “HEAD LAMP” on

“SELECT TEST ITEM” screen.

2. Select “DATA MONITOR” on “SELECT DIAG MODE” screen.

3. Make sure that “LIGHT SW 1ST”, “HEADLAMP SW 1” and

“HEADLAMP SW 2” turns ON-OFF linked with operation of light-

ing switch.

OK or NG

OK >> GO TO 2.

NG >> Check combination switch (lighting switch). Refer toLT- 11 8 , "

Combination Switch Inspection".

2.CHECK IPDM E/R

1. Start engine running.

2. Select “IPDM E/R” on CONSULT-II. Select “DATA MONITOR”

on “SELECT DIAG MODE” screen.

3. Make sure “DTRL REQ” turns ON when lighting switch is in OFF

position.

OK or NG

OK >> Replace IPDM E/R. Refer toPG-26, "Removal and

Installation of IPDM E/R".

NG >> Replace BCM. Refer toBCS-17, "

Removal and Installa-

tion of BCM".

CONSULT-II screen

displayTest item Description

EXTERNAL

LAMPTAIL Tail lamp relay operation Allows tail lamp relay to operate by switching operation ON.

HI, LOHeadlamp relay (HI, LO)

operationAllows headlamp relay (HI, LO) to operate by switching operation (HI, LO)

ON. (Headlamp high beam repeats ON-OFF every 1 second)

FOGFront fog lamp relay oper-

ationAllows front fog lamp relay to operate by switching operation ON.

OFF — Stoptheactivetest.

When lighting switch is

OFF position:LIGHTSW1STOFF

: HEAD LAMP SW 1 OFF

: HEAD LAMP SW 2 OFF

SKIB6468E

Engine running : DTRL REQ ON

SKIB6469E

Page 2140 of 3171

AUTO LIGHT SYSTEM

LT-57

C

D

E

F

G

H

I

J

L

MA

B

LT

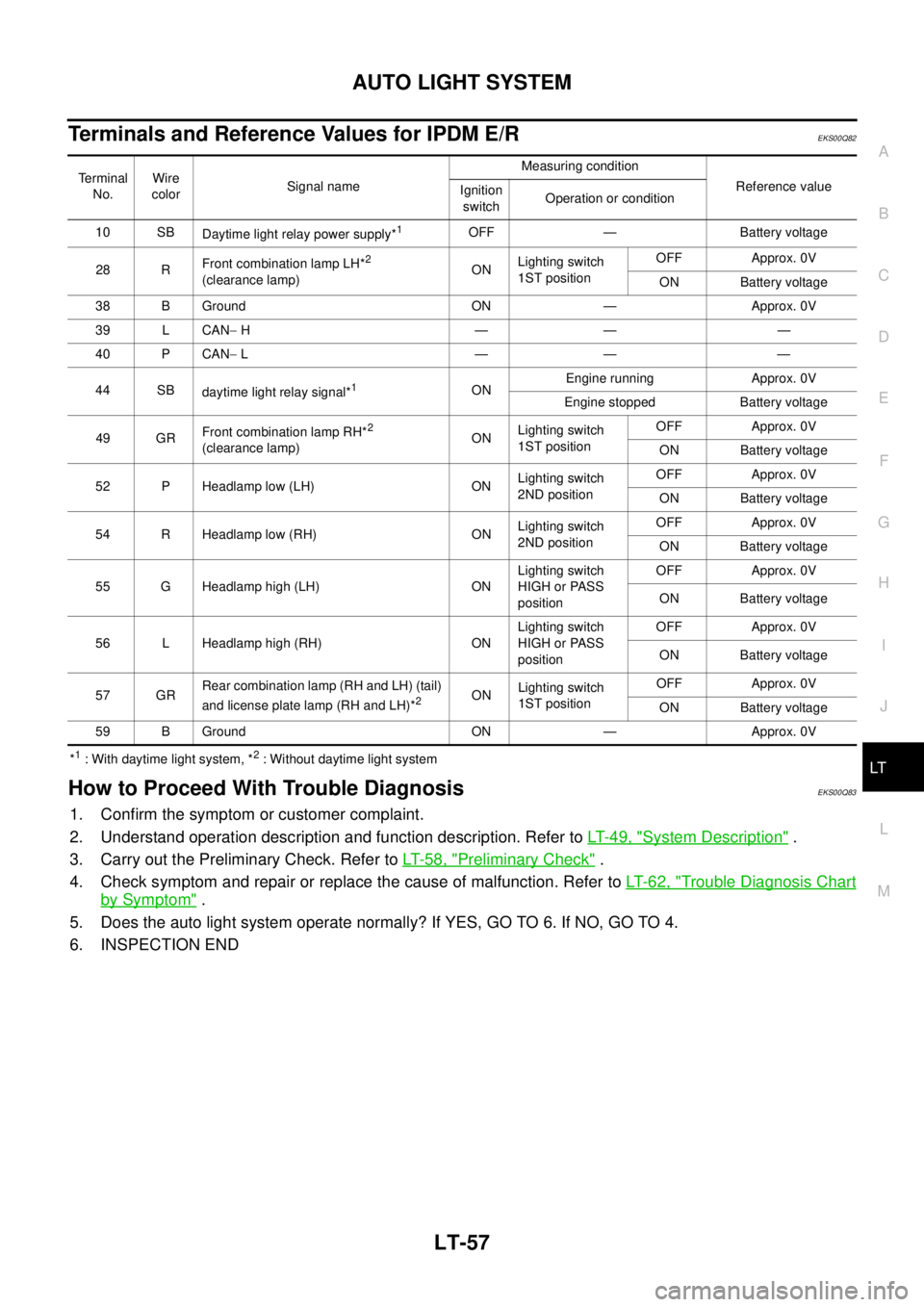

Terminals and Reference Values for IPDM E/REKS00Q82

*1: With daytime light system, *2: Without daytime light system

How to Proceed With Trouble DiagnosisEKS00Q83

1. Confirm the symptom or customer complaint.

2. Understand operation description and function description. Refer toLT-49, "

System Description".

3. Carry out the Preliminary Check. Refer toLT-58, "

Preliminary Check".

4. Check symptom and repair or replace the cause of malfunction. Refer toLT-62, "

Trouble Diagnosis Chart

by Symptom".

5. Does the auto light system operate normally? If YES, GO TO 6. If NO, GO TO 4.

6. INSPECTION END

Terminal

No.Wire

colorSignal nameMeasuring condition

Reference value

Ignition

switchOperation or condition

10 SB

Daytime light relay power supply*

1OFF — Battery voltage

28 RFront combination lamp LH*

2

(clearance lamp)ONLighting switch

1ST positionOFF Approx. 0V

ON Battery voltage

38 B Ground ON — Approx. 0V

39 L CAN-H———

40 P CAN-L———

44 SB

daytime light relay signal*

1ONEngine running Approx. 0V

Engine stopped Battery voltage

49 GRFront combination lamp RH*

2

(clearance lamp)ONLighting switch

1ST positionOFF Approx. 0V

ON Battery voltage

52 P Headlamp low (LH) ONLighting switch

2ND positionOFF Approx. 0V

ON Battery voltage

54 R Headlamp low (RH) ONLighting switch

2ND positionOFF Approx. 0V

ON Battery voltage

55 G Headlamp high (LH) ONLighting switch

HIGH or PASS

positionOFF Approx. 0V

ON Battery voltage

56 L Headlamp high (RH) ONLighting switch

HIGH or PASS

positionOFF Approx. 0V

ON Battery voltage

57 GRRear combination lamp (RH and LH) (tail)

and license plate lamp (RH and LH)*

2ONLighting switch

1ST positionOFF Approx. 0V

ON Battery voltage

59 B Ground ON — Approx. 0V

Page 2258 of 3171

LU-1

ENGINE LUBRICATION SYSTEM

B ENGINE

CONTENTS

C

D

E

F

G

H

I

J

K

L

M

SECTIONLU

A

LU

ENGINE LUBRICATION SYSTEM

PRECAUTIONS .......................................................... 2

Precautions for Liquid Gasket .................................. 2

LIQUID GASKET APPLICATION PROCEDURE..... 2

PREPARATION ........................................................... 3

Special Service Tools ............................................... 3

Commercial Service Tools ........................................ 3

LUBRICATION SYSTEM ............................................ 4

Lubrication Circuit .................................................... 4

ENGINE OIL ............................................................... 5

Inspection ................................................................. 5

ENGINE OIL LEVEL ............................................. 5

ENGINE OIL APPEARANCE ................................ 5

ENGINE OIL LEAKAGE ........................................ 5

ENGINE OIL PRESSURE CHECK ....................... 5

Changing Engine Oil ................................................ 6

OIL FILTER ................................................................. 8

Removal and Installation .......................................... 8

REMOVAL ............................................................. 8

INSTALLATION ..................................................... 8

INSPECTION AFTER INSTALLATION ................. 8

OIL FILTER BRACKET .............................................. 9

Components ............................................................. 9

Removal and Installation .......................................... 9

REMOVAL ............................................................. 9

INSTALLATION ................................................... 10

INSPECTION AFTER INSTALLATION ............... 10OIL COOLER ............................................................ 11

Components ........................................................... 11

Removal and Installation ........................................ 11

REMOVAL ........................................................... 11

INSPECTION AFTER REMOVAL ....................... 12

INSTALLATION ................................................... 12

INSPECTION AFTER INSTALLATION ................ 12

OIL PUMP ................................................................. 14

Removal and Installation ........................................ 14

REMOVAL ........................................................... 14

INSTALLATION ................................................... 14

INSPECTION AFTER INSTALLATION ................ 14

Components ........................................................... 14

Disassembly and Assembly .................................... 14

DISASSEMBLY ................................................... 14

INSPECTION AFTER DISASSEMBLY ................ 15

ASSEMBLY ......................................................... 16

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 17

Standard and Limit .................................................. 17

OIL PRESSURE .................................................. 17

OIL CAPACITY (APPROXIMATE) ....................... 17

OIL PUMP ........................................................... 17

REGULATOR VALVE .......................................... 17

Page 2262 of 3171

ENGINE OIL

LU-5

C

D

E

F

G

H

I

J

K

L

MA

LU

ENGINE OILPFP:KLA92

InspectionEBS01E56

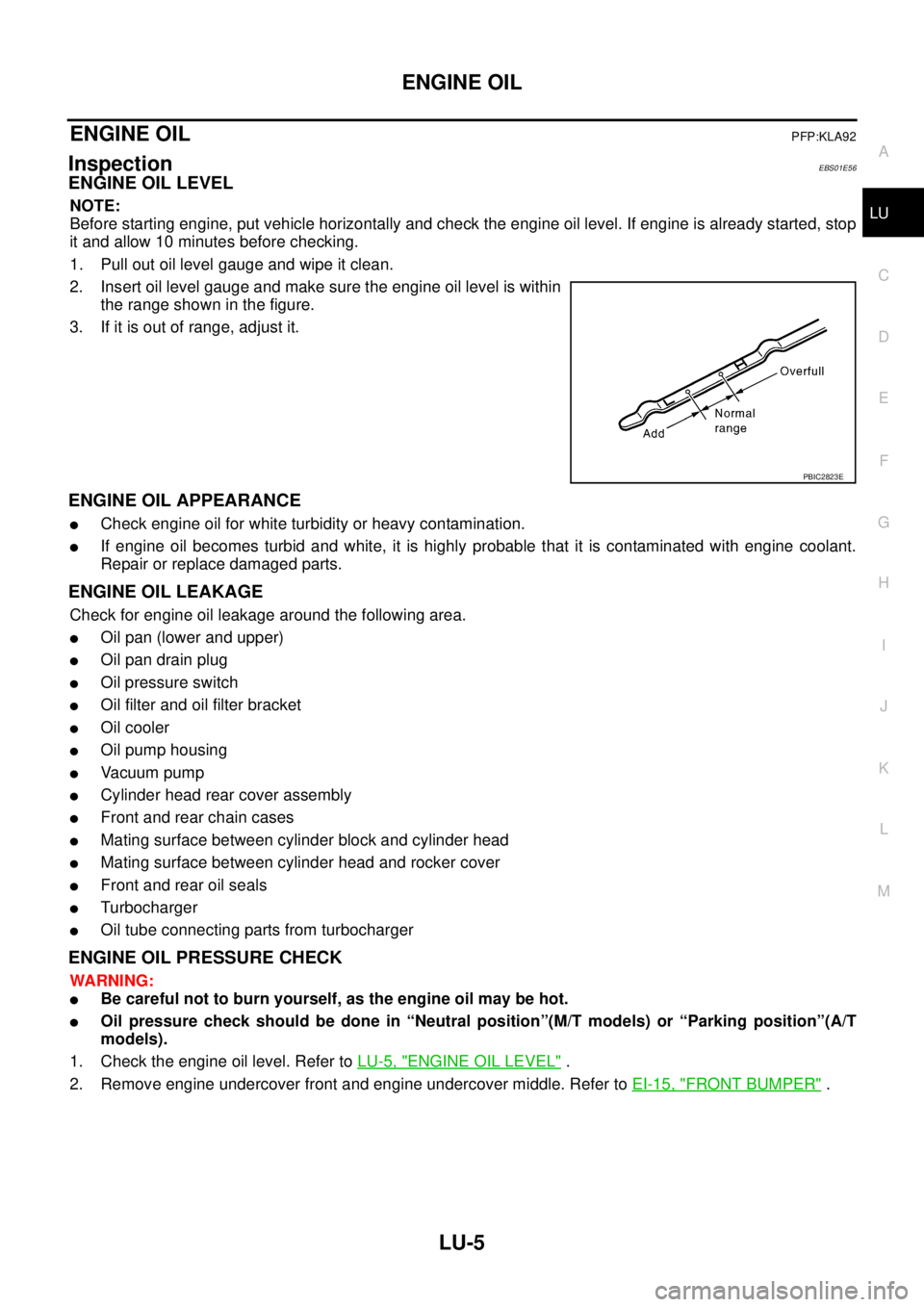

ENGINE OIL LEVEL

NOTE:

Before starting engine, put vehicle horizontally and check the engine oil level. If engine is already started, stop

it and allow 10 minutes before checking.

1. Pull out oil level gauge and wipe it clean.

2. Insert oil level gauge and make sure the engine oil level is within

the range shown in the figure.

3. If it is out of range, adjust it.

ENGINE OIL APPEARANCE

lCheck engine oil for white turbidity or heavy contamination.

lIf engine oil becomes turbid and white, it is highly probable that it is contaminated with engine coolant.

Repair or replace damaged parts.

ENGINE OIL LEAKAGE

Check for engine oil leakage around the following area.

lOil pan (lower and upper)

lOil pan drain plug

lOil pressure switch

lOil filter and oil filter bracket

lOil cooler

lOil pump housing

lVa c u u m p u m p

lCylinder head rear cover assembly

lFront and rear chain cases

lMating surface between cylinder block and cylinder head

lMating surface between cylinder head and rocker cover

lFront and rear oil seals

lTurbocharger

lOil tube connecting parts from turbocharger

ENGINE OIL PRESSURE CHECK

WARNING:

lBe careful not to burn yourself, as the engine oil may be hot.

lOil pressure check should be done in “Neutral position”(M/T models) or “Parking position”(A/T

models).

1. Check the engine oil level. Refer toLU-5, "

ENGINE OIL LEVEL".

2. Remove engine undercover front and engine undercover middle. Refer toEI-15, "

FRONT BUMPER".

PBIC2823E

Page 2263 of 3171

LU-6

ENGINE OIL

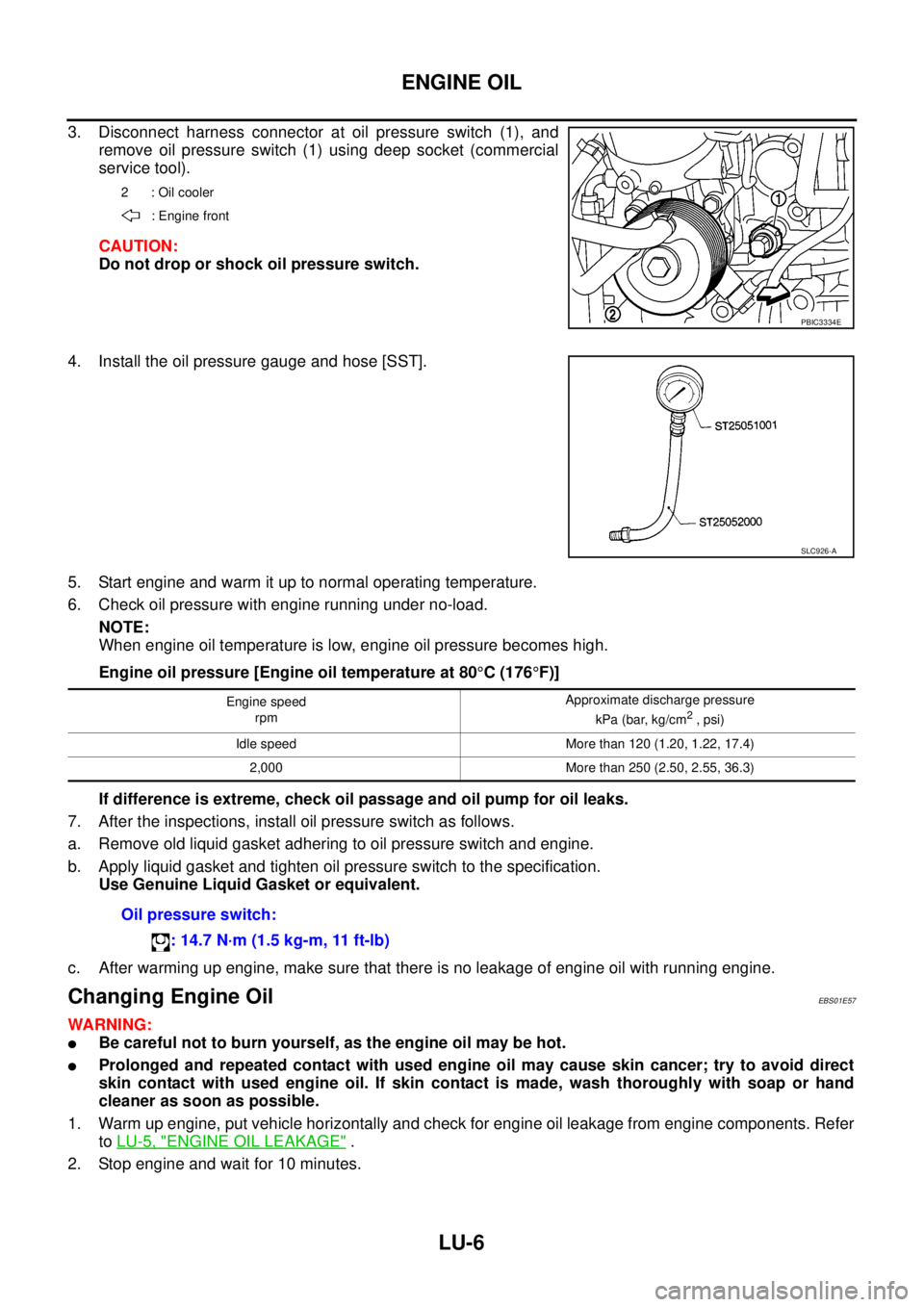

3. Disconnect harness connector at oil pressure switch (1), and

remove oil pressure switch (1) using deep socket (commercial

service tool).

CAUTION:

Do not drop or shock oil pressure switch.

4. Install the oil pressure gauge and hose [SST].

5. Start engine and warm it up to normal operating temperature.

6. Check oil pressure with engine running under no-load.

NOTE:

When engine oil temperature is low, engine oil pressure becomes high.

Engine oil pressure [Engine oil temperature at 80°C(176°F)]

If difference is extreme, check oil passage and oil pump for oil leaks.

7. After the inspections, install oil pressure switch as follows.

a. Remove old liquid gasket adhering to oil pressure switch and engine.

b. Apply liquid gasket and tighten oil pressure switch to the specification.

Use Genuine Liquid Gasket or equivalent.

c. After warming up engine, make sure that there is no leakage of engine oil with running engine.

Changing Engine OilEBS01E57

WARNING:

lBe careful not to burn yourself, as the engine oil may be hot.

lProlonged and repeated contact with used engine oil may cause skin cancer; try to avoid direct

skin contact with used engine oil. If skin contact is made, wash thoroughly with soap or hand

cleaner as soon as possible.

1. Warm up engine, put vehicle horizontally and check for engine oil leakage from engine components. Refer

toLU-5, "

ENGINE OIL LEAKAGE".

2. Stop engine and wait for 10 minutes.

2 : Oil cooler

: Engine front

PBIC3334E

SLC926-A

Engine speed

rpmApproximate discharge pressure

kPa (bar, kg/cm2, psi)

Idle speed More than 120 (1.20, 1.22, 17.4)

2,000 More than 250 (2.50, 2.55, 36.3)

Oil pressure switch:

: 14.7 N·m (1.5 kg-m, 11 ft-lb)