NISSAN NAVARA 2005 Repair Workshop Manual

Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 351 of 3171

PREPARATION

ATC-17

C

D

E

F

G

H

I

K

L

MA

B

AT C

Recovery/Recycling/

Recharging equipment (ACR4)Function: Refrigerant recovery and

recycling and recharging

Electrical leak detectorPower supply:

DC 12V (Cigarette lighter)

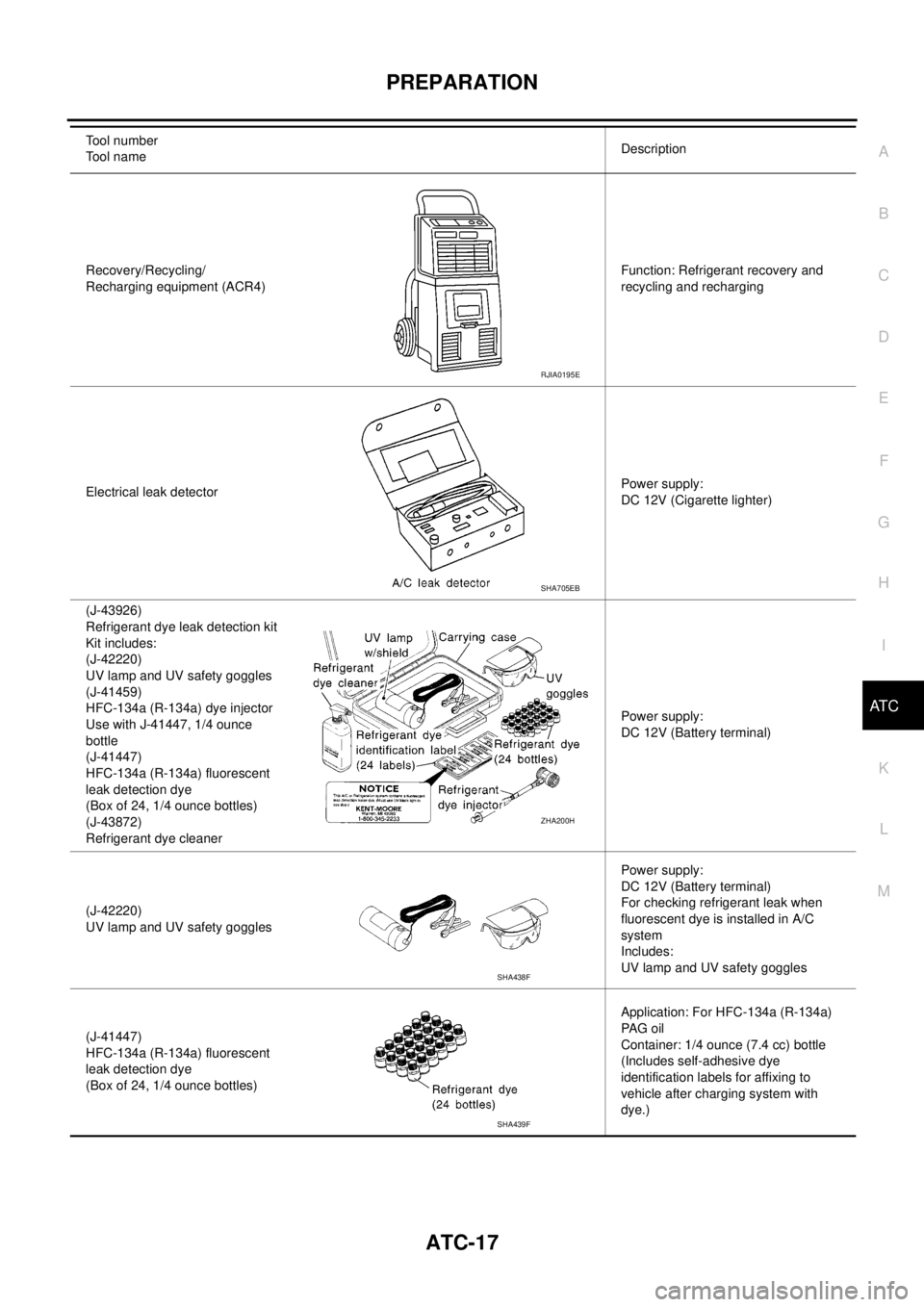

(J-43926)

Refrigerant dye leak detection kit

Kit includes:

(J-42220)

UV lamp and UV safety goggles

(J-41459)

HFC-134a (R-134a) dye injector

Use with J-41447, 1/4 ounce

bottle

(J-41447)

HFC-134a (R-134a) fluorescent

leak detection dye

(Box of 24, 1/4 ounce bottles)

(J-43872)

Refrigerant dye cleanerPower supply:

DC 12V (Battery terminal)

(J-42220)

UV lamp and UV safety gogglesPower supply:

DC 12V (Battery terminal)

For checking refrigerant leak when

fluorescent dye is installed in A/C

system

Includes:

UV lamp and UV safety goggles

(J-41447)

HFC-134a (R-134a) fluorescent

leak detection dye

(Box of 24, 1/4 ounce bottles)Application: For HFC-134a (R-134a)

PA G o i l

Container: 1/4 ounce (7.4 cc) bottle

(Includes self-adhesive dye

identification labels for affixing to

vehicle after charging system with

dye.) Tool number

Tool nameDescription

RJIA0195E

SHA705EB

ZHA200H

SHA438F

SHA439F

Page 352 of 3171

ATC-18

PREPARATION

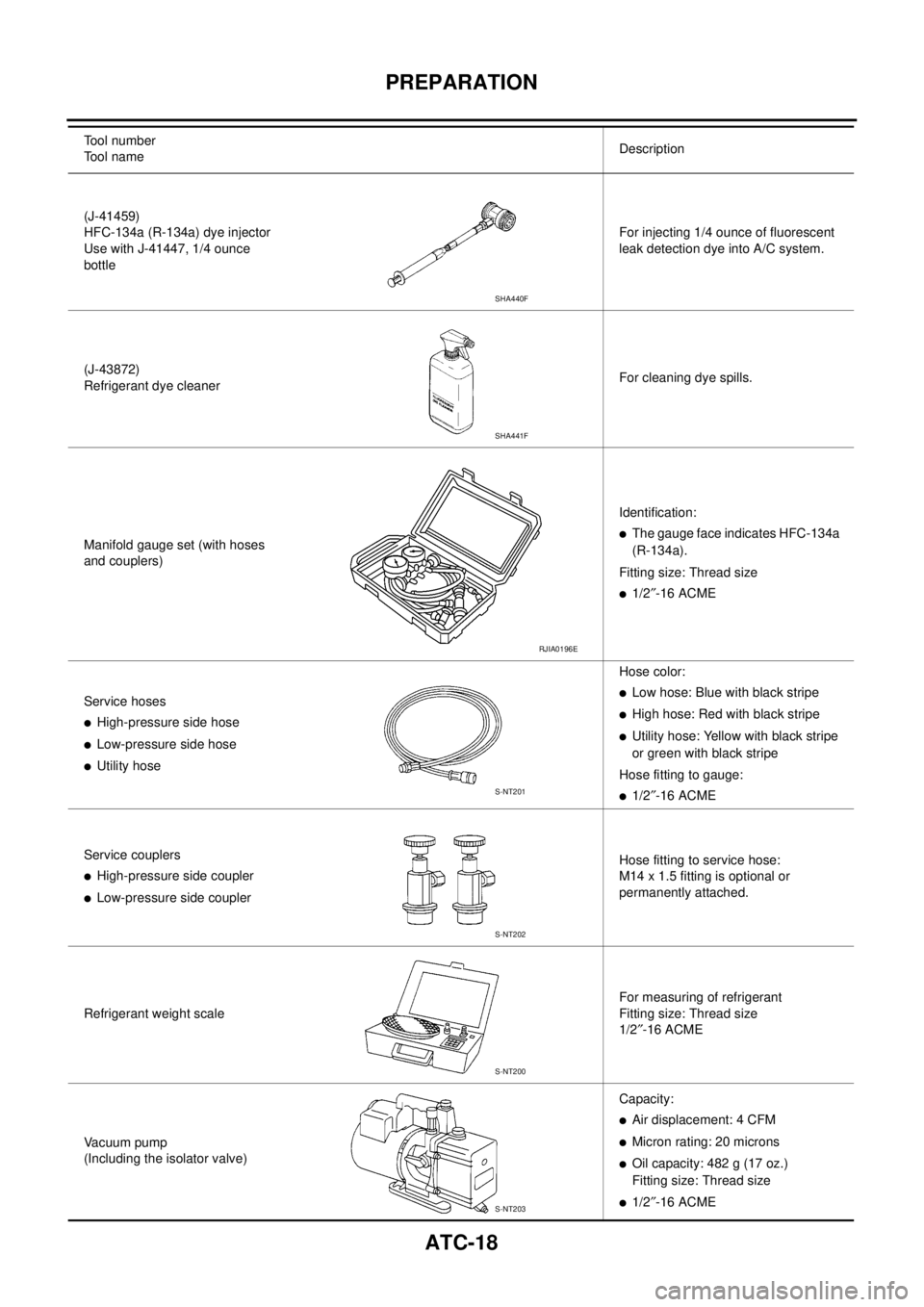

(J-41459)

HFC-134a (R-134a) dye injector

Use with J-41447, 1/4 ounce

bottleFor injecting 1/4 ounce of fluorescent

leak detection dye into A/C system.

(J-43872)

Refrigerant dye cleanerFor cleaning dye spills.

Manifold gauge set (with hoses

and couplers)Identification:

lThe gauge face indicates HFC-134a

(R-134a).

Fitting size: Thread size

l1/2²-16 ACME

Service hoses

lHigh-pressure side hose

lLow-pressure side hose

lUtility hoseHose color:

lLow hose: Blue with black stripe

lHigh hose: Red with black stripe

lUtility hose: Yellow with black stripe

or green with black stripe

Hose fitting to gauge:

l1/2²-16 ACME

Service couplers

lHigh-pressure side coupler

lLow-pressure side couplerHose fitting to service hose:

M14 x 1.5 fitting is optional or

permanently attached.

Refrigerant weight scaleFor measuring of refrigerant

Fitting size: Thread size

1/2²-16 ACME

Vacuum pump

(Including the isolator valve)Capacity:

lAir displacement: 4 CFM

lMicron rating: 20 microns

lOil capacity: 482 g (17 oz.)

Fitting size: Thread size

l1/2²-16 ACME Tool number

Tool nameDescription

SHA440F

SHA441F

RJIA0196E

S-NT201

S-NT202

S-NT200

S-NT203

Page 353 of 3171

PREPARATION

ATC-19

C

D

E

F

G

H

I

K

L

MA

B

AT C

Commercial Service ToolsEJS006AV

Tool number

Tool nameDescription

(J-44614)

Clutch disk holding toolClutch disk holding tool

WHA230

Page 354 of 3171

ATC-20

REFRIGERATION SYSTEM

REFRIGERATION SYSTEM

PFP:KA990

Refrigerant CycleEJS006AW

REFRIGERANT FLOW

The refrigerant flows in the standard pattern, that is, through the compressor, the condenser with liquid tank,

through the evaporator, and back to the compressor. The refrigerant evaporation through the evaporator is

controlled by an externally equalized expansion valve, located inside the evaporator case.

FREEZE PROTECTION

Under usual operating conditions, when the A/C is switched ON, the compressor runs continuously, and the

evaporator pressure, and therefore, temperature is controlled by the V-6 variable displacement compressor to

prevent freeze up.

Refrigerant System ProtectionEJS006AX

REFRIGERANT PRESSURE SENSOR

The refrigerant system is protected against excessively high or low pressures by the refrigerant pressure sen-

sor, located on the condenser. If the system pressure rises above or falls below the specifications, the refriger-

ant pressure sensor detects the pressure inside the refrigerant line and sends a voltage signal to the ECM.

The ECM de-energizes the A/C relay to disengage the magnetic compressor clutch when pressure on the high

pressure side detected by refrigerant pressure sensor is over about 2,746 kPa (28 kg/cm

2, 398 psi), or below

about 120 kPa (1.22 kg/cm

2,17.4psi).

Page 355 of 3171

REFRIGERATION SYSTEM

ATC-21

C

D

E

F

G

H

I

K

L

MA

B

AT C

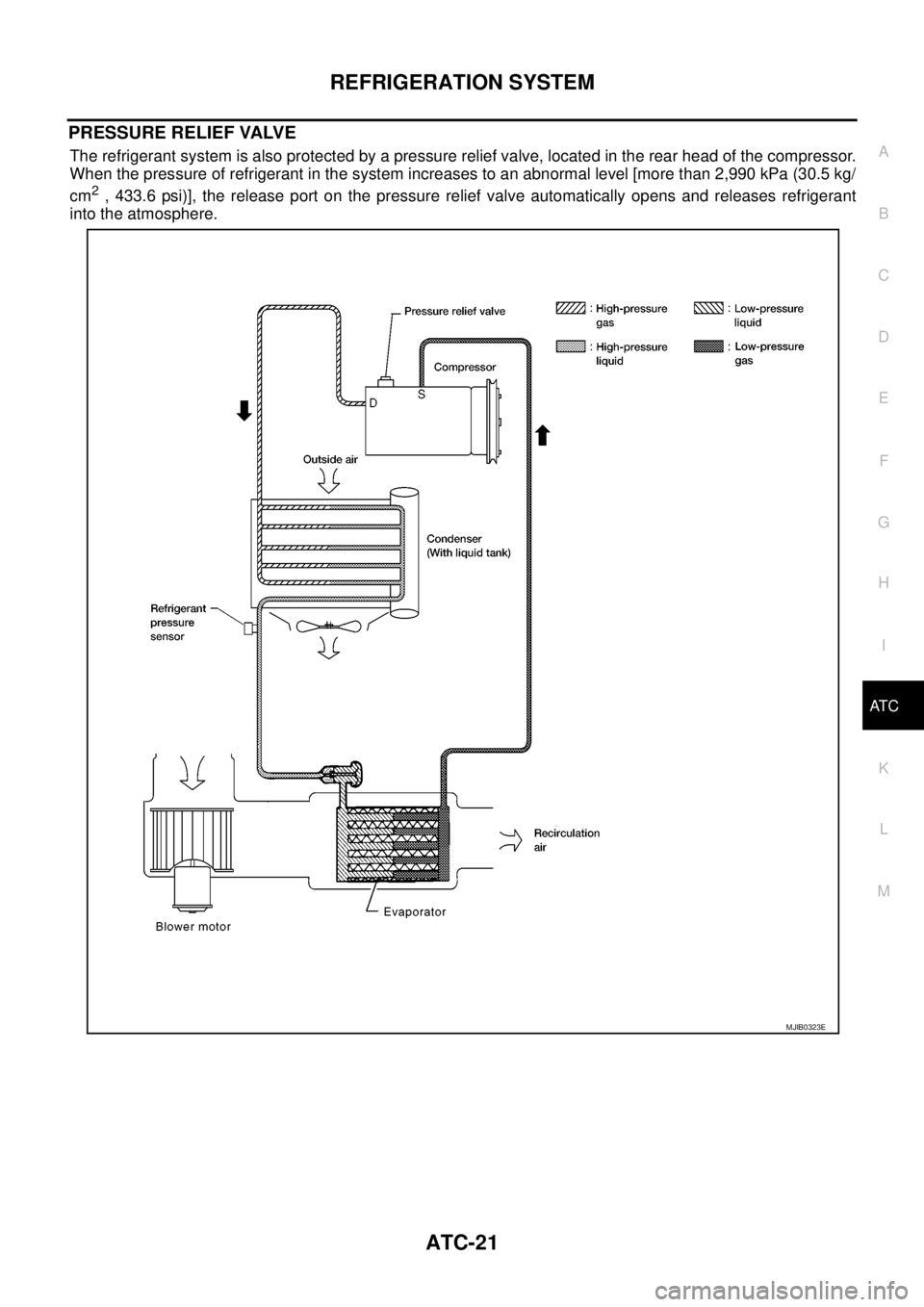

PRESSURE RELIEF VALVE

The refrigerant system is also protected by a pressure relief valve, located in the rear head of the compressor.

When the pressure of refrigerant in the system increases to an abnormal level [more than 2,990 kPa (30.5 kg/

cm

2, 433.6 psi)], the release port on the pressure relief valve automatically opens and releases refrigerant

into the atmosphere.

MJIB0323E

Page 356 of 3171

ATC-22

REFRIGERATION SYSTEM

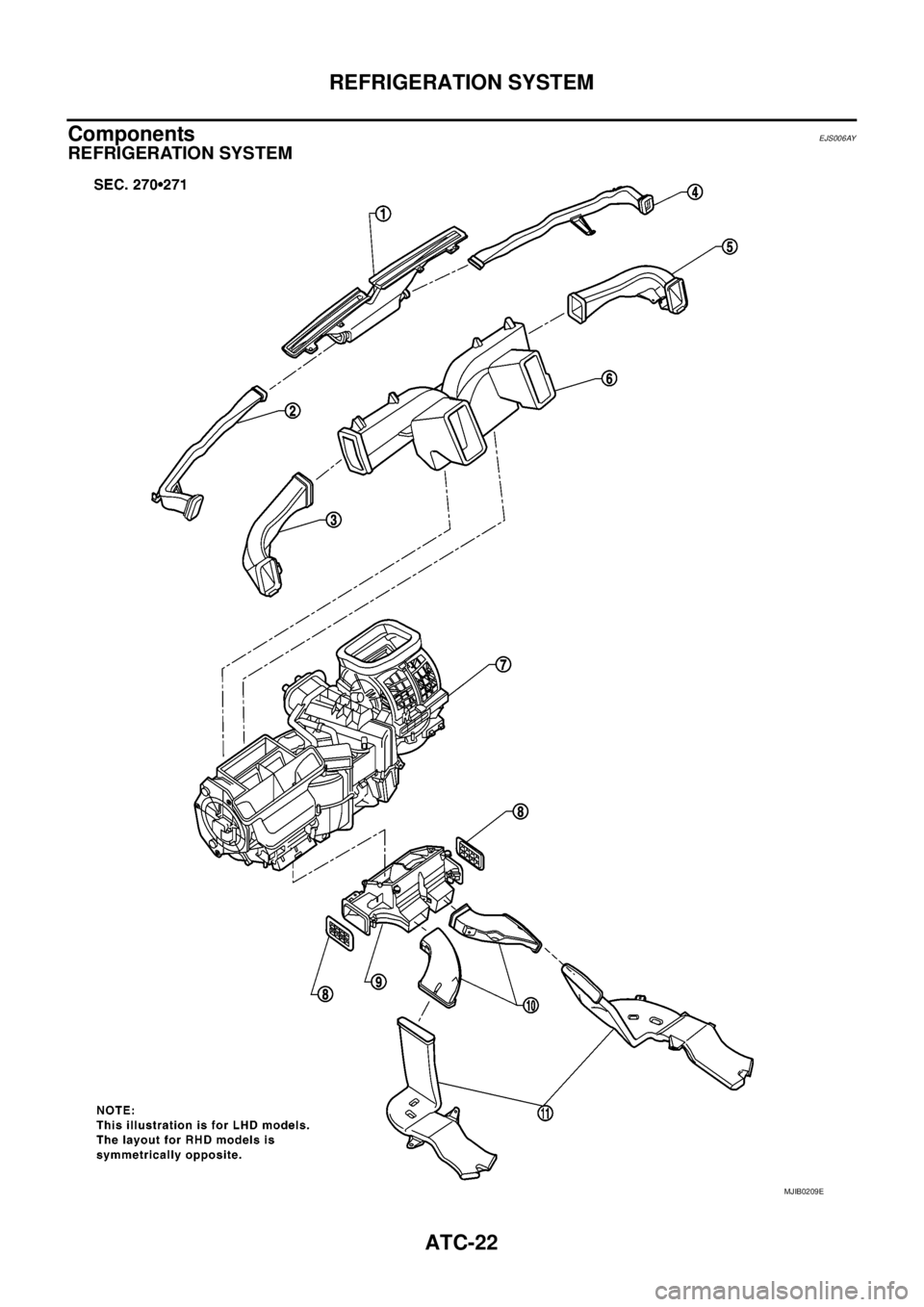

Components

EJS006AY

REFRIGERATION SYSTEM

MJIB0209E

Page 357 of 3171

REFRIGERATION SYSTEM

ATC-23

C

D

E

F

G

H

I

K

L

MA

B

AT C

1. Defroster nozzle 2. LH side demister duct 3. LH ventilator duct

4. RH side demister duct 5. RH ventilator duct 6. Center ventilation duct

7. Heater and cooling unit assembly 8. Floor connector duct grilles 9. Floor connector duct

10. Front floor duct 11. Rear floor duct

Page 358 of 3171

ATC-24

LUBRICANT

LUBRICANT

PFP:KLG00

Maintenance of Lubricant Quantity in CompressorEJS006AZ

The lubricant in the compressor circulates through the system with the refrigerant. Add lubricant to compres-

sor when replacing any component or after a large refrigerant leakage has occurred. It is important to maintain

the specified amount.

If lubricant quantity is not maintained properly, the following malfunctions may result:

lLack of lubricant: May lead to a seized compressor

lExcessive lubricant: Inadequate cooling (thermal exchange interference)

LUBRICANT

Name: NISSAN A/C System Lubricant Type S (DH-PS) or equivalent

Part number: KLH00-PAGS0

CHECKING AND ADJUSTING

CAUTION:

If excessive lubricant leakage is noted, do not perform the lubricant return operation.

Start the engine and set the following conditions:

Test Condition

lEngine speed: Idling to 1,200 rpm

lA/C switch: On

lBlower speed: Max. position

lTemp. control: Optional [Set so that intake air temperature is 25°to 30°C(77°to 86°F)]

lIntake position: Recirculation ( )

lPerform lubricant return operation for about ten minutes

Adjust the lubricant quantity according to the following table.

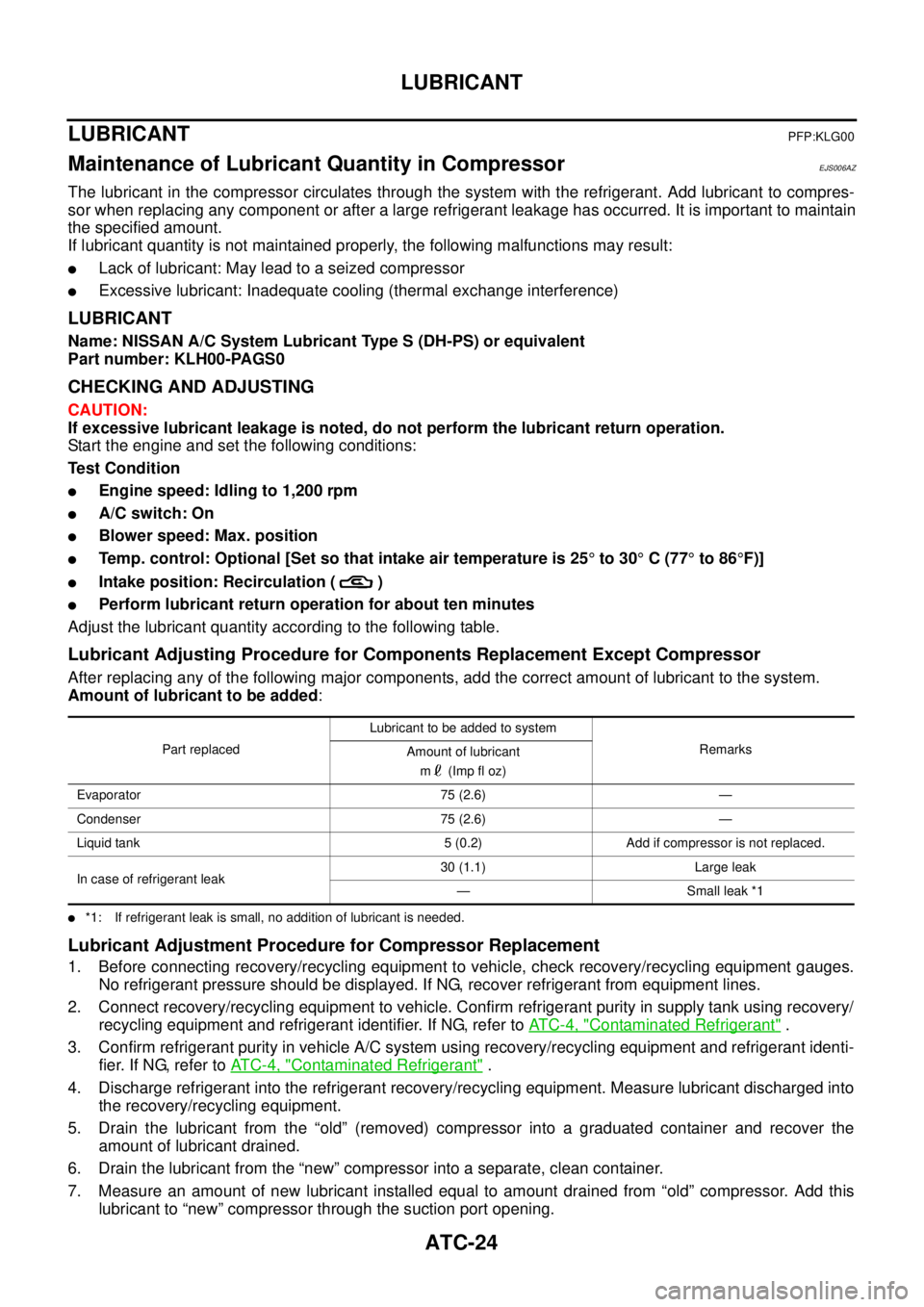

Lubricant Adjusting Procedure for Components Replacement Except Compressor

After replacing any of the following major components, add the correct amount of lubricant to the system.

Amount of lubricant to be added:

l*1: If refrigerant leak is small, no addition of lubricant is needed.

Lubricant Adjustment Procedure for Compressor Replacement

1. Before connecting recovery/recycling equipment to vehicle, check recovery/recycling equipment gauges.

No refrigerant pressure should be displayed. If NG, recover refrigerant from equipment lines.

2. Connect recovery/recycling equipment to vehicle. Confirm refrigerant purity in supply tank using recovery/

recycling equipment and refrigerant identifier. If NG, refer toAT C - 4 , "

Contaminated Refrigerant".

3. Confirm refrigerant purity in vehicle A/C system using recovery/recycling equipment and refrigerant identi-

fier. If NG, refer toAT C - 4 , "

Contaminated Refrigerant".

4. Discharge refrigerant into the refrigerant recovery/recycling equipment. Measure lubricant discharged into

the recovery/recycling equipment.

5. Drain the lubricant from the “old” (removed) compressor into a graduated container and recover the

amount of lubricant drained.

6. Drain the lubricant from the “new” compressor into a separate, clean container.

7. Measure an amount of new lubricant installed equal to amount drained from “old” compressor. Add this

lubricant to “new” compressor through the suction port opening.

Part replacedLubricant to be added to system

Remarks

Amount of lubricant

m(Impfloz)

Evaporator 75 (2.6) —

Condenser 75 (2.6) —

Liquid tank 5 (0.2) Add if compressor is not replaced.

In case of refrigerant leak30 (1.1) Large leak

— Small leak *1

Page 359 of 3171

LUBRICANT

ATC-25

C

D

E

F

G

H

I

K

L

MA

B

AT C

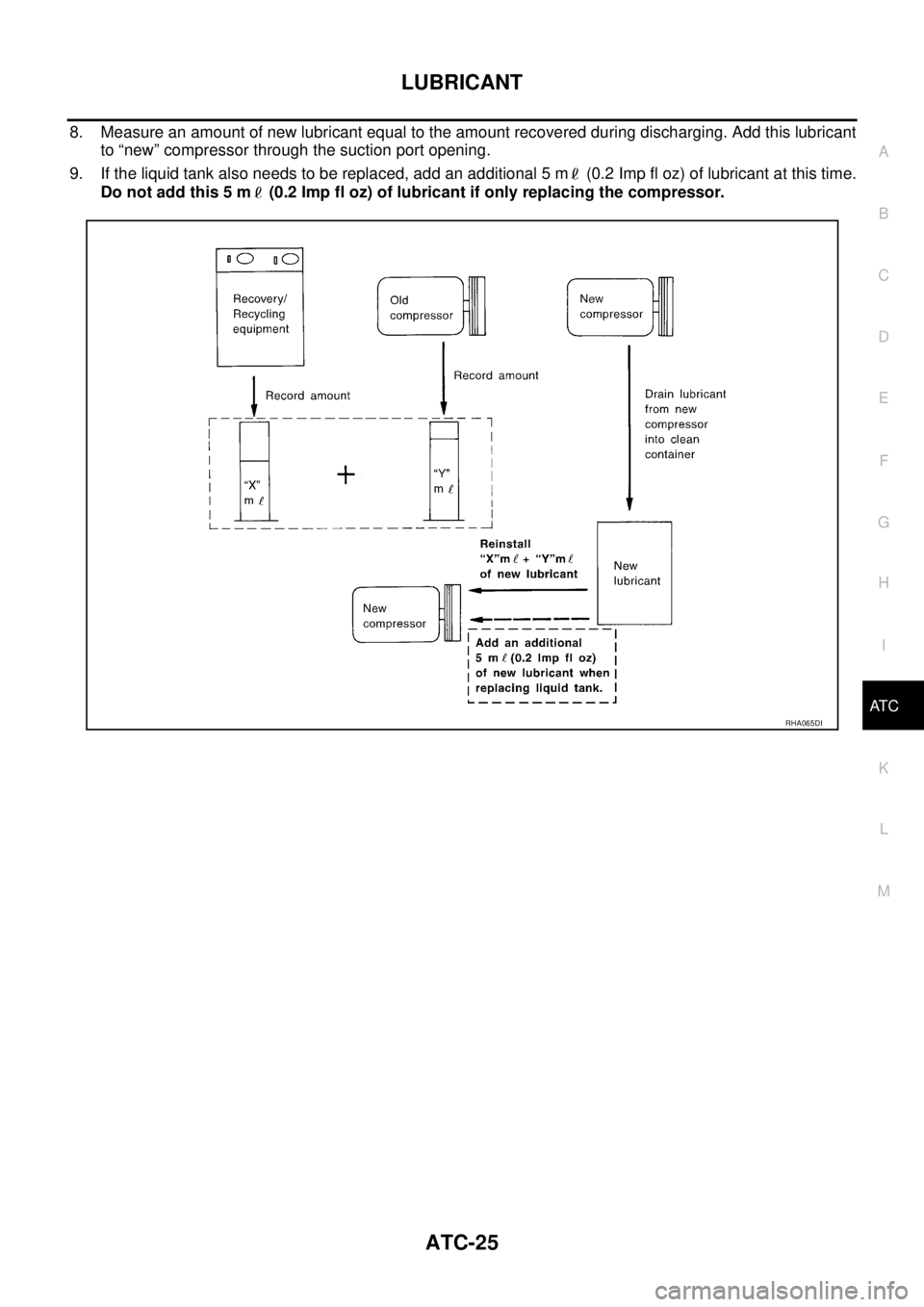

8. Measure an amount of new lubricant equal to the amount recovered during discharging. Add this lubricant

to “new” compressor through the suction port opening.

9. If the liquid tank also needs to be replaced, add an additional 5 m (0.2 Imp fl oz) of lubricant at this time.

Do not add this 5 m (0.2 Imp fl oz) of lubricant if only replacing the compressor.

RHA065DI

Page 360 of 3171

ATC-26

AIR CONDITIONER CONTROL

AIR CONDITIONER CONTROL

PFP:27500

DescriptionEJS006B0

The front air control provides automatic regulation of the vehicle's interior temperature. The system is based

on the driver's and passenger's selected “set temperature”, regardless of the outside temperature changes.

This is done by utilizing a microcomputer, also referred to as the front air control, which receives input signals

from the following six sensors:

lAmbient sensor

lIn-vehicle sensor

lIntake sensor

lOptical sensor (one sensor for driver and passenger side)

lPBR (Position Balanced Resistor).

lVehicle speed sensor

The front air control uses these signals (including the set temperature) to automatically control:

lOutlet air volume

lAir temperature

lAir distribution

The front air control is used to select:

lOutlet air volume

lAir temperature/distribution

OperationEJS006B1

AIR MIX DOORS CONTROL

The air mix doors are automatically controlled so that in-vehicle temperature is maintained at a predetermined

value by the temperature setting, ambient temperature, in-vehicle temperature and amount of sunload.

BLOWER SPEED CONTROL

Blower speed is automatically controlled by the temperature setting, ambient temperature, in-vehicle tempera-

ture, intake temperature, amount of sunload and air mix door position.

When AUTO switch is pressed, the blower motor starts to gradually increase air flow volume (if required).

When engine coolant temperature is low, the blower motor operation is delayed to prevent cool air from flow-

ing.

INTAKE DOOR CONTROL

The intake door is automatically controlled by the temperature setting, ambient temperature, in-vehicle tem-

perature, intake temperature, amount of sunload and the ON-OFF operation of the compressor.

MODE DOOR CONTROL

The mode door is automatically controlled by the temperature setting, ambient temperature, in-vehicle temper-

ature, intake temperature and amount of sunload.

DEFROSTER DOOR CONTROL

The defroster door is controlled by: Turning the defroster dial to front defroster.