air condition NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 3050 of 3171

TROUBLE DIAGNOSIS FOR SYSTEM

TF-83

C

E

F

G

H

I

J

K

L

MA

B

TF

DIAGNOSTIC PROCEDURE

1.CHECK ATP SWITCH SIGNAL

With CONSULT-II

1. Start engine.

2. Select “DATA MONITOR” mode for “ALL MODE AWD/4WD” with CONSULT-II.

3. Read out the value of “ATP SWITCH”.

Without CONSULT-II

1. Start engine.

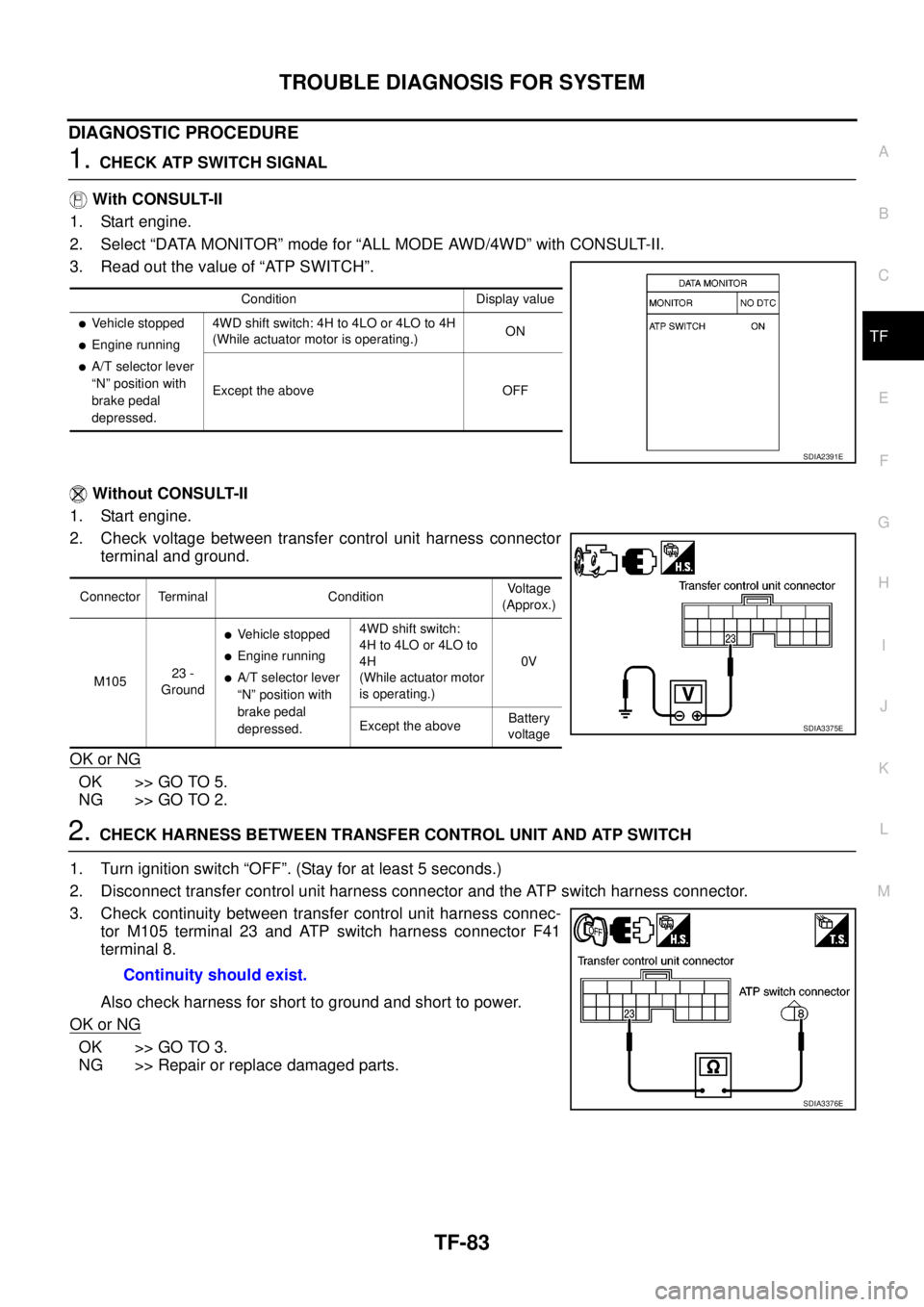

2. Check voltage between transfer control unit harness connector

terminal and ground.

OK or NG

OK >> GO TO 5.

NG >> GO TO 2.

2.CHECK HARNESS BETWEEN TRANSFER CONTROL UNIT AND ATP SWITCH

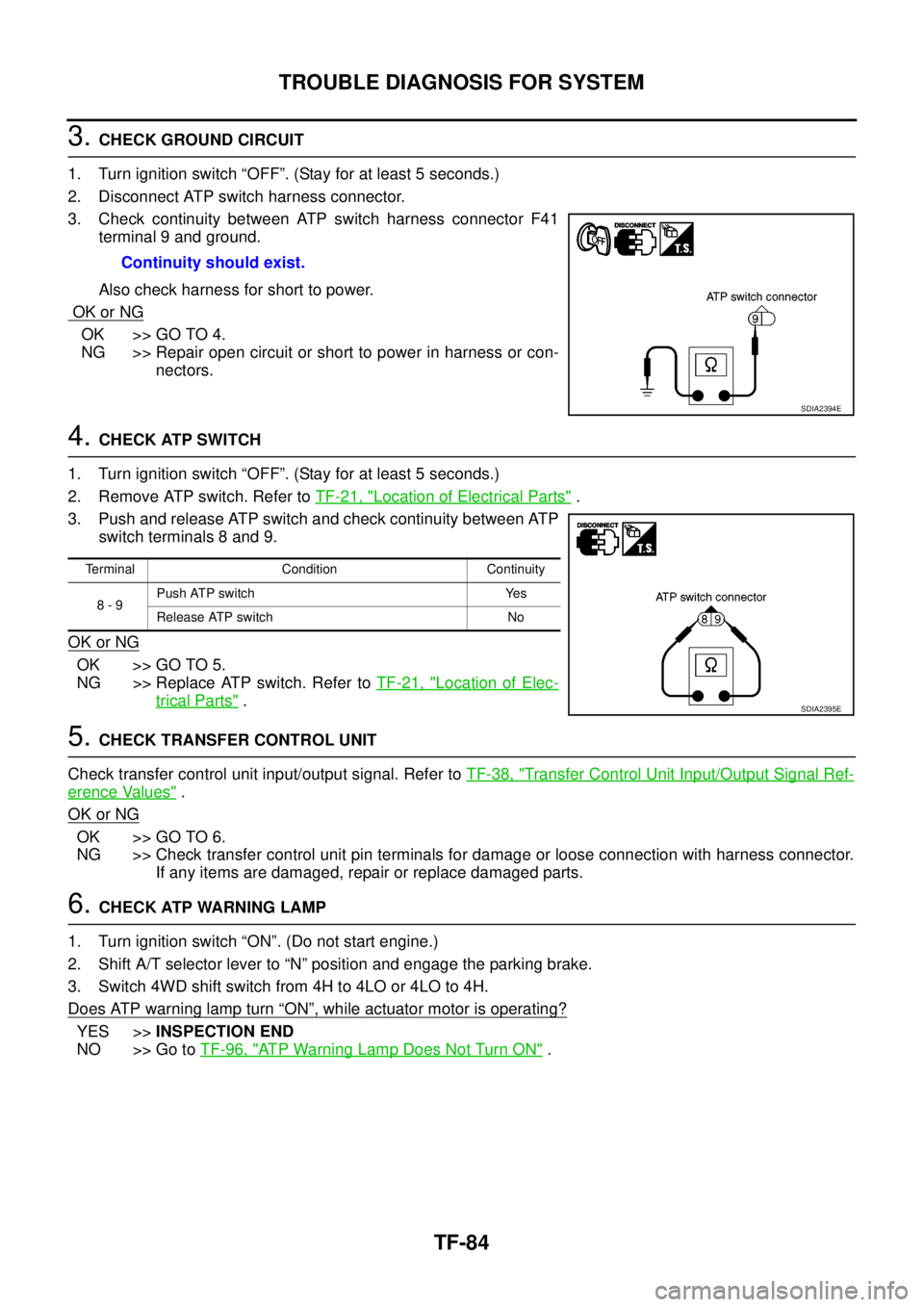

1. Turn ignition switch “OFF”. (Stay for at least 5 seconds.)

2. Disconnect transfer control unit harness connector and the ATP switch harness connector.

3. Check continuity between transfer control unit harness connec-

tor M105 terminal 23 and ATP switch harness connector F41

terminal 8.

Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace damaged parts.

Condition Display value

lVehicle stopped

lEngine running

lA/T selector lever

“N” position with

brake pedal

depressed.4WD shift switch: 4H to 4LO or 4LO to 4H

(While actuator motor is operating.)ON

Except the above OFF

SDIA2391E

Connector Terminal ConditionVoltage

(Approx.)

M10523 -

Ground

lVehicle stopped

lEngine running

lA/T selector lever

“N” position with

brake pedal

depressed.4WD shift switch:

4H to 4LO or 4LO to

4H

(While actuator motor

is operating.)0V

Except the aboveBattery

voltage

SDIA3375E

Continuity should exist.

SDIA3376E

Page 3051 of 3171

TF-84

TROUBLE DIAGNOSIS FOR SYSTEM

3.CHECK GROUND CIRCUIT

1. Turn ignition switch “OFF”. (Stay for at least 5 seconds.)

2. Disconnect ATP switch harness connector.

3. Check continuity between ATP switch harness connector F41

terminal 9 and ground.

Also check harness for short to power.

OK or NG

OK >> GO TO 4.

NG >> Repair open circuit or short to power in harness or con-

nectors.

4.CHECK ATP SWITCH

1. Turn ignition switch “OFF”. (Stay for at least 5 seconds.)

2. Remove ATP switch. Refer toTF-21, "

Location of Electrical Parts".

3. Push and release ATP switch and check continuity between ATP

switch terminals 8 and 9.

OK or NG

OK >> GO TO 5.

NG >> Replace ATP switch. Refer toTF-21, "

Location of Elec-

trical Parts".

5.CHECK TRANSFER CONTROL UNIT

Check transfer control unit input/output signal. Refer toTF-38, "

Transfer Control Unit Input/Output Signal Ref-

erence Values".

OK or NG

OK >> GO TO 6.

NG >> Check transfer control unit pin terminals for damage or loose connection with harness connector.

If any items are damaged, repair or replace damaged parts.

6.CHECK ATP WARNING LAMP

1. Turn ignition switch “ON”. (Do not start engine.)

2. Shift A/T selector lever to “N” position and engage the parking brake.

3. Switch 4WD shift switch from 4H to 4LO or 4LO to 4H.

Does ATP warning lamp turn

“ON”, while actuator motor is operating?

YES >>INSPECTION END

NO >> Go toTF-96, "

ATP Warning Lamp Does Not Turn ON". Continuity should exist.

SDIA2394E

Terminal Condition Continuity

8-9Push ATP switch Yes

Release ATP switch No

SDIA2395E

Page 3053 of 3171

TF-86

TROUBLE DIAGNOSIS FOR SYSTEM

2.CHECK HARNESS BETWEEN TRANSFER CONTROL UNIT AND PARK/NEUTRAL POSITION

SWITCH

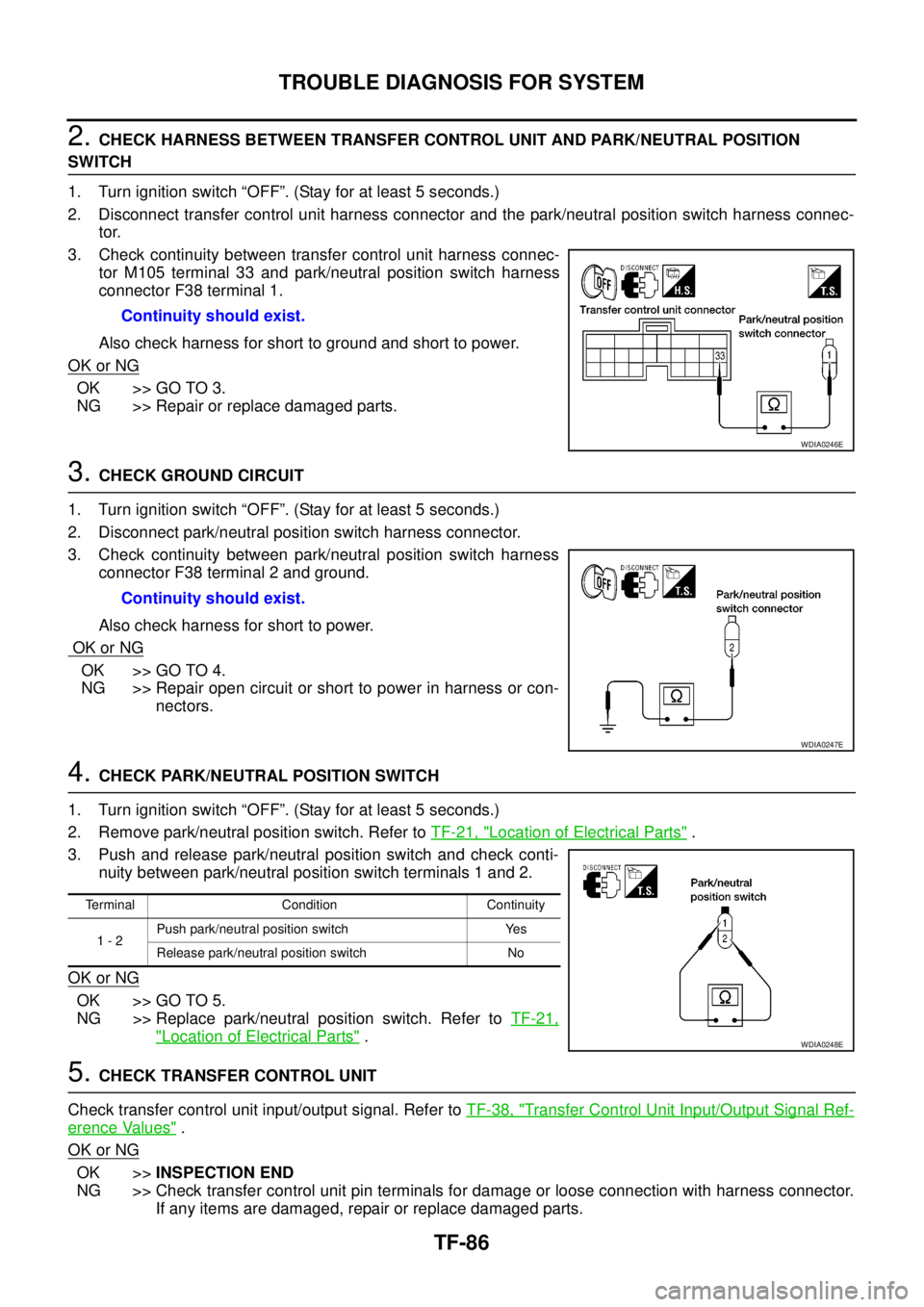

1. Turn ignition switch “OFF”. (Stay for at least 5 seconds.)

2. Disconnect transfer control unit harness connector and the park/neutral position switch harness connec-

tor.

3. Check continuity between transfer control unit harness connec-

tor M105 terminal 33 and park/neutral position switch harness

connector F38 terminal 1.

Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace damaged parts.

3.CHECK GROUND CIRCUIT

1. Turn ignition switch “OFF”. (Stay for at least 5 seconds.)

2. Disconnect park/neutral position switch harness connector.

3. Check continuity between park/neutral position switch harness

connector F38 terminal 2 and ground.

Also check harness for short to power.

OK or NG

OK >> GO TO 4.

NG >> Repair open circuit or short to power in harness or con-

nectors.

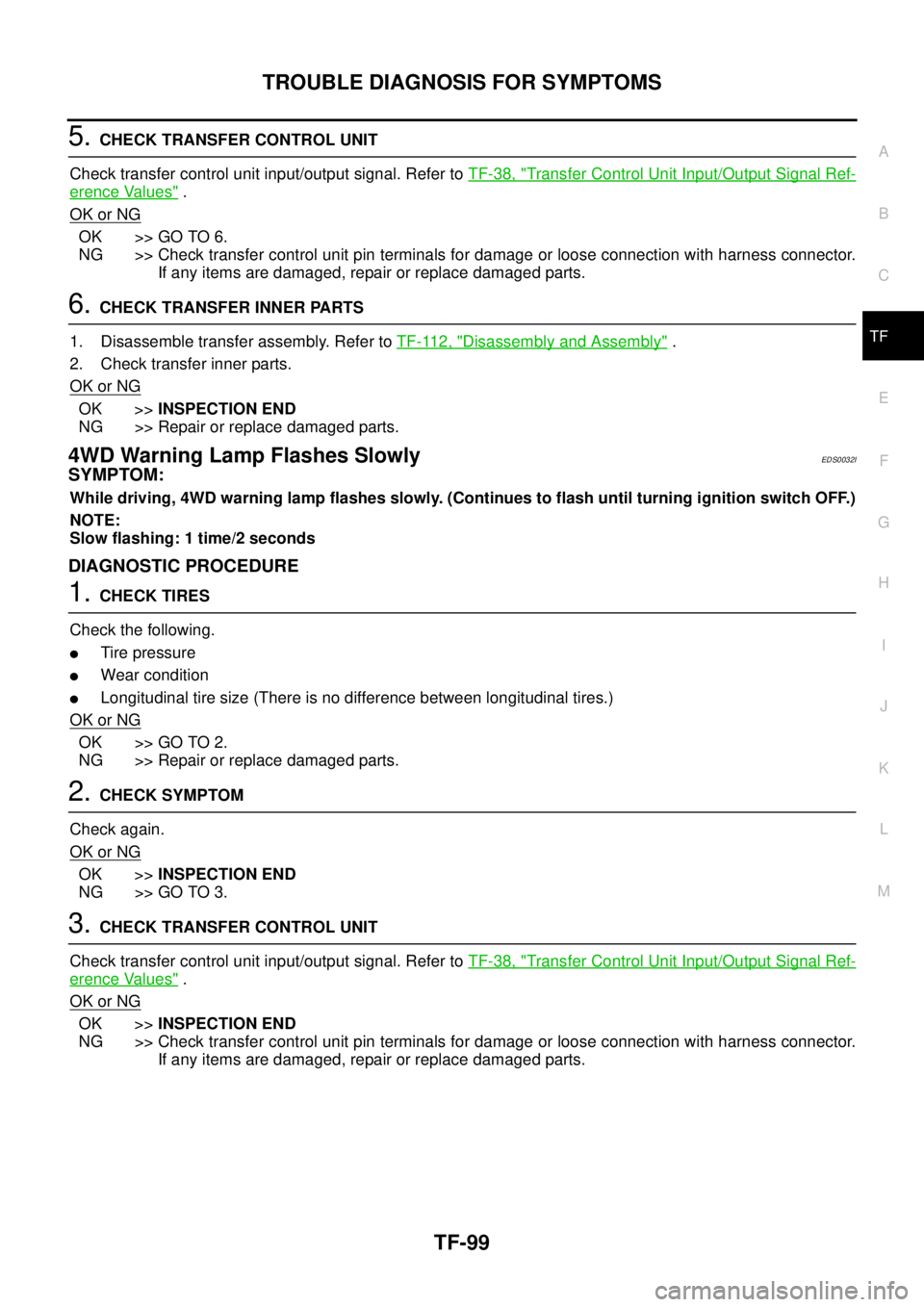

4.CHECK PARK/NEUTRAL POSITION SWITCH

1. Turn ignition switch “OFF”. (Stay for at least 5 seconds.)

2. Remove park/neutral position switch. Refer toTF-21, "

Location of Electrical Parts".

3. Push and release park/neutral position switch and check conti-

nuity between park/neutral position switch terminals 1 and 2.

OK or NG

OK >> GO TO 5.

NG >> Replace park/neutral position switch. Refer toTF-21,

"Location of Electrical Parts".

5.CHECK TRANSFER CONTROL UNIT

Check transfer control unit input/output signal. Refer toTF-38, "

Transfer Control Unit Input/Output Signal Ref-

erence Values".

OK or NG

OK >>INSPECTION END

NG >> Check transfer control unit pin terminals for damage or loose connection with harness connector.

If any items are damaged, repair or replace damaged parts. Continuity should exist.

WDIA0246E

Continuity should exist.

WDIA0247E

Terminal Condition Continuity

1-2Push park/neutral position switch Yes

Release park/neutral position switch No

WDIA0248E

Page 3066 of 3171

TROUBLE DIAGNOSIS FOR SYMPTOMS

TF-99

C

E

F

G

H

I

J

K

L

MA

B

TF

5.CHECK TRANSFER CONTROL UNIT

Check transfer control unit input/output signal. Refer toTF-38, "

Transfer Control Unit Input/Output Signal Ref-

erence Values".

OK or NG

OK >> GO TO 6.

NG >> Check transfer control unit pin terminals for damage or loose connection with harness connector.

If any items are damaged, repair or replace damaged parts.

6.CHECK TRANSFER INNER PARTS

1. Disassemble transfer assembly. Refer toTF-112, "

Disassembly and Assembly".

2. Check transfer inner parts.

OK or NG

OK >>INSPECTION END

NG >> Repair or replace damaged parts.

4WD Warning Lamp Flashes SlowlyEDS0032I

SYMPTOM:

While driving, 4WD warning lamp flashes slowly. (Continues to flash until turning ignition switch OFF.)

NOTE:

Slow flashing: 1 time/2 seconds

DIAGNOSTIC PROCEDURE

1.CHECK TIRES

Check the following.

lTire pressure

lWear condition

lLongitudinal tire size (There is no difference between longitudinal tires.)

OK or NG

OK >> GO TO 2.

NG >> Repair or replace damaged parts.

2.CHECK SYMPTOM

Check again.

OK or NG

OK >>INSPECTION END

NG >> GO TO 3.

3.CHECK TRANSFER CONTROL UNIT

Check transfer control unit input/output signal. Refer toTF-38, "

Transfer Control Unit Input/Output Signal Ref-

erence Values".

OK or NG

OK >>INSPECTION END

NG >> Check transfer control unit pin terminals for damage or loose connection with harness connector.

If any items are damaged, repair or replace damaged parts.

Page 3127 of 3171

WW-16

FRONT WIPER AND WASHER SYSTEM

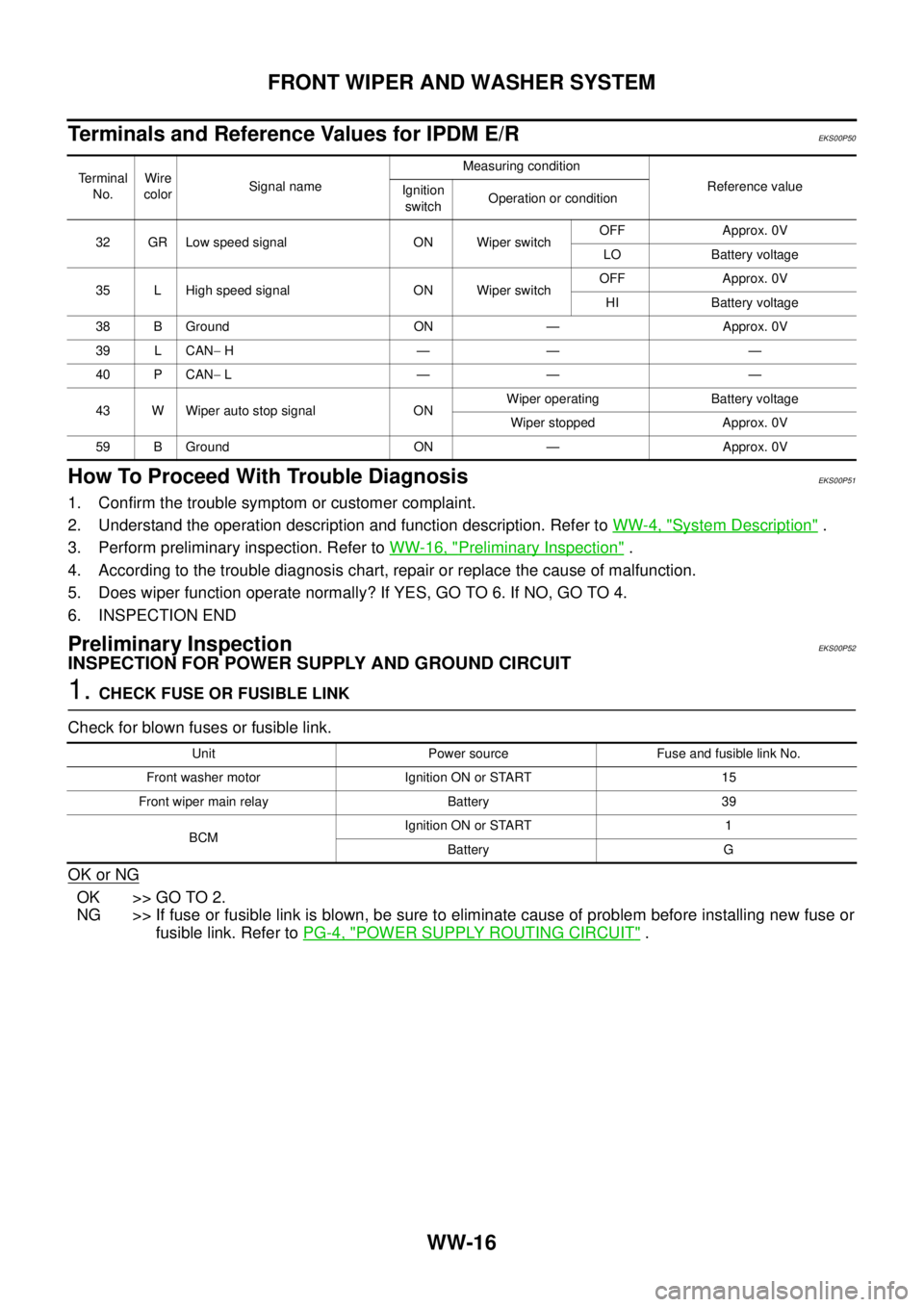

Terminals and Reference Values for IPDM E/R

EKS00P50

How To Proceed With Trouble DiagnosisEKS00P51

1. Confirm the trouble symptom or customer complaint.

2. Understand the operation description and function description. Refer toWW-4, "

System Description".

3. Perform preliminary inspection. Refer toWW-16, "

Preliminary Inspection".

4. According to the trouble diagnosis chart, repair or replace the cause of malfunction.

5. Does wiper function operate normally? If YES, GO TO 6. If NO, GO TO 4.

6. INSPECTION END

Preliminary InspectionEKS00P52

INSPECTION FOR POWER SUPPLY AND GROUND CIRCUIT

1.CHECK FUSE OR FUSIBLE LINK

Check for blown fuses or fusible link.

OK or NG

OK >> GO TO 2.

NG >> If fuse or fusible link is blown, be sure to eliminate cause of problem before installing new fuse or

fusible link. Refer toPG-4, "

POWER SUPPLY ROUTING CIRCUIT".

Te r m i n a l

No.Wire

colorSignal nameMeasuring condition

Reference value

Ignition

switchOperation or condition

32 GR Low speed signal ON Wiper switchOFF Approx. 0V

LO Battery voltage

35 L High speed signal ON Wiper switchOFF Approx. 0V

HI Battery voltage

38 B Ground ON — Approx. 0V

39 L CAN-H—— —

40 P CAN-L—— —

43 W Wiper auto stop signal ONWiper operating Battery voltage

Wiper stopped Approx. 0V

59 B Ground ON — Approx. 0V

Unit Power source Fuse and fusible link No.

Front washer motor Ignition ON or START 15

Front wiper main relay Battery 39

BCMIgnition ON or START 1

Battery G

Page 3134 of 3171

FRONT WIPER AND WASHER SYSTEM

WW-23

C

D

E

F

G

H

I

J

L

MA

B

WW

Front Wiper Does Not Operate in Rain (Front Wiper Switch Turned to INT Posi-

tion)

EKS00Q9V

1.CHECK CONDITIONS OF WINDSHIELD ( LIGHT AND RAIN SENSOR DETECTION AREA)

Check light and rain sensor detection area of windshield for dirt such as greases.

OK or NG

OK >> GO TO 2.

NG >> Clean light and rain sensor detection area of windshield fully.

2.CHECK LIGHT AND RAIN SENSOR INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Turn ignition switch ON.

4. Check waveform between BCM harness connector and ground.

OK or NG

OK >> Replace light and rain sensor. Refer toLT-65, "Removal and Installation of Light and Rain Sensor"

. If front wiper does not operate, replace BCM. Refer toBCS-17, "Removal and Installation of

BCM".

NG >> GO TO 3.

3.CHECK LIGHT AND RAIN SENSOR SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector and light and rain sensor connector.

3. Check continuity between BCM harness connector (A) and light

and rain sensor harness connector (B).

4. Check continuity between BCM harness connector (A) and

ground.

OK or NG

OK >> GO TO 4.

NG >> Repair harness or connector.

Terminal

Condition Voltage (+)

(-)

BCM

connectorTerminal

M42 24 GroundIgnition

switchON

OFF Batterly voltage

SKIB6405E

PKIC1618E

AB

Continuity

Connector Terminal Connector Terminal

M42 24 R3 2 Yes

A

GroundContinuity

Connector Terminal

M42 24 No

PKIC1377E

Page 3162 of 3171

HEADLAMP WASHER

WW-51

C

D

E

F

G

H

I

J

L

MA

B

WW

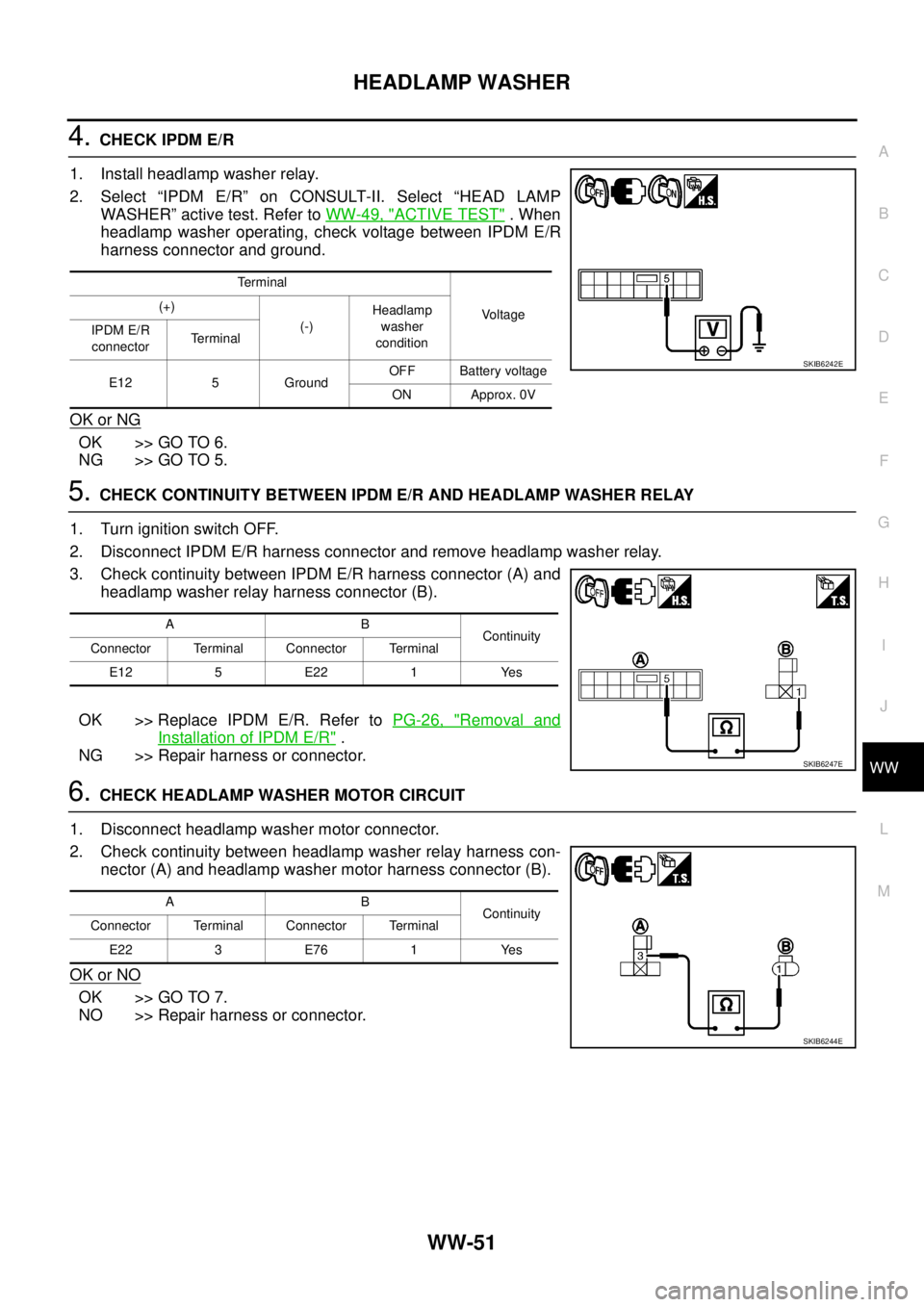

4.CHECK IPDM E/R

1. Install headlamp washer relay.

2. Select “IPDM E/R” on CONSULT-II. Select “HEAD LAMP

WASHER” active test. Refer toWW-49, "

ACTIVE TEST".When

headlamp washer operating, check voltage between IPDM E/R

harness connector and ground.

OK or NG

OK >> GO TO 6.

NG >> GO TO 5.

5.CHECK CONTINUITY BETWEEN IPDM E/R AND HEADLAMP WASHER RELAY

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R harness connector and remove headlamp washer relay.

3. Check continuity between IPDM E/R harness connector (A) and

headlamp washer relay harness connector (B).

OK >> Replace IPDM E/R. Refer toPG-26, "

Removal and

Installation of IPDM E/R".

NG >> Repair harness or connector.

6.CHECK HEADLAMP WASHER MOTOR CIRCUIT

1. Disconnect headlamp washer motor connector.

2. Check continuity between headlamp washer relay harness con-

nector (A) and headlamp washer motor harness connector (B).

OK or NO

OK >> GO TO 7.

NO >> Repair harness or connector.

Terminal

Vo l ta g e (+)

(-)Headlamp

washer

condition IPDM E/R

connectorTerminal

E12 5 GroundOFF Battery voltage

ON Approx. 0V

SKIB6242E

AB

Continuity

Connector Terminal Connector Terminal

E12 5 E22 1 Yes

SKIB6247E

AB

Continuity

Connector Terminal Connector Terminal

E22 3 E76 1 Yes

SKIB6244E

Page 3163 of 3171

WW-52

HEADLAMP WASHER

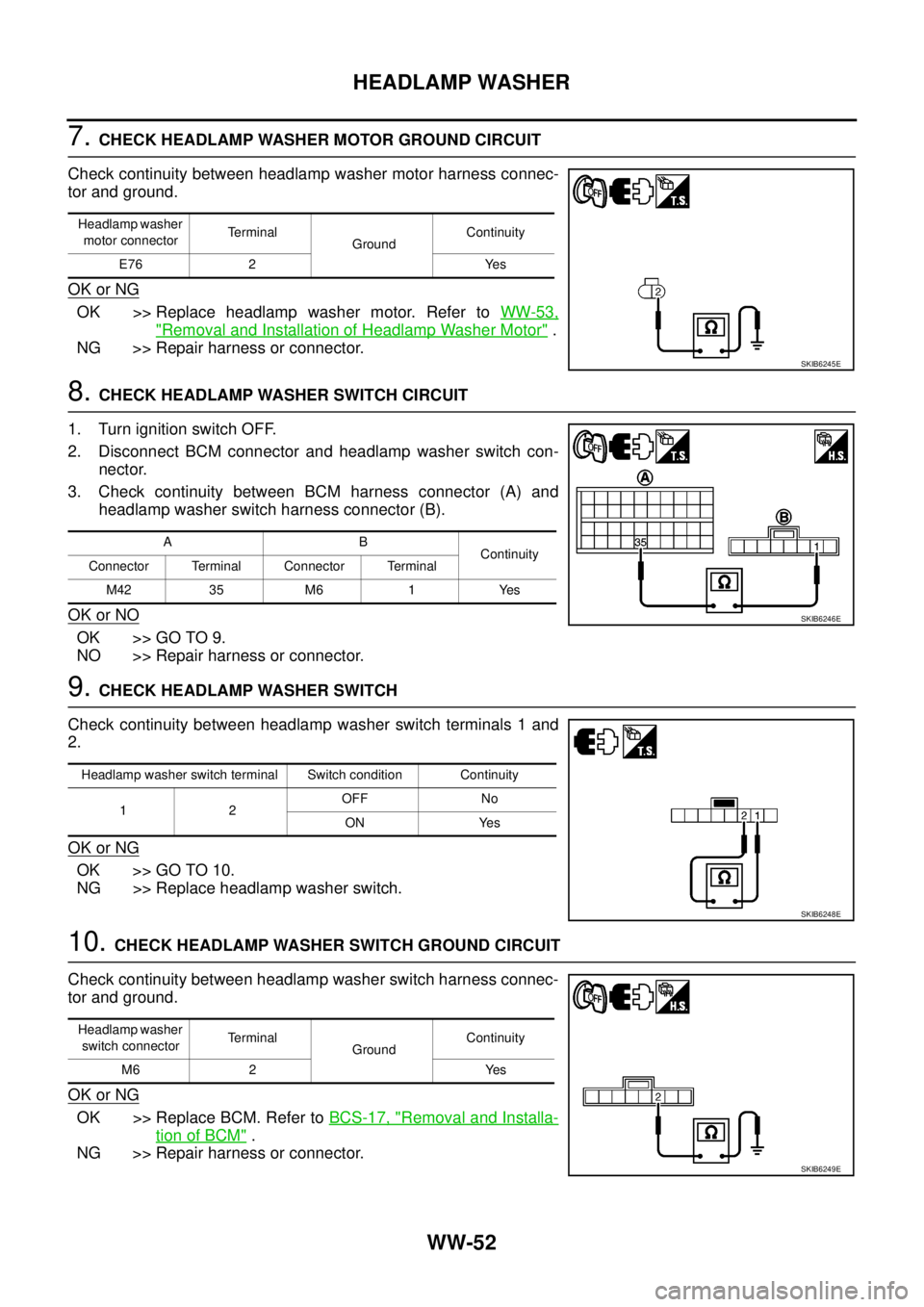

7.CHECK HEADLAMP WASHER MOTOR GROUND CIRCUIT

Check continuity between headlamp washer motor harness connec-

tor and ground.

OK or NG

OK >> Replace headlamp washer motor. Refer toWW-53,

"Removal and Installation of Headlamp Washer Motor".

NG >> Repair harness or connector.

8.CHECK HEADLAMP WASHER SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector and headlamp washer switch con-

nector.

3. Check continuity between BCM harness connector (A) and

headlamp washer switch harness connector (B).

OK or NO

OK >> GO TO 9.

NO >> Repair harness or connector.

9.CHECK HEADLAMP WASHER SWITCH

Check continuity between headlamp washer switch terminals 1 and

2.

OK or NG

OK >> GO TO 10.

NG >> Replace headlamp washer switch.

10.CHECK HEADLAMP WASHER SWITCH GROUND CIRCUIT

Check continuity between headlamp washer switch harness connec-

tor and ground.

OK or NG

OK >> Replace BCM. Refer toBCS-17, "Removal and Installa-

tion of BCM".

NG >> Repair harness or connector.

Headlamp washer

motor connectorTerminal

GroundContinuity

E76 2 Yes

SKIB6245E

AB

Continuity

Connector Terminal Connector Terminal

M42 35 M6 1 Yes

SKIB6246E

Headlamp washer switch terminal Switch condition Continuity

12OFF No

ON Yes

SKIB6248E

Headlamp washer

switch connectorTerminal

GroundContinuity

M6 2 Yes

SKIB6249E