air condition NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2479 of 3171

MTC-92

TROUBLE DIAGNOSIS

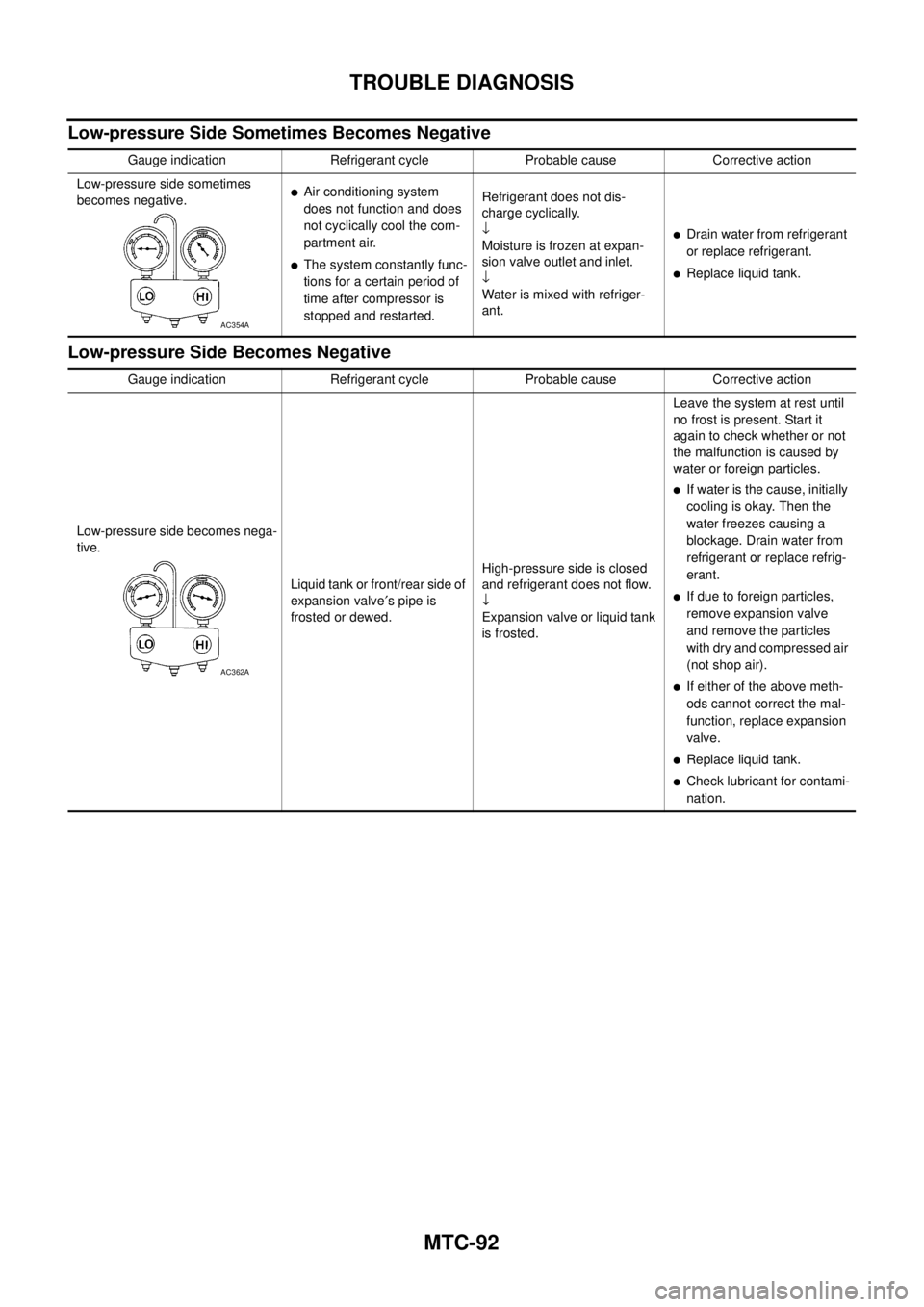

Low-pressure Side Sometimes Becomes Negative

Low-pressure Side Becomes Negative

Gauge indication Refrigerant cycle Probable cause Corrective action

Low-pressure side sometimes

becomes negative.

lAir conditioning system

does not function and does

not cyclically cool the com-

partment air.

lThe system constantly func-

tions for a certain period of

time after compressor is

stopped and restarted.Refrigerant does not dis-

charge cyclically.

¯

Moisture is frozen at expan-

sion valve outlet and inlet.

¯

Water is mixed with refriger-

ant.

lDrain water from refrigerant

or replace refrigerant.

lReplace liquid tank.

AC354A

Gauge indication Refrigerant cycle Probable cause Corrective action

Low-pressure side becomes nega-

tive.

Liquid tank or front/rear side of

expansion valve¢spipeis

frosted or dewed.High-pressure side is closed

and refrigerant does not flow.

¯

Expansion valve or liquid tank

is frosted.Leave the system at rest until

no frost is present. Start it

again to check whether or not

the malfunction is caused by

waterorforeignparticles.

lIf water is the cause, initially

cooling is okay. Then the

water freezes causing a

blockage. Drain water from

refrigerant or replace refrig-

erant.

lIf due to foreign particles,

remove expansion valve

and remove the particles

with dry and compressed air

(not shop air).

lIf either of the above meth-

ods cannot correct the mal-

function, replace expansion

valve.

lReplace liquid tank.

lCheck lubricant for contami-

nation.

AC362A

Page 2488 of 3171

AIR CONDITIONER FILTER

MTC-101

C

D

E

F

G

H

I

K

L

MA

B

MTC

AIR CONDITIONER FILTERPFP:27277

Removal and InstallationEJS005GW

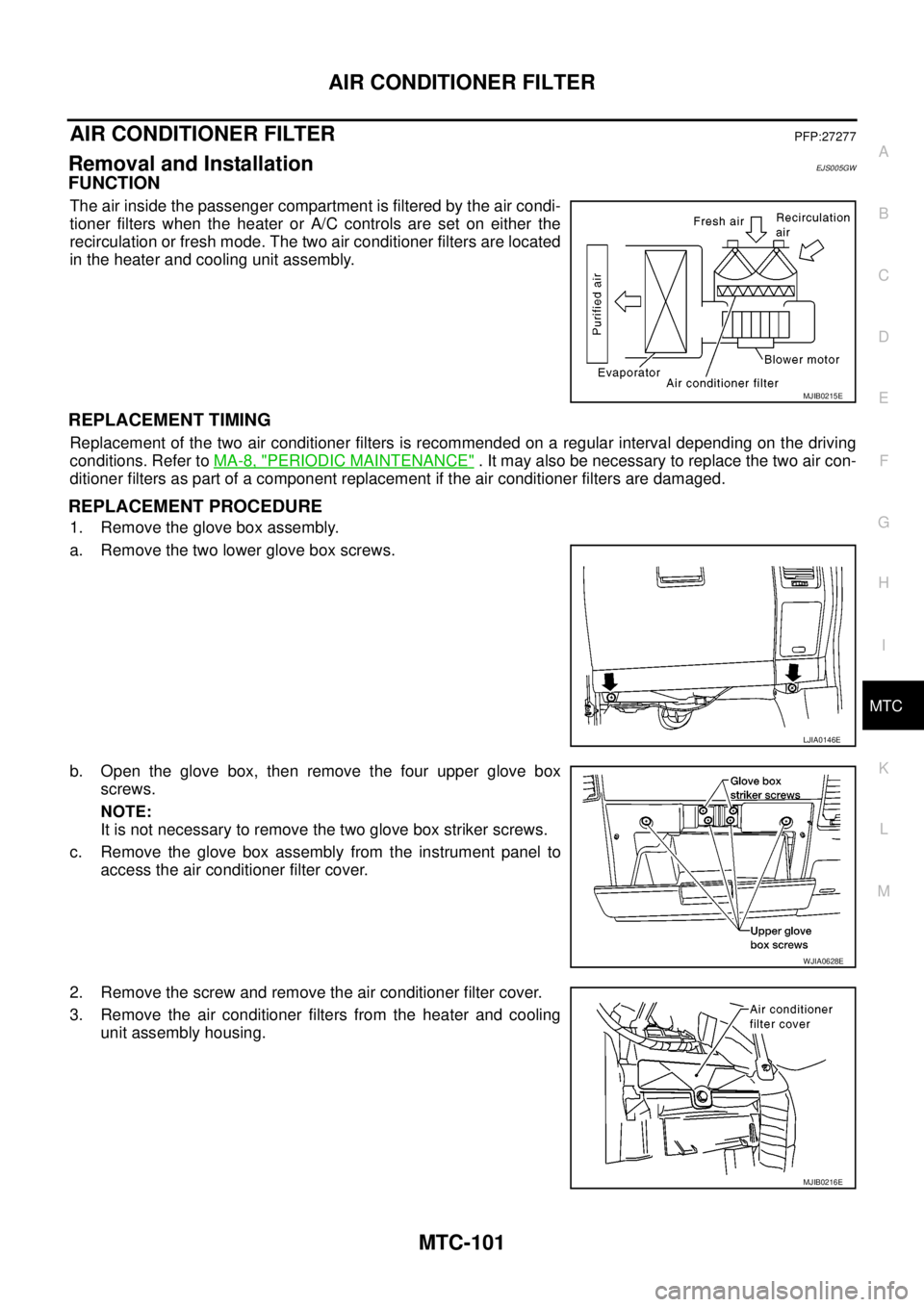

FUNCTION

The air inside the passenger compartment is filtered by the air condi-

tioner filters when the heater or A/C controls are set on either the

recirculation or fresh mode. The two air conditioner filters are located

in the heater and cooling unit assembly.

REPLACEMENT TIMING

Replacement of the two air conditioner filters is recommended on a regular interval depending on the driving

conditions. Refer toMA-8, "

PERIODIC MAINTENANCE". It may also be necessary to replace the two air con-

ditioner filters as part of a component replacement if the air conditioner filters are damaged.

REPLACEMENT PROCEDURE

1. Remove the glove box assembly.

a. Remove the two lower glove box screws.

b. Open the glove box, then remove the four upper glove box

screws.

NOTE:

It is not necessary to remove the two glove box striker screws.

c. Remove the glove box assembly from the instrument panel to

access the air conditioner filter cover.

2. Remove the screw and remove the air conditioner filter cover.

3. Remove the air conditioner filters from the heater and cooling

unit assembly housing.

MJIB0215E

LJIA0146E

WJIA0628E

MJIB0216E

Page 2489 of 3171

MTC-102

AIR CONDITIONER FILTER

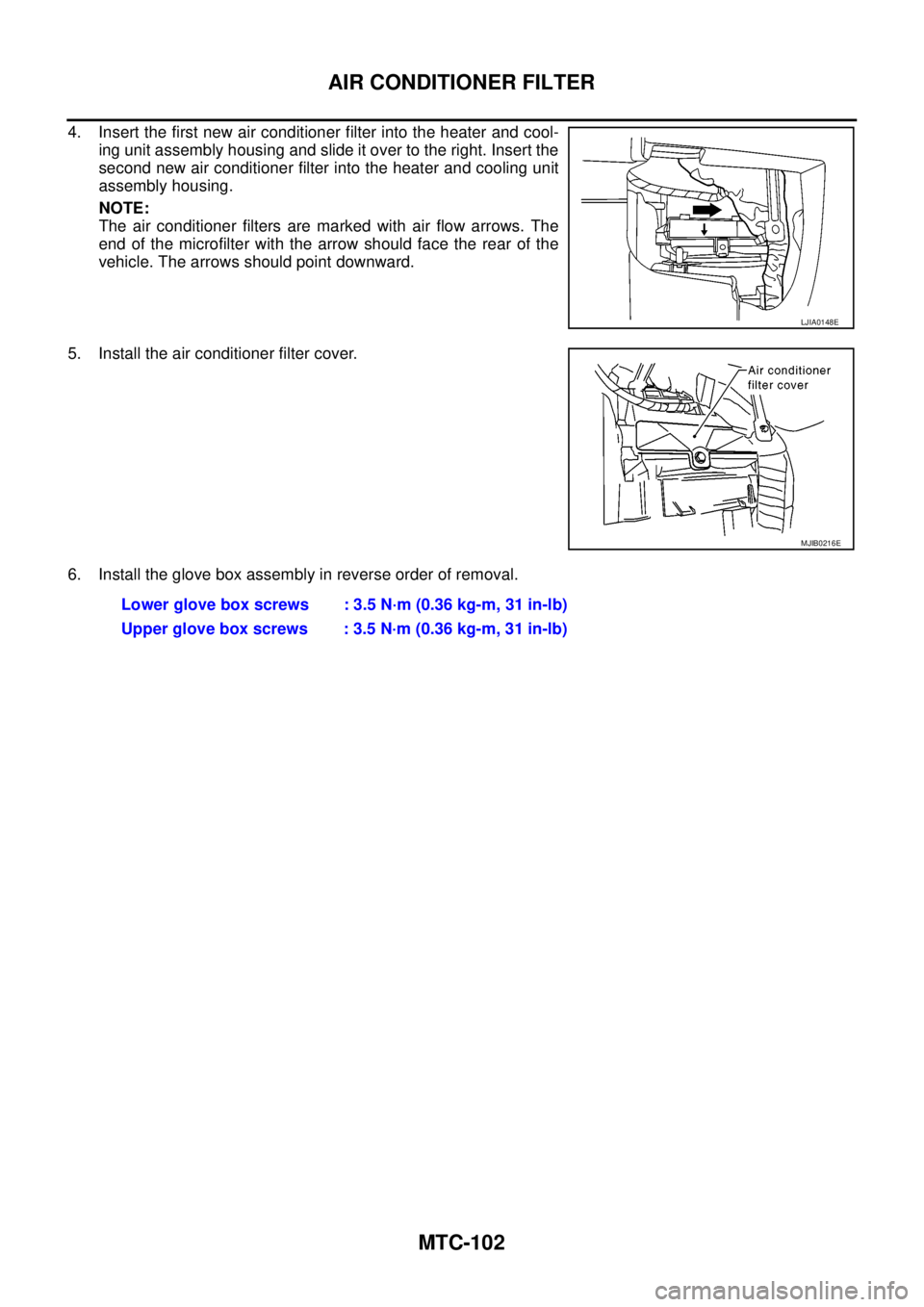

4. Insert the first new air conditioner filter into the heater and cool-

ing unit assembly housing and slide it over to the right. Insert the

second new air conditioner filter into the heater and cooling unit

assembly housing.

NOTE:

The air conditioner filters are marked with air flow arrows. The

end of the microfilter with the arrow should face the rear of the

vehicle. The arrows should point downward.

5. Install the air conditioner filter cover.

6. Install the glove box assembly in reverse order of removal.

LJIA0148E

MJIB0216E

Lower glove box screws : 3.5 N·m (0.36 kg-m, 31 in-lb)

Upper glove box screws : 3.5 N·m (0.36 kg-m, 31 in-lb)

Page 2494 of 3171

HEATER CORE

MTC-107

C

D

E

F

G

H

I

K

L

MA

B

MTC

Removal and InstallationEJS005H0

REMOVAL

1. Remove the heater and cooling unit assembly. Refer toMTC-103, "HEATER&COOLING UNIT ASSEM-

BLY".

2. Remove the four screws and remove the upper bracket.

3. Remove the four screws and remove the heater core cover.

4. Remove the heater core pipe bracket.

5. Remove the heater core.

NOTE:

If the air conditioner filters are contaminated from coolant leak-

ing from the heater core, replace the air conditioner filters with

new ones before installing the new heater core.

INSTALLATION

Installation is in the reverse order of removal.

MJIB0216E

Page 2518 of 3171

REFRIGERANT LINES

MTC-131

C

D

E

F

G

H

I

K

L

MA

B

MTC

Checking for Refrigerant LeaksEJS0062F

Perform a visual inspection of all refrigeration parts, fittings, hoses and components for signs of A/C lubricant

leakage, damage and corrosion. A/C lubricant leakage may indicate an area of refrigerant leakage. Allow

extra inspection time in these areas when using either an electronic refrigerant leak detector or fluorescent

dye leak detector.

If dye is observed, confirm the leak with an electronic refrigerant leak detector. It is possible a prior leak was

repaired and not properly cleaned.

When searching for leaks, do not stop when one leak is found but continue to check for additional leaks at all

system components and connections.

When searching for refrigerant leaks using an electronic leak detector, move the probe along the suspected

leak area at 1 to 2 inches per second and no further than 1/4 inch from the component.

CAUTION:

Moving the electronic leak detector probe slower and closer to the suspected leak area will improve

the chances of finding a leak.

Checking System for Leaks Using the Fluorescent Leak DetectorEJS0062G

1. Check A/C system for leaks using the UV lamp and safety goggles [SST: J-42220] in a low sunlight area

(area without windows preferable). Illuminate all components, fittings and lines. The dye will appear as a

bright green/yellow area at the point of leakage. Fluorescent dye observed at the evaporator drain open-

ing indicates an evaporator core assembly (tubes, core or expansion valve) leak.

2. If the suspected area is difficult to see, use an adjustable mirror or wipe the area with a clean shop rag or

cloth, with the UV lamp for dye residue.

3. After the leak is repaired, remove any residual dye using dye cleaner [SST: J-43872] to prevent future mis-

diagnosis.

4. Perform a system performance check and verify the leak repair with an approved electronic refrigerant

leak detector.

NOTE:

Other gases in the work area or substances on the A/C components, for example, anti-freeze, windshield

washer fluid, solvents and lubricants, may falsely trigger the leak detector. Make sure the surfaces to be

checked are clean.

Clean with a dry cloth or blow off with shop air.

Do not allow the sensor tip of the detector to contact with any substance. This can also cause false readings

and may damage the detector.

Dye InjectionEJS0062H

(This procedure is only necessary when recharging the system or when the compressor has seized and was

replaced.)

1. Check A/C system static (at rest) pressure. Pressure must be at least 345 kPa (3.45 bar, 3.52 kg/cm

2,50

psi).

2. Pour one bottle (1/4 ounce / 7.4 cc) of the A/C refrigerant dye into the injector tool [SST: J-41459].

3. Connect the injector tool to the A/C Low-pressure side service fitting.

4. Start engine and switch A/C ON.

5. When the A/C operating (compressor running), inject one bottle (1/4 ounce / 7.4 cc) of fluorescent dye

through the low-pressure service valve using dye injector tool J-41459 (refer to the manufacture’s operat-

ing instructions).

6. With the engine still running, disconnect the injector tool from the service fitting.

CAUTION:

Be careful the A/C system or replacing a component, pour the dye directly into the open system

connection and proceed with the service procedures.

7. Operate the A/C system for a minimum of 20 minutes to mix the dye with the system oil. Depending on the

leak size, operating conditions and location of the leak, it may take from minutes to days for the dye to

penetrate a leak and become visible.

Page 2597 of 3171

PG-68

HARNESS

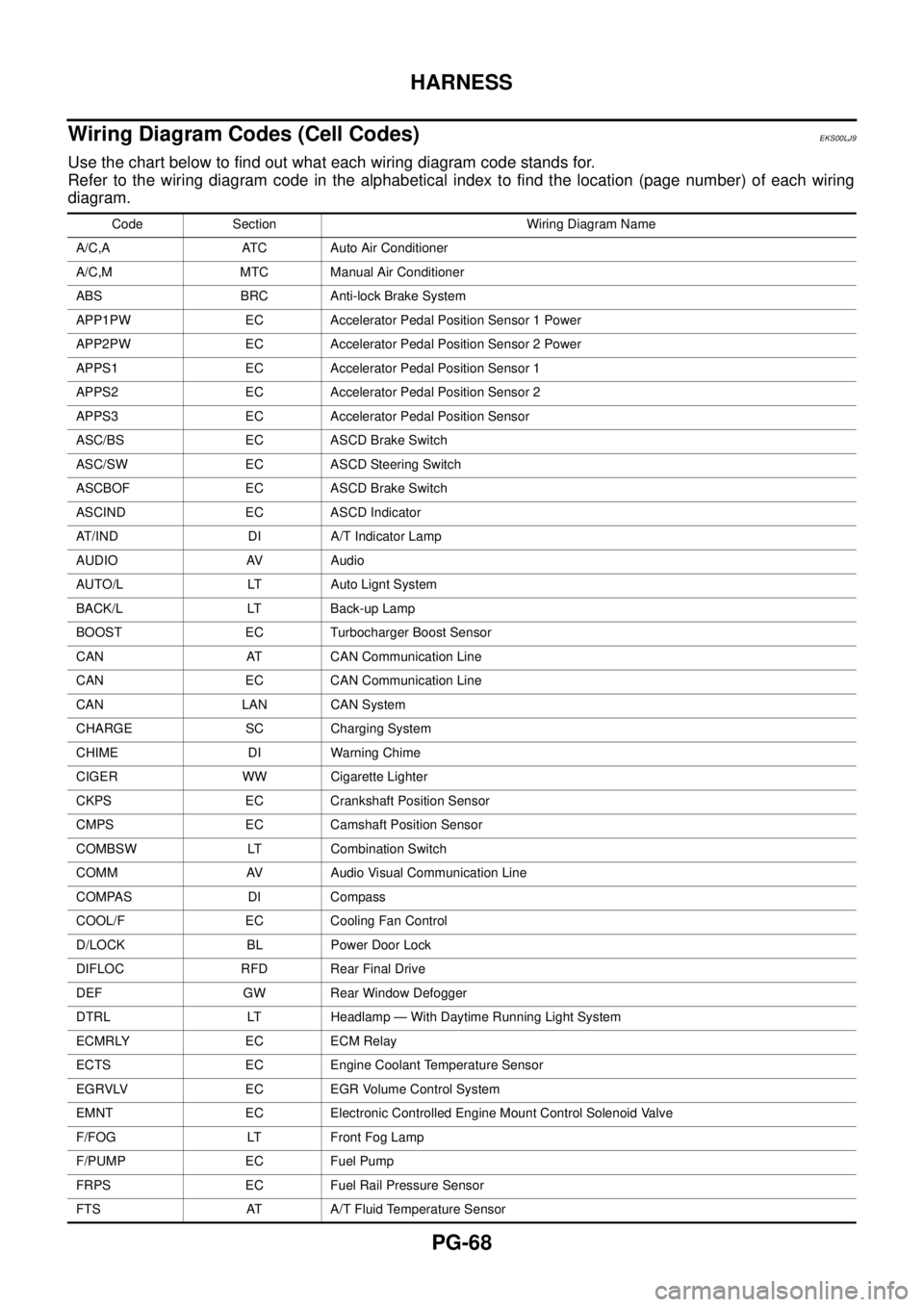

Wiring Diagram Codes (Cell Codes)

EKS00LJ9

Use the chart below to find out what each wiring diagram code stands for.

Refer to the wiring diagram code in the alphabetical index to find the location (page number) of each wiring

diagram.

Code Section Wiring Diagram Name

A/C,A ATC Auto Air Conditioner

A/C,M MTC Manual Air Conditioner

ABS BRC Anti-lock Brake System

APP1PW EC Accelerator Pedal Position Sensor 1 Power

APP2PW EC Accelerator Pedal Position Sensor 2 Power

APPS1 EC Accelerator Pedal Position Sensor 1

APPS2 EC Accelerator Pedal Position Sensor 2

APPS3 EC Accelerator Pedal Position Sensor

ASC/BS EC ASCD Brake Switch

ASC/SW EC ASCD Steering Switch

ASCBOF EC ASCD Brake Switch

ASCIND EC ASCD Indicator

AT/IND DI A/T Indicator Lamp

AUDIO AV Audio

AUTO/L LT Auto Lignt System

BACK/L LT Back-up Lamp

BOOST EC Turbocharger Boost Sensor

CAN AT CAN Communication Line

CAN EC CAN Communication Line

CAN LAN CAN System

CHARGE SC Charging System

CHIME DI Warning Chime

CIGER WW Cigarette Lighter

CKPS EC Crankshaft Position Sensor

CMPS EC Camshaft Position Sensor

COMBSW LT Combination Switch

COMM AV Audio Visual Communication Line

COMPAS DI Compass

COOL/F EC Cooling Fan Control

D/LOCK BL Power Door Lock

DIFLOC RFD Rear Final Drive

DEF GW Rear Window Defogger

DTRL LT Headlamp — With Daytime Running Light System

ECMRLY EC ECM Relay

ECTS EC Engine Coolant Temperature Sensor

EGRVLV EC EGR Volume Control System

EMNT EC Electronic Controlled Engine Mount Control Solenoid Valve

F/FOG LT Front Fog Lamp

F/PUMP EC Fuel Pump

FRPS EC Fuel Rail Pressure Sensor

FTS AT A/T Fluid Temperature Sensor

Page 2628 of 3171

PS-1

POWER STEERING SYSTEM

G STEERING

CONTENTS

C

D

E

F

H

I

J

K

L

M

SECTIONPS

A

B

PS

POWER STEERING SYSTEM

PRECAUTIONS .......................................................... 2

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 2

Precautions for Steering System .............................. 2

PREPARATION ........................................................... 3

Special Service Tools [SST] ..................................... 3

Commercial Service Tools ........................................ 4

NOISE, VIBRATION, AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 5

NVH Troubleshooting Chart ..................................... 5

POWER STEERING FLUID ........................................ 6

Checking Fluid Level ................................................ 6

Checking Fluid Leakage ........................................... 6

Air Bleeding Hydraulic System ................................. 6

STEERING WHEEL .................................................... 8

On-Vehicle Inspection and Service .......................... 8

CHECKING CONDITION OF INSTALLATION ...... 8

CHECKING STEERING WHEEL PLAY ................ 8

CHECKING NEUTRAL POSITION STEERING

WHEEL ................................................................. 8

CHECKING STEERING WHEEL TURNING

FORCE .................................................................. 8

CHECKING FRONT WHEEL TURNING ANGLE..... 9

Removal and Installation ........................................ 10

REMOVAL ........................................................... 10

INSTALLATION ................................................... 10

STEERING COLUMN ................................................11

Removal and Installation ......................................... 11

COMPONENT ...................................................... 11

REMOVAL ............................................................ 11

INSPECTION AFTER REMOVAL ....................... 12

INSTALLATION ................................................... 12

INSPECTION AFTER INSTALLATION ............... 13

POWER STEERING GEAR AND LINKAGE ............ 14Removal and Installation ........................................ 14

COMPONENT ..................................................... 14

REMOVAL ........................................................... 14

INSTALLATION ................................................... 15

INSPECTION AFTER INSTALLATION ................ 15

Disassembly and Assembly .................................... 16

COMPONENT ..................................................... 16

DISASSEMBLY ................................................... 17

INSPECTION AFTER DISASSEMBLY ................ 18

ASSEMBLY ......................................................... 20

POWER STEERING OIL PUMP ............................... 25

On-Vehicle Inspection and Service ......................... 25

CHECKING RELIEF OIL PRESSURE ................ 25

Removal and Installation ........................................ 25

REMOVAL ........................................................... 25

INSTALLATION ................................................... 26

Disassembly and Assembly .................................... 26

COMPONENT ..................................................... 26

INSPECTION BEFORE DISASSEMBLY ............. 26

DISASSEMBLY ................................................... 27

INSPECTION AFTER DISASSEMBLY ................ 27

ASSEMBLY ......................................................... 28

HYDRAULIC LINE .................................................... 30

Component (RHD Models) ..................................... 30

Component (LHD Models) ...................................... 32

Removal and Installation ........................................ 33

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 34

Steering Wheel ....................................................... 34

Steering Angle ........................................................ 34

Steering Column ..................................................... 34

Steering Outer Socket and Inner Socket ................ 34

Steering Gear ......................................................... 35

Oil Pump ................................................................. 35

Steering Fluid .......................................................... 35

Page 2629 of 3171

PS-2

PRECAUTIONS

PRECAUTIONS

PFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EGS001M0

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions for Steering SystemEGS001L9

lIn case of removing steering gear assembly, make the final tightening with grounded and unloaded vehi-

cle condition, and then check wheel alignment.

lObserve the following precautions when disassembling.

–Before disassembly, thoroughly clean the outside of the unit.

–Disassembly should be done in a clean work area. It is important to prevent the internal parts from becom-

ing contaminated by dirt or other foreign matter.

–For easier and proper assembly, place disassembled parts in order on a parts rack.

–Use nylon cloth or paper towels to clean the parts; common shop rags can leave lint that might interfere

with their operation.

–Do not reuse non-reusable parts.

–Before assembling, apply the specified grease to the directed parts.

Page 2642 of 3171

POWER STEERING GEAR AND LINKAGE

PS-15

C

D

E

F

H

I

J

K

L

MA

B

PS

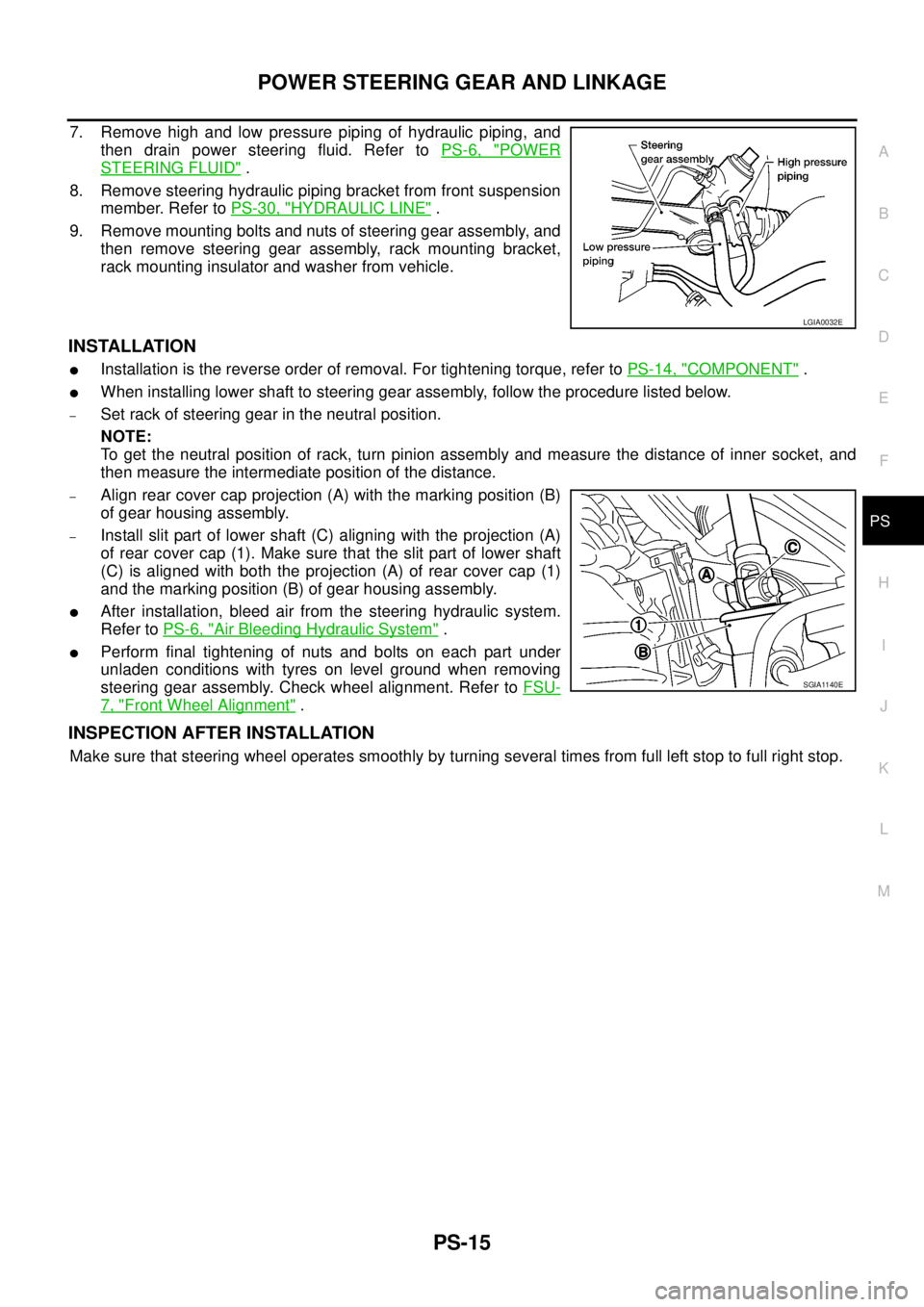

7. Remove high and low pressure piping of hydraulic piping, and

then drain power steering fluid. Refer toPS-6, "

POWER

STEERING FLUID".

8. Remove steering hydraulic piping bracket from front suspension

member. Refer toPS-30, "

HYDRAULIC LINE".

9. Remove mounting bolts and nuts of steering gear assembly, and

then remove steering gear assembly, rack mounting bracket,

rack mounting insulator and washer from vehicle.

INSTALLATION

lInstallation is the reverse order of removal. For tightening torque, refer toPS-14, "COMPONENT".

lWhen installing lower shaft to steering gear assembly, follow the procedure listed below.

–Set rack of steering gear in the neutral position.

NOTE:

To get the neutral position of rack, turn pinion assembly and measure the distance of inner socket, and

then measure the intermediate position of the distance.

–Align rear cover cap projection (A) with the marking position (B)

of gear housing assembly.

–Install slit part of lower shaft (C) aligning with the projection (A)

of rear cover cap (1). Make sure that the slit part of lower shaft

(C) is aligned with both the projection (A) of rear cover cap (1)

and the marking position (B) of gear housing assembly.

lAfter installation, bleed air from the steering hydraulic system.

Refer toPS-6, "

Air Bleeding Hydraulic System".

lPerform final tightening of nuts and bolts on each part under

unladen conditions with tyres on level ground when removing

steering gear assembly. Check wheel alignment. Refer toFSU-

7, "Front Wheel Alignment".

INSPECTION AFTER INSTALLATION

Make sure that steering wheel operates smoothly by turning several times from full left stop to full right stop.

LGIA0032E

SGIA1140E

Page 2681 of 3171

RF-4

SQUEAK AND RATTLE TROUBLE DIAGNOSES

SQUEAK AND RATTLE TROUBLE DIAGNOSES

PFP:00000

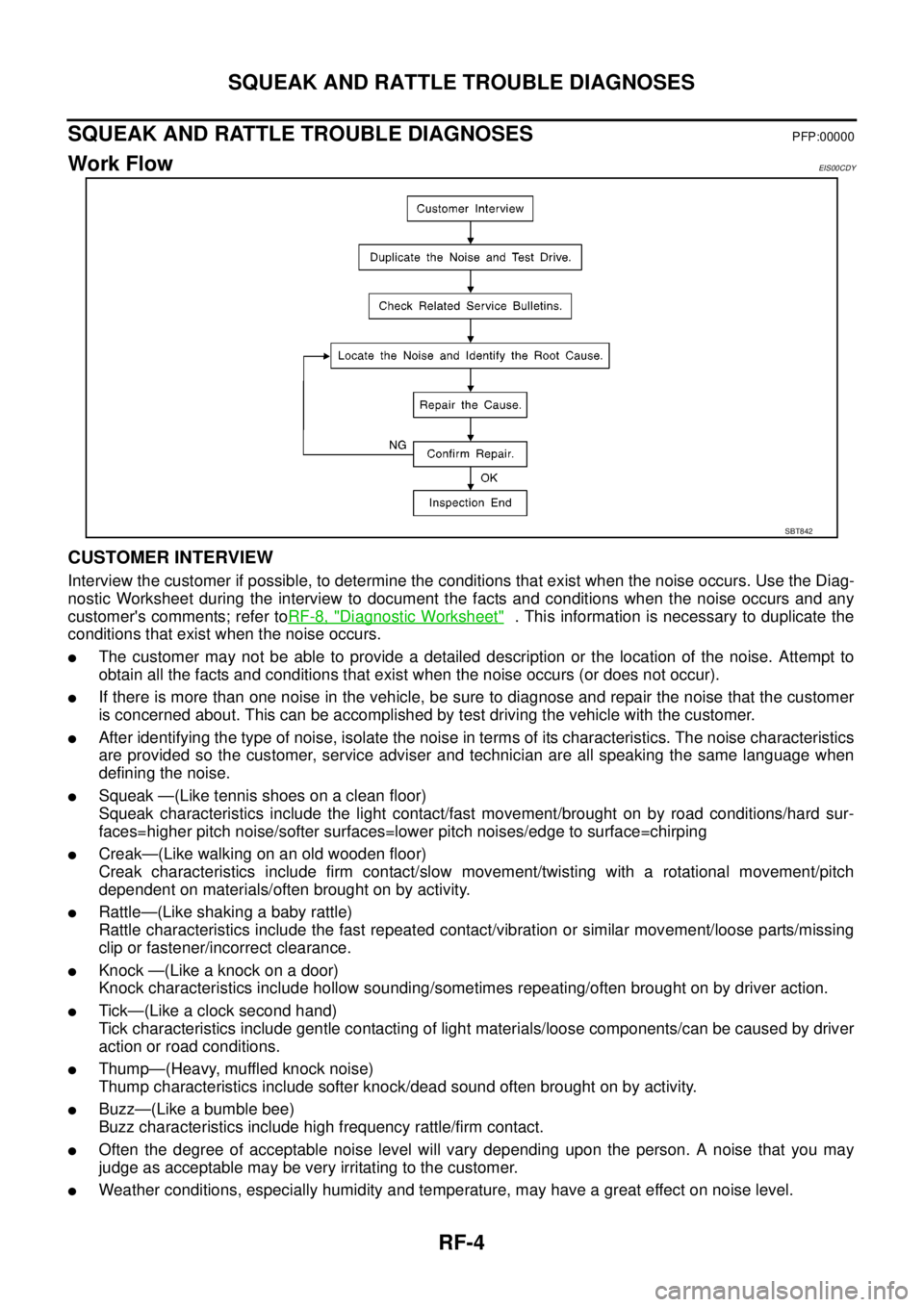

Work FlowEIS00CDY

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interview to document the facts and conditions when the noise occurs and any

customer's comments; refer toRF-8, "

Diagnostic Worksheet". This information is necessary to duplicate the

conditions that exist when the noise occurs.

lThe customer may not be able to provide a detailed description or the location of the noise. Attempt to

obtain all the facts and conditions that exist when the noise occurs (or does not occur).

lIf there is more than one noise in the vehicle, be sure to diagnose and repair the noise that the customer

is concerned about. This can be accomplished by test driving the vehicle with the customer.

lAfter identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so the customer, service adviser and technician are all speaking the same language when

defining the noise.

lSqueak —(Like tennis shoes on a clean floor)

Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard sur-

faces=higher pitch noise/softer surfaces=lower pitch noises/edge to surface=chirping

lCreak—(Like walking on an old wooden floor)

Creak characteristics include firm contact/slow movement/twisting with a rotational movement/pitch

dependent on materials/often brought on by activity.

lRattle—(Like shaking a baby rattle)

Rattle characteristics include the fast repeated contact/vibration or similar movement/loose parts/missing

clip or fastener/incorrect clearance.

lKnock —(Like a knock on a door)

Knock characteristics include hollow sounding/sometimes repeating/often brought on by driver action.

lTick—(Like a clock second hand)

Tick characteristics include gentle contacting of light materials/loose components/can be caused by driver

action or road conditions.

lThump—(Heavy, muffled knock noise)

Thump characteristics include softer knock/dead sound often brought on by activity.

lBuzz—(Like a bumble bee)

Buzz characteristics include high frequency rattle/firm contact.

lOften the degree of acceptable noise level will vary depending upon the person. A noise that you may

judge as acceptable may be very irritating to the customer.

lWeather conditions, especially humidity and temperature, may have a great effect on noise level.

SBT842